Accident-Tolerant Materials for Light Water Reactor Fuels Raul B. Rebak (Editor)

Visit to download the full and correct content document:

https://ebookmass.com/product/accident-tolerant-materials-for-light-water-reactor-fuel s-raul-b-rebak-editor/

Visit to download the full and correct content document:

https://ebookmass.com/product/accident-tolerant-materials-for-light-water-reactor-fuel s-raul-b-rebak-editor/

RaulB.Rebak

GeneralElectricResearch,Schenectady,NY,UnitedStates

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices,or medicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterof productsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-817503-3

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: ChristinaGifford

EditorialProjectManager: JoshuaMearns

ProductionProjectManager: R.VijayBharath

CoverDesigner: MatthewLimbert

TypesetbyMPSLimited,Chennai,India

Theaimofthisbookistoprovideasnapshotonthestate-of-the-artdevelopmentofafamilyofmaterialscalledaccidenttolerantfuels(ATF)forcommerciallightwaterreactors.Thesematerialsincludeadvancedcladding componentsandfuelforms.Thisbookisnotmeanttobeacomprehensive orexhaustivecollectionofdataorinformationonmaterialsforcivilian nuclearpowergenerationsinceitsstatusiscontinuouslychanging,practicallyonaweeklybasis.Adescriptionisprovidedonhowtheenthusiasmof thecurrentdevelopmentofnewerinnovativematerialsstartedaftersixdecadesofstagnationorcomplacencyinthenuclearindustry.Thebookis intendedforgraduatestudentsornewprofessionalswhoaregettingstarted inthefield;sotheycanputthingsinperspectiveandunderstandhowwe reached2019,theyearofATF.

TheconceptofATFwasbornafterthe2011unfortunateeventsatthe FukushimaDaiichinuclearpowerstations.Initially,therewasastateofgreat concernthatthedestructivetsunamiwavenotonlywashedawaythediesel generatorsattheaffectedplants,butitalsosweptawaytheresolveofusing nuclearfissiontogeneratecivilianelectricity,especiallyinthewestern world.However,onlyafewmonthsafterthedisaster,thenuclearmaterials’ internationalcommunitywasabletorecoverfromthenegativereporting regardingtheexplosionsshownliveontelevisionworldwideandoffermaterialssolutionstoensurethattheeventsofFukushimawouldnotrepeatthemselves.Itwasabeautifulthingtowitnesshowgovernmentalfunding agencies,nuclearfuelvendors,regulatoryagencies,tradeorganizations,universityprofessors,reactorownerutilities,researchinstitutesscientists,and plantoperatorscameseamlesslytogethertooffersolutionsforthecontinuing useoflightwaterreactors.Theefforttolookforsolutionscametolifeat bothnationalandinternationallevels,andtherewas(is)agreatcontinuous cooperationbetweenalltheinvolvedparts.Thedevelopmentalprogramsare evolvingsoquicklythatalltheinitialschedulesarebeingbeaten.Thereis alsosuchanagilityintheexecutionoftheprogramsthatmanyinitialideas notdeemedviableoffastimplementationarebeingshedquicklyand researchersarejoiningforcesonthegrowthoftheremainingmorerobust concepts.Therefore,thefocusofthisbookistodescribeandassessthetechnologyreadinesslevelofonlythefewstrongestideasratherthantomeander tryingtocoverallearlyproposedideasthatmaybefarawayfromfruition.

Initialchapterssuccinctlydescribethehistoryandevolutionofnuclear energyasasourceofcivilianelectricity,praisingthematerialsthatwere abletomakepossibletheexistenceofnuclearpowerforalmostsevendecades.Themaingoalofthemoretechnicalchapterswastoreviewtheliteraturedatausingthesamesetofguidelines,metrics,orparameterstoevaluate thematurityofeachconceptandtoassesstheprogressorimportantgaps thatexistineachoftheengineeringanswerstothenewermaterialschallenge.Thisbookdoesnotcovereffortsandresultsfromthefieldofmodelingandsimulation.Ineachoneoftheproposedsolutionsthereisasolid foundationofsciencejustifyingtheviabilityofeachconcept,butforautility tobeabletoimplementtheproposedaccidenttolerantfuel,italsoneedsto besimple,practical,economical,andsafe.

Itisanexcitingtimetobeworkinginthefieldofadvancedtechnology materialsformakinglightwaterreactorssafertooperate.Theuseofelectricityoriginatingfromnuclearsourcesrepresentsacrucialcontributiontoa cleanenvironmentandtothereductionintheatmosphericreleaseof climate-changinggreenhousegases.

Finally,Iwouldliketoacknowledgethepatienceandunderstandingof myhusbandWilliamW.Wickline,whomakesmelaughandwhoprefersto ignorethetravailsoftherealworldbywatchingvintageHollywoodmovies.

ANL ArgonneNationalLaboratory(UnitedStates)

AOOs Anticipatedoperationaloccurrences

ATF Accident-tolerantfueloradvancedtechnologyfuel

ATR Advancedtestreactor

BDBAs Beyond-design-basisaccidents

BNL BrookhavenNationalLaboratory(UnitedStates)

BWR Boilingwaterreactor

CANDU CanadaDeuteriumUranium

CA-PVD Cathodearcphysicalvapordeposition

CEA FrenchAlternativeEnergiesandAtomicEnergyCommission

CHF Criticalheatflux

CILC Crud-inducedlocalizedcorrosion

CMC Ceramicmatrixcomposite(SiC/SiC)

CNL CanadianNuclearLaboratories

CRIEPI CentralResearchInstituteofElectricPowerIndustry(Japan)

CTE Coefficientofthermalexpansion

CVD Chemicalvapordeposition

CVI Chemicalvaporinfiltration

DBA Design-basisaccident

DNB Departurefromnucleateboiling

DOE DepartmentofEnergy(UnitedStates)

EATF Enhancedaccident-tolerantfuel

EBSD Electronbackscatterdiffraction

ECCS Emergencycorecoolingsystem

ECR Equivalent-claddingreacted

EDF Electricite ´ deFrance

EDS Energydispersivespectroscopy

EGATFL ExpertGrouponAccident-TolerantFuelsforLightWaterReactors(NEA)

EPR Europeanpressurizedreactor

EPRI ElectricPowerResearchInstitute

ETF Elongationtofailure

HFIR High-fluxisotopereactor

HWC Hydrogenwaterchemistry

IAEA InternationalAtomicEnergyAgency

IMAGO IrradiationofMaterialsforAccident-tolerantfuelsintheGosgenreactor

INL IdahoNationalLaboratory(UnitedStates)

xii Listofabbreviationsandacronyms

IRSN Institutderadioprotectionetdesu ˆ rete ´ nucle ´ aire(France)

JAEA JapanAtomicEnergyAgency

KAERI KoreaAtomicEnergyResearchInstitute

KIT KarlsruheInstituteofTechnology(Germany)

KTH RoyalInstituteofTechnology(Sweden)

LBM Laserbeamwelding

LFA Leadfuelassembly

LFR Leadfuelrods

LHGR Linearheatgenerationrate

LOCA Loss-of-coolantaccident

LTA Leadtestassemblies

LTR Leadtestrod

LWR Lightwaterreactor

METI MinistryofEconomy,TradeandIndustry(Japan)

NDE Nondestructiveevaluation

NEA NuclearEnergyAgency

NEAMS Nuclearenergyadvancedmodelingandsimulation

NFD NipponNuclearFuelDevelopment

NPP Nuclearpowerplant

NPS Nuclearpowerstation

NRC NuclearRegulatoryCommission(UnitedStates)

NWC Normalwaterchemistry

OD Outerdiameter

ODS Oxidedispersionstrengthened

ORNL OakRidgeNationalLaboratory(UnitedStates)

PCI Pellet cladinteraction

PCMI Pellet cladmechanicalinteraction

PIE Postirradiationexamination

PNNL PacificNorthwestNationalLaboratory(UnitedStates)

PRW Pressureresistancewelding

PSI PaulScherrerInstitute(Switzerland)

PVD Physicalvapordeposition

PWR Pressurizedwaterreactor

RBMK HighPowerChannel-TypeReactor(Russia)

RCS Reactorcoolantsystem

RE Rare-earthelements

RIA Reactivity-initiatedaccident

RPV Reactorpressurevessel

RT Roomtemperature

SBO Stationblackout

SCC Stresscorrosioncracking

SEM Scanningelectronmicroscopy

TD Theoreticaldensity

TIG Tungsteninertgas

TREAT Transientreactortestfacility

TRISO Tri-structuralIsotropic

TRL Technologyreadinesslevel

UTS Ultimatetensilestrength

VHT Veryhightemperature

VVER Water waterenergeticreactor(Russia)

XRD X-raydiffraction

YS Yieldstress

ChapterOutline

Overview1

Introduction1

Benefitsofnuclearenergy5

Thefirststepsofcommercialnuclear power8

Overview

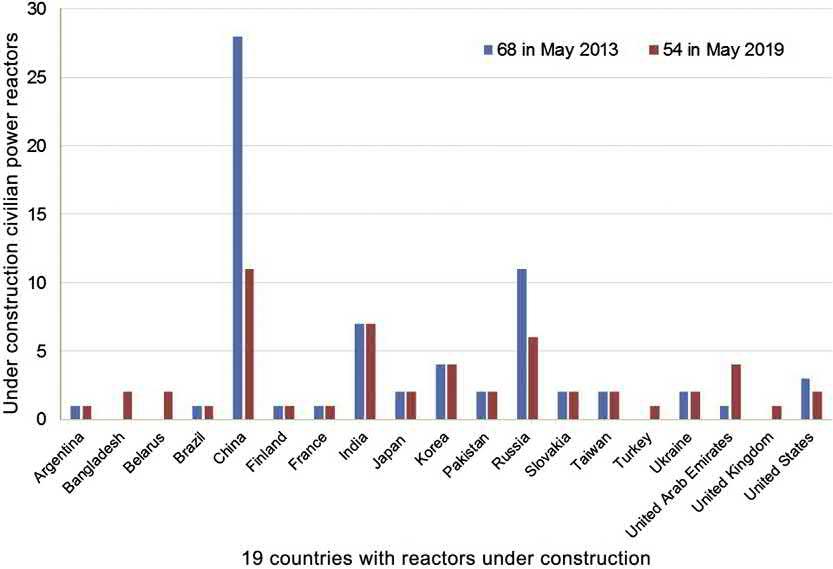

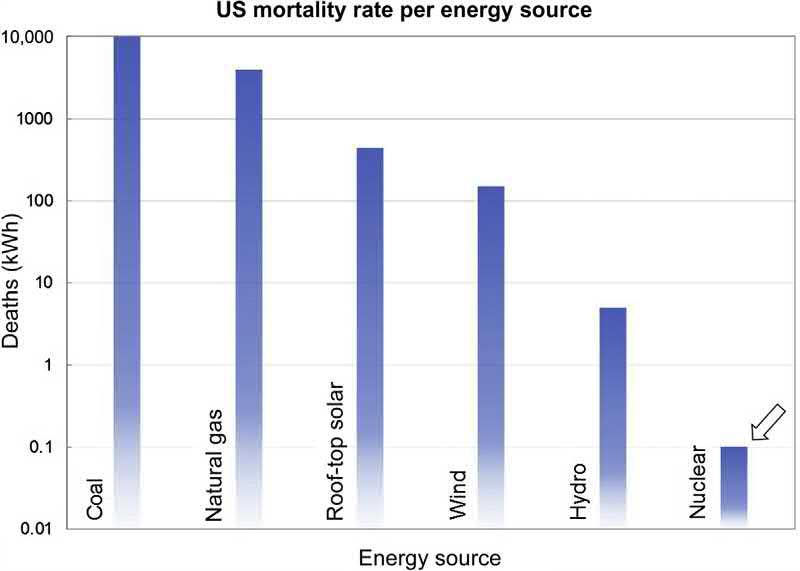

Theelectricityintheinterconnectedcommercialgridcomesfrommany sourcesincludingfossilfuels,renewableenergies(e.g.,solarandwind),and nuclearenergy.Theenergyharvestedfromnuclearfissionsourcesisclean, itdoesnotreleasegreenhousegasestotheenvironment,anditdoesnotcontributetoclimatechange.Moreover,nuclearsourcedelectricityisthesafest typeforcivilianuse.IntheUnitedStatesandaroundtheglobe,thenumber ofhumandeathsperkilowatthourofgeneratedelectricityfromnuclear sourcesisfiveordersofmagnitudelowerthanforcoalandotherhydrocarbonsources.Nuclearelectricityisevensaferthansolarorwindelectricity. Nuclearpowerwasfirstusedformilitarypurposes,especiallyforthepropulsionofsubmarines.However,intheearly1950s,theUnitedNationsprogramofAtomsforPeace,boththeUnitedStatesandtheSovietUnion developedtheirfirstciviliannuclearpowerplantswhichwereconnectedto theirrespectivegridsinthelate1950s.Ataroundthistime,thetrustedfuel rodpairofzirconiumalloycladdingcontainingpelletsofuraniafuelwas bornandusedformanydecadessince.Currently,thereareapproximately30 nationswhichuse451civilianreactorstogenerateelectricity.Thelargest expansionofnuclearreactorswasinthedecadesof1970sand1980s.In 2019therewere54newreactorsunderconstruction,mainlyinAsia.

Introduction

Cleanenergyisanenergythatdoesnotpollutetheenvironmentnor increasestheamountofgreenhousegasesthatmaycontributetoclimate change.Nuclearenergyiscleanenergysinceitdoesnotchangethecarbon footprintintheplanet.Nuclearenergyisalsothesafestformofallenergies

usedtogenerateelectricity.Nuclearenergyisevensaferthantherenewable solarorwindenergies.Electricitygeneratedusingfossilfuelsmayincrease thecarbonfootprintbyreleasingmethanegastotheatmosphereinthe upstream(duringexplorationandproduction)andthenreleasingcarbon dioxidetotheatmosphereinthedownstreamwhenthefossilfuelsorhydrocarbonsareburnttoextracttheheat.

SteamturbinesgeneratemostoftheelectricityusedintheUnitedStates andintheplanet.Powerplantsthatarefedbyuraniumorcoalaresimilarin thesensethatbothusesteamturbinestomovethegeneratorstoproduce electricity.Nuclearandcoalplantsdifferinthewayhowtheymaketheir steamneededfortheturbines.Onetypeofplantsplitstheatomthrougha fissionreactionwhichgeneratesvastamountsofenergy,andtheothertype ofpowerplantburnshydrocarbonsthroughacombustionreaction.Overall, theoperationofbothtypesofplantsgreatlydiffersinthefactthatoneplant producessteaminthesafestandcleanestwaypossiblewhiletheotherdoes not.

Worldwide,thegenerationofelectricpowerhasseveralsourcesof energythatcanbegroupedas:(1)fossilfuels(coal,petroleum,andnatural gas),(2)nuclear,and(3)renewable(wind,solar,hydroelectric,geothermal, biomass,etc.)sources. Fig.1.1 showsthattheworldenergyconsumptionin thenexttwodecadeswillbestilldominated(B80%)bytheburningoffossil fuels(liquid,gas,andcoal).Nuclearenergyrepresentsonly6%oftheenergy consumedworldwide.IntheUnitedStates,30%oftheconsumednaturalgas isusedtogenerateabout20%oftheelectricalpowerproducedinthecountry.Theother70%oftheconsumednaturalgasisusedforpurposesother thantogenerateelectricity,forexample,forheating.Onthecontrary,100% ofthenuclearenergygeneratedisusedtoproduceelectricity.

Nuclearoratomicenergyisreleasedwhenatomsaresplitinareactor. Thereleaseofnuclearfissionenergyistransferredtowater,whichmakes

steamthatisusedtospintheturbineswhichrotatestheshaftoranelectrical generator.Electricitygeneratedusingnuclearsourcesrepresentsabout20% ofalltheelectricalpowerconsumedintheUnitedStates.Inothercountries, suchasFrance,theelectricitygeneratedfromnuclearfissionrepresentsover 70%ofthetotalelectricityconsumedinthenation.Therearecurrently around30countriesintheglobethatusenuclearsourcestogeneratecivilian electricity(IAEA,2019).

Fig.1.2 showsthattheworldwidenumberofoperationalreactorsslightly increasedbetween2013and2019from430to446(IAEA,2019).ThelargestincreaseinnewerpowerreactorswasinAsiaandEasternEurope(China, Korea,India,Pakistan,andRussia).ThenotableincreasewasinChinawhere thenumberofreactorsmorethandoubledfrom18in2013to46in2019.In thewesternworld,thenumberofoperationalreactorsmostlydecreased, exceptforArgentinawhereitincreasedfromtwotothree.

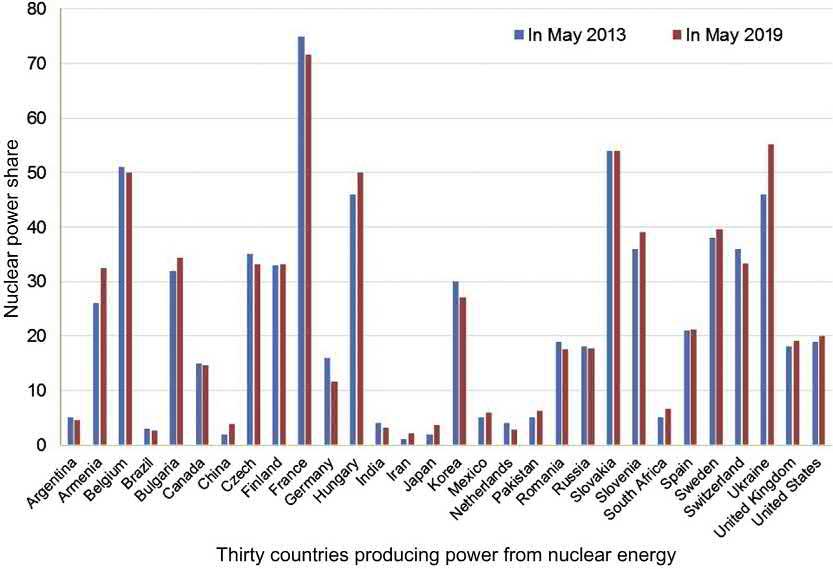

Fig.1.3 showsthenuclearpowerpercentageofthetotalelectricityconsumedinthe30currentcountrieswithnuclearpowerfor2013and2019 (IAEA,2019).Thecountrieswiththelargestshareofnuclearpowerare France,Slovakia,Ukraine,Belgium,andHungary.Franceisalsoexporting electricitytoneighboringcountriessincetheircostofpowergenerationis lowcomparedtoothernonnuclearsourcesinthoseneighboringcountries. Therewaslittlechangebetweentheshareofnuclearpowerbetween2013 and2019forthe30countrieslisted.IntheUnitedStates,forexample,the shareofnuclearpowerstayedthesameat20%betweenthese2years,consideringthatthecountryhadfourfewerreactorsin2019thanin2013.One

ofthereasonsisthatthepowerreactorsbecamemoreefficientandanother reasonisbecausethetotalconsumptionofelectricitydecreasedduetheenvironmentalgreenmeasures.

Fig.1.2 showsthatJapanhadapproximately40operationalreactors between2013and2019buttheshareofnuclearpowerwasonlyintheorder of3%.ThereasonforthisisthatmostoftheJapanesereactorswerenotproducingelectricityinthisperiodbecauseoftheirtemporaryshutdownfollowingtheFukushimaaccidentofMarch2011.Beforetheaccidentatthe Fukushimasite,thenuclearpowershareinJapanwasapproximately30% (IAEA,2019).

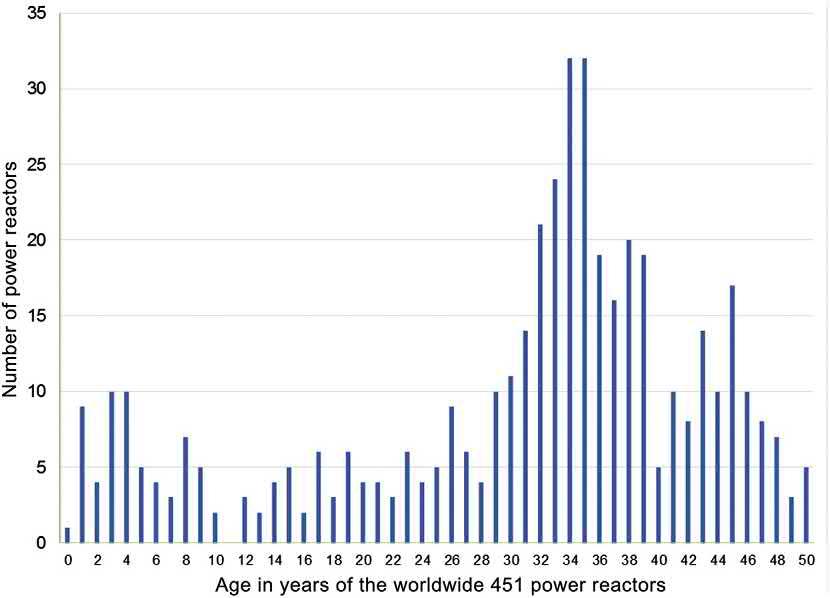

Fig.1.4 showstheagedistributionofthe451powerreactorsoperating worldwideinMay2019(IAEA,2019).Sixty-eightpercentofthereactors are30ormoreyearsoldandonly13%ofthereactorshaveanageof10 yearsorless.Theworldwidefleetofpowerreactorsisaging,butitalso appearsthatthereisaslightincreaseinthenumberofreactorswith5years orlessinage.Itisimportanttopreventtheshutdownofolderreactorsby licenserenewal.Oneofthemeasurestopreventtheshutdownofolderreactorsistoretrofitthemusingaccidenttolerantfuels,whichwillmakethe reactorssafertooperate.

IntheUnitedStates,therearecurrently98operatingcommerciallight waterpowerreactors,34boilingwaterreactors(BWRs),and64pressurized waterreactors(PWRs).Approximately90%oftheUSpowerreactorsareat least30yearsoldand45%ofthereactorsareatleast40yearsold.Onlyone

FIGURE1.3 Nuclearpowershare(IAEA,2019).

newreactorwasconnectedtothegridintheUnitedStates,inthelast25 yearsandonlytwonewreactorsarecurrentlyunderconstruction(2019).

Fig.1.5 showsthat19countrieshavecurrentlypowerreactorsunderconstructionascomparedto15countriesin2013.Fourcountries(Bangladesh, Belarus,Turkey,andUnitedArabEmirates)thatdidnothavenuclearpower beforearecurrentlyplanningtoentertheinternationalcommunityofgeneratingelectricityfromnuclearenergy(IAEA,2019).China,India,andRussia havecurrentlythelargestamountofnuclearpowerplantsunderconstruction, eventhoughtheconstructionrateinChinaseemedtohavesloweddownin thelastquinquennium.TheUnitedArabEmirateshasfourreactorsunder constructionwhichismorethandoublethanitwasin2013.Itislikelythat EgyptwillfollowsoonwithapowerreactoroftheirownintheArabcommunity.Egypthashadanuclearprogramsince1954.Therearealsocurrent advocacygroupstobringnuclearpowertoAustralia,consideringthat Australiahasmorethan30%oftheworlddepositsinuranium,similartothe depositsofCanadaandKazakhstan.

Nuclearpowerplantsworkallthetime,andtheydonotneedspecificclimaticconditionstooperate.Nuclearenergyprotectstheenvironmentsinceit doesnotreleasenitrogenoxide,sulfuroxide,orcarbondioxide.The

productionofnuclearelectricitydoesnotgenerateparticulatesorspread mercuryanditdoesnotcontributetothereleaseofmethanetotheatmosphere.Nuclearenergyisalsothesafesttypeofenergysinceithistorically

FIGURE1.5 Reactorsunderconstruction.producedthelowestnumberofcasualtiesorfatalitiesperkilowatthourof energygenerated(Fig.1.6).Thelargestnumberofhumancasualtiesaround theworldbecauseofgeneratingelectricityiscausedbyairpollution,more specificallybythepresenceoffineparticulatematter( , 2.5 µmdiameter)in theatmosphere.Thefinesuspendedparticulatematter,whichoriginates mainlythroughtheburningofcoal,maycausemorethan2milliondeathsa yearmainlyintheformofcardiopulmonarydiseasesandlungcancer(Silva etal.,2013).MostoftheseannualprematuredeathsareinAsia(India, SoutheastandEastAsia)(Silvaetal.,2013).

Fig.1.6 showsthemortalityrateintheUnitedStatesperkilowatthourof electricitygeneratedaccordingtofivesourcesofenergy.Thehumanfatalities causedbytheburningofcoalarefiveordersofmagnitudehigherthanthe fatalitiescausedbynuclearpower.Majoraccidentscausingimmediatedeaths andrelatedtotheproductionofelectricityincludethecollapseofdams (hydroelectricity),coalminingaccidents,andtheruptureofpipelinesfollowedbyexplosions.Forexample, theruptureoftheShimantanDamin 1975producedmorethe170,000humanf atalities.Coalminingaccidents producedalmost5000immediatedeath sin2006inChinaalone.Moreover, inChina,morethan70,000minersayearsufferfromtheblacklungdisease (pneumoconiosis).IntheUnitedStates,thefatalitiesincoalmineswerein theorderof1500peryearuntilthe1970s,whicheventuallydeclinedtoless than100peryearbetween1990and2012.Incontrast,intheUnitedStates, therewerezerofatalitiesrelatedtotheproductionofelectricityfromnuclear sources.

Whydoesnuclearpowerstillhaveamixedsupportinthepublic?Itis mainlybecausenuclearenergyiscomplexandnontransparent.Thegenerationofcivilianpowerusingnuclearenergyhasanunprecedentedandunparalleledsafetyrecord.Itsimplementationfollowsstrictlicensingprocedures andregulationsandthenuclearpowerplantsareoperatedandmaintainedby highlytrainedprofessionals.Onlythreemajoraccidentsarerelatedtothe productionofcommercialelectricityfromnuclearfissionsourcesandare describedin Table1.1.TheaccidentthatcausedthelargestnumberofcasualtieswasinUkrainebytheChernobylReactorNumber4.Approximately 30firstresponders’firefightersdiedduringorimmediatelyafterthe Chernobylaccidentanditisestimatedthatthehumancasualtiesmayhave reachedseveralthousandsinthethreedecadessincetheaccident,mainly becauseofcancer.Bycontrast,theaccidentofThreeMileIslandhadzero immediateandlong-termcasualties.TheFukushimaaccidentsitssomewhere inthemiddle.TheonlycasualtiesattheFukushimasiteduringthetsunami andtheimmediateeventswereduetothedrowningoftwotechnicianswho wereinthebasementwhenthesecondwavehittheturbinebuildings. RelatedprematurecasualtiesbecauseoftheFukushimaaccidentemanated fromtheevacuationofelderlyandailingresidentsfromnearthepower

Commercial nuclear accident

ThreeMile Island,1979

Chernobyl, 1986

Whathappened?Directhumancasualties (delayed,estimated)

PartialmeltdownofthePWRUnit2 reactorduetoalossofcoolantinthe primarycircuitcausedbyavalve stuckopen.Cause,humanerror,& lackoftraining.

Steamexplosionfollowedbyopen airgraphitefireofthelightwater graphitemoderatedRBMKUnit4 reactorduringatesttosimulatea stationblackout.Thefireburnedfor 9daysreleasingfissionproductsto theatmosphere.Cause,operator error,negligence,&lackoftraining orknowledge.

0(0)

30(134upto1996, maybeatotalof4000, leukemiaandcancer)

Fukushima Daiichi,2011

Hydrogengasexplosionsbecauseof lossofcoolantduetostationblack outcausedbyatsunamiwave. Releaseofradioactiveproductsto theatmospherefromBWRUnits1, 2,and3.Cause,failureofoperator tomeetbasicsafetyrequirements.

2drowned(1600elderly relatedtoevacuation,not toradiation)

station.CasualtiesduetoirradiationexposureintheFukushimaPrefecture maynotbeprovenyet.

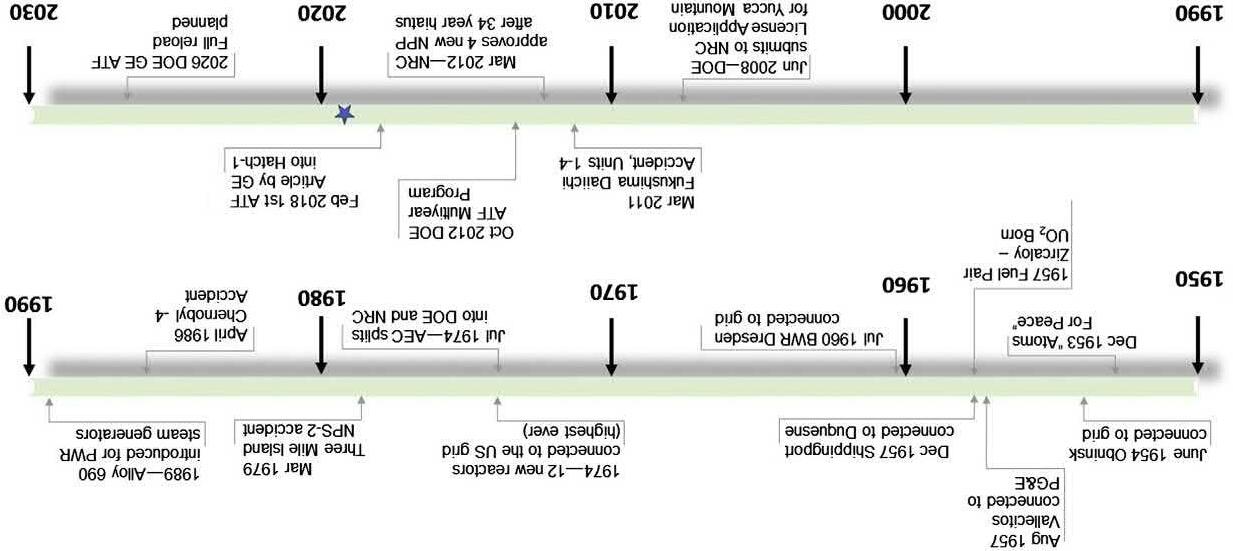

CiviliannuclearpowerwasdevelopedalmostsimultaneouslyintheUSSR andintheUnitedStatesinthemidtolate1950s. Fig.1.7 showsafewmilestonesofnuclearpowerfrom1950,mostlycenteredaroundeventsinthe UnitedStates.Theutilizationofnuclearenergytogenerateelectricityoriginatedfromthediscoveryofthenuclearfission(andthereleaseofheat)in December1938inGermany.Thecontrolledreleaseofnuclearenergybya self-sustainingchainreactionwasrealizedbyEnricoFermiattheUniversity ofChicagoinDecember1942.CriticalitywasreachedintheFermibuiltpile reactorwithnaturaluranium.Areactorachievescriticalityandbecomescritical,wheneachfissioneventreleasesenoughneutronstosustainanongoing

BWR,Boilingwaterreactor; PWR,pressurizedwaterreactor; RBMK comesfrom“ReaktorBolshoy MoshchnostiKanalnyy”whichmeans“HighPowerChannel-typeReactor”. FIGURE1.7 Nuclearpowertimeline.

FIGURE1.7 Nuclearpowertimeline.

seriesofreactions,producingacontinuousreleaseofheat.Approximately 99%ofthenaturaluraniumistheuranium-238(U-238)isotopewhichis nonfissile.Thenaturaluraniumalsocontainsapproximately0.7%ofthefissileU-235isotope.AftertheFermisustainedchainreactiondemonstration, effortswereundertakenattheClintonEngineerWorksatOakRidgeto enrichtheuraniumfuelintheU-235isotopefromapproximately0.7%to levelsintheorderof3% 5%.Theearly1940seffortsandactionstoharvest energyfromnuclearfissionwereacceleratedasaresponsetotheWorldWar IIeventsinEurope.

TheuseofnuclearfissionenergytoproduceelectricityintheUnited Stateswasmainlytheresultofthelaborsofoneperson,HymanGeorge Rickover.RickoverwasanofficerintheUSNavyandafterspendingtime duringWorldWarIIinthePhilippinesandJapan,hereturnedtotheUnited Statesanddecidedtoreinventhisowncareerbydedicatinghimselftolearn howtousenuclearenergytopropelasubmarine.Between1946and1947, RickoverspentayearatOakRidgetolearnasmuchashecouldabout nuclearenergyandthenhereturnedtoWashington,DC,tobethedirectorof reactordevelopmentinthenewlycreated(1946)AtomicEnergy Commission.Rickover’smainobjectivewastobuildareactorforasubmarinebutbecauseofpoliticalbacklash,theUSpoliticalsystemdecidedto demonstrateintheearly1950sthatnuclearenergycouldbeusedforpeacefulpurposes,suchasgeneratingelectricityfortheciviliandistributiongrid.

Thefirstpressurizedlightwatercooledpowerreactortobeconnectedto theelectricalgridandtooperatecommerciallywastheatomicpowerstation 1(APS-1)atObninsk,USSR,onJune27,1954(Simnad,1981).The Obninskreactoralsoservedasaresearchstationforseveraldecadesuntilit wasdecommissionedin2002.Researchanddevelopmentconductedatthe ObninskpowerstationhelpedinthedesignandimprovementoftheRBMK sovietpowerreactor,atypeofpowerreactorwhichisstillinusetoday. AfteranRBMKtypereactorsufferedtheaccidentinChernobylinUkraine inApril1986,theexistingoperatingRBMKreactorsweremodifiedandretrofittedtomakethemmoreresilienttoaccidents.TheRBMKdesignissimple,ituseslightwaterforcoolant,graphitewithboroncarbideforcontrol rods,andzirconium niobiumcladdingfor2%enricheduranium235inuraniafuel.

Asmentionedearlier,thefirstwesternproductionofelectricitybyways ofharvestingnuclearfissionenergywasapoliticalmovebytheUnited Statestofulfillthegoalofpeacefulusesofatomicenergy,asafollow-upof theDecember8,1953,“AtomsforPeace”speechbytheUSPresident DwightD.EisenhowerdeliveredattheUnitedNationsGeneralAssembly.A PWRthatwasunderconstructionintheearly1950sattheWestinghouseoperatedBettisLaboratories(nearPittsburgh)foranaircraftcarrierwas repurposedtobeusedfortheciviliangenerationofelectricity.TheUS AtomicEnergyCommissionpartneredwiththeWestinghouseCoandthe

DuquesneLightCompanytotakethisfirstcivilianpowerreactortocompletion(Lustman,1981;VanDuysenandMericdeBellefon,2017).ThelocationforthisfirstcivilianreactorwasShippingportinBeaverCountyonthe OhioRiverapproximately40kmsouthofPittsburgh.Theresponsibilityof theconstructionofthereactorwasgiventoRearAdmiralH.G.Rickover, DirectoroftheAtomicEnergyCommissionDivisionofNavalReactors.The constructioncompanyfortheShippingportreactorwasWestinghouseand theutilitythatwasgoingtoparticipateintheconstructionandlaterdistribute theelectricitywastheDuquesneLightCompany.ThegroundbreakingceremonyfortheciviliannuclearpowerstationonShippingportwason September6,1954(Karoutasetal.,2018).Thenuclearpowerstationreached criticality3yearslater,onDecember2,1957(Fig.1.7).Thefirstelectricity fromthisplantarrivedattheelectricgridonDecember18,1957,andthe plantgeneratedelectricityuntilitwaspermanentlyshutdownin1982.The objectivebytheUSAtomicEnergyCommissionintheearly1950swasto haveapublicutilityrunanuclearpowerreactorbeforetheSecondUnited NationsInternationalConferenceonthePeacefulUsesofAtomicEnergyin GenevaSeptember1 13,1958(UnitedNations,1958;Lustman,1981).As inthecaseoftheObninskpowerplantintheUSSR,Shippingportwasbuilt toserveadualpurpose,notonlyasapowergeneratorforthegrid,butalso asatestfacilityfortheadvancementofnuclearpowertechnology.

ThereactoratShippingportwasaPWRbasedonpreviousdesignsmade fortheUSNavynuclearsubmarinessuchastheMark1prototypebuiltin IdahoandthesecondcomparablereactorbuiltfortheNautilussubmarine (Lustman,1981;VanDuysenandMericdeBellefon,2017).ThefirstsubmarinetypePWRcalledS1Wwasbuiltonlandanditachievedcriticalityon March30,1953.ThesecondPWRwasinstalledintheNautilussubmarine andcommissionedonSeptember30,1954.Twoengineeringandmaterial issueshadtoberesolvedatthattime:(1)whattouseforthefueland(2) whattouseforthecladdingofthefuelinthereactors.ThecorrosionbehaviorofnuclearcandidatematerialsintheUnitedStatesintheearlier1950s wascharacterizedbyurgencyandsecrecy(WanklynandJones,1962). Remarkably,inthemidtolate1950s,thebasicphenomenaoftheoxidation ofZircaloy-2inair,waterandsteamwerealreadyratherwelltestedandrecognized.Then,thedecisionwasmadethatShippingportwasgoingtouse Zircaloy-2ascladdingforthefuelbasedonthepositiveresultsfromtheprevioustwobuiltreactors,thelandbasedinIdahoandtheNautilusone,even thoughZircaloywasveryexpensiveatthattimesincetheKrollproduction processwasnotoptimizedyet.Also,atthetimeofthefabricationofthe ShippingportreactoratBettis,theonlyknownfuelwasmetallicuranium, sometimesminimallyalloyedtocontrolgrainsize(Lustman,1981). Compatibilitystudiesofmetallicuraniumwithhotwaterthatmaycomein contactviacladdingdefectswerenotoptimistic.When9% 12%ofmolybdenumwasaddedtotheuraniummetal,theresearchersachievedthegamma

orface-centeredcubic-phasestabilizationoftheuraniummetalanda decreaseofseveralordersofmagnitudeinthecorrosionrateofmetallic uraniuminhotwater.ItwasalsobelievedthatMoadditionswouldlimit swellingduringirradiation(Lustman,1981).Ataroundthesametimeinthe mid-1950s,Glatter,aBettisceramist,waspushingfortheconsiderationof urania(UO2)forthefuelinthethreereactorsbuiltorunderconstructionin theUnitedStates(Lustman,1981).Oneofthemainissuesthatmanyresisted ontheimplementationofuraniaasfuelwasitspoorthermalconductivity. Highthermalconductivityisneededtoremovetheheatquicklyfromthe fuel,viathecladdingandintothecoolantwater.Nevertheless,uraniawas consideredattractivebecauseofitsresistancetointeractionwithwaterinthe caseofacladdingbreachandbecauseofitsresistancetoirradiationdamage (AngandBurkhammer,1960).Eventuallyinthe1950s,aftermanyfabricationandperformancetrials,themanufacturingofuraniawasdeemedareproducible,controllable,andpredictableprocess(Lustman,1981).Thereforein thelate1950s,thecoupleorpairofuraniafuelandZircaloy-2claddingwas bornandadoptedeversinceformanydecadestocomeallovertheworld (Fig.1.7)(Lustman,1981).Atthesametime,theUSNavyusedZircaloy claddingfortheuraniumdioxide(UO2)oruraniafuel,butintheearly 1960s,thecostofzirconiumwashighenoughthatmostofthecommercial nuclearpowerstationsbuiltintheUnitedStatesusedstainlesssteelsforthe claddingoftheuraniapellets(Simnad,1981).EventuallyasthecostofzirconiumstartedtodecreaseaftertheKrollproductionprocesswasoptimized, thecommercialplantsshiftedfromausteniticstainlesssteelssuchastype 304toZircaloy-2orZircaloy-4.

Thedesign,construction,andtestingofBWRs,withoutasecondloopto producesteam,wereexploredbothintheUnitedStatesandtheUSSRonthe mid-1950stoearly1960s(Simnad,1981).IntheUnitedStates,Argonne builtanexperimentalBWRwhichoperatedbetween1956and1967demonstratingthefeasibilityofanintegratedBWRplant.GeneralElectricbuiltthe VallecitosprototypeBWRwhichoperatedbetweenOctober1957and December1963.TheGEVallecitosreactorstartedoperation4monthsbefore theWestinghouseShippingportinPennsylvania(Fig.1.7).Eventhough VallecitosgeneratedelectricityforthePacificGas&Electriccompanygrid, itspowercontributionwassmallenoughthatVallecitosisnotgenerally acceptedasthefirstUScivilianpowerreactor,therecordthatbelongsto Shippingport(VanDuysenandMericdeBellefon,2017).TheactualfirstUS civilianBWRwastheDresdenpowerstationdesignedbyGE,whichstarted operationsin1960inIllinois(VanDuysenandMericdeBellefon,2017).

Dresdenwasthefirstreactordesignedandbuiltbyprivateinitiativeand withoutgovernmentassistance.MeanwhileintheUSSR,acoreofaBWR startedtestinginsidetheObninskAPS-1reactorin1954(Simnad,1981).

ThefirstfullycommercialPWRintheUnitedStateswasYankee-Rowe powerstationinwesternMassachusetts,whichstartedoperationinJanuary

1961andendedinFebruary1992.InitiallythefuelintheYankee-Rowe PWRplantwasuraniapelletsandthecladdingwastype348austeniticstainlesssteel,withsomeelementshavingZircaloy-2cladding(Simnad,1981).

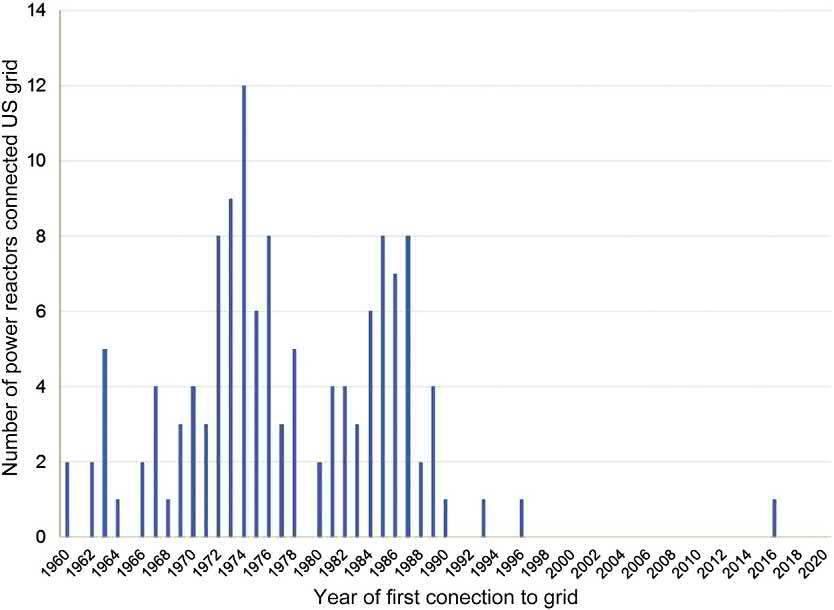

Figs.1.7and1.8 showthatthehighestnumberofpowerreactorsconnectedtotheUSgridwas12in1974(IAEA,2019). Fig.1.8 showsfora spanof60yearsthenumberofreactorsconnectedannuallytotheUSelectricalgrid.Mostofthereactorswereconnectedinthefirst30years (1960 90).Forthelast30years(1990 2019),onlyfournewreactorswere connectedtothegrid.Thelargestnumberofreactorswasconnectedinthe mid-1970sandlateragaininthemid-1980s.

TheVallecitosreactorinSunol(California)hadtheUSAtomicEnergy CommissionPowerReactorLicenseN 1.Vallecitoswasthefirstprivately ownedcommercialprototypeBWRownedbyGeneralElectric.Thisreactor initiallyusedaustenitictype304SScladdingforslightlyenrichedurania fuel.LatersomeofthecladdingwasreplacedusingZircaloy-2andZircaloy4(Simnad,1981).Eventually,someofthetype304SScladdingwasfound tosufferintergranularstresscorrosioncrackingfromthecoolantside,mainly becauseoftheradiolyticoxygen-containingenvironment(Terrani,2018). Thetype304SSusedinthe1960scontainedaconsiderableamountofcarbonandduringtheweldingoftheendcaps,theausteniticsteelwouldsensitize,makingtheweldseamareavulnerabletostresscorrosioncrackingfrom thecoolantside,mainlybecauseofthehighcorrosionpotentialinthewater

bythepresenceofradiolyticoxygenandhydrogenperoxide.Sinceatthe timewhenenvironmentalcrackingwasobservedintheweldsoffuelrods theprocessoffabricationofZircaloywasoptimizedandoflowercost,the useofausteniticstainlesssteelwasdiscontinuedforfuelcladdinguse. Becauseofthecurrenteffortstodevelopadvancedaccidenttolerantfuel materials,andmanydecadesafterausteniticstainlesswerediscontinued,the useofferriticstainlesstypealloyshasbeenproposedforfuelcladding.In contrasttoausteniticstainlesssteels,ferriticstainlesssteelsareresistantto stresscorrosioncrackinginhightemperaturewater.Moreover,duetotheir lowcarboncontent,modernferriticstainlessalloyscanbeweldedwithout undergoingsensitizationbyusingpressureresistancewelding,asolid-state weldingprocess.

Lightwaterreactors(LWRs)havebeengeneratingelectricityforoverfive decadesfortheelectricalgridofmorethan20countries.Mostofthesereactorsarebuiltusingaseriesofalloysandmaterialsthathavechangedvery littleoverthemanydecades.Themostcommonstructuralmaterialsare basedonthethreeelements,iron(Fe),chromium(Cr)andnickel(Ni)such asstainlesssteelsandnickel-basedalloys.MostoftheFe-Cr-NialloyscontainenoughCrtorenderthempassivewithlowgeneralcorrosionintypical LWRenvironments.Sincethechemistryofthewaterinthereactorishighly controlled,withoutaggressiveimpuritiessuchaschlorideorsulfateions, localizedcorrosionisnotaproblemforthecommonstructuralalloys.The mostcommonfailuremodeoftheFe-Cr-Nialloysisenvironmentally assistedcrackingorstresscorrosioncracking(SCC),whichiscurrentlywell understoodandsuccessfullymitigated,mainlybydissolvinghydrogengas intothecoolant.

Accident-TolerantMaterialsforLightWaterReactorFuels.

DOI: https://doi.org/10.1016/B978-0-12-817503-3.00002-X

© 2020ElsevierInc.Allrightsreserved.

Theotherfundamentalmaterialinthereactorcoreisthezirconium-based alloyusedforcladdingofthefuelrods.Thetraditionalfuelrodalloyswere Zircaloy-2andZircaloy-4,whichwereusedregularlyinboilingwaterreactorandpressurizedwaterreactorsystems,respectively.Veryearlyinthe developmentofthealloys(early1950s),itwasunderstoodthatasmall amount( , 2%)ofalloyingelementsgreatlyreducedthegeneralcorrosion rateofthezirconiumalloys.Thetraditionalcorrosionproblemsofzirconium alloys,suchasnodularcorrosion,shadowcorrosionfromthewaterside,and SCCfromthefuelside,arenowwellunderstoodandundercontrol.Debris frettingfromthecoolantsideremainsthemainfailuremodeofzirconium alloysfuelcladding.Overtimethedegradationprocessesofzirconiumalloys weresuccessfullyidentifiedandmanagedtoallowfortheiruseinnuclear powergenerationformorethansixdecades.

Inanuclearpowerreactor,theheatreleasedduringthefissionofuraniumin thefueliscapturedbythewatersurroundingthefuelrodstoproducesteam, whichisusedtospintheturbinestogenerateelectricity.Thewaterthat extractstheheatgeneratedbythenuclearfissionreactioniscalledthecoolant.Thefuelinsidetherodsisurania(oruraniumdioxideUO2),whichis usedintheformofapproximately10-mmtalland10-mmdiameterpellets thatarepiledabout4-mhighinsideverticalmetallictubescalledthecladding.Ametallictubefilledwiththeceramicfuelpelletsiscalledafuelrod. Currentlythealloyforthecladdingisgenerallyazirconiumalloysuchas Zircaloy-2,Zircaloy-4,M5,orZirlo(Rebaketal.,2009;Bragg-Sittonetal., 2014;Mottaetal.,2015;Tangetal.,2017).IntheUnitedStatesandaround theglobe,therearetwomaintypesoflightwaterpowerreactors:(1)boiling waterreactors(BWRs)and(2)pressurizedwaterreactors(PWR)(IAEA, 2019).Currently,thereare451operablecivilianpowerreactorsintheglobe, ofwhich299arePWRand73areBWR.Theothertypesofpowerreactors are49pressurizedheavywatermoderatedandcooledreactors,14gascooled graphitemoderatedreactors,13lightwatercooledgraphitemoderatedreactors,andthreefastbreederreactors(IAEA,2019).Themaindifference betweenthetwocommonlightwaterreactors(LWRs)isthatintheBWR, thecoolantthatmakesthesteamisindirectcontactwiththefuelrods.In thePWR,thewatercoolantthatisindirectcontactwiththerods(primary side)transfersitsheatthoughasteamgeneratortowaterinthesecondary side,whichmakestheneededsteamfortheturbines.InboththeBWRand PWRsystems,thewaterincontactwiththeexternalwallofthefuelrodsis keptliquidatabout275 C 288 Cwith7.5-MPapressureinBWRsandat 290 C 330 Cwith15.5-MPapressureinPWRs(ZinkleandWas,2013). Thechemistry(composition)ofthecoolingwaterishighlycontrolled.The watermaycontaindissolvedhydrogengastolowerthecorrosionpotentialof

themetalliccomponentsincontactwiththewater.Thepresenceofhydrogen inthewatergasdepressesthecorrosionpotentialofmostofthemetallic materialstoelectrochemicalpotentialregionswherethegeneralcorrosion andstresscorrosioncracking(SCC)ofthealloysisminimized(Fordetal., 2006;ScottandCombrade,2006).Thatis,thepurposeofthereducing hydrogengasdissolvedinthewateristobringtheopencircuitpotentialor corrosionpotentialoftheengineeringcomponentsalloystothevicinityof the“a”lineinaPourbaixdiagramwhereSCCisessentiallycontrolled (JonesandNelson,1990).InPWRsthewatermayalsocontaindissolved boricacid(asaneutronmoderator)andlithiumhydroxide(tocontrolthe valueofthepHtominimizecorrosion)(ScottandCombrade,2006).Other additionstothewatermayincludelowconcentrationsofzincinjectionsto increasetheprotectivenessoftheoxidefilmsformedonmetallicsurfacesin contactwiththecoolant(Betovaetal.,2011).

Zirconiumalloyshavebeenusedforoversixdecadestocladtheurania fuelinlightwaterpowerreactors.Zirconiumalloyshaveadequateresistance tocorrosioninhigh-temperaturewaterunderthestandardoperationconditionsofPWRsandBWRsatnear300 C(Lemaignan,2006;Mottaetal., 2015).However,thecorrosionresistanceinwaterandsteamofzirconium alloysdecreasesrapidlyasthetemperatureincreasesabove400 C.Theoxidationofzirconiumwithwaterishighlyexothermic.DuringtheplantblackouteventsofMarch2011attheFukushimaDaiichinuclearpowerstations, thewatertemperatureinsidethereactorincreasedtoabovethenormaloperationconditionvaluesforthereactorsandthezirconiumalloysreactedrapidlywithwaterandsteamforminghydrogengasandreleasinglargeamounts ofoxidationreactionheattotheenvironment.Afteralmostsevendecadesof successfullyusingzirconiumalloysinthereactors,theinternationalnuclear materialscommunityisnowsearchingforsaferandmoreresistantalternativematerialsforthefuelcomponents.

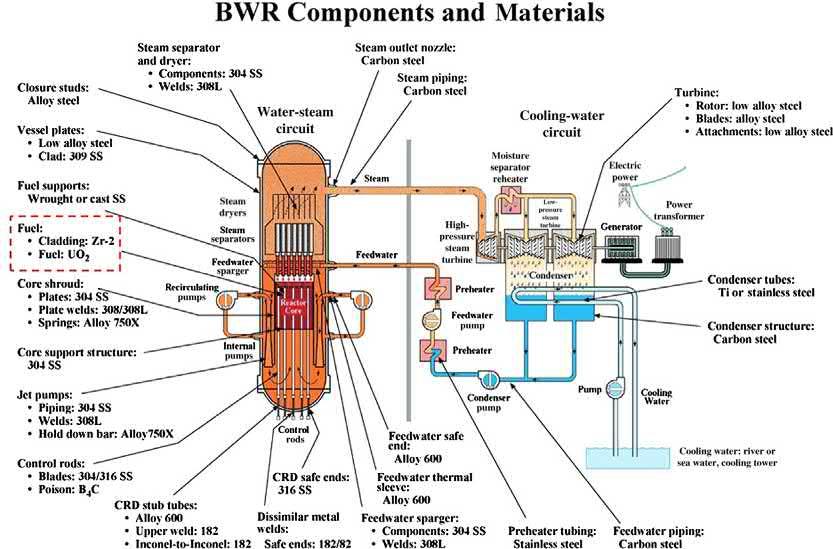

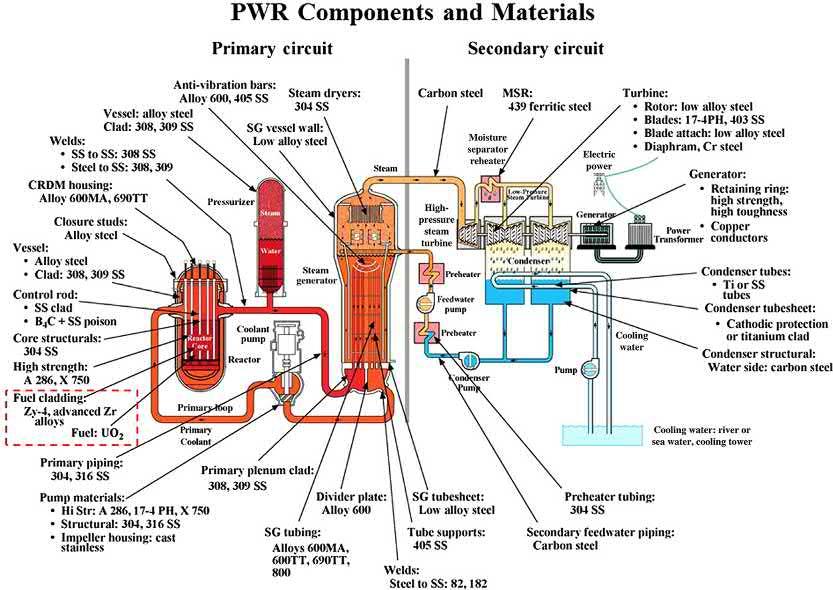

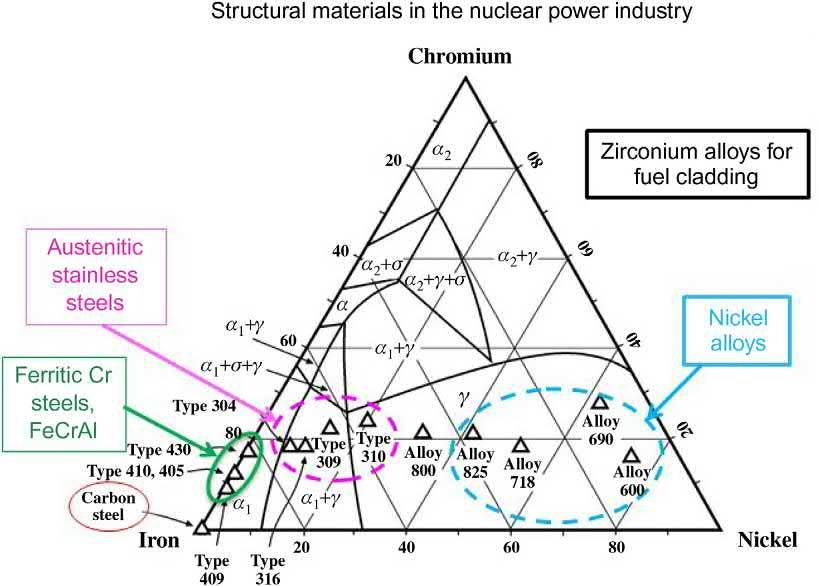

Therearetwowell-establishedtypesofLWRs:(1)boilingwaterreactorsof BWRand(2)pressurizedwaterreactorsofPWR(Figs.2.1and2.2).ThecircuitintheBWRissimplerthaninthePWRconfiguration,whichrequires twowatercircuits.Exceptforthetwosmallerredboxesin Figs.2.1and2.2 showingthefuelcomponentsinbothreactors,almostallothercomponents aremadewithalloyscontainingthethreecommonelements:iron(Fe),chromium(Cr),andnickel(Ni)(Fig.2.3).Ironisusedforstructurallow-cost components,andchromiumandnickelareusedtoprovideresistancetoenvironmentaleffects.Aroundtheworld,BWRsrepresentapproximately20%of theinstallednuclearpowercapacityandPWRsrepresent67%ofthenuclear power(NNL,2018).Theconceptofalightwaterpowerreactorwasinitially conceivedatOakRidgeNationalLaboratoryin1946(VanDuysenand

MericdeBellefon,2017).Alsoin1946,whileworkingatOakRidge,H.G. RickovermadethehistoricaldecisiontouseLWRsovergascoolingreactors topowerthesubmarinesfortheUSNavyhewassponsoringanddesigning atthattime.

FIGURE2.2 Pressurizedwaterreactormaterials. CourtesyfromR.W.Staehle. FIGURE2.1 Boilingwaterreactormaterials. CourtesyfromR.W.Staehle.

AfteritsoriginalconceptionatOakRidge,thetechnicaldevelopmentof BWRswasconductedatArgonneNationalLaboratory,andprototypeswere builtinthemid-1950sinIdahoandIllinois(Simnad,1981;NNL,2018). GeneralElectric(GE)establishedanatomicpowerbusinessunitin1955and pickeduptheBWRdesigntobuildthefirsteverUS-licensedreactoratthe VallecitossitenearSunol,California.TheVallecitosBWRwasthebasisfor thefutureconstructionofcommercialpowerBWRsallaroundtheglobe. ThisGEseriesofworldwideBWRconstructionsbeganin1959withthe DresdenUnit1reactorinMorris,Illinois,whichstartedtogeneratecivilian electricityin1961.ThedesignoftheBWRsevolvedthroughthedecades andcurrentlyseveraltypesandformsofBWRnuclearpowerstationsare foundintheUnitedStates,Japan,Sweden,Finland,Spain,Switzerland, Germany,Mexico,andIndia(NNL,2018).

AstheBWRswerefirstengineeredatArgonneNationalLaboratory,thefirst PWRsweredesignedandtechnicallydevelopedatWestinghouseBettis AtomicPowerLaboratorynearPittsburgh,withtheinitialpurposeofusing thePWRsystemforthepropulsionofnuclearsubmarines(Cumminsand Matzie,2018).CurrentlyintheUnitedStates,PWRpowerisusedfor

propulsionofsubmarines,aircraftcarriers,andicebreakers.Besides Westinghouse,twoothercompaniesintheUnitedStates(Combustion EngineeringandBabcock&Wilcox)alsosupplieddesignsandcomponents forPWRs,bothfortheNavyandcivilianpower(CumminsandMatzie, 2018).Eventually,CombustionEngineeringbecameapartofWestinghouse andBabcock&WilcoxbecameapartofFramatome.ThefirstcivilianUSproducedelectricityusingPWRatomicpowerwastheShippingportreactor fortheDuquesneLightCompany,southofPittsburgh,autilitythatwas foundedbyGeorgeWestinghousein1912(CumminsandMatzie,2018).

ThematerialsofconstructionforLWRshavechangedverylittleinthesix decadesofciviliannuclearpower(Allenetal.,2010;Rippon,1984). Figs.2.1 and2.2 showthemostrelevantmaterialsofconstructionforLWRs.Mostof thealloysarebasedonthethreeelementsiron,chromium,andnickel (Fig.2.3). Table2.1 showsacondensedlistofalloysandtheirchemicalcompositionusedfortheconstructionofLWRs.Iron-basedalloyscontaining enoughchromiumforpassivationarestainlesssteels. Fig.2.3 showsthatmost stainlesssteelscontainapproximately20%ofchromium.Ifthestainlesssteels containsomenickel,theywouldbeausteniticbecausetheyadopttheFCCor gammaphasestructure.Whenthesteeldoesnotcontainnickel,itsphase wouldbeferritic,BCC,oralpha. Fig.2.3 (right)showsthenickel-based alloys,whichalsocontainapproximately20%chromiumforpassivation.The lowestchromiumcontentinthenickelalloysareinX-750andalloy600and thehighestchromiumcontentis29%foralloy690(Table2.1).

ThemainfailuremodeofausteniticstainlesssteelsandchromiumcontainingnickelalloysduringnormaloperationinthereactorcoreisSCCor environmentallyassistedcracking(EAC).Thecrackingsusceptibilityof structuralstainlesssteelsandnickelalloysisgenerallyminimizedbyloweringtheredoxpotentialinthecoolantviatheinjectionofhydrogengas (JonesandNelson,1990).Allthealloyscontainingatleast12%chromium wouldhavealowgeneralcorrosionratebecauseoftheformationofaprotectivechromiumoxidefilmontheenvironmentexposedsurface,which kineticallypassivatesthemetallicstructuresandthedissolution(orcorrosion)ofthecomponentbecomesnegligible.Mostofthematerialsin Table2.1 havebeenusedformanydecades.Thenewestmateriallistedin thistableisAlloy690(N06900),whichwasintroducedforsteamgenerators tubinginPWRsin1989.Thatis,thenewestmaterialusedinLWRsiscurrently30yearsold.Materialsnotlistedin Table2.1 arethezirconiumalloys forfuelrodcladding,whicharediscussedseparately.

In Figs.2.1and2.2 thereisaverticalgrayline.Totherightofthevertical grayline,bothreactorsystemsaresimilarsincethecommonfeatureisthe

ductcarryingthesteamacrossthisverticalgraylinetopropeltheturbines. Evenfossilfuelplantshaveasimilarconfigurationasthecomponentsshown ontherightofthegrayline.Thecomponentstotheleftofthegrayline [includingthereactorpressurevessel(RPV)andtheheatexchangers]are enclosedinthereinforcedconcretecontainmentbuildingofthenuclear powerstation.Theconcretecontainmentbuildingisthelastbarrierforradionuclidesandothercontaminantsbeforetheycanreachtheexternal