March 5-8, 2026

Wyndham Grand Rio Mar

Rainforest | Beach | Golf Resort | Río Grande, Puerto Rico

March 5-8, 2026

Wyndham Grand Rio Mar

Rainforest | Beach | Golf Resort | Río Grande, Puerto Rico

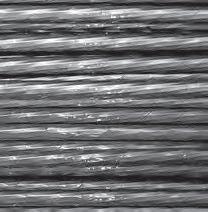

For over six decades, our customers have relied on us as their trusted source for wire and strip solutions. At Gibbs Interwire, we’re consistently investing in our equipment, products, processes, and people to meet the needs of our customers, now and in the future.

of Springs: From the Vault

Do I Grow My Business?

Customer

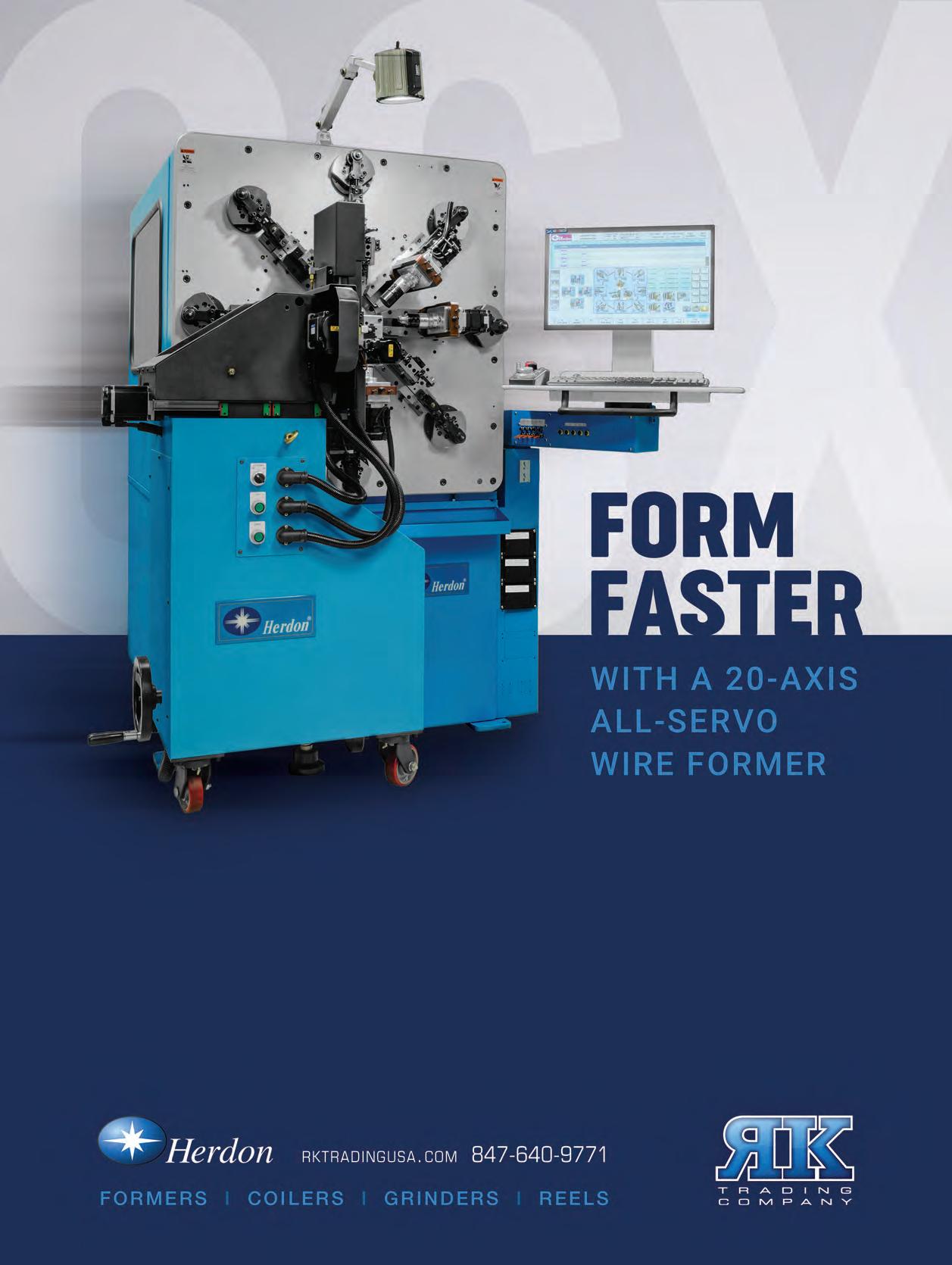

RK Trading’s CSX series of Herdon formers keeps your operation running smoothly. This technology offers a high-speed 20-Axis All-Servo Wire Former that supports multiple servo spinners, the 4-axis AT system and the EA attachment. With a next-generation processor and larger touch-screen monitor, this enhanced operating system provides increased versatility and faster production speeds so you can make more parts complete in less time.

Give us a call today to get up and running with a 20-Axis All-Servo Wire Former from Herdon. SCAN HERE

In the late 19th and early 20th centuries, the heart of American springmaking pulsed in two regions: New England and Chicago. New England’s manufacturing belt drew skilled artisans from Germany, Switzerland and Italy, many of them trained in the exacting trades of watchmaking and gunsmithing. Factories in Hartford, Worcester and Springfield advertised for “experienced spring hands” and “wire workers,” often relying on local immigrant enclaves to fill orders. Company managers knew that precision coiling, tempering and finishing were skills passed within families and ethnic networks. Chicago, meanwhile, became a magnet for Eastern European immigrants — Polish, Bohemian and Slovak machinists—who staffed the growing carriage, mattress and machinery plants of the Midwest. Employers often worked directly through community halls and immigrant newspapers, recruiting entire shifts through word-ofmouth. These shop floors were multilingual spaces where newcomers not only found work but also transmitted craft traditions across generations.

Today, the pattern continues. While automation has transformed production, immigrant workers remain central—now hailing from Latin America, South Asia and East Africa. In New England tool shops or Chicago’s industrial suburbs, they join family-owned spring businesses descended from earlier immigrant founders. Springmaking has always been an industry wound together by migration.

The “immigration puzzle” in springmaking is not about controversy but continuity. A specialized craft, transplanted through migration, helped American industry leap forward and still sustains it today.

“Everywhere immigrants have enriched and strengthened the fabric of American life.”

— John F. Kennedy

Don Jacobson III Newcomb Spring Corp.

D3@newcombspring.com

Contact Us

Spring Manufacturers Institute

PO Box 5668

Elgin IL 60121

Main phone z 847-450-6848

Gary McCoy z 847-450-6240

Gaby Carrasco z 847-857-6432

SMI Executive Committee

President: Don Jacobson III, Newcomb Spring

Vice President: David DeVoe, John Evans’ Sons

Secretary/Treasurer: Dave Deerwester, The Yost Superior Co.

Past President: Gene Huber Jr., Winamac Coil Spring

At-Large: Joe Devany, Betts Company

Executive Director: Gary McCoy, SMI

SMI Board of Directors

Julie Arenz, R&L Spring/Medicoil I Markus Arnold, WAFIOS I Tim Bianco, Iowa Spring I Jodi Boldenow, IDC Spring I Adam Jacobson, FENN/Torin I Chris Kozka, MW Components I Don Lyons, JonSpring I Alex Melnikow, Midstate Spring I Keith Porter Jr., Newcomb Spring I Sanjeev Rivera, Lee Spring I Timo Roeger, Kern-Liebers USA I Monica Shaffer, Novi Spring I Jason Sicotte, Associated Spring I Bernie Taylor, Hoosier Spring I Tim Zwit, Motion Dynamics Corporation

Springs Magazine Staff

Gary McCoy, Executive Director/Publisher, gary@smihq.org

Phil Sasso, Managing Editor, phil@smihq.org

Gaby Carrasco, Associate Editor, gaby@smihq.org

Lisa Plefka Haskin, Art Director, lisahaskin95@gmail.com

Communications Committee

Chair, Keith Porter Jr., Newcomb Spring I Reb Banas, Stanley Spring & Stamping I Hale Foote, Scandic Springs, Inc. I Patrick Gillum, Gilco Spring of Florida, Inc. I Adam Jacobson, FENN/Torin I Lucas Karabin, Acme Monaco I Gary McCoy, SMI I Phil Sasso, SMI I Michael Shapiro, Gibraltar Corporation I Bill Wynn, Gardner Spring, Inc.

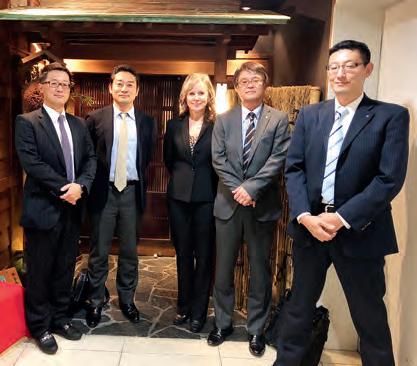

Advertising Sales I Japan

Ken Myohdai, Sakura International Inc.

Head Office: 3F,4F, ENDO Sakaisuji Bldg., 1-7-3, Bingomachi, Chuo-Ku, Osaka 541-0051, Japan

Phone: 81-6-6624-3601 I Fax: 81-6-6624-3602

Tokyo Global Office: 5F Kamei No. 2 Bldg., 2-17-13, Kiba, Koto-Ku, Tokyo, 135-0042, Japan Phone: 81-3-5646-1160 I Fax: 81-3-5646-1161

E-mail: info@sakurain.co.jp

Advertising Sales I Taiwan

Charlie Yu, Worldwide Services Co. Ltd. 11F-B, No 540, Sec. 1, Wen Hsin Rd. Taichung, 408 Taiwan Phone: +886-4-2325-1784 I Fax: +886-4-2325-2967

E-mail: marketing@acw.com.tw

Springs (ISSN 0584-9667) is published quarterly by SMI Business Corp., a subsidiary of the Spring Manufacturers Institute: PO Box 5668, Elgin IL 60121 Phone: 847-450-6848; Website: smihq.org

Address all correspondence and editorial materials to this address.

The editors and publishers of Springs disclaim all warranties, express or implied, with respect to advertising and editorial content, and with respect to all manufacturing errors, defects or omissions made in connection with advertising or editorial material submitted for publication.

The editors and publishers of Springs disclaim all liability for special or consequential damages resulting from errors, defects or omissions in the manufacturing of this publication, any submission of advertising, editorial or other material for publication in Springs shall constitute an agreement with and acceptance of such limited liability.

The editors and publishers of Springs assume no responsibility for the opinions or facts in signed articles, except to the extent of expressing the view, by the fact of publication, that the subject treated is one which merits attention.

Do not reproduce without written permission.

Cover designed by Lisa Plefka Haskin utilizing Shutterstock imagery.

Please archive or recycle this magazine.

Springs archives: smihq.org/springs-magazine

Join us on social media!

Stanley Spring and Stamping has acquired Hudson Tool & Die Company, a Franklin Park, Illinois–based manufacturer of metal stampings, wireforms and assemblies.

Founded in 1952 by Werner Eric Hellwig, Hudson Tool has remained a family-led business for more than 70 years, most recently under the leadership of Linda Hellwig Salerno. The company has maintained a long-standing relationship with Stanley Spring and the acquisition ensures continuity for Hudson’s experienced workforce and customer base.

Stanley Spring president Reb Banas noted that Hudson’s capabilities in heavy wireforming and metal stamping complement Stanley Spring’s operations and align with its emphasis on quality, service and timely delivery.

Hudson Tool customers will transition to production at Stanley Spring’s 85,000-square-foot Chicago facility. The acquisition is Stanley Spring’s fourth since 2021, following Precision Forming & Stamping, KBWF-Kerr-Buffalo Wire Forming Company and RICH Industries.

MW Components has appointed Thomas A. Amato chairman and CEO. He succeeds Simon Newman, who has stepped down.

Amato will work with MW’s leadership team and American Securities, its private equity owner, to build the company’s growth and oversee its portfolio of brands and products.

Most recently, Amato was president and CEO of TriMas Corporation, where he guided the company’s transformation into an aerospace and packaging business. He was previously CEO of Metaldyne, LLC, and later co-president of Metaldyne Performance Group, which was taken public in 2014 and sold to American Axle in 2017. He also serves as a director at AMETEK, where he chairs the compensation committee.

Rotor Clip received the 2025 Supplier Excellence Award from Caterpillar, marking consecutive years of recognition for consistently exceeding performance and reliability. The award highlights Rotor Clip’s role as a trusted supplier and manufacturer of retaining rings, wave springs and hose clamps used across Caterpillar’s equipment and global manufacturing operations. The award is given to suppliers who meet or exceed Caterpillar’s expectations across key areas of supply chain performance.

The L.S. Starrett Company, a global manufacturer of precision measuring tools, gages and metrology systems, has announced four key executive appointments at its Athol, Massachusetts headquarters.

Roger N. Amrol, Jr. was named president and chief executive officer, succeeding Douglas A. Starrett, who retired after a 48-year career with the company. Amrol brings more than two decades of leadership experience from Robert Bosch Tool Corporation and Techtronics Industries

Barry D. Laughlin joined as chief operating officer, with more than 35 years in manufacturing operations, including senior roles at Group DEKKO, Caterpillar and Navistar

Allen E. Look was appointed global chief information officer, contributing more than 25 years of IT leadership, cybersecurity and data analysis expertise.

Jon-Michael Raymond has assumed the role of chief revenue officer, bringing extensive experience in sales and marketing across the industrial sector, including prior leadership positions at Starrett and other global manufacturers.

FENN Torin marked its 125th anniversary by hosting an educational tour and celebration with The Wire Association International’s New England Chapter Oct. 9, 2025. The program was held at FENN Torin’s facility in East Berlin, Connecticut, with a tour showcasing forming machinery and advancements in rolling and swaging. It was followed by a networking reception. Proceeds went to support the WAI’s New England Chapter scholarship fund.

CGR International has acquired Industrial Spring Corporation (ISC), a North Kansas City–based manufacturer of precision spring components. The acquisition marks CGR’s first U.S. operation and expands its international presence.

Founded more than 55 years ago, ISC supplies springs to sectors including agriculture, industrial machinery, automotive, consumer products and medical devices.

According to CGR CEO Alexis Martel, the acquisition strengthens the company’s ability to serve North American clients and pursue new opportunities across multiple industries. ISC CEO Phil Jones noted that the partnership supports ISC’s long-term continuity while maintaining its local identity.

CGR plans to build on ISC’s established reputation while introducing additional technologies such as mechatronics and cold forming, with potential applications in U.S. markets including medical, automotive and aerospace.

From April 13–17, 2026, the global wire, cable, tube and pipe industries will gather in Düsseldorf, Germany, for wire and Tube 2026, the world’s leading trade fairs for these sectors. With 2,700 exhibitors from 65 countries spread across more than 1,290,000 square feet, the event is a major international platform for innovation and industrial technologies of the future.

The wire exhibition will span Halls 9 to 17, showcasing wire, cables, products and technologies, including the new “World of Cables” in Hall 13. Special areas will highlight Chinese innovations, fastening technology, springs and mesh welding machines with live demonstrations.

Key themes for 2026 include stainless steel and special materials, hydrogen technologies, e-mobility, fiber optics, fastening and joining technology, spring manufacturing and more. The program also features expert forums, a hydrogen and e-mobility congress and digital ecoMetals trails spotlighting sustainable exhibitors.

For further information, contact Messe Düsseldorf North America at 312-781-5180, email info@mdna.com or visit www.wire-tradefair.com, www.tube-tradefair.com and www.mdna.com.

The Japan Society of Spring Engineers (JSSE) held its semiannual lecture meeting, poster session and general meeting on June 3, 2025, at Meiji University in Tokyo.

The program included seven technical lectures, a report on “Selecting Spring Technological Heritage” and a special lecture on the role of generative AI in operational efficiency. Topics ranged from machine learning applications for spring steels to advanced testing methods for ultra-fine materials and space mechanisms.

A poster session featured seven research projects, with first place awarded to fatigue strength evaluation of spring steel under combined bending and torsion, by Masafumi Morimoto of NHK Spring Co., Ltd. et al.

Following the meeting, JSSE held its annual general meeting and a reception attended by 83 participants. Remarks were given by leaders from JSSE, academia and the Japan Spring Manufacturers Association, with the event concluding in traditional fashion with an “Icchou Jime” single clap.

On July 16, 2025, the Indian Spring Manufacturers Association (ISMA) hosted a webinar to showcase SMI’s activities, spring design software and a snapshot of the North American spring industry to ISMA members and spring industry professionals worldwide.

The event drew 62 participants. SMI President Don Jacobson III led the presentation with the support of SMI Executive Director Gary McCoy

The webinar opened doors for North American spring manufacturers to partner with their Indian counterparts and explore new opportunities for importing and exporting raw materials and finished goods. Indian companies also showed a strong interest in SMI’s ASD7 software solution.

This kickoff of a potential long-term collaboration between SMI and ISMA promises to strengthen business ties between the two countries. The timing capitalizes on India’s booming economy and projected growth across all sectors over the next several years.

North American and Indian companies interested in exploring partnerships can reach out to ISMA at info@ismaworld.com. z

The next SpringWorld Expo and Symposium will take place Oct. 7-9, 2026, at the Donald E. Stephens Convention Center in Rosemont, Illinois. SpringWorld is renowned for bringing together spring-related business professionals, with attendees and exhibitors from around the world. Details will be posted on the CASMI website as they become available.

Want to exhibit at SpringWorld 2026? Email Sydney Harris at s.harris@casmi-springworld.org or call the CASMI office at 414-908-4963.

For 2025, CASMI has awarded eight $2,500 undergraduate scholarships and one $5,000 postgraduate scholarship to dependents of CASMI member company employees. This year’s awards bring the total value of scholarships awarded through the CASMI Scholarship Program to $987,749 since its inception in 1989.

The CASMI Scholarship Program is administered by Scholarship America, a nationally recognized not-for-profit foundation. Their independent management of the processes ensures an objective and equitable system for all applicants.

These scholarships are made possible through the continued support of CASMI members and SpringWorld exhibitors, whose contributions directly support the educational journeys of these remarkable students and their families.

We extend a special thank you to Rosemont Exposition Services, whose generous support partially funded the postgraduate award again this year.

Visit the CASMI website for details on the 2025 recipients. If you’re interested in donating to the 2026 Scholarship Program, contact CASMI at info@casmispringworld.org.

The 2025 CASMI Golf Outing was not only a day of friendly competition and connection, but it was also a day of meaningful impact. Thanks to the incredible generosity of our members, sponsors and participants, we raised $565 in support of The American Cancer Society.

For more about CASMI, visit www.casmi-springworld.org.

Illinois

Events are subject to change. Visit www.casmi-springworld.org for the latest information.

By David DeVoe, John Evans’ Sons, NESMA President

The New England Spring and Metalstamping Association (NESMA) continues to advance its mission of supporting and promoting the region’s springmaking and metalforming industry. Through advocacy, technical training and networking initiatives, the association provides members with resources to strengthen operations, expand professional connections and remain competitive in a global marketplace.

WAFIOS presented its Spring End Grinding Training Sept. 23 in Branford, Connecticut. The course provided a practical, live demo of grinding processes.

In June, NESMA’s Future Leaders in Manufacturing (FLM) committee hosted an axe-throwing networking activity at Montana Nights in Southington, Connecticut. The event brought together industry professionals for an evening of friendly competition, engaging conversation and fun. Sponsored by Plymouth Spring and Rowley Spring, the program exemplified FLM’s mission: “To empower members to achieve their full potential by fostering a collaborative and innovative environment where every participant feels valued and supported.” Through such initiatives, FLM contributes to the development of the next generation of manufacturing leaders.

The NESMA annual golf outing in August was a sell-out. This year’s outing was held at the Country Club of Farmington. Foursomes enjoyed a full day on the course, combining the spirit of friendly rivalry with the opportunity to strengthen professional relationships.

The event concluded with an evening program. Attendees gathered for cocktails, dinner and a raffle drawing.

NESMA will host its Holiday Party on Dec. 4 and Annual Meeting on Dec. 5, 2025 at the Farmington Country Club.This year-end celebration and business meeting brings members together to review accomplishments, discuss upcoming initiatives and connect with others in the community.

NESMA delivers significant value to members, including state and national lobbying, technical seminars and networking events. The association plays a vital role in ensuring the continued success and competitiveness of New England’s spring and metalstamping sector.

For more about NESMA, visit www.nesma-usa.com. z

Dec. 4 NESMA Annual Holiday Party

Farmington Country Club

Farmington, Connecticut

Dec. 5 NESMA Annual Membership Meeting

Farmington Country Club

Farmington, Connecticut

For an updated calendar of NESMA events, visit www.nesma-usa.com.

Laura Helmrich-Rhodes, CSP, Ed.D., SHRM-SCP

There is no doubt that immigration is a hot issue. Let’s look at this highly politicized topic from a different yet practical standpoint. Specifically, let’s list the safety implications and, more importantly, let’s consider the OSHA obligations and resources to help bridge the communication gaps in your workplace.

Let’s assume you already have foreignborn workers who speak English as a second language (ESL), not necessarily immigrants, but non-native speakers. According to www.babble.com, in 2022, 18.1% of the U.S. labor force was foreign-born and more than 67 million residents spoke a language other than English at home.

“The Occupational Safety and Health Administration (OSHA) estimates that language barriers are a contributing factor in 25% of job-related accidents,” says Toni Hale in the article “Training in Native Language Makes Workplaces Safer” on www.shrm.org. Furthermore, the National Safety Council magazine, Safety+Health, reported statistics in January 2025 showing a need for better communications to protect Hispanic workers from injury and death.

OSHA has weighed in on this subject years ago under Dr. David Michaels, the Assistant Secretary of Labor for OSHA from 2009 to 2017. He created a letter of interpretation that is a worthwhile read for anyone responsible for employee training. In this letter of interpretation, OSHA requires that nonEnglish speaking employees receive training and instructions “in a language and vocabulary they can understand” (www.smihq.org/go/osha-ltr-2010).

Some of the communication hurdles impacting employee safety are obvious. Some are not immediately evident and are worth addressing. Here are a few:

• Poor or incomplete new employee training in workplace hazards. Most workers don’t realize how dangerous wire and forklifts can be, since most of your new hires have no experience with these kinds of hazards.

Employers are required by OSHA to inform employees of all workplace hazards.

• Supervisors’ inability to answer questions and concerns. Dr. Michael’s letter of interpretation states not just training but work instructions should be in a language employees understand. Ensure supervisors can answer questions about important safety topics like hazardous chemicals in their department, cleanup and first-aid procedures and other safe job procedures, including hot work permits and PPE requirements. They should also be able to take suggestions for improvements from their subordinates.

• Emergency response delays. These can arise from communication issues with an injured ESL speaker or when a non-native speaker needs to report or describe an incident to EMS personnel.

• Using co-workers as interpreters. Explaining technical safety and health topics can create misunderstandings. OSHA requires that information be provided “in their own language by someone with safety experience.” A typical co-worker is not likely to be able to explain the difference between a mutagen and a teratogen or a nitrile glove versus a chemical-resistant glove during hazard communication training. There are technical terms in safety that are not easily translated and can only be done by someone with a large command of synonyms.

• Supporting English language proficiency for employees and their families. Provide small group English-speaking and reading activities called “sheltered immersion.” This is mostly in English and adapted to the student’s skill level. Like full immersion, these events can improve language skills in a comfortable environment. Consider financially supporting language learning apps like Duolingo for employees and their family members, and incentivize improvements in English scores. Encouraging families to practice English at home through fun activities and apps can improve workers’ English skills

• Form a safety subcommittee of ESL speakers so that they can openly discuss their concerns and offer suggestions for improvement.

• Investigate the use of an on-demand interpreter service. Many hospitals and OSHA use on-demand services to translate important discussions. Companies with ESL employees should investigate and contract those services, so they are ready when needed. Remember, not just safety information needs to be conveyed, but also work instructions.

Let’s look at some more tips on language in the shop:

Laura Helmrich-Rhodes, CSP, Ed.D., SHRM-SCP, is SMI’s regulatory compliance consultant. She is an associate professor in the Safety Sciences Department at Indiana University of Pennsylvania, teaching graduate and undergraduate classes. Contact Rhodes at SMI: 847-450-6848 laurahrhodes@gmail.com. and perhaps even the scholastic/vocational success of their school-age children.

• Never use co-workers as interpreters for safety training or any discussions that involve high risk, such as non-routine tasks, like moving manufacturing equipment or the use of scissor lifts for annual maintenance. Before starting infrequent jobs, plan the work, identify hazards and put controls in place.

• Consider holding separate English and other language environment, health and safety (EHS) training sessions to save time and create a comfortable environment for asking clarifying questions. It takes twice as long for an interpreter to repeat and explain what is said. More importantly, separating the ESL speakers allows them freedom to ask questions without fear of retribution from co-workers.

• Post safety-related signs in the languages of your workforce. It is paramount to continuously communicate hazards and controls in English and your worker’s primary language. Signage helps prove to OSHA you are doing that and sends a message of care and concern to all. These signs and posters should reflect the cultural values of the non-native English speakers.

• All important documents should be in English, as well as the languages represented by your workers. Be certain they are written at a reading level appropriate to your workers, too.

• Use technology to assist. Translation apps and other technology can help, but they are not perfect yet. I used Google Translate in a gift shop while on vacation in Russia years ago. It was OK. We muddled through my questions. My communication course students in safety sciences use Google Translate to create safety handouts for a semester project, but I suspect they may not be entirely accurate. I suggest it as a starting point, but all documents should be closely proofread by an expert proofreader. Many of my friends and associates are surprised to learn that my bilateral Starky brand hearing aids also translate when I set the language using my phone app. I’ve used it to take a question from an Arabicspeaking student, but I couldn’t respond to him since it is one-way only. These are great tech tools in their infancy. I would not want to rely on any of them for life-anddeath discussions.

• Alert consultants, trainers and contractors to your language needs. Don’t surprise them with language barriers when they arrive. The cost of those services can be significant. Failing to prepare safety, hazardous waste, finance, forklift or other trainers before their visit can reduce their impact and not give you your money’s worth. If they can’t communicate with part of your workforce, they can’t fully meet your needs. Many OSHA fact sheets are available in multiple languages, so your safety consultant can come prepared. Furthermore, if you are contracting maintenance help, several safety items need to be communicated and established, such as lockout/ tagout procedures, hazard communication and confined space, to name a few.

There are many paid services for printed EHS materials in other languages. An internet search brings up too many to mention. However, there are some “tried and true” resources — two of which are free!

• Susan B. Harwood federal grants

These grants have funded many OSHA training programs available to the public, including some in other languages. PowerPoints, quizzes, handouts and more. can be found at www.smihq.org/go/hg-language.

• The American Society of Safety Professionals (www.assp.org)

In my professional opinion, this is the best international group of individuals working to protect employees from EHS hazards. They have a Hispanic Safety Professionals specialty group with more than 500 members who create outreach, research and professional development opportunities. They also offer a mentoring program to up-and-coming Hispanic safety professionals.

• The National Institute for Occupational Safety and Health (NIOSH)

Offers downloadable print and video materials. Some may not apply to manufacturing, however, there are many poignant downloadable posters, handouts and other information—all for free.

• The National Safety Council

This is a member organization and one of the oldest dedicated to reducing injuries on and off the job. There are member benefits that include access to materials in English and Spanish.

Cross Cultural Communication

Language barriers in the industrial sector have long been a concern. But supporting workers’ efforts to improve English has been part of our industrial heritage. As a Pittsburgh native (Go Steelers!), there still exist culturally rich, ethnic neighborhoods that originated during the Industrial Revolution.

My family and I have benefited from the cultural richness of our region in the arts, dance, language, customs and, of course, food! The same can happen in your workplace by creating opportunities to share arts, values, customs and recipes to foster a caring and cooperative workplace while supporting efforts to improve ESL efforts. These

activities create an inviting workplace, one where workers want to stay and grow. There has been plenty of research and literature focused on overcoming language barriers to improve productivity, quality, efficiency and reduce employee turnover. Hopefully, this provides a safety-first view of integrating ESL programs to reduce serious incidents. z

OSHA website of Spanish-language materials www.smihq.org/go/osha-spanish

Susan B. Harwood Grant Safety Training Materials in Other Languages www.smihq.org/go/osha-by-lang

NIOSH downloadable Spanish safety training materials www.smihq.org/go/niosh-spanish

Breaking Language Barriers www.smihq.org/go/lang-barriers

Role of Language in the Workplace www.smihq.org/go/language-role

Precision Matters: 5 Key Considerations for Technical Translations www.smihq.org/go/tech-trans

Babble Workplace Language Barriers www.smihq.org/go/babble-safer

Forbes: How Learning an Additional Language Could Influence Your Business www.smihq.org/go/forbes-language Safety+Health Magazine: Communication on Bilingual Construction Worksites www.smihq.org/go/safety-health

and regulatory compliance audits

for Occupational Safety and Health Administration (OSHA) inspections. Members who participate have experienced fewer lost-time injuries, reduced workers’ compensation costs and avoidance of significant regulatory fines.

In addition to audits, SMI offers in-house safety training sessions and seminars. These can be scheduled in advance to meet specific organizational needs. For details, contact Gaby Carrasco at gaby@smihq.org.

Dan Sebastian

The age-old question is: “Now that I have a spring business, what do I do with it?” Here are some possible options:

• Keep running it the way it is

• Find ways to grow it

• Sell it off

A strong, stable business is a viable option if business threats are minimal, product lines are sustainable, customers are satisfied and your financial position is strong.

For most businesses in the spring industry, all these conditions are seldom met, so the choices are either to grow it or to sell it. That usually means we grow our business to sustain it.

Growth generally comes organically (from within the business) or externally by acquiring a company or licensing unique products or processes.

Organic growth is hard work, but it is at the core of any strong business. It requires you to find new customers by creating aggressive sales and marketing programs and developing new products or processes that open up new markets. Finding new customers can be time-consuming and costly. Developing new products and processes requires research and development investments and can also require additional capital and a significant amount of resource hours.

The way to grow quicker is through acquisition. That will potentially add customers, eliminate competitors and add new products or processes.

Although sometimes difficult, organic growth can be the most rewarding. Why? It brings value to the business that investors like, and it is something that drives employees to succeed. Nothing builds morale more than employees being part of something they contributed to.

Some of the traditional activities that can stimulate growth:

• New products

• New customers

• New markets

• New technologies

• New processes

• Aggressive selling and marketing programs

• Outstanding customer service (things they are unlikely to get elsewhere)

• World-class quality

• Strategic purchasing of materials or services (better pricing or timeliness)

• Geographic relationships (proximity to customer)

• Terms and conditions

• Inventory management (consigned)

In the methods I’ve described to drive organic growth, one of the greatest challenges is to communicate these new opportunities to your sales force. In most spring companies, this can be especially challenging due to the use of manufacturers’ representatives who are not as familiar with your new product offerings as company employees.

Acquiring another company can be a fast way to jump-start growth, but it can be costly and has inherent risk. You can acquire a business to instantly gain new customers and expand your market share. But it is important to understand, to the extent possible, how these new customers will react to your new position.

In a similar fashion, if the acquisition improves your market share, you need to know if customers like the fact that there are fewer suppliers to compete for their business, or if they are going to leverage your increased size to extract price reductions. If the objective of the acquisition is to gain new products, there are other things to consider. Are the processes similar to your current ones or are they significantly different? If the processes are different, who are the key personnel with knowledge of them, and are they going to stay after the acquisition? If

they do not stay, how long will it take for your personnel to acquire a working knowledge?

The most underestimated aspect of acquiring a company is the creation of a common culture that brings the two teams together with a common purpose. New employees can feel like outsiders or second-class citizens, and the acquiring company’s employees may feel threatened. It is like bringing a new baby home — you have to create an environment where everyone feels safe. Failure to establish a common culture can make any acquisition a difficult undertaking.

Acquisitions can create significant opportunities for any business. Opportunities for improved operational efficiencies, greater leverage with material suppliers, increased processing technologies and more management “best practices” can make your company much stronger.

The cost associated with financing an acquisition can be challenging, but when completed, it can and should bring a much stronger company from an economic perspective. Size does matter when working with your bank and investors.

For most businesses, growth is the key to a strong and healthy future. Organic growth is critical to offset the constant changes you face due to ever-present shifts in the economy. Acquisitions can also be useful and provide the impetus for a quantum leap in both revenue and business viability, but with the inherent opportunity also come risks if they are not executed properly. z

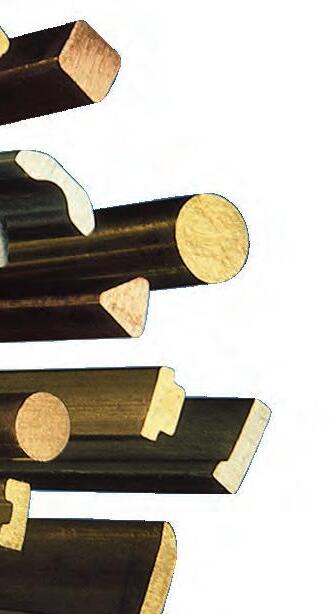

At Anchor Abrasives we specialize in the design and manufacture of resin, epoxy and oxychloride bonded nut inserted discs and cylinders...plus centerless and rollwheels.

At Anchor Abrasives we specialize in the design and manufacture of resin, epoxy and oxychloride bonded nut inserted discs and cylinders...plus centerless and rollwheels. Today, in our modern manufacturing facility, we are ready to continue our tradition of innovative quality products and unmatched customer service. For more information contact Anchor Abrasives Company, 7651 West 185th Street, Tinley Park, IL 60477 U.S.A. Phone: 708-444-4300; Fax: 708-444-1300.

Today, in our modern manufacturing facility, we are ready to continue our tradition of innovative quality products and unmatched customer service. For more information contact Anchor Abrasives Company, 7651 West 185th Street, Tinley Park, IL 60477 U.S.A. Phone: 708-444-4300; Fax: 708-444-1300. www.anchorabrasives.com

At Anchor Abrasives we specialize in the design and manufacture of resin, epoxy and oxychloride bonded nut inserted discs and cylinders...plus centerless and rollwheels. Today, in our modern manufacturing facility, we are ready to continue our tradition of innovative quality products and unmatched customer service. For more information contact Anchor Abrasives Company, 7651 West 185th Street, Tinley Park, IL 60477 U.S.A. Phone: 708-444-4300; Fax: 708-444-1300.

At Anchor Abrasives we specialize in the design and manufacture of resin, epoxy and oxychloride bonded nut inserted discs and cylinders...plus centerless and rollwheels. Today, in our modern manufacturing facility, we are ready to continue our tradition of innovative quality products and unmatched customer service. For more information contact Anchor Abrasives Company, 7651 West 185th Street, Tinley Park, IL 60477 U.S.A. Phone: 708-444-4300; Fax: 708-444-1300.

In our quest for continuous improvement, the SMI technical committee developed a satisfaction survey focused on future spring design software needs. SMI members and Universal Technical Systems, Inc. (UTS) users of the Advanced Spring Design (ASD7) software participated in a customer feedback survey. To those who participated, thank you! SMI values your input to shape our future software offerings.

SMI and UTS have partnered on the ASD software since 2002.

Participants were asked to provide input on the current software offerings and ways to improve ASD7 and CalcEdge™ software applications. CalcEdge is a cloud-based platform that enables authors and domain experts using TK Solver1 and Galaxy2 to create and share calculations globally.

Questions were focused on three areas:

1. Product Improvement and Feature Requests — 12 Questions

2. Competitor Insight — 7 Questions

3. CalcEdge Applications — 3 Questions

Some questions required “yes/no” responses, while others requested comments.

Here are key findings from the survey that may interest SMI members and ASD7 software users, along with actions already underway.

A summary of selected findings from respondents is shown below.

Would you be interested in a new ASD for Excel add-in, which allows Excel users to add ASD calculations that will dynamically update in their spreadsheets as inputs are changed?

74% replied “yes.”

Status: UTS has already moved forward to create the ASD for Excel add-in, which some clients are currently using on a limited basis.

Why is this important? Some users require additional calculations beyond the scope of typical spring design criteria. The Excel add-in allows those users to do all of the calculations in one place.

Would you find value in a cloud-based version of ASD, accessed via a browser interface on smartphones, laptops or desktop PCs, with the ability to store and access spring designs online?

63% replied “yes.”

Status: UTS has created an ASD web version of the software. SMI technical committee members are currently evaluating it.

Should shop floor operators have direct access to ASD software for daily use?

64% replied “no.”

Would incorporating inspection reports directly into ASD improve your workflow?

55% replied “no.”

Would it be helpful to include quality documentation capabilities within ASD?

53% replied “yes.”

Would you like the ability to save setup documentation and notes along with each spring design?

66% replied “yes.”

Should SMI be looking to incorporate AI into the Advanced Spring Design software to enhance the spring design process?

57% replied “yes.”

C. Richard (Rick) Gordon is SMI’s technical director. He has more than 50 years’ experience in the steel and wire industries and is available to help SMI members and non-members with metallurgical challenges such as fatigue life, corrosion, material and process related problems. Contact Gordon at 574-514-9367 or c.richard.gordon@ gmail.com.

Have you used spring design software from other providers?

64% replied “no.”

Comment: Some respondents use Microsoft Excel spreadsheets for simple calculations, while others use commercially available spring design software products. Does your company have in-house developed software for spring design? 64% replied “no.”

Do you use any of the CalcEdge apps related to springs?

100% replied “no.”

Comment: On the CalcEdge website, if you type “spring” in the search box, 55 applications are displayed. All registered ASD users can obtain a free subscription to CalcEdge.

SMI appreciates the contributions of SMI members and ASD users who responded to this survey. The SMI technical committee and UTS are reviewing the detailed comments to identify future enhancements to the ASD software. Stay tuned. z

References

1. TK Solver is a comprehensive mathematical modeling and equation solving software tool for engineers (www.uts.com/Products/TKSolver).

2. UTS Galaxy software manages calculationbased knowledge in a client organization (www.uts.com/Products/Galaxy).

Spring Design 202 — Extension Spring Design Training Program Webinar scheduled for Thursday, Nov. 20, 2025, 1–5 p.m. ET on Microsoft Teams. To register for this class or others, go to http://smihq.org/go/tech-classes.

• Configurations to accomodate a wide range of wire sizes & weights

• Ease of use

• Seamless operation with Torin Spring Coilers & other machinery

• Integrated safety features between machines

• End-to-end support and service by FENN Torin certified technicians

can also be custom engineered to your unique requirements.

www.fenn-torin.com sales@fenn-torin.com 860.259.6600

By Phil Sasso

According to the Bureau of Labor Statistics, about one in five American workers was not born in the U.S. There’s a long history of immigrants in manufacturing, from the factory founders to the skilled laborers producing products.

I know firsthand. My dad was a stonemason in Italy before immigrating at 27. His first job in the U.S. was sweeping floors at a metal fabricator, but the owners saw potential in him. They put him through trade school and sponsored his apprenticeship. He went on to build a 35-year career as a journeyman tool and die maker, only retiring when CNC became a required skill.

Ironically, the SMI Communication Committee chose an immigration theme more than a year ago, long before it was making daily headlines. Our goal for this issue is not to be divisive but to focus on common ground, celebrate our immigrant heritage and share resources to help develop the foreign-born workforce.

When you look at two of our industry’s oldest springmakers, John Evans’ Sons and Betts Company, you see the profound influence of immigrants.

In 1847, John Evans, a Welsh blacksmith, came to America. He opened a small back street shop in New Haven, Connecticut, in 1850, which would become John Evans’ Sons. His first products were flat suspension springs for horse-drawn carriages and buggies. “An industrious and visionary man, he personified the entrepreneurial spirit of his time,” reads the company website. “His success was evidenced by his ability to innovate and adapt technology throughout the decades leading up to the 20th century.”

Betts Company was founded in 1868 by English ironworker William Michael Betts, who emigrated to the U.S. He opened the first springmaking shop west of the Mississippi during the post-Civil War Reconstruction era. “With a bold move to San Francisco, young William launched his namesake company that quickly became

known for expertly crafting springs for wagons and buggies of all kinds,” says the Betts website. Today, William Michael “Bill” Betts V, is president. He is the sixth generation of continuous family ownership and management.

“While automation has transformed production, immigrant workers remain central,” writes Don Jacobson III in his President’s Message (p. 4). “In New England tool shops or Chicago’s industrial suburbs, they join family-owned spring businesses descended from earlier immigrant founders.”

Nataliia Markova, a design engineer at Lee Spring in Brooklyn, New York, tells her harrowing tale of uprooting her family in Fleeing Russia, Finding Springs (p. 25). Markova and her husband left successful careers in Moscow to find freedom in the U.S. “It was safe for us to leave for vacation, but a week after we left, they began to put people in prison, and the police came for my husband,” Markova says. “After that, it was a quick decision not to go back.”

In Tapping a Hidden Talent Pipeline (p. 32), Clay Martin challenges springmakers to consider a unique way to import skilled labor—from a U.S. territory. “Because Puerto Ricans are U.S. citizens, no visas or red tape are required. Employers avoid the immigration bureaucracy that complicates international hiring.”

Non-native English speakers can face challenges on many levels. But help is available.

“My biggest obstacle was that I didn’t speak English,” recalls Audra Liaugaudiene, a Lithuanian immigrant in her Women in Springs profile, Think Beyond the Fix (p. 44). “For a few years, I went backward before I started going forward.”

“Some of the communication hurdles impacting employee safety are obvious. Some are not,” says Laura Helmrich-Rhodes, SMI’s regulatory compliance officer, in her Be Aware column (p. 13).

“OSHA requires that information be provided in their own language by someone with safety experience,” explains Rhodes. “A typical co-worker is not likely to be able to explain the difference between … a nitrile glove versus a chemical-resistant glove during hazard communication training.”

Rhodes shares professional tips and resources to provide safety training and information to help meet compliance obligations.

“Increasingly, manufacturers are partnering with community colleges to offer on-site English as a second language (ESL) classes for nonnative speaking employees, often supported by grant dollars.” In my article, Workplace Literacy: Why Manufacturers Pay Employees to Learn English (p. 28), you’ll discover that “A side benefit of these workplace literacy classes is improved employee recruitment, retention and productivity.”

“If leaders want new staff members to stay and reach high levels of productivity, they must be attuned to the culture and ensure intentional onboarding,” says leadership trainer Jennifer Goodrich in Onboarding That Retains People (p. 30). “The goal is to help employees feel welcome, prepared and clear about their role.”

“Leadership plays a crucial role in fostering this sense of purpose and cultivating an environment in which each employee feels appreciated,” writes SMI Executive Director Gary McCoy in his column Every Employee Supports Your Mission (p. 51). Making each employee feel welcome and an integral part of your mission can have a major impact on your retention and morale.

Also in this issue, grant writer Micki Vandeloo discusses Apprenticeship and Internship Grants (p. 34) available for your employees, including immigrant workers. “Apprenticeship programs provide structured, hands-on training that help manufacturers develop a highly skilled workforce while ensuring institutional knowledge is passed on to new employees.”

Springmakers face a skilled labor shortage puzzle. The immigrant workforce may be one of the pieces to solve it. Many immigrant workers bring ambition and a positive attitude. Springmakers can offer them jobs and training.

Hopefully, the stories and resources in this section inspire you to explore new options. Welcoming immigrant talent is not just an industry tradition—it can be good business. z

By Phil Sasso

When war broke out in Ukraine in February 2022, Nataliia Markova and her husband, Artem, were concerned. “I told my husband we might need to leave Russia because we had always been against the regime,” Markova says.

“When we were away on holiday in Turkey, the police went to his coffee shop in the center of Moscow looking for him. After that, we realized it was dangerous for us to go back. So, from Turkey, he sold all his coffee shops and our car to have money to move forward.”

“We went on holiday in April and never went back,” she explained. “It was safe for us to leave for vacation, but a week after we left, they began to put people in prison and the police came for my husband. After that, it was a quick decision not to go back.”

The family abruptly left their life in Moscow behind and headed to New York to seek asylum. They may never be able to return to Russia and visit friends or family again unless the political regime changes. Artem liquidated his six coffee shops, and Markova walked away from her job as a manufacturing engineer at a research institute of automation and hydraulics. The company’s main customer was a government defense contractor.

In Russia, Markova had worked as a manufacturing engineer for almost a decade — designing products, overseeing factory processes and preparing documentation. But in the United States, she had to start from scratch.

“For the first year I worked as a housekeeper,” she says of her earliest job in the U.S. In between

cleaning clients, she would use her laptop to complete AutoCAD drawings for her other part-time job. Eventually, she began applying for professional jobs in engineering. The first opportunity didn’t go well. “I received a call from a company in New Jersey,” Markova says. “But I failed the interview because I didn’t prepare. My English was not very good, so I just failed it.”

It was four months before she received another call — this time from Lee Spring.

Markova felt she had to improve her English. The family lived in Brighton Beach, where a Jewish community center offered free English classes. “I attended these classes, but it was not much help because they were older people, and it was a beginning English class. So, my English was better than anyone else in the class,” she says. “I think I really learned English when I started working and speaking with American people.”

A big breakthrough came when prepping for her Lee Spring interview. She passed the company’s initial screening, completed a technical test and was invited for an in-person interview.

“I was preparing for one week,” she says. “I just went on YouTube and saw what questions they might ask and how I can answer them. So, for one week, I prepared my speaking, learned some words and practiced my answers.”

The preparation paid off when she was hired as a design engineer. The position required engineering, pricing and customer communication. A perfect fit for her as an engineer, but one that stretched her comfort zone.

“For me, the hardest part was not understanding the engineering — that was not difficult for me,” she says. “But the salesperson part, connecting with customers, trying to sell something and calculating prices, this was a little difficult.”

But support was there. “When I first started, my English was not so good,” she admits. “But I could ask questions to other engineers, or my manager, and everyone was very helpful.”

When Markova started at Lee Spring, she knew very little about springs. “We had some springs in our assemblies,” she says of her Russian work. “But I never designed a spring or calculated physical parameters for them.” When she had worked parttime doing AutoCAD for patent drawings, she had noticed some springs in the inventions.

But that didn’t mean she had the technical knowledge. “I didn’t know about the formula for range, spring rate or how to calculate loads or about wireforms and flat springs. So, I learned here,” she says.

She adapted quickly. Supported by co-workers and managers, she asked questions, studied documentation and absorbed everything she could. “They answered my questions and gave me instructions,” she says. “Anytime I wasn’t sure, I asked.”

One early mistake still stands out in her memory. “A customer sent a photo with a ruler, and I thought it was metric,” she says. “But it was inches. I did the whole calculation in millimeters, and it caused a mess.” It was a jarring reminder that even with math — often considered the universal language — things can be lost in translation.

“I started to work as an engineer in my fifth year in university. So, all my career I worked as an engineer,” Markova says. In Russia, her role was firmly rooted in technical design. “We did drawings. We oversaw all factory processes, engineering and documentation.”

“In Russia, I didn’t speak with customers much. It was very strict. I couldn’t discuss anything with them, I just explained and answered questions. It was not a friendly talk,” Markova says. “But here I can call the customer, and the customer can call me and we can discuss everything. So here I feel more freedom — I don’t need to ask permission. In Russia, three or more people needed to check and sign off on my drawings, with the final approval from a military person.”

At Lee Spring, she found herself in a very different job.

“I work as an engineer and salesperson,” she says. “In Russia, I worked just as a design and manufacturing engineer. So, my main goal was to make a product or to complete drawings and documents for a product through the prototype stage.”

“Here I start from design and finish with giving a price to the customer,” Markova explains. “Now I work for another division of Lee Spring, and they gave me more space to deal with more interesting client design requests, calculate prices for customers by myself and speak with customers.”

Markova was often the only woman engineer in Russia. “We’d have four groups of people for a project, and in every group we have around six or eight engineers. And only one or two were women. Most of the women worked in the electronics department, not in the mechanical area where I was.”

Her experience as a woman in engineering in the U.S. has been welcoming. She feels accepted and doesn’t find being a woman makes her job harder. “I felt accepted in Russia, too,” Markova says. “But both in Russia and the U.S., there are not a lot of women in engineering.”

She hopes more girls pursue technical careers. “It’s a job where you need to be very attentive, and there are a lot of small details that you can miss,” she explains. “You need to sit for a very long time on one task.” She believes a woman can do that as well as, or even better than, a man.

Markova’s daughter, Eva, was just one-and-a-half years old when they arrived in the U.S. “She just spoke a little Russian. But now she speaks, reads and writes in Russian, and she also speaks, reads and writes in English,” she says.

On career day at her daughter’s day care class, Markova shared what she does as an engineer.

“I brought paper and some pencils and asked them to draw a car for a Peppa Pig toy. All of them were very excited,” she laughs. “I was there for an hour, and they were all very busy and very interested.”

“I told them about springs and they started trying to find springs everywhere.”

She doesn’t want to push her daughter, now five years old, in any direction. “If she wants to be an engineer, I will be happy. Right now, she wants to be a teacher, but that could change, too.”

When they left Russia, Nataliia and Artem’s only goal was to give their family a brighter future.

“I didn’t know if I’d be an engineer again,” she says. “I just wanted my family to be safe and my daughter to have choices.” z

By Phil Sasso

Manufacturers are partnering with community colleges to offer on-site English as a second language (ESL) classes for non-native speaking employees, often supported by grant dollars. A side benefit of these workplace literacy classes is improved employee recruitment, retention and productivity.

“The best way to think of it is contextualized English language instruction,” said Adam Schauer, dean for adult and workforce education at Waubonsee Community College. Schauer’s program, based in Aurora, the second-largest city in Illinois, encompasses 22 municipalities and parts of five counties. It serves a large industrial and manufacturing base.

Like many workplace literacy programs, Waubonsee’s team designs courses around each employer’s goals, incorporating industry

terminology, safety procedures, HR policies and company culture into the lessons. They also provide metrics to measure and report success.

Employer costs vary, depending on funding models. Many are free.

“If the employer is able to meet grant requirements, the cost is zero,” Schauer said. Federal Workforce Innovation and Opportunity Act (WIOA) funds, along with state support, make many of these programs possible with no curriculum or course fees.

For companies that do not qualify for grantfunded programs, community colleges can develop employer-paid options customized to the organization’s needs.

Classes aren’t one-off seminars. The preferred cadence is two to three days per week in two-to three-hour blocks. Trying to accomplish too much in one day can be counterproductive. Grant-funded programs generally require five to six hours of weekly instruction over 12 weeks, often embedded into the workday. Generally, employees are released from their workstations and paid their hourly wage to attend classes on-site.

Employer-paid versions can be more flexible, with classes running two or three hours a week, over 10 to 15 weeks.

“The first thing we do is assess all the participating employees utilizing an English language test approved by the federal government,” Schauer said. From there, the college creates a curriculum that blends language development with

workplace-specific content. After about 40 hours of instruction, employees are reassessed and results are shared with the employer.

“We also track employee retention,” Schauer said. “We generally find employees who participate in these programs have a higher retention level than those who do not participate.”

“We have students from 42 different countries speaking 38 different languages,” Schauer said. That diversity requires instructors to adapt lessons to multiple skill levels and literacy backgrounds. The classes are often supported by technology such as the popular BurlingtonEnglish program, a blended, digital English language learning curriculum for adult learners.

There are benefits that extend beyond language proficiency. Classrooms also foster connections across departments and levels.

“We like to see administration and HR visible in these classes, so it breaks down walls a little bit,” Schauer said. “They’re thinking, ‘You know, this is a company that cares about me. They want to see me grow. I’m going to do my best to help them grow.’”

Employers sometimes expand the programs. One manufacturer asked Waubonsee to create a “Spanish for Managers” course to help English-speaking supervisors communicate better with their teams. Another added a leadership-focused ESL track for non-English speaking team leads that focused on business and management language.

The investment has a payoff.

“We’ve had a 98.8% retention rate one year after completion of these classes with our local employers,” Schauer said.

That retention reflects both improved communication and a stronger bond between workers and employers. “Oftentimes they’ve never worked for an employer that would run programs like this,” Schauer said. “They may have been through an employment agency and

they’ve never felt connected to an employer. I think a lot of times they’re shocked and impressed that an employer is looking to provide them with opportunities like this.”

At one company, classes not only improved language skills but also became a recruitment tool. Waubonsee hosted a job fair for students in its community ESL classes and the company hired 14 people from the pool. “The students were like, ‘Wait, I can go to work for your company, make the same if not more money, instead of giving up six hours of my free time to take English language classes?’” Schauer said.

Schauer encourages manufacturers outside his district to contact their nearest community college. “That is essentially what our role is, as we want to be that workforce development partner for our employers,” he said. “Oftentimes they’re able to provide workplace literacy instruction at low to no cost because that’s what we’re designed to do.”

He calls it a “win-win-win” — community colleges fulfill their mission, employers recruit and retain skilled workers and employees gain English listening, speaking, reading and writing skills.

For manufacturers struggling to fill shifts and keep talent, workplace literacy may be one of the most cost-effective investments they can make. z

By Jennifer Goodrich

As leaders, we know that a strong corporate culture drives performance. But did you know culture can also improve employee retention? According to Ernst & Young, 92% of employees said workplace culture directly impacts their willingness to stay in a job.

Workplace culture doesn’t happen by accident — it starts with effective onboarding.

Whether you’re launching a new department or replacing a key employee, how you onboard people can shape their perception of your company, their performance and how long they stay. Onboarding is especially important when onboarding people from different cultural backgrounds and languages.

Your culture is built on the written and unwritten rules that guide your staff’s behaviors. Culture can be built intentionally through careful design or by accident when bad behavior goes unchecked. Your culture might be casual, where even a branded polo shirt and khaki pants feel ‘too corporate,’ or formal, where managers are addressed as Mr. or Ms. Harris. In some workplaces, employees must ask permission before taking risks, while in others they act first and ask forgiveness later. Teams may view themselves as family or as competitors. Regardless of your cultural style, your culture has power! Employees who do not understand your culture can become misfits and unproductive.

Successful organizations often blend different types of culture depending on their goals and the nature of their industry. Clearly defined cultures create cohesive teams. Poorly defined cultures become the undefinable root cause of productivity loss. But even the best-defined culture can become a barrier to productivity and employee retention if your new hires are clueless about what your culture is and why your culture works.

The best onboarding makes every new employee feel welcome.

One of my clients began a new job as vice president of marketing. On her first day, her boss — the company president — was out of town. Her office wasn’t ready, so she sat

in the conference room. Her badge, laptop, business cards and parking pass weren’t prepared either—as evidenced by her car being towed out of the employee parking lot.

In contrast, another client shared a much more positive onboarding experience. Two weeks before her start date, she received her HR paperwork (insurance forms, etc.) and was able to review them with her spouse at her own pace. Along with the forms came a packet outlining her first-week schedule and providing background on the projects she’d be managing or supporting. The packet even included short bios of her new teammates, including their education, tenure, strengths and pet peeves. On her first day, she received company shirts, business cards, a badge, a laptop and her parking pass. She felt welcome and ready to be productive on day one.

According to the Human Capital Institute, most new employees decide whether they’ll stay with a company within their first few weeks. If leaders want new staff members to stay and reach high levels of productivity, they must be attuned to the culture and ensure intentional onboarding. The goal is to help employees feel welcome, prepared and clear about their role.

Before the employee’s first day:

• Send non-confidential documents (insurance forms, etc.)

• Provide an agenda for the first week or two

• Set up their workstation

• Order business cards, uniforms or other materials During the first week:

• Complete any pending HR paperwork

• Introduce the company’s history, current projects and goals

• Introduce them to key people (colleagues, clients, cross-functional partners)

• Ensure technology and workspaces are ready

• Distribute company materials (badges, shirts, cards, etc.)

Hiring globally means access to the best talent—but it also brings added complexity. Some new hires may share a language and culture. Others may have different first languages and cultural backgrounds.

Email can be a powerful tool. It gives employees time to read carefully and respond thoughtfully. Pre-recorded videos, digital onboarding platforms and shared documents can make the process more flexible and accessible.

Language differences can impact how well employees understand expectations and policies. Infographics and illustrated manuals can be particularly effective for communicating physical procedures, especially around safety and operational protocols.

For management-level employees, language may be less of a concern — but cultural nuance can still be an issue.

Translating words like “gift” can mean “present” in English, but “poison” in German. “Oficina” means “office” in Spanish but “workshop” in Portuguese. Would your new vice president of finance like her office to be called a “workshop?”

Non-verbal cues vary across cultures, too. Direct eye contact is common in the U.S. but may be seen as overbearing in Japan. In India, a side-to-side headshake means “yes.” In the Middle East, a thumbs-up gesture can be offensive. In many cultures, touching with the left hand is discouraged. When onboarding someone from a different culture, take the time to learn about differences. Ask questions. A little curiosity goes a long way toward avoiding misunderstandings and building rapport.

Cultural differences also affect holidays, travel and worklife expectations. In India, weddings can span several days and require extended travel. In Mexico, a girl’s 15th birthday (quinceañera) may be as elaborate as a wedding.

Dutch social psychologist Geert Hofstede is known for his groundbreaking research on cross-cultural organizations. He identifies eight cultural dimensions that can affect workplace behavior:

Power distance — How employees view authority and hierarchy

Individualism vs. collectivism — How much employees should focus on personal vs. group goals

Gender egalitarianism — How employees’ view gender roles

Achievement orientation — The extent to which employees are results-driven vs. relationship-driven

Uncertainty avoidance — Employees’ comfort with ambiguity or incomplete info

Long-term orientation — Whether and for how long employees are willing to defer rewards

Assertiveness — Employees comfort level with direct communication

Humane orientation — Employees emphasis on kindness and consideration

Rather than avoiding these differences, embrace them. Ask new hires to share their perspectives, traditions or expectations. Showing interest builds respect—and connection.

Onboarding that welcomes team members builds retention. Show new hires they are valued by preparing their workspace, tools and materials for their first day. Take the time to introduce the company, processes and key people. When employees feel connected, including those from different cultural backgrounds, they’ll engage quickly and be more productive. Embrace every new employee from day one, and you’ll build retention, participation and performance. z

Jennifer Goodrich is president of Benchmark Leadership Training and a faculty member of the University of Tennessee at Chattanooga. She trains on topics including multigenerational workplace, emotional intelligence, customer service, team building, employee development and communication effectiveness. Goodrich has worked for Moen Faucets, Avery-Dennison and Newell-Rubbermaid. She holds a B.A. in economics, an MBA and a Ph.D. in industrial and organizational psychology. Contact her at Jennifer-GoodrichOl@UTC.edu or 423-280-6604.

By Clay Martin

As springmakers know, finding reliable, skilled manufacturing workers is a growing challenge. One promising solution for importing skilled workers lies just beyond the mainland, but firmly within U.S. territory: Puerto Rico. These workers are U.S. citizens, many with manufacturing experience, bilingual skills and motivation to relocate.

In 2016, a layoff pushed me to rethink my career. Through my experience with the Peace Corps in Latin America and translating and recruiting for farms and factories in upstate New York, I identified an overlooked opportunity: connecting Puerto Rican workers with mainland employers.

So, I bought a one-way ticket and spent several months driving around the island in my purple Jeep, building trust and creating a recruiting firm. I have since placed thousands of Puerto Rican job seekers in manufacturing, hospitality and healthcare jobs.

This U.S. territory offers advantages over international recruitment. The island’s manufacturing history and ongoing economic struggles make many workers eager to relocate for better opportunities.

Manufacturing has long been central to Puerto Rico’s economy. Pharmaceutical plants, medical device factories, electronics assembly and textiles have provided decades of experience for workers across the island. These industries trained employees in precision

processes, safety compliance and quality control, all of which are directly transferable to mainland operations.

Many Puerto Rican workers are bilingual, comfortable working in both Spanish and English and familiar with U.S. cultural and workplace norms. That combination of technical expertise and adaptability makes them well-suited for mainland employers seeking reliable labor.

Puerto Rico is a beautiful island with a rich culture, yet its economy has struggled for years. In June 2025, the unemployment rate stood at 6.2%, compared to 4.1% on the mainland. Median household income is about $24,000 per year, less than a third of the $74,580 U.S. median. Even skilled workers often earn far less than they would in similar roles on the mainland.

My goal is to provide people with better opportunities, regardless of their background or desired destination. Residents of Puerto Rico share with me their desire for optimal employment opportunities to grow as a professional, provide for their family and have consistent work.

Relocation is rarely an easy decision. Leaving behind family and community is difficult and the transition requires adjusting to new cultural and logistical realities. Still, many Puerto Rican workers make the move because the benefits outweigh the costs.

It’s common for me to hear things like “In Puerto Rico I make $8 an hour, can you offer me something better? I want a clear path for my career. I want to grow!”

Their motivation is deeply personal: financial stability, better living conditions and the chance to build a more secure future. For many workers, particularly younger generations, relocating to the mainland represents the most reliable path toward advancement.

For U.S. manufacturers, recruiting in Puerto Rico presents several clear benefits.

Because Puerto Ricans are U.S. citizens, no visas or red tape are required. Employers avoid the immigration bureaucracy that complicates international hiring. Many, but not all, speak English. This eliminates

uncertainty, reduces costs and speeds up the process of moving workers into open positions.

Cultural familiarity is another advantage. Workers are already accustomed to U.S. systems and many are bilingual. This helps reduce onboarding friction and ensures smoother integration into the workplace.

While the advantages are clear, challenges remain.

Relocation costs are a major factor. Flights, moving expenses and initial housing can be prohibitive for workers without employer support. Companies that provide relocation assistance or guidance stand a far better chance of successfully bringing in candidates.

Finally, Puerto Rican workers are in demand across multiple sectors, from healthcare to construction. Manufacturers must compete not only with other manufacturing employers but also with other industries recruiting on the island. In one week, I can get calls from a hospital recruiting nurses to a hotel needing cooks to a construction firm looking for heavy equipment operators to a manufacturer wanting skilled workers or forklift drivers.

In my decade of experience recruiting from the island, the biggest lesson I’ve learned is there is a unique human aspect to this progressive approach. It requires companies willing to go above and beyond to welcome these workers and get them established and comfortable.

These men and women are uprooting their entire lives and moving across an ocean to a place they’ve never been. That is very overwhelming. I’ve seen companies be so desperate for employees that they disregard the importance of orientation and training and put recruits to work immediately. There is no room for this when dealing with human capital, a company’s most valuable asset.

When recruiting from Puerto Rico, it‘s paramount to provide a thorough

orientation. Consider potential misunderstandings and provide information to avoid them. Just like with any new employee, don’t assume they know anything.

My most successful clients hold at least one full day of orientation followed by job training.

The U.S. manufacturing sector will continue to face labor shortages. The labor force in Puerto Rico may not be large enough to solve all of America’s labor challenges, but for companies willing to take a progressive approach, it can provide exactly the solution they need.

Employers that approach this labor pool with care, reduce relocation barriers, offer transparent job packages and invest in worker training can build teams that improve these employees’ lives and their own operations. z

Clay Martin is the founder of Isla Talent, a recruiting firm specializing in connecting employers with job seekers from Puerto Rico. With more than a decade of recruiting experience on the island and four years in the Peace Corps working with communities in Latin America, Martin brings cultural insight, trust and proven expertise to help companies solve critical workforce needs. Contact Martin at 513-904-8576, clay@recruitingpuertorico.com or www.recruitingpuertorico.com.

“Because Puerto Ricans are U.S. citizens, no visas or red tape are required.”

By Micki Vandeloo

Spring manufacturers face an ongoing challenge of securing skilled labor to meet customer demand while maintaining operational efficiency. Workforce shortages continue to put pressure on manufacturers to find creative solutions for attracting, training and retaining employees. Fortunately, there are funding opportunities available to support both apprenticeship and internship programs, which can be valuable tools for workforce development in the spring manufacturing industry.

Funding for these programs is available to immigrant workers if they’re properly documented and employed full-time by the company.

ers develop a highly skilled workforce while ensuring institutional knowledge is passed on to new employees. The Department of Labor highlights the many benefits of registered apprenticeship programs (RAPs), including:

• About 90% of apprentices retain employment after completing their training.

• Registered apprenticeships allow employers to develop the exact skills needed for production efficiency.

• Apprenticeships enhance employee productivity, profitability and retention rates.

• These programs help manufacturers build a diverse and highly skilled workforce.

A RAP typically includes three essential components:

1. Required Technical Instruction (RTI)

Classroom training to teach apprentices the theoretical knowledge necessary for their roles.

2. On-the-Job Training (OJT)

Practical, hands-on training under the supervision of experienced mentors.

3. Wage Progression

Incremental wage increases tied to skill acquisition and certification milestones. While these programs offer numerous benefits, they also come with significant costs, including training expenses, mentorship costs and wage increases. To offset these expenses, manufacturers can take advantage of various grants and funding opportunities.

There are various sources for apprenticeship grants, and a variety of ways you can find these grants:

• Grants.gov

This federal database lists grants from the Department of Labor and other agencies that support apprenticeship programs. While manufacturers typically cannot apply directly, they can collaborate with community colleges or workforce organizations that receive these funds.

• State Economic Development Websites

Many states offer apprenticeship grants. Conducting state-specific searches can help manufacturers identify relevant funding opportunities.

For more grant opportunities, see “Manufacturing Grant Database.”

Internships offer manufacturers a costeffective way to bring in temporary labor while identifying potential full-time employees. Internships typically last one semester or summer and allow students to gain hands-on experience in manufacturing settings. The advantages of internships include:

• Providing temporary skilled labor at a lower cost.

• Offering employers the chance to evaluate potential full-time hires.

• Giving students real-world exposure to manufacturing careers, increasing industry interest.

However, internships are inherently temporary, meaning knowledge retention and long-term employee conversion can be challenging. To make internships more financially viable, many states offer grants to subsidize wages and encourage manufacturers to provide internship opportunities.

Several states provide funding for internship programs, including:

• Connecticut’s Engineering Internship Program (EIT) Offers up to $7,000 for two interns in eligible manufacturing companies.

• Iowa STEM Internship Program Funds up to $5,000 per internship, with a cap of $50,000 per company.

• Massachusetts Clean Energy Internship Program

Provides stipends covering up to $8,640 per summer intern.

• Nebraska’s InternNE Grant Program

Covers 50% of intern wages, up to $7,500 per internship.

This is not an exhaustive list of available funding. See “Manufacturing Grant Database” for more state and federal programs that support internships.