Responsible Business Report

2024/2025

2024/2025

Being the second generation of the owner family at Spectre, I’m proud to say that doing business responsibly has always been core to Spectre. Over the last few years, we have made a lot of effort to translate that consciousness into a process of identifying and assessing the broad range of impact risks and opportunities of our business model across the value chain and consequently setting measurable targets and specific actions to address those. The process led to the development of Spectre’s Responsible Business Strategy 2030.

”As a garment manufacturer we depend a lot on people to skilfully and consciously develop and produce the garments, and this turns our employees into the very foundation of our business. This is why creating a good and attractive workplace is a logical choice for us, and something that truly makes sense”.

As a specialized, functional garment manufacturer, we are midway in the value chain where many things must come together to create a high-quality product. In this position we have close partnerships both with the brands we produce for and with our fabric and trims suppliers. This relationship defines our role and responsibility towards environmental and social impacts in the value chain. Impacts that are true to the B Corp mindset.

Moreover, more than ever we need to make sure that we produce in an environmentally sound way. Our ambition is to be among the companies that lead the change to a responsible and sustainable industry by setting the example and to excel as a lighthouse among manufacturers.

“We have publicly set Science Based Targets on climate aiming for ambitious reductions by 2030 and net zero by 2047 – the year our company turns 100 years old”

These climate targets put us in the same boat as our likeminded brand partners and suppliers in building a road to a decarbonized apparel value chain and facing these challenges together.

To do so we hope to further build on the strong partnerships that we have and contribute, as much as we can, through industry initiatives like Cascale and European Outdoor Group, and other brave initiatives that we are proud members of.

The journey towards giving back more to the planet than we take, and towards net contributing positively to the local community, which we are part of, is long and with many obstacles to overcome. To remain focused, we concentrate on staying true to our values and make real progress every year.

Results worth mentioning are the reduction in GHG emissions in our own operations by 96% from 2022 by installing on-site solar energy systems, purchasing renewable energy and switching to electric cars.

Furthermore, all our factories in Vietnam are now Fair Trade certified – a testament to our high social and environmental standards and a result of partnering with leading responsible brands.

We have also made sure to implement content claims certifications like GRS, RWS and OCS in our factories. This way we can enable our customers to make reliable claims about the more sustainable choice they have made in sourcing materials for their product.

“With an ambitious action plan in place to secure the strategy implementation I am confident we will continue seeing progress on our responsibility journey year by year.”

Jesper Klausen Co-owner, Chief Business Development & Responsible Business Officer

Officially validated near-term and net-zero targets by SBTi

All factories in Vietnam Fair Trade certified

Higg FSLM top quartile target – Driving social performance benchmark.

100% permanent contracts. No temp or zero-hour workers

More than 90% of employees receive a living wage

100% renewable electricity in Vietnam factories

Improved employee satisfaction in Vietnam – Positive trend confirmed by survey.

Targets set to reduce own operations’ emissions by 42% and value chain emissions by 25% by 2030 (from 2022 baseline)

2024/2025

3’671’931 garments produced

1’483 tons of fabric used 47% of fabric composed of recycled materials

7’732 m3 of water consumed

10’182 MWh of energy consumed

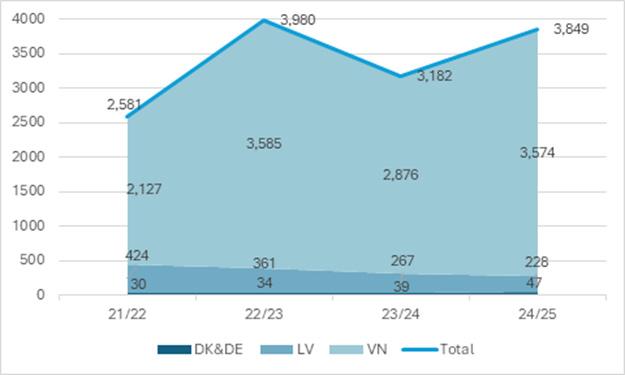

3’849 employees worldwide (year average)

The environmental footprint from Spectre’s manufacturing of a JACKET¹ compared to last year

2.53 kWh of energy consumed: -8% 1.92 liters of water used: -21%

0.05 kg of CO2e emitted in Spectre’s operations: -52%

197 g of waste: -38%

1 For a typical jacket requiring 70 attributable minutes in production

Our vision

We want to become the outdoor sports and activity brands’ preferred development and manufacturing partner for functional garments.

Our mission

We work to strengthen our customers’ brand value through our competence in the development and manufacturing of high-quality functional clothing in a sustainable and responsible way.

We are manufacturing partners to some of the world’s leading outdoor and performance brands, and we specialize in transforming globally sourced technical materials into high-quality, functional garments — built to last and produced with care for people and planet.

We believe that when we aim high together, we create more than strong products. We build strong relationships based on the philosophy of the triple bottom line where people, planet, and profit go hand in hand. That’s what drives our shared, long-term success.

“As part of the B Corp community, we believe that our company must serve as a vehicle for creating a positive impact on employees, local communities and the environment.”

Our factories in Vietnam, supported by competence centers in Europe, are where designs come to life. Here, we turn fabrics and trims into finished garments that are quality-assured, custom packed, and shipped to our customers’ distribution hubs across Europe, North America, and Asia.

We collaborate closely with our brand partners to ensure that products are not only technically advanced and manufacturable but also meet growing expectations for sustainable and responsible production. Design, marketing, and distribution lie with the brands. Our focus is on co-developing the product, managing the entire production process, thereby ensuring production is efficient, ethical, and traceable. Responsible sourcing is a shared commitment between our brand partners, our trusted

suppliers, and ourselves, and we’re proud to work with partners who expect more.

Positioned at the center of a complex value chain, we interact daily with suppliers, logistics partners, and global brand teams, and we manage compliance with social, environmental, and quality standards, monitor potential risks, and keep production on track. When challenges arise, we act fast — always with a focus on minimizing impact and maximizing outcome.

As regulatory demands increase, particularly in the EU and US, we are not just keeping pace, we’re moving ahead.

Our ambition is to lead through action and transparency, showing what responsible manufacturing can look like at scale.

We’re proud to be partners of a portfolio of renowned international brands — primarily headquartered in Europe and North America, many of which have an increased focus on the Asian market, and we take our role seriously:

To develop, manufacture and deliver garments with consistent quality, drive progress in our industry, and help strengthen the value of the brands we work with.

Office, Group HQ

SPECTRE A/S

Ikast, Denmark

Competence Centers

SPECTRE GMBH Münich, Germany

SPECTRE LATVIA SIA

Kalnciems, Latvia

Production sites

SPECTRE GARMENT TECHNOLOGIES VCL

Nam Dinh, Vietnam

Thai Binh, Vietnam

SPECTRE GARMENT TECHNOLOGIES AN GIANG VCL

An Giang, Vietnam

At Spectre, we uphold a set of long-standing core company values that reflect our approach and our attitude towards colleagues, customers, and other business partners. Our work is driven by the ambition to achieve the best possible results, create a high-quality working environment, and ensure our customers are always satisfied.

At Spectre, everything we do is driven by one word: Ambitious.

It fuels our innovation, shapes our sense of responsibility, and defines how we build partnerships both inside and outside the company. Ambition is a mindset and a shared promise across teams, locations, and functions. It’s what connects us.

We show passion and commitment in everything we do. We strive to perform tasks to the best of our ability and remain loyal to the company and our colleagues. We always go the extra mile for our customers. Through our passion and commitment, our partners experience the clear benefits of collaborating with us.

We care about sustainability and act with integrity. We take responsibility for our workplace and the external environment, solving tasks responsibly to achieve the best results for our company, customers, and business partners. This includes finding balanced solutions for long-term sustainable business practices.

We trust and help each other and live our valu es

Show passion and commitment in what we do

We care for sustainability and act with honesty

Our performan ce exceeds expectations “not just to be good, but to be the best”

Integrity

We trust and support each other, staying true to our values, company policies, and guidelines in our work and interactions with business partners and colleagues. By trusting and helping each other, we form a strong team capable of achieving our goals.

Our performance exceeds expectations—not just to be good, but to be the best. By anticipating situations, we strive to find the best solutions and leverage the advantages of being one step ahead. Our ambition to be the best sets us apart, as our customers seek the best business partners in the market.

Spectre has established a responsible business governance framework that emphasizes accountability and transparency, promoting responsible business practices and laying a solid foundation for sustained long-term value creation. At the core of our governance system is the Board of Directors, which holds ultimate oversight of Spectre’s sustainability strategy and performance. It includes a dedicated sustainability specialist, as well as a Responsible Business Director—both of whom bring subject matter expertise and a strong commitment to embedding responsible practices across the organization.

To ensure ongoing visibility and effective decision-making, the Board receives quarterly updates on Responsible Business (RB) performance, integrated within our broader financial reporting. This enables sustainability considerations to be factored into core business reviews and long-term planning.

Meets on a monthly basis

Review progress in non-conformances, key projects/initiatives

Set out plans for the following month

Key responsible person from Responsible Business

Executes RB Strategy, ensuring alignment of RB procedures, policies, initiatives and reporting across the group

Communicates on progress

Spectre’s Responsible Business committee consists of senior representatives from key business areas, including sourcing, marketing, finance, commercial, executive leadership, and Responsible Business. The committee is collectively responsible for aligning sustainability goals with the overall business strategy and for disseminating priorities and practices within their respective functions. Each member is accountable for sustainability-related performance within their area, ensuring a consistent and embedded approach throughout the company. Responsible business is not a standalone function at Spectre—it is an integral part of strategic and operational planning.

We maintain internal sustainability reporting mechanisms to ensure timely, data-driven decision-making and performance monitoring. In addition to quarterly reports to the Board, internal performance reviews and working group updates allow continuous alignment with our goals.

Spectre also maintains transparent communication with external stakeholders through public sustainability reporting, stakeholder consultations, and our participation in multi-stakeholder initiatives. In order to continuously improve every area of our business we have established Process Excellence Organization (PEx) where dedicated team members meet each month to discuss the progress on ongoing improvement projects and initiates the new ones.

Ultimate oversight of sustainability/ responsibility

Accountable as a whole, one of BoD being a specialist in RB area

Receives a quarterly RB report which is integrated in the financial report

Group RB Committee

Meets quarterly to report on KPIs, progress in the last quarter, plans for the next quarter

Consults on overall direction of RB activities and new initiatives

Oversees all sustainability activities

Accountable for all sustainability activities within their function

CSCO responsible for supplier policies on due diligence and sustainability initiatives in supply chain

Sourcing Manager carries out the supplier due diligence and manages supplier sustainability data

Ensure management of RB according to set procedures and policies in compliance with management standards

Employees as well as employee representatives are involved in decision making

Are informed and consulted on sustainability progress by RB Committee and provide minor input to the process (e.g. finance prepares RB related data for the final report)

The world is changing rapidly. Consumer beliefs, regulatory frameworks, and industry expectations are evolving at an unprecedented pace, demanding greater transparency, circular material use, and accountability for supplier practices. At Spectre, we recognize that sustainability is not just a choice. It is an essential foundation for long-term success. Our intention is clear: to balance economic growth with environmental and social responsibility. This means continuously evaluating and adjusting how we operate, understanding the impact our business has on the surrounding world, and proactively addressing both risks and opportunities. Most importantly, it means embedding responsibility into the core of our business—not as an afterthought, but as a guiding principle for growth.

At Spectre, we are not here solely for financial profit. On the contrary, we believe in using our company as a force for positive change – fully in line with the B Corp mindset - creating value not just for shareholders but for all stakeholders—employees, environment, customers, suppliers, and society at large.

To achieve this balance, we are committed to:

• Create good jobs that ensure fair wages, safe working conditions, and employee well-being.

• Be on the leading edge among peers on climate and environmental ambition

• Becoming a valuable partner for customers in tackling their sustainability challenges.

• Contribute positively to society, actively supporting social and environmental initiatives.

Recognizing the need for a comprehensive sustainability strategy, Spectre embarked on a structured development process in 2023/2024, which continued through 2024/2025. This strategy aims to address the limitations of our current business model while tackling the most pressing sustainability issues identified through a Double Materiality Assessment.

Customer insights played a crucial role in shaping our priorities. With 80% of our revenue generated from key brand partners, we sought their perspectives through surveys and discussions. Their feedback highlighted GHG emissions as the top priority, followed closely by waste management. In the social domain, brands emphasized working time, human rights, labor conditions, and living wages as critical areas for improvement.

The Double Materiality Assessment identified relevant sustainability topics, but to ensure maximum impact, we have strategically clustered them into three core focus areas:

1. GHG Emissions – Reducing carbon footprints across operations and supply chains.

2. Resource Outflows – Minimizing waste and optimizing material usage.

3. Social Responsibility – Ensuring fair wages, responsible working conditions, and ethical supplier management.

“Only by taking bold steps to reduce our impacts we can grow without becoming part of the problem but instead part of the solution to global and local sustainability challenges.”

- Jesper Klausen, Chief Business Development and Responsible Business Officer (CBRO)

Becoming the outdoor sports & activity and manufacturing partner

Mission : Strengthen the customer brand value by our competence in development and way Vision

We produce high-quality garments in high-quality work environment – and we expect the same of our suppliers

A safe, attractive and engaging working environment at Spectre

We have a net zero climate environmental impact

On a science-based path

Spectre’s supply chain meets high standards of social risk management Spectre is an inclusive workplace and contributes to local communities

Data management & reporting

Governance

Training & capabilities

Reduced impacts on resource

Responsible environmental practices

We want to transparent about the sustainability footprint of

We want to work towards our sustainability targets as one Spectre

We want to continuously educate ourselves to be able to spar

Without decisive action, a linear business model—where materials enter and products exit— would lead to an unsustainable increase in environmental impact. To ensure that growth does not come at the expense of the planet or people, sustainability must be fully integrated into Spectre’s future trajectory.

Our commitment to sustainability is now formalized under the Responsible Business Strategy 2030, a framework that replaces the conventional CSR (Corporate Social Responsibility) approach. The shift is not just about terminology—it is a recognition that responsibility is not an initiative, but a fundamental aspect of how we do business.

This strategy is built like a house, structured around key elements:

The roof represents Spectre’s overarching vision and mission to manufacture in a sustainable and responsible way.

Vision activity brands’ preferred development partner for functional garments

and manufacturing of high - quality functional clothing in a sustainable and responsible way

climate footprint and minimal across the value chain

path to net zero

We collaborate with our customers to produce garments in the most sustainable and responsible way

• Spectre provides eco-design data and services to customers

resource use

environmental management

• Production relies on responsible suppliers

of our operations, products and suppliers.

Spectre – empowering everyone at Spectre to contribute their best.

spar with our partners on sustainability – for customers, suppliers and internally.

The pillars represent our three core action areas:

Leading the change

Focusing on the commercialization of Spectre’s leading sustainability performance

Environmentally sound

Addressing the environmental impacts in Spectre’s operations and in the supply chain

Human-centered

Bringing into focus our efforts to make Spectre an even better workplace, ensuring social standards in the supply chain, promoting inclusive practices and contributing to society.

The foundation consists of the enabling factors that drive real change—transparency, cohesion and continuous improvement.

As part of our commitment to sustainability and transparency — and being proactive in adopting the Corporate Sustainability Reporting Directive (CSRD) requirements — we conducted our first Double Materiality Assessment (DMA) in 2022, even before the final regulatory framework was approved. In 2024, we reviewed and updated our DMA methodology to align with the latest European Sustainability Reporting Standards (ESRS), ensuring a robust and compliant assessment process.

Our double materiality approach, based on European Sustainability Reporting Standards (ESRS), aligns closely with the B Impact Assessment data points. This ensures that both frameworks work together to provide transparency on Spectre’s sustainability performance.

Our assessment follows the double materiality principle, considering:

Impact materiality: How our business operations affect people and the environment, both positively and negatively.

Financial materiality: How sustainability-related topics create risks and opportunities for the Spectre Group, potentially impacting financial performance.

We will review the DMA annually in a light version unless significant changes occur in our business model or the global market. If major changes are identified, a more extensive review will be conducted, involving relevant stakeholders.

impact

have

GHG emissions (own & value chain)

E

S

Material fl ows (incoming material, outgoing product, waste)

Pollution in the value chain

Water impacts in the value chain

Living wage and conditions (own & value chain)

Working time (own & value chain)

Surrounding communities

H&S in the value chain

Measures against violence and harassment

Worker rights in the value chain

Supplier management

Stakeholder engagement in double materiality assessment (SBM-2)

To ensure the accuracy and relevance of our materiality assessment, we engage with key internal and external stakeholders. Ongoing dialogue helps us identify new risks, opportunities, and expectations related to sustainability.

Feedback from this process is regularly shared with the Responsible Business Committee, ensuring that our sustainability priorities remain aligned with stakeholder concerns and regulatory developments.

In the following table examples of how we engage with key stakeholders are outlined.

Stakeholder Stakeholder engagement

Shareholders Board meetings

Strategy seminar

Trade union Collective bargaining agreements

Employees relation issues mediation

Purpose

Following on financial and operational indicators

Own workforce directly

Subcontractors (onsite and process)/ their employees

Satisfaction survey

Evaluation interviews/ performance assessment

Training (work & safety, employees’ rights, living wage etc.)

Reporting channels

Brand partners (customers)

Introducing company strategy; look back on achievements

To foster collaboration, ensure compliance with labor laws, enhance worker and support fair and sustainable workplace practices

To understand and address employee needs, improve engagement, foster employment, and create a productive, positive workplace

Measuring performance, providing feedback, identifying development aligning individual contributions with organizational goals while fostering and accountability

To ensure all employees are informed about company values, what are what is expected from them

Provide the

Pprovide an opportunity to inform the employer about their observations,

Informational posts in intranet Inform and educate, increase engagement

Employees conference

Online/in person meetings

Inform

Notify on our requirements and values

Catch up online meetings

In person meetings

Survey on significant topics

Customer engagement plan

Through multi stakeholder initiatives (EOG - webinars and discussions, Cascalepresentations)

Mutual exchange on sustainability topics. Catch up on progress

worker welfare,

Engagement frequency

Every quarter

Annual

Ad hoc

Ad hoc

foster long term

Themes important to stakeholders

Return on investment, profitability

Governance and risk management

Company’s growth

ESG performance

Workers’ rights, fair wages, job security, and workplace safety

Annual Remuneration

Impact on operations, business model and strategy

Development of Responsible business strategy and overall business strategy 2030

Develop and ensure ESG data quality/CSRD readiness

Targets on accident-free workplace, living wage, working hours compliance

Implemented social and labor management standards (SA 8000, Fair Trade)

Targets and monitoring on living wage needs, and fostering motivation

Annual The company facilities (cafeteria, restrooms, drinking water, parking)

are their rights and Annual Equity, fair compensations/benefits

observations, concerns Regularly Good leadership

Regularly Working conditions/ work related rights

Annual

Regularly

Regularly

Fair contracts and prices, timely payments

Fair wages, safe working conditions

Timely and predictable work planning

Employees safety/working time/ living wage

Social and environmental management systems implemented

Renovation in Nam Dinh factory

LEED certification

Targets on DEI

Target on ensuring social compliance of process and on-site contractors

Working time compliance- implemented managers bonus to reduce overtime

Quality, delivery time, price Adequate payments - target on living wage

Climate change mitigation, renewable energy

Specific certification and initiatives requirements (Fair Trade, GRS)

Sustainability data availability/traceability/due diligence

Regularly

Once in two years

Annual

Regularly

Verified social management systems

Set SBTs, LEED certification, ISO 9001

Fair trade, GRS certificates

Develop and ensure ESG data quality/CSRD readiness

Responsible suppliers targets in strategy

Capacity building to perform product LCAs

Targets on ensuring data availability of material/supplier specific information

Stakeholder Stakeholder engagement

Supply chain employees/ Supplier

Online meetings with sustainability teams

Code of conduct

Direct communication on improving materials quality

Supplier assessments

Research and publications on the industry

Educational institutions and students

Circularity project

Internships

Company tours

Purpose

To learn what their approach to sustainability topics is, their knowledge upstream suppliers. To align on necessary data exchange

Inform about our requirements, work ethics

Predictable materials quality helps ensure continuous workflow and reduce

Risks management, Regulatory requirements

To identify and assess potential risks

To build a skilled talent pipeline, foster innovation, enhance reputation, contribute to community and industry development through collaboration education.

Community Voucher day (Nam Dinh & Thai Binh) To promote Spectre's brand and enhance its visibility. Attract new talent production growth. Strengthening partnerships and presence in the local

Local soccer match (An Giang) To highlight our brand and image to employees from other organizations from the local area and attract new colleagues

State/ Municipality Inspections

To ensure that company is operating in accordance with legal requirements

To issue permits

Multi stakeholder initiatives

Webinars, online trainings Publications, research Conferences, exhibitions Forums

Membership requirements

To encourage collaboration, enhance knowledge, strengthen reputation, innovation, enabling organizations to align with industry trends, CSR goals, stakeholder expectations.

Engagement frequency

Themes important to stakeholders

knowledge about their Annual Climate change, environmental practices

Impact on operations, business model and strategy

Target on promoting switch to renewable energy among suppliers

When starting cooperation Legislative requirements Support suppliers in improving their environmental management practices

reduce waste Regularly Workplace safety, ethical treatment and fair wages

Annual

Regularly

reputation, and collaboration and

talent to support local area.

Suppliers social and environmental performance monitoring and target on managing their critical non-conformances within 3 months

Due diligence process

Once

Ad hoc

Access to industry insights, research opportunities, internships, and career prospects

Education and training cooperation

Jobs and traineeships

Ad hoc Join research projects

Once Local development, job creation, social impact

organizations and visitors Annual Pollution, environmental stewardship

Environment management systems

One day for local community requirements Environmental compliance

Social and environmental management systems implemented

reputation, and drive goals, and

Regularly

Regularly

Regularly

Regularly Annual

Fire and workplace safety, Labour regulation compliance

All kind of legislative compliance

Climate, SDGs

Set SBTs

Suppliers assessment and Higg deployment

The DMA process incorporated stakeholder insights to ensure a well-rounded assessment. This ensures that our sustainability priorities, projects, and policies are aligned with the expectations of our stakeholders and regulatory bodies.

Process for identifying and assessing material impacts, risks, and opportunities

Our double materiality assessment followed a structured process:

1. Reviewing and updating the 2022 DMA findings

We began by reviewing the findings from our 2022 DMA and updating the methodology to meet current ESRS requirements. We mapped potential sustainability impacts across environmental, social, and governance topics, using insights from previous assessments, industry research, and operational data. As no major structural changes had occurred, the original value chain mapping from 2022 was maintained.

2. Initial screening of IROs

In the first phase, internal workshops were conducted to screen impacts, risks, and opportunities (IROs). Predefined scenarios were refined based on internal and external insights. The assessment focused on areas with the greatest sustainability impact — especially textile production — identifying key supplier regions, fiber types, and transport methods.

3. Validation with internal experts

A cross-functional team, including finance, sourcing, and HR/CSR representatives, validated the findings. All participants were introduced to the assessment criteria and scoring methodology to ensure consistency. Where needed, regional or industry-specific insights were supplemented by global data. Experts were encouraged to add new IROs if any material matters had been overlooked.

Scoring and prioritization of IROs

All IROs were scored using a structured methodology aligned with ESRS 1. Topics above a defined threshold were included in our sustainability reporting. Disclosures that are voluntary or within a phased-in period were excluded from this year’s report

5. Confirming material sustainability matters

The Responsible Business Committee validated the final list of material IROs. Although ESRS E-4 (Biodiversity and Ecosystems) and ESRS S-3 (Affected Communities) were identified as material, they are not included in this year’s report due to the need for additional policy and target development.

No IROs were identified for consumers or end-users, as we operate strictly B2B and do not engage directly with consumers.

Our value chain and shared responsibility

Our brand partners are responsible for design, marketing, and distribution to retailers or end-users. They also nominate most of the suppliers and materials, making supply chain responsibility a shared commitment.

To date, we have gathered insights into Tier 2 material suppliers through their FEM (Facility Environmental Module) and FSLM (Facility Social & Labor Module) assessments.

In the coming year, we will implement a full Responsible Supplier Framework to integrate environmental and social practices into a broader supplier evaluation process. We are aware that many key suppliers are located in high-risk countries — such as Taiwan, China, and Thailand — and this factor is carefully considered in our IRO identification and Due Diligence Management Approach (DMA).

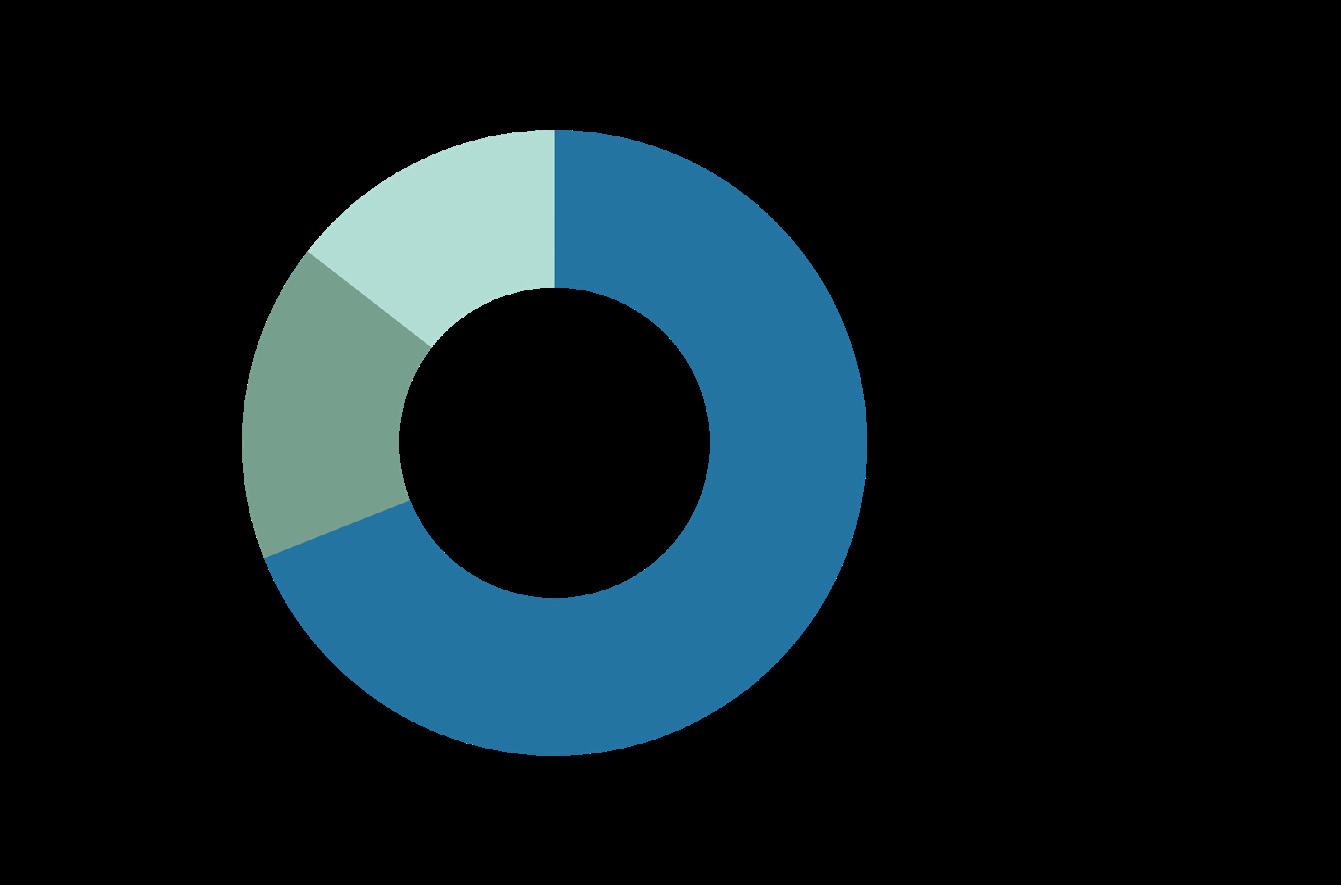

As a result of the DMA, we identified 34 material subtopics, categorizing them as follows and colored in the chart: highly material (dark blue) - 9, mildly material (colored in blue) -8 and the rest 17 as moderately material (the green). The identified IROs are detailed in the corresponding topical sections.

The categorization was applied as follows: All IROs were scored on a scale from 1 to 5, with materiality activated at a score of 3 or higher.

Mildly material:

IROs scoring exactly 3 points (classified as either impact material or financially material, but not both).

Moderately material:

IROs scoring above 3 but below 4 (also classified as either impact material or financially material).

Highly material:

IROs scoring above 4 and/or classified as double material (both impact and financial materiality).

DMA topics

E1 Climate change

E2 Pollution

E3 Water

E5 Waste

Category Raw materials

Textile production Apparel

Typhoons and other EWEs in SE Asia

Extreme heat

Contribution to global warming

Switch to renewables

Production processes polluting air

Water pollution of textile production

Water pollution of sea freight

Pollution from chemicals

Substances of concern in products

Microplastics pollution from synthetic fabrics

Water consumption in textiles production

Water withdrawals in textiles production

Grey water and wastewater discharges

Textile waste and leftovers

S1 Own workforce Demand

Limited

Living

S2 Workers in the value chain

G1 Governance, risk management and internal controls

Informality and temporary contracts in materials supply chain

Safe and fair working conditions

Forced labour

Water quality in Asia

Apparel production

Time horizon changes carbon footprint optimization

culture whistle-blowers lobbying of sustainability related legislation management management compliance accidents employees complaints fluctuations and relocation of operations violations due to peak seasons overtime for white collar employees policy efficiency

As previously mentioned, Spectre’s Responsible Business Strategy 2030 was developed based on the findings of the Double Materiality Assessment (DMA).

However, it extends beyond the DMA — the B Corp philosophy and our core beliefs are also embedded in the strategy to ensure Spectre continues growing into the company we aspire to be.

To address the negative impacts and risks identified during the DMA, we must implement policies, set targets, and define key performance indicators (KPIs).

These tools will help measure progress, track performance, and guide the actions needed to reach the Group’s goals.

To support this, we have developed the Responsible Business Deployment Plan, scheduled for execution between 2025 and 2030.

Most of the planned activities, outlined below, will take place within the first two years, as new initiatives are expected to emerge from existing ones. Additionally, several initiatives will establish recurring events over the coming years — including physical events and ongoing reporting and improvement cycles — that will continuously drive Spectre toward its targets.

S1-Own Workforce

S2- Workers in the value chain

E1- Climate change

E2- Pollution

E-3 Water and marine resources

E5

ES.2.3

ES.2.4

Some activities impact targets across multiple pillars — particularly new frameworks or policies. While all targets are addressed through initiatives, some KPIs will not be tackled in the initial years. This is not due to oversight, but because the related initiatives were not prioritized for phase one.

The table below outlines the material topics for which targets have already been set, along with the initial actions planned to achieve them.

G1Governance, risk management and internal controls

Protection of whistle-blowers

Political engagement and lobbying activities

STRATEGY TARGETS

ES.3.1 Achieve leading environmental performance of Spectre’s factories

ES.3.2 Increase % LEED certified production

ES.3.3 Promote transparency of environmental impacts in the supply chain

ES.3.4 Improve access to safe water for people in Vietnam

ES.3.5 Balance environmental plastic footprint

LC.1 Spectre provides eco-design data and services to customers(1)

LC.1.1 Build capacity to perform product LCAs

LC.1.2 Ensure availability of material/supplier specific information for PEF

LC.1.3 Aid customers in designing products to improve durability and longevity

LC.1.4 Cooperate with customers to improve product end-of-life treatment

LC.2 Production relies on a responsible supply chain

LC.2.1 Develop due diligence processes in line with CSDDD

LC.2.2 Prioritize sourcing from responsible suppliers

LC.2.3 Ensure supply chain traceability of at-risk materials

LC.2.4 Suppliers commited to Spectre's requirements

In March 2024, by committing to set net-zero Science-Based Targets (SBTs), we reinforced our proactive approach to tackling climate change. By the end of the same year, our targets were officially validated by the Science-Based Targets initiative (SBTi), marking a significant milestone in our sustainability journey.

Our science-based targets reflect our commitment to limit global warming to 1.5°C. Having our commitment publicly verified by a third party demonstrates that we take tracking and reporting seriously — even amidst the challenges faced across the apparel industry.

We commit to:

“...reduce carbon emissions by 42% in our own operations, and by 25% in the value chain by 2030 from a 2022 baseline. These

reductions

will put us on a course to become a net-zero climate impact business by the time Spectre turns 100 years old — in 2047.”

Our plans to grow make these targets more ambitious than the numbers alone suggest. Setting bold targets is an important first step, but real progress comes from concrete action.

We have conducted a comprehensive analysis of our emissions, identifying key impact areas. More than 90% of our emissions originate from our value chain — particularly in materials production, logistics, and distribution. This is where strong partnerships with suppliers, brand partners, and industry stakeholders will be essential to achieving our goals.

At the same time, we recognize the need to address emissions that fall entirely within our own operations, and we are already taking meaningful steps in that direction.

Science-based targets remain one of the cornerstones of Spectre’s Responsible Business Strategy 2030, setting a clear direction for initiatives aimed at reducing GHG emissions. Over the past years, we have made significant strides toward decarbonizing our operations — and these efforts have continued into 2024/25.

Solar panels were installed on the rooftop of our headquarters in Denmark, further accelerating our transition to renewable energy. We continue to purchase Renewable Energy Certificates (RECs), covering the entire amount of grid electricity used in Vietnam.

To further reduce emissions from our own operations, we have begun replacing internal combustion engine (ICE) vehicles with electric vehicles (EVs) in Vietnam.

At our Vietnam facilities, we introduced charging stations for electric scooters last year, allowing employees to charge their vehicles for free. This year, we are launching an awareness campaign on sustainable mobility. As part of the initiative, two employees at each facility won a brand-new electric scooter in our New Year’s lottery.

”An electric motorbike is a great vehicle, fitting perfectly with the trend of doing better for the environment while also saving on fuel. I and others at Spectre support environmental causes.”

Mrs. Nguyen Thi Hoa Pattern Marker Staff from PPD dept. - Nam Dinh

“Using the electric scooter, I can say that it’s easy to drive, lightweight, safe. I am happy about its battery range and that riding it is better for the environment than a regular scooter. In addition, Spectre also provides charging stations which are very convenient and thoughtful.”

Mrs. Nguyen Hai Yen Worker in line 07 – Nam Dinh

At the beginning of the fiscal year, we selected a new waste management contractor for our Nam Dinh and Thai Binh facilities. This ensures that fabric waste is either recycled or incinerated with energy recovery, and that paper, cardboard, plastic, and metal waste is systematically recycled.

Even though we’ve already taken major steps — especially in decarbonizing our own operations — we recognize that the biggest challenges still lie ahead. As we move forward, we remain committed to integrating sustainability across all operations, strengthening industry collaboration, and continuously seeking new ways to reduce our environmental footprint.

The industry increasingly acknowledges the urgent need for climate action — a fact reinforced by the findings of our DMA. Membership requirements from organizations like Cascale (SBT validation) and EOG (Race to Zero) highlight this growing recognition.

However, many stakeholders still face difficulties turning these commitments into concrete action — particularly in tackling value chain emissions, where influence is limited.

For Spectre, meeting necessary emissions reduction targets requires close collaboration with both suppliers and customers. Through multi-stakeholder initiatives and trusted partnerships, we aim to drive collective progress and contribute to both our own and global climate targets.

We have now maximized rooftop photovoltaic installations wherever feasible. This year, additional solar panels were installed at our headquarters in Denmark.

To offset non-renewable energy use in Vietnam — where most of our operational energy is consumed — we purchase RECs. The remaining fossil fuel energy in Vietnam is used mainly for company vehicles.

This year, we purchased our first EV in Vietnam, increasing the EV share of our global fleet to 48%. Additional charging stations were installed at our offices and factories to support the transition. With employee commuting accounting for 8% of our Scope 3 emissions, switching to EVs remains a key strategy for carbon reduction.

We are also working to optimize inbound shipments by collaborating with our logistics partner, DSV — a company with validated science-based targets. DSV now operates 30% of its truck fleet on biofuel, directly supporting our upstream emissions reduction goals.

Decarbonization requires strong collaboration — supported by reliable data to guide decision-making. One of our next steps involves integrating Higg FEM data into our GHG inventory.

Before this can be implemented effectively, we must strengthen relationships with our Tier 2 suppliers to better understand their local processes and contributions to material-related emissions.

Upcoming EU requirements such as the Digital Product Passport (DPP) and expanded life cycle assessments (LCAs) will raise the bar for transparency. Meeting these expectations will require collective effort from material manufacturers, brand partners, and Spectre as the final assembler.

Because raw materials are the largest contributor to our emissions, collaboration with brands and producers is critical. Together, we must transition to preferred materials, improve supplier performance, and support our partners in setting climate targets, adopting renewable energy, and enhancing energy efficiency.

› Supplier energy efficiency and switch to renewables

› Customer switch to preferred materials

› Recycled fibers, packaging

› More efficient production technologies

› Local sourcing

› Material efficiency

› Reduction of leftovers

› Incoming material quality means less waste

› Waste recycling in own operations and supply chain

› Sustainability services: 3D product development, repair, product developement/enviromental optimization as service etc.

› Switch to renewable energy

› Energy efficiency improvement Transport

› Route optimization

› Reduction of airfreight

› Switch to biofuels

› Incentivizing better commute options

Material impacts, risks and opportunities (IROs)

As a global company with sourcing and manufacturing primarily in Asia and distribution to clients in Europe,North America and Asia, Spectre has a direct impact on climate change and the environment. We have already taken the first steps in analyzing the resilience of our strategy and business model to climate change by assessing the risks. Climate issues are addressed in our Responsible Business strategy, Environmental Policy, Code of Conduct and in our overall business model.

We actively address these impacts through the implementation of our Responsible Business Strategy, which includes decarbonization efforts within our own operations and collaborative engagement with suppliers and brands to reduce GHG emissions across our value chain. While the goals have been defined, not all key performance indicators (KPIs) have been fully implemented yet. Several of these are scheduled to be activated during the upcoming financial year 2025/2026.

Typhoons and other N; R Upstream EWEs in SE Asia Own operations

Actual Yes Downstream

Extreme heat N; R Upstream Potential Yes Own operations

[N- negative impact; R-Risk]

At the same time, extreme heat is an increasing concern. With more days exceeding 35°C, ensuring adequate cooling systems will be essential to maintain production efficiency and protect employee well-being. Similar heat-related challenges may also affect our suppliers across Asia, requiring investments in better cooling infrastructure to maintain material quality and ensure safe working conditions. The financial impact of these risks can be measured through investments in cooling systems, higher electricity costs and decreased efficiency due to poor working conditions in case a proper cooling Identified IRO Category Value chain Actual/Potential Target

A significant portion of Spectre’s production is based in Vietnam, a high-risk country for tropical cyclones and extreme heat, according to the WWF Risk Filter. This year, our Nam Dinh and Thai Binh facilities were impacted by a typhoon, causing production disruptions and minor damages. Similar extreme weather events are likely to recur, posing risks such as building damage, operational halts, and supply chain delays, especially as key Tier 2 suppliers in China and Taiwan face the same cyclone risks. Additionally, typhoons, hurricanes, and floods can have severe social impacts, including job losses, reduced working hours, and economic strain on affected communities. While past natural disasters in Vietnam have not led to significant financial losses, the inherent financial risk remains substantial, as damages from such events are not insured.

system is not in place. These risks are scientifically backed, and we have already witnessed their effects at our Vietnam sites. To mitigate risks associated with climate change—and other unforeseen events, Spectre has established a comprehensive emergency response procedure. This protocol outlines how to act swiftly and effectively in case of emergencies. In many cases, natural disasters such as storms or floods can be anticipated in advance. This allows us to carry out preventive measures and contingency planning to safeguard our employees, assets, and operations.

Ensuring a safe and comfortable working environment during extreme heat conditions is also a key priority. To support this, we have set a target to produce more than 90% of our garments in LEED-certified factories. Our An Giang facility, built in compliance with the LEED Gold certification, is designed to support climate resilience by incorporating energy-efficient systems, enhanced ventilation, and heat-mitigation features. Similarly, our Nam Dinh factory, which is currently working toward LEED O&M certification (expected to reach in 2026/27 fiscal year), is in the process of implementing advanced air quality improvement systems to further enhance indoor environmental quality and employee well-being. While currently only our An Giang facility holds LEED certification, its growing contribution to total production minutes has positively influenced our performance on this KPI. Any new Spectre facility, including our exciting Spectre Garment Technologies Thai Binh (due for opening summer 2026), will also be LEED-certified.

Existing buildings that meet high sustainability standards can attain LEED operations & maintenance certification.

LEED O&M covers the same topics as new building certificate but with more emphasis on energy efficiency and materials used in mainteance:

Integrative process Energy and atmosphere

Location and transportation

Sustainale sites

Water efficiency

Materials and recources

Indoor envrionment

Contribution to

The textile sector is known for its major negative impact on the environment and its contribution to global carbon emissions, with the majority originating from Tier 2 and Tier 3 production processes. These emissions, which we have limited direct influence over, pose a significant negative impact on our sustainability targets.

Additionally, high GHG emissions contribute to climate change, leading to more extreme weather events, ecosystem disruptions, and long-term environmental and social consequences. At the same time, increasing scrutiny on product-level emissions presents an opportunity. While Lifecycle Assessments (LCAs) have traditionally been the brands’ responsibility, we see potential in actively contributing to product development by suggesting lower-carbon materials and innovative designs, as well as focusing on digital solutions that can reduce waste thru better fabric utilization. Though LCA reporting is not mandatory, it aligns with Spectre’s RB strategy, offering a competitive edge.

Switching to renewable energy is a key positive impact in reducing emissions and ensuring long-term energy cost stability. Already 95% of our own operations are powered by renewable energy, and we see further potential in collaborating with brands to encourage our suppliers to transition, thereby reducing the carbon footprint of raw materials.

Business operations and manufacturing processes inherently consume energy, making this the primary source of emissions within our own operations. To reduce our climate impact, we are focused on improving energy efficiency and transitioning to renewable energy sources.

In Vietnam — where most of the Spectre’s production takes place — electricity is the dominant energy source. Air conditioning, which is essential for maintaining safe and comfortable working conditions, accounts for the largest share of electricity consumption. This is followed by production equipment such as sewing machines, air compressors, and various types of specialized machinery.

As such, switching to renewable electricity has been a key strategy in reducing our environmental footprint.

Currently, two out of three Spectre facilities in Vietnam are equipped with rooftop solar panels, supplying 20% of their electricity needs.

However, due to limited rooftop space, we began purchasing Renewable Energy Certificates (RECs) in the 2023/24 financial year to cover the remaining electricity use. Through this combined approach, we have now achieved a full transition to renewable electricity across our Vietnam factories.

The only remaining non-renewable energy consumption in Vietnam comes from fuel used by company cars and other combustion engines — accounting for just 2% of total energy use. Even though this figure is expected to decline, we continue transitioning to electric vehicles.

The first step has already been taken: an electric car was introduced at the Nam Dinh facility in early 2025. We expect to expand the electric fleet further in the 2025/26 business year.

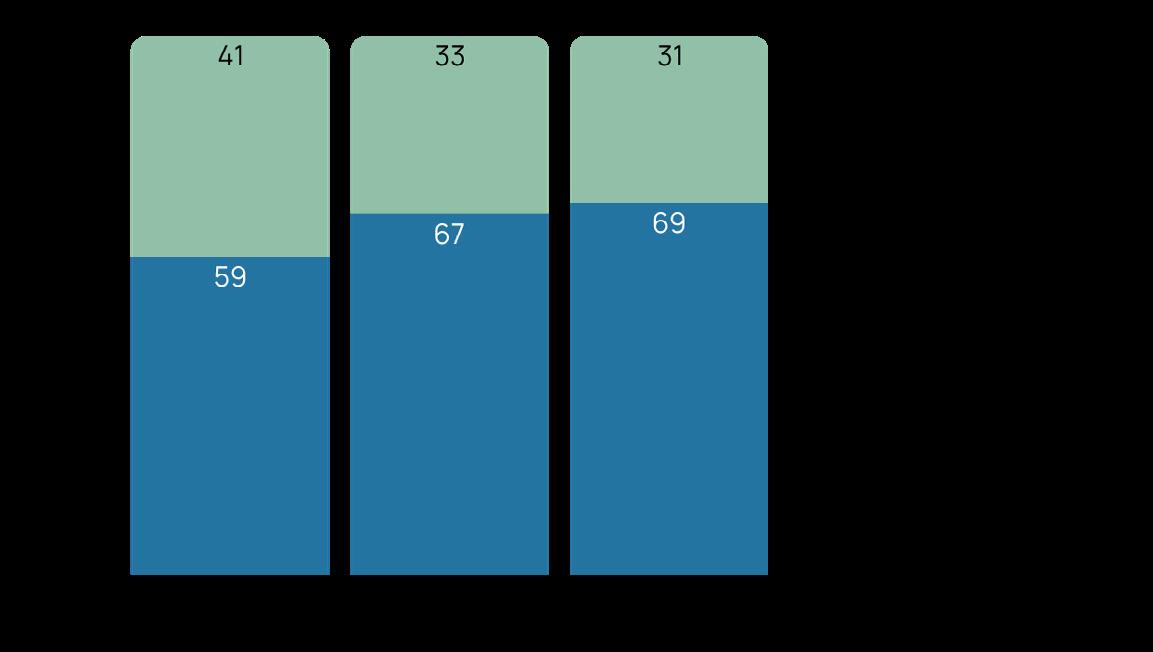

Energy consumption in Spectre Vietnam factories

Energy consumption in Spectre’s operations by percentage by type of energy

At Group level, the share of renewable energy is slightly lower due to non-renewable electricity use at one of our Latvian production sites and the fact that our European car fleets are not yet fully electric — although an increasing number of vehicles have already been replaced with electric models. Despite an 18% increase in overall energy consumption driven by higher production volumes, the proportion of renewable energy has also risen, reaching 95%. This progress is largely attributable to the high output from our Vietnam facilities, which significantly influence the Group’s overall energy profile.

biomass (also comprising industrial and municipal waste of biologic origin, biogas, renewable hydrogen, etc.)

In Europe, we operate production sites — all located in Latvia — along with our headquarters in Denmark and an office in Germany. Although the German office runs on 100% renewable electricity, its energy data is not included here, as the office is rented, and utility invoices are not received. However, its energy use is estimated and reported under Scope 3.

Across our European operations, the share of energy from renewable sources reached 78% in the 2024/25 financial year. The largest contributor is the use of wood pellets for heating at our Latvian sites. At our Danish headquarters, we benefit from municipal district heating, 76% of which is generated from renewable sources. When it comes to electricity, nearly all of it is renewable — with one exception: one Latvian production facility currently lacks access to renewable electricity, accounting for approximately 15% of our total electricity consumption in Europe.

Although our Danish office already operates on 100% renewable electricity, we took an additional step at the end of the financial year by installing rooftop solar panels. This initiative will enable on-site generation of a portion of our electricity, further reducing our environmental footprint and strengthening our energy independence.

In the 2024/25 financial year, we observed a slight 3% increase in GHG emissions intensity per minute of production compared to the previous year. However, when benchmarked against our base year of 2022/23, we achieved a substantial 50% reduction, reflecting strong progress toward our long-term climate targets.

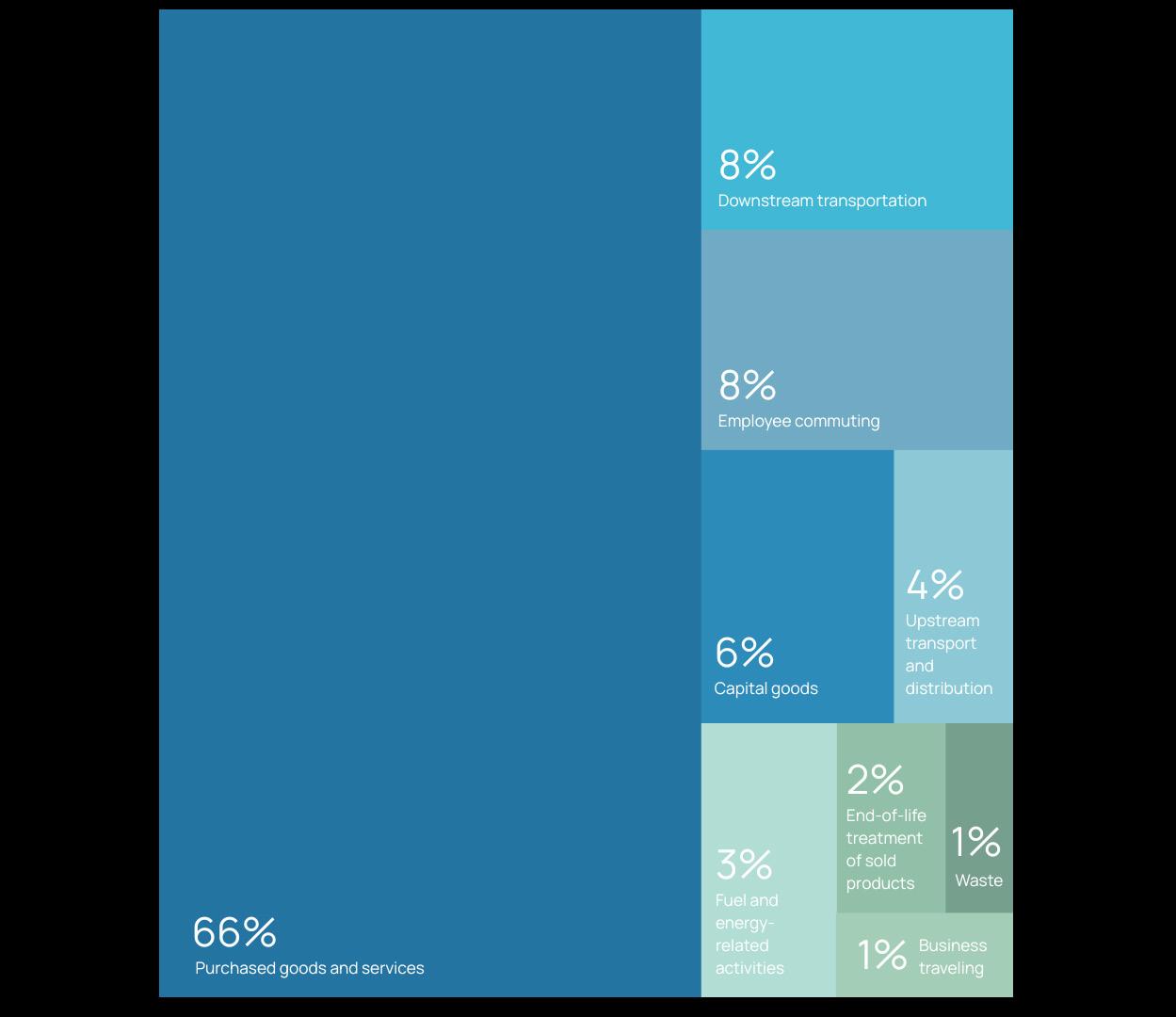

We view fluctuations in total emissions and their intensity as a natural part of our decarbonization journey. As our operations expand, we anticipate that major investments in facilities and equipment will lead to temporary increases in absolute emissions. These investments, however, are essential to enable greater production capacity and long-term efficiency gains. This dynamic was visible in the 2024/25 increase in emissions from capital goods, as growing production demands in the latter half of the year required additional workforce and new machinery thus reaching 6% share of total Scope 3 emissions.

One of the key challenges ahead is reducing absolute GHG emissions in alignment with our Science-Based Targets (SBTs), while simultaneously managing projected growth in both output and headcount. This highlights the importance of deploying our climate strategy successfully and embedding sustainability into every operational decision.

Already in 2024/25, employee commuting emissions increased by over 30%, driven by a growing workforce and a 5% increase in average commuting distance. As one of the few Scope 3 categories where we have direct influence, commuting remains a critical area of focus. However, this year total emissions from commuting reached 8% from total Scope 3 emissions being third biggest category after purchased goods and services and downstream transportatioin. In Vietnam, 94% of commuting is still done via fuel-powered mopeds, which emit nearly five times more CO₂ per kilometer than electric alternatives. Encouraging a transition to electric vehicles, especially two-wheelers—will be key to reducing our commuting-related emissions.

We are also encouraged by a 52% reduction in emissions from business travel compared to the base year, demonstrating the impact of more conscious travel decisions resulting in 1% share in Scope 3 emissions. While in-person meetings remain valuable in certain contexts, remote collaboration technologies have proven effective in maintaining alignment and communication without the environmental cost of frequent travel.

Furthermore, improved waste management practices have significantly contributed to our environmental progress. During the financial year, we switched waste vendors at two of our Vietnamese facilities. As a result, fabric waste is now either downcycled or, where that is not possible, co-processed with energy recovery—rather than being entirely incinerated as in previous years. This change along with the total waste reduction generated in European facilities led to a 60% drop in emissions from operational waste compared to the base year. With production volumes expected to grow, ensuring access to the most sustainable waste management solutions remains a priority. We are therefore continuing this effort and working toward a similar vendor transition at our An Giang facility, with the goal of fully eliminating incineration in favor of more environmentally preferable practices. This progress highlights our ongoing commitment to reducing waste-related impacts across our operations.

KPI

GHG emissions 0.5 t CO2e/ employee 0.55 t CO2e/ + >90% from employee employee commute

This year, we achieved a 19% reduction in total GHG emissions from purchased goods and services not included in the bill of materials, bringing us closer to our reduction target of 25%.

The primary driver of this decrease was a significant drop in production volumes at subcontractors, with subcontracted sewing minutes declining by 88% compared to the base year. As part of our commitment to offering the most sustainable production possible, we aim to keep manufacturing in-house. This approach allows us to deliver products with a lower carbon footprint to our customers. However, emissions from consumables and other purchased goods and services—calculated based on their monetary value—have increased. Even after adjusting emission calculations for inflation, overall expenditures in this category rose, which in turn affected the total emissions figure.

In tonnes of CO2e equivalent (tCO2eq)

Scope 1 GHG emissions

Gross Scope 1 GHG emissions (tCO2eq)

Scope 2 GHG emissions

Gross location-based Scope 2 GHG

(tCO2eq)

(tCO2eq)

Gross indirect (Scope 3) GHG

(tCO2eq)

3.

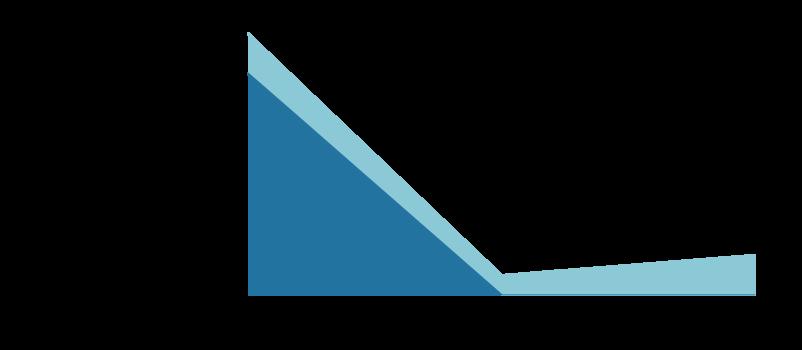

Our goal is to reduce the carbon footprint of our logistics operations, with a specific target of decreasing GHG emissions from upstream transportation by 25%.

Reduce carbon 1627 t CO2e

footprint of logistics emissions

t CO2e/ +

This focus on upstream logistics is intentional, as it’s the area where we can make the most impact through decisions such as selecting preferred logistics partners or optimizing routes. More on this topic is shared in the chapter about Logistic emissions.

Notably, we have already achieved a 33% reduction in total upstream logistics emissions compared to the base year. This has been largely driven by a 57% decrease in emissions from air transport, as the total weight transported by air has dropped by 30%.

We continue to assess the necessity of air freight, which is now primarily reserved for samples and other urgent shipments. With the introduction of 3D technologies, we expect our reliance on air logistics to decline even further in the future.

The majority of our shipments by weight are transported by sea, followed by road transportation.

The overall distribution of emissions across Scope 3 categories remains similar to previous years, with Category 1 (purchased goods and services) accounting for more than half of total Scope 3 emissions. Within this category, fabric is the dominant emission source, contributing approximately 80%. Trims account for 8%, while other purchased goods and services (including packaging, processing materials etc.) make up the remaining 12% of Category 1 emissions.

Our supply chain spans multiple times and countries and with it, complex, energy-intensive material production processes. A significant share of our Scope 3 emissions comes from this very stage. In fact, fabric production alone accounts for 53% of our total Scope 3 footprint, and the total emissions stemming from purchase of products account for 66%.

To meet our Science-Based Targets - including a 25% reduction in Scope 3 emissions by 2030 - we need action where it matters most: at the source of material production. That’s why a key focus of our Responsibility Business Strategy 2030 is supporting the shift to renewable energy among our Tier 2 suppliers.

We use the Worldly platform to collect environmental data from our largest fabric producers through the Higg Facility Environmental Module (Higg FEM). These insights give us a more accurate picture of energy consumption patterns and track where change is happening, and where it is not.

• Cascale is the new name of the industry alliance formerly known as the Sustainable Apparel Coalition (SAC). It brings together manufacturers, brands, NGOs and other stakeholders to drive positive changes across the global apparel and footwear industry. Spectre is proud to be a Cascale member.

• Worldly is the tech platform that powers the tools developed by Cascale. It enables manufacturers and brands to measure and manage their environmental and social impacts across the value chain.

• The Higg Index is the name of the suite of tools created by Cascale and hosted on the Worldly platform. These tools provide standardized, credible data on sustainability performance – covering everything from factory working conditions to carbon emissions.

So far, progress has been slower than we had hoped. But we are not standing still.

We are actively engaging with suppliers to explain why transparency is not optional. It is essential. Not just for the brands we work with, but for Spectre too. As a Tier 1 partner to some of the world’s most respected outdoor brands, we see it as our responsibility to help raise the bar across the value chain.

Our RB Strategy 2030 puts this into concrete targets:

25% of energy used by key suppliers should come from renewable sources by 2030

80% of our fabric spend should go to suppliers with verified Higg FEM assessments

These targets are not just numbers. They represent a path forward, towards greater visibility, accountability, and progress. Together with our partners, we are committed to making meaningful changes, one kilowatt at a time.

As part of our strategy to reduce our carbon footprint and achieve 100% renewable energy at our own facilities, we have invested in a solar panel system at our headquarters in Denmark. In connection with this investment, the supplier has advised us on the optimal placement of the panels to ensure the highest possible efficiency of the system.

The new solar panel system will generate approximately 29,351 kWh annually, corresponding to the entire electricity consumption at Spectre HQ in Denmark, of which a large part is consumed for recharging electric vehicles. This results in an annual CO2 reduction of 13,784 kg.

To put this into perspective, an annual reduction of 13,784 kg CO2 is equivalent to:

• Driving approximately 92,000 km in an average gasoline car

• Avoiding the consumption of 6,000 liters of gasoline

• Planting around 230 trees, which would take a year to absorb the same amount of CO2

In the 2024/25 financial year, fabrics alone accounted for 53% of Spectre’s total greenhouse gas (GHG) emissions – and 80% measured on emissions only from purchased goods and services – underscoring their dominant role in our overall environmental impact. As a Tier 1, OEM garment manufacturer, Spectre does not directly select the materials used in production; instead, we remain largely dependent on the choices made by our brand partners and their nominated suppliers.

Distribution of GHG emissions in Scope 3 Category 1

“Purchased goods and services”, 2024/25

Due to their significant role in our industry’s value chain, fabrics and fabric suppliers have become a central focus of our decarbonization strategy, and addressing their impact requires close collaboration across the value chain—from material producers to the brands themselves. Several of our strategic goals are directed toward this area, as we recognize that the most effective levers for reducing emissions at the material level include improving energy efficiency and transitioning to renewable energy sources in textile manufacturing.

% of virgin, fossil- 55%

based material of total

While we may not choose our suppliers directly, we do choose the brands we partner with. Working with brands that share our values and climate ambitions makes it significantly easier to influence material choices and ensure alignment throughout the supply chain. With like-minded partners, the challenge of supplier engagement becomes far more manageable—and progress toward shared decarbonization goals is more achievable.

Therefore, as much as we like to prioritize sourcing from responsible, forward-thinking suppliers, the same goes for brands we produce for. As a result, in 2024/25, the share of virgin fossil-based fabrics decreased by 5% compared to our base year, marking some progress toward more sustainable sourcing. Whilst this is a positive trend, it’s worth noticing that only 14% of the global, annual production of textile polyester fibers for the apparel industry are recycled and only underline the importance of the industry’s players showing decisiveness.

We’re also seeing a steady shift in the market: more brands are transitioning to preferred materials, such as recycled fibers, whether derived from fossil-based or renewable sources. To credibly communicate these material shifts to consumers, many brands now are interested in Global Recycled Standard (GRS) certification, which provides a transparent chain of custody and verified content claims. GRS certification is not just a label—it builds trust across the supply chain and empowers brands and consumers to make evidence-based, climate-conscious decisions.

Spectre’s facilities in Nam Dinh and An Giang received GRS certification in late 2024, with our Thai Binh facility on track to achieve certification by the end of 2025. These certifications position us to better support our customers’ sustainability goals and increase the traceability and accountability of our own operations.

Recycled, 47%

Virgin fossil, 50%

Virgin, 53%

Virgin renewable, 3%

Virgin renewable blend, 3%

Distribution of amounts of fabric disaggregated by composition fibers by circularity properties, 2024/25

In 2024/25, 47% of all fabrics used in Spectre’s production were made from recycled fibers—a 7% increase from the previous year. While this is a meaningful step forward, we recognize that fabric composition also plays a crucial role in long-term sustainability.

Mono-material fabrics, such as 100% polyester, are generally easier to recycle and have better circularity potential. However, in practice, only 37% of our fabric use in 2024/25 consisted of mono-materials, a decline of 7% compared to the previous year. This drop reflects a persistent challenge: fiber blends are often essential for achieving performance, comfort, and technical specifications demanded by customers. As long as blends remain the norm, innovation in both fabric development and waste management systems will be key to enabling better recyclability and reducing climate impact.

*Includes such fibers as elastane and other polyamide

**Lycra and other polyamide materials recycled

***Includes lyocell, viscose, modal

Although polyester—both recycled and virgin—continues to be our most widely used fiber, accounting for 68% of total purchased fabric by weight in 2024/25 (see fabric mix table above), it is often blended with other fibers to achieve specific functional properties. Other commonly used materials include polyamide-based fibers (such as nylon) and elastane (including spandex and lycra). As a result, the overall fabric mix is heavily technical and synthetic, with only 3% derived from renewable sources such as cotton and wool (and some share of other even less used). This reflects the realities of the outdoor and activewear industry, where performance requirements drive material choices—but it also means we share responsibility for the environmental impacts, including the use of certain chemicals and the release of microplastics.

Our role as a Tier 1 manufacturer means we often work with nominated, pre-selected material compositions, but we are committed to informing and influencing brands through data, dialogue, and innovation partnerships that advance decarbonization at scale.

Per- and polyfluoroalkyl substances (PFAS) have long been a pressing concern in the textile and apparel industry due to their persistence in the environment and potential risks to human health. Regulatory actions are rapidly advancing across the globe to restrict or ban their use, particularly in consumer goods and textiles. In Europe, the proposed REACH restriction—expected between 2025 and 2026—could significantly limit or prohibit the presence of PFAS in most applications, including water-repellent and waterproof treatments.

Looking ahead, we are expanding our production of waterproof garments that rely on various membrane technologies and durable water-repellent (DWR) treatments (the latter is also used for other fabric categories). Encouragingly, our research indicates that the waterproof laminates currently in use by our brand partners largely employ more sustainable membranes, such as polyester or polyurethane, and are treated with DWR finishes labeled as “C0-DWR” or “PFC-free DWR”, but the data we have still is not sufficient. These are considered more environmentally responsible alternatives to traditional fluorinated chemistries.

Due to evolving legislation, it will become part of our responsibility and future reporting obligations to track, minimize, and eventually eliminate PFAS from our value chain. This includes improving our awareness of current material usage and identifying any PFAS-containing substances still present—particularly in waterproof fabrics and membranes used in our production.

While a complete overview of current PFAS use across our supply chain has yet to be established, it is clear that many of our customers are already taking proactive steps. Approximately 95% of our revenue comes from customers who acknowledge the harmful impact of PFAS. Some have made public commitments —though often specifically addressing PFCs (perfluorinated compounds), a subgroup of PFAS. Still, even those who have not yet formalized a position will likely be required to comply with upcoming legislation to maintain market access.

* Packaging weight data presented in this table is currently estimated, based on average weights of comparable products and packaging types. As detailed tracking of packaging weight is not yet in place, we recognize this as a limitation and are committed to improving the accuracy of this data in the coming year through more systematic collection processes

Packaging plays a significant role in the overall environmental footprint of the garment lifecycle. While it may appear to be a small component of the supply chain, its cumulative impact is substantial. At Spectre, we are continuously working to minimize this impact wherever possible.

The primary materials used for packaging—by weight—are cardboard boxes and cartons. Currently, 97% of these materials are sourced from suppliers who hold valid FSC certification and have shared their certificates with us. However, in order to officially claim that the boxes used in our production are FSC certified, two additional conditions must be met: the FSC claim must appear on the supplier’s invoice, and the boxes or cartons themselves must be labeled accordingly. As of now, we do not have this level of documentation in place. Our current focus is therefore on ensuring that future purchases include the appropriate FSC claim on invoices, providing the necessary proof to support any FSC-related statements. These materials are not only essential for protecting products during transportation but are also among the most sustainable options when managed responsibly. Spectre prioritizes the internal reuse of both boxes and polybags to reduce waste generation. Once these materials can no longer be reused, they are sorted and recycled in accordance with local waste management and recycling systems.

Finished products are packed in accordance with brand-specific guidelines, typically using materials chosen by the brands themselves. This makes collaboration and shared sustainability values critical—brands with similar standards and mindsets provide the most effective path toward adopting more sustainable and innovative packaging solutions.

In the 2024/25 fiscal year, 78% of the polybags used across our operations were made from recycled plastic, significantly reducing reliance on virgin plastic and supporting circularity. An additional 8% were produced using biodegradable materials, offering a more environmentally friendly alternative that breaks down more easily when disposed of appropriately.

Transportation plays a crucial role in the movement of raw materials, finished goods and waste across supply chains, but transportation also significantly contributes to the emission of greenhouse gases. Every production company knows the challenge of reducing emissions and simultaneously ensuring the delivery of raw materials to the factory and delivering finished goods to the customer.

At Spectre, freight of goods through air, sea and road transportation is the source of GHG emissions. In 2023/24, 6,8% of our total GHG emissions came from inbound, outbound and internal deliveries. Addressing these challenges is essential to meeting our sustainable goals by 2030 and reducing the overall environmental impact.

Every year, we work to get a more detailed carbon footprint emissions report, and by consolidating our transportation with one main logistics partner, we can secure high CSR standards, transparency and a more detailed overview of our carbon footprint. This will enhance our ability to continuously measure the carbon footprint for each garment with increasing precision and thereby work on the reduction of our GHG emissions.

We request logistics partners provide us with CSR strategies and reliable, specific GHG data for our transportation operations. By consolidating our transportation with DSV, it is possible to optimise and consolidate shipments and improve the overall efficiency of logistics and align strategies and cooperate on increasing sustainable logistics. DSV’s commitment to achieving sustainable logistics solutions aligns with our commitment to reducing our carbon emissions in our operations and in the value chain.

We have decreased our transport emissions from 10% in FY 2023/24 to 9% in 2024/25 due to our ongoing project of consolidating our transportation with DSV. A continuous struggle is to limit the amount of air

We know that responsible production is not just about the garments we create – it is also about the choices we make along the way, among others, how we manage something as problematic as fabric leftovers.

We want to change this, and therefore, we have set a clear target: by 2030, no more than 5% of fabric from our production should go unused. It is an ambitious goal, but ambition drives us. Achieving it will take innovation, collaboration, and a shift in industry mindsets.

Internal electric fleet.

As a part of our commitment to reduce carbon emissions, we have replaced fossil-fueled company cars both in Vietnam and Denmark. This represents a key milestone for us in reducing our direct transportation emissions. Our strategy is to not only encourage the transition away from fossil-fueled transportation and facilitate the possibility of EV charging but to be a leading part of this transition.

Fabric leftovers – the surplus of usable material that remains after production – are an inevitable part of garment manufacturing, and it accounts for up 20% of all material used to produce garments – adding up to millions of tons of waste in the global garment industry, of which the majority is taken for landfill or incineration. In other words, our industry is still at the bottom of the waste hierarchy.

We have chosen another path and are using our fabric leftovers in ways that bring value and turn waste into resources.

Over the past year, we have been busy with various activities:

• Partnered with a local university student to explore scalable reuse strategies.

• Co-developed limited-edition styles with customers utilising leftover stock.

• Worked with local businesses in Vietnam and Latvia to upcycle and repurpose fabrics.

• Recycled more than 214,000 meters of leftover fabric through verified partners in Vietnam.

• Out of the fiscal year 2024/25 the 214.000 m. fabric leftover accounts for 3,73% of our total textile consumption. The fabric leftover was accumulated throughout 2022-2024.

Each initiative brings us closer to our goal and proves that responsible disposal is not only possible but scalable, even in high-volume manufacturing.