Repair of Old Buildings Course

SPAB

2022 Handbook: Additional resources

Additional resources

The SPAB Approach

Need for old buildings to breathe Control of Damp

Energy Efficiency

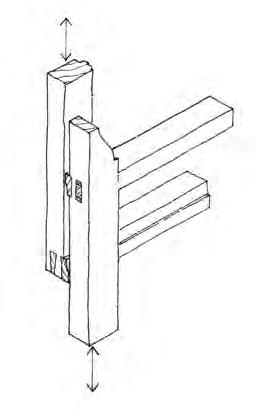

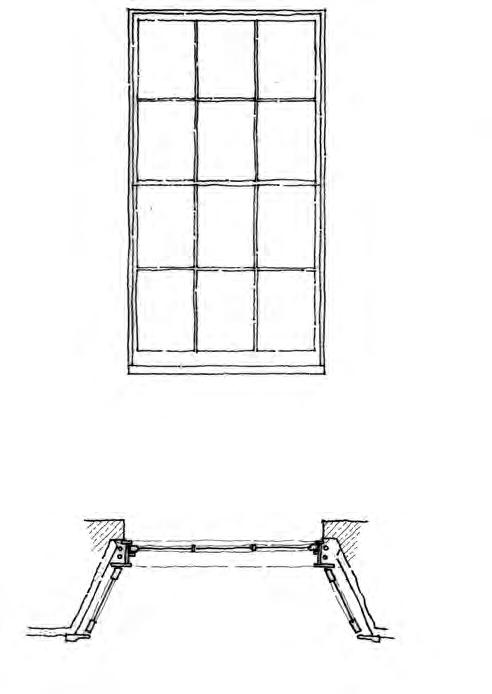

Repair of Wood Windows

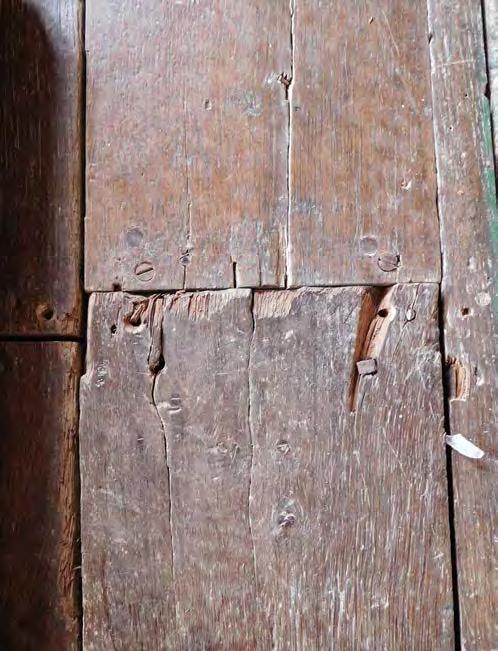

Patching Old Floorboards

Caring for Old Floors

Gypsum Plaster Floors

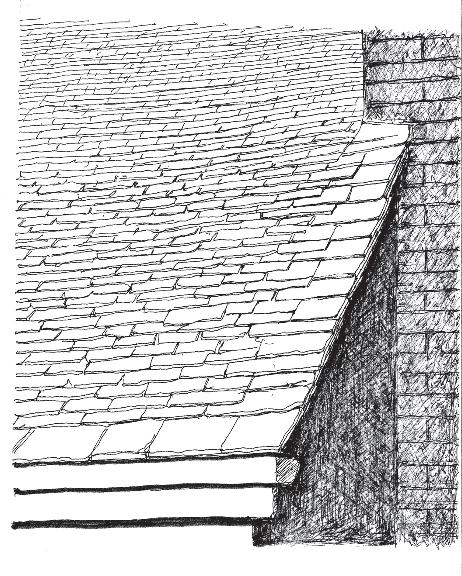

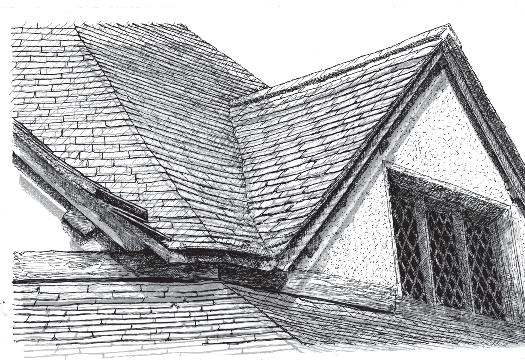

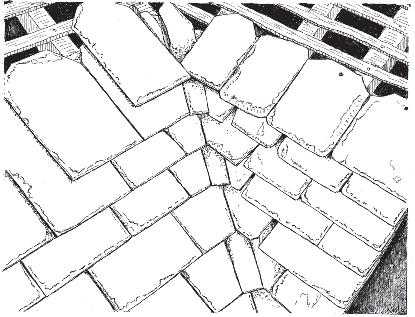

Slate and Stone Roofing in Wales and the Marches

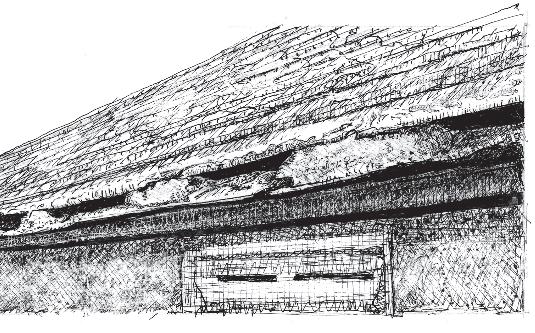

Slating in the East Midlands

Slating in South-West England

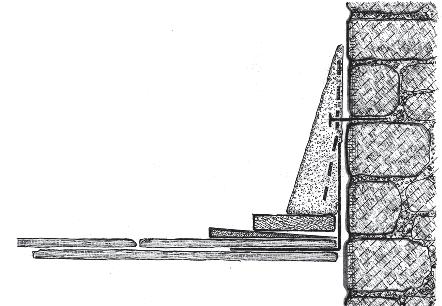

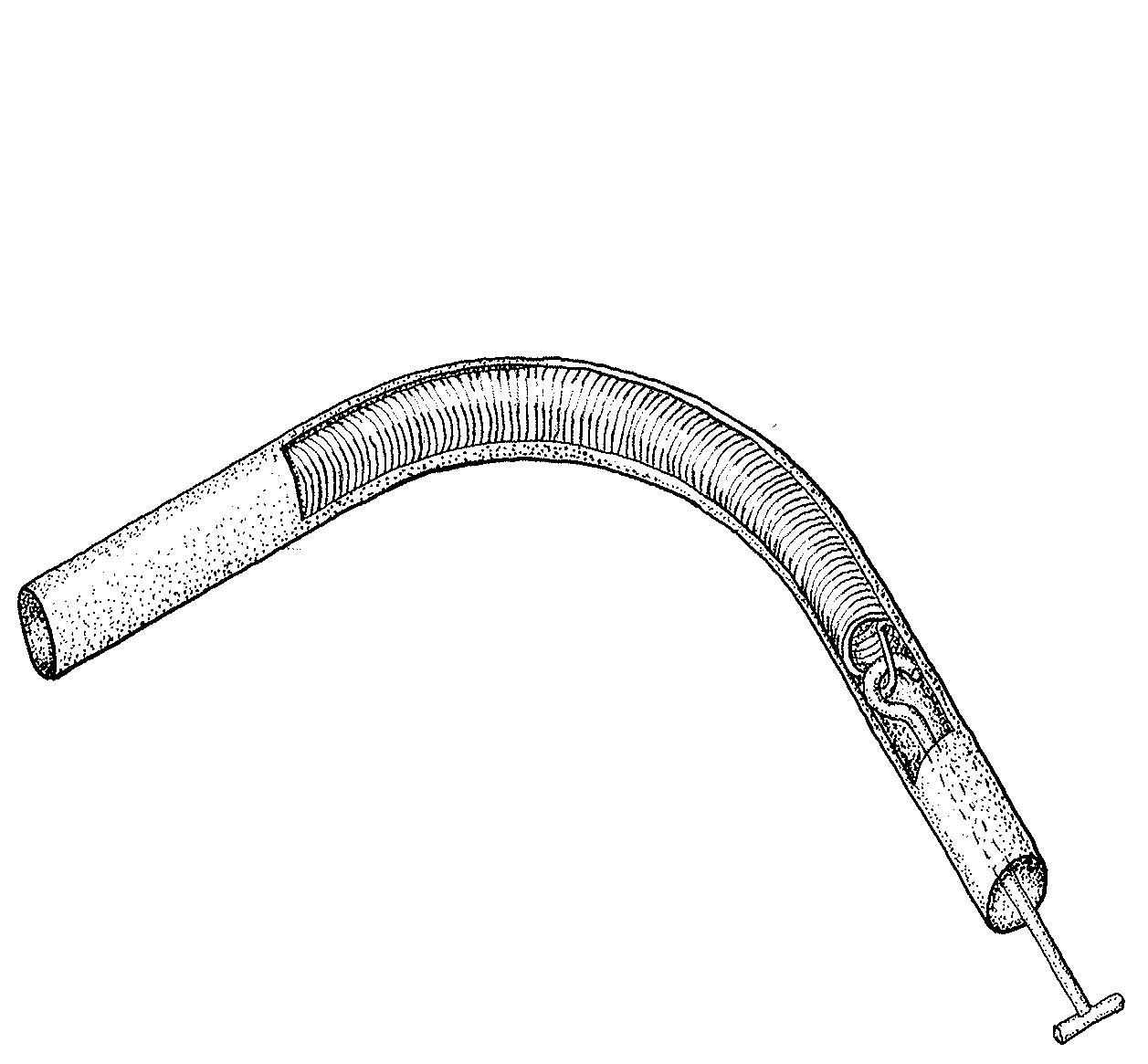

Plumbing Leadwork:

Conservation

and

Charity number 1113753 Company number 5743962

Scottish charity number: SC 039244

Registered in Ireland: 20158736

Contents

Joints

Pipes

of Decorative Leadwork The SPAB 37 Spital Square London E1 6DY 0207 377 1644 education@spab.org.uk / info@spab.org.uk

b

SPAB William Morris Craft Fellow, Andrew Johnson

Picture: Ralph Hodgson

“

The Great British conservation movement ... draws its intellectual energy and passion from the wellspring that is the Society for the Protection of Ancient Buildings. ”

Ke vin Mc c loud, SPAB Me MB er, de S igner A nd T v P re S en T er.

Foreword

The SPAB is over 140 years old and is widely admired around the world as the fount of conservation thinking for the built heritage. It is still involved in the everyday problems and battles that old buildings face today.

One of the reasons for the Society’s longevity is its founding, not on commercial or political ground, but on a philosophy that offers proven and sustainable conservation ideas.

The principles contained in the elegant, precise prose of William Morris’s Manifesto have served to enlighten those who care for old buildings since the founding of the Society, but each generation has had to consider how those principles apply to the particular problems of the age.

The aim of this document, under the title the SPAB A PP ro A ch is to re-present and interpret the Manifesto for new audiences in the 21st century. It provides practical guidance for building owners and professionals who manage or need to repair an old building, while, for the Society, the Approach informs our strategic direction as well as providing a basis for much of our work including campaigning, training and advice.

At the same time, we seek to reach the widest possible audience, including our new members, writers, grant funders, peer organisations and the next generation of home owners, so that they can appreciate the singular and reasoned line of thought that helps us ‘protect our ancient buildings, and hand them down instructive and venerable to those that come after us’.

Iain Boyd, Chairman

a

St Mary Magdalene, Caldecote, Hertfordshire.

Picture: SPAB

THE SPAB APPROACH4

THE SPAB APPROACH6

b

Introduction

t he SPAB A PP ro A ch to building conservation combines well-proven principles with practical repair techniques. It has influenced building conservation worldwide and underpins much in UK heritage legislation. Other conservation approaches exist, but the Society’s principles are viewed by most as the yardstick.

t he SPAB A PP ro A ch began as an outcry against destructive work, but the guidance the Society offers today is practical and positive.

It aims to promote the value and good sense of caring for the fabric of old buildings. The SPAB takes a long-term view, urging that in our own actions we consider the legacy we will leave to future generations.

“ It is for all these buildings, therefore, of all times and styles, that we plead, and call upon those who have to deal with them, to put Protection in the place of Restoration. ”

q“ Stave off decay by daily care ” — from the SPAB Manifesto

Tile repair to the door of Rottingdean Church, Sussex, 1920s

Picture: SPAB

THE SPAB APPROACH 7

Historical background

The SPAB’s ideas stem from the thoughts of John Ruskin. In his ‘Seven Lamps of Architecture’ (published 1849) Ruskin railed against destructive work to old buildings, described at the time as ‘restoration’. Ruskin called restoration ‘a lie from beginning to end’ because it sought to change the character of an old building by erasing the evidence and record of its true history. The SPAB’s founders, led by writer and designer William Morris and architect Philip Webb, took up Ruskin’s ideas and translated them into the Society’s founding Manifesto. The Manifesto remains a concise and beautifully poetic expression of SPAB conservation principles, as relevant to the needs of today as to those of the 19th century. SPAB members have applied the Manifesto’s ideas to the care and repair of thousands of historic structures in the UK and beyond.

Early on, the SPAB was nick-named ‘Antiscrape’ as it rejected the 19th century fashion for removing historic surfaces and emphasised that leaving the fabric of old buildings unaltered was the best way to ensure their history and character remained intact.

St John the Baptist Church, Inglesham, Wiltshire. William Morris paid for its conservative repair.

Picture: Diana Neale/ The CCT

St John the Baptist Church, Inglesham, Wiltshire. William Morris paid for its conservative repair.

Picture: Diana Neale/ The CCT

THE SPAB APPROACH8

A conservation philosophy

t he SPAB A PP ro A ch is based on the protection of ‘fabric’ — the material from which a building is constructed. A building’s fabric is the primary source from which knowledge and meaning can be drawn. Materials and construction methods embodied in building fabric illustrate changes in people’s ideas, tastes, skills and the relationship with their locality. Fabric also holds character and beauty; the surfaces, blemishes and undulations of old buildings speak of the passage of time and of lives lived. Wear and tear adds beautiful patination that new work can only acquire through the slow process of ageing.

Building fabric is precious. A concern for its protection helps ensure that the essence of an old building survives for future generations to appreciate. t he SPAB A PP ro A ch therefore stands against Restorationist arguments that it is possible and worthwhile to return a building to its original — or imagined original — form. Equally, the SPAB A PP ro A ch generally rejects arguments that original design or cultural associations are more important than surviving fabric. For the Society, protecting fabric allows meaning and significance to be drawn from it by individuals, groups and successive generations.

q

“ Prop a perilous wall or mend a leaky roof by such means as are obviously meant for support or covering, and show no pretence of other art, and otherwise to resist all tampering with either the fabric or ornament of the building as it stands…”

— from the SPAB Manifesto

THE SPAB APPROACH 9

The S PAB Approach

RE GULAR MAINTENANCE

The starting point for the SPAB A PP ro A ch is care and maintenance. Some deterioration of a building over time is almost inevitable, but maintenance helps slow the rate and lessens the need for larger campaigns of work. Major interventions tend to be more costly, disruptive and damaging to building fabric. Good maintenance involves simple, frequent checks and minor works: clearing gutters and drains, fixing slipped slates or tiles, or replacing missing putty around glass. Maintenance is a continuous obligation for building owners, but the effort always pays dividends in protecting a building’s historic and monetary value. The most important message of the SPAB Manifesto is: ‘stave off decay by daily care’.

SPAB Scholar Marianne Suhr supporting SPAB National Maintenance Week.

SPAB Scholar Marianne Suhr supporting SPAB National Maintenance Week.

THE SPAB APPROACH10

L

UNDERS TANDING

All conservation work involves decision-making. For these decisions to be well-considered, knowledge and understanding are essential. t he SPAB A PP ro A ch calls for an understanding of history, design and construction. Buildings are the product of decisions made at the time of their construction and in every era since. This sequence of change, and the relative importance of the elements that make up the whole, need to be explored and assessed. Past changes often add interest and value; but sometimes they will have caused damage and need reconsidering. Equally important is understanding of structural issues. For example, is the lean of a wall worsening, or did it occur and cease years ago? Is the decay of a timber superficial or a structural threat? Often the best first step, where a potential structural problem is identified, is simply to monitor, watch and learn. Thought and investigation should precede any action.

CONTEXT AND CONTINUITY

Old buildings invariably have a strong connection with their locality. This can result from the materials and construction techniques used, as well as the relationship between people and buildings that helps create a sense of community. Buildings are also likely to age and weather according to the conditions on a particular site. For these reasons, the Society does not support the moving of buildings to new locations nor their reduction to mere facades. Also, repairs carried out in situ, rather than on elements dismantled and moved to the workshop, will help ensure that the maximum amount of existing fabric is retained, thus maintaining integrity and continuity. It is extremely rare for there to be no hope for a building.

THE SPAB APPROACH 11

L L

RESPECT FOR AGE

The ‘oldness’ of a historic building is a precious quality. It is the patina of age that distinguishes old from new. Those signs of age, often held in the slender surface layers of an old building, deserve special consideration. They may be the undulations of old plaster, the dip in a roof ridge, or the wear on stair treads. Sometimes wear and tear becomes a practical problem, but, wherever possible, t he SPAB

A PP ro A ch encourages restraint. Through respect for the signs of age in surfaces and architectural features, the integrity of the whole as an old building will be retained. Thoughtful management and maintenance help slow down the more harmful effects of decay.

ESSENTIAL WORK ONLY

The Society’s approach very often involves carefully considered inaction. Where no problems exist, or where a problem has no major effect on use or conservation, an old building is best left alone and simply enjoyed.

Problems need to be tackled, but the Society encourages work which is no more – but no less – than is essential. Restricting work to these things helps ensure the maximum survival of historic fabric. As a secondary benefit it should also reduce effort and cost. Sometimes more work than essential is undertaken in a bid to secure long-term benefits. There are certainly occasions when the opportunity of access makes it sensible to

Weathered carving, All Saints Church, Theddlethorpe.

Picture: SPAB

THE SPAB APPROACH12

L L

carry out more work than is immediately necessary, but generally the best conservation approach is to deal with present problems alone.

L

REPAIR NOT RESTORATION

Restoration of the kind opposed by Ruskin and Morris sets out to turn back the clock or to recreate the past. Its often a destructive process and may leave a building without the signs of age or evidence of its past interaction with people. Knowledge of an original design is not sufficient reason for erasing later change, particularly where this change has added positively to a building’s historic interest. Also, the Society believes that damaged or missing elements of a building do not necessarily need to be replaced, except where there is a functional need. Then, small-scale, localised reinstatement may be justified, but only if carried out for well-considered, practical reasons.

Reinstatement for the sake of tidiness, or to recreate historic design or detail is at odds with the SPAB A PP ro A ch .

Monument at St George's Church, Hinton St George, Somerset conserved without restoration of lost detail.

OVERLEAF a

Archbishop’s Palace, Charing, Kent. Changes and additions add interest to the original.

Picture: SPAB

Picture: SPAB

THE SPAB APPROACH 13

Conservative repair to a window head replaces as little fabric as possible.

CONSERVATIVE REPAIR

t he SPAB A PP ro A ch champions ‘conservative repair’ in opposition to ‘restoration’. Conservative repair can embrace a wide range of techniques. Its aim is to retain as much as possible of a building’s historic fabric. Sometimes it involves matching the existing materials of a building and sometimes use of compatible alternatives. Conservative repair is based on thorough investigation and understanding of the whole building and of the element directly concerned. It requires careful planning and appropriate craft skills. A good repair deals quietly and modestly with a problem, with a skilled repairer knowing when to hold back and when to intervene with the aim that work is done quietly, modestly and humbly but effectively.

FITTING NEW TO OLD

t he SPAB A PP ro A ch calls for new work to be fitted to the old. All too often, old work is cut back or levelled off to make the job of inserting the new simpler. Modelling the new to fit the old can be more complex and technically challenging, but it is necessary to ensure protection of an old building’s surviving fabric.

Picture: SPAB

THE SPAB APPROACH16

L L

MATERIALS

LA careful choice of materials is essential to the sympathetic and effective repair of old buildings. Often it is best for new materials to match the old, ensuring fabric remains compatible in terms of structural movement or ‘breathability’. Sometimes though, use of alternative materials may be more fitting and effective, allowing new work to be distinguished from the old, and illustrating that an intervention has occurred. Equally, use of alternative materials can sometimes assist the maximum retention of historic fabric.

The Society does not generally encourage re-use of materials on a building when they have been taken from another structure. This is because the inclusion of historic materials from else-where can confuse an old building’s history. Furthermore, salvaged materials are a finite resource, and damage or loss of interest sometimes results when they are taken from one building for use on another. Production of traditional building materials helps ensure a continuing supply for future repair work.

Tile repair: a method sometimes used by SPAB members to follow the eroded contours of a building and minimise fabric replacement.

Picture: SPAB

THE SPAB APPROACH 17

The SPAB has led the revival in use of traditional lime and earth-based mortars, plaster and renders.

PROVEN METHODS

Conservation work often requires creative thinking and ingenious planning. Despite this, the techniques to be used should be tried and tested. New techniques of repair may become useful once proven, but old buildings are not the place where experimentation should occur. There are many instances where new repair methods and products, considered a panacea in their day, have proven ill-advised and harmful over time. Much effort is expended in undoing well-intentioned but misguided works of the past.

CRAFTSMANSHIP AND PRACTICAL KNOWLEDGE

Skilful repair requires skilled people. Some old buildings were constructed by people with no more than basic craft skills, and this simple workmanship can lend a building charm. But the old buildings that have survived into the present are precious, and any work done to them today should be tackled by people who have gained conservation experience and expertise but show a willingness to keep learning. The SPAB supports conservation training in all the disciplines that are needed to ensure sensitive care and repair of old buildings. The Society has also argued,

Picture: SPAB

THE SPAB APPROACH18

L L

since its earliest days, that people involved with old building care as owners, managers or professionals benefit from gaining hands-on practical experience of construction and repair methods.

L

GOOD NEW DESIGN TO COMPLEMENT THE OLD

The Society recognises that, from time to time, old buildings may need sympathetic alteration, adaptation or extension to ensure their continuing usefulness. There are occasions, the SPAB Manifesto argues, when it may be better to leave an old building unaltered and to build a new one if the adaptation required would involve serious damage. These cases are the exception. Generally, modest, sympathetic new works allow continuing life for old buildings and can contribute positively to their interest and story. Further alterations and additions, the Society believes, are best when they complement what exists. They should not compete unduly with the old building in form or position; nor should they mimic the original or pretend to be historic. They should fulfil modern needs in a way that respects both the old building’s form and context. The new should not harm the old where they meet, nor create problems with future maintenance.

New complements the old at Astley Castle, Warwickshire.

Picture: SPAB

THE SPAB APPROACH 19

EMERGENCY WORK AND A LONG-TERM VIEW

t he SPAB A PP ro A ch involves taking a long term view of a building’s care and needs. The Society has seen many examples where repair for re-use has been considered unviable at a certain point in time – usually by virtue of cost or surroundings – only to become a more attractive proposition at some later date. Many country houses or old cottages, for example, were viewed as ‘white elephants’ in the mid 20th century, but where they have survived are now considered valuable and useful property. Sometimes full repair is not possible at a particular point. In such cases, temporary repair can buy time for a building, halting decay or reducing its rate.

Emergency work to fire-damaged Tonge Hall, Tonge, Middleton, Greater Manchester.

Picture: SPAB

SUSTAINABILITY AND THE SPAB APPROACH

If we are to be ‘trustees for those that come after us’ in William Morris’s words, we need to consider the impact of our treatment of old buildings on future generations. Overall, the SP AB

A PP ro A ch is about understanding, care and conservative repair. It is a simple message of sustainability. Through protection of building fabric the stories and beauty embodied in old buildings can be enjoyed by us and by generations to come. This is as much an issue for us today as it was in 1877.

THE SPAB APPROACH20

L L

PASSING ON KNOWLEDGE

LThe Society’s founders were concerned not only with conservation theory, but also its practice. This interest in the practical has been developed through the work of the Society’s members over many generations. Passing on and developing knowledge is a vital part of the SPAB A PP ro A ch . The Society seeks to help those entering the conservation field, and all those who wish to develop their existing skills and experience of old building care and management.

Ruins — structures which are roofless and without active use — can be picturesque and beautiful. Their ruination may also result from an important historical event. Where a ruinous structure is reasonably resistant to decay, and the reasons for ruination are of historic importance, the Society would not normally support reconstruction for re-use.

In other cases re-use may be sensible and appropriate — particularly where the reasons for ruination are of lesser importance, or where decay is likely to be rapid because of the structure’s constructional type. Where ruination has resulted from a recent disaster, pause for thought may be needed before decisions about its future are taken, though temporary protection must still be considered.

Picture: SPAB

OVERLEAF a Ruin conservation at Penicuik House, Midlothian

Picture: SPAB

Sharing traditional skills with school children at a SPAB Working Party.

Sharing traditional skills with school children at a SPAB Working Party.

THE SPAB APPROACH 21

Our work today

The Society is the longest established building conservation body in the UK and continues to be recognised for its knowledge base, training expertise, and promotion of the built historic environment’s value.

The Society’s mission

• To supply expertise that keeps old buildings useful, beautiful and part of people’s lives

• To be the most recognised organisation for building conservation knowledge and skills

• To connect with all people who appreciate old buildings or care for them.

Today this is put into action through:

• Campaigning for individual buildings and for historic places through our formal casework role in the planning system as well as media outreach and public engagement.

• Technical research and guidance, including the information service provided by our website, advice line, publications and appearances at events and exhibitions.

• Training and courses for those involved professionally, and for owners and enthusiasts

• Opportunities for involvement as a SPAB member through social events, lectures, volunteering and participation in working parties.

THE SPAB APPROACH24

The SPAB puts its ideas into practice through its training, advice, working parties and events.

Pictures: Ralph Hodgson

THE SPAB APPROACH 25

O O O O O O O O O

Become a member of the SPAB

Join the Society for Protection of Ancient Buildings and help us to protect, care and repair historic buildings into the future. We need your support to continue our unique education and training programmes, provide advice, carry out essential research and campaign to save old buildings from decay, harmful alteration and demolition.

With your SPAB membership you’ll receive:

U The S PAB Magazine, a must-read for those who love old buildings

U A copy of our annual Property List publication as well as access to our online directory of historic and interesting buildings for sale

U Priority booking on selected SPAB courses and training

U A programme of member-only events

U Activities organised by regional membership groups

U Exclusive online content

U Occasional offers from partner organisations

Visit spab.org.uk for more information or contact 020 7377 1644, membership@spab.org.uk

Y Y Y Y Y Y Y Y Y Y Y Y Y Y

Leave a gift in your will.

Y Y Y Y Y

You can give old buildings a future. Leaving a legacy to the SPAB is a powerful and effective way to ensure that our work can continue.

Y Y Y Y Y

Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y

Demands for the SPAB’s help and support are ever-increasing. To meet them we rely on the assistance of those passionate about the charity’s philosophy. William Morris left us the SPAB as his legacy. We hope that you will join us in continuing the important work he started in 1877. By leaving a legacy you can help protect old buildings for future generations.

Y Y Y Y Y

Visit spab.org.uk for more information or contact 020 7377 1644, development@spab.org.uk

Y Y Y Y Y Y

Y Y Y Y Y Y

Y Y Y Y Y Y

Y Y

Y

Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

THE SPAB APPROACH26

O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O O

Y

Y Y

Y Y

Y

Y Y

Y

Y

Y

Y Y

Y

Y Y Y

Y

q

Society for the Protection of Ancient Buildings

37 Spital Square, London, E1 6DY

020 7377 1644

info@spab.org.uk

www.spab.org.uk

Charity No. 111 3753

Scottish Charity No. SC 039244 Company No. 5743962

The Need for Old Buildings to ‘Breathe’

SPAB Technical Advice Note

Philip Hughes BSc, MRICS (Chartered Building Surveyor) and SPAB Scholar

The Society for the Protection of Ancient Buildings

37 Spital Square London, E1 6DY 020 7377 1644

info@spab.org.uk

www.spab.org.uk

Contents

In order to repair a building one needs to be able to understand the building’s construction and the causes of its decay. From the mid-19th century, rapid changes in construction methods occurred and a number of new building materials were introduced. Many of these materials are perfectly suitable for contemporary buildings, but have been found to be incompatible with the construction of old buildings. The aim of this Technical Advice Note is to examine these differences and draw conclusions about the way old buildings should be treated.

1 Introduction ....................... 3

2 Problems caused by the use of impervious materials

3 The correct treatment of old buildings

4 References

5 Other advice

Cover image: The walling materials and finishes on old buildings were generally absorbent so allowed the fabric to ‘breathe’.

Photo: Matthew Slocombe

4

7

8

8

SPAB The Need for Old Buildings to

‘Breathe’2

.......................

.......................

.......................

.......................

1 Introduction

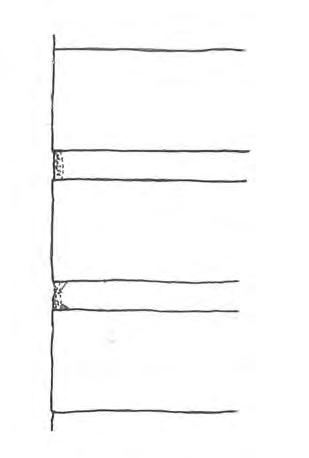

Modern buildings tend to rely on an impervious outer layer or a system of barriers to prevent moisture penetrating the walls, whereas buildings constructed before the mid-19th century generally rely on allowing the moisture which has been absorbed by the fabric to evaporate from the surface (see figure 1). The thickness of the wall alone in these earlier buildings may have been relied upon to achieve acceptably dry conditions internally.

The walling materials of old buildings in Britain are usually stone, brick, timber and earth (cob, wattle and daub), which are all absorbent. Mortars used to construct walls of brick and stone were usually of lime and sand, but earth or earth/lime mortars were sometimes used. The porous nature of these mortars permits evaporation of moisture from within the wall. As the mortars are usually more permeable than the materials they bond, walls are often dependent upon the evaporation of moisture from the joints to remain acceptably dry.

External rendering was usually lime-based, and therefore absorbent. Where this was used to improve the weather-resistance of the wall, it is common to find that this render has a rough open-textured surface, which tends to maximise the surface area and thus the amount of moisture able to evaporate is increased.

Buildings used to be decorated, internally and externally, almost exclusively with limewash, which could be coloured with natural pigments. Limewash is again, a porous material and allows the wall to ‘breathe’.

The concept behind the construction of old buildings is that moisture entering the wall should be able to evaporate. Whereas modern buildings rely on keeping water out by a system of barriers.

Technical terms used in this guidance are defined in our online glossary.1

Evaporation of moisture

Rain Rain

Cavity - barrier to penetrating dampness

Interstitial condensation (water vapour)

Damp-proof coursebarrier to rising damp

Evaporation of moisture

Rising dampness

1(a)

Interstitial condensation (water vapour)

Evaporation of moisture

1(b)

Rising dampness

Figure 1: Understanding the behaviour of old walls: (a) Basic modern cavity wall. (b) Solid wall of porous materials.

Illustrations: Philip Hughes

SPAB The Need for Old Buildings to ‘Breathe’

SPAB The Need for Old Buildings to ‘Breathe’

3

2 Problems caused by the use of impervious materials

2.1 Different building types

In a modern building, the damage or failure of one of its moisture barriers will lead to severe problems of dampness penetration. In an old building, anything that prevents the evaporation of moisture from walls will lead to similar difficulties. Hence the two building types need to be handled in completely different ways: modern buildings will be damp without a barrier to moisture, because the economy of design does not provide a massive and absorbent structure, but old buildings will become damp if an impervious layer is applied to them, because this prevents water within the structure from evaporating.

As the moisture content of the wall increases, the likelihood of decay also increases. Timbers may succumb to wet or dry rot attack because their moisture content is too high. Timbers often occur in solid masonry walls in the form of lintels, spreaders for beam or joist ends, as bonding timbers or as fixing blocks. In masonry walls, the mortar will also be susceptible to decay if excessive moisture levels persist. This is particularly so of the lime/earth mortars used in vernacular buildings. Cob (a mixture of natural soil, straw and cow dung, compacted in layers to form walls) will decay extremely rapidly if it becomes wet and unable to dry out (see

2.2 Paint systems

Paint systems for exterior use tend to prevent evaporation of moisture from the surface. They are designed to prevent the ingress of moisture, but when used on the solid walls of old buildings, water inevitably gets behind the paint film in time (see figure 3). Unable to evaporate from the surface, this moisture is trapped and unless it is able to evaporate from the inner face of the wall the moisture content of the wall will gradually increase. In hot weather, moisture behind the paint film will vaporise, causing blistering, and in cold weather the wall surface may be damaged by frost action (see figure 4).

As the surface layer of paint begins to break down, further water penetration will occur leading to increased dampness.

2.3 External renders

Strong cement renders have a very similar effect to impervious paint films, but renders are even more susceptible to cracking and subsequent breakdown (see figure 5). The resulting decay is often more dramatic. Strong cement renders tend to form hair cracks as they set: these are hardly visible to the eye, but moisture enters the wall by capillary action. Once in the wall,

Figure 2: Water penetration has resulted in the decay of these cob walls. The cement render applied externally prevented them from drying out and led to the suddenness of the collapse.

Photo: Chris Shapland

prevented by the impermeability of the render. Where the render has been applied over soft brick or stone, severe breakdown of the weak underlying material can occur.

2.4 Pointing

External cement-rich pointing of an old wall has slightly different implications (see figures 6 to 9). Once again, water will get into the wall through the masonry or through cracks in the pointing, and due to the impermeability of the mortar will be unable to evaporate from the joints, as originally intended. Moisture within the wall will, therefore, have to evaporate from the surface of the masonry rather than from the pointing, leading to increased decay of the masonry due to the deposition of salts or frost action at its surface.

It is preferable that a soft lime mortar with rough texture and lower strength than surrounding masonry be used for pointing

and bedding. This encourages moisture to evaporate through the joints, rather than through the masonry units. Deposition of most of the salts will therefore occur at these mortar joints and the mortar will decay more rapidly than the masonry. Thus the pointing may be regarded as sacrificial. It is also, of course, cheaper and easier to repoint at intervals than to replace bricks or blocks of stone. This also helps to maximise retention of historic fabric.

2.5 Internal plaster

If the wall has been left with original lime plaster, then water unable to evaporate from the exterior will evaporate from the interior, with consequent disturbance to finishes. Furthermore, increased moisture content leads to decreased thermal insulation of a wall. Evaporation of moisture has a cooling effect on the surroundings and excessive levels of dampness will represent a considerable heat loss.

Figure 5: Strong cement render on a cob wall. The render is being forced off the wall and is taking the surface of the cob with it. The cob behind this is decaying. Photo: Philip Hughes

Figure 3: Frequently overflowing hopper head and gutter have saturated the wall behind an impervious paint layer. Decay of the walling immediately behind the paint film has resulted in flaking.

Photo: Philip Hughes

Figure 4: Moisture trapped behind an impervious paint film has caused it to blister. The effect of salts and frost has led to further decay. Photo: Philip Hughes

Figure 6: Dense cement pointing splurged over the face of the stonework inhibits the evaporation of water from the wall and leads to rapid decay of the stone. Photo: Philip Hughes

Figure 5: Strong cement render on a cob wall. The render is being forced off the wall and is taking the surface of the cob with it. The cob behind this is decaying. Photo: Philip Hughes

Figure 3: Frequently overflowing hopper head and gutter have saturated the wall behind an impervious paint layer. Decay of the walling immediately behind the paint film has resulted in flaking.

Photo: Philip Hughes

Figure 4: Moisture trapped behind an impervious paint film has caused it to blister. The effect of salts and frost has led to further decay. Photo: Philip Hughes

Figure 6: Dense cement pointing splurged over the face of the stonework inhibits the evaporation of water from the wall and leads to rapid decay of the stone. Photo: Philip Hughes

SPAB The Need for Old Buildings to ‘Breathe’5

If dense plasters are used internally, moisture will again be prevented from evaporating and the level of dampness in the wall will increase. A gradual increase in salt concentrations within the wall and the deposition of crystals below the surface will tend to blow the plaster off the wall, or lead to expansion of the plaster layer itself and consequent bulging.

Where dense plasters are used to cover a wall suffering from rising dampness, the effect may be only to drive the moisture higher up the wall (see figure 10). This may cause old plaster which had remained sound hitherto to become affected, or may force moisture up the wall and into contact with timber, making it susceptible to decay.

2.6 Modern extensions

All the factors must be considered carefully when repairing, altering or extending an old building. Extensions cause particular difficulties because the materials in use for the new extension will often be quite unsuitable for works to the fabric of the old building, and yet it is common for work to be carried out on new and old at the same time. It is important to take great care to ensure that damaging work is not executed. Where a full specification has been prepared, it may be necessary to include two sets of workmanship and materials clauses: one set for the new extension and one for work to the existing building.

RainRain

Water in liquid form

Strong cement pointing

Deposition of salt crystals

Interstitial condensation (water vapour)

Evaporation of moisture

Usual decay pattern when mortar used for pointing is softer and more porous than walling material

9(a)

Evaporation of moisture

Water in liquid form

Interstitial condensation (water vapour)

Deposition of salt crystals

Usual decay pattern when wall materials are more porous than pointing

9(b)

Rising dampness Rising dampness

Figure 7: Strong cement-based mortar survives while the wall it was used to point up decays. This could have been avoided by the use of a lime-based mortar, weaker than the brickwork.

Photo: Philip Hughes

Figure 8: This wall has been repointed in a cement-based mortar. It is suffering severely from the deposition of salts. Efflorescence is occurring on the surface of the bricks instead of on the mortar joints as would be the case had a porous lime mortar been used.

Photo: Philip Hughes

Figure 9: Movement of moisture: (a) Wall built of porous materials. (b) Effect of imperious pointing. Illustrations: Philip Hughes

Figure 7: Strong cement-based mortar survives while the wall it was used to point up decays. This could have been avoided by the use of a lime-based mortar, weaker than the brickwork.

Photo: Philip Hughes

Figure 8: This wall has been repointed in a cement-based mortar. It is suffering severely from the deposition of salts. Efflorescence is occurring on the surface of the bricks instead of on the mortar joints as would be the case had a porous lime mortar been used.

Photo: Philip Hughes

Figure 9: Movement of moisture: (a) Wall built of porous materials. (b) Effect of imperious pointing. Illustrations: Philip Hughes

SPAB The Need for Old Buildings to ‘Breathe’6

3 The correct treatment of old buildings

Under normal circumstances, older buildings will function well if they are allowed to work as they were intended to do. Mortars, plasters, renders and finishes should all be of relatively permeable materials, allowing moisture to pass through them and evaporate from the surface.2

Traditionally mortars, plasters and renders were usually lime-based, and decoration was with limewash.

In the case of an old building which has already been treated in some way with an impervious material, watch the building carefully for any signs of the problems mentioned in this Advice Note, and at the first sign of these occurring take remedial action if possible (see figures 11 and 12).

Remedial action should ideally involve the removal of any impervious materials and their replacement with permeable ones. This is not always possible without doing further damage to the fabric of the building and compromise may be necessary.

Cement renders can sometimes be removed after working over the surface thoroughly with a hammer to fracture the render into small units (see figure 13). Levering off large sheets of render will cause severe damage to soft underlying materials. Where a render is so hard that it does not respond, it is probably best to leave it to age naturally. Rendering should be in a lime mix.3

Figure 10: Strong cement-based render has been used to replace plaster affected by dampness on the lower part of these massive walls. As a result the dampness has risen higher in the wall and has now affected the old plaster that had remained sound.

Photo: Philip Hughes

Figure 11: Salt crystallisation behind the strong cement patches on this plinth has led to both these being forced off and to further disintegration of the stonework.

Photo: Philip Hughes

Figure 12: Strong cement pointing being forced off the wall by crystallisation of salts behind. Increased levels of dampness within the wall have caused decay of the earth-lime mortar, leading to compaction of the wall – also forcing off the dense pointing.

Photo: Philip Hughes

Figure 13: Cement render has been applied over a lime roughcast on this timber-framed building. The cement is being carefully removed in small pieces by forming hairline cracks with a lump hammer.

Photo: Philip Hughes

Figure 10: Strong cement-based render has been used to replace plaster affected by dampness on the lower part of these massive walls. As a result the dampness has risen higher in the wall and has now affected the old plaster that had remained sound.

Photo: Philip Hughes

Figure 11: Salt crystallisation behind the strong cement patches on this plinth has led to both these being forced off and to further disintegration of the stonework.

Photo: Philip Hughes

Figure 12: Strong cement pointing being forced off the wall by crystallisation of salts behind. Increased levels of dampness within the wall have caused decay of the earth-lime mortar, leading to compaction of the wall – also forcing off the dense pointing.

Photo: Philip Hughes

Figure 13: Cement render has been applied over a lime roughcast on this timber-framed building. The cement is being carefully removed in small pieces by forming hairline cracks with a lump hammer.

Photo: Philip Hughes

SPAB The Need for Old Buildings to ‘Breathe’7

Cement pointing should be cut out but sometimes it adheres so well that its removal will damage the surrounding masonry. In these circumstances it is usually best to leave what cannot be removed easily and to patch point with a lime-based mortar.4

Paints can sometimes be scraped off when they have started to blister and peel or may be removed by any of the methods suggested in the SPAB Information Sheet on Removing Paint from Old Buildings. Paints which adhere strongly and which resist the usual removal methods are best left until they age. If, in the latter case, they should become patchy, the wall can be redecorated in limewash until the paint is sufficiently decayed to remove.

Where walls have been mistreated in any of the ways mentioned, it is essential they are kept as dry and as well ventilated as possible. Water must not be allowed to enter the top of the wall or behind the impervious material.

Solid walls which have become saturated may take many months or even years to dry out. During the drying process, salts will be deposited on the surfaces, and this can lead to severe breakdown of the materials. In some cases it may be necessary to poultice the wall or apply another finish over it to draw the salts out of the masonry. This is particularly important where ornamental work may be at risk.

If in any doubt, seek professional advice from an architect or building surveyor experienced in the repair of historic buildings. The SPAB can usually suggest names of people with experience in this field.

4 References

1 See https://www.spab.org.uk/advice/glossary

2 for more about permeability, see SPAB

statement on Breathability and Old Buildings

3 Further advice on lime renders is given in English Heritage, 2011

4 For more about repointing, see SPAB

Technical Pamphlet 5 on Repointing Stone and Brick Walling

5 Other advice

5.1 Contacts

Where work to old buildings is being considered, the SPAB may be able to suggest suitable specialists, including contractors.

5.2 Further reading

English Heritage (2011) Mortars, Renders and Plasters, Practical Building Conservation , Farnham: Ashgate Publishing Ltd

English Heritage (2012) Timber, Practical Building Conservation, Farnham: Ashgate Publishing Ltd Kent, D D (2018) Control of Dampness, SPAB Technical Advice Note, London: SPAB. Available at: https://www.spab.org.uk/sites/ default/files/SPAB%20Control_of_Dampness_ Edn_01_Rev_01_0.pdf

Oxley, R (1999) Is Timber Treatment Always Necessary? An Introduction for Homeowners, SPAB Information Sheet 14, London: Society for the Protection of Ancient Buildings Schofield, J (1985) Basic Limewash, SPAB Information Sheet 1, London: Society for the Protection of Ancient Buildings

Slocombe, M (2017) The SPAB Approach to the Conservation and Repair of Old Buildings, London: Society for the Protection of Ancient Buildings

Society for the Protection of Ancient Buildings (1990) The Surface Treatment of Timber-Framed Houses, SPAB Information Sheet 3, London: Society for the Protection of Ancient Buildings Society for the Protection of Ancient Buildings (2016) Breathability and Old Buildings. Available at: https://www.spab.org.uk/advice/ breathability-and-old-buildings

Torraca, G (1988) Porous Building Materials: Materials Science for Architectural Conservation, 3rd edition, Materials Science for Architectural Conservation, Rome: International Centre for the Study of the Preservation and Restoration of Cultural Property. Available at: https://www.iccrom.org/sites/default/ files/2018-02/2005_torraca_porous_building_ eng_106444_light.pdf (Accessed 13 February 2020)

Wright, A (1994) Removing Paint from Old Buildings, 3rd edition, SPAB Information Sheet 5, London: Society for the Protection of Ancient Buildings

SPAB The Need for Old Buildings to ‘Breathe’

8

The content of this publication is offered in good faith, but neither the author nor the Society can accept responsibility arising from incorrect or incomplete information that may be included. The use of traditional materials may incur risks that are different from those associated with modern materials. Manufacturers’ and suppliers’ guidelines should always be observed. This document is intended as a contribution to a continuing debate and we welcome comments.

Written by Philip Hughes. This publication revises and supersedes our former Information Sheet 4 (1st edition, 1986 as amended). The author is indebted to Paul Bedford for his help with the preparation of this document. Grateful thanks to Judith Rodden for editorial advice. Produced by Catherine Peacock. The sources of illustrations are given adjacent to them together with any copyright where not belonging to the SPAB.

The help and advice of the following with the first edition is also acknowledged: Ian Angus, Shawn Kholucy and Annette Downing.

Warning

The term ‘breathing’ is often applied to many products which are only slightly vapour permeable. In general, no synthetic modern materials should be applied to the masonry or plaster surfaces of historic buildings. If in any doubt, contact the SPAB.

The Society for the Protection of Ancient Buildings (SPAB) believes old buildings have a future. From cottages to castles and from churches to cathedrals we are here to help buildings and the people who care for them. Through our unique training schemes, courses, advice and research we help people put our expertise into practice.

Today the SPAB encourages excellence in new design to enrich and complement the built historic environment. We train new generations of architectural professionals and building craftspeople to conserve this landscape with sensitivity and skill, and we play a statutory role as adviser to local planning authorities. In our casework we campaign actively to protect old buildings at risk.

SPAB: hands on history. Join today to support our positive, practical approach to building conservation.

Published by the SPAB in February 2020

© SPAB 2020 Edn 2 Rev 0

SPAB ref: T5304M www.spab.org.uk

ISBN 978-1-898856-39-9

The Society for the Protection of Ancient Buildings 37 Spital Square, London E1 6DY Tel 020 7377 1644 info@spab.org.uk www.spab.org.uk

A charitable company limited by guarantee registered in England and Wales Company No 5743962 Charity No 111 3753 VAT No 577 4276 02

Control of Dampness

SPAB Technical Advice Note

Douglas Kent BSc (Hons), BSc, MSc, MRICS

Douglas Kent BSc (Hons), BSc, MSc, MRICS

The Society for the Protection of Ancient Buildings

37 Spital Square London, E1 6DY 020 7377 1644

info@spab.org.uk www.spab.org.uk

Contents

Most forms of deterioration that affect old buildings in the United Kingdom are attributable to the presence of excessive moisture. Dampness promotes timber decay, the corrosion of metals and even structural collapse. It mobilises soluble salts that harm masonry and increases frost damage. Damp fabric also reduces thermal efficiency. Dampness inside buildings spoils plasterwork, decorations and furniture, and creates conditions that are uncomfortable or harmful to the health of occupants.

This Technical Advice Note explains the nature and causes of dampness together with its diagnosis, control and prevention in buildings predating c1919. Despite dampness problems being commonplace, their cause is frequently misdiagnosed and ineffective remediation undertaken. Unnecessary treatments are often carried out, including the insertion of damp-proof membranes to create barriers to moisture. Action to address basic maintenance or lifestyle issues is usually more appropriate, as well as measures that respect the need for old buildings to ‘breathe’.

Cover image: Dampness problems are commonly misdiagnosed. Rainsplash, as shown here, is incorrectly stated to be rising dampness in many cases.

Photo: SPAB

1 Introduction ....................... 3 2 Sources and symptoms ....................... 5 3 Causes ....................... 8 4 Diagnosis ....................... 11 5 Work in general ....................... 13 6 Control ....................... 15 7 Prevention ....................... 22 8 References ....................... 22 9 Other guidance ........................ 23

1 Introduction

The term ‘dampness’ is used in the context of buildings to refer to the presence of excessive moisture that, if not addressed, may harm them or their occupants (see figure 1).

The source of this moisture can be either liquid water or water vapour in the air. Buildings remain dry when water from various ‘moisture sources’ (for example, moist, warm air rising out of a bath) is balanced by its dissipation via ‘moisture sinks’ (such as good ventilation for a humid bathroom) or storage in ‘moisture reservoirs’ (for instance, absorbent materials). If this equilibrium is upset, however, buildings may become damp.

To understand how this equilibrium arises in older buildings, it is necessary to consider first the way they are built (see figure 2). Pre-c1919 buildings are typically of ‘traditional’ construction. They tend to have solid walls, and sometimes solid floors, built using ‘breathable’ materials that allow the free passage of moisture.1 These include stone, soft brick, unfired earth, lime-based mortars and plasters, and limewash. They take in more moisture than their modern substitutes but allow it to evaporate readily when conditions become drier.

As well as being of traditional construction, many older buildings are vernacular (indigenous) in nature so possess features adapted for the local climate. The UK’s maritime climate means that pitched roofs to shed water quickly are usual, generally with gutters and downpipes or otherwise generous overhanging eaves.

Ventilation through gaps where tile (or slate) beds against tile, dries out any damp timbers

Wind dries the external surfaces

Limewash holds any condensation until it can be re-evaporated

Evaporation of rising dampness

Damp rising through floor Evaporation of rising damp Simple lifestyle generates only small quantities of water vapour

Open fires drawing large quantities of air

Penetration by driving rain

Figure 1: Dampness can lead to serious deterioration if left unattended, as with this cottage that was later demolished as a result.

Photo: Douglas Kent

Figure 2: The movement of moisture through a traditionally constructed building. Illustration: SPAB

Wind blown rain and snow

SPAB Control of Dampness3

During rain, a certain amount of moisture deposited on the outer face of a solid wall will be taken in by capillary action and seep slowly inwards. The vapour permeability of the building fabric will enable this moisture to be drawn back to the surface and evaporate when the rain has stopped, before it can reach the inner face, although extra protection is sometimes required.

Various traditional methods exist to give walls extra protection from the rain with little hindrance to evaporation. These include the application of lime render, comprising roughcast (or harling) in more exposed regions, with limewash.2 Slate-hanging is an alternative seen in the south-west and tile-hanging in the south-east. Weatherboarding is associated with the south-east and parts of East Anglia. Good weatherings are important, too, such as projecting cills, stringcourses, hood moulds and pentice boards (see figure 3). Internally, solid walls can be lined with lath and plaster on timber battens to create an air gap that reduces the likelihood of moisture penetration.

Most pre-c1919 buildings were built without damp-proof courses (DPCs) or damp-proof membranes (DPMs) to act as barriers to moisture in walls and floors respectively. Moisture will rise to some degree as it is drawn by capillary action into the pores of permeable materials, such as brick or stone, that are in contact with damp soil. This is usually not a problem where the construction can ‘breathe’, allowing evaporation.

The absorbed moisture will rise in a wall to a height at which there is a balance between the forces of capillary rise and that of gravity and evaporation. This height will vary somewhat

with the time of year, wall thickness, pore size and the level of the water table in the ground. Flagstone or brick floors used to be laid directly upon the bare earth and the moisture that rose through these floors would be carried away by ventilation (see figure 4). Additionally, the hygroscopic nature of many traditional building materials means they absorb small quantities of moisture from the air when it is humid and rerelease it under drier conditions.

Old buildings are not inherently damp. Before central heating was commonplace, they were heated by open fires that drew in large quantities of air through loosely fitting windows and doors. Generally, this high rate of ventilation would have quickly evaporated ‘structural moisture’ from the breathing fabric internally while such moisture on external wall surfaces would be driven away by the wind. There was, therefore, in theory, an inherent equilibrium.

In practice, this equilibrium may be upset for various reasons with the consequence that liquid water persists for long enough to adversely affect the physical structure of materials, or that relative humidity increases to a detrimental level of 70% or higher. Where dampness exists, it should not be ignored. Although a decision may be taken not to carry out any remedial work, this should only be made after the dampness has been investigated carefully.

This Technical Advice Note considers next the sources and symptoms of dampness, along with its causes (sections 2 and 3). Understanding these is an important prerequisite for diagnosing, controlling and preventing dampness problems (sections 4 to 7).

Figure 3: Traditional architectural details, such as pentice boards, function to protect buildings from the rain.

Photo: Douglas Kent

Figure 4: Traditional solid floors allow the ready evaporation of below-ground moisture from their surfaces.

Photo: Douglas Kent

SPAB Control of Dampness4

2 Sources and Symptoms

2.1 Types of dampness

There are different types of dampness. They are classified according to their source and the distinction between them is important to understand because each requires different treatments. The sources of dampness fall into two main categories:

• From liquid moisture: This includes rainwater penetration, below-ground moisture and plumbing leaks. Flooding is beyond the scope of this guidance.3

• From the air: This covers condensation, high humidity and dampness due to hygroscopic salts.

2.2 Rainwater penetration

Rainwater penetration refers to the ingress of rainwater at various points in the external envelope of a building. It can occur directly through roofs, chimneys and openings, such as windows and doors. It can also happen indirectly, for example, via spillage from a blocked or leaking gutter or gulley through an external wall or ground floor. Rainwater penetrates buildings by various mechanisms, for example, gravity, wind pressure and capillary action.

Rainwater penetration usually produces welldefined damp patches or leaks. The dampness

may evaporate in a few days but will reappear after a period of heavy rain. The symptoms of rainwater penetration internally include stains and peeling paint on ceilings, external walls and chimney breasts. Outside, signs of rainwater penetration may be dark patches that appear after rain, especially on the more exposed parts of a building, such as chimneys, parapets and south-west or west-facing walls, as well as near gutters and downpipes. Patches of green algal growth externally are also commonly attributable to rainwater penetration. (See figures 5a and 5b.)

2.3 Below-ground moisture (including rising dampness)

Below-ground moisture problems relate to the entry of groundwater into a building. This may take place laterally, for example, through a cellar wall under hydrostatic pressure. Alternatively, moisture may enter via upward movement through the bases of walls or floors. This is often due to capillary action, where the result is termed ‘rising dampness’. Rising dampness is usually much less of a problem than commonly supposed. It may extend only 10 to 50 mm above the internal floor level in walls, though can rise to 900 mm or higher, depending on the external ground levels, masonry type, water table level and evaporation rate. (See figure 6.)

The symptoms of groundwater moisture in a building include moist patches on floors and damp floor perimeters. The level of the water table can vary but in general the dampness is more constant than that arising from rainwater penetration. Contaminating salts may be seen as white deposits or feathery crystals. On walls, the effects of rising dampness exhibit a sharp

Figures 5: Common symptoms of rainwater penetration. (a) Water staining internally. (b) Green algal growth externally.

Photos: Douglas Kent

5(b)

SPAB Control of Dampness5

5(a)

change from wet to dry or a ‘tidemark’ stain on finishes. They can also include peeling paint, rotten skirting boards, and possibly mould and an accompanying musty smell.

2.4 Plumbing leaks

The escape of liquid water inside a building from water supply or waste water systems will cause dampness or localised flooding. This may arise where tanks, pipes, valves, radiators, sanitary fittings and appliances, such as washing machines, develop leaks. Dripping overflow pipes for WC cisterns are a further source. (See figures 7a and 7b.)

The symptoms are localised stains, sometimes with a fan-like pattern, and a presence of moisture that is unrelated to the weather. Plumbing leaks may be associated with

mould growth, as well as decay in ducts or voids (although this will frequently not be immediately visible) and can, therefore, result in severe decay if there has been even a slight but long-term problem. Leaks can sometimes be heard or noticed because of higher than usual water bills.

2.5 Condensation

Condensation is the release of water that occurs internally when air comes into contact with colder building components so is cooled to its dewpoint temperature and can carry less moisture as vapour. Condensation is, therefore, dependent upon the temperature of surfaces and the humidity of the surrounding air.

Condensation commonly affects rooms where a large amount of moisture is produced, such as kitchens, bathrooms and bedrooms. It is also found in areas where ventilation is inadequate, particularly in lofts, subfloor voids and chimney flues.⁴ Wardrobes and cupboards built against external walls are often badly affected, as well as room corners and walls behind furniture or pictures. North-facing walls are particularly prone to condensation problems. Condensation is an intermittent form of dampness. It is usually worse in rainy weather but is not dependent on rain.

The condensate will form tiny droplets of moisture on hard, shiny surfaces, for example, glass, metal or plastic-based paint. Because single-glazed windows commonly provide the coldest surface inside a room or space in winter, condensation usually forms on these first – with the glazing acting effectively as a dehumidifier. (See figure 8.)

Control of Dampness

Figure 6: Rising dampness exists but is rarer than commonly supposed.

Photo: Caroline Rye

Figure 7: Plumbing leaks associated with: (a) Defective pipework above a kitchen unit (b) Overflowing WC cistern.

Photos: Douglas Kent

7(b)7(a)

SPAB

6

There may be accompanying rot in softwood window frames. Where windows are doubleglazed, condensation often occurs on the adjacent plaster reveals instead. At other times of the year, surfaces such as stone flags at ground level or the lower part of ground floor walls may be affected.

Condensation on porous surfaces, as with lime plastered walls, is characterised by diffuse areas of moisture. It is often accompanied by black mould on wallpaper and plaster, and white spot mould on timber in voids (see figure 9).The acidic condensate formed within chimney flues will attack mortar and can carry tarry deposits through the brickwork into the building to stain wallpaper or plaster.⁵

Interstitial condensation – as opposed to surface condensation - occurs within building elements, such as walls. Water vapour exerts a pressure that causes humid air to move through permeable building materials towards drier air

on the other side, usually the outside. Interstitial condensation results when the temperature of the diffusing water vapour falls below its dewpoint within the construction. The resulting dampness will reduce the thermal insulation value of the building fabric, in turn increasing the risk of condensation on the internal surface.

2.6 Hygroscopic salts

This form of dampness is linked to hygroscopic salts, such as chlorides and nitrates, that absorb moisture from the air when it is humid. Some salts are so hygroscopic (or ‘deliquescent’) that they dissolve in the moisture they absorb. Additionally, as salts cycle through their liquid and crystal phases in response to humidity fluctuations (ie between deliquescence and drying), recrystallisation within the pores of masonry leads to its damage.

Prolonged rising dampness can leave a wall contaminated by hygroscopic salts carried up

Figure 10: Hygroscopic salt deposits can be a sign of a current or past rising dampness problem.

Photo: Douglas Kent

Figure 11: Decay of floor structures can result from high humidity in voids below. Photo: Douglas Kent

Figure 8: Condensation forms on the coldest surfaces first, such as windows or their surrounding reveals.

Photo: Douglas Kent

Figure 9: Black spot mould is commonly associated with condensation. Photo: Douglas Kent

Figure 10: Hygroscopic salt deposits can be a sign of a current or past rising dampness problem.

Photo: Douglas Kent

Figure 11: Decay of floor structures can result from high humidity in voids below. Photo: Douglas Kent

Figure 8: Condensation forms on the coldest surfaces first, such as windows or their surrounding reveals.

Photo: Douglas Kent

Figure 9: Black spot mould is commonly associated with condensation. Photo: Douglas Kent

SPAB Control of Dampness7

from the ground (see figure 10). Their presence will keep moisture levels high even after the rising dampness itself has been eliminated. Hygroscopic salts can also be deposited within chimney flues from combustion gases and will remain long after flues have been disused, causing dampness on plasterwork around chimney breasts.

The symptoms of dampness due to hygroscopic salts will be increased moisture levels when conditions are muggy. Salt concentrations may be evident in locations where evaporation occurs but deposits are not always visible.

Efflorescent salts, usually sulfates, also occur in damp buildings. Efflorescence indicates that water has passed through a material, leaving white or off-white salty deposits. Efflorescent salts, while unsightly, are seldom hygroscopic so do not absorb moisture from the atmosphere.

2.7 High humidity

Exceptionally high levels of relative humidity alone can result in dampness, especially under suspended timber ground floors but also in cellars. Wood is hygroscopic so its moisture content varies with the temperature and humidity of the surrounding air. In a normal, dry living environment, the moisture content of timber will generally be between approximately 9 and 16%. Where it exceeds 21%, timber becomes susceptible to fungal decay. The symptoms of dampness resulting from high humidity, therefore, are decayed floor structures, though dry rot fungal decay can also travel across masonry without harming it. (See figure 11).

3 Causes

3.1 Understanding the problem

It is important to understand the causes of dampness problems, as well as their signs and symptoms, because this will help when it comes to implementing effective control measures. Addressing the cause of dampness is always preferable, where possible, to dealing merely with the symptoms.

3.2 Poor maintenance and damage

Neglect (especially where access for maintenance is difficult), deterioration and vandalism are commonly associated with rainwater penetration. (See figures 12a and 12b.) Problems will be most acute during prolonged spells of heavy rain.

Leaves, moss and dirt can build up quickly in gutters and hopper heads, obstructing the free passage of water and causing leakage or overflow. Leaks from parapet and valley gutters are particularly serious because the spaces beneath tend to be warm, poorly ventilated and contain the bearings of the roof trusses. In these conditions, water from blocked or defective parapet/valley gutters can give rise to severe fungal growth.

Cracked hopper heads or downpipes, especially where the crack may be undetected against the wall, are another source of dampness in walls. A downpipe will often become choked with leaves, causing water to back up the pipe and spurt out of the joints or cracks onto the adjacent wall. Such concentrated and continued

Figure 12: (a) Rainwater penetration due to missing gutter. (b) Damage from lead theft.

Photo: Douglas Kent

12(b)12(a)

SPAB Control of Dampness8

wetting is likely to erode mortar joints, corrode fixings (potentially leading to further failure), promote moss growth externally, which prolongs the dampness by retaining moisture, and may also lead to frost damage. (See figure 13.)

Defective drains or gulleys, or leaking water pipes can add considerably to the moistureload of the ground in proximity to the base of walls. Often problems of rising dampness are caused by failures of this nature rather than the presence of ground water per se.

Driving rain can penetrate even a thick wall through weak points, such as cracks and open joints. Roofs, chimneys and parapets, normally being the most exposed parts of a building, are particularly susceptible to rainwater penetration. Something as straightforward as a displaced tile or defective flashing or mortar fillet can cause significant damage. Water may also be drawn by capillary action through cracks in leadwork.

3.3 Inappropriate methods and materials

Traditional and modern buildings handle moisture in different ways and mixing the two types of construction can cause dampness. Unlike older, traditional construction with solid walls and floors that rely on the need to ‘breathe’ to stay dry, modern buildings are normally built with cavity walls and floors that employ ‘vapour-closed’ materials of low permeability, for example, ordinary Portland cement. They depend on excluding water with barriers and moisture breaks. The two types of construction are like overcoats and raincoats respectively. Old buildings usually become damp when barriers to moisture are added. New buildings, on the other hand, become damp when such barriers fail.

Any impervious covering, such as linoleum, vinyl etc, laid over a solid ground floor in contact with the ground will become soaking wet underneath and problems may also follow the installation of a DPM. Water trapped under the floor could be forced up the walls and, where there is no DPC, cause rising dampness there. The installation of a DPM in the floor of a cob, wychert, clay lump or other earth-walled building can increase dampness in the walls to such a degree that they collapse.

Attempts to seal walls (for example, with dense plasters, polyvinyl acetate (PVA) or impervious paint) will impede the evaporation, trapping moisture or displacing it elsewhere, and can lead to spalling or powdering of surfaces.⁶ (See figures 14a and 14b.) The use of impermeable plastic-based materials for decoration and repair also results in more humid internal environments and tends to encourage condensation.

Figure 13: Moss growth can compound problems arising from rainwater penetration. Photo: Douglas Kent

Figure 14: Traditional, solid walls can suffer from dampness and deterioration where inappropriate impermeable finishes are used, such as: (a) Plastic-based paints. (b) Bitumastic products.

Photos: Douglas Kent

SPAB Control of Dampness9

14(a) 14(b)

Modern cement renders and pointing are brittle, of low permeability and tend to crack easily as walls undergo small thermal or structural movements (see figure 15). Water commonly streams down the surface of such render and is drawn into fine cracks by capillary action where it becomes trapped. Consequently, moisture may build up behind the render and eventually find its way to the inside face.

Using hard cement renders, vapour barriers or impermeable thermal insulation on walls also increases the likelihood of interstitial condensation. Cement renders hinder the evaporation of moisture in the wall from the external surface. In certain solid walls at specific times of the year, moisture bound within the wall fabric may evaporate from both the external and internal wall faces. For these walls, the inclusion of a vapour control layer (VCL) close to the internal wall face will restrict the amount of moisture accessing the surface for evaporative purposes and may cause moisture to accumulate in the masonry of the wall. This is also likely with internally insulated walls that incorporate a VCL.

Other inappropriate work includes the stripping of lime render from buildings – a practice longopposed by the SPAB and which lead to its early nickname of the Anti-Scrape Society.

3.4 Reduced ventilation

Compared to their modern counterparts, older buildings require greater ventilation to remove structural moisture from their breathing fabric, in addition to the water vapour generated by the activities of their occupants. Even though old buildings are often overgenerously

ventilated, excessive draughtproofing and the installation of double-glazing has contributed to an increase in condensation problems in recent years. Ventilation levels should not be reduced excessively (to below 0.4-0.5 ach).⁷

Chimney flues can become damp through condensation because modern boilers and closed stoves draw in considerably less air than open fires. The warm humid flue gases rise slowly and are likely to condense on any part of the flue which is exposed or has poor thermal insulation. Disused flues may also suffer from condensation if they are closed off without adequate ventilation at the top and bottom.

Experience shows bitumen-coated fabric on the outside of roofs or spray-on coatings underneath prevent proper inspection, hinder the reuse of slates or tiles and, by reducing ventilation, increase the risk of timber decay. They are a false economy, and cases have been reported of serious damage resulting to the structure. These treatments can adversely affect the mortgageability of properties.

The blocking up of subfloor vents may lead to condensation problems and serious timber decay in the associated voids.

3.5 Modern lifestyles and use

Our modern, more sedentary, interior lifestyles have changed the moisture equilibrium in old buildings. Internal room moisture is increased by cooking and washing activities (such as drying laundry, boiling kettles and bathing) that can distribute more moisture into rooms.

Condensation may occur in a thick-walled or solid-floored building of high thermal capacity,

SPAB Control of Dampness

Figure 15: Hairline cracks resulting from the inappropriate use of cement render on traditionally constructed buildings can admit moisture via capillary action. Photo: Douglas Kent

Figure 16: The use of moisture-generating bottled gas heaters is best avoided in thick-walled, solid-floored buildings.

Photo: Douglas Kent

10

such as a church, if it is heated intermittently, particularly where moisture-generating flueless bottled gas stoves and heaters are used. (See figure 16.) The heating installation does not have time to warm the surfaces above the dewpoint temperature, so moisture from the already warmed air condenses on them. (A rapid change from cold to warm, humid weather can produce a similar effect.)

Additionally, where patios, paths and other hard surfaces are laid up to walls, inadequate drainage or rainsplash commonly soaks them.

Moisture movement can increase when central heating is first installed or turned on after the summer months: sometimes soluble salts are drawn to the wall surface that crystallise. The effect can be cyclical with salts going back into solution when the internal relative humidity rises and then being redeposited.

3.6 Poor workmanship and detailing

Rainwater penetration can be caused by poor workmanship. An example is where roof tile laps are reduced by stretching the gauge during retiling to economise on materials. This will increase the chances of moisture penetration, including as a result of wind-driven rain or ingress by melting snow on roof slopes.

Poor detailing can also cause dampness. Cold spots from gaps in insulation are conducive to condensation. Roofs on porches or extensions may be of inferior quality, with poor weatherings and rainwater disposal.

4 Diagnosis

4.1 Methodical investigation

An accurate diagnosis of the type and cause of a dampness problem is essential if it is to be treated effectively. It is alarming, however, how often this stage is skipped or a problem misdiagnosed. This can lead to unnecessary and expensive ‘remedial’ work that damages the building fabric, notably through some irrelevant solution for a non-existent rising dampness problem (see section 4.3).

Sometimes the diagnosis may be self-evident, (see figure 17); frequently, however, it is less obvious and needs investigating. Applying staged remedies can help to accurately diagnose the cause of dampness. Before embarking on extensive work, therefore, the first step may entail nothing more than basic maintenance, such as clearing a blocked gulley, to see if it addresses the problem or further action is needed.

It might be necessary to employ an appropriate independent specialist to diagnose a dampness problem. It is strongly advisable to seek advice required with diagnosing a major dampness problem separately from quotations for work to address it. Taking such advice first (for example, from a chartered building surveyor or other appropriately qualified individual) will prevent vested commercial interests giving rise to recommendations for more work than is strictly necessary (which can occur when a remedial treatment contractor is asked to both diagnose and resolve dampness). Free surveys are also best avoided.

In the SPAB’s experience, mortgage lenders can demand unnecessary damp-proofing work during house purchases. Although mortgage valuers have a duty to follow a trail of suspicion, some simply pass all responsibility onto remedial treatment contractors with a vested commercial interest encouraging over-specification. It is worth challenging any diagnosis you believe is questionable and, if necessary, seeking a second opinion in writing from an independent chartered building surveyor or consultant (note, not contractor). The SPAB may be able to advise you on suitable names.

A methodical step-by-step approach is advocated, as described in sections 4.2 to 4.5.⁸

Figure 17: Diagnosis of a dampness problem is sometimes, but not always, obvious.

Photo: Douglas Kent

SPAB Control of Dampness11

4.2 Step 1: Visual inspection

The human senses must not be undervalued because the sight, feel and smell of dampness can often provide adequate information. Be very wary of tasting deposits to determine the presence of salts, however, because hazardous chemicals, such as entachlorophenols, were used in the past to treat areas of decay. The starting point is to check for the symptoms discussed earlier in section 2, taking into consideration the date the property was built, whether it is unoccupied or unheated, the occupancy type, exposure and recent weather, dampness duration, location, colour and shape of patches, stains, mould and salts.

A careful inspection of the roof, parapets, parapet and valley gutters, and abutments should be made, especially exposed horizontal surfaces and areas likely to collect water. Water from leaks can run down rafters or, more occasionally, the underside of the roof to appear inside the building some distance away.

It is often instructive to observe the performance of the rainwater disposal system below the roof during heavy rainfall. The rainwater head, gutters and downpipes that appeared to deal adequately with average rainfall can fail under heavy and prolonged periods of rain. There have been occasions when dampness has been due to the failure of downpipes which had been embedded at an earlier date within walls. The inspection of gulleys during rain can also reveal blockages.

The height of ground levels and condition of external wall faces should be examined carefully. Pay particular attention to the pointing, which can be very vulnerable to water penetration. Traditional lime mortars tend to absorb moisture and release it later. Modern cementitious mortars often permit water penetration through hairline cracks on the perimeter of, and within, the pointing material.

Joints in protruding elements such as parapets are particularly vulnerable, especially if not covered (for example, with lead sheet or slate).

4.3 Step 2: Electrical moisture meters (EMMs)

Diagnosis sometimes requires more scientific approaches than the sight, feel and smell of dampness. Dampness can be hazardous long before it is detectable by human senses and electrical moisture meters help to establish the presence and amount of moisture scientifically. (See figure 18.)

Using electrical moisture meters to plot the distribution of moisture can give very helpful clues about its source (Table 1). Electrical moisture meters are also particularly useful for detecting changes in the moisture content of materials.