3 Textile Players Spearhead New Era of Sustainable Recycled Cotton

Faux Fur, Real Reach Polartec Launches

Plant-Based OdorFighting Agent

Additive Helps Medical Scrubs Fight Microplastic Pollution

Ganni Ramps Up Material Innovation ‘Arms Race’ with Clothes-FromCarbon Exclusive

Made-in-LA Activewear Uses Microalgae for Moisture-Wicking

55 57 58 60 62 65

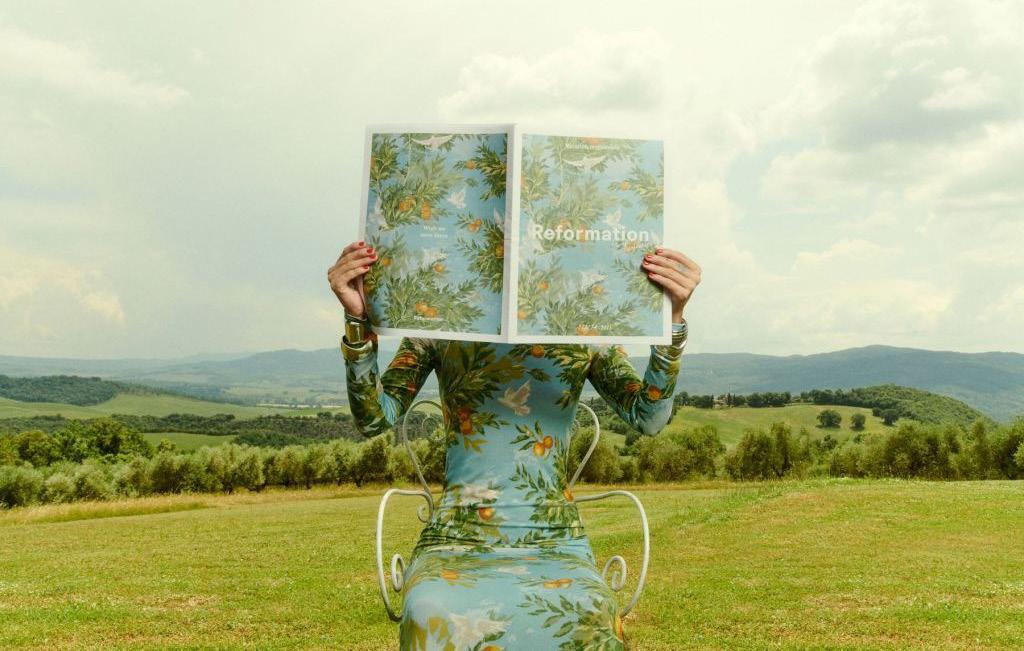

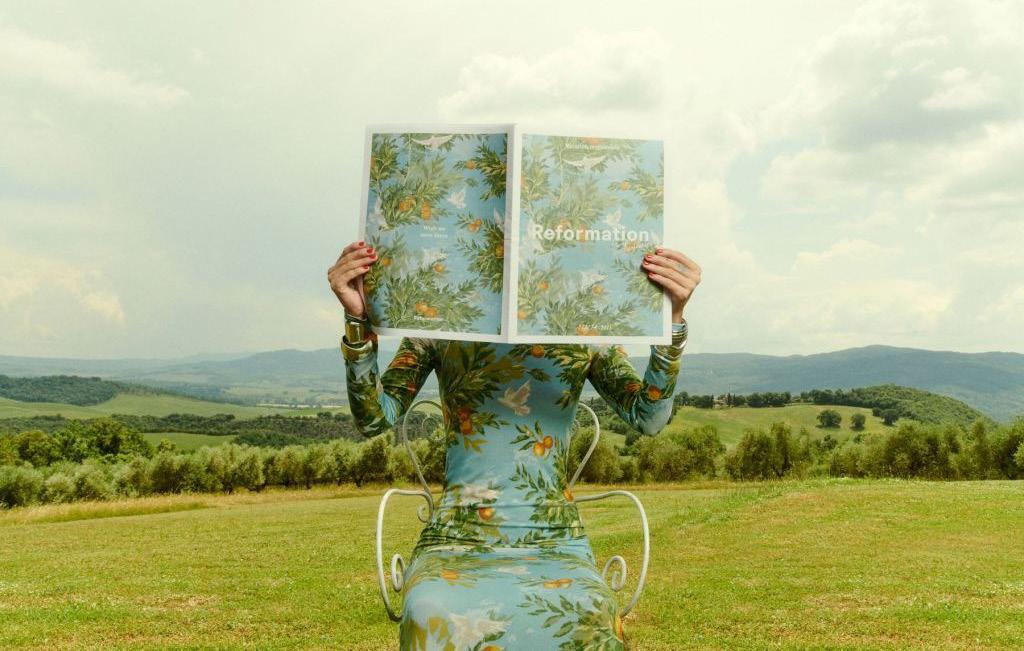

Reformation Turns to Tencel For Cool Summer Clothes

MAS Invests in HeiQ’s Cellulose-Based Synthetic Alternative Vaude and UPM Biochemicals in Joint Venture For Bio-based Polyester

Circ Enlists Taiwan Textile Partner to Boost Recycled Lyocell Production

MycoWorks Marks

10 Years With New Product Updates

Cocona Labs Looks Beyond Synthetics

Ambercycle Teams With Bestseller, Tombogo on Regenerated Polyester

04 04 MATERIAL INNOVATION Table of Contents 06 08 10 14 22 26 29 Executive Summary Changemakers Material Moves: Experts Share Innovations to

The Input Revolution is Gaining Steam Partnerships Bring Innovations to a Broader Audience Going Bananas in India What Chemists and Academics Say We Need for a Full PFAS Phase-out 33 36 39 42 45 49 52

Watch

*Cotton products are recyclable only in a few communities that have appropriate recycling facilities. †In composting tests, cotton fabric samples underwent a weight loss of approximately 50-77% after 90 days in a composting facility. Li, Lili; Frey, Margaret, Browning, Kristie (2020). Journal of Engineered Fibers and Fabrics. 5 (4). https://journals.sagepub.com/doi/pdf/10.1177/155892501000500406

AMERICA’S COTTON PRODUCERS AND IMPORTERS. Service Marks/Trademarks of Cotton Incorporated. © 2023 Cotton Incorporated.

Executive Summary

With each passing day, new ideas, new technologies and new formulations are creating a seismic shift in our marketplace.

Legacy inputs are increasingly making way for more sustainable options as the industry and the consumers that fuel it become ever more conscious of environmental impact.

In that vein, revolutionary ways of using natural ingredients in the textile and apparel field are being brought to market at a rapid rate. From the banana leaf to coffee grounds to algae, a whole ecosystem is being created around taking what was once considered waste and utilizing it anew.

Perhaps the biggest challenge being faced by these nascent breakthroughs (besides funding, of course) is the ability to produce at scale, at reasonable cost and actually getting these products into garments, on store shelves and ultimately to the end consumer.

One way this is being tackled is through collaborations. Fast-fashion behemoths H&M and Zara are leading the charge on this crusade, though they are not alone. We take a look at what they’re doing as well as others including Bestseller and Reformation inside this report.

There is also collaboration further upstream, such as the partnership between Recover, Rieter

and Polopiqué, who have combined forces to produce yarns with a higher percentage of mechanically recycled fibers.

Two other fields that have benefited from recent innovations are antibacterial fabrics and thermoregulation properties in garments. The latest endeavors in those categories are covered as well.

PFAS use continues to be a concern and while progress has been made, and legislation passed to prevent it, we are not out of the woods. As the Hohenstein Institute America’s Debbie Chronicle puts it: “Successful phase-out of PFAS in the entire apparel and footwear value chain will only be possible by eliminating their use from all relevant manufacturing processes.”

We’ve also spoken with leading industry executives about what gets them excited and where they feel the largest challenges ahead lie.

As a whole, the rate of progress from a mere decade ago is mind-boggling. This enthusiasm is tempered, however, by the realities of ramping up production levels, bringing pricing in line with legacy inputs and building a consumer appetite. Interesting times indeed.

Peter Sadera Editor in Chief Sourcing Journal

MATERIAL INNOVATION

06 06

CELLIANT WITH REPREVE

DIVERSE CARRIER SOLUTIONS

CELLIANT infrared technology can be incorporated into a variety of formats to suit your sourcing and product needs.

CELLIANT PRINT

CELLIANT VISCOSE

CELLIANT PET AND RPET

CELLIANT NYLON

@celliant

celliant.com

Ecovative Raises $30M

Ecovative’s last round of funding was used to construct the world’s largest mycelium farm. Its latest funding will get products grown from that mycelium farm into consumers’ hands.

The mycelium technology company announced the initial closing of a Series E round of over $30 million. It said it will reinvest $15 million into its MyForager Foods subsidiary, founded in 2020, with the rest going toward scaling Ecovative’s Forager business offering sustainable textile and foam products. Viking Global Investors led the round, which included Standard Investments, FootPrint Coalition Ventures and AiiM Partners, bringing Ecovative’s total raise to $120 million.

“It’s amazing what mushrooms can do. Ecovative has shown mycelium’s potential across industries, demonstrated productmarket fits that are already addressing the needs of the Earth,” Jon Schulhof, managing partner at Footprint Coalition Ventures, said. “And this is just the beginning, with huge addressable markets and the potential to make real, lasting change for circular manufacturing.”

Mycelium technology has gained popularity in the textile world in the past decade, with dozens of companies from Bolt Threads and MycoWorks to Von Holzhausen spawning mycelium-based

creations as an alternative to animal leather, adopted by the likes of Stella McCarney, Hermès and Ganni. According to Grand View Research, the non-animal leather market is expected to approach $67 billion by 2030. Ecovative said it’s working toward meeting market demand while focusing on commercial and environmental applications using biology to produce high-performing, planetfriendly outputs—including textiles, packaging and food.

“We’re proud of our team, and the immense progress they have made in a short time, rising to the occasion to bring mycelium technology to scale,” Eben Bayer, co-founder and CEO of Ecovative, said. “Our goal is to hack capitalism to support spaceship Earth: building factories that produce clean air, clean water and healthy soil while growing delightful materials that meet everyday needs and produce extraordinary profits.”

Ecovative has entered into product development agreements with over 15 global brands for fashion and footwear, including Ecco Leather and Pangaia, though many are under NDA agreements. It said the new funding should help it have products such as handbags and shoes commercially available by mid-2024.

In March 2021, Ecovative received $60 million in Series D funding from investors, including Viking Global Investors, with support from AiiM Partners, Senator Investment Group, Trousdale Ventures and other undisclosed backers. While that round of funding was used to construct the world’s largest mycelium farm (capable of growing 3 million pounds of mycelium on one acre of land thanks to the company’s AirMycelium technology), this latest round is focused on funding the manufacturing and distribution of its Forager Foams and Hides for use in finished consumer goods like handbags, apparel and footwear. —Alexandra Harrell

Ramping Up Production

The world’s transition to sustainable materials got a boost with the startup of Origin 1, the first ever commercial plant making CMF or chloromethyl furfural.

A chemical building block, CMF is used to build numerous downstream products like para-xylene, the precursor to PET plastic, and FDCA, furandicarboxylic acid, which is used in sustainable products and materials like the next generation polymer, PEF, polyethylene furanoate. Located in Sarnia, Ontario, the plant will also produce HTC, hydrothermal carbon, whose applications include sustainable carbon black for automotive tires.

These are intermediate chemicals and materials that go into a wide range of end uses, including clothing, textiles, plastics, packaging, car parts, tires, carpeting, toys, fuels, among others, with a $1 trillion addressable market. The new plant represents a significant scale-up of Origin’s technology platform for converting sustainable wood residues into versatile intermediate chemicals. Origin Materials is based in West Sacramento, California.

The plant is expected to play a key role in the development of higher-value products and applications for CMF, HTC and other co-products. These highervalue products are expected to be produced and sold at world-scale from future plants, including Origin 2 and Origin 3, and possibly licensed plants. According to John Bissell, co-founder and co-CEO of Origin, the commercialization of a molecule like CMF is historic.

“We are thrilled to be making our intermediates available to industry on a scale never before achieved.”

—Claire Wilson

2023 SUSTAINABILITY REPORT 08

08

Ecco Leather x Ecovative mycelium blue roll.

REDUCED SHEDDING, NOT PERFORMANCE.

Our new Shed Less Fleece is just as warm, fuzzy and cozy as ever. There’s only one difference: It sheds less. Way less. 85% fewer fiber fragments lost during home laundering.* Now that’s a fleece you can feel warm and fuzzy about.

*Compared to the baseline Polartec 200 Series Fleece, tested using the AATCC TM212-2021 test method

Material Moves: Experts Share Innovations to Watch

Sustainability is catalyzing changes in the building blocks of apparel, textiles and footwear. Brands and material suppliers are scoping out and developing new or improved materials that are less environmentally harmful while also providing the performance and properties that customers expect.

From alternatives to animal inputs to PFAS-free functional wear, here is the lowdown on the most notable advances in material innovation this year and what to watch next from individuals in the industry.

which we’ve shared in our Green Paper so that other brands can follow suit.

As state policy in California and proposed legislation at the state and federal level have catapulted PFAS into the limelight, and retailer requirements and litigation have maintained the attention, PFAS is and should be at the top of everyone’s minds. We are looking forward to even more PFAS-free water repellency innovations in the years to come.

KIRSTEN BLACKBURN, director of The Keen Effect, Keen

A big focus for Keen has been eliminating PFAS (per- and polyfluoroalkyl substances), otherwise known as “forever chemicals,” from our supply chain. In 2018, Keen became one of the first footwear companies to remove PFAS from our products, and most recently in 2022, we hit the milestone of removing PFAS from our packaging as well. Critical to this success was using the precautionary principle, which eliminated nearly 65 percent of our PFAS use by removing durable water repellency technology manufactured with PFAS from products that didn’t need water repellency at all, like sandals. For the remaining product necessitating water and dirt repellency, we invested over 11,000 hours of R&D to unlock safe, effective and affordable alternatives,

ALI STAYART, apparel and accessories director, Salomon North America

There have been significant strides made in the integration of sustainability concepts to materials. Whether it is bio-based membranes, regenerative fibers or circular recyclable materials, we have really seen a commercialization of radical sustainable materials and construction within the industry.

10 10 MATERIAL INNOVATION

The next innovation the industry should be watching for is the plus one in sustainability above and beyond materials.”

ALI STAYART, Salomon North America

The next innovation the industry should be watching for is the plus one in sustainability above and beyond materials. Chemical treatments that affect water resistance or anti-microbial will shift to more eco-friendly and bio-based options, like Noble’s Ionic+ Botanical used in our new Salomon Sense Aero collection in Spring ‘24. Consumer usage of products through rentals and recycling will continue to grow, and brands’ ways of monitoring CO2 impact and efforts to decrease emissions will start to go into full effect as well.

more sustainable farming methods by Pragati, of which Arkema is a founding member. The dress was realized with a technology that knit directly from spools, eliminating waste by using exactly the amount of yarn needed.

Natural Fiber Welding (NFW) introduced a new Mirum x Tencel development this year. The Tencel is traceable through Lenzing’s Fiber Identification technology and, when combined with NFW’s Mirum, is a circular material option within the bio-based leather alternative space. I think it will be exciting to see the evolution and adoption of this material in the market.

Next-gen and low-impact cellulosic-based fibers are ones to keep an eye on, mainly if from agri-waste feedstock. Bioprocessing is greatly progressing, producing materials, dyestuff and auxiliaries, ensuring high properties. The real leading player is again processing technologies able to have high impact that are building up the factories of the future, with high resource efficiency to shift from wet to dry processing in dyeing, treatments and finishing. Green chemistry is glowing—specifically ionic liquids—not new, but finally in the right way.

KEVIN HANRAHAN, chief marketing officer, high performance polymers, Arkema Inc.

Arkema and RadiciGroup unveiled a 100 percent bio-based dress crafted entirely from castor beans. The dress was made of RadiciGroup’s Biofeel Eleven yarn, which is based on Arkema’s Rilsan Polyamide 11. Rilsan PA11, entirely derived from castor beans, reduces carbon emissions by up to 70 percent compared to traditional nylons (PA6, PA6.6). Many of the world’s castor bean growers have been trained to use

In recent years, there have been notable advancements in sustainable and innovative materials. The biggest material breakthrough this year is the launch of Modern Meadow’s Bio-Vera, a novel, sustainable, animal-free biomaterial that looks and naturally ages like traditional leather or suede. This non-woven material is engineered to surpass the strength of leather while delivering the authentic look, feel and wearability of traditional leather. With an extensive range of colors and finishing options, Bio-Vera redefines possibilities in both durability and aesthetics. The potential for

CALLIE CLAYTON, global client relations manager, Spiber

CHRISTIAN TUBITO, Material Innovation Lab director, Kering

CATHERINE ROGGEROLOVISI, CEO, Modern Meadow

11 11 MATERIAL INNOVATION

highly creative ready-to-wear, footwear and accessories is boundless, as Bio-Vera unlocks endless design possibilities for fashion designers and creators alike.

KATHERINE HOMUTH, CEO, SRTX

Honestly the problem in materials and fashion is that there isn’t enough innovation. I genuinely can’t point to anything new I’ve seen in the last year that I’m really excited about. It’s why we do the work we do.

A. SYDNEY GLADMAN, PH.D., chief scientific officer, Material Innovation Initiative

While fungi, in the form of mycelium leather, took the stage in the early rise of next-gen materials, we see a new trend of innovators harnessing the unique properties of algae and seaweed for skins, fibers and components like coatings and additives. As notable carbon sinks with unique chemical building blocks, this new wave of exploration could create a “sea change” in the next-gen materials industry, producing environmentally preferable alternatives to silk, wool, leather, petro-synthetics and more.

TESSA CALLAGHAN, co-founder and CEO, Keel Labs

Despite the turmoil we’ve all experienced this year, the growth and implementation of material innovations has only gotten stronger. Action and tangibility are clearly growing themes in 2023, with both brands and innovators coming together in unique and productive ways to bring the next generation of materials to the market. From Nike ISPA’s launch with Living Ink to the partnership of two critical leaders in the space, Natural Fiber Welding and Lenzing, it is inspiring to see the new era of innovation taking form through collaboration, community and new business approaches. As a sector, it’s becoming more important to show than to tell. We can expect to see an influx of real-world products showcased and proven out throughout the market.

Honestly the problem in materials and fashion is that there isn’t enough innovation.”

12 12 MATERIAL INNOVATION

KATHERINE HOMUTH, SRTX

INTRODUCING FATES ™ OPEN CELL SHEETSTOCK TECHNOLOGY

THE SIMPLEST AND MOST COST-EFFECTIVE METHOD TO ADOPT THE INDUSTRY-LEADING BIO-BASED FOAM SOLUTION

MINIMAL END-OF-LIFE IMPACT

Detoxifying and biodegrading properties

HIGH PERFORMANCE

Ensuring optimal comfort, support and durability

LOW CARBON FATES™ industry leading plant-based bio-content

COST EFFECTIVE

Low tooling costs

FATES™ IS USDA BIO-PREFERRED AND VEGAN CERTIFIED Find out more at EVOCOLTD.COM

POWERED BY NATURE.

The Input Revolution Is Gaining Steam

BE IT IN THE FIELD OR IN THE LAB, NEW TECHNOLOGIES ARE UPENDING THE RAW MATERIALS LANDSCAPE.

By Alexandra Harrell

In tandem with shifting consumer priorities and the development of new technologies, interest in innovative materials has grown drastically in recent years. In fact, a study between the Material Innovation Initiative (MII) and North Mountain Consulting Group found that in the United States, nearly all participants (94 percent) surveyed stated they were at least somewhat likely to purchase next-gen materials, while almost half (45 percent) were highly likely to buy. With that in mind, more than $455 million was invested in next-gen material companies in 2022, the MII reported. And what they’re investing in is found (or made) in three key areas: the land, the sea and the lab. The inputs being explored—from seaweed and shrimp to bacteria and beer—are slowly (but surely) replacing traditional resources.

From the Land

Von Holzhausen

WHO: Vicki von Holzhausen

WHAT: A material innovator using science to replace plastic and leather with plants that believes “someone’s trash is someone else’s treasure,” Von Holzhausen wants to revolutionize how the industry thinks about agricultural waste—starting with the banana leaf.

WHERE: Malibu, California

WHEN: Since 2016

WHY: “The fashion industry doesn’t want limits, and we are built to really supply

material that can express their aesthetics,” Von Holzhausen said. “Just because it’s made out of very earthy substances doesn’t mean it needs to look earthy.”

HOW: The raw material is sourced directly from Indian farming cooperatives where piles of plant waste cover the ground after harvesting. That waste would otherwise be burned, releasing CO2 into the air and toxins into the soil. Farmers collect and send the plant fibers to fiber suppliers, who dispatch them to be spun into yarn via a non-viscous process. Mills knit the material and back it with pesticide-free organic cotton before scientists coat it with the company’s plant-based resin for durability.

Modern Meadow

WHO: Andras Forgacs, Gabor Forgacs, Karoly Jakab, Francoise Marga

WHAT: Modern Meadow’s Bio-Vera is billed as a sustainable, animal-free biomaterial that looks, feels and naturally ages like animal leather. The biotechnology company’s biomaterial is powered by the proprietary Modern Meadow Bio-Alloy technology application platform.

WHERE: Nutley, New Jersey

WHEN: Since 2011

WHY: Having raised more than $183 million in funding, according to Crunchbase, Modern Meadow aims to catalyze real-world impact, moving the industry away from relying on petrochemical and animal-derived inputs.

14 14 MATERIAL INNOVATION

▼ Von Holzhausen was founded in 2016.

HOW: Sustainable and solvent-free, Bio-Vera starts with a 100 percent renewable non-woven scaffold powered by Bio-Alloy that ensures high performance. The engineered material uses renewable, traceable inputs and requires no special preservation or storage conditions and is readily available at scale with reduced manufacturing complexity and costs. Modern Meadow said it’s committed to responsible sourcing. It “carefully selected” the biomaterials used in Bio-Vera from a combination of post-consumer waste and

bio-renewable technologies. Modern Meadow’s Bio-Alloy is a proprietary mixture of plant-based protein and biopolymer. But the company said the specific sourcing details of the final and finished materials used in Bio-Vera will depend on partner requirements.

Desserto

WHO: Adrián Lopez Velarde

WHAT: Desserto, an alternative leather company known for its cactus-based product, marked its fourth anniversary by

launching a new biomaterial by upcycling a tequila industry by-product: Desserto Agave. Described as a “gift from Mexico to the world,” the plant-based material comprises lignocellulosic materials, which play an important role as substitutes for fossil fuels.

WHERE: Guadalajara, Mexico

WHEN: Since 2019

WHY: “This is a solution that aims to reduce the environmental impact from the tequila and materials industry by offering a plant-based material that is durable and sustainable,” Velarde said.

HOW: The company’s latest innovation upcycles tequila production’s pulpy fibrous “bagasse” waste into “a material that can be used to make handbags, garments, accessories and furniture.” Desserto Agave, made with up to 80 percent bio-based content, is available “on-demand” for brands whose values “match our sustainability practices,” Velarde added.

Unless Collective

WHO: Tara Moss, Eric Liedtke

WHAT: Regenerative fashion company

Unless Collective makes 100 percent plant-and-mineral-based clothing and footwear, creating the first brand whose products leave zero waste at the end of life.

WHERE: Portland, Oregon

WHEN: Since 2020

WHY: Unless Collective was inspired by the opportunity to build a plastic-free future for fashion to offer a “better way” to operate

15 15 MATERIAL INNOVATION

▼ Clockwise from top left: Modern Meadow’s Bio-Vera is a sustainable, animal-free biomaterial; Unless Collective products are 100 percent biodegradable; Desserto uses the waste from tequila production.

than the fast fashion “villain” and its plastichappy status quo.

HOW: The company is exploring end-of-life strategies such as repair and reuse, recycling and composting; that way, even if one of its products does end up in a landfill— or buried in the backyard—it will decompose naturally without spewing plastic waste into the ecosystem. Unless sources cotton from the U.S. and Turkey and corozo nuts from India to produce apparel. It lists all ingredients with each product drop, including threads, trims, embellishments, dyes and inks. For example, the Plant Power Biodegradable Tee is made from 8 oz. 100 percent cotton interlock fabric, cotton thread, cotton tags and labels. Unless tests all products against the American Apparel & Footwear Association (AAFA) restricted substances list and only uses water-based dyes free of solvents and plastisol.

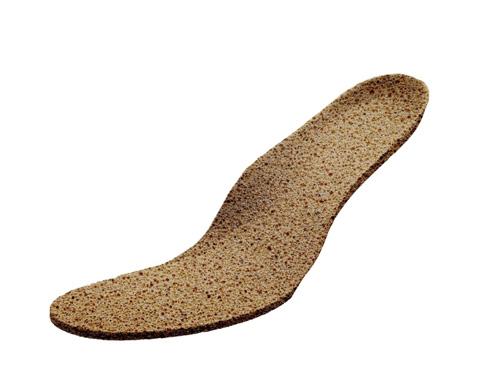

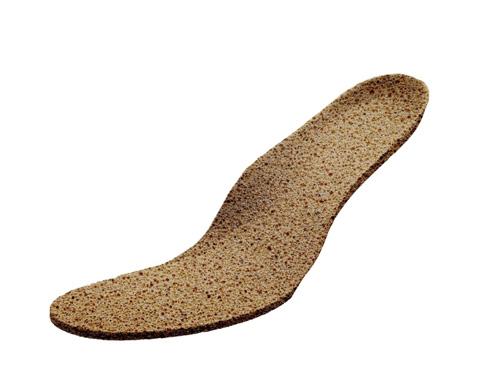

Dahsheng Chemical (DSC)

WHO: Shi-Liang Chang

WHAT: The latest sustainable innovation from Dahsheng Chemical (DSC) turns some of the spent grounds from the 2.25 billion cups of coffee the world consumes daily into its new Dreamcell Xpresso insole foam technology with odor- and moisturecontrolling features.

WHERE: Taichung City, Taiwan

WHEN: Since 1945

WHY: “DSC is committed to reducing our impact on the environment by using innovative biomaterials to reduce waste and fossil fuel usage,” Johnson Chang, CEO of Dahsheng Chemical, said. “With Dreamcell Xpresso, we can extend the lifecycle and support a circular economy that benefits both manufacturers and consumers without compromising on comfort and performance.”

HOW: Used coffee grounds sent to landfill produce methane, causing a greenhouse effect 28 times higher than carbon dioxide.

DSC works with local coffee providers in Vietnam—the world’s second-largest coffee producer—whose average annual coffee ground waste totals 180,000 tons. Dreamcell Xpresso tackles greenhouse gas emissions

by rerouting those grounds to a footwear component. The Dreamcell Xpresso polyurethane (PU) open-cell foam is made with 20 percent coffee ground waste, decreasing the amount of fossil fuels and energy in the production process. For every one million pairs of Dreamcell Xpresso insoles produced, DSC will recycle approximately 2.19 metric tons of spent coffee grounds, which amounts to a 0.53 metric ton reduction in landfill methane emissions. That’s the equivalent of carbon sequestered by 219 tree seedlings grown for 10 years.

Stella McCartney

WHO: Stella McCartney

WHAT: Stella McCartney debuted an exclusive creation on the April 2023 cover of Vogue: BioSequins, a biodegradable and non-toxic material innovated from plantbased cellulose, using no metals, minerals or synthetic pigments or colorants.

WHERE: London, England

WHEN: Since 2001

WHY: “I am amazed by the iridescent beauty of our BioSequin all-in-one—handcrafted in my London atelier from plant-derived, non-toxic sequins that are even more stunning than conventional options,” McCartney said. “Who says sustainability can’t be sexy?”

16 16

used coffee grounds in Vietnam.

MATERIAL INNOVATION

▼ Stella McCartney’s BioSequins.

HOW: Collaborating with Radiant Matter, a startup developing a new generation of color and material solutions for the circular economy, brings the LVMH-owned label one step closer to its sustainable goals. Since 2010 Stella McCartney has been a PVC-free brand, including the sequins it uses in its collections. Radiant Matter uses cellulose derived from wood to create a natural iridescence for its glitter without using petroleum or metals.

From the Sea

TômTex

WHO: Uyen Tran

WHAT: TômTex uses seashells and mushrooms to offer cruelty-free and naturally biodegradable textiles that can mimic fabrics like leather, suede, latex, vinyl and more. The bio-based material from the company, whose name mashes up the

Vietnamese word for “shrimp” with “textile,” is petrochemical-free, plastic-free and tanning-free.

WHERE: Brooklyn, New York

WHEN: Since 2020

WHY: After raising $1.9 million in funding, according to Crunchbase, the 2021 LVMH Innovation Award finalist wants to make use of the massive amounts of agricultural waste coming out of Vietnam’s seafood exports as well as shine a light on how green chemistry can move the industry forward and eliminate greenwashing.

HOW: The textile is made from the complex sugar, chitin, found in shrimp shells. This chitin is converted to its most well-known derivative, chitosan, the second most abundant polymer found in nature. Chitosan is also found in the cell walls of mushrooms, which TômTex also utilizes.

Carbonwave

WHO: Geoff Chapin and Ben Ellis

WHAT: Seaweed provides a sustainable and regenerative platform to address CO2 sequestration, pollution and volatility from the Earth’s climate crisis. Carbonwave says it’s the first company to produce a wide range of Sargassum-based biomaterials that can displace fossil fuel-based products, including textiles.

WHERE: Boston, Massachusetts

WHEN: Since 2020

WHY: Sargassum seaweed mats have long been a feature of the North Atlantic Ocean, but over the past 12 years, warming ocean temperatures and pollution runoff have triggered the largest seaweed bloom on the planet—in the Caribbean. Known as the great Atlantic Sargassum belt, this yearly bloom threatens regions from West Africa to the Gulf of Mexico, where it clogs bays and beaches, harms the local ecology and jeopardizes tourism. Accumulated seaweed mats on beaches and landfills also release vast amounts of climate-harming methane while decomposing.

HOW: The seaweed bloom upcycler has raised $12 million in funding, with its latest investment of $5 million led by Mirova, a

17 17 MATERIAL INNOVATION

▼ TomTex uses seashells and mushrooms to offer cruelty-free and naturally biodegradable textiles; Carbon wave is repurposing the ocean’s Sargassum.

Natixis Investment Managers affiliate focused on sustainable investment, with participation from Viridios Capital, Popular Impact Fund and Katapult Ocean. Carbonwave charts a route for profitable Sargassum processing and has developed a proprietary method of extracting its biopolymers, which are more valuable than the single compounds when extracted separately.

From the Lab

Kintra Fibers

WHO: Billy McCall, Alissa Baer-Lentz

WHAT: Kintra Fibers is a material science company that’s developed a proprietary bio-based and biodegradable polyester polymer with plug-and-play manufacturability through the synthetic textile value chain.

WHERE: Brooklyn, New York

WHEN: Since 2018

WHY: Baier-Lentz said the startup wants to help fashion “transition to be more naturealigned,” noting how the molecular structure of the maker’s bio-inputs are “inherently biodegradable in an oxygen rich environment.” And by eliminating the need to blend with cotton or spandex, Kintra’s mono-material fabric construction allows for easier chemical and mechanical textile recycling.

HOW: Through a Series A funding round, Kintra raised $8 million led by H&M Group and supported by Bestseller and Fashion

for Good, with Parade’s founder and CEO, Cami Téllez, involved as an angel investor. That funding will accelerate the company’s research and development and scaling timeline.

Impermea Materials

WHO: David Zamarin

WHAT: Impermea Materials has worked to identify the unique molecules to “functionalize ordinary substrates to perform in extraordinary ways” with coatings that offer liquid repellency and resistance to stains, fading and mildew. These molecules are also PFAS-free, 100 percent fluorine free, non-toxic, water-based, and are as recyclable, compostable and repulpable as the substrate they’re applied to. When applied to textiles, the water-based coating technology creates a superoleophobic and superhydrophobic repellent coating for various fabrics, ideal for weather gear and menstrual underwear.

WHERE: Framingham, Massachusetts

WHEN: Since 2013

18 18

▼ Impermea Materials makes coatings that offer liquid repellency.

MATERIAL INNOVATION

▲ Billy McCall and Alissa BaerLentz of Kintra Fibers.

WHY: Until a 2016 class-action lawsuit against Dupont thrust PFAS into the mainstream, “no one really knew what PFAS was,” Zamarin said, describing the challenge of finding a sustainable option that wouldn’t compromise performance, even though “in reality we did” in the earliest days.

HOW: Hydro-Tex 1000 is powered by Siloalkoxyurysilane, a water-based technology designed to develop a breathable, durable, superhydrophobicrepellent textile coating. It’s a safe, non-toxic, fluorine-free treatment optimized for use on cotton, linen, rayon, polyester, denim, nylon and spandex. Hydro-Tex + UV 1010 is also a water-based technology designed to develop a breathable, durable, superhydrophobic repellent coating for textiles that blocks harmful UV rays.

Hydro-Tex + Virushield 1030 is Impermea’s patent-pending protective coating technology designed to turn a conventional textile into a breathable, superhydrophobic barrier that repels larger droplets and traps smaller droplets that may prevent transmission by containing active viruses.

Cornell University

WHO: Juan Hinestroza, Phillip Milner, Tyler Azbell, Yelin Ko

WHAT: Researchers at Cornell University have found a way to chemically break down clothing and reuse polyester compounds to create fire-resistant, antibacterial or wrinkle-free textile coatings. The proof-ofprinciple study (which uses a method known as controlled crystallization) was partly funded by the National Science Foundation and should inspire the fashion industry, which generates 20 percent of global solid waste—much of which ends up illegally dumped in other countries

WHERE: Ithaca, New York

WHEN: The article “Upcycling of Dyed Polyester Fabrics into Copper-1,4Benzenedicarboxylate (CuBDC) Metal–Organic Frameworks” was published in the Industrial & Engineering Chemistry Research journal in late March.

WHY: “I went to some countries and I saw a lot

of textile garbage that was supposed to be recycled or donated, and I was concerned about that,” Hinestroza said. “I wanted to see if we could reuse these materials into something that will have more value.”

HOW: A journal study describes the process of cutting up textiles and chemically decomposing them into a “soup” of raw materials, dyes, additives, dirt

the selective removal of anionic pollutants from aqueous solutions” was published in Chemical Engineering Journal in April.

WHY: “The textile industry is one of the largest contributors to dye wastewater pollution,” Nashef, professor of chemical engineering at Khalifa University, said. “We have developed this nanomaterial which demonstrates high adsorption capacity and strong affinity toward various types of dyes based on their charge, and can be employed as an effective absorbent to remove dyes from textile wastewater. Integrating this technology into the wastewater treatment process can help reduce the industry’s environmental impact and ensure compliance with regulatory standards.”

and esters. A metal solution is added to that soup and building blocks from the polyester share an affinity with the metal, selectively linking together compounds to form tiny cages, also known as metalorganic frameworks, that settle at the bottom of this so-called soup. These cages are then used to make coatings, though the coatings may need structural tweaks to tailor to individual uses (wrinkle resistance, antibacterial).

Khalifa University

WHO: Hassan Arafat, Rawan Abu Alwan, Botagoz Zhuman, Dr. Mahendra Kumar, Dr. Enas Nashef

WHAT: Taking inspiration from the adhesive properties of mussels, which are known for their ability to attach themselves to various surfaces, scientists at Khalifa University have attempted to replicate this ability in their selective nano-adsorbent material, which extracts toxic dyes from wastewater.

WHERE: Abu Dhabi, United Arab Emirates WHEN: The article “Mussel-inspired polydopamine functionalized with ionic liquid as a novel, eco-efficient adsorbent for

HOW: Since polydopamine functionalized ionic liquid materials combine the adhesive properties of polydopamine and the tunability of ionic liquids, this material can be used in various applications such as coatings, catalysis, biosensing, energy storage, and more. Plus, the nano polydopamine-ionic liquid (NPDA-IL) can be regenerated and reused, which is helpful for dye-related wastewater treatment, Nashef said.

The Deutsche Institute für Textil-und Faserforschung Denkendorf (DITF), the University of Hohenheim, Naturamus

WHO: Benjamin Ewert, Stephen Baz, Thomas Stegmaier, Jamal Sarsour, Isabell Hildermann, Caroline Weiler, Peter Schmich, Ralf Kunert, Matthias Adam

WHAT: The Deutsche Institute für Textil-und Faserforschung Denkendorf (DITF), the University of Hohenheim and natural cosmetics company Naturamus are testing cultivation methods for lavender in organic farming and developing energy-efficient strategies for essential oil production.

WHERE: Denkendorf, Germany

WHEN: The cooperative research project began in mid-2021.

WHY: Distilling essential oils often creates plant-residue by-products. DITF is researching how these residues can be used

19 19 MATERIAL INNOVATION

I wanted to see if we could reuse these materials into something that will have more value.”

JUAN HINESTROZA, Cornell University

to produce fiber composites for textiles.

HOW: Fibers for textiles can be obtained from the lavender stem. DITF is already working on testing the raw material and separating the fibers. The fibers are bound together by wood (lignin) and pectin. Researchers use aerobic and anaerobic bacteria, alkaline or acidic solutions and enzymes to break the “glues” around the fibers, Stegmaier said.

Columbia University, the Fashion Institute of Technology (FIT)

WHO: Dr. Theanne Schiros, Helen Lu, Romare Antrobus

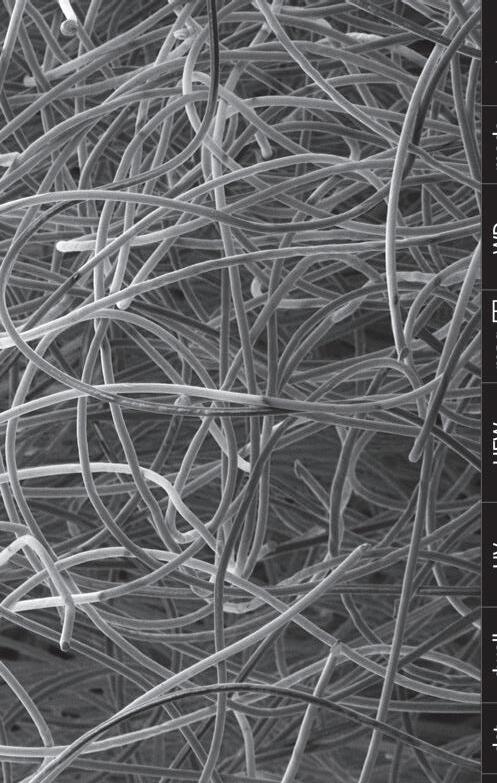

WHAT: Researchers at Columbia University and the Fashion Institute of Technology (FIT) are developing a compostable, flame-retardant bio-leather based on microbial nanocellulose.

WHERE: New York,

WHEN: The article “Microbial nanocellulose

biotextiles for a circular materials economy” was published in Environmental Science Advances in July 2022.

WHY: “I think what the big lesson learned was that combining microbial biofabrication, bio-based green processing and waste-to-resource strategies for both dyeing and for sourcing raw materials produces a regenerative, high-performance textile with a dramatically reduced environmental impact,” Schiros said. “This is an order of magnitude lower environmental footprint; it’s got a 97 percent lower carbon footprint [than] vegan synthetic leather.”

HOW: The bio-fabrication process begins with feeding the bacteria a carbon source and a nitrogen source. As the bacteria eat, it creates cellulose, which sits atop the liquid as a hydrated biofilm called pellicle. Drawing inspiration from pre-industrial and indigenous science, the pellicle goes through a plantbased lecithin emulsion process before it becomes the leather-like biomaterial.

MATERIAL INNOVATION 20 20

▲ Researchers at Columbia University and the Fashion Institute of Technology are developing a compostable, flame-retardant bio-leather based on microbial nanocellulose.

Sustainable

*Via mass balance approach © 2023 Eastman Chemical Company. Eastman brands referenced herein are trademarks of Eastman or one of its subsidiaries or are being used under license. TEX-WW-17719 7/23 eastman-naia Discover the beauty of Naia at naia.eastman.com.

style,

Partnerships Bring Innovations To a Broader Audience

FAST-FASHION GIANTS LIKE H&M AND ZARA ARE AMONG THE ESTABLISHED NAMES HELPING NASCENT TECHNOLOGIES SCALE AND COME TO MARKET. By

Alexandra Harrell

Partnerships are crucial to any business but are of particular interest to startups for somewhat obvious reasons: capital, connections and coverage. And the fashion industry, where brands often collaborate with emerging designers or relevant celebrities, is no exception. But when it comes to material innovation, these partnerships are even more vital for the realization of long term aims.

“Brands who step up and work with innovators are in a position to influence the development of next-gen materials and fibers with their aesthetic and performance metrics; they can be a critical force for building a new sustainable materials industry,” Thomasine Dolan, director of material innovation and design at Material Innovation Initiative (MII), said. “In addition to asserting influence in a burgeoning industry, collaborating with material innovators brings a brand closer to achieving their sustainability goals when the fiber or material becomes production ready.”

Co-developing with an emerging innovator is a smart way to ultimately replace core programs that no longer meet a brand’s sustainability goals, Dolan continued, acknowledging that a brand’s involvement with an innovator is not only helpful to that startup but to the industry as a whole when considering price concerns or scaling efforts.

“Collaborations between material innovators and brands are not just important, they are critical,” a spokesperson for MycoWorks, said. “Without partner input and feedback, innovators risk losing sight of

the importance of quality which can result in cutting corners for the sake of speed.”

The mushroom leather leader utilizes its patented Fine Mycelium technology to grow its flagship product, Reishi, in its California facilities. According to the biomaterials company, Reishi features the inherent strength, durability and hand feel of animal leather with a lower environmental impact. It’s tanned and finished by the firm’s European heritage tannery partners using MycoWorks’ proprietary chrome-free tanning and dying technologies.

Following the mycelium inoculum and waste sawdust-based material’s 2020 debut at New York Fashion Week, MycoWorks has collaborated with several brands to showcase the bovine alternative, starting first with luxury hatmaker Nick Fouquet last July on a collection comprising an Ecuadorian straw hat with a Reishi band, a baby suede felt fedora with Reishi quarter binding edge finishing and wax thread stitching band as well as a 100-percent Reishi bucket hat.

In October, MycoWorks partnered with General Motors to co-develop the startup’s Fine Mycelium materials for potential use in various applications within automotive design, seemingly still in development. And two months later, furniture company Ligne Roset brought Reishi into the luxury furnishings market with limited-edition pillows called Teneo that were scheduled to be available for purchase starting this year, though they aren’t currently available. Also in

22 22 MATERIAL INNOVATION

December, there was a collaboration with designer Heron Preston on a limited edition, single piece of art titled “A Fruit Bowl by Heron Preston for MycoWorks,” representing the first of many product launches between the two.

“We work with the world’s best luxury brands, partnering closely with their teams to develop and refine Reishi to meet their high-quality standards,” MycoWorks said. “Our material is used in heritage-quality designs that will be handed down from generation to generation [and] our partners have helped us get there by demanding the very best.”

Textile innovator Evrnu has taken a different approach, working with more accessible brands to accelerate the adoption of its NuCycl lyocell fiber, which is made from pre- and post-consumer textile waste and is up to four times stronger than other cellulosic fibers. It can also be recycled up to five times without compromising performance or quality, thus leading the company to believe it can perform on par with virgin fibers.

“As a fiber ingredient, we are dependent upon brands to integrate NuCycl into their garments in order to reach the consumer and make it into their wardrobe,” Stacy Flynn, CEO and co-founder of Evrnu, said. “This allows us to generate trial, interest and repeat demand. Collaborations are also an endorsement that sustainable fashion fulfills the same desired fashion aesthetics that consumers have come to expect from their favorite brands while providing an added emotional benefit that they are helping the planet through their selection of recycled and recyclable goods.”

Last December, Evrnu collaborated with Zara on a capsule collection comprising two oversized collared shirts and wide-leg trousers featuring the renewable fiber, made using textiles from Zara’s consumer product returns. It sold out in the first week, Flynn said, and the two are currently working on the next phase of their partnership as well as additional capsule collections set to launch next year. In February, material science brand Pangaia released the Renu jacket, the company’s first

denim product made completely from cotton textile waste via the NuCycl.

“The adoptions, and associated publicity and promotion that partnerships afford, has increased our brand awareness and interest, and led to new brand inquiries and adoptions which will be coming to market and further supports the validity of our fibers and innovations,” Flynn said. “These adoptions have also required us to expand the range of end use garments that can be made with our fiber—for example, denim—thus increasing the addressable market for us.”

On the other side of the coin, H&M has invested in numerous future-focused material innovators, such as financing the

23 23

▲ Algreen received the H&M Foundation’s Global Change Award.

MATERIAL INNOVATION

Swedish textile recycling company Renewcell, who later supplied the brand with tons of virgin-quality Circulose fibers, which are made from unusable textile waste—think old jeans and T-shirts that have been discarded at an industrial scale. The fast-fashion giant has also financed Alchemie Technology and Imogo, two organizations supporting sustainable textile processing. Last year, H&M funded research from Karolinska Institutet and the Swedish University of Agricultural Sciences (SLU) to scale the production of a protein-based fiber that mimics spider silk. Not to mention H&M Foundation’s Global Change Award,

now in its eighth year, which honors the world’s most disruptive innovations.

“We have an urgent opportunity to support innovations that could transform the entire fashion industry—that’s why we’re doubling the grant and the number of winners,” Karl Johan Persson, an H&M Foundation board member, said of this year’s winning class. “We’re giving these innovators a total of two million euros and access to our accelerator program—but we’re also giving the industry an opportunity to connect with these brilliant innovators. I’m excited to see the impact these innovators will make on the industry.”

This year’s winners featured six materialfocused startups, including Algreen, which focuses on biobased foams, adhesives and coatings crafted from natural resources; Nanoloom, which makes high-performance fibers fueled by graphene and the biomimicry of butterflies; and PhycoLabs, which spins seaweed fibers.

“There’s a wide range of solutions among this year’s winners,” Christiane Dolva, strategy lead at the H&M Foundation, said. “If scaled, I believe they could have a real impact on the industry—which needs a holistic transformation if we are to reach a planet positive fashion future.”

24 24 MATERIAL INNOVATION

▼ Evrnu has partnered with Pangaia and Zara

Going Bananas in India

MAKING THE MOST FROM UNDERUTILIZED INPUTS, INNOVATORS TURN TO NATURE. By

Mayu Saini

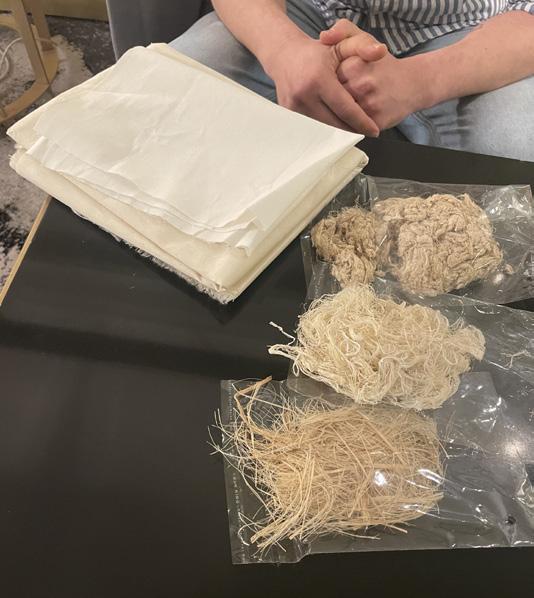

Kim Rohde Morgensen, a co-owner at Copenhagen, Denmark-based innovation house Textile Pioneers ApS, traveled a long way to find the material he has been seeking. All the way to Coimbatore in Southern India, in fact.

Having worked in Europe and sourced from countries across Asia, Morgensen has been narrowing down his locales to find the most durable material—and one that will fit the fast changing sustainability guidelines in Europe.

The material that has satisfied this eco-dream? Banana textile.

He’s not just pleased, but as he puts it, “very much excited.”

There are many reasons for this exuberance, he said, showing off the T shirts that are both soft and flexible, a complete change from the rough, harsher texture that has been the usual result of working with these kinds of fibers in the past.

“The banana tree fiber is long, and it has the strength of polyester, while being completely natural. Instead of adding polyester, which is man-made, we are turning to banana which is 100 percent cellulose, and is also 100 percent biodegradable,” he said.

It also satisfies sustainability requirements, he added. “The life of a banana tree is finished after it has borne fruit, and so there is no special land area or water used in this process, it is already waste fiber.”

As he explained it, the pricing too has become more acceptable over time, as has the quality since he first started working with it in 2019.

Banfab Textiles India Pvt Ltd ‘s A Sivakumar, who researched and engineered the product, and has been

awarded the “best banana entrepreneur” by the Indian Council of Agricultural Research (ICAR) reiterated the point: a banana plant completes its life cycle after its fruit is ripe. It can then either be used as agri-waste or cast aside. “India has the largest banana plantations globally, more than 30 percent of global banana fruit is grown in India; one third of all banana trees

pointing out that most banana farmers had small farms, mostly with multi-cropping through the rest of the year.

“It improves the options for farmers who are often struggling,” he said.

The enzyme process for softening the fabric is chemical free process and can make the product softer or tougher as needed.

Talking about the global brands the company is working with, Sundaresh Ramanathan, executive director, Banfab, said the applications of the fiber were across categories.

are grown here, so that gives us an advantage,” he said.

The bananas take about nine months to grow, and the banana trunk, the psuedostem, yields the fiber, with the outer layer being the roughest, and the inner layer the softest.

“We have developed a machine that can be taken to the inside of the plantation itself, so that there is a minimal waste of energy for transportation of the stems, and it is one way of taking the factory to the field. Farmers can also use the agri-waste right away, and this also increases their income,” he said,

“Since the fiber is very strong, with different treatment we can make it harder, for suitcases and other things. It makes a completely bio-degradable sole for shoes, and it is also being used as an upper mesh. Another use is for acoustic panel insulation materials which are in offices and houses in the West, using polyurethane chemical. But the banana panels are stronger, thicker, made from agri-waste and on par with other acoustic panels. It is, of course, very good for textiles, and reduces the chance of skin allergies. We have an office and a factory and a facility for processing 1,000 tons a year capacity,” he said.

Having decided to focus their energy on innovation and collaboration, the options are easily extended, he said. “There are a number of textile mills around, so we can create yarn, textile or garments, very quickly. We are not that keen on the manufacturing side because there is no big value addition in that. We have tied up with two mills with 70,000 spindles each, which are GOTS certified,” Ramanathan added.

Sivakumar, who spent a few years studying and fine-tuning the process said

26 26 MATERIAL INNOVATION

This is not just about working with people who are doing it to make money—there has to also be the heart in it, and we feel like we need to go to a country where there is a big heart and a big brain.”

KIM ROHDE MORGENSEN, Textile Pioneers ApS

that the percentage of banana fiber in its blend with wool, silk or any other material was still yielding new ways of creativity.

“Once a fiber has more than 52 percent in the mix, it is known by its own name— banana fiber. In this case, what we are making is not banana blended with cotton but rather cotton blended with banana. We are confident about the 70/30 blend between banana and cotton, but are going with 60-40 percent banana to cotton, just to be very safe.”

Both from the Danish-consumer end and the Coimbatore origin, the goal is similar: commercial scalability. Both sides pointed out that funding didn’t come in from other resources, and that meant the focus was on the product—and the material—which spoke for itself.

Morgensen made a comparison with bamboo, which is one of the banana material’s main competitors.

“If you take bamboo and have to make it

soft, you have to use the viscose way, to use a massive amount of chemicals, so you are breaking down everything and building it up again, but here you are only using natural enzymes and no chemicals at all, so carbon emission and water consumption is very low comparted to cotton and other fibers,” he pointed out.

Banana fiber has other global options for sourcing, and uses in various formats, including kimonos in Japan, rugs from Nepal, and sarees in India. ICAR’s National Research Centre for Banana (NRCB) in Tiruchi has been pursuing these channels.

Morgensen has two reasons for choosing the Indian one: “This is not just about working with people who are doing it to make money—there has to also be the heart in it, and we feel like we need to go to a country where there is a big heart and a big brain. That’s why we went mainly to India. There is a lot of production but there is also by tradition a

lot of recycling due to the Indian culture, and the Hindu religion where being sustainable is a part of the religion and culture. It was a lot easier to work with these factories because they have the same mind-set.”

In comparison to the production in other countries, like Bangladesh, he observed: “India is still years ahead.”

The potential for conversion though, is relatively unutilized, with less than 5 percent of the banana stems being used for the production of fiber, according to industry analysts who said that an approximate 1.5 million tons of dry banana fiber can be produced from the pseudostem each year.

As Morgensen pointed out, the material isn’t just about the past. It’s potential was only hindered by the amount of learning ahead, as banana materials emerge with their grease proof, heat resistant properties, and a natural shimmer.

“It’s a lot about looking ahead,” he said.

MATERIAL INNOVATION 27 27

▼ Drying banana fiber; Left: A Sivakumar in the fields

Chosen for beauty, function and feel.

Golden Hour, Supima Field supima.com

What Chemists and Academics Say We Need For a Full PFAS Phase-out

SOME IN THE INDUSTRY WANT THE EPA TO ENACT NATIONAL PFAS LEGISLATION TO END THE ‘PATCHWORK’ OF STATE LAWS CURRENTLY INFLUENCING STANDARDS.

By Jennifer Bringle

Six years ago, investigators uncovered an environmental catastrophe in North Carolina. A team of researchers from North Carolina State University had been studying the Cape Fear River watershed, an area in the central and southeastern part of the state that provides drinking water for around 1.5 million people. As they tested water from the river, as well as groundwater, they found unusually high concentrations of a shortchain organofluorine chemical compound known as GenX.

The chemical had been created by the DuPont-owned Chemours facility located in Fayetteville, N.C., as a replacement for perfluorooctanoic acid or PFOA, which has been found to cause cancer and other diseases. But GenX, which is one of many synthetic organofluorine compounds collectively known as per- and polyfluoroalkyl substances, or PFAS, has been found to cause some of the same issues as PFOA.

North Carolina’s GenX contamination served as a startling worst-case scenario during a meeting of chemists, academics and other stakeholders at the recent American Association of Textile Chemists and Colorists PFAS in textiles summit.

Dr. Detlef Knappe, professor of civil, construction and environmental engineering at N.C. State, worked on the study of the Cape Fear River watershed that discovered GenX contamination. He said that this kind

of environmental disaster should serve as a warning and catalyst for companies to dial back their use of PFAS chemicals.

“The impacts on the lifestyle of this community are dramatic,” he said. “They can no longer drink their water without additional treatment, they no longer feel

safe eating food they grow in their garden, they can no longer fish in their lakes. If you must use PFAS, I implore you to use pollution control equipment so that it doesn’t go into the environment.”

PFAS is an umbrella term for a large class of compounds that are used in a variety of products to provide water- and stainrepellency. In apparel, PFAS can be found in

29 29 MATERIAL INNOVATION

Successful phase-out of PFAS in the entire apparel and footwear value chain will only be possible by eliminating their use from all relevant manufacturing processes.”

DEBBIE CHRONICLE, Hohenstein Institute America

outdoor clothing such as raincoats, footwear and athletic apparel, among other uses. Many PFAS are known as “forever chemicals” because of their persistence in the environment and even the human body. While some PFAS such as GenX have been identified as toxic, others are still regularly used and haven’t been found to be harmful.

“There’s toxicity that’s associated with certain PFAS that are well-understood in terms of their toxicity, but others are not well-understood,” Knappe said. “Impacts associated with PFAS exposure are immuno-toxicity, liver toxicity and cancer.”

Those PFAS that aren’t well-understood seem to be the tipping point, with some states and companies proposing outright bans for all PFAS while chemical makers and others insist there isn’t have enough information available to write off every compound in the class.

“Because PFAS is an umbrella term, and it’s a subjective term and not an objective one, it’s difficult to define,” said Frank Adamsky, regulatory affairs manager, Daikin, which produces fluorochemicals used in textiles. “We have a legacy environmental contamination issue. The sooner we focus on the actual issue, the greater ability we have to solve it.”

According to the National Institute of Environmental Health Sciences, there are around 9,000 PFAS chemicals in existence. And a University of Toronto study from September 2022 found that 65 percent of clothing products tested contained PFAS, with school uniforms containing the highest concentrations.

Stain resistance on clothing, furniture upholstery and home textiles has proven the most difficult issue to resolve without PFAS. While PFAS-free durable water repellents (DWR) exist, a solution that repels oil-based stains remains elusive.

“We are quite far away from getting a non-fluorinated solution that will repel oil,” said Dr. Luka Kovacevic, senior technical and business development manager, German chemical manufacturer, Rudolf.

Kovacevic said the next generation of

PFAS-free water repellants will use plantbased building blocks and small molecules, extending and polarizing them to make polymers that meet repellency requirements better. But even using natural sources, chemists have to be careful with how they make these alternatives.

“The trend is to move to more sustainable solutions, and we have started looking into renewable, plant-based materials,” he said. “When you start doing that, you must be sure you’re not competing with feed or fuel because that’s reducing the sustainability.”

As consumers become more aware of PFAS, the backlash against use of the chemicals has grown. Class-action lawsuits against apparel makers REI and Thinx have raised the profile of PFAS concerns.

“There is this visceral reaction that members of the public are having,” said Sean M. Sullivan, partner, environmental and natural resources group, Williams Mullen. “Sooner or later, PFAS will become a consumer differentiation criterion.”

In response to those growing concerns about PFAS, several states—California, Colorado, New York, Maine and Washington—have passed legislation

30 30

▲ Academics and industry expert discuss what’s needed to leave PFAS in the past.

MATERIAL INNOVATION

banning or limiting the use of the chemicals in products sold within their borders. And according to the American Chemistry Council, a total of 276 bills were introduced by states on PFAS in the 2023 legislative session, although not all of them apply to textiles.

As states legislate the use and sale of PFAS and products containing them, companies are finding it harder to maintain compliance.

“Some wish the Environmental Protection Agency [EPA] could enact a national solution to this problem, but even so, these state regulations will still exist, so we’ll still have this patchwork,” Sullivan said.

In the meantime, several apparel and footwear companies have taken proactive measures to eliminate or significantly reduce the use of PFAS in their products. Levi’s was one of the first to phase out PFAS, and H&M also has made a commitment to remove the chemicals from its products. Keen, the footwear brand, also made the move to ban PFAS chemicals from its supply chain.

“Keen inventoried product categories and determined that a sandal designed to get wet didn’t need PFAS,” said Amanda Cattermole of Cattermole Consulting. “That one decision reduced the company’s use of PFAS by 80 percent.”

Cattermole said apparel and footwear brands must first determine if the use of PFAS is necessary, and if so, can an alternative substance be used. The other key is for brands and retailers to fully understand and monitor their supply chains,

where exposure to PFAS can happen in unexpected places due to the pervasive nature of the chemicals.

“Even with the most robust manufacturing systems in place in the supply chain, products may still contain PFAS even if they haven’t been treated with the chemicals,” said Debbie Chronicle, senior sales

executive, textile testing company Hohenstein Institute America.

Chronicle said completely removing PFAS from clothing and shoes is possible, but it will take time and cooperative work across global supply chains.

“Successful phase-out of PFAS in the entire apparel and footwear value chain will only be possible by eliminating their use from all relevant manufacturing processes,” she said. “Considering the persistence of PFAS, this is a really ambitious goal, and it’s going to require international collaboration and a sufficient amount of time to achieve it.”

Because PFAS is an umbrella term, and it’s a subjective term and not an objective one, it’s difficult to define.”

31 31 MATERIAL INNOVATION

FRANK ADAMSKY, Daikin

Supima’s Industry Leading AQRe Program Brings Transparency Front and Center

The industry is seeking supply chain visibility, particularly in raw materials. U.S. Pima cotton brand Supima is supporting this quest for transparency through its newly launched AQRe™ Project, which combines forensic verification with blockchain technology. Here, Supima president and CEO Marc Lewkowitz discusses what sets Supima cotton apart—from traceability to tensile strength.

Sourcing Journal: Why is AQRe Project a gamechanger for Supima cotton transparency?

Marc Lewkowitz: In combining TextileGenesis™ for real-time digital traceability with Oritain™ for physical authentication, AQRe Project (pronounced acre) has created an integrated platform that provides, for the first time in textile industry history, both complete chain of custody and authentication of Supima content across the supply chain. Most companies still do not have much—if any—insight past their Tier 1 suppliers. Our investment in AQRe creates a framework to deliver new industry benchmark-setting processes to enable Supima partners to achieve credibility in product provenance and integrity.

What are some of the challenges of creating full visibility across the cotton ecosystem outside of U.S.-grown American Pima?

M.L.: The AQRe Project is possible only because of the rigorous standards that have developed around the cultivation and marketing of Supima over the past century. Where Supima cotton is grown, there are distinct farming and agricultural practices, required fiber classification and tracking and strict regulations in place. The broader cotton production complex is a massive industry that represents the largest natural fiber crop in the world along with disparate producing areas and regions, multiple fiber varieties and qualities and numerous different practices. This entails a much more complicated structure that cannot yet be simplified into a singular “cotton” conversation.

The farm is a center of cotton innovation. What latest advancements are you seeing that boost the sustainability of cotton cultivation?

M.L.: Supima growers are considering various solutions and possible practices that continue to build on the best

practices already implemented. Based on the region and unique production environment, the challenges vary by grower, soil type and microclimate. Options and solutions for improving best practices are highly variable from grower to grower and season to season. Data has a great capacity to bring equity across a larger data set but is hampered by the technological investment needed for this to happen. One of the goals of AQRe is to launch a process to synthesize past production data to create industry benchmarks across different aspects of production.

What are some of the most innovative ways your partners have used Supima fibers recently?

M.L.: Fundamentally, Supima is a premium cotton and can be used in any products that are typically made from cotton or other fibers. The benefits of a Supima cotton reside within the special qualities of the fiber’s strength, fineness and length that naturally yield better feeling and performing fabrics. A novel application by material brand Solucell™ uses Supima cotton in a core-spun process in which a recyclable core filament is wrapped in Supima. During the finishing process, the core dissolves and is recovered, leaving a hollow yarn core structure like a capillary pathway that imparts enhanced yarn characteristics. This facilitates quick dry, moisture management and thermoregulation properties.

As you mentioned, Pima is a premium fiber choice. How is demand for Pima cotton trending in apparel and textiles?

M.L.: Slowly but surely, the sustainability aspect of long-lasting, natural fibers like Supima is connecting with consumers. Transparency and authenticity of Supima’s supply chain, supported by AQRe, only serve to enhance and advance these advantages. Consumers win because they are provided highquality clothing with better performance characteristics like durability, longevity and comfort along with the credibility of the brand or retailer that has engaged a verified, transparent supply chain.

32 SJ STUDIO

“ POWERED BY

Our investment in AQRe creates a framework to deliver new industry benchmark-setting processes to enable Supima partners to achieve credibility in product provenance and integrity.”

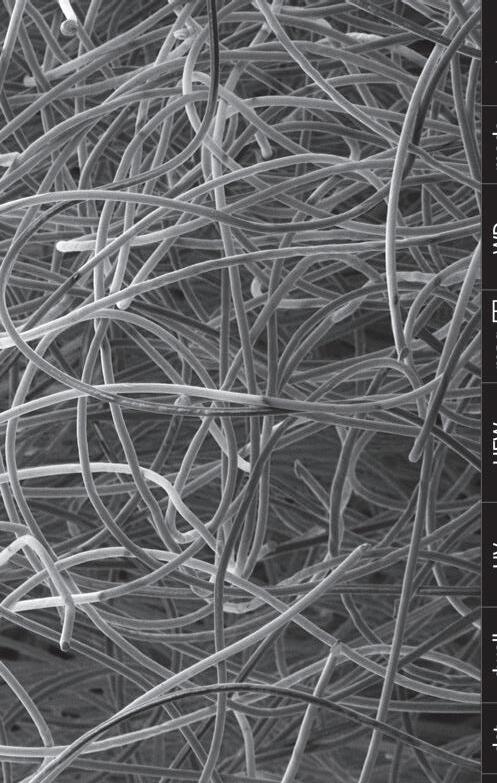

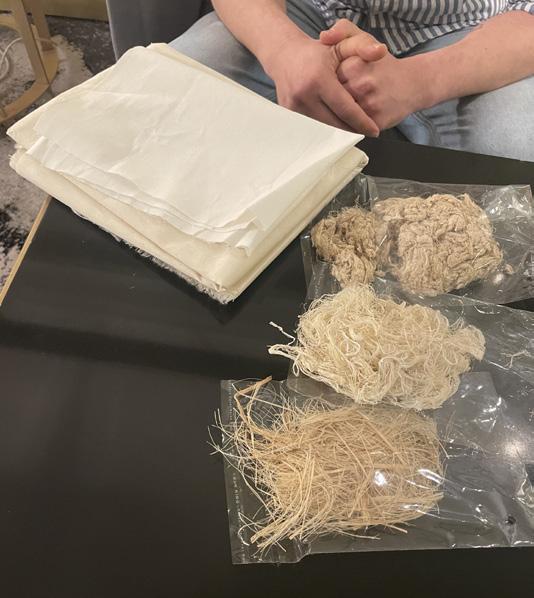

3 Textile Players Spearhead New Era of Sustainable Recycled Cotton

RECOVER, RIETER AND POLOPIQUÉ HAVE JOINED FORCES TO PRODUCE YARNS WITH A HIGHER PERCENTAGE OF MECHANICALLY RECYCLED FIBERS. By

Alexandra Harrell

Recover, Rieter and Polopiqué—three players in different stages of the textile supply chain—have partnered up to help the industry produce yarns with a higher percentage of mechanically recycled fibers.

The three companies are responding to rising demand for high-quality and fine ring-spun cotton yarns with a higher proportion of recycled fibers, a challenge the industry is struggling to tackle. Revealed during ITMA 2023 in Milan, this partnership aims to meet this demand, which could open up new possibilities for yarn production.

By combining Recover’s recycling technology with Rieter’s experience in spinning systems and machines along with Polopiqué’s textile manufacturing prowess, the trio has created a high-quality, sustainable garment. It’s made from a Ne 30 compact yarn containing 40 percent recycled post-industrial fabric waste, versus the usual 20 percent of recycled fiber content found in most recycled ring yarn.

“We’re proud to team up with Recover and Polopiqué in a breakthrough effort that will pave the way toward a more sustainable future,” Franziska Häfeli, head sales and marketing, business group machines and systems at Rieter, said. “Our specialized expertise in spinning recycled fibers will help achieve our shared goals so together we will make recycling mainstream.”

The ring-spinning process used for this

project includes Rieter’s comber and compacting device, Compactdrum. Recover’s recycled cotton fibers were blended with virgin cotton at a 50/50 ratio. When combining the blend, the undesirable short fibers are removed, enhancing yarn quality and improving the running performance of the ring spinning machine.

Plus, those fibers removed by the comber are suitable for processing in the Rieter rotor spinning machine. The process aims to be Global Recycling Standard (GRS) certified.

“Recover is thrilled to collaborate with Rieter and Polopiqué in this partnership that is spearheading a new era of sustainability in the textile industry,” Alfredo Ferre, CEO of

33 33 MATERIAL INNOVATION

We’re proud to team up with Recover and Polopiqué in a breakthrough effort that will pave the way toward a more sustainable future.”

FRANZISKA HÄFELI, Rieter

Recover, said. “By increasing the percentage of the recycled content in the yarn and final product, we can achieve our goal to scale the adoption of sustainable fibers, like Recover, and make a lasting positive impact on the planet.”

As demand for recycled cotton continues to mount, particularly under the growing pressure of regulatory requirements, this partnership aims to serve as a “catalyst for change.” The trio will continue to collaborate and explore further opportunities to accelerate fashion’s adoption of sustainable practices.

“Polopiqué’s mission to continuously test,

develop and create new and exciting products, through the use of cutting-edge technology and new and innovative raw materials, is and has been achievable through the partnerships created over the years,” Eduardo Guimarães, weaving director at Polopiqué, said. “Being able to come together with Rieter and Recover, both long-standing partners of ours, is a privilege, especially considering the aim and focus for this project. Coming together and sharing knowledge and how know has allowed us to reach our collective product objective, and excitement for the impact that this will have on our industry.”

MATERIAL INNOVATION 34 34

▲ The trials successfully created a garment made from a Ne 30 compact yarn that contains 40 percent of recycled post-industrial fabric waste.

Photo by Ana Palacios

How Sateri Utilizes Advanced Technology to Raise Circularity and Lower Carbon Emissions

As excess waste continues to pose a significant problem for the fashion industry, many manufacturers across the globe are looking for technological advancements to solve the problem.

Here, Ben Huang Wen Bin, senior sustainability manager for innovation and Miranda Chen Jie, strategic marketing director at Sateri, tells Sourcing Journal how the viscose rayon manufacturer is improving its technology to increase the content of recycled raw materials and how the company is lowering its carbon footprint.

Sourcing Journal: How does Sateri plan to achieve net-zero carbon emissions by 2050?

Ben Huang Wen Bin: In our journey toward net-zero by 2050, Sateri is prioritizing minimizing our carbon footprint, focusing on the following four areas to reach our goals; improvements in energy efficiency, utilization of renewable energy, innovation in lowcarbon products and cooperation toward a low-carbon value chain.

Recently, we completed carbon footprint accounting—a way of calculating how much greenhouse gas an organization emits—at product and enterprise levels and established a systematic carbon data management system. Sateri’s commitment to its low-carbon transformation is not only reflected in our operations, but also focused on empowering the entire supply chain. We researched the low-carbon transformation status of key category suppliers and investigated trends in the industry to help identify suitable low-carbon strategies for the supply chain. We will continue to explore science-based means of progressing toward an increasingly low-carbon supply chain while ensuring stable and high-quality supply.

What is Sateri’s Lyocell fiber, and what is it derived from? What are some of the sustainable qualities the fiber possesses?

Miranda Chen Jie: Sateri’s Lyocell—a biodegradable fiber—is made from wood pulp that comes from sustainable plantations. The manufacturing process is eco-friendly, using a closed-loop technology that requires minimal chemical input and an organic solvent that is non-toxic and harmless.

Additionally, the solvent can be 99.7 percent recovered and recycled.

What raw materials innovations do you currently have in the works? How is Sateri practicing a circular economy?

M.C.J.: The fashion industry’s current economic system can be considered a “linear economy,” built on a model of extracting raw materials from nature, turning them into products and then discarding them as waste. This burdens the environment and contributes to the climate, biodiversity and pollution crises. Circular economy, on the other hand, aims to minimize waste and promote sustainable use of natural resources,

through smarter product design, longer use, recycling and more.

Sateri is practicing a circular economy. A large amount of fast-fashion clothing is discarded in China every year [China throws away 26 million tons of clothes every year, less than 1 percent of which is reused or recycled, according to state news agency Xinhua] so there is an urgent need to address the issue of recycling textile waste. That’s why Sateri independently developed an innovative and circular next-generation cellulosic fiber-containing recycled content, FINEX™—short for Fiber Next—using textile waste as the raw material.

Additionally, Sateri has introduced concrete changes to promote zerocarbon development within the industry. In 2022, Sateri launched three carbon neutral products under the EcoCosy® (viscose), a biodegradable textile fiber made from sustainably-managed plantations, Sateri Lyocell and FINEX™ brands. All three products have obtained PAS 2060 verification—a standard designed to help companies achieve true carbon neutrality through earnest means. This is a giant leap forward for Sateri on its path toward green, low-carbon, sustainable development.

Our high-quality products are born from our strong culture of market back innovation, and we are committed to advancing the concept of technological innovation and transformation throughout the entire industry.

35 SJ STUDIO

“

BY

A large amount of fast-fashion clothing is discarded in China every year, so there is an urgent need to address the issue of recycling textile waste.”

POWERED

Faux Fur, Real Reach

BIOFLUFF’S MARTIN STÜBLER DISCUSSES THE ART OF COMBINING MODERN TECHNOLOGY WITH CENTURIES-OLD TANNING TRADITIONS.

By Alexandra Harrell

Despite proposed fur band across the U.S. and the EU and waning consumer interest in the animal by-product, the search for a cruelty-free and environmentally-friendly solution has been going on for some time.

Enter BioFluff, which has created what it deems the world’s first 100 percent plant-based, petrochemical-free, sustainable alternative to animal- and plastic-based fur targeting the luxury market. According to an internal life cycle analysis (LCA), BioFluff emits 95 percent less greenhouse gas emissions than animal fur and 75 percent less than synthetic fur.

In November, the San-Francisco-based company, which was founded in 2021, closed a pre-seed round of $500,000 with funding from SOSV’s IndieBio fund, venture capitalist partnership Joyance partners and entrepreneurial asset management firm Ataraxia Partners Limited, among others. And though it’s still in stealth mode, the LVMH Innovation Award nominee is on track to close a significantly larger funding round and has drummed up support from some of the leading labels in the luxury sector.

Here, BioFluff’s co-founder and CEO Martin Stübler talks with Sourcing Journal about the company’s mind-set, materials and momentum.

Sourcing Journal: Walk me through the mission and ethos of BioFluff.

Martin Stübler: BioFluff is a B2B materials supplier to existing fashion or lifestyle brands with the long-term vision of replacing all animal and all synthetic fur. Our goal is to remove animals from the

supply chain, but we see a much bigger challenge in removing microplastics and toxins from the environment.

As an undergrad, I studied farming, mechanical engineering and food science in Austria. I then went to grad school in upstate New York and did some more research around plant materials. After I graduated with a couple of different degrees, I was like, I have absolutely no idea where I’m going—

time, I was exposed for the very first time to not just leather but also fur. And that was the lightbulb moment for BioFluff. I thought, “we have so many companies creating leather alternatives, why is no one tackling fur?”

SJ: One of the issues I see in the material innovation sector is the ability to go from lab to market. Tell me how you scaled from working in a vacuum, so to speak, to an industrial level.

M.S.: For us, it was really luck. I knew that in order to create a scalable process, I needed to understand what’s out there and what the best practices are right now. And it’s hard to get up-to-date industry knowledge about how this process is executed; the textile industry is very protective of their trade secrets, their knowledge, their IP. I couldn’t get ahold of anyone on e-mail—I knew there were manufacturers I needed to talk to, but they didn’t want to talk to me, and that’s totally understandable.

no transferable skills for the workforce. So I did what everybody does when looking for meaning or purpose: I moved to California.

I joined a small startup there in 2019, the first and oldest company producing mycelium leather, MycoWorks. And then, in 2020, I ran out of a work visa, so I had to return to Europe for a few weeks. I was planning on staying for a short time, but due to an unfortunate event, I ended up staying for about a year and a half. So, I started working hands-on in a tannery. During this

So, I would go to Italy, show up to a factory with a bottle of wine and be like, “Ciao!” and try to convince them to let me in and establish a relationship. I did this throughout Spain, Italy, France, Germany, to really get to know people and understand what the best practices are right now. And from there, we decided there are two manufacturing partners—one in Belgium, one in Italy—that work really well; we can bring them up to speed on our process easily because they have almost the perfect machinery, the right know-how, the right resources. And that’s how I started the BioFluff process: by finding the right people that can execute.

36 36 MATERIAL INNOVATION