SOURCING

to our new readers , welcome to sj denim

To long-time readers and industry friends, welcome to the next evolution of Rivet.

Ten years ago, Sourcing Journal (a.k.a. SJ) launched Rivet as a separate publication tailor-made for the denim sector. Fast forward to today, and so much has changed. Denim is no longer confined to the traditional denim-only brands; a more diverse range of companies are now integrating denim into their collections, raising new challenges and perspectives that some industry players may have overlooked. The stigma once associated with secondhand shopping has shifted toward fast fashion, opening exciting resale opportunities for brands. Add to that the pressing realities of climate change, trade wars, and volatile economies, which are pushing denim manufacturers to stay informed and make smarter business decisions.

With sourcing, boycotts, tariffs and corporate responsibility dominating the news, the time has come to strengthen Rivet’s connection to SJ and leverage its global reputation as a leader in supply chain news. Rest assured, our core team remains unchanged, as does our unwavering commitment to representing the global denim industry.

SJ Denim will go even deeper into the business of denim, highlighting disruptors, innovators, and tapping into the expertise of denim legends who have shaped the industry.

Think of it like when Levi’s updated the red tab on its jeans from “Levi’s” with a big E to “Levi’s” with a small e in the 1970s. While the look changed, the quality and fit that consumers had come to expect remained the same. Similarly, SJ Denim will continue to deliver the same deep, engaging denim content that Rivet pioneered, but with a fresh perspective and expanded focus.

This debut spring issue exemplifies our renewed mission. In “Game Changers” on pg. 34 we reflect on the 10 innovations that changed the denim industry forever. From advanced finishing technologies to recycling machinery, to water treatment facilities, it is clear how every part of the supply chain has played a role in making denim a more responsible industry.

Looking ahead, fabric mills discuss the potential positive impact of digitally printed jeans in “Digital Denim” on pg. 48. In “Elastic Ethics,” (pg. 52) fiber producers share how they’re leaning into renewable resources to produce stretch denim. In “Fade Away,” (pg. 54) chemical suppliers and manufacturers reveal the challenges in eliminating potassium permanganate from production, and the reasons why they remain hopeful for green chemistry.

Whether it’s new trends and brands or technological breakthroughs, denim is always in motion. Know that wherever the industry goes SJ Denim will be there and take you along for the ride.

FAIRCHILD

EDIT OR IAL

Peter Sadera Editor in Chief, Sourcing Journal Angela Velasquez Executive Editor

Vicki M. Young Executive Financial Reporter

Jasmin Malik Chua Sourcing & Labor Editor

Kate Nishimura Senior News & Features Editor Glenn Taylor Logistics Editor Meghan Hall Business Editor Alexandra Harrell Sustainability & Innovation Reporter

Lauren Parker Director Fairchild Studio/SJ Studio

Sarah Jones Senior Editor, Strategic Content Development

Andre Claudio Staff Writer, Strategic Content

ART DEPARTMENT

Ken DeLago Art Director Logan Case Senior Designer Eric Pak Senior Designer Trinity Krakora Designer

SOURCING JOURNAL ADVERTISING

Deborah B. Baron Advertising Director

PRODUCTION

Anne Leonard Production Manager

Adeline Saez Production Manager

Therese Hurter PreMedia Specialist

ADVERTISING

Melissa Rocco Senior Vice President, Sales Samantha Rumsky Advertising Director Jennifer Petersen Advertising Director, Fashion & Luxury

Stacey Lankind West Coast Director

Katherine Hogan Account Manager, Tech

INTERNATIONAL OFFICES

Olga Kouznetsova European Director, Italy Giulia Squeri European Director, Italy

Elisabeth Sugy Rawson European Director, France

MARKETING

William Gasperoni Vice President Christine Staley Senior Director, Marketing & Fairchild Studio Sara Shenasky Head of Client Activation Barbra Leung Director, Integrated Marketing Alexa Dorfman Senior Marketing Manager

Kayla Gaussaint Associate Integrated Manager

OPERATIONS

Ashley Faradineh Executive Director, Operations

Rosa Stancil Media Planner

Emanuela Altimani Senior Sales Coordinator

SOURCING JOURNAL IS OWNED AND PUBLISHED BY PENSKE MEDIA CORPORATION

Jay Penske Chairman & CEO

Gerry Byrne Vice Chairman

George Grobar Chief Operating Officer

Sarlina See Chief Accounting Officer

Ryan Young Chief Security Officer

Craig Perreault Chief Digital Officer

Todd Greene EVP, Business Affairs & Chief Legal Officer

Celine Perrot-Johnson EVP, Operations & Finance

Paul Rainey EVP, Operations & Finance

Tom Finn EVP, Operations & Finance

Jenny Connelly EVP, Product & Engineering

Ken DelAlcazar EVP, Finance

Debashish Ghosh Managing Director, International Markets

Dan Owen EVP, GM of Strategic Industry Group

Brian Levine Sebior Vice President, Revenue Operations

Brooke Jaffe Vice President, Public Affairs & Strategy

David Roberson Senior Vice President, Subscriptions

Doug Bandes Head of Live Event Partnerships

Frank McCallick Vice President, Global Tax

Gabriel Koen Vice President, Technology

Jessica Kadden Senior Vice President, Programmatic Sales

Judith R. Margolin Senior Vice President, Deputy General Counsel

Ken DelAlcazar Senior Vice President, Finance

Lauren Utecht Senior Vice President, Human Resources

Marissa O’Hare Senior Vice President, Business Development Nelson Anderson Senior Vice President, Creative

Adrian White Vice President, Associate General Counsel

Andrew Root Vice President, Digital Marketing

Andy Limpus Vice President, Executive Search

& Head of Talent Acquisition

Anne Doyle Vice President, Human Resources

Ashley Snyder Vice President, Associate General Counsel

Brian Vrabel Head of Industry, CPG and Health

Constance Ejuma Vice President, Content Performance & Analytics

Courtney Goldstein Vice President, Human Resources

Dan Feinberg Vice President, Associate General Counsel

Danielle Levine Vice President, Associate General Counsel

Denise Tooman Vice President, Marketing, Strategic Solutions Group

Eddie Ko Vice President, Advertising Operations

Greta Shafrazian Vice President, Business Intelligence

Jamie Miles Vice President, eCommerce

James Kiernan Head of Industry, Agency Development

Jennifer Garber Head of Industry, Travel

Jerry Ruiz Vice President, Acquisitions & Operations

Joni Antonacci Vice President, Production Operations

Karen Reed Vice President, Finance

Karl Walter Vice President, Content

Katrina Barlow Vice President, Business Development

Kay Swift Vice President, Information Technology

Keir McMullen Vice President, Human Resources

Matthew Cline Head of Automotive Industry

Mike Ye Vice President, Strategic Planning & Acquisitions Noemi Lazo Vice President, Customer Experience

& Marketing Operations

Richard Han Vice President, International Sales

Scott Ginsberg Head of Industry, Performance Marketing

Sonal Jain Vice President, Associate General Counsel

Richard Han Vice President, International Sales

Scott Ginsberg Head of Industry, Performance Marketing Sonal Jain Vice President, Associate General Counsel

Angela Jean Velasquez EXECUTIVE EDITOR

Trump’s

Trade show organizers are bracing for

The bohemian spirit of the 2010s is making a stylish comeback, reimagined with fresh touches of western flair, vintage charm

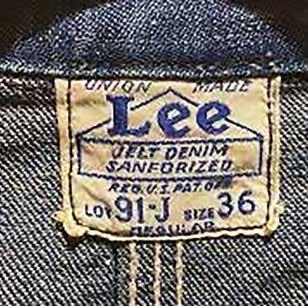

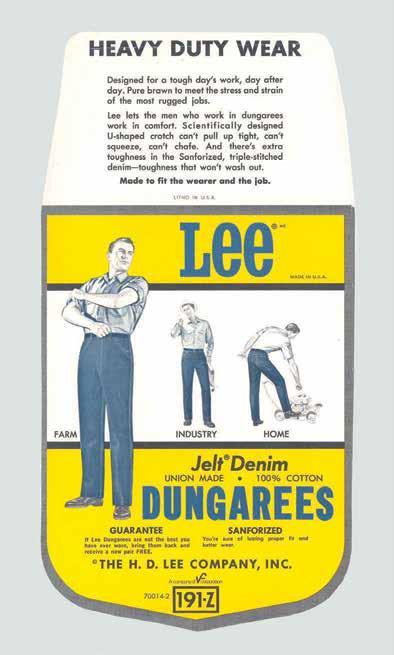

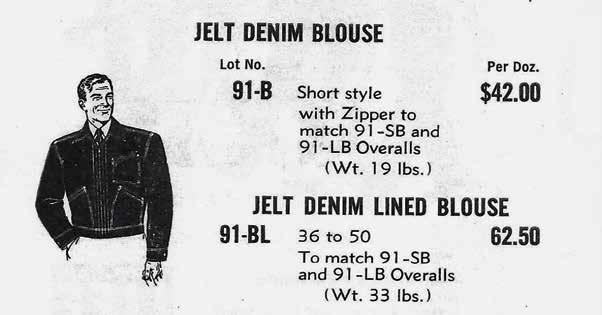

lee’s jelt denim turns 100 this year, highlighting the brand’s unwavering commitment to delivering garments built to last. The fabric is a reminder how consumers have valued durability and comfort since denim’s beginning.

In 1925, Lee worked with Canton Mills of Canton, Ga., to develop a fabric touted as “New Lee Denim,” a stronger, tighter weave for durable work and western wear. This 11.5-oz denim was made by twisting the yarn tighter than ever before and engineered as a tougher, stronger denim—harder to snag, tear or rip—and yet pliable and comfortable. In 1931, Lee renamed this fabric “Jelt.” The trademark was granted in 1933.

The fabrication was used in several of Lee’s iconic workwear products, including overalls and the 91-J chore jacket. In 1925, it was introduced to wear over Lee overalls. Jelt was also used in the launch of the 91B, a waist-length zipper-front work jacket with angled pockets, introduced in 1940 and consistently sold until 1982.

The strength and durability of the fabric was a key feature for advertising. In the mid30s, Lee partnered with American cartoonist Robert Ripley, showcasing nearly unbelievable feats all without tearing or splitting the fabric. The first photograph ad of the 91B also highlighted its durability.

The unique fabric has endured denim’s evolution from its roots as durable workwear to becoming a treasured addition to heritageinspired collections. Nowadays, the centennial fabric is reserved for select premium pieces, particularly new iterations of Lee’s heritage workwear, like the 91W jacket and carpenter pants, currently sold in Europe.

“While Jelt may not always be a featured part of our collection, it remains an integral part of our brand’s DNA,” said Frank Gilbert, Lee men’s senior designer. “Our goal is to honor its legacy while pushing the boundaries of design and performance, ensuring Jelt continues to evolve while staying true to Lee’s roots.”

www.pantherdenim.com

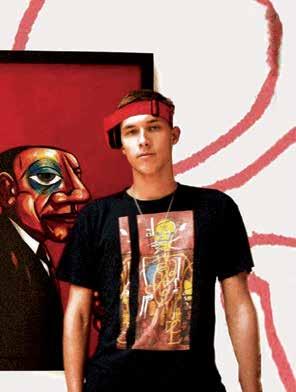

I’M CONTINUOUSLY WORKING TO REDEFINE FASHION BY MERGING ART AND CLOTHING, CREATING TIMELESS PIECES THAT CHALLENGE TRADITIONAL FASHION NORMS.” Raf Reyes, Veryrare

J. Cole-approved brand Veryrare is shaking up fashion,particularly with its unique denim pieces.

by Andre Claudio

veryrare is on a mission to revolutionize fashion with its “bold, fresh and reimagined” designs.

Founded by Raf Reyes, the Paris-based brand emerged in 2020 during the pandemic while Reyes was a postgraduate student at the Royal College of Art in London. According to the designer, the brand was born from a desire to merge art and fashion, creating pieces that “democratize art” by making it wearable and accessible.

“The concept behind the brand is to reference design’s history and signal its presence within the colliding worlds of archive and 21st-century fashion,” Reyes told SJ Denim. “Selected visuals feature various universes, ranging from collector ’90s aesthetics to contemporary subculture imagery. These elements are either amplified or stripped down to create a fresh and reimagined clothing style—where opposing ideas speak to one another—resulting in very rare pieces.”

Five years in and the brand has built a strong international presence, reaching customers in over 86 countries, with the U.S. as its primary market. This growth has been fueled by its online platform and partnerships with prominent retailers such as Selfridges in London, H Lorenzo, Wolf & Badger, Simons in Canada and HBX in Hong Kong.

This rapid growth has helped the brand gain

recognition from some of pop culture’s hottest names, including J. Cole, Jake Paul, Jaylen Brown, Lil Tjay, Rich The Kid and Famous Dex, to name a few.

“With my brand, I’m continuously working to redefine fashion by merging art and clothing, creating timeless pieces that challenge traditional fashion norms, [which is what] Veryrare consumers love,” Reyes said.

A key aspect of Veryrare’s buiness is its distinctive denim designs, which often feature “ultra-limited” lifestyle pieces that combine “intertwined narratives and visuals,” Reyes noted. Take, for example, the Sakura jean—made of 100 percent cotton—which features vibrant cherry blossom embroidery running up each side of the leg. Reyes said the $129 jean takes over 15 hours to hand-embroider, a process that incorporates various techniques, including chain stitch and piqué.

Veryrare sources fabrics globally, collaborating with textile associates in France, Portugal, Turkey, China and Japan. “We are committed to finding the best fabrics in terms of quality, durability and originality, ensuring each piece meets our high standards,” Reyes said. “We even know each of our denim artisans by name, visiting their weaving mills and dyeing factories regularly to ensure the craftsmanship and materials align with our [ethos] of transparency and authenticity.”

What’s one word to describe Veryrare? Unapologetic.

Who (or what) inspires your designs the most?

The global community, humanity, existence and the creative tribe—our mentors, the scenius, the collective genius of everything we’ve made and conceptualized since emerging from our Neanderthal caves.

• Coffee or tea while designing? Coffee.

What’s a guilty pleasure you have when it comes to fashion?

Indulging in maximalist designs and collaborating with friends (shoutout to Kiji Opera, my homie with the matcha tea saloon—we’ll be doing a matcha set/box together soon).

E Veryrare merges art with denim.

F E Veryrare founder Raf Reyes.

G Veryrare infuses denim with a rebellious spirit.

What’s the best compliment you’ve received about your brand? Being told that our pieces are timeless and inspirational.

• What’s your favorite city to visit for fashion inspiration? Tokyo.

If Veryrare was a music genre, what would it be?

Probably a fusion of synthwave, ambient, phonk, punk, indie, house, hip-hop/rap, jungle, DnB, UK garage, drill, trap and jazz.

What’s the most important thing you want customers to feel when they wear your designs?

All the pieces I release are designed to be worn like armor or second skins for the absurd reality we navigate daily. So flex them, rock them proudly. They say things you don’t need to express aloud; they speak for you.

Source: Cotton

2) Source: Marielis C. Zambrano

on

(2021).

p. 112030. https://doi.org/10.1016/j.marpolbul.2021.112030.

by Angela Velasquez

baytech-hms (Hand Made Stone) is settling into its first international office space in London.

In October, the Turkish supplier of ecological pumice stone alternatives, won first prize in the Techstyle for Social Good Global Innovation Challenge organized by The Mills Fabrica for its innovative and sustainable approach to denim washing. The grand prize includes mentorship from the sustainable materials science company Pangaia, complimentary office space in London, and incubation by The Mills Fabrica—support that’s providing valuable resources to propel Baytech-HMS’s growth.

SJ Denim caught up with Beyza Baykan, founder and managing director of BaytechHMS (Hand Made Stone), to learn how the company is leveraging its winnings to take their impact to the next level.

SJ Denim: What do you aim to achieve during the incubation?

Beyza Baykan: My primary goal is to leverage this opportunity to scale HMS into a globally recognized leader in sustainable denim washing solutions. Specifically, I aim to secure strategic funding, expand HMS’s reach in retail and manufacturing, strengthen our business strategy, enhance industry collaborations and build community and awareness. Ultimately, my goal is

to leave Mills Fabrica with a stronger network, increased adoption of HMS, and a clear pathway for long-term growth in both industrial and retail markets.

SJD: What have you learned from Pangaia’s mentorship?

BB: One of the biggest lessons we’ve learned so far is the importance of having a welldefined brand bible—a clear and structured identity that guides everything from our messaging to visual storytelling. This realization is helping us strengthen HMS’s presence and communicate our values more effectively.

SJD: What’s unique about denim style in London?

BB: Being in the Camden-King’s Cross area, steps away from Central Saint Martins, has exposed us to some of the most creative iterations of personalized denim. The influence of fashion students is undeniable—many have distinct, eye-catching styles. London street style is a mix of vintageinspired workwear, oversized and deconstructed silhouettes, and bold customization. Denim is a key staple throughout the city, whether styled in a bold, statement-making way or kept refined and timeless.

MY PRIMARY GOAL IS TO LEVERAGE THIS OPPORTUNITY TO SCALE HMS INTO A GLOBALLY RECOGNIZED LEADER IN SUSTAINABLE DENIM WASHING SOLUTIONS.” Bayza Baykan, Baytech—HMS

E Bayza Baykan colleted the grand prize.

E E HMS is a pumice replacement that disintegrates slower and requires less water and energy to use.

SJD: What’s next for HMS after this prize ends?

BB: Our focus is on scaling up sustainably by expanding our manufacturing capacity, securing key partnerships with brands and retailers, and driving the adoption of HMS as the industry standard in both denim and non-denim washing. We also aim to deepen our global footprint. While we already sell to many countries, there are key regions where we’d like to establish a stronger presence. So, who knows? After our London adventure, we might find ourselves in yet another part of the world.

Vintage Style Research Archive Vo. 1: The Golden Age of Hong Kong Vintage Collectors is the latest tome from U.K.-based denim consultancy Endrime. The 400page book features 70 rare styles from six Hong Kong collectors David Cheng, Patrick Sui, Gary Kwan, Kenny Chiu, Victor Chu and Ricci Lau—whom Endrime co-founders Mohsin Sajid and Sadia Rafique met while teaching denim design at the Hong Kong Design Institute in 2023.

“We were invited to dinner one evening, and after dinner, these collectors started pulling out vintage from their backpacks,” Sajid said. “I just stopped them, as I immediately recognized most of the pieces from denim and workwear auction sites. I was blown away by the quality of what this group of friends had collected. One of the collectors showed me his phone and scrolled through what seemed like a never-ending collection of incredible pieces.”

That evening, Sajid agreed with the collectors that Endrime would publish a series of books about the collectors. “We returned to Hong Kong soon after, hired a photographic studio, and started cataloging the Vintage Style Research archive,” he said.

Spanning denim, workwear, military, fashion, and rare denim scraps, each garment is accompanied by detailed descriptions and historical context in English and Chinese. The book is available at Inspiration LA and Kingpins Amsterdam. It will also be available on endrime. com in May. A second volume will publish April 2026. AV

Kantamanto Social Group highlights the potential of sustainable fashion while raising awareness of the global overproduction crisis.

by Angela Velasquez

kantamanto social group is on a mission to repurpose a fraction of the textile waste discarded in West Africa and resell it to the Global North. c Founded by Anabel Poh and Daan Sonnemans, this innovative venture supports a diverse network of retailers, tailors, designers, and recyclers at Kantamanto Market in Accra, Ghana—the world’s largest secondhand clothing market. Through pop-ups and e-commerce platforms, Kantamanto Social Group showcases one-ofa-kind garments crafted from discarded denim and tapestries, while raising awareness about the harmful cycle of overproduction and overconsumption that plagues the fashion industry.

The marketplace is the product of a residency program with the Or Foundation, a not-for-profit organization working to develop solutions to fashion’s global waste crisis and the communities that are most impacted by it. The hybrid online program offers an in-depth exploration of the secondhand textile system, focusing on how vast quantities of clothing end up in Africa. Participants are encouraged to initiate small interventions in their local communities as part of the program.

“For us, we thought what if we sell these upcycled garments back to the consumer at a premium price to showcase the absurdity of the secondhand textile ecosystem,” Sonnemans said. “And that’s what we did, starting with a small exhibition in London.”

The Or Foundation estimates 15 million secondhand garments arrive weekly from the Europe and North America to the market. A community of more than 30,000 people working in the market is responsible for recirculating 25 million pieces of secondhand clothing every month through resale, reuse, repair, and remanufacturing. However, of the 15 million garments that enter Kantamanto every week, 40 percent leave as garbage because they’re too stained or damaged to resell.

DENIM IS OFTEN OF HIGHER QUALITY THAN OTHER MATERIALS MAKING IT A PREFERRED CHOICE FOR DESIGNERS WHO APPRECIATE ITS DURABILITY AND AESTHETIC.”

Though still in its early stages, Kantamanto Social Group reinvests all profits into developing the project. Sonnemans currently works with eight designers, with plans to expand. Communication with designers largely takes place via WhatsApp, and Sonnemans plans to return to the market this spring to strengthen these connections. Garments are transported using the “suitcase trade” method, where items are carried by individuals traveling between Europe and Ghana, helping to keep the operation sustainable despite its small scale.

The garments range from bleached denim kimonos to jean jackets featuring Marvel comic prints. Sonnemans explained that denim is often of higher quality than other materials like cheap synthetics, making it a preferred choice for designers who appreciate its durability and aesthetic, particularly for patchwork designs.

Support for the vendors has never been greater. On Jan. 1, an inferno of unknown origin devastated the market, killing two people and burning eight acres of stalls, or the equivalent of 60 percent of the market’s retail-facing side. More than 10,000 vendors have witnessed their livelihoods literally go up in smoke, including several of the businesses that work with Kantamanto Social Group. Two designers lost their whole shops, while others lost machinery and inventory. Sonnemans said some had to take out loans to buy new machines and have been struggling financially to get new materials to work with.

While selling one-of-a-kind garments online presents challenges— especially due to the variability in sizing—Sonnemans remains optimistic about the project’s long-term impact. He believes Kantamanto Social Group’s broader mission, to establish the market as a circular and sustainable fashion ecosystem, will resonate with consumers.

“I think it’s time to have communities like this take the lead in the conversation on how we should move to more sustainable, regenerative fashion,” he said.

most brands scale back when business slows, but Blackhorse Lane Atelier (BLA), the London-based smallbatch denim manufacturer, did the opposite by opening a second London store in SoHo last fall. c The new store is a response to the post-pandemic disruptions in denim retail and manufacturing and a strategic move by founder Han Ates to safeguard BLA’s workforce. During the pandemic, many brands faced supply chain breakdowns and turned to U.K.-based production, prompting a surge in orders. To keep up with the demand, BLA expanded its team, but as restrictions lifted, Ates said brands returned to cheaper suppliers in countries like Turkey.

“It was a business decision, so we found ourselves having to make one, either we were going to let people go, or we were going to be more creative and increase our own brand’s production,” he said. “With that, we decided to open another store in Soho, in order to look after our workforce really.”

The store is a showcase of BLA’s denim expertise as both a direct-to-consumer brand and a manufacturing partner. Around 70 percent of the products are BLA’s own denim, while 30 percent comes from small, likeminded brands from the UK and Europe with whom BLA has strong partnerships. Located at 96 Berwick Street, nestled among centuries-old buildings on the historic haberdashery street, the 700-square-foot ground floor is dedicated to jeans and fabric, while the 4,400-squarefoot basement houses BLA’s made-to-measure services. The first BLA store is just a 30-minute tube ride away in Coal Drops Yard. Ates steps away from BLA’s Walthamstow factory once or twice a week to visit the stores. He compares those days to a crash course on

customers’ expectations and lifestyles. “It teaches us so much like how they love the fact that the jeans are made in London. That’s important for them,” he said.

Providing top-tier service is also central to BLA’s mission of creating the best jeans in the world. By not hemming any jeans in advance, BLA ensures that customers can personalize the fit right in the store. “We create that kind of constant connectivity on the spot with the customer, so that we understand them a bit better. It’s a two-way street,” Ates said. “They see our professionalism and understand our quality.” That commitment to quality, combined with competitive price points, has resonated with consumers. BLA’s sales grew by 40 percent last

THEY SEE OUR PROFESSIONALISM AND UNDERSTAND OUR QUALITY.” Han Ates

year, and despite the high costs of producing denim in London, eliminating wholesale and retail profit margins allows BLA to offer Italian denim jeans for for 220-240 pounds and Japanese denim jeans for 280 pounds—prices that Ates notes would typically exceed 700 pounds through traditional wholesale channels.

The SoHo store serves as a key asset in BLA’s efforts to raise awareness not only for the brand but for higher quality denim. Ates said consumers are increasingly recognizing that they can purchase a pair of locally made small batch jeans crafted from premium fabrics at a price comparable to mass-produced options.

“I think people are more knowledgeable, and they really want to invest in good quality clothes,” he said.

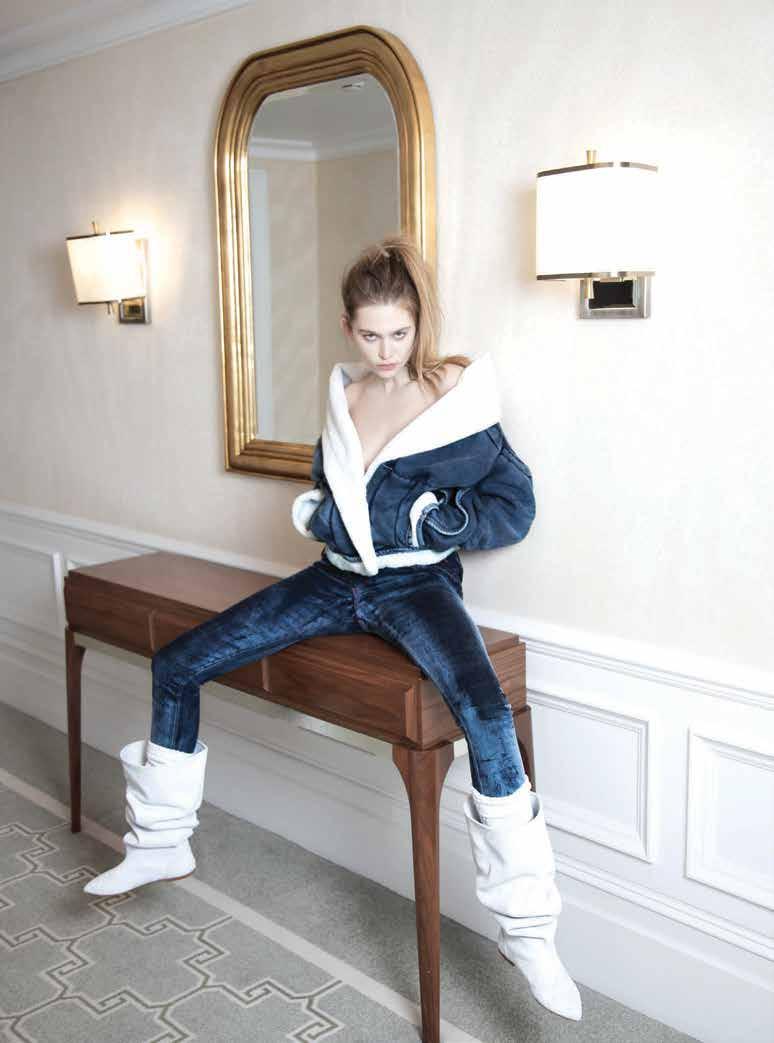

“there’s a certain intimacy in the details we’re not meant to see,” according to Ukranianborn, London-based designer Masha Popova. c With her Fall/Winter 2025 collection, the creative seeks to strip away the polished veneer inherent to dressing for public view, instead exalting the theme of “unfiltered dressing”—clothes that are “lived in rather than styled.” c Since launching her eponymous brand three years ago, Popova said she’s rarely stayed in one place for more than a few months, never fully unpacking. Her jet-setting lifestyle, along with stumbling upon a book by photographer Sophie Calle called “The Hotel,” fed into a desire to design a collection that feels ephemeral and maybe a little undressed.

“She was working as a chamber maid in a hotel,” she said of Calle, “and she was taking pictures of empty rooms while she was cleaning; unpacked suitcases and lipstick on the mirrors and all the things people have forgotten.”

Speaking with SJ Denim, Popova said she was inspired by “temporary spaces—how you make them your own and leave your trace behind.”

Bringing the feeling these images evoke to life, Popova’s line of womenswear, dubbed “Do Not Disturb,” features dynamic draping reminiscent of hotel curtains, a jacket cut like a bathrobe with an off-the-shoulder shawl collar and shirting with a texture like rumpled bedding.

While the line contains an array of garments—tops, dresses, outerwear and trousers—made with different materials, denim weaves its way through the collection like the protagonist of an epic odyssey.

“Transforming the garments and fabrications, for me, is one of the most

important things,” she said. “That’s why I really like denim, because it’s a very moldable, transformative fabric. It’s like an empty canvas, and we can reuse it through seasons and transform it, so it always looks different.”

Structure versus softness and the interplay between tradition and explorative new technique are on display across the line. Ever-present in Popova’s catalog, denim “is distressed, aged, and treated, shaping structured yet slouchy silhouettes.”

It’s a fabric she continues to come back to even as her perspective shifts with each new collection. “It’s in a way a sustainable approach, because by using these fabrics all the time, I never have unused stock,” she said. “I’m reusing it from season to season. And now I take the same approach with other fabrications.”

That approach is a unique one that sets her garments apart from the pack, even within the endless scroll of an online marketplace like

SSENSE or Revolve. It relies on the strategic lifting of color from the denim—whether it’s blue or a more unconventional hue—to create patterns and motifs that wrap around pant legs and swirl across shirts. The fabric is overlaid with hand-painted wax, shielding certain areas from treatment with dye and creating unexpected textures and aged effects.

“When I was still at school, I did some little tests, but obviously I had to do it at home with bleach,” she explained—a process she knew was unpolished, unsustainable and tough to replicate at scale. “My teachers were like, ‘Wow, this is exciting, why don’t you develop it more?’”

Following university, Popova worked with Italian denim finishing technology firm Tonello to develop her signature. “I learned the technical side of denim treatments with them initially; I just went down for a few days, and we were figuring out how to make my samples, but in sustainable way.”

“We tried different ways of doing it, like ozone laser and washing, and every season I try to take it further with different dyes and cold dyes,” she explained. “They’re amazing experts, they love the challenge. And we would always come up with amazing techniques.”

In addition to dyes and washes, Popova plays with texture, manipulating denim to mimic other fabrics. “I do reinterpret, for example, this season a bonded denim like a fake fur,” she said. “As we finish it, it looks like a shearling jacket.” The indigo, ecru and soot palette of the denim offering is complemented by the fall line’s more classic fabrics, like cotton and velvet, in metallics, washed blues, earth tones and neutrals.

While Popova used to produce her denim pieces in Ukraine and more recently London, she’s had to find new partners due to the ongoing war and the closure of denim laundries where she is now based. She’s recently made inroads with new producers in Spain but said

TRANSFORMING THE GARMENTS AND FABRICATIONS, FOR ME, IS ONE OF THE MOST IMPORTANT THINGS. THAT’S WHY I REALLY LIKE DENIM, BECAUSE IT’S A VERY MOLDABLE, TRANSFORMATIVE FABRIC.” Masha Popova

finding suppliers capable of replicating her unique approach, even on a small scale, is the most pressing issue with sourcing. “That was the biggest challenge: figuring out a new place that will be able to do our treatments,” she said. But navigating those hurdles can sometimes lead to discovery. “You know what you expect [from a process] and what you already know, you can sort of improve,” she said. “But the little things that come from mistakes are always the most exciting.”

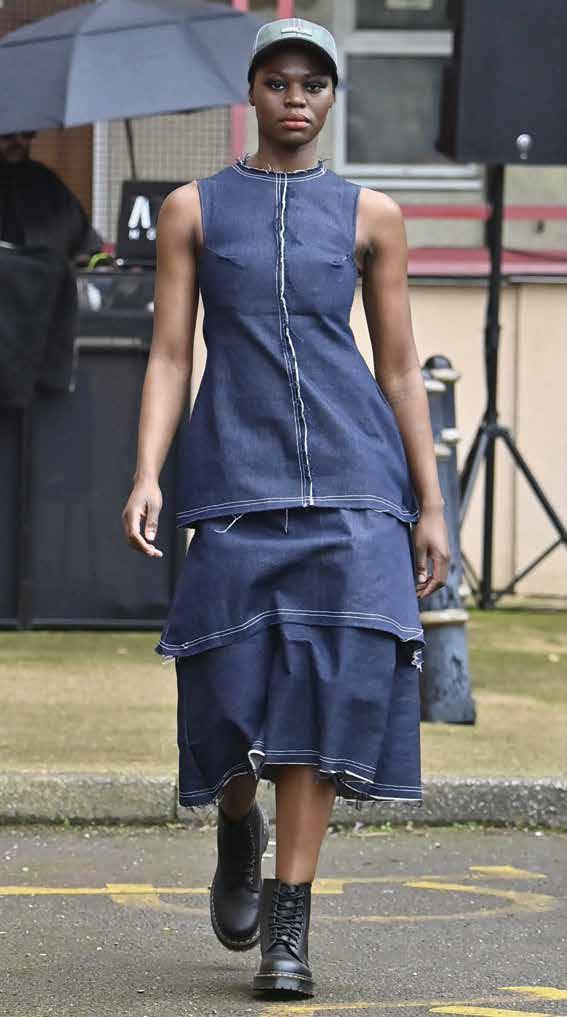

denim took center stage in New York, London, Milan, and Paris, each city showcasing unique interpretations of this timeless fabric. In New York, designers highlighted dark washes, bootcut and ’90s skate influences, while London designers experimented with deadstock materials.

Milan’s offerings included low-rise jeans and embellished denim. In Paris, designers leaned into avant-garde approaches with material mixing and layered garments. Each city brought a distinct take on denim, from practicality and nostalgia to experimental and artistic designs.

Ultra-wide-leg jeans, denim coordinates, and deep, dark washes made a striking impact at New York Fashion Week. Designers showcased their F/W 2526 collections, seamlessly blending denim with everything from elegant dresses to sleek minimalist suiting and cropped leather jackets.

Despite the slowdown of viral fashion cores and aesthetics, the New York runway was home to several distinct fashion tropes.

R13 delivered the fit of the moment—the bootcut—in a collection that introduced a goth element to the brand’s signature downtown New York vibe. Dark floral denim, inky blue slim jeans and cuffed and cropped jeans showed off witchy black boots.

The ’90s skate-inspired jeans in Coach’s presentation were crafted from repurposed secondhand denim. The mostly light wash baggy jeans puddled over sneakers adorned with charms and pompoms. Some were layered beneath 1920s style day dresses.

Sandy Liang kept the Polly Pocket aesthetic alive in a collection inspired by childhood. Fur trimmed the hems of ankleskimming jeans, a cropped jacket and matching miniskirt.

Cinq à Sept joined the boho revival with a collection of dark wash denim pieces styled with suede jackets, Penny Lane coats, studded belts and fringe handbags.

Dark wash jeans grounded several collections including Khaite and Tory Burch, which presented a structured utilitarian jacket. Ulla Johnson showed a dark jean caplet jacket and matching denim trousers. Tibi experimented with celestial dye effects on dark denim, as well as jeans that zipped off into Bermuda shorts.

Calvin Klein referenced French workwear with a faded blue jacket and jeans in its return to the runway. Black jeans and baggy light wash jeans were also part of the minimalist collection. Eckhaus Latta played with grayscales and presented an abstract interpretation of animal prints on jeans. Tanya Taylor continued to surprise with proportions with a range of vivid indigo denim.

F Skate

F Dark washes

F Boho

In London, emerging designers and established names took a bold departure from traditional denim.

Chopova Lowena continued to recycle folkloric fabrics and deadstock materials in a collection that referenced dream girls and the U.K. rave culture of the late ’80s. “Rebellious brightness” permeated the collection of pleated denim miniskirts and dresses, each adorned with childlike bands of beaded inserts. A denim skirt was layered over jeans—both trimmed with fur and decorated with punk patches.

Luxury streetwear designer Abigail Ajobi showed “I’m not English, I’m British,” a collection patchwork and warped tartan juxtaposed to dark wash denim pieces with unfurled seams. Silhouettes spanned flare jeans with center seam details to men’s paper bag waist jeans and jean shorts.

In his London Fashion Week debut, Jawara Alleyne stacked cargo denim shorts over jeans. Other styles in the collection called “Construction,” were made from deconstructed jeans with different washes, stitched and pinned together.

Following a lavishly embellished Spring 2025 collection, Simone Rocha dialed down the extravagance with pared-back denim pieces. A distressed denim jacket was cinched by a chain belt with an engraved padlock. A distressed midi skirt and shrunken jacket with pearl baubles shared a blue-gray wash. The denim was balanced by several black leather and fur looks.

Sinéad O’Dwyer, a semi-finalist for the 2025 LVMH prize, used a tinted blue-gray wash for several body-hugging looks as well. In a show that promoted body diversity, the silhouettes of bodysuits, collar-less jackets and jeans were emphasized by seam details and hi-low contrasts.

Gradient denim pieces that went from dark into to white were part of SRVC’s collection. Jeans and skirts were embellished with long straps and undone belts and styled with plaid shirts and deconstructed athleisure jackets.

F Deadstock F Ombré F Distressing

Explore Soorty’s AW2627 Collection, Denim Reflections.

Powered by the sun and the wind. Transforming waste. Empowering communities. Traceable by DNA marking & blockchain.

Denim was artfully woven into collections presented at Milan Fashion Week.

Some jeans were a blast from the past for millennials who grew up with low rises and flare fits in vogue. References from the aughties underpinned several collections.

Diesel delivered the week’s viral moment with its collection of bum-bearing low-rise jeans. In general, the collection balanced classic straight fits with extreme silhouettes like distressed denim hot pants and micro skirts. Jackets were often collarless; coatings mimicked the appearance of lamination and distressed houndstooth was carried through men’s and women’s pieces.

Dsquared2 celebrated its 30th anniversary with a collection that featured all the brand’s hallmarks, including glittery embellishments, paint splatter and brash washes. Jeans with peel-away constructions, shortshorts and skinny overalls with a micro bib were among the label’s boldest denim looks.

Italian cinema served as the blueprint for Blumarine’s dramatic denim pieces. Creative director David Koma decorated faded blue and black jeans with 3-D denim flowers made from the same material, cutouts and masses of silver metal hardware applied in organic shapes.

The mostly low-rise slim jeans flared over pointed toe stilettos and were styled with large medallion-like belts.

Denim broke up an abundance of black leather and silk prints Versace’s baroque collection.

Slouchy fits with grungy washes were embellished with baubles, distressing and color contrasting patchwork. Men’s jeans were finished with leopard print trim, crystals and clear sequins for a liquid-like shine.

Giuseppe di Morabito and Philipp Plein also showed crystalcovered jeans.

Ferrari and Federica Tosi experimented with washes with crinkled effects. MSGM added dimension to loose-fitting jeans with purple and yellow tints.

Colorful floral prints gave Etro’s denim pieces a ’70s flower child vibe. Vivetta and Ports 1961 kept denim traditional with inky dark washes.

F Bling

F Crinkle effects

F Low-rise

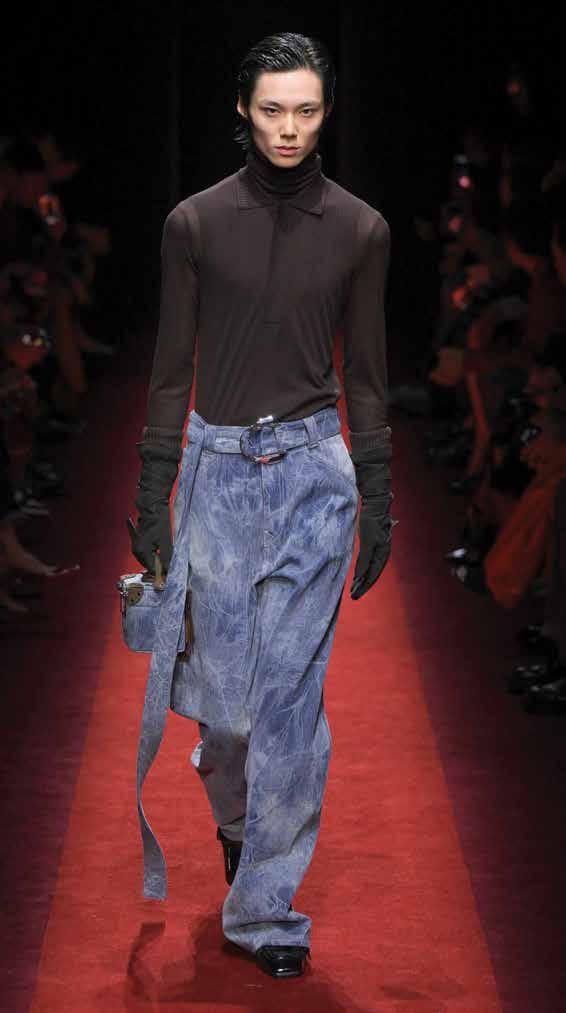

Designers in Paris leaned heavily on avant-garde silhouettes, textures and shadowy contrasts.

Material mixing made up part of Rick Owens’ tattered and frayed denim skirts and column dresses. Junya Watanabe spliced indigo jeans with swaths of black fur. Ukrainian designer Litkovska pieced denim with tailoring fabrics to create skirt and pant layers.

In a collection inspired by opulent and grand interiors, Ganni played with velvet-touch zebra denim, cozy knit denim and pearlescent denim. Skirts layered over baggy jeans created a peplum silhouette.

Ottolinger reimagined the basic skinny jeans with shadow pockets and pocketing and knee panels that peeled away from the body. In keeping with the bum-barring trend set a week prior on the Diesel runway, Duran Lantink showed bare back sculptural jeans that folded away from the body. Chanel married the transparency trend with denim prints.

Center seam details continued to trend thanks to labels like Gaucher and Alainpaul, which added undone hems to baggy styles. Sharp center creases highlighted the contrast washes Dice Kayek’s collection.

There were elements of near nostalgia in collections as well. Chloé maintained its bohemian aesthetic with split hem flare jeans. Coperni’s denim had an early 2000s vibe with tinted bootcut jeans, miniskirts and shrunken jackets. Isabel Marant brought a New Wave edge to men’s and women’s denim, mixing mini wrap skirts and vests with red tartan tops.

F Center seams

F Layered garments

F Opulent textiles

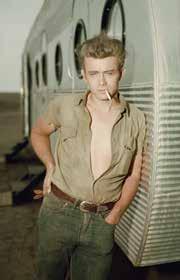

the evolution of fashion from offering comfort and security in 2020 during the uncertain early days of the pandemic to becoming an expression of joy and freedom in 2022 as consumers emerged from lockdown— perfectly illustrates how trends capture the zeitgeist. Denim, with its deep ties to cowboys, James Dean, and counterculture movements, frequently offers a window into the mindset of youth. From its rise as a symbol of teenage rebellion in the ’50s to its role as a canvas for political expression in the ’60s, and later its embrace by ’90s hip-hop culture, denim has consistently been at the forefront of shaping cultural identity. c Fashion responds to social shifts, but what happens when there’s no time to pause and take stock of unprecedented events? And how do brands navigate self-expression during a time of extreme divisiveness?

From an industrial and business perspective, Celik said global crises will push the denim industry in two main directions that will disrupt supply chain structures. “Political instability, trade restrictions and resource shortages will force brands to rethink supply chains. We need to expect more localized and close market production hubs to reduce reliance on unpredictable global markets,” she said. Secondly, brands are examining deadstock and circular denim solutions. Celik said these solutions will shift from niche to mainstream as businesses grapple with rising raw material costs and sustainability mandates.

“Nowadays, amidst conflict, fashion is trying to balance between function and expression,” said Ana Paula Alves de Oliveira, founder and strategic director of Be Disobedient, a denim and creative consultancy company.

Recent examples of street style reveal a shift toward denim with extreme silhouettes, DIY details and brash washes—perhaps a sartorial cry for help or a declaration of non-conformity in the wake of more demure trends like quiet luxury and trad wife. “We see distressed finishes, dirty dyes and worn-out textures evoking survival, alongside upcycling and material reuse as a response to scarcity. Simultaneously, deglobalization fuels a return to local craftsmanship, merging tradition with innovation. The industry is not just adapting; it’s redefining sustainability through necessity,” Alves de Oliveira said.

“We have been in a cycle of unprecedented times for some years now, the times just keep getting more and more unprecedented,” said Amy Leverton and Shannon Reddy of the consultancy, Denim Dudes. “Some sociopolitical figures are estimating that we are witnessing what is known as an ‘extinction burst’ which sounds terrifying, but for the more optimistic, it actually points toward the idea that what we’re seeing socially, politically and economically is the last major grasp at outdated ideologies and systems, and the tension we’re experiencing is essentially the growing pains before a transformation for the better.” This ideology is being applied to fashion as well, from the creation of new supply chains and the decline of aspirational purchases from luxury brands to consumers investing in one-of-one, small-batch designers that support individualistic style instead of viral micro trends. As news cycles, global affairs, legislation and technological advancements become overwhelming, Denim Dudes said consumers are retreating from the expectation to keep up with it all and turning their attention inward toward themselves and hyper local communities.

“Denim, at its core, has always been a mirror of societal shifts—whether it’s rebellion, resilience or reinvention. In a world currently on fire, denim won’t stay untouched. Denim has always absorbed the world’s tension and transformed it into wearable narratives,” said Sinem Celik, Bluprojects sustainability expert.

Denim Dudes sums up this feeling of global tension and polarization in Superpower Pivot, a Fall/Winter 2025-2026 theme that places designers’ heritage, opinions and experiences front and center.

American Sabotage—the brand AWGE, A$AP Rocky’s creative agency, presented at Paris Fashion Week Men’s last summer—is a visual example of the trend, Denim Dudes said. The collection featured American flag skirts, U.S. Marine jackets with restrictive silhouettes, and jeans with stacked waistbands.

“In the past we’ve seen brands, artists and consumers shy away from directly referencing political stances and letting their work speak and be interpreted for itself. Creatives are now not only directly vocalizing their viewpoints through their work, but they are also commandeering iconography typically associated with opposing viewpoints and re-writing the narrative around it and what it could represent in the future,” Denim Dudes stated.

The runway is an ideal stage to bring stories to life. GmbH founders Serhat Isik and Benjamin Alexander Huseby explore their heritage as Muslim immigrants in Germany in collections. Denim Dudes noted how they’ve been vocal about their heritage and beliefs when putting on runway shows, even aligning with the United Nations a couple of seasons ago. Mexican American designer Willy Chavarria played the audio of Bishop Budde’s sermon at President Trump’s inauguration during the finale of his Paris show in January, “giving grace and power to the immigrant and queer community,” Denim Dudes said.

“Fashion can be a really rich vehicle for symbolism and social signaling; these designers really lean into their platform in order to invoke positive change and unity in a time of division,” Denim Dudes said.

Christine Rucci, denim expert and founder of Godmother NYC, Inc., is less impress with recent efforts to subvert. “I think the division of runway, luxury, and streetwear has been blurred,” she said, adding that most fashion houses are making inauthentic dupes of denim worn by youth culture or made by small designers.

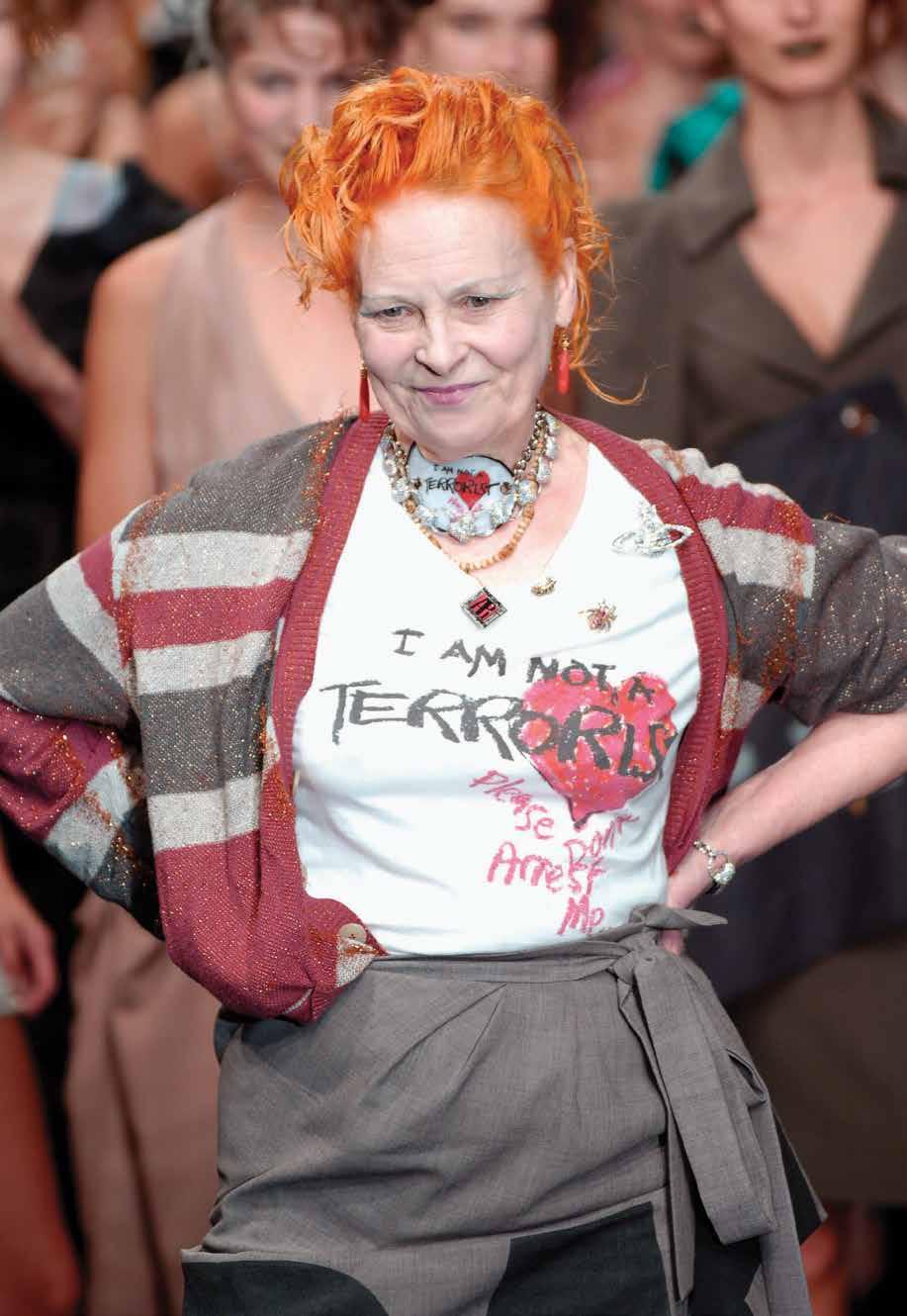

What it lacks, she said, is the outspoken political activism of designers like Katherine Hamnett, Vivienne Westwood, Claire McCardell and Franco Moschino.

Alves de Oliveira argues that disruptive fashion can be subtle. Stella McCartney seamlessly blends sustainable materials with red carpet-worthy designs, with the only noticeable clue of the designer’s passion for the environment being the adorable animals featured in her ad campaigns.

“In this century, Stella McCartney is the undisputed leader in turning fashion into a manifesto for innovation and sustainability. She has set the standard for how responsibility, ethics, and creativity can coexist, proving that well-communicated values become powerful industry drivers,” Alves de Oliveira said.

On the other hand, Alves de Oliveira said Ukrainian denim designer and Adidas collaborator, Ksenia Schnaider, embodies resilience as her country remained embattled in a war with Russia. “Operating between the U.K. and Ukraine, her brand transformed crisis into strength, proving that fashion can be a direct response to geopolitical reality,”

Alves de Oliveira said. “Both illustrate that transparency, honesty, and purpose are not just possible, they are essential. And both are women, which speaks volumes.”

Off the runway, social media has become the de facto platform for brands to address social and geopolitical issues.

In 2022, following the U.S. Supreme Court’s decision to overturn Roe v. Wade, several women’s denim brands took to social media to voice their opposition. Brands like Good American, Frame, Citizens of Humanity, and Madewell publicly expressed their dissatisfaction with the ruling and shared resources advocating for reproductive rights.

Under Chip Bergh’s leadership as president and CEO for 12 years, Levi Strauss & Co. (LS&Co.) emerged as one of the fashion industry’s most outspoken advocates, championing causes such as gun violence awareness, reproductive rights protection, voting rights protection and LGBTQIA+ equality. “Saturday Night Live” poked fun at the denim giant’s wokeness in 2017 with a spoof ad featuring cast members dressed in ill-fitting gender-free jeans. The company also regularly faced backlash from the NRA for

DENIM, HAS ALWAYS BEEN A MIRROR OF SOCIETAL SHIFTS—WHETHER IT’S REBELLION, RESILIENCE OR REINVENTION. IT HAS ALWAYS ABSORBED THE WORLD’S TENSION AND TRANSFORMED IT INTO WEARABLE NARRATIVES.” Sinem Celik, Bluprojects

its left-leaning opinions on guns. In an exit interview last year with Sourcing Journal’s sister publication WWD, Bergh said, that “navigating divisiveness” and geopolitics had made his job more challenging.

LS&Co. has seemingly stepped off the proverbial soapbox since Michelle Gass’ takeover in early 2024, choosing to focus on more bi-partisan topics like voting registration, and promoting its nostalgic ad campaign with Beyoncé.

“Brands are becoming more selective in their activism, navigating hyper-polarization and economic risks. While Levi’s may no longer make sweeping statements, its commitment is evolving—moving from loud declarations to tangible actions,” Alves de Oliveira said. “The key is authenticity. Empty messaging is no longer enough; brands that align their actions with their values will remain relevant and influential.”

G

Celik anticipates that there will be some disruption on the branding and marketing off and greater shift toward activism and transparency. “More brands will align their messaging with socio-political themes, positioning denim as a statement—whether through war-time aesthetics (militaryinspired, patchwork, survival gear) or messages of unity and resilience,” she said. “Transparency will become non-negotiable. With heightened consumer awareness, brands will be forced to show proof of ethical labor practices, material sourcing, and true circularity rather than just greenwashing.”

Indeed, turmoil is not a time for brands to fly under the radar or abandon activism in it’s many forms. Target, which announced in January that it would end its diversity, equality and inclusion initiatives, has become a target of a 40-day boycott, a lawsuit from shareholders and a diatribe of comments on their social media accounts. Over the last 12 months, Denim Dudes said there’s been an unprecedented amount of brand and product-specific boycotts, mindful purchase worksheets going viral on social media, and an uptick of content focused on ethical retailers to support, and ones to avoid.

Instead, Alves de Oliveira said companies must learn about the issues that affect their customer base, engage with consumers through authentic dialogue, and practice active listening. “Those who do will not only remain relevant but will also shape the industry’s future,” she said.

In an era of heightened visibility and exposure, where social media amplifies calls for cancellation into powerful nationwide boycotts, and tolerance for differing views continues to diminish, Alves de Oliveira remarked that every statement now carries a double-edged sword. Yet, she emphasized, “Avoiding reality is not neutrality; it’s willful blindness.”

“Fashion has always been a means of communication, and denim is not an exception. In times of crisis, brands with a solid audience have the opportunity and responsibility to foster meaningful conversations,” she said.

baggy, designer, artisan —those are just a few themes that have disrupted the industry, transforming blue jeans from durable workwear to statement-making fashion. How they’re executed has changed with the times—influenced by the ideas of new generations and talent—but they continue to be symbols of denim’s evolving style. Here’s a look at how out-of-the-box ideas continue to transform jeans.

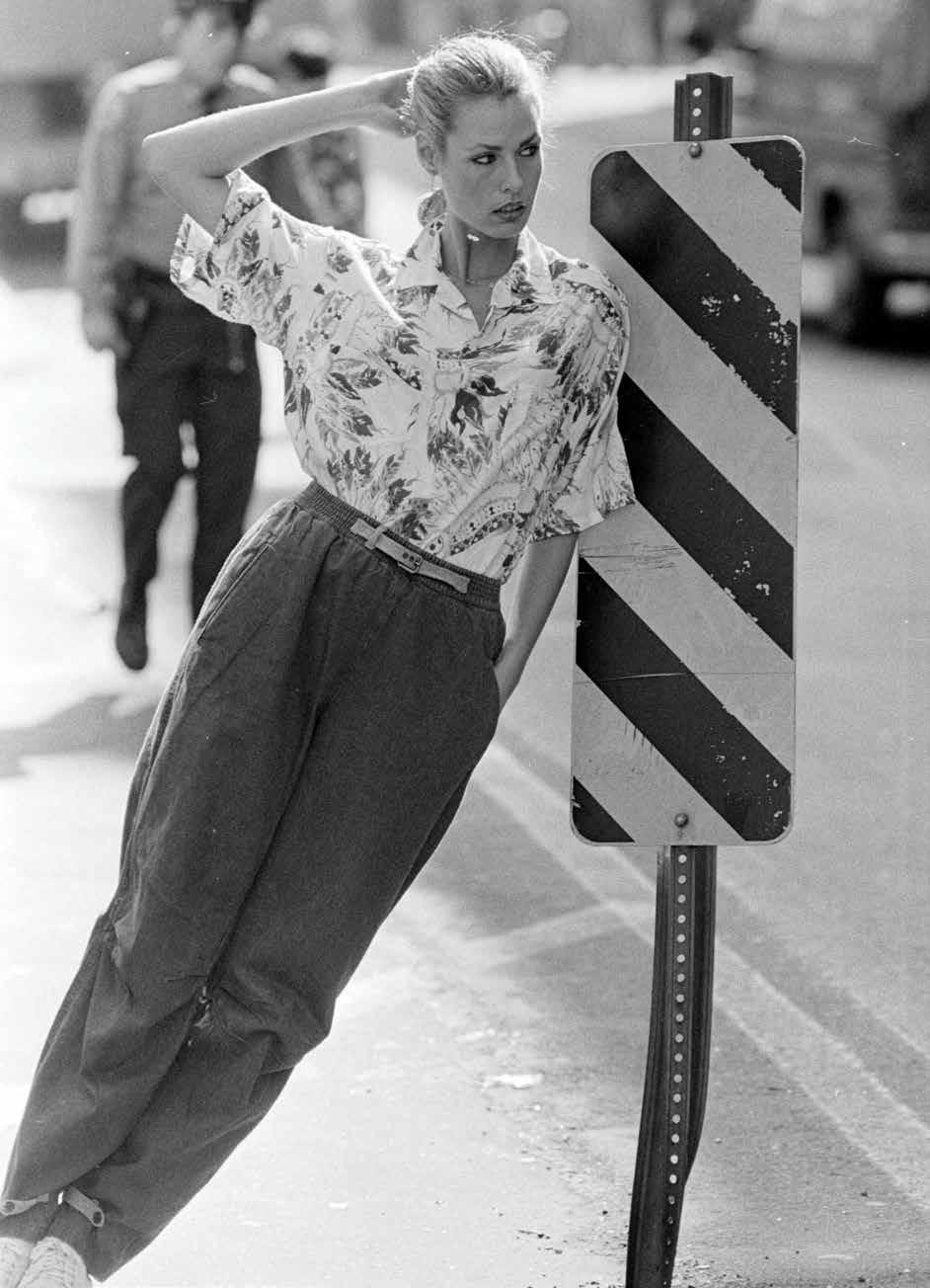

French designers Marithé Bachellerie and François Girbaud, who introduced the first baggy jeans to fashion at the beginning of the 1980s, were at the forefront of denim and jean style innovation. Produced in Italy, under the brand label, Closed, the baggy jean replaced the disco era’s tighter fits and was a welcomed change for consumers in the U.S.

The style wove a new frontier in denim, inspiring a multitude of new fits and styles still seen in the jean category today. The trend has come and gone and come back again, now with runway appeal and streetwear edge as the go-to jean fit for a generation that values comfort and fashion.

1 Baggy jeans by Marithé et François Girbaud for Closed in 1979.

2 Baggy jeans from Tommy Hilfiger’s Spring 2025 ready-to-wear show.

Logo Mania

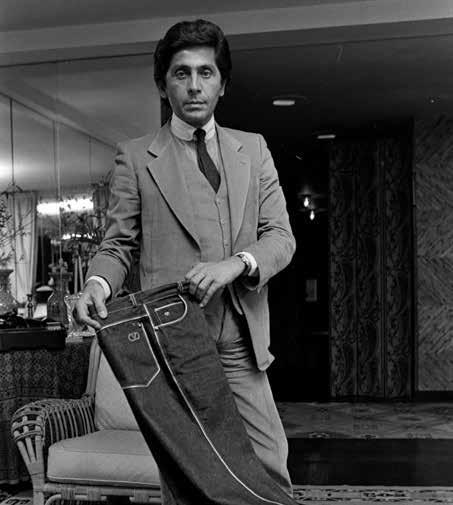

The lasting impact of the designer denim revolution may hinge on one key aspect: branding. Calvin Klein was the first to rally the industry around more stylish branded elements for fashion-conscious women. His straight cut, slim fit, dark blue jeans hemmed perfectly for strappy high-heel dancing shoes were perfected for the moment. However, the pocket size and placement, with the signature loop stitch and designer label sewn at the top edge of the right pocket, immediately carved out a niche category in fashion.

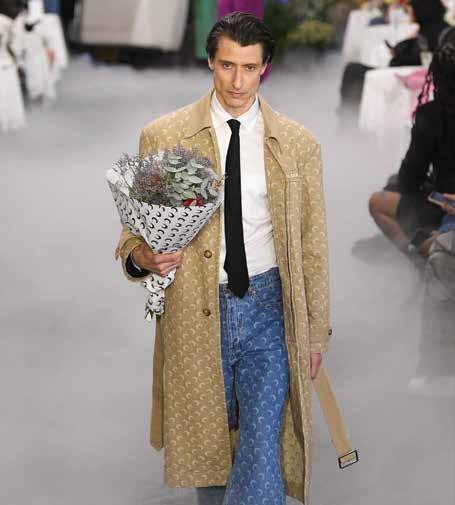

Up until that point, branding served a more functional than fashionable purpose on many women’s jean styles. Noted fashion labels including Valentino and Pierre Cardin, and emerging jean brands like Sergio Valenti, Fiorucci and Bonjour, to name a few, followed suit, assisting the creation of what is now a global billion-dollar industry. The signature pocket design and branded label served as an ID of distinction. Decades later, designers are amplifying their logo with head-to-toe prints. Elevated by the next generation of creatives, logo mania will cement the status quo for designer denim today.

1 Designer Valentino Garavani introduces his new line of designer denim label, Valentino Viva, in 1979.

2 Logo jeans from Marine Serre’s Fall 2024 readyto-wear runway show.

Crafting Culture

From embroidery, beadwork, metal studs and patchwork to purposely splashed paint and rips and tears, jeans have been an artistic canvas for designers and consumers alike for decades. While no one person is credited with the trend, the popularity of the doit-yourself embellishments gained more acceptance during the 1970s when the counterculture used jeans by Levi’s, Lee and Wrangler to communicate views on protest and power.

Artisan denim grew more refined in the 1980s and 1990s, as jean culture coincided with streetwear and designer denim. Hip-hop brands that were big on bling, like Rocawear and Baby Phat, joined the runway with established denim designers like Tommy Hilfiger and Ralph Lauren. Jean Paul Gaultier was the first to debut denim in the haute couture in 1999.

DIY continues to inspire in a post-pandemic world, even becoming a part of the consumer experience. Levi’s Tailor Shop, where customers can add patches, fringe and other custom baubles, is one example of how the brand has successfully reestablished itself as the go-to denim brand for a new generation.

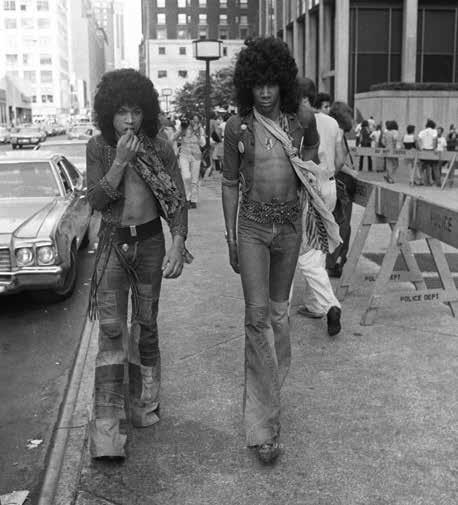

1 Concert goers in DIY patchwork denim outside The Rolling Stones concert at Madison Square Garden in 1975.

2 Imaan Hamman on the runway in painted and embellished denim from Ralph Lauren’s Spring 2024 collection.

Fashion Icon for Self-Expression

Jeans have a long been a cultural conversation, one often as complicated as their history. Their evolution as a symbol of rebellion is connected to youth culture in the 1950s and 1960s. Jeans have often been a marker of protest and solidarity during decades of activism. Jeans they continue to represent durability, style and personal expression. Those who admire them exude cool confidence in their own unique way.

From early purveyors like Marlon Brando and James Dean to Marilyn Monroe and Katherine Hepburn, and musicians like Bob Dylan, Bob Marley and Joan Jett, these icons helped propel jeans to their ultra cool status. Fashion influencers from Jane Birken to Yves Saint Laurent have also worn jeans to embody personal style, uplifting their social status. Today, jeans go from day to evening with names like A$AP Rocky giving them red carpet approval and Pharrell Williams, whose love for denim goes beyond fashion, continuing to elevate their iconic status.

1 Yves Saint Laurent on the roof of El Hanch, his home in Marrakech, Morrocco in 1972.

2 Pharrell Williams at Paris Fashion Week in 2023.

the denim industry has undergone a remarkable transformation driven by a blend of technological innovations and sustainable practices. Advances in stretch denim have reshaped the workwear fabric’s place in fashion. Cutting-edge finishing technologies have not only enhanced the look and durability of denim but also reduced water and energy consumption. Integrating artificial intelligence and 3D prototypes has streamlined design processes, enabling more precise, personalized, and efficient production methods. Additionally, regenerative agriculture and textile recycling have emerged as vital solutions to address environmental concerns. Together, these innovations are redefining denim, making it more sustainable, efficient, and adaptable to the ever-changing demands of the modern consumer. c Here, industry experts discuss the impact of these innovations and how they continue to evolve. F

“Denim plays a vital role in moving towards a more sustainable fashion industry and the role of recycled fibers is huge. This is because denim is particularly resource-intensive to produce, consuming significant amounts of water and chemicals, and using just a small percentage of recycled cotton fiber can make huge environmental savings without compromising on quality,” said Matthew Neville, chief commercial officer of Recover. This familyowned materials science company launched the Recover brand of recycled fibers in 2014.

As recycling technology advanced and sustainability concerns rose, the denim industry began to wake up to this possibility. Neville said a big shift came as brands like Levi’s began incorporating recycled cotton into denim in the mid-2010s and making it more mainstream.

Indeed, recycled cotton has increasingly become a key component in denim production. However, achieving the quality and scale necessary to make a meaningful impact wasn’t always guaranteed. Significant investments made by denim mills in advanced mechanical textile recycling systems have greatly accelerated the production of recycled cotton, positioning these innovations as crucial drivers of circularity in the industry.

“With increasing demand for recycled fabric content, brands are encouraging suppliers to expand product offerings with both post-consumer waste and post-industrial waste cotton,” said Ali Tekin, AGI Denim’s R&D director.

“When our leadership first invested in mechanical textile recycling, there was curiosity but essentially no clear requirement for recycled cotton from the brands. Today, we are proud to say, that nearly all our clients require it in their fabrics and that policy is built into their sustainability goals. To go from that original status quo to the current environment where exciting conversations are had about what else we can provide from recycled viscose, lyocell, polyester and even linen—that is inspiring,” he said.

Last year, AGI produced more than 30 million meters of fabric with recycled cotton.

Recycling technology has made denim production more resource-efficient by reducing waste and minimizing its environmental footprint, Tekin added. Having its own recycling system and supply chain gives the vertically integrated mill greater control over its products from an earlier stage.

Additionally, because recycled fiber requires more optimization in downstream production, it has led the Pakistani mill to assess different parts of our operation for inefficiencies.

Recent investments have been designed with recycled fibers in mind, ensuring all processes are optimized for it. Overall, Tekin said it has encouraged the company to take a more holistic approach to making denim with recycled fibers.

“AGI Denim’s leadership has a history of investing in new technologies, and we are proud to say we were one of the pioneers who brought denim recycling by introducing one of the first dedicated mechanical cotton recycling plant in Pakistan,” Tekin said. “The technology has changed a bit since then, to say the least, but our commitment to turning waste denim

into new fibers and materials has not altered. Last year, we produced over 30 million meters of fabric with recycled cotton.”

Siddiqsons’ investment in recycling machinery has enhanced sustainability, reduced waste, lowered production costs, and strengthened its market position by offering eco-friendly denim solutions. The Pakistani mill began investing in cotton recycling in 2013, integrating advanced recycling machinery into its operations. Siddiqsons’ setup includes post-industrial waste and postconsumer waste plants, a waste recycling plant, and a recycled waste yarn plant, enabling the company to minimize waste, enhance resource efficiency, and contribute to a more sustainable denim industry.

The mill recycles 14,400 kg of waste yarn annually and has a shredding waste recycling capacity of over 4,380 tons annually.

“Textile recycling machinery has significantly enhanced sustainability in the denim industry by minimizing waste, optimizing resource utilization, and enabling large-scale recycling of blended fabrics,” said Abbas Jan, Siddiqsons director of sales and marketing.

“Beyond promoting circularity, investing in recycling machinery enhances resource efficiency, reduces production costs, minimizes environmental impact, and strengthens compliance with sustainability regulations.”

However, Jan noted that challenges persist in securing cost-effective raw materials, traceability and maintaining fiber quality,

THE TECHNOLOGY HAS CHANGED A BIT SINCE THEN, TO SAY THE LEAST, BUT OUR COMMITMENT TO TURNING WASTE DENIM INTO NEW FIBERS AND MATERIALS HAS NOT ALTERED.”

Tekin, AGI

necessitating continuous innovation and collaboration.

Zahra Ahmed, Artistic Denim Mills (ADM) director, said textile recycling has profoundly transformed denim production at ADM.

The Pakistani mill produces 12,000 tons of recycled cotton annually.

In 2020, ADM began its investment in recycling by partnering with Recover. The strategic collaboration enables ADM to offer clients a traceable and scalable solution for integrating recycled fiber into their products and valuable insights into the recycling process.

“We aim to demonstrate to our brands that recycling is a viable future without compromising product quality. While not all recycled goods are created equal, our commitment to innovation ensures that we offer products on par, all while reducing our environmental impact. This strategic approach positions us as leaders in sustainable denim production,” Ahmed said.

Beyond promoting circularity, investing in recycling machinery allows the vertical mill to initiate fabric innovation ahead of competitors

and has prompted ADM to experiment with different blends. “Our goal at ADM is to continue fabric innovation,” Ahmed said. “For instance, we’ve combined recycled cotton with hemp to develop a product that offers a unique soft hand feel while lowering the impact of the garment. This innovative, proprietary blend not only enhances the texture and appearance of our denim but also introduces a new aesthetic, that wasn’t previously available in the market. This opens exciting possibilities for both product differentiation and consumer appeal.”

While the fundamentals of mechanical textile recycling machinery have not changed in the last-half century, Neville said Recover has innovated how it uses machinery. Through continuous learning and improvements, the company has developed proprietary technology that optimizes the output. Recover’s annual production capacity is approximately 65,000 metric tons. “The result in a consistent, high-quality fiber that is spinnable even in ring spinning (which makes up most of the industry), and this is something that sets us apart from a lot of recyclers,” he said. There is still room for improvement in mechanical recycling, and this focuses mostly on improving the uptake of the fiber by spinners. Neville said the industry is also investing heavily in automated sorting technology, which would enable the industry to turn the huge quantities of post-consumer waste into valuable feedstock for textile-totextile recycling.

Traceability technologies are evolving the relationship between mills and brands. Up against consumer demand for transparency and legislation requiring digital product passports (DDP), suppliers have adopted various solutions to aid with traceability. FibreTrace, a technology that uses a unique identifying luminescent pigment to raw fiber that can be followed from farm to shelf in real-time, and Oritain, a fiber-testing technology that precisely pinpoints the area down to a few meters where a product or raw material originated, are some of the tools being utilized by mills.

Cone Denim, for instance, minted a partnership with Oritain to verify the origins of its cotton and share that data with customers.

Steve Maggard, president of Cone Denim, said that, since the partnership began in 2020, clients have responded favorably to the added security origin verification provides. Oritain’s fiber-testing technology verifies that cotton is compliant with legislation like the U.S.’s Uyghur Forced Labor Prevention Act (UFLPA).

“Cone Denim has publicly committed to operating sustainably and transparently, and Oritain is a key tool to meet that commitment. Not only is it admissible in a court of law, but it has been vetted and is recognized by our customers as valid,” he said.

Traceability and transparency are closely linked. Pakistan’s AGI Denim partners with Oritain as well as Green Story, which uses technology to generate information about a fabric or style’s footprint via a digital product passport (DPP). That data gives buyers insight into how much water, energy and land use went into making a fabric or style—and how much emissions are associated with the creation of such a product.

AGI is targeting EU and U.S. customers with the life cycle assessment (LCA) information; in the EU, incoming legislation will begin to mandate DPPs for a slew of products. This year, AGI will debut 100 styles—up from just a few in 2024—all featuring hang tags with a QR code directing buyers to a full LCA completed by Green Story.

AGI plans to continue working with Green Story to refine DPPs and LCAs for the denim industry. Henry Wong, AGI Denim’s VP of product development and marketing, said the mill wants the technology to be plug-and-play ready for other companies interested in providing their customers with the same information.

“Despite all the competition we have in our space, we still all live in the same world, so we want to see it be more than okay—be great,” he said.

CONE DENIM HAS PUBLICLY COMMITTED TO OPERATING SUSTAINABLY AND TRANSPARENTLY, AND ORITAIN IS A KEY TOOL TO MEET THAT COMMITMENT.”

The denim industry’s water consumption sparked controversy in 2013 when Levi Strauss & Co. released the lifecycle impact of a pair of 501 jeans, revealing that each pair requires 3,781 liters of water—equivalent to three days’ worth of total water usage for a typical U.S. household.

The denim industry’s reliance on water, along with solutions to minimize water waste, has become a central focus for investment. Mills from all regions including Artistic Milliners in Pakistan, Arvind in India, Crystal International in Cambodia and Kaltex in Mexico are taking proactive steps to reduce water usage by implementing wastewater treatment facilities to collect, recycle and reuse water.

Among them, Advance Denim stands out as a

leader in driving these efforts. Mark Ix, director of North American marketing for Advance Denim, said the company built its wastewater treatment plant next to its factory in China. The wastewater produced during denim finishing is piped into the treatment plant, where it goes through a bioreactor, is filtered to remove indigo and chemicals and is then turned into clean water that can be reused in the factory. Advance measures its ammonia and chemical oxygen demand (COD) to ensure levels of water output by the treatment plant are far lower than government standards.

The plant can process 9,000 tons of water daily, but Ix said the mill doesn’t come close to using that capacity. “The key is, don’t use so much water—create your manufacturing process to limit the amount of water you use,” he said. To achieve that goal, Advance has, in tandem, worked to reuse the indigo filtered out of the water to decrease the amount of water waste it produces, before it ever hits the treatment plant.

Ix said the company has reduced the

THE KEY IS, DON’T USE SO MUCH WATER—CREATE YOUR MANUFACTURING PROCESS TO LIMIT THE AMOUNT OF WATER YOU USE.” Mark Ix, Advance Denim

amount of water it uses in denim production by 73 percent. On average, Advance Denim uses about 600,000 tons of water annually, meaning the treatment plan processes less than 2,000 tons a day. He added that the goal is to create a [wastewater] system that is robust but not overstressed. “The water you’re actually sending to your reverse osmosis system is just a trickle [compared] to what it was seven years ago,” he said. For Advance, the next item on the docket at its wastewater treatment facility is using renewable energy to power it. By the end of 2025, Ix projects that “no less than 40 percent of the power will come from renewable energy, as well.”

Cotton continues to be the foundation of jeans, but the introduction of additional fibers has propelled the garment into exciting new dimensions.

Textile expert Tricia Carey said the denim market has always been a hotspot for fiber innovation because its unique construction allows experimentation with new materials. “Denim’s coarser yarn counts make it more forgiving for fibers that may not be optimized for quality. Additionally, weft innovation provides opportunities to incorporate fibers that may not have the strength in warp applications since they don’t require dyeing,” she explained.

Additionally, Carey said the presence of vertical suppliers—where spinning, weaving, and sometimes garment-making happen within the same company—enables seamless integration of new fiber technologies and supports cost efficiencies.

Lenzing has worked closely with vertical suppliers to scale the use of Tencel lyocell in denim. The fiber’s foray into denim goes back to the ’90s but Tuncay Kiliçkan, head of global business development for denim at Lenzing, said it took some time for the industry to fully understand the characteristics of the man-made cellulosic fiber that’s derived from wood pulp. “Fiber innovations progress at a slower pace compared to other raw materials, and their adoption takes time. However, these advancements open new chapters for the industry. Brands are no longer willing to rely solely on cotton, making the adoption of alternative fibers like Tencel more essential than ever,” he said.

Tencel has become a key ingredient in the denim sector for its low amounts of water, low carbon footprint and softness. It has also become a point of differentiation in a denim market that has an increasingly homogenized look. “For consumers, little remains to justify a premium feel and a comfortable pair of jeans—aside from a luxurious hand feel, which Tencel fibers naturally provide,” Kiliçkan said. “As a result, there is strong demand for authentic yet soft denim products in both the EU and U.S. markets. Both mills and brands are well-acquainted with this solution, and it has now become a mainstream trend.”

Tencel has also created a blueprint for additional fiber solutions such as Refibra technology, which transform recycled cotton textile waste into new fiber, and Tencel Modal with Indigo, a fiber that Kiliçkan said significantly reduces water, chemical, and carbon footprints while offering superior fastness compared to traditionally indigo-dyed fibers. “I can say that it’s the next-gen denim fiber which can easily adopt to other segments than denim like activewear and knit,” he said. There’s room for growth, Kiliçkan added. “If the industry can be more patient and supportive, we will see greater diversity in the fiber portfolio. With these added innovations, denim will continue to evolve in both look and feel—while also driving more significant resource savings,” he said.

Denim is also deeply rooted in storytelling, making it an ideal platform to introduce and market fiber innovations in a way that

resonates with consumers, Carey added. “Most importantly, the denim industry is a highly collaborative community with deep technical expertise, where brands, mills, and innovators work together to push boundaries and drive meaningful innovation. This combination of technical adaptability and industry-wide cooperation makes denim a natural fit for pioneering new fiber solutions,” she said.

In 2019, Levi’s and Outerknown captured consumers’ attention by launching jeans made from a blend of 70 percent cotton and 30 percent hemp, engineered to feel just like cotton. This fiber innovation, called cottonized hemp, had been under development by The Flax Company—famous for cottonizing linen 50 years earlier—since 2000. Based in Northern France, The Flax Company began bulk production in 2019 with the debut of Marmara Hemp.

“The denim sector is facing major challenges in meeting market expectations, whether in terms of innovation, durability or even cost, and not just in terms of spinning, weaving or finishing. Fiber innovation is one of denim producers’ major allies in meeting brand challenges. Marmara is a golden opportunity to broaden the scope of possibilities while matching the new market rules,” said Denis Druon, CEO of The Flax Company.

The environmental benefits of hemp have intrigued the denim industry. However, hemp’s rough texture previously prevented it from being widely adopted.

“When we speak of a cottonized hemp fiber, we mean a 100 percent hemp fiber that we have tailored to similar specifications in terms of length and fineness, so that it can be spun as a blend on a cotton spinning system (ring

or open end) without modification of the existing equipment,” Druon said. “Hemp does not require water to grow or to be produced. So, each kilo used significantly saves water for our planet. Adding Marmara hemp to denim is a big step towards product sustainability.”

Over the past six years, Druon said the firm has worked with supply chain partners to reach the quality standards required by the spinning mills, particularly in terms of fineness/spinnability, to secure sowings to guarantee volumes, and to certify its production chain with an LCA, a C2C certificate and sustainability certification.

Cottonized hemp poses a unique set of challenges—the biggest being the selection of the raw material. “The process starts well before the plant even grows as there is a tremendous amount of work in seed selection, land preparation, straw cutting date in the field and then retting process,” Druon said. “For textile applications, we need fineness and fiber division, which is difficult to achieve with hemp fiber, but we’re getting there.”

The other challenge is to turn a natural fiber, where each field and each batch of fiber has its own particularities, into a fiber that will be homogeneous for every delivery and available in industrial quantities on a regular basis. This is the challenge met by Marmara Hemp, Druon said.

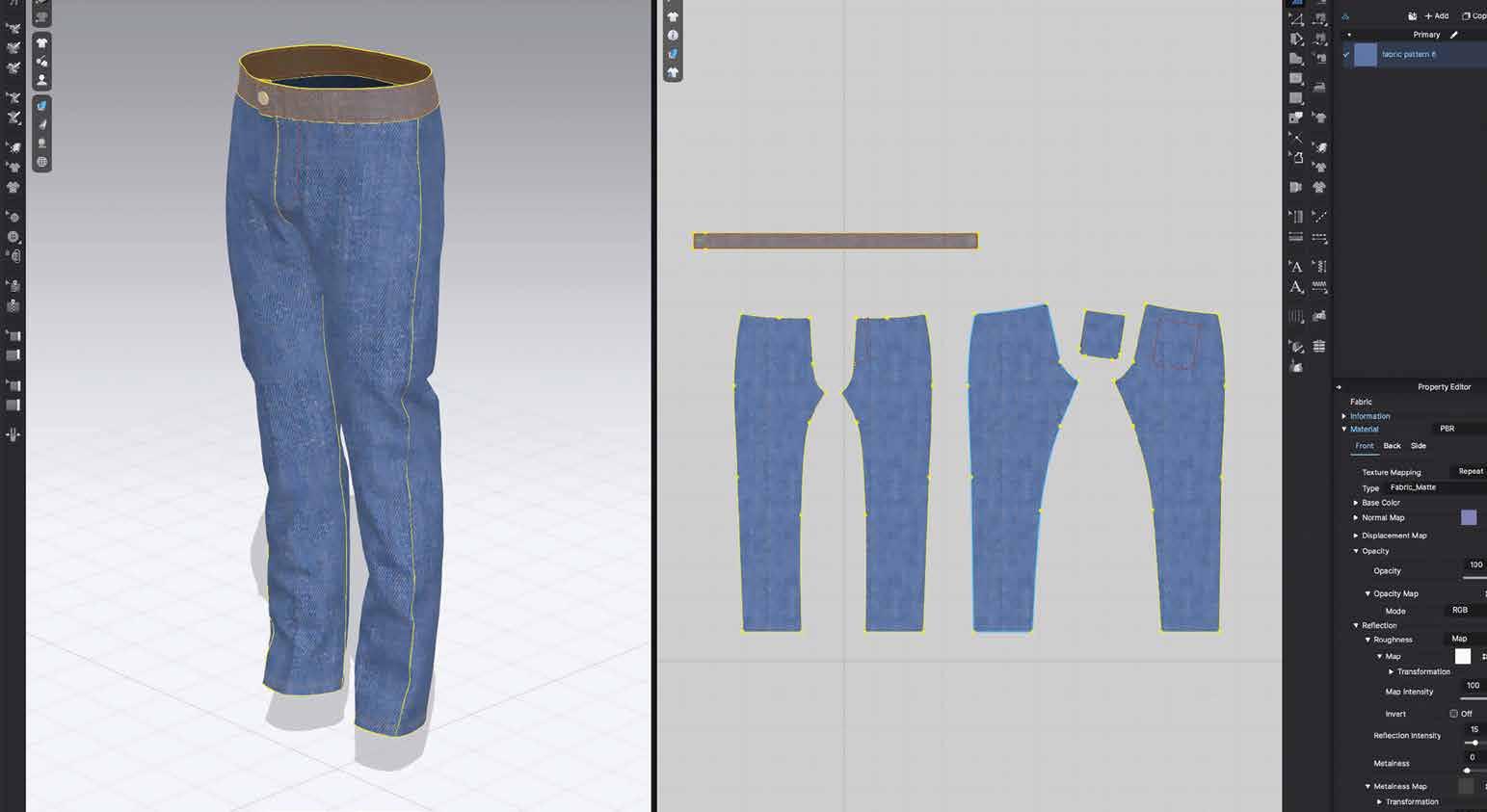

The key advantage of 3D prototyping is that designers can iterate and adjust styles in realtime, seeing photorealistic versions of their designs and assessing fit without producing a physical sample.

From fit and finish to shrinkage and wash, countless factors go into perfecting a pair of jeans. As the demand for efficiency grows, design is increasingly leaning on digital prototypes to minimize the need for physical sampling. Companies like Browzwear and CLO are leading the charge in 3D digital prototyping. CLO boasts clients like Diesel, Hugo Boss, L.L. Bean and Levi’s, and Browzwear has customers like Columbia Sportswear, Under Armour, Walmart and Kohl’s.

In the denim industry, creating fewer samples is particularly impactful because of the myriad steps that go into dyeing and finishing garments, as compared with a less-involved garment. By dynamically adjusting designs digitally, brands can reduce the number of samples they request before production, which decreases the emissions associated with producing the samples and shipping them, whether domestically or, more commonly, internationally.

“As a technical designer, I find it invaluable for quickly sharing designs and options with

I FIND [3D PROTOTYPING] INVALUABLE FOR QUICKLY SHARING DESIGNS AND OPTIONS WITH JUST A FEW CLICKS.”

Maria

just a few clicks,” said Maria Gunnarsson, founder of AMK Atelier.

Using 3D prototyping software can also aid brands and retailers in getting products to market faster. Rather than waiting for several iterations of a physical sample from faraway suppliers, designers can complete most of their vetting digitally, sending only the most finalized version of a product’s tech pack to a manufacturer for sampling.

One of the most effective ways brands reduce their environmental footprints is through advanced finishing technologies.

“If the denim industry didn’t have advanced laundry technologies like laser and ozone, we would see significantly more pollution, water waste, and fewer sustainable finishing options,” said Carey. “Design possibilities would also be more limited, as traditional methods rely heavily on chemicals and manual labor to achieve desired aesthetics.”

Indeed, laser technology has revolutionized denim finishing, enabling companies to achieve worn and aged effects without potassium permanganate and manual scraping. The cutting-edge technology replicates an authentic vintage look while opening up

limitless creative possibilities—from natural 3D textures and effects to custom damages, lettering, and imagery. Designers can create a digital file of their desired finish, upload it into the laser system, and within seconds, the power of light effortlessly transfers the design onto the garment.

“This technology drastically increases productivity, improves quality, and enhances worker safety, ensuring precision and repeatability while eliminating harmful manual processes. It enables brands to scale up production efficiently while reducing dependency on skilled labor for finishing,” said Carmen Silla, marketing director of Jeanologia, which launched its laser technology in 1999.

Since Italian tech firm Tonello introduced the technology for garment processing in 1995, laser systems have evolved into highly precise and efficient tools, with innovations like B.O.P. (Be On Point), an AI-powered garment detection system that ensures accurate, error-free marking.