» Smart Manufacturing—taking your manufacturing to the next level » Seven Practical Steps to Build a Culture of Safety and Human Reliability » ROEQ Announces New Cart System for OMRON Autonomous Mobile Robot LD-250, Doubling Payload Capacity » How Semiconductor Fabricators are Working Through Global FFKM Shortages » How We Can Inspire Our New Generation Into Engineering » Shop Automation Isn’t Rocket Science » Short Run Tool Shop Has Long History Of Success » What Manufacturers Should Know About Setting Quality Management Goals Radwell.com UNWANTED INVENTORY TAKING UP VALUABLE SPACE? Radwell.com purchases industrial automation product BENEFITS -Lower warehousing costs Increases cash flow -Liquidate aging inventory -Liquidate slow-moving inventory -Eliminate used or overstock inventory -Increases warehouse space -A better option than placing it in a dumpster -Go Green Selling your surplus inventory to us gives you a financial return on products you’d normally pay to have it disposed of. Radwell’s Asset Recovery Service always provides FREE freight service for your surplus stock. hether you have one facility or multiple our Asset Recovery program is an exceptional resource for your company. We offer cash for parts and products you don’t need. In many cases, selling your excess inventory to Radwell gives you the opportunity of adding dollars SELLING TO US IS AS EASY AS Gather it 1. 2. 3. Box it Arrange free pick up Radwell.com - 800.884.5500 - sellto@radwell.com 5/22/2020 4:20:26 PM Whether you have one facility or multiple facilities, our Asset Recovery program is an exceptional resource for your company. We offer cash for parts and products you don’t need. In many cases, selling your excess inventory to Radwell gives you the opportunity of adding dollars to your bottom line. BENEFITS • Lower warehousing costs • Increases cash flow •Liquidate aging inventory • Liquidate slow-moving inventory • Eliminate used or overstock inventory • Increases warehouse space Radwell.com Radwell.com UNWANTED INVENTORY TAKING UP VALUABLE SPACE? Radwell.com purchases industrial automation product BENEFITS -Lower warehousing costs Increases cash flow -Liquidate aging inventory -Liquidate slow-moving inventory -Eliminate used or overstock inventory -Increases warehouse space -A better option than placing it in a dumpster -Go Green Selling your surplus inventory to us gives you a financial return on products you’d normally pay to have it disposed of. Radwell’s Asset Recovery Service always provides FREE freight service for your surplus stock. hether you have one facility or multiple our Asset Recovery program is an exceptional resource for your company. We offer cash for parts and products you don’t need. In many cases, selling your excess inventory to Radwell gives you the opportunity of adding dollars SELLING TO US IS AS EASY AS Gather it 1. 2. 3. Box it Arrange free pick up Radwell.com - 800.884.5500 - sellto@radwell.com 5/22/2020 4:20:26 PM Radwell-FC-01-2022.indd 1 12/16/21 3:32 PM IndustrialMachineryDigest.com | December 2022 North America’s Manufacturing Resource for Industry Professionals Since 1986

DRILL. TAP. REPEAT. Engineer ed Tough for Year After Year Relia bility H Y PNEU M AT. C O M • 414 - 423 - 740 0 Automatic Drilling and Multiple Spindle Heads

is exclusively distributed in the US and Canada by Do you often move loads with surfaces that require protection? Then it is essential to avoid damage by lifting means at all costs. The solution: the new TXP-Texolution-Point. Its round sling reliably protects high-quality surfaces. Damaging contacts between lifting means and load surface are practically no longer an issue. And that with guaranteed total WLL. This preserves values and increases efficiency.

WORLD’S FIRST! First textile lifting point with tested and guaranteed total WLL. THE NEW TXP-TEXOLUTION-POINT.

MEETS STEEL. solutions.rud.com

TEXTILE

4 | IMD December 2022 Table of ConTenTs feaTURes 20 mANUFAc TUrING SHOWcASe rOeQ Announces New cart System for OmrON Autonomous mobile robot LD-250, Doubling Payload capacity 22 INDUSTrIAL AUTOmATION & FAbrIcATION How Semiconductor Fabricators are Working Through Global FFKm Shortages Greene Tweed Leads the Response By Nick McNeal, Director Semiconductor Strategy, Greene Tweed and Thyag Sadasiwan, Director Chemraz®, Greene Tweed 28 WOrKFOrce DeVeLOPmeNT How We can Inspire Our New Generation Into engineering 30 NeW TecH Short run Tool Shop Has Long History Of Success 32 PrOceSS benefits and Drawbacks of Sustainable manufacturing 34 INDUSTrY INSIGHTS What manufacturers Should Know About Setting Quality management Goals ColUMns 14 bUSINeSS 4.0 Smart manufacturing—taking your manufacturing to the next level By: Rahul Garg, Vice President of Industrial Machinery, Siemens Digital Industries Software 18 SAFe TY & mAINTeNANce Seven Practical Steps to build a culture of Safety and Human reliability By Jake Mazulewicz, Ph.D. DePaRTMenTs 6 eDITOrIAL DIrec TIONS 8 INDUSTrY NeWS 36 PrODUc T SHOWcASe 47 SUrPLUS bUYING & SeLLING 49 cLASSIFIeDS 50 ADVerTISer INDe X on THe CoVeR cover Sponsor: radwell Photo: iStock Photo

Customized Safety Lifting Devices For Any Application SAFELY Lifts Up To 500 lbs! Ergonomic Portable Lightweight Meets OSHA & ASME 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com Available in both CHAIN & CABLE Configurations

Hello and welcome to the December 2022 issue of Industrial Machinery Digest! It’s the most wonderful time of the year — christmastime. Here in Pelham, Alabama, it may not get as cold as it does in the Northeast, midwest, and other parts of the country, but we are experiencing some freezing temperatures and may even get some snow before Santa shimmies down any chimneys.

The holiday season always prompts me to reflect on the past year and what’s to come in the next. There’s no surprise that for the world of industrial manufacturing and metalworking, automation and other smart manufacturing practices are expected to be an ongoing trend in 2023. With that in mind, we’ve included articles in this issue we hope you find insightful and helpful as we all embrace a new year.

In this edition of ImD, you’ll learn why machine shop automation isn’t rocket science and shouldn’t be so intimidating that manufacturers shy away from it. As you’ll read in the “New Technology” article starting on page 30, “most shops are simply looking for a low-cost automation application that is easy to set up and use, cost-efficient and, most importantly, provides unattended machining time.”

We’ve also included a riveting piece by rahul Garg, Vice President of Industrial machinery, Siemens Digital Industries Software, that explores how (and why) manufacturers are discovering that digitalization is the new equalizer to achieve a new level of smart manufacturing, as well as an insider’s look into rOeQ and OmrON’s new partnership for providing top modules and cart systems for the company’s autonomous mobile robot, the LD-250.

Additionally, in this issue, you’ll find articles that discuss topics including: how to practically build a culture centered around safety and human reliability, what the current workforce can do to inspire the next generation of engineers and skilled laborers, exactly what manufacturers need to know about setting quality management goals, and a company profile on T.J. Grinding, Inc. a leader in high-quality, short-run tool production that sells nationwide both directly to end users and through a network of distributors based out of Waukesha, Wisconsin.

As always, happy reading, my friends, and happy holidays from everyone here at ImD! I hope you enjoy this issue and maybe even learn something new. Please do not hesitate to reach out with any comments, questions, or article ideas. I’d love to hear from you.

William Strickland

Publisher, Industrial Machinery Digest wstrickland@indmacdig.com

Publisher, Industrial Machinery Digest wstrickland@indmacdig.com

William C. Strickland III, Publisher william.strickland@indmacdig.com 800-366-0676 ext. 103 | Fax: 866-826-5918

Anna Claire Howard, Editor-in-Chief achoward@indmacdig.com 800-366-0676 ext. 104 | Fax: 866-826-5918

Shane Bell, Creative Director sbell@indmacdig.com

SALES

Lisa Hanschu, Sr. Account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William C. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

Adrienne Gallender, Media Adviser agallender@indmacdig.com 888-407-7737

Susan Strickland, Accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

ImD, 3590-b Hwy 31 South, Suite 233, Pelham, AL 35124 circulation@indmacdig.com | Fax: 866-826-5918

6 | IMD December 2022 eDiToRial DiReCTions

CIRCULATION & SUBSCRIPTIONS

REPRINTS

purchase article reprints please

source media llc 360 A PUBLICATION OF: Source 360 Media LLC 3590-b Hwy 31 South Pmb #233 Pelham, AL 35124 INDUSTRIAL MACHINERY DIGEST (ISSN 1542-5223) is published 12x per year by Source 360 Media. POSTMASTER: Please send change of address to INDUSTRIAL MACHINERY DIGEST, 3590-B US Hwy 31 South, PMB 233, Pelham, AL 35124. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. to qualified individ uals. Publisher reserves the right to reject nonqualified subscribers. Oneyear subscription to nonqualified individuals in the United States: $9600. Single copies available (prepaid only) $2000 each. Alabama Automotive Manufacturers Association SERVING AMERICAN MANUFACTURERS FOR OVER

YEARS

To

call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com

36

North America’s Manufacturing Resource for Industry Professionals Since 1986

POLISHERS &

INDUSTRY NEWS

Authentise Releases Guidelines

Pioneering rules engine changes the way tribal knowledge is collected, compliance is ensured, and artificial intelligence (AI) is delivered.

Authentise, the leader in data-driven engineering & manufacturing workflow tools, has released Guidelines, a major new rules engine that puts operators back at the heart of digital manufacturing.

Guidelines is a new set of features accessible to users of ameS, Authentise’s end-to-end, connected workflow engine for additive manufacturing. It enables users to formulate if-this-then-that rules that use any type of engineering or production data as input. These rules then trigger suggestions at any point in the process. With Guidelines, a combination of machine sensor feedback, geometry features, or QA measurements, among others, can be used as triggers to suggest changes in behaviour or parameters that will ensure a more successful and sustainable production outcome. These suggestions are delivered to the user when required, during the engineering stages or in production.

“If-this-then-that rules are not new in robotic process automation but have yet to be used successfully in the manufacturing context beyond basic principles such as quoting”, says Andre Wegner, ceO of Authentise. “We realized their broader power almost immediately and spent the last 10 years building, with ameS, a contextual data engine capable of harnessing them. They represent a break from more prescriptive tools, such as our workflow generator. This permissive approach makes them the ideal channel to ensure that rules are followed while giving experienced engineers and operators the latitude to make the decisions necessary on a case-by-case basis. We’re fortunate to work with partners such as ASTm to ensure that

this novel framework is not only filled with tribal knowledge present within each organization but uses existing standards as a starting point.”

“There is great value in considering how Standards can be fully applied in the digital world”, says Dr martin White, Head of Additive manufacturing Programs – europe at ASTm Additive manufacturing center of excellence. “Guidelines has the potential to evolve how Standards can be accessed and embedded in manufacturing processes with increased accessibility. We’re excited to work with Authentise to ensure that users can access applicable standards in this way. Not only does this have the potential to ensure greater compliance but doing so in a digital framework allows our partners to potentially reduce audit costs too.”

The delivery of Guidelines was supported by Innovate UK’s Transforming Foundation Industries challenge under the SAmrcD grant, under which Authentise and ASTm collaborate with Photocentric, mPI and TWI.

“Guidelines very intentionally puts the power to make decisions back into the hands of those on the frontlines, whom most of the Industry 4.0 movement has so far marginalized,” adds Simon mccaldin, VP of Open Innovation at Authentise. “We believe this will, in the medium term, also help us deliver more acceptable forms of Artificial Intelligence to the industry. ameS has now reached the level of maturity necessary to capture the data that can drive advanced machine learning systems. However, operators are rightly cautious of adopting systems operating as a black box with no oversight. Guidelines represent a more transparent delivery method and will increase real-world acceptance, while ensuring compliance with process control procedures. Now that it is built, Authentise will not monopolize the channel that Guidelines represents. We’re

8 | IMD December 2022 inDUs TRy news

WANT TO BE FEATURED? Send your

releases to editorial@indmacdig.com www.IndustrialMachineryDigest.com Streamlining Credential Processes Bringing Global Technology to a Local Level Manufacturing IndustrialMachineryDigest.com October2021 MANUFACTURING SHOWCASE: FEATURED STORIES: Cincinnati, Inc. IMPACTING DROP ZONE Wildeck Provides Increased Safety for Moving Palletized Loads the » Empowering Employees » Surpassing Energy Savings Manufacturer in Oxnard, CA experiences the benefits of Green Hydraulic Power Units » Lifting Higher Combi-PPT - A High Capacity Powered Pallet Truck Streamlining Control Siemens Offers Optimized Control Panel Construction to Machine Tool Builders IndustrialMachineryDigest.com March 2019 IndustrialMachineryDigest.com June2021 ESTABLISHED IN 1986 AND IS THE INDUSTRY’S Most Extensive Industrial Publication. GETTING BACK TO WORK!! 2021 INDUSTRIAL MACHINERY DIGEST’S

industrial Machinery Digest's industry news features the latest news and press releases from some of the industry's top companies.

press

American Punch Company Announces the Appointment of Matt Bendula to VP of Operations

American Punch company announces that matt bendula has been named VP of Operations, effective immediately. mr. bendula joined the staff of American Punch in 2016 as a roving operator in grinding, finishing, heat-treat prep, and inventory control then quickly joined the sales department. He previously spent six years in industrial sales after earning a bA in marketing from Kent State University. mr. bendula went on to earn his mbA from Ohio University, with a concentration in executive management.

In his new role, mr. bendula will be responsible for overseeing all day-to-day manufacturing operations, define and implement operations strategy and processes, and plan for future growth and expansion of manufacturing capabilities. He will also be responsible for maximizing workflow efficiency.

bob Olson, owner and president of American Punch believes that mr. bendula is the right man for the job. “matt has worked hard since the day he joined our organization to learn our processes and industry. He has the experience, training, and education to help American Punch prepare

for our future as we lead the metalworking, stamping and rollforming industries for high performance tooling.”

The American Punch company is the leading manufacturer of punches, dies, and shear blades used in the structural steel and metal fabricating industries. In addition, American Punch supplies precision tooling to the stamping, roll forming and metalforming industries. Their world-class manufacturing facilities allow American Punch company to provide customers with the flexibility to produce both on-demand stock tooling and engineered, made-to-order tooling. American Punch company is ISO-certified, and is a member of all major trade organizations.

For more information, visit their website at www.AmericanPunchco.com.

Global Shop Solutions Employees Celebrated As Emerging Leaders By NTMA

Developing homegrown leaders is one of the most important things companies can do to pave the way for continued success. Global Shop Solutions, a global leader in erP software for manufacturers, is proud to announce cynthia Ashby and ryan carpenter were identified as emerging Leaders by the National Tooling and machining Association (NTmA).

NTm A is a U.S.-based trade association with 1,200 tool & die and precision manufacturing companies

INDUST r IA L MACHINERY DIG e ST cOm IMD | 9 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986 Convenient & Free. We bring Scotchman machinery to your location. See them in action & test cut your material without leaving your place of business, anywhere in the lower 48. Scan QR code or Call. (800) 843-8844 www.scotchman.com • Ferrous & Non-Ferrous Cold Saw Models • Manual to Fully Automatic • Financing Available When CuttinG Tube SPEED & Precision MATTER Scotchman IMD Half Page Ads 2022.indd 1 11/14/22 12:06 PM committed to keeping this new delivery method open to all smart algorithms providers and are grateful to Innovate UK for believing in this approach and supporting the creation of Guidelines.”

representing more than $35 billion in sales. e ach year NTm A selects 15 individuals – nominated by their employers – for recognition in the association’s emerging Leaders rising program. This program recognizes the hard work and accomplishments of future leaders in manufacturing.

“We’re very proud to have cynthia and ryan on our team,” says Dusty Alexander, President and ceO of Global Shop Solutions. “cynthia attained her current position as manager of the Financial Data Analysis Team by earning the respect, admiration, and trust of senior leaders, supervisors, fellow employees and customers. As an Operations consultant on our continuous Improvement Team, ryan has greatly impacted our customers by continuously helping them improve their fluency with our software and resolve issues from quote to cash. It’s employees like cynthia and ryan that have made Global Shop Solutions great today and into the future.”

each emerging Leaders class is profiled in The record, NTmA’s monthly Precision manufacturing magazine and are invited to attend manufacturing engage – the annual precision manufacturing conference – where they are recognized on stage during the awards ceremony. They are also invited to attend the annual emerging Leaders conference where they can connect with each other and continue to develop their leadership skills.

“It’s an honor to receive this award, but I wouldn’t be where I am today without the guidance of others,” says Ashby. “becoming an emerging Leader has motivated me to work harder and continue growing in my career while helping others succeed.”

“I am honored to be chosen as an emerging Leader,” says carpenter. “every day I do my best to ensure our customers’ needs are met, and I hope to pioneer a path for new hires by demonstrating the effectiveness of young leaders.”

Loc Performance Names Jason Atkinson as President and CEO

Loc Performance (Loc) has named Jason Atkinson as the company’s new president and ceO, effective immediately. Atkinson has served as a key member of Loc’s leadership team since 2008, when he joined the company as chief operating officer. In his new role, Atkinson will continue to lead the technical efforts for all new business opportunities and launches.

Loc Performance, a leading agricultural and military provider, named Jason Atkinson as its new president and ceO.

“I have worked with Jason for more than 20 years, and he is more than ready to thrive in this new role,” said Lou burr, former Loc ceO. burr will no longer be active in Loc’s day-to-day operations but will continue to serve as a strategic consultant.

During his time as Loc’s cOO, Atkinson oversaw all aspects of the business operations, including production, quality, materials, engineering, IT and human resources.

He spearheaded the development of tools that accelerated Loc’s growth, including Loc’s QmS supplier development system and the launch of Plex, Loc’s fully automated erP system. Under his direction and management, Loc launched and delivered flawlessly on significant programs such as ecP1 for the bradley Fighting Vehicle, which increases ground clearance and survivability.

“I am excited to step into this expanded leadership role,” said Atkinson. “Loc is uniquely positioned for growth in the military, agricultural and construction markets, and I look forward to continuing the company’s positive momentum.”

Atkinson also led several significant acquisitions for Loc, including Demmer’s North Lansing plant in 2017, Lapeer Industries in 2019, and continental’s St mary’s location in 2020. Under Atkinson’s leadership, Loc has deployed millions of dollars in capital equipment, facility expansions, and new product launches, such as the mLrS IAc program in the Lansing facility. As a certified six sigma black belt, Atkinson has built his career on continuous improvement efforts.

Prior to joining Loc, Atkinson developed strong leadership experience in the automotive industry. Starting his career at a Tier 1 automotive supplier while going to school at m-T ec , Atkinson had full P&L responsibility as a plant manager for a multi-site operation that produced underbody, suspension components and mechanical assemblies for chrysler, G m , and Ford. Over this twelve-year period in the auto industry, he launched hundreds of millions of dollars in business, obtained Q1 with Ford, maintained QS9000, TS16949, and A2LA certifications, and developed a cost reduction and lean manufacturing program yielding significant savings. With five plants and over 800 employees, Jason received Pm P certification to support multisite program launches and developed a program management process with multi-gate reviews to ensure on-time delivery and overall customer satisfaction.

Learn more at www.locperformance.com.

Veterans Play Key Role in Workforce Development

at Mazak

company relies on veterans for their transferrable skills and rock-solid work ethics

crucial to its workforce development strategy, mazak North America credits veterans as essential to the company’s ability to overcome the manufacturing industry’s severe lack of skilled labor and fill vital positions. This year alone, mazak has hired 13 veterans and now employs a total of 87 within mazak departments ranging from field service and parts to production and purchasing.

Also as part of its strategic workforce development strategy, mazak leveraged its relationship with the Lucas Group to locate and hire more veterans. The recruiting firm specializes in matching up those individuals transitioning from the military with companies like mazak seeking qualified, talented and dedicated people.

10 | IMD December 2022

The Best Tool Cabinet You Will Ever Buy GUARANTEED 100%MADE IN THE USA INEVERY WAY WWW.STORLOC.COM • 1-800-STORLOC 1-800-786-7562 MADE BY AMERICAN CRAFTSMEN IN THE USA sales@storloc.com

According to mazak Human resources Director bill Weier, managers praise the company’s veteran employees for their diagnostic skills and their ability to reason through solutions. "Their dedication, creativity and can-do attitude along with a strong work ethic, focused time management and problem-solving skills,” he said, “set an example of how to excel and advance within the industry. We are truly grateful for their service to their country and to have them as members of the mazak team.”

Throughout the organization, veterans contribute their accountability, seasoned perspective and mature outlook to make mazak an even better place to work. The company is also committed to providing these veterans with the continuous training and development they need to build thriving, sustained careers with the company.

Veterans who are interested in manufacturing careers can apply for one of the many positions on the mazak career page:

For more information visit www.mazakusa.com

Innovative Employer Engagement Process Establishes Effective On-The-Job Training (OJT)

The National Institute for metalworking Skills (NImS) has developed a new approach to help employers struggling with On-The-Job Training (OJT). It’s a five-step method that is briefly described in a video that can be

accessed by clicking here. NImS created the process to address the urgency many employers are experiencing getting employees training in today’s manufacturing technologies and methods.

Step 1 is “Familiarize” – introduces the Smart Training Principles that NImS outlines on its website, www. nims-skills.org.

Step 2 is “Discover” – includes a quick online self-evaluation assessment that reveals perceived versus actual training behaviors occurring in a shop or factory.

Step 3 is “Analyze” – the shop owner or training manager and trainers participate in a session with a NImS expert to bring clarity to the assessment results. This session returns a comprehensive needs analysis and a Training Playbook that the company can use to enhance its training program.

Step 4 is “enhance” – the details of the organization’s training program are developed on site at the company’s

•

• Our 1100MX runs on our intuitive and easy-to-use CNC controller, PathPilot®. A short learning curve is a real dealmaker.

• Feel free to build out the machine you want because it’s modular, so you can include options like an ATC, PathPilot Operator Console, or a microARC 4 4th Axis table whenever

12 | IMD December 2022

CNC MILLS | CNC LATHES | CNC PLASMA TABLES | CNC ROUTERS | INDUSTRIAL ROBOTS | AUTOMATIC FEED BANDSAWS NEED A SECOND OPS PART MAKER OR A PERFECT PROTYPING MACHINE? Make one-off and small batch parts in-house while your bigger machines handle production.

With its compact size, the 1100MX sneaks into unexpected places. With servo motors and a BT30 spindle, it’s built to mill anything. Set it up, make chips, and cut parts.

Learn more and build yours at tormach.com/1100MX/IMD

you want.

location. This is the step that has the greatest and most empowering impact. The materials for training are created with a NImS expert, and real training sessions are practiced and fine-tuned.

Step 5 is “recognize” – the final step to ensure that all stakeholders in the program get acknowledged for their role in reaching the desired performance goals.

According to montez King, executive Director of NImS. “The first steps are somewhat academic, but we caution companies to not get turned off by those. They are quick and necessary for the subsequent steps that are practical and real-world, using a company’s specific parts and processes. They successfully resolve the OJT needs in a relatively short time frame. Further, NImS is here to help employers at every step of the journey.”

For more information contact NImS at (703) 352-4971 or email support@nims-skills.org.

Hexagon and Raytheon Technologies developing simulation tool to improve 3D printing build quality

Hexagon and raytheon Technologies partner to deliver a simulation tool that will enable evaluation and optimization of metal additive manufacturing (Am) processes through the prediction of thermal history and defects at the laser path and powder layer scale combining technologies from Hexagon’s manufacturing

Intelligence division and raytheon Technologies’ Pratt and Whitney business, the new software will predict defects before the expensive and time-consuming printing process begins. This analysis will help designers and engineers evaluate the print outcome and test combinations of materials, geometries, and print processes.

“We have partnered with raytheon Technologies to deliver an intuitive and accessible tool that will help engineers quickly predict and mitigate risks,” said Jeff robertson, Hexagon’s director of global business development. “The ability to evaluate full laser powder bed fusion (L-PbF) parts on the meso-scale will reduce the effort to achieve part certification and thereby support industrialization of metal 3D printing.”

The software will be made available to a range of companies engaged in additive manufacturing and will be complementary to Hexagon’s existing Simufact Additive tool. The similarity to the existing user interface will allow easy integration into existing manufacturing processes by users without the need for extensive training.

“by combining our additive manufacturing expertise with Hexagon’s, we are bringing a solution to market that helps manufacturers with all levels of experience make better products with greater efficiency,” said David Furrer, Pratt & Whitney senior fellow for materials and processes.

For more information, visit hexagonmi.com.

INDUST r IA L MACHINERY DIG e ST cOm IMD | 13

Visit Our Website Or See Us Online At : (251) 937-0947 P l a t e R oll s 2 0 G a t o 6 ” C a pa c i t i e s , 8 0 M od el s C N C O pt i o n s A n gl e R oll s 1 ” t o 1 0 ” 3 0 M od el s C u s t o m M a ch i n e s C N C O pt i o n s S e c t i o n B e n d e r s H e a v y D u t y 1 " t o 3 " C a p a c i t i e s Pipe & Rebar Benders, Ornamental Benders, CNC Controls, Custom Machines & More! MEMBER sales@carellcorp.com • www.carellcorp.com sales@eaglebendingmachines.com • www.eaglebendingmachines.com JUST ROLL WITH IT! T w i s t O pti o n s A v ail abl e Machines for any job or budget • Superior PLATINUM Warranties 28

Smart Manufacturing— taking your manufacturing to the next level

By: Rahul Garg, Vice President of Industrial Machinery, Siemens Digital Industries Software

By: Rahul Garg, Vice President of Industrial Machinery, Siemens Digital Industries Software

Manufacturers are searching for innovative ways to tackle a multitude of challenges, from rising product complexity and emerging sustainability goals to consumer demands for more customization. At the same time, they are dealing with global competition, supply chain and labor shortages.

Fortunately, manufacturers are discovering that digitalization is the new equalizer to achieve a new level of smart manufacturing. In the past, automation was focused on reducing costs. but today, if done right, digitalization can take manufacturing processes to a whole new level. Digitalization delivers more data and better data—key for improving operational efficiencies to achieve a host of benefits: high availability, maximized factory utilization, real-time management of supply chains, and most importantly, improved time to market. It also can enhance manufacturing flexibility – enabling individualized products at mass-produced goods pricing.

There are three key capabilities digitalization supports that will lead to smart manufacturing.

» The first step is the convergence of information

technology (IT) with operational technology (OT). This is crucial for extracting and analyzing all the data generated during operations to uncover actionable insights.

» That, in turn, enables closed-loop manufacturing and execution focused on creating and optimizing the actual process and expediting customer orders.

» Finally, closed-loop quality is achievable to ensure products are delivered right the first time, regardless of the lot size.

IT/OT fusion delivers actionable insights

The convergence of IT and OT is the initial crucial step to achieving smart manufacturing. Operation technology is the software that governs the operation of the physical equipment, the controls and the technology that's driving the machines such as the PLcs. The software instructs the machine on what to do and ensures the hardware executes those instructions. On the other hand, IT is the organization’s computer technology used to store, retrieve, process, analyze, and recommend action on digital

14 | IMD December 2022 bUsiness 4.0

Manufacturers are discovering that digitalization is the new equalizer to achieve a new level of smart manufacturing.

data extracted from operations. As a result, IT is used by management to make decisions, and operation technology is used by the factories to drive actions.

So where does all this data come from? most factories today are a mix of older and newer equipment. Newer smart machines are designed to share data with a network, whereas older machines are data islands. A network of sensors is added to the factory to connect those islands to ensure robust data across all manufacturing operations, bringing operational data together for IT to analyze. As a result, in almost every factory, today, data is collected by a wide variety of physical sensing technologies, including programmable logic controllers (PLcs), sensors and gauges, IoT devices, etc.

This IT/OT fusion leads to:

» Greater flexibility and visibility into operations, empowering manufacturers to make much better decisions in an integrated manner. Now real-time process monitoring of the shop floor is possible, enabling managers to quickly assess the business impact of manufacturing activity.

» It also supports and encourages collaboration across planning and scheduling as well as factory performance, leading to superior efficiency.

» Additionally, artificial intelligence and machine learning can be applied to these large data sets, uncovering non-conformance and non-regular data to quickly make decisions based on that information.

Closed-loop Manufacturing for continuous operational improvement

closed-loop manufacturing and execution are now achievable based on the data and insights delivered by IT/ OT fusion. closed-loop manufacturing synchronizes and optimizes production across product design, production planning, manufacturing execution, automation and even intelligence from consumer use in the field. The result is a collaborative, connected loop of information that continuously improves the cost, time and quality of the manufacturing process to accelerate the delivery of products. In short, it tightens the alignment of the

Fiberglass/Composite

Machining

• Multiple drills, flex shaft driven

• Easily adaptable for tight spaces

• Suitable for harsh environments

SUHNER INDUSTRIAL PRODUCTS CORP.

25 Anderson Rd SW, Rome, GA 30161 706.235.8046 machining.us@suhner.com

AD5996g Composite 2021 IMD

Multiple Machining

Tailor made and standard multi-spindle heads for drilling and tapping in tight spaces and in the shortest amount of cycle time

SUHNER INDUSTRIAL PRODUCTS CORP.

43 Anderson Rd SW, Rome, GA 30161 706.235.8046 machining.us@suhner.com

INDUST r IA L MACHINERY DIG e ST cOm IMD | 15

– North America’s Manufacturing

Industry Professionals Since 1986

IMD

Resource for

Suhner

Suhner AD5996a Mutiple 2021 IMD

Closed-loop manufacturing provides crucial real-time quality data that enables manufacturers to continually adjust the processes to optimize quality in real-time.

as-planned product with the as-built and as-used product in a continuous, iterative process.

closed-loop manufacturing ensures that all teams have real-time information at each step in the manufacturing process—from product planning and engineering, through enterprise resource planning (erP), across the supply chain and into actual manufacturing operations management (mOm). The rise of mOm on the factory floor enables manufacturers to collect and maintain a wealth of data on the production and the physical products being produced. It is now possible to encompass quality management, advanced planning and scheduling, manufacturing execution systems, enterprise manufacturing intelligence and more. engineering teams can receive timely manufacturing feedback to expedite problem resolution and ensure optimal product evolution. It allows tracking of what has been built with all the data, how it was built, and with what materials and parts. It also fuels innovation by accelerating new product introduction for faster time to market, while maintaining fidelity to quality and compliance requirements.

There is a myriad of benefits to be reaped from real-time data from IT/OT fusion being shared in an iterative process in closed loop manufacturing. For instance, it is invaluable when identifying issues in assembly production that might require a change in a work instruction during volume production to optimize process planning. Or when a machine goes down, a manufacturer can quickly assess the impact on mid- to long-term planning, immediately identify alternate resource capacity, order prioritization, sequencing and synchronization, and quickly make the appropriate production changes.

besides helping to adapt to immediate challenges, closed-loop manufacturing supports a host of higher-level smart manufacturing capabilities that can be efficiently and cost-effectively implemented. These include enterprise and multi-plant visibility, the development of key performance calculations, root cause analysis and advanced analytics.

99 percent quality compliance with closed-loop quality

Once closed-loop manufacturing is established, the third stage in achieving smart manufacturing is closed-loop product quality. Quality is a well-defined term in manufacturing: it is when the product outcome meets the intended expectations for product performance and features. The goal is to deliver on the intended quality for each and every product manufactured. closed-loop manufacturing provides crucial real-time quality data that enables manufacturers to continually adjust the processes to optimize quality in real time. Or if real-time process adjustments are not feasible, closed-loop quality identifies parameter trends and their sources to allow adjustment at the first available downtime. When quality is subpar, the manufacturer can quickly identify and correct non-conformance as soon as practical, leading to overall improved quality of the product, while minimizing scrap and rework.

Specifically, closed-loop quality ensures complete visibility of quality-related metrics from planning through delivering on the quality of the completed product. It also focuses on improving the overall product quality over time. The first crucial step is planning for the quality upfront. That requires developing well-defined expectations and capabilities, defining expected failure modes, developing procedures for addressing those issues, and even looking at environmental and machinery conditions that may impact quality and the overall production processes. Those requirements often include vibrations, temperature, tolerances, machine condition and wear and the required precision or quality to ensure the product meets requirements.

Once all these quality conditions are clearly defined, it is crucial to monitor them throughout the manufacturing process. That involves capturing output parameters or as-built conditions against the requirements and closing the loop on the process to identify and zero in on the source of any parameter trends or deviations. Here is where the IT/OT data collection and closed-loop feedback in the manufacturing processes are essential. Now it is possible to optimize critical quality characteristics during the assembly of the product—whether a part or a complex system—and to continuously verify the product against the engineering requirements throughout the development and manufacturing process. It is even possible to extend this to include supplier quality management – especially in today’s highly challenged and often broken supply chain environment.

Organizations that establish closed-loop quality processes achieve a median product compliance rate of 99 percent, with a majority performance ranging from 97-100 percent. manufacturers without this capability have significantly more variability in performance, with a majority ranging from 90 to 98 percent. This disparity in performance could mean the difference between being first or second to market, avoiding a major product recall or winning future contracts. One of the key advantages implementing a closed-loop quality system is that it shifts quality to being a shared responsibility instead of treating it as a disconnected or isolated process.

Realizing a truly comprehensive digital twin Smart manufacturing, once implemented, supports the whole concept of a digital twin of the manufacturing environment. This is a critical game-changer for manufacturers positioning themselves for the future. The digital twin is a virtual, digital replica of the physical objects of an entire machine or the entire manufacturing system or the entire shop floor in a digital environment. While the factory operates, the digital twin provides a physically accurate simulation that combines the virtual and physical worlds to provide new insights and efficiencies for product manufacturing through data analytics and AI. more data equates to a higher fidelity digital twin. The IT and OT convergence delivers the requisite real-time data

16 | IMD December 2022

and information to create a comprehensive digital version of the factory. As a result, while the factory is running, the digital twin of the entire factory with each individual machine is mirroring that activity in a replica, digital format. All that operational data ensures much higher fidelity of the digital twin and provides insight into real-world operations.

The comprehensive digital twin is the basis for finally improving the real-world version via simulation of the digital model, thus closing the loop for manufacturing operations and quality. In addition, it provides manufacturers with a mechanism to understand what will or could happen in the future. As a result, they can confidently use the digital twin for optimizing operations, predicting maintenance, enabling more efficient commissioning, better changeovers and faster production line changes. All key capabilities for business operations to conduct their business in a more efficient manner. And a change in a digital environment does not cost anything; it's a zero cost. That encourages managers to examine a broader range of feasible approaches before committing to physical implementation on the production floor.

Tomorrow’s smart manufacturing today

All the capabilities for creating tomorrow’s smart manufacturing are available today for those determined take their operations to the next level. The fusion of IT with OT data delivers a wealth of data that can be used

to continuously improve operational efficiencies within a closed-loop manufacturing environment. That, in turn, enables a closed-loop quality approach to continuously enhance product quality. With a more agile and adaptable smart manufacturing process, it is feasible to optimize throughput while lowering costs and improving overall sustainability by minimizing resource usage, electricity, and water waste. Ultimately leading to the coveted Triple Zero in manufacturing: zero downtime, zero defect, and zero harm.

ABOUT THE AUTHOR

rahul Garg, Vice President of Industrial machinery, Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry-leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. rahul’s experience and insight are derived from 25-year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in r&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.

INDUST r IA L MACHINERY DIG e ST cOm IMD | 17

Seven Practical Steps to Build a Culture of Safety and Human Reliability

By Jake Mazulewicz, Ph.D.

By Jake Mazulewicz, Ph.D.

Atechnician spills a toxic chemical. She isn’t injured, but easily could have been. The Hazmat cleanup costs over $10,000, and shuts down a critical building for a week.

An electrical engineer flips the wrong switch in a substation control room. He isn’t injured. but within seconds, a $50,000 transformer is destroyed.

Three financial clerks in two different countries are processing payments for a large bank. They intend to schedule a routine $8 million payment. Antiquated software makes errors hard to catch. The clerks accidentally wind up sending $893 million instead.

From Talk to Action

Talking about building a culture of safety and human reliability is easy. but how many great ideas get talked about and never actually get put into practice?

The real skill is to be able to transform good ideas into practical steps that you and your people can apply immediately. In this article, that’s what you’ll get.

There is no one secret or solution. Instead, many successful companies around the world have built a culture of safety and human reliability using a “consolidation of Subtleties” – a combination of practical steps like these.

»

Take a Learning-Based Approach to Errors

If you’re in a work culture that’s stuck in the old-school, control-based Approach of eliminating all errors, then consider labeling it that way. “Hey, are we stuck in a control-based Approach as we’re discussing Tuesday’s incident?” The more you label it, the more you’ll be aware of it, and the less you’ll be stuck in it. When

ready, propose the alternative – the Learning-based Approach. How? After the next incident or unwanted error, don’t start by asking, “What went wrong this time?” Instead, start by asking, “How do you all get this job get done right 99% of the time?”

» Create Psychological Safety

It’s easy to destroy and challenging to create. Yet research from Dr. Amy edmonson at Harvard and Google’s Project Aristotle reveal that Psychological Safety is key to successful, safe, engaged, and reliable teams. After an error, instead of saying, ”Joe failed to do [X]...” ask, “What DID Joe do, and why did it make sense for him (at the time) to do that?”

»

Lead After Action Reviews (AARs)

For over 30 years, these psychologically safe, semi-structured, post-job team debriefs been used by an increasing number of high-hazard industries worldwide. After your next successful, complex project, instead of asking, ”What could we have done better?”, ask these four questions initially developed to accelerate learning in the US Army.

1. What did we set out to do?

2. What did we actually do?

3. How did it turn out that way?

4. What will we do differently next time?

» Transform Investigations

Traditional investigations often “Name, shame, blame & retrain.” The result? Fear, silence and box-checking on corrective Actions. The alternative? Instead of asking, “What was the error, and who made it?” ask, “How did our processes set that person up to make that error?

18 | IMD December 2022 safe T y & MainTenanCe

And how can we improve our processes to set our people up for reliability and success instead?”

» Apply Defenses

Peer checks. Three-Step communication. checklists. These and other simple, yet powerful defenses have proven successful for decades. You can learn them in a few hours, and get real-world results immediately. Pick a job that you and your team regularly do. consider writing or updating the checklist for that job to include ONLY the 3-7 items most often missed. One physician from baltimore helped save 1,500 lives in 18 months with this classic defense.

» Improve Systems

Instead of trying to “fix” your workers, improve your work processes & systems. How? Pick a process that you regularly do. With trusted front-line experts, brainstorm one low-cost, low-risk, low-fear, low-maintenance process improvement that would make it easier for front-line experts to do the right thing in that process. For example: companies with fleets of trucks have dramatically reduced serious injuries and save millions of dollars each year by simply avoiding left-hand turns.

» Build Resilience (Advanced)

The world’s most High reliability Organizations (HrOs) don’t try to eliminate all errors. They don’t “Proceduralize everything” either. Instead, they build resilience so that most errors become easier to detect,

recover from, and learn from. How do HrOs do this? One method they use is to look for “weak signals,” like the sound an engine makes when it’s just starting to develop a problem. Novices miss weak signals. but experts sense them and act on them quickly to manage errors before they cascade into catastrophes. So talk with 1-2 trusted peers and identify one weak signal for a complex job that you all do. Name that weak signal, and what to do about it. Then teach that to your apprentices instead of hoping that they’ll discover it on their own.

If these seven steps seem like a lot, don’t worry. Just pick the one that resonates with you the most right now, and discuss it with a few trusted colleagues. When ready, try it out in a low-cost, low-risk micro-experiment. A few small, quick wins will help you build momentum fast!

ABOUT THE AUTHOR:

Jake mazulewicz, Ph.D. shows leaders in high-hazard industries why errors are signals, not failures, and how to address the deeper problem, so that everyone can work more reliably and safely. He keynotes and advises all across North America. He has a decade of experience in Safety for electric utilities, and served as a firefighter, an emT and a military paratrooper. To learn more, visit www. reliableorg.com

INDUST r IA L MACHINERY DIG e ST cOm IMD | 19

IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

Form your own inserts. • Cost savings (up to 90%) • High load threads - stronger joints • High process reliability • Faster production cycles Advantages & Benefits • No special machinery required • Small investment • Increased material thickness • Long tool life 773-290-1040 | info@formdrill-usa.com | www.formdrill-usa.com • Chipless process • Innovative technology suitable for steel, stainless steel, copper, brass, and aluminum Drill. Tap. Assemble.

ROEQ Announces New Cart System for OMRON Autonomous Mobile Robot LD-250, Doubling Payload Capacity

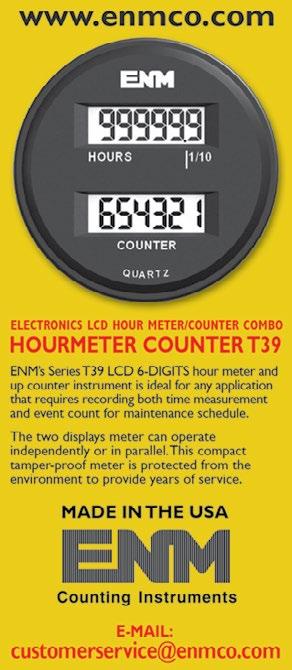

RoeQ, a leader in mobile robotic equipment, has entered into a new partnership with oMRon, providing top modules and cart systems for the company’s autonomous mobile robot, the lD-250, doubling the aMR’s payload capacity to 500kg (1,102lbs).

Businesses deploying the OmrON LD-250 autonomous mobile robot (Amr) now have a powerful new option to dramatically increase payload without having to invest in a larger, more expensive Amr solution. The rOeQ solution with the new Tmc500 top module and cart500 developed for the OmrON LD-250, not only doubles the Amr payload, it also provides a standardized, safe, and flexible solution for internal logistics tasks.

“This exciting new relationship with rOeQ gives our customers access to fast and cost-effective options for their toughest mobile automation initiatives,” says Kyle Hable, Group Product manager, OmrON robotics and Safety

Technologies, INc . “OmrON customers around the world depend on our mobile robots for their flexibility, reliable performance, and best-in-class fleet management.

rOeQ’s global presence is a perfect match to aid customers with successful autonomous intralogistics solutions.”

michael ejstrup Hansen, managing Director at rOeQ, emphasizes how the new product and OmrON partnership is part of a rOeQ strategy to expand its mobile robotic equipment (mre) solutions to more Amr brands: “As a leading quality global brand of Amrs, OmrON is a natural partner for us,” he says. “We developed the cart solution for the LD-250 due to its flexible use and the clear benefits

20 | IMD December 2022

ManUfaCTURing sHowCase

that it adds in both automotive manufacturing, digital and semiconductor industries, food and consumables, warehouse and logistics, and medical verticals.”

released in 2019, the LD-250 is a fast-growing solution within its performance class. OmrON is one of the Amr pioneers, having sold its first mobile robot fleet in 2013, a fleet still in operation today.

The rOeQ Tmc500 solution consists of a top module and the rOeQ cart500. The solution is versatile, with free-space pick up and mounting holes on the cart500 for attaching crates and shelves on top of the cart. The robot can dock to the cart from both ends – for greater logistics efficiency – and has easy access to the emergency stop button for cargo up to 120 cm (47.2”). The rOeQ solution comes with software for easy and consistent setup of the system, enabling a seamless integration between the rOeQ Tmc500 and the OmrON LD-250. The software

includes rOeQ Assist and rOeQ safety zones definitions and the solution works with the OmrON operating panel. “With this new product offering and partnership, we look forward to providing OmrON customers with a powerful and cost-effective solution,” says michael e. Hansen, emphasizing how the rOeQ mre enables compact Amr models to transport heavier load while maintaining maneuverability even in narrow spaces.

INDUST r IA L MACHINERY DIG e ST cOm IMD | 21

Hydraulex is now one of five Authorized Linde Service Centers within the USA & Canada. Being a part of the Linde Service Center (LSC) Program - we have factory-trained technicians, and are factory-supported by Linde Hydraulics. We can help with your Linde HPV, HPR, HMV, HMF, HMA, CMV and CMF series components with replacement units, repairs and parts. To learn more, give us a call, email us or visit us at HYDRAULEX.COM 1.800.323.8416 seattlesales@hydraulex.com WE’RE AN AUTHORIZED LINDE® SERVICE CENTER www.hydraulex.com IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

How Semiconductor Fabricators are Working Through Global FFKM Shortages

g reene Tweed leads the Response

By Nick McNeal, Director Semiconductor Strategy, Greene Tweed and Thyag Sadasiwan, Director Chemraz®, Greene Tweed

The decade began with a semiconductor shortage that made the world acutely aware of how critical these tiny components are in many aspects of everyday life and for most sectors of the economy. Demand for semiconductors skyrocketed driven by a pandemic-led rise in remote work, distance learning, gaming, entertainment, internet shopping, data analytics, and soaring sales of vehicles, and will continue to grow, doubling the global chip market to over $1 trillion by 2030.

Keeping up with this demand, however, has been complicated by a different shortage — the limited availability of small but critical components required by the chip fabrication process: chip fabrication processes depend on the FFKm (perfluoroelastomer) O-rings, gaskets, and other seals that can stand up to the extremely high temperatures and aggressive chemicals while controlling particulate excursions that cause contamination.

Unsurprisingly, this has triggered an even higher demand for FFKm seals already popular in the semiconductor industry. While most manufacturers are expanding capacity as quickly as possible, demand continues to

outpace supply – further increasing the need for FFKm materials and leading to shortages. The current global shortage of FFKm is caused by limitations in the supply of raw materials occurring at the same time as the acceleration in demand for FFKm products.

Causes of the global supply shortages

First let’s look at the supply constraints. The global supply of raw material feedstocks necessary for FFKm production has been severely limited by two factors — environmental restrictions and geo-political events.

Increasing environmental restrictions

environmental and regulatory agencies around the world have been tightening regulations on several industrial products and manufacturing processes around the world that directly impact FFKm production. restrictions on per- and poly-fluoroalkyl substances (PFAS), with more complex and stringent regulations, have been squeezing availability for several years. Some of the FFKm suppliers have either had plants shut down or lines interrupted by regulators. In response, PFAS

suppliers for FFKm production are in midst of multi-year processes of engineering fluorosurfactants out of their manufacturing processes.

Tetrafluoroethylene (TFe ) a fluorocarbon with the chemical formula c 2F4 is a raw material used in all FFK m . It is extremely dangerous to handle. Therefore, the time-consuming process of engineering, siting, and permitting makes it difficult for existing facilities to expand capacity and poses very barriers to entry for new facilities.

Geopolitical situation

In 2022, the russia-Ukraine conflict has exacerbated supply shortages. FFKm formulations are extremely unique and require a multitude of specific chemistries working in unison to create the final formulation. Some of those unique chemistries are constrained due to the technologies only being available in areas impacted by the russia-Ukraine conflict..

Chemraz® FFKM seals

Superior Performance

» minimal metallic ion content

» exceptional plasma resistance

» Low particle generation

» High dimensional stability

22 | IMD December 2022

inDUs TRial fabRiCaTion & aUToMaTion

Operational benefits

» Superior reliability

» enhanced repeatability

» maximum system uptime

» Lower cost of ownership

fabrication?

As chipmakers pack in more and tinier transistors in their chips, they are turning to more demanding manufacturing processes that rely on ultraclean processing. They need seal materials with excellent chemical stability and high heat tolerance. The chemical properties of FFK m make it ideal for many demanding sealing applications in semiconductor fabrication, as its name “perfluoroelastomer” describes:

» elastomer — a synthetic rubber characterized by elastic properties. elastomers are built upon long chains of carboncarbon polymer with crosslinks that serve as a backbone that

Greene Tweed offers a full spectrum of FFKM materials to suit the needs of a variety of semiconductor fabs, including Etch, Deposition and Aqueous processes. Greene Tweed has sealing solutions for fabs that use the most advanced technology nodes in the most aggressive operating environments, as well as those requiring less-stringent particle process controls.

provides the elasticity (recovery from deformation) that provide durable, effective mechanical seals (in contrast to PTFe, which lacks elasticity). However, the long chains and crosslinks that connect elastomers can break down

under extreme temperatures and pressures and chemical attacks.

» fluoroelastomer — Therefore, the carbon backbone is surrounded by relatively large fluorine atoms, creating a robust shielding effect against

•

•

•

•

INDUST r IA L MACHINERY DIG e ST cOm IMD | 23

What is driving the demand for FFKM in semiconductor

C-FRAME PRESSES HYDRAULIC MACHINES OF IOWA A Division of Betenbender Mfg. Inc Phone: 319.435.2378 | Fax: 319.435.2262 www.betenbender.com • Heavy Gauge

• Press

WE CAN BUILD A CUSTOM MACHINE FOR YOU! WWW.MACMHYDRAULIC.COM 7355 N. Lawndale Ave., PO Box 6, Skokie, IL 60076 PHONE: 847-676-2910 FAX: 847-676-0365 CHAR-LYNN HYDRAULIC PRODUCTS LOW SPEED HIGH-TORQUE MOTORS… The Char-Lynn motor range consists of three major types based on the valving used to distribute fluid through the Orbit gear set (geroler or gerotor), Spool Valve, Disc Valve and VIS (Valve-in-Star). A variety of displacement sizes are available in each of the three motor types to provide a wide range of speeds and torques. GEAR PUMPS… Eaton Series 26 gear pumps with 13-tooth gears minimizes flow ripple to reduce noise and vibration. Bearing lubrication system uses inlet oil rather than high pressure oil, improving volumetric efficiency and power output. The 13 available displacements and many mounting configurations provide for an easy retrofit. Other series available. STEERING CONTROL UNITS… offer these advantages:

Steel Design

Bed bolted on, not welded, to prevent distortion. • Large press bed to accommodate a variety of tooling other than just punching. • Pump, motor, valve and reservoir are all easily accessible for maintenance. • Large rectangular tubes used at base of machine to give safe, instant portability.

Minimal steering linkage reduces cost, provides design flexibility.

Complete isolation of load forces from the control station.

Continuous, unlimited control action with low output torque.

Wide

of control circuits and meter sizes.

selection

of power steering pumps or fluid

IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

• Works with many kinds

supply.

chemical attack. The carbonfluorine bond is the most stable in organic chemistry resulting in extreme resistance to high temperatures and pressures.

» perfluoroelastomer — The “per” prefix means “fully” fluorinated, for the highest level of temperature and chemical performance in the fluoroelastomer family. At a fluorination level of 73%, perfluoroelastomer (FFKm) provides higher temperature and chemical resistance than fluoroelastomer (FKm) which has a fluorination level of 66-70%.

The fully fluorinated FFKm takes advantage of the strong carbonfluorine bond (approximate bond energy of 105 Kcal/m), compared to the carbon-hydrogen bonds (approximately 80 Kcal/m) present in FKm and other elastomers.

Superior performance for the most demanding fabrication methods combining the broad, almost universal chemical resistance of PTFe with the resilience of elastomers, FFK m seals are found throughout a broad range of mission-critical equipment in key process areas of the world’s semiconductor fabs, including etch, deposition, aqueous, and electro-chemical (electroplating).

As the first in the nation to use cleanroom manufacturing, Greene Tweed has continually evolved to meet the rapidly changing needs of the semiconductor industry. Greene Tweed’s line of chemraz® FFKm seals, feature the highest chemical compatibility and temperature resistance of all elastomers, up to 615°F/324°c and are designed to withstand the latest plasmas used in cutting-edge deposition and etch wafer process operations. Our range of integrated solutions leverages bonding, encapsulation, and coating capabilities to provide extra protection for critical components. These FFKm integrated sealing solutions boost productivity while reducing contamination and

maintenance expenses. by extending mTbr (mean time between repair), FFKm seals reduce costly unplanned downtime and the associated production losses, safety hazards, and environmental degradation.

Broad spectrum of FFKM solutions tailored to each application

These sealing solutions have continually advanced to resist the harsh plasmas and chemicals found in the latest methods of wafer cleaning, patterning, deposition, and various other wafer fabrication processes.

Rapid Development of New Compounds

The elastomer center of e xcellence located at the Greene Tweed Advanced Technology Group Headquarters in Kulpsville, PA, is dedicated to the advancement of new elastomer compounds and offers complete integration of processes –from initial raw material mixing and development to prototype product packaging. The center brings speed, efficiency, and agility that accelerates the pace of new semiconductor compound development.

The center contains a large all-inclusive cleanroom environment to deliver the industry’s most advanced perfluoroelastomers that meet stringent quality and cleanliness requirements The process systems feature some of the highest industry lab standards and include mixing mills/internal mixers, extruders, press systems, post-cure ovens, inspection systems, and a cleaning and packaging area. In addition, the center can conduct application-specific exposure experiments with plasma etch systems and UV/ozone systems and extensive testing capability for composition/morphology and material properties.

Rapid Development of New Product to Mitigate the FFKM Shortage

This new product development capability has also positioned

Greene Tweed to lead the market in the rapid introduction of new FFK m products that replace ingredients that are supply constrained with more readily available feedstock materials.

This year, the center has prioritized its work to focus almost exclusively on developing substitutes for supply-constrained chemraz products that our semiconductor customers have identified as most critical to their operations.

These new formulations are subjected to rigorous testing to ensure that they meet the extreme thermal and chemical resistance requirements of demanding semiconductor fabrication applications without causing harmful particulation.

The first replacements to be released will be materials equivalent to c hemraz 657 and c hemraz e 38, for dry plasma and O2 plasma etching processes requiring minimal contamination. These new product offerings will be available for testing on a limited basis in late 2022 and generally available in mid 2023.

Greene Tweed application engineers will also continue to work with semiconductor customers to identify existing Greene Tweed products that can serve as substitutes for FFKm products that have limited availability and will continue to utilize the center’s capabilities to rapidly create samples for testing and verification of the customer’s sealing application.

Future Outlook

The Global FFK m shortage will continue well into 2023. Throughout the remainder of 2022 and into 2023, Greene Tweed will continue to launch new materials aimed at achieving performance equivalency but with a more robust supply chain.

The global supply shortage of FFKm raw material feedstock is expected to ease during the first half of 2023, with an expected increase in feedstock asset capacity during 2024-2025.

24 | IMD December 2022

For over 50 years! www.betenbender.com Call for a free catalog! Phone: 319-435-2378 | Fax: 319-435-2262 | sales@betenbender.com Hydraulic Shears: 1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4” Press Brakes: 50-Ton to 550-Ton C-Frame Presses: 40-Ton to 200-Ton Custom Designs: for Custom Applications Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications. Precision Knife Sharpening AMERICAN-MADE SHEARS & PRESS BRAKES

ABRASIVE POWER TOOLS AND PROCESS SOLUTIONS

Since 1969, Dynabrade has been a global leader in the innovative design and manufacture of industrial abrasive power tools and related accessories. We’ve earned an outstanding reputation and position of leadership in the pneumatic tool market and have been supplying high quality, American Made power tools to customers through a worldwide network of professional distributors.

Discover The Dynabrade Difference...

SALES SUPPORT

Factory-trained experts on tools, air systems, accessories and abrasives.

– “Process Solutions” approach: sales personnel outfitted with tools, accessories and abrasives for on-site demonstrations.

COST SAVINGS

Let us analyze your air system with our Performance Assurance Kit.

– “Same Day/Next Day” shipping on most USA orders.

– USA Flat Rate Repair Program offers quick repairs by factory-trained experts. End-user conversion programs.

TRAINING

On-site tool training clinics to educate your personnel.

– USA Mobile Training Units bring products directly to the workplace.

– Online demonstration videos available.

CUSTOMER SERVICE

Talk with a trained Customer Service Representative.

– Discuss tool specs and applications with an experienced Technical Support Person.

– Utilize our online literature library.

PROUDLY DESIGNED, ENGINEERED, AND BUILT IN AMERICA SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | WE LISTEN. WE OBSERVE. WE OPTIMIZE.

“The Original” Dynafile® Pipe Belt Finisher PROUDLY DESIGNED, ENGINEERED, AND BUILT IN AMERICA SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | WE LISTEN. WE OBSERVE. WE OPTIMIZE.

How We Can Inspire Our New Generation Into Engineering

It’s no secret that the engineering sector is experiencing a shortage of workers. In fact, research shows that the industry will need to train and employ around 200,000 people by 2024 to fill the gap.

Here, we’ll explore how your business can inspire students and professionals to become the engineers of tomorrow.

Inspiring young people into engineering

First and foremost, your business can focus on encouraging young people into engineering, whether they’re secondary-school leavers or graduates seeking roles within the industry.

Partnering with educational institutions

In order to do this, your business should consider partnering with educational institutions to inspire people before they enter higher education. One way you can do this is by offering career events in secondary schools. These events enlighten young people about the inner workings of the industry, such as using complex building design software

that they would not have previously come into contact with. As well as this, you can make graduate programs available to those leaving university. multiple institutions are willing to partner with reputable businesses, such as how Teesside University and ITS Ltd, a specialist automation systems developer, came together in an effort to tackle industry staff shortages within the North east of england.

Offering worthwhile apprenticeships

Your business can also offer engineering apprenticeships for school leavers. These can train people interested in an engineering career even if they don’t want to attend university. The benefits of these for students are endless, from being able to work alongside professionals within the engineering industry to prioritising 20% of their time to training and studying.

engineering apprenticeships, as well as other industry placements, are also available to seasoned workers as long as they’re over the age of 16. This approach could be critical to rebuilding the workforce, especially considering that 71% of engineering employers who are experiencing difficulties

28 | IMD December 2022 woRkfoRCe De VeloPMenT

filling employment positions claim the issue lies with a lack of engineering or technical skills in the talent pool.

Graduate schemes

As well as this, your business can offer graduate programmes. These are a great way to connect with emerging talent in the industry, especially while the engineering sector is experiencing a shortage of skilled workers.

Graduate programmes are beneficial for both employers and employees. It is an attractive route for people wanting to break into the engineering industry, with research showing that the average salary for

Sources

graduate engineering programmes is £28,000 in the UK. On the other hand, they are a great way for businesses to employ and nurture new talent while they can.

Recruiting professionals into engineering

On the other hand, your business can help to solve the shortage of skilled workers by focusing on training and retaining professionals.

Back-to-work schemes

It’s not uncommon for people to take a break from their careers. This might be to upskill in other areas or to prioritise personal issues such as caring for family members. While common, it may be difficult for people to return to the workplace after this break.

In fact, this is also an issue within the engineering sector. research shows that 40% of women who choose to take a prolonged break from their career in STem to care for their children feel there are barriers to returning to their careers.

To tackle this and encourage people to return to their STem jobs, including engineering jobs, businesses can offer back-to-work schemes. These are common practices around the nation, as companies run 12-week paid return schemes or training schemes to potential workers.

Improving company culture

It’s no secret that multiple businesses across the nation are struggling to retain their staff. The engineering sector is also experiencing this hardship, with research discovering that 32% of

engineering workers left companies due to their employer’s company culture. The logical solution, therefore, would be to improve company culture wherever possible.

Your engineering company can boost company culture in a number of ways. This can come in the form of employee recognition, social events, hybrid working schemes, or employee rewards. The trick is to have fun while doing it!

Career progression

career progression is an attractive selling point in any career. No one wants to feel like they are stuck in the same position or same level for too long. This can become monotonous, possibly leading to your employees leaving their for another.

In fact, according to research, 86% of workers within engineering, as well as architecture and building industries, are eager to learn new work skills. And 28% believe career progression is one of the most important goals of their professional careers.

To ensure your employees feel fulfilled in their role, your business can create career progression plans. This can be something like offering educational courses that will continue to challenge their knowledge and work as a method of upskilling.

While it may take time and resources, there is hope that the industry will be able to fill the skills shortage in time. If, in this case, businesses do their part and encourage people – both school leavers and current employees – to become engineers.

https://www.crooton.com/2022/02/22/what-is-the-future-of-recruitment-in-the-engineering-sector/ https://educationhub.blog.gov.uk/2021/02/11/women-in-stem-week-2021-how-were-empowering-the-next-generation/ https://www.mazakeu.co.uk/inspiring-the-next-generation/ https://www.tees.ac.uk/schools/scedt/news_story.cfm?story_id=7914

https://www.gov.uk/employing-an-apprentice

https://pwemag.co.uk/news/fullstory.php/aid/4928/engineering_skills_crisis_prompts_calls_for_urgent_government_action.html https://uk.talent.com/salary?job=engineering+g raduate+Programme

https://employernews.co.uk/news/recruitment-bias-preventing-talented-engineers-from-returning-to-work-after-a-career-break/ https://engineering-jobs.theiet.org/article/returning-to-your-engineering-career https://www.fenews.co.uk/employability/the-engineering-sector-has-trouble-retaining-staff-heres-why-your-workers-need-regulartraining-and-motivation/

INDUST r IA L MACHINERY DIG e ST cOm IMD | 29

Since 1986

IMD – North America’s Manufacturing Resource for Industry Professionals

Shop Automation Isn’t Rocket Science

Machine shop automation doesn’t have to be of the Star Wars variety to produce a solid return on investment. In fact, most shops are simply looking for a low-cost automation application that is easy to set up and use, cost-efficient and, most importantly, provides unattended machining time.

For many, however, automation conjures images of sophisticated, high-tech machinery with other-worldly price tags. In addition to the perception of high cost, many shop owners share the belief that automation will actually slow production down with steep learning curves on programming, operation and maintenance, limiting the variety and scope of the shop’s work.

most of the concern is unfounded, however, as there is no universal automation solution for all production processes. rather, automating operations is based on an application-by-application evaluation. The decisions to automate and then to what extent are not and should not be automatic. A variety of considerations precede a determination as to what type and how much automation is necessary to improve throughput while getting a good return on the investment.

The first step in automating is defining and setting realistic production goals: What, specifically, does a shop want or need to improve? The result of that analysis sets

the parameters for the amount of automation and aids in determining what jobs/operations will benefit most.

How much automation is necessary?

It doesn’t have to be complicated. A turning operation can be automated with the simple addition of a bar feeder and parts catcher. bar feeders, if correctly matched to the application, are efficient, effective solutions that immediately increase productivity. Available in several lengths, bar feeders autonomously load barstock into cNc turning centers, freeing the operator to monitor multiple operations and opening the door to practically unattended and lights-out operation. Job shops typically running high-mix, low-volume production runs generally benefit more with a short bar feeder while high-volume, low-mix operations are usually more suited to the longer bar feeders.

In the same vein, gantry loader (GL) automation provides fast loading and unloading for turning centers in high-volume manufacturing applications involving larger work pieces that won’t fit through the spindle. GL automation provides high-speed, high-accuracy workpiece loading/unloading for unmanned operation over extended periods of time. This can be particularly beneficial when paired with a twin-spindle multi-Tasking machine that can also transfer parts, enabling DONe IN ONe® processing.

30 | IMD December 2022

new TeCHnology

However, special attention to fixturing or workholding may be required when machining large work pieces to process hefty parts through complex setups.