Single Wire

Multi Wire

Bunches & Strands

Welding Wire

Single Wire

Multi Wire

Bunches & Strands

Welding Wire

Elcowire is a sustainable partner for companies that are key to the ongoing energy transition and electrification of our society.

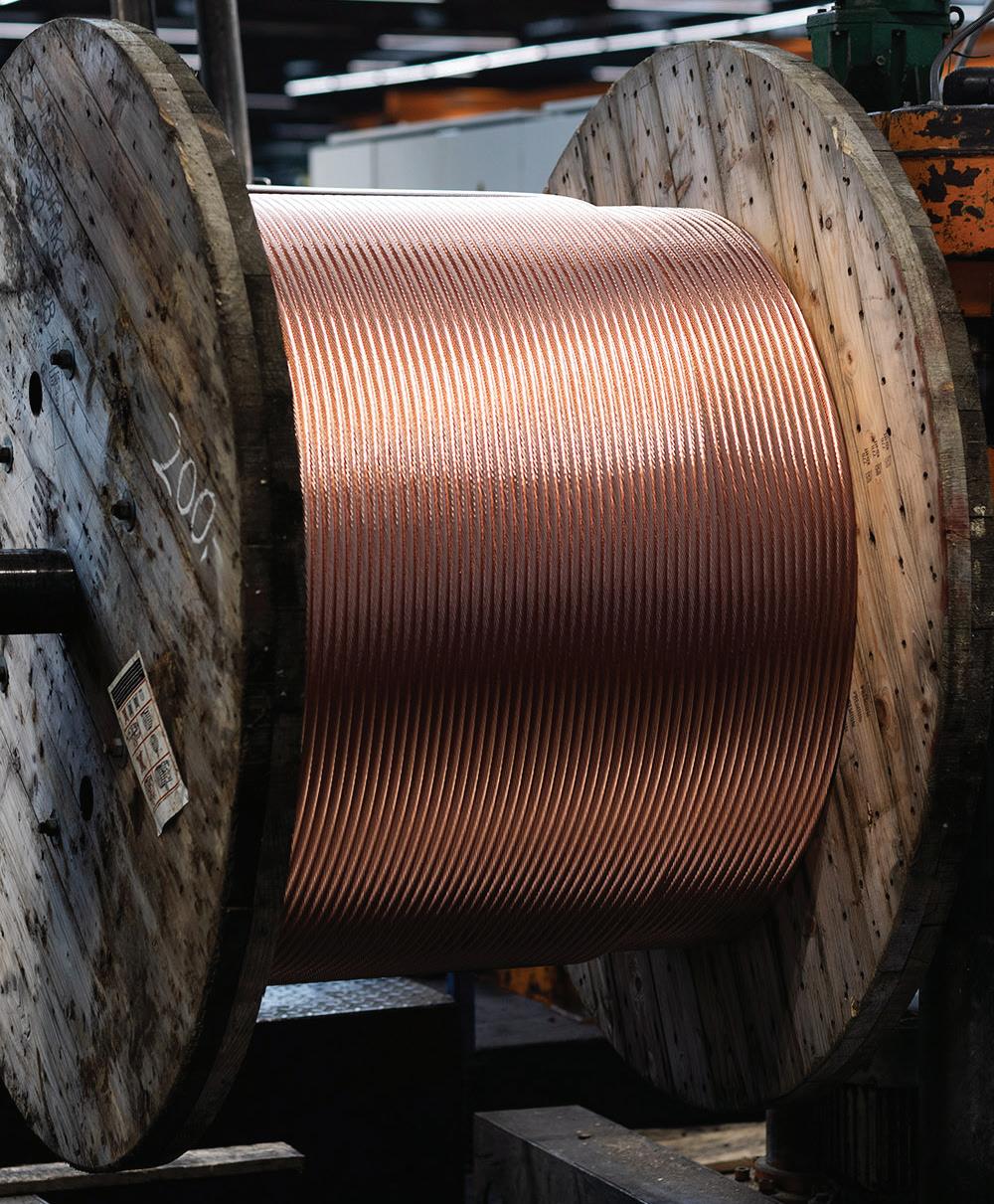

With an annual capacity of 300 000 tons Elcowire is one of the largest manufacturers in Europe of copper wire rod, wires, stranded conductors, profiles and overhead catenary systems made from copper, copper alloys and aluminium.

Elcowire can offer Low-carbon Copper, standard materials and customized solutions aiming to support our customers in meeting their specific targets.

Our high quality products offer a range of benefits, such as reduced energy loss, increased efficiency, enhanced reliability, longer lifespan and recyclability. These benefits make Elcowire an excellent choice that meets the energy needs of the society while minimizing environmental impact.

As of today, we offer products less than half of the global average CO2 emissions, as confirmed by the International Copper Association (ICA), and we also see a large potential both in terms of improved efficiency in the processes and the increased use of renewable energy sources such as solar, wind and hydropower capacity.

Business Unit Wire & Strands offer bare and tin plated drawn copper wire products of a wide range in terms of dimensions, constructions and qualities depending on the need and specification from the next user in the value chain – all made with our own copper wire rod and our passion. With two production facilities (Germany and Sweden) we are certain to offer our customers a reliable supply chain.

The copper business is not just about the products at Elcowire. Our dedicated colleagues are like family, and many of Elcowire's staff is second or third generation. Every day, we strive to adopt more environmentally sustainable workplace practices, to fulfill corporate social responsibility, and because sustainability makes business sense in terms of improved employee health and well-being.

The tradition of more than 200 years of knowledge is a torch that gets passed down from one generation to the next and we wish you will join us on our continuing journey to reach net zero carbon emission.

Let us get ready for the most sustainable solutions.

elcowire.com

As Northern Europe's leading provider of copper wire products, Elcowire is devoted to supporting our planet's shift to greener energy sources and raw materials.

We focus on developing solutions that enable electrification of transportation, expanding solar and wind power sources and the the widespread growth of a modern and sustainable infrastructure.

We are a dynamic international group with strong attention to our customers' needs.

We work directly with you, providing excellent customer support, the highest quality products, reliability, a focus on detail and a close technical partnership.

- The focus is sharp and offer strong on sustainable products and solutions.

ELCOWIRE AB

ELCOWIRE GMBH

With two production sites we can offer flexibility and a reliable supply chain.

Elcowire in Sweden produces soft and hard drawn copper wires, from own wire rod, between 1,1 and 4,1 mm with a bare surface for the utilization, such as rod break down wire in the cable industry and conductor for welding applications.

Our single wires are also used for our production of strands.

Elcowire in Germany produces a wide range of soft and hard drawn copper wire products, from own wire rod, made of diameters between 0,05 and 4,6 mm. We supply our drawn wires to our customers in the cable industry and packaging industry in different shapes; single wire, multi wire, bunches and strands with a bare or tinned surface.

AS ONE OF THE LEADING EUROPEAN SUPPLIERS OF COPPER PRODUCTS, ELCOWIRE IS COMMITTED TO SUSTAINABLE COPPER SOURCING.

MINING

Elcowire is working with the eco-friendliest mines in the world, together we are finding solutions to minimize the climate impact of our supply chain.

Our contact wires power electrified trucks at the mine, as well as the trains that deliver copper to our production sites.

We produce and deliver sustainable products with high quality and low CO2footprint to our customers, and when the final application needs to be replaced, the copper is returned to a recycling process and reused in our copper production:

A new product with high quality and low CO2footprint is produced and delivered to our customers.

Producing new products from existing copper products in applications that needs to be replaced, instead of taking raw material from the mine, is what we call: Urban mining.

with less than 50% CO2

Smelters are powered by electricity from renewable sources, mainly hydro power.

Excess heat from smelting process is transferred to the cities´ heating system

Our lean manufacturing takes in account the use of renewable energy sources, low waste and negligible use of chemicals.

With the input of conducting material, delivered customers produce their own products with an lower

WITH SUSTAINABLE SOLUTIONS

We ensure the loop continues to go around and around and around...

WE ARE DEVELOPING ADVANCED TECHNOLOGIES TO PROVIDE OUTSTANDING ENERGY SAVING PRODUCTS WITH MAXIMUM USEFUL LIFE TO ENABLE SUSTAINABLE SOLUTIONS – TAILOR-MADE TO OUR CUSTOMERS' NEEDS.

ELCOWIRE CAN OFFER STANDARD MATERIALS, LOWCARBON COPPER, RECYCLED COPPER AND CUSTOMIZED SOLUTIONS AIMING TO SUPPORT OUR CUSTOMERS IN MEETING THEIR SPECIFIC PURPOSES.

Elcowire’s drawn wire products are made of Elcowire’s own copper wire rod and comply with the highest quality requirements. We have a completely integrated and closed cycle which we keep in our hands, starting with the production of our own wire rod and with good quality wire rod we produce outstanding product variety of drawn wires, with excellent drawability, conductivity, product flexibility and surface.

Our upstream technologies to produce wire rod guarantee that every application receives exactly the right material. This sets a high standard in the market. Elcowire sells semi-finished wire products at every level of finish. That allows our customers to conduct their own business flexibly and in their own way, thereby gaining a competitive advantage.

Based on the experience of 200 years we manufacture bare and tinned wires in different shapes. Starting from a single wire, drawing up to 16 multiwires simultaneously we continue to produce bunches and strands followed by testing, packaging and transportation.

All our drawn wire products are supplied in specially made, standard-compliant and secure packaging. Our packaging solutions guarantee retention of shape ensuring that product’s properties are preserved to the outmost after leaving the factory and during the utilization of our products in the customer’s downstream process.

We produce our drawn wires in pure copper and alloys according to European and international standards or to the specifications defined by our customers. And it’s a part of our mission to support our customers to develop new specifications and to optimize existing products. In that way we create significant opportunities to make products with outstanding characteristics made for specific purposes and targets.

Today we are a leading supplier in Europe, in the aspect of drawing, tinning, bunching and stranding. We installed all the test equipment and procedures needed to check fulfilment of the requirements of common wire standards like EN 13602 and individual customer's specifications.

Our activities, our business processes and structures are based on well-established management systems for quality ISO 9001:2015, environment ISO 14001:2015 and energy ISO 50001:2018 and we also meet the high requirements set by the automotive quality standard IATF 16949.

Half of the carbon emissions over its production processes, compared to the global average footprint for standard copper.

Low-carbon Copper is made possible through production that has undergone a substantial transformation due to electrification and automation of various stages of the process.

The Low-carbon Copper has also been made possible by a very efficient ore concentration process and a world-class green energy mix. The result is copper wire that has a low impact on nature and the climate.

The significantly lowe r CO2 emissions of the Low-carbon Copper are verified through several validation processes. The reporting protocol that is used for verification is the Greenhouse Gas Protocol – Product Life Cycle Accounting and Reporting Standard.

The product is also validated and reviewed against the general principles in ISO 14064-3 Standard.

Environmental declarations have been developed for Elcowire’s products, including Low-carbon Copper.

Our footprint is verified through mass balance-based self-declarations for Low-carbon Copper Wire Rod and Low-carbon Copper Profiles, as per the framework in ISO 14021.

This is a first important milestone for Elcowire and the next step is to perform calculations of the carbon footprint for drawn wire products.

Elcowire aims to be a sustainability leader in its business, and therefore the carbon footprint is strategically important.

For more information, please visit our website; elcowire.com

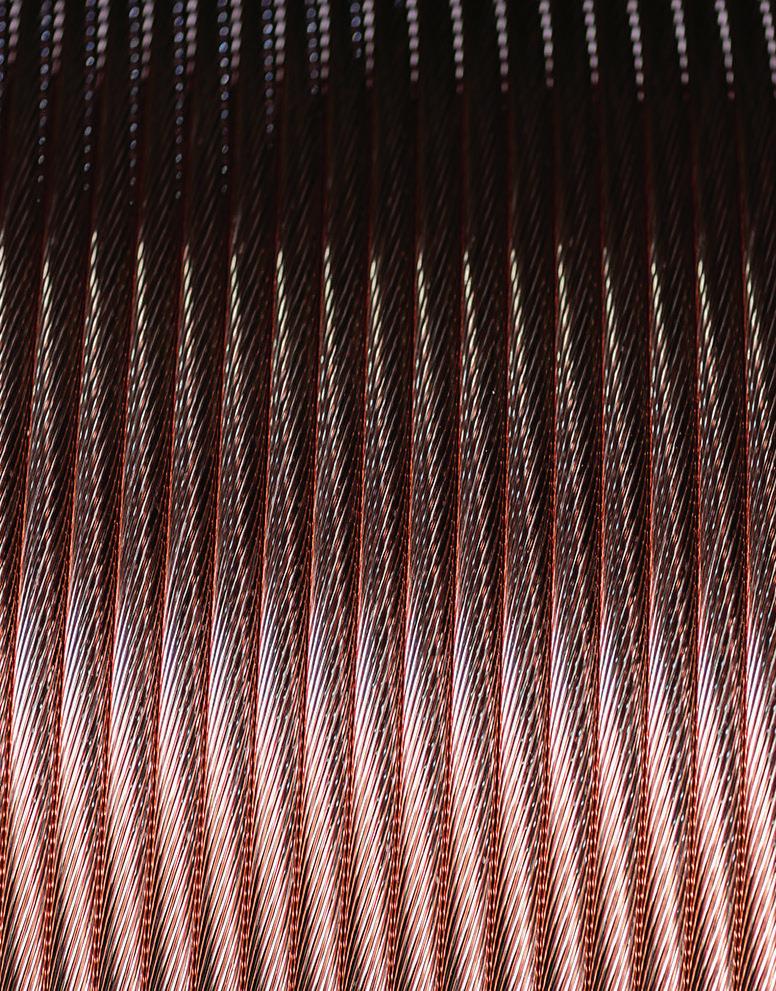

By element we don’t mean water, fire, air or earth. Our element is copper. In Elcowire we draw copper wires in a range of diameters between 0,05 mm and 4,6 mm, with bare and tinned surfaces designed for applications requiring an excellent processability with regard to drawability and wire surface. Delivered at an outstanding high service level our single wires and multi wires create the base for applications of our customers as well as for the downstream process in Elcowire’s manufacturing of bunches and strands.

Round drawn copper wire compliant with EN 13602, as well as individual customer specifications;

Surface bare or tinned;

wire diameter for tinned wires 0,3 mm to 2,8 mm; total tin coating on pre-drawn wires between 2,5 µm and 13 µm; total tin coating on finished wires min.0,8 µm;

hard drawn or soft annealed test certificate 3.1 according to EN 10204 with mechanical values (chemical values on request)

Round drawn copper wire compliant with EN 13602, as well as individual customer specifications; Surface bare or tinned;

Total tin coating: 0,05 mm to 0,14 mm min.0,4 µm >0,14 mm to 0,29 mm min.0,6 µm >0,29 mm min.0,8 µm

Soft annealed:

wire bundles consisting of 5 to 16 ends; dynamically or statically spooled depending on wire diameter test certificate 3.1 according to EN 10204 with mechanical values (chemical values on request

All of our products come in specially made or standard-compliant, secure packaging. Our packaging guarantees retention of shape, ensuring that a product's properties are preserved to the utmost after leaving the factory. Sea-worthy packaging is also standard for our overseas clients. We can also assess individual requirements provided they can be presented as a drawing.

- Mini barrel / E 500, max. capacity 300 kg filling weight

- Cardboard octabin type N, max. capacity 1200 kg filling weight

- Cardboard octabin type J, max. capacity 1700 kg filling weight

- Cardboard octabin type SNXXL, max. capacity 1700 kg filling weight

- Cardboard octabin type SXXL / Oct 1200, max capacity 2300 kg filling weight

BUNCHED & STRANDED WIRE

BARE AND TINNED

HOT WIRED - TO A SUSTAINABLE FUTURE

STANDARD AND SET-UPS IN DIN EN 60228 / VDE 0295

2, 5 AND 6

IN MM² CLASS 2 CLASS 5 CLASS 6

Real-time communication, e-mobility, green energy transition for a more sustainable living together - none of these trends can be reality without copper, particularly without our bunches, strands and ropes. 7 – 19 – 37 – 61 is the code for flexibility.

Elcowire manufactures copper bunches, strands and ropes in a cross section range between 0,05 mm² and 1000 mm² with bare or tinned surface.

Our optimised conductors with high conductivity and outstanding surface quality are made precisely for our customers’ specific needs for applications which require high flexibility.

Bunches, strands and ropes made of round drawn copper wires compliant with EN 60288 (VDE0295), as well as individual customer specifications;

Surface bare or tinned; wire diameter in tinned bunches, strands and ropes 0,05 mm to 2,8 mm; total tin coating for wire diameters:

0,05 mm to 0,14 mm min.0,4 µm >0,14 mm to 0,29 mm min.0,6 µm >0,29 mm min.0,8 µm

Soft annealed, hard drawn on request; cross section 0,05 mm² to 1.000 mm²; delivery of compacted ropes on request test certificate 3.1 according to EN 10204 with mechanical values (chemical values on request)

DELIVERY

SOME EXAMPLES OF PACKAGING

STRANDED WIRE:

All of our products come in specially made or standardcompliant, secure packaging.

Our packaging guarantees retention of shape, ensuring that a product's properties are preserved to the utmost after leaving the factory.

We also offer sea-worthy packaging where required, or specific packaging as per your technical drawings.

We supply in all standard sizes and, on request, in other specifications and materials.

The direction in which stranded wire and wire rope is twisted is indicated by the letters S and Z. Regardless of which side you look at it from , the direction i salways the same:

S= left twist, Z= right twist.

The strands of concentrically structured stranded wire have a precisely defined position around the core of the wire. That ensures an absolutely regular structure.

Concentric stranded wire: 19-strand 37-strand

7-strand

The lay length is the length along the axis of a cable which an element of the wire needs to twist one whole time around that axis. It is defined either in mm or as a multiple of the diameter of the stranded wire.

We supply bunched stranded wires and concentric stranded wire: soft annealed bare or tinned using pure tin in lay direction S or Z.

Numerous strands or bundles of wires are bunched together. The strands within the wire do not have any particular order; their position in relation to one another changes constantly along the length of the wire.

For concentric stranded wire with more than seven strands we different between four different types in terms of lay length:

Unilay: True concentric:

WIRE ROPE:

Wire rope is either flexible or rigid. it is available bare or tinned (using pure tin), wound in lay direction S or Z, sealed or unsealed, soft or hard.

STRUCTURES:

7-strand= 1 + 6

19-strand= 1 + 6+ 12

37 strand= 1 + 6 + 12 + 18

61 strand= 1 + 6 + 12 + 18 + 24

This is wire rope with a symmetrical structure consisting of and wound using pre-stranded wires. The following variations of this type of stranding are available. STRANDED WIRE ROPEL

EQUAL LAY ROPE:

The lay direction of the pre-stranded wire and the rope itself are the same. The diameter of wire ropes made this way is smaller than reverse lay and ordinary lay ropes.

REVERSE LAY ROPE:

The lay direction of the pre-stranded wires is the same as their position and it changes from layer to layer.

CROSS LAY ROPE:

The lay direction of the pre-stranded wires is counter to their position and changes from layer to layer.

Lay directions can also oppose, e.g. Equal lay rope in Z throughout.

Equal lay:

Reverse lay:

Cross lay:

Unilay concentric: same lay direction same lay length

Unidirectional concentric: same lay direction different lay length

Equilay concentric: changing lay direction same lay length

Conventional concentric: changing lay direction different lay length

Equal lay:

S S S S Strand: S S S S - Wire rope: Reverse lay:

Strand:

rope:

lay:

In many regions of the world packaging made of metal is common.

Fruit, vegetable and edible oil can be better protected from light and temperature in tins and cans for a long time.

Flammable substances such as paints, varnishes and technical oils can be stored safely in C anisters and aerosol cans.

A can is the perfect sustainable packaging.

Air ventilations systems define the future standard in modern buildings. They create a healthy environment for the people living and working inside there. And they support to reduce the consumption of energy in those buildings.

Copper welding wire is indispensable for the production of cans and ventilation ducts.

The high quality of our welding wire, its oustanding conductivity and circularity as well as its stable mechanical properties allow to make these products with a high processing speed above the common state of the art level. And after its utilisation the wire starts a second career in the recycling process.

It is a sustainable product for sustainable applications.

The Group has expanded and this has added production capacity, but perhaps even more importantly, sales capacity, technical competence and experience. Capacity is important, but even more so is the knowledge of our Elcowire colleagues.

Language: German, English & French

christoph.busch@elcowire.com +49(0)3476 89 2265

Mobile +49 (0)151 1610 1347

Withsustainabilityinmind,combinedwithwidetechnical knowledgeandexperienceinestablishingnewareasof operationandbusiness,wearelookingforwardtogiveyou answerstoyourquestions... ”

Markets:

Language: German, English

denny.kolbe@elcowire.com

Mobile +49(0)160 96 32 89 32

Markets: Sweden, Denmark, Norway, Finland

Language: Swedish & English

calle.croona@elcowire.com

Mobile +46 (0)705 300 696

Markets: Poland, Czech Republic, Slovakia

Language: German, Polish & English

krzysztof.koenig@elcowire.com

Mobile +48 (0)790 890 350

Markets: Africa, Middle East

Language: Arabic, English & French

walid.touzi@elcowire.com

Mobile +216 24 326 990

Language: Swedish & English

tony.hill@elcowire.com

Mobile +46 (0)703 195 366

Language: German & English

franziska.wedler@elcowire.com

+ 49 (0) 3476 89 2526

CUSTOMER

ANIKA BENDEL

Hettstedt

Language: German & English

anika.bendel@elcowire.com

+49 (0)3476 89 2153

MANUEL LANGER

Hettstedt

Language: German & English manuel.langer@elcowire.com

+49 (0)3476 89 2142

EMMELI ROOS

Helsingborg

Language: Swedish & English

emmeli.roos@elcowire.com

Mobile +46 (0)791 429 157

SABRINA GROSSMANN Hettstedt

Language: German, English & French sabrina.grossmann@elcowire.com

+49 (0)3476 89 2360

MICHAEL CONRAD

Hettstedt

Language: German & English michael.conrad@elcowire.com

+49 (0)3476 89 2268

DÖRTE LÛTHJE-FRISTEDT

Helsingborg

Language: Swedish & English

louise.olsson@elcowire.com

+46(0)42 19 53 15

KERSTIN RIEGLER

Hettstedt

Language: German kerstin.riegler@elcowire.com

+49 (0)3476 89 3031

KAREN CARLSTRÖM

Helsingborg

Language: English & Swedish karen.carlstrom@elcowire.com@ Mobile

+46 (0)790 890 350

ISABELLE

Helsingborg

Language: German, Swedish & English

dorte.fristedt@elcowire.com

+46 (0)42 19 53 42

Helsingborg

Language: German, Swedish, English & French

isabelle.persson@elcowire.com

+46 (0)42 19 53 40

OUR SOLUTIONS ARE AN ESSENTIAL COMPONENT IN THE ELECTRICAL AND INFRASTRUCTURE INDUSTRIES. WITH RESPECT FOR THE ENVIRONMENT AND FUTURE GENERATIONS, WE ARE DEVELOPING ADVANCED TECHNOLOGIES TO PROVIDE YOU WITH OUTSTANDING ENERGY-SAVING PRODUCTS WITH MAXIMUM CIRCULARITY.

Our copper is responsible sourced to prevent abuses of human rights, avoid contributing to conflicts, as well as safeguarding health and safety of miners in the supply chain.

Our cathodes are LME Grade A and in accordance with the standard ASTM B115, or EN 1978.

The Low-carbon Copper has less than half of the CO2 emissions per kg copper compared to standard copper. The reduced CO2 emissions of our Low-carbon Copper have been validated scientifically and will play an important role in the transition, to achieve the goal of net-zero CO2 emission by 2050 set by the EU. The carbon emissions reduction by using Low-carbon Copper is based on using copper mines with electrified production, Elcowire's lean prodution methods, very efficient ore concentration process and a world-class green energy mix.

Elcowire sets the example by producing semi-fiished and finished products that have a low impact on nature and climate.

One of the most significant benefits of copper is its recyclability. Copper is a highly sought-after material in the recycling industry because it can be recycled over and over again without losing its quality or purity. This means that copper can be reused in new products, reducing the need for mining and extraction of new copper ore. Recycling copper also reduces energy consumption and greenhouse gas emissions associated with copper production, making it an environmentally friendly choice. Elcowire's waste management and processing of materials are focused on going from linear flows to circular flows, supporting the core of a circular economy.

End-of-Life materials can be sent back to smelters to be refined inseveralprocesssteps Metals are extracted withlowestpossible impactfrom suppliers' mines

Mines Suppliers(smelters)

Cathods(rawmaterial) manufacturing

Internalmetalscrap isrecycled

Processscrap from customers canberecycled at Elcowire

Elcowire -Wire,rodandconductor materialmanufacturing Customers -Cableandothercopperbased soluctionsmanufacturing

Elcowire's circularity process enables our customers to reduce their CO2 emissions.

End-of-Lifecoppercanbesentbackto Elcowiretoberecycled

End-of-Life - At the material end-of-life thereareseveralpossibilities forthematerialtogetanewlife

Elcowire Group AB

Elektrogatan 20, 251 09 Helsingborg, Sweden

Elcowire Group | LinkedIn elcowire.com