PRODUCT CATALOGUE HIGH VOLTAGE

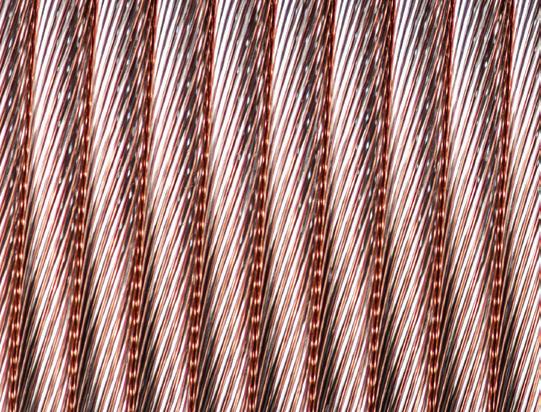

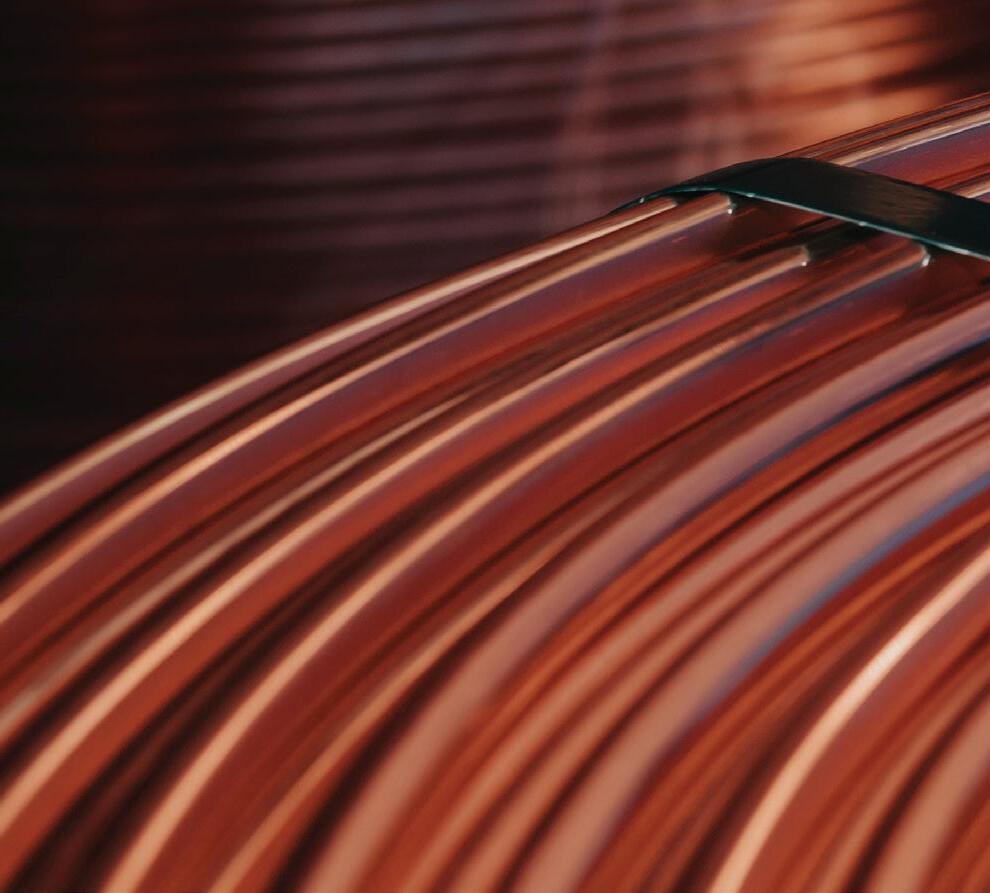

COPPER AND ALUMINIUM CONDUCTOR MATERIALS FOR HIGH VOLTAGE CABLE MANUFACTURING

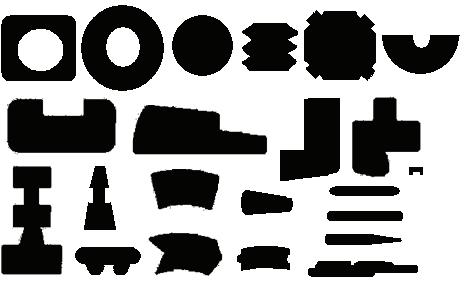

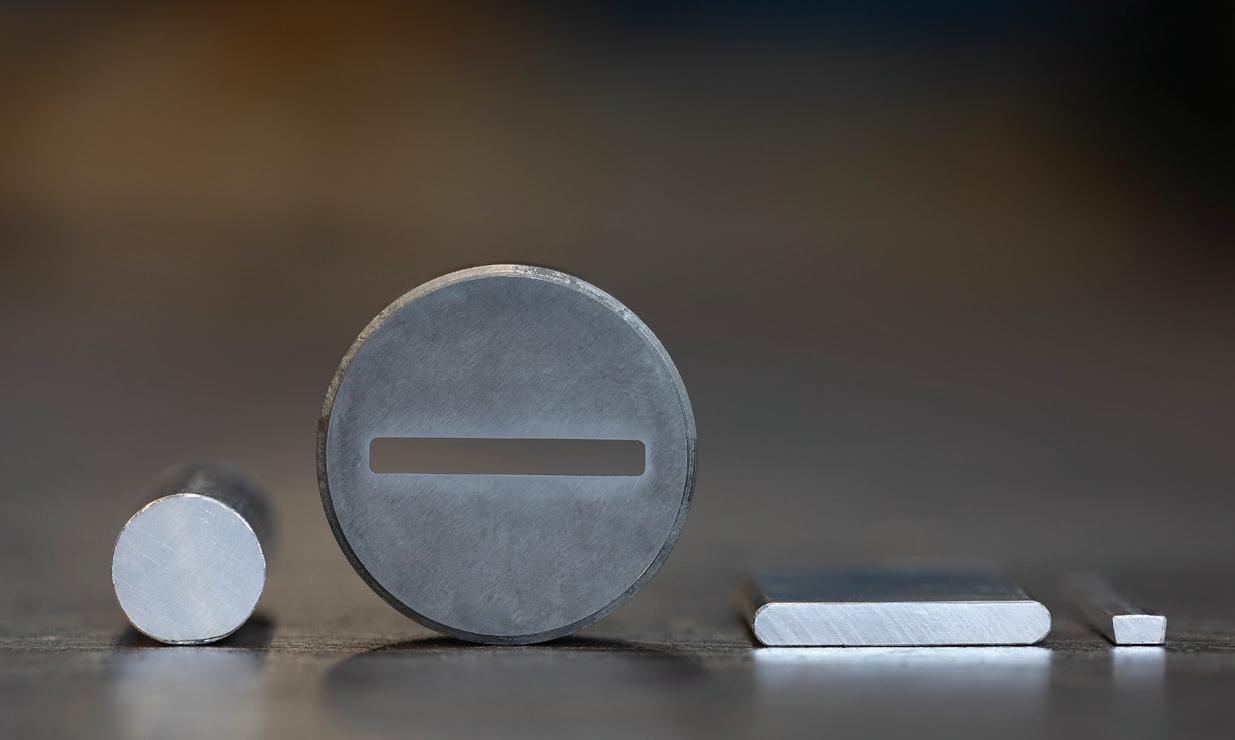

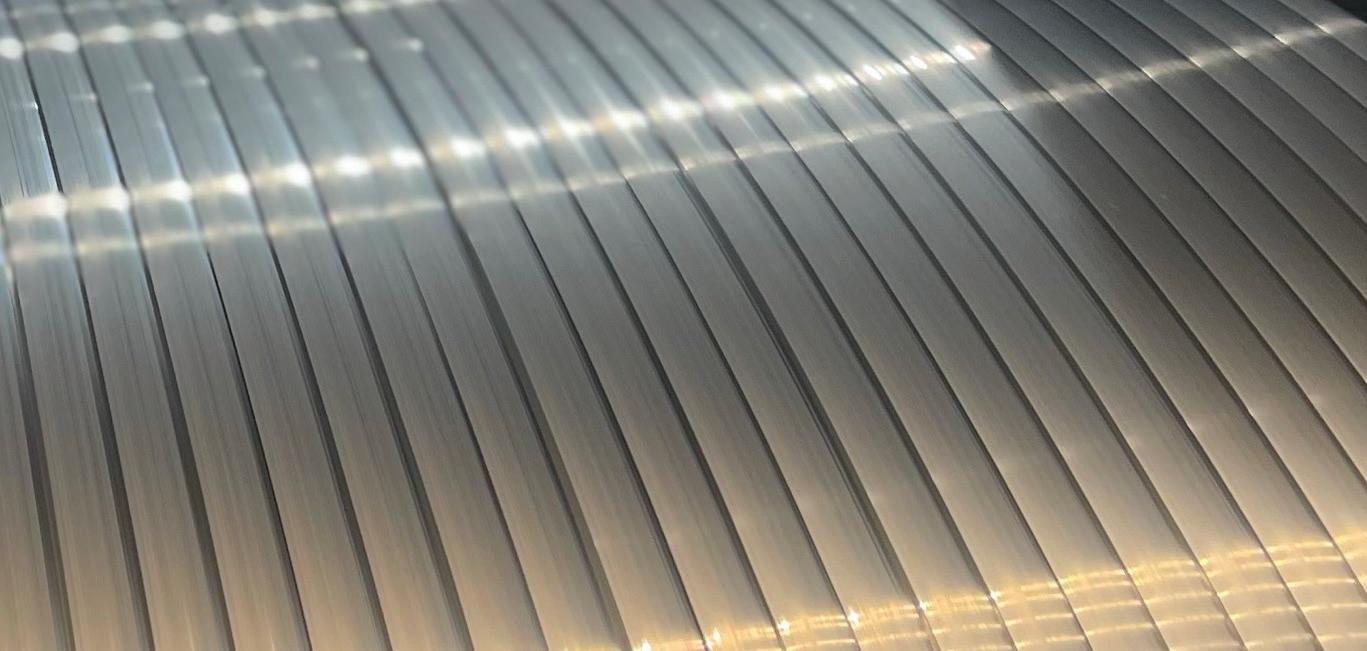

Profiles

Center wires

Round wires

ELCOWIRE SUSTAINABLE COPPER PRODUCTS

Elcowire is a sustainable partner for companies that are key to the ongoing energy transition and electrification of our society.

With an annual capacity of 300 000 MT Elcowire is one of the largest manufacturers in Europe of copper wire rod, wires, stranded conductors, profiles and overhead catenary systems made from copper, copper alloys and aluminium. Elcowire can offer Low-carbon Copper, standard materials and customized solutions aiming to support our customers in meeting their specific targets.

Our high quality products offer a range of benefits, such as reduced energy loss, increased efficiency, enhanced reliability, longer lifespan and recyclability. These benefits make Elcowire an excellent choice that meets the energy needs of the society while minimizing environmental impact.

As of today, we offer products less than half of the global average CO2 emissions, as confirmed by the International Copper Association (ICA), and we also see a large potential both in terms of improved efficiency in the processes and the increased use of renewable energy sources such as solar, wind and hydropower capacity.

Business Unit High Voltage offer its services and products mainly to manufactures of high voltage and extra high voltage cables. Our conductor materials are being used in cables for interconnections, off shore wind parks, underground power links etc.

We have a long tradition and know-how as a worldwide supplier of copper and aluminium materials. We are proud to count the main and leading cable manufacturing companies as our customers.

The copper business is not just about the products at Elcowire. Our dedicated colleagues are like family, and many of Elcowire's staff is second or third generation. Every day, we strive to adopt more environmentally sustainable workplace practices, to fulfill corporate social responsibility, and because sustainability makes business sense in terms of improved employee health and well-being.

The tradition of more than 200 years of knowledge is a torch that gets passed down from one generation to the next and we wish you will join us on our continuing journey to reach net zero carbon emission.

We look forward to start a dialogue with you and explore how we can collaborate to achieve your goals.

elcowire.com

OVERVIEW

Elcowire contributes to the global transition to renewable energy as a supplier of copper wire rod, wires, stranded conductors, profiles and overhead contact line systems made of copper, copper alloys and aluminium.

We are a Swedish company with operations in Helsingborg, Sweden and Hettstedt, Germany with approx. 440 employees and an annual production of about 300.000 MT.

Elcowire‘s five Business Units: Rod, Wire & Strands, High Voltage, Rail and Specials, are served from three Elcowire production sites, benefitting from many years of experience, a wide range of technologies, capacity, flexibility and a reliable supply chain.

From electric vehicles to power transmission within and between countries, above and below ground, our solutions enable the efficient transport of energy. In short: everything related to electrification.

ELCOWIRE AB

HELSINGBORG

ELCOWIRE GMBH

HETTSTEDT

ELCOWIRE RAIL GMBH

HETTSTEDT

With three production sites we can offer flexibility and a reliable supply chain.

SWEDEN GERMANY

Elcowire AB in Helsingborg serves North European market with Rod and has an annual capacity of 150.000 MT. Helsingborg also specializes in production of Profiles (extrusion process) and with an annual capacity of more than 50.000 MT we serve the whole European market.

Elcowire GmbH in Hettstedt serves Central, East and South European market with Rod and has an annual capacity of 15 0.0 00 MT.

Hettstedt also specializes in production of drawn wire, bunches and strands and have an annual capacity of more than 30.000 MT which are delivered in Europe, Middle East and Africa.

Elcowire Rail GmbH serves the worldwide market for overhead contact lines, offering a wide range of standards and customized solutions. Contact wires, dropper wires, catenary wires from Hettstedt are in commercial service around the world.

Technologies with sustainable solutions, such as our contact and messenger wire “Valthermo” has a 70-year lifespan, (to compare with pure copper with a lifespan of 25 years).

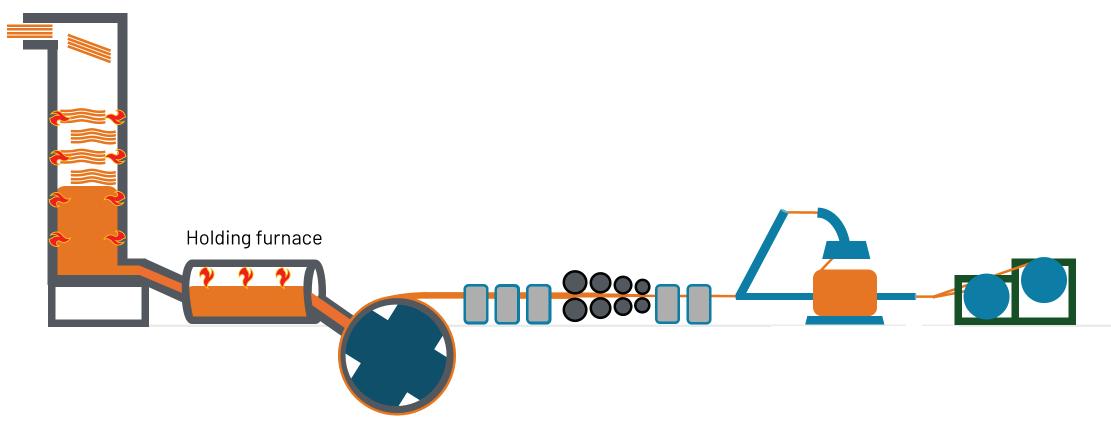

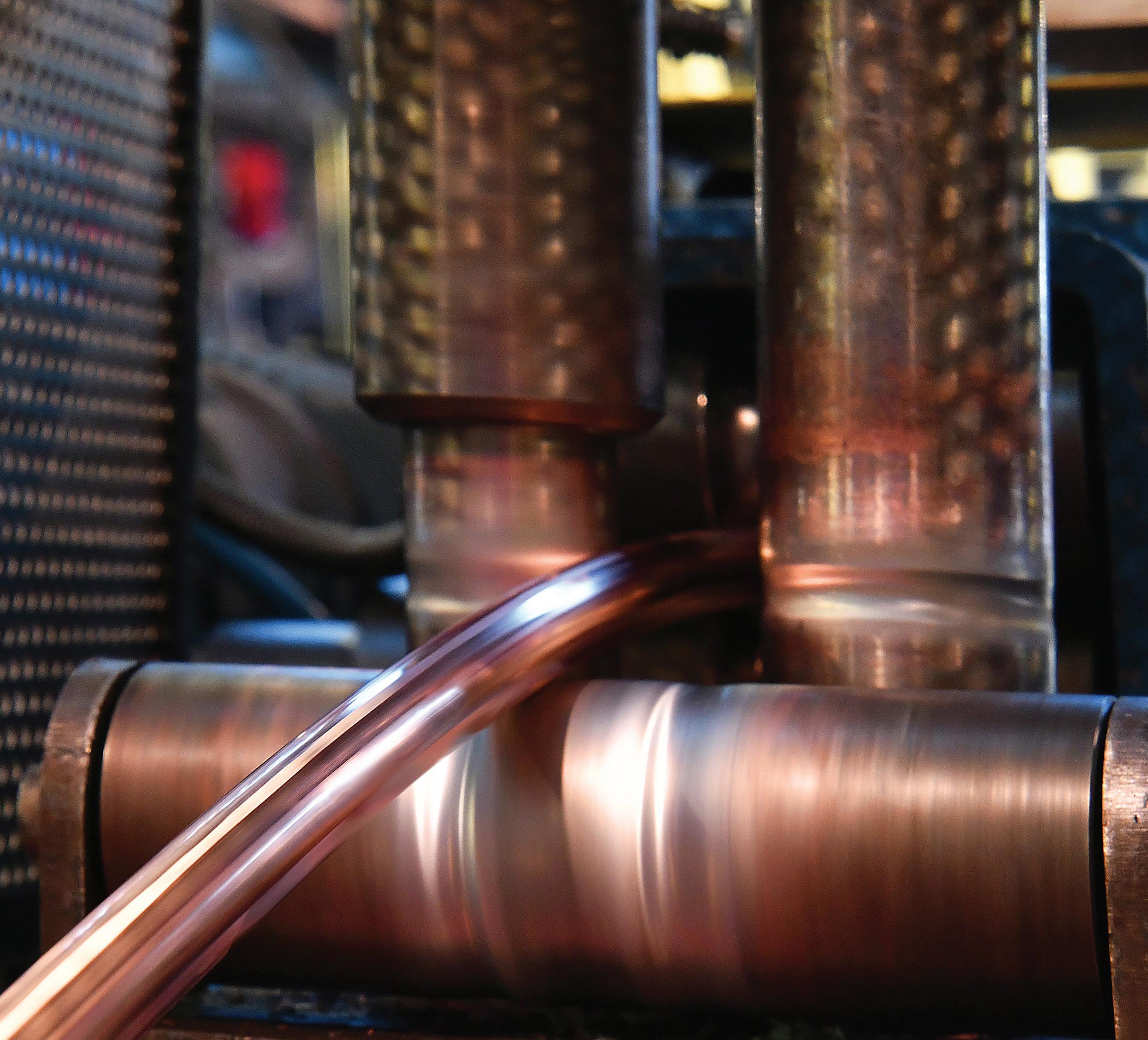

PRODUCTION PROCESS

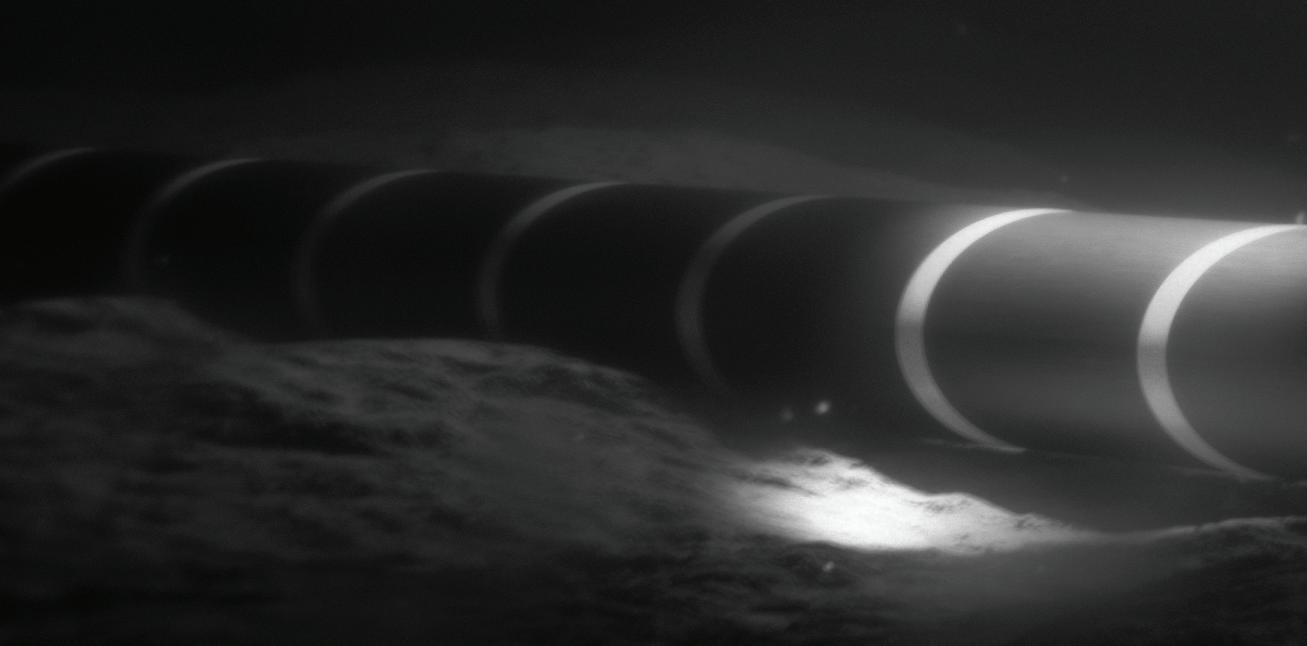

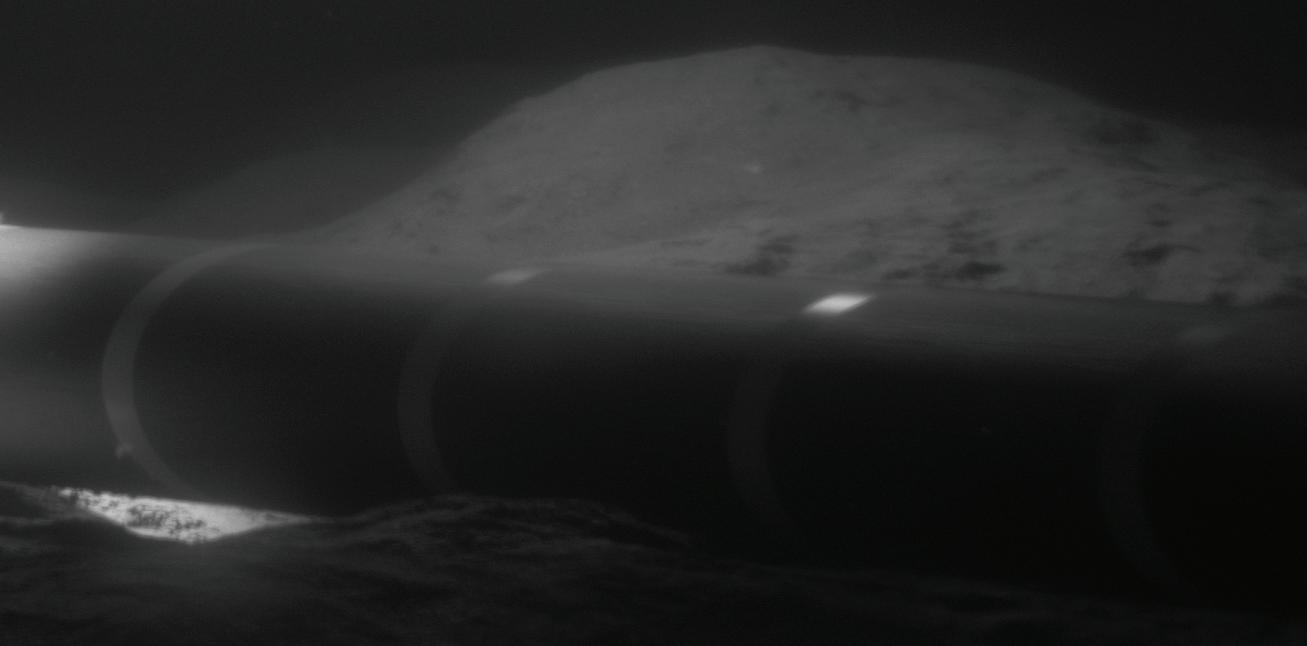

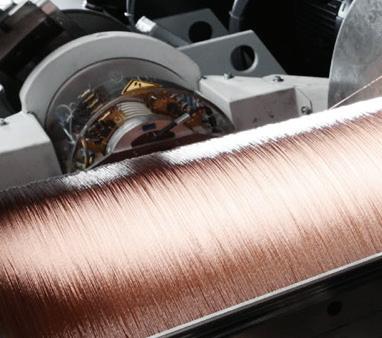

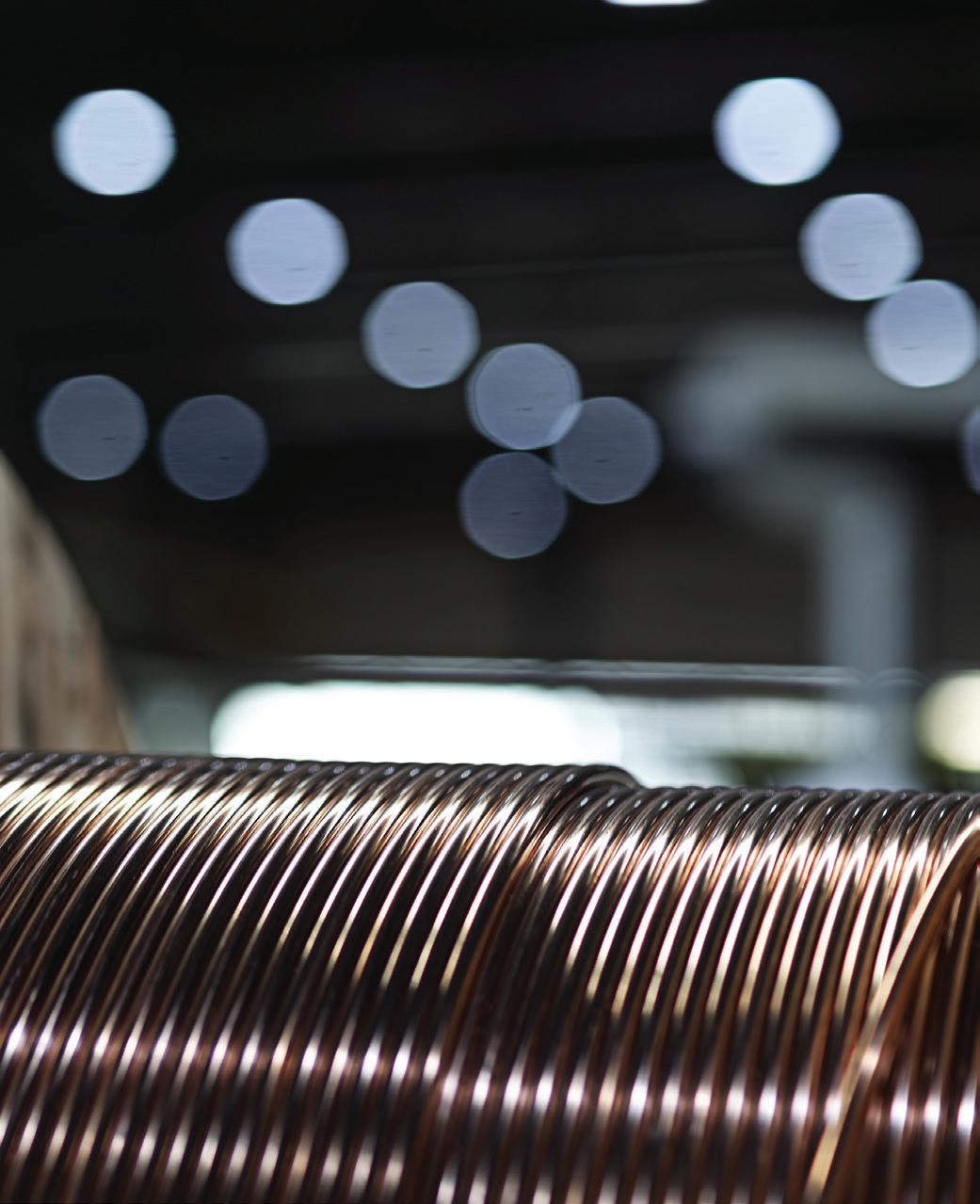

The Elcowire Production Process starts with the melting of Copper Cathodes. The melted copper is then casted into a bar which is rolled down to a wire rod of various dimensions and qualities. For the production of High Voltage conductor material the rod is then transformed to a profile through an extrusion process.

1)

2)

WIRE ROD PROCESS

EXTRUSION PROCESS

Coiler for 8 mm Wire Rod

Coiler for Wire Rod over-dimension Casting wheel

Rolling mill

Cathode shaft furnace

SUSTAINABLE PRODUCTS FOR SPECIFIC PURPOSES

WE ARE DEVELOPING ADVANCED TECHNOLOGIES TO PROVIDE OUTSTANDING ENERGY SAVING PRODUCTS WITH LONG LASTING SERVICE LIFE TO ENABLE SUSTAINABLE SOLUTIONS – TAILOR-MADE TO OUR CUSTOMERS' NEEDS.

ELCOWIRE CAN OFFER STANDARD MATERIALS, LOW-CARBON COPPER, RECYCLED COPPER AND CUSTOMIZED SOLUTIONS AIMING TO SUPPORT OUR CUSTOMERS IN MEETING THEIR SPECIFIC PURPOSES.

TECHNICAL KNOW HOW

Elcowire’s profiled conductor products are made of Elcowire’s own copper wire rod and comply with the highest quality requirements.

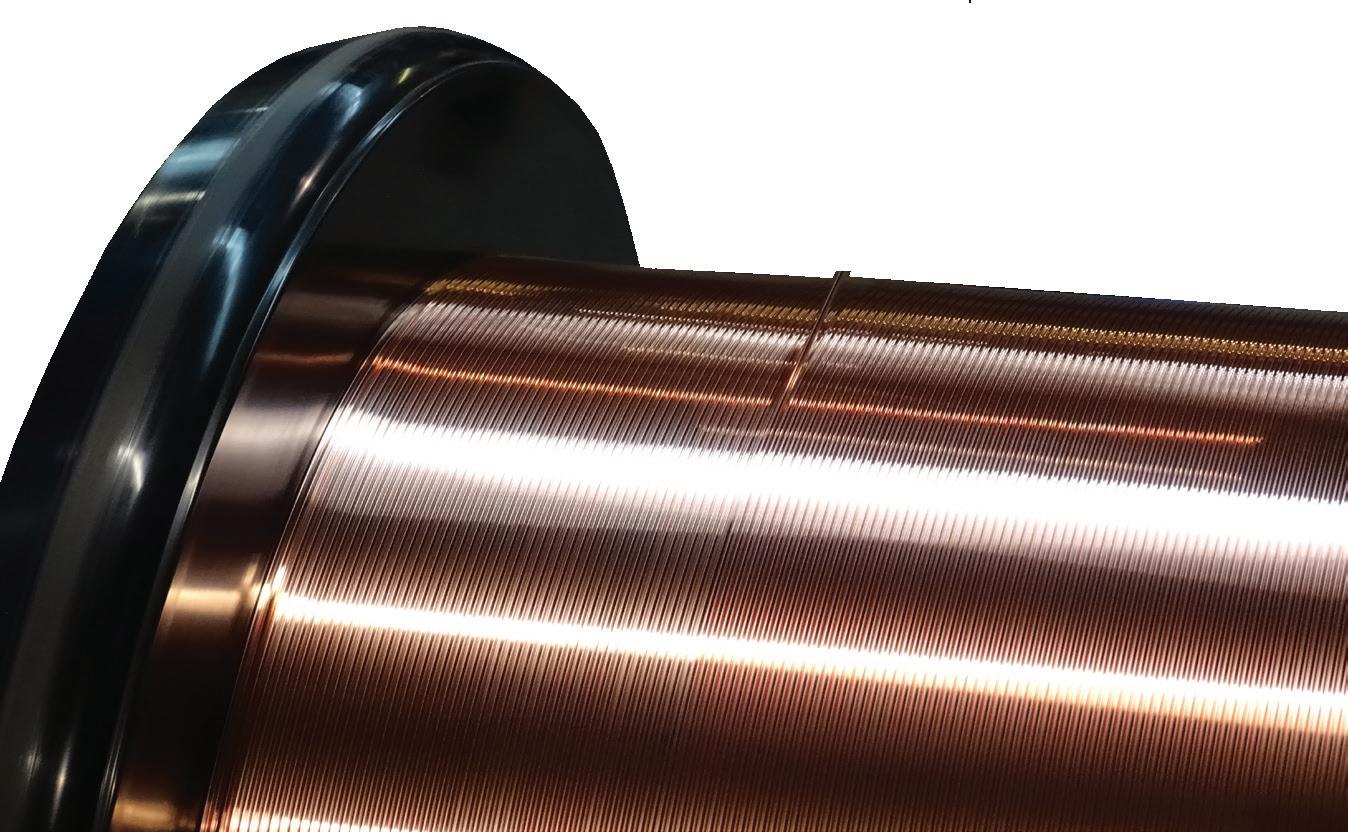

We have a completely integrated and closed material cycle which we keep in our hands, starting with the production of our own wire rod which is further processed into an outstanding product variety of profiled conductors specifically dedicated for High Voltage purposes, with excellent conductivity, product flexibility and surface.

Our upstream technologies to produce wire rod guarantee that every application receives exactly the right material. This sets a high standard in the market.

The Elcowire High Voltage products are produced according to our customers specific demands in terms of electrical and mechanical properties, dimensions, packaging and delivery form. This allows our customers to conduct their own business flexibly and in their own way, thereby gaining a competitive advantage.

Based on the experience for more than 70 years we manufacture copper and aluminium wire products in different shapes followed by testing, packaging and transportation.

All our High Voltage conductor products are manufactured in machines with high flexibility allowing almost any kind of spools to ensure smooth and efficient handling for our customers.

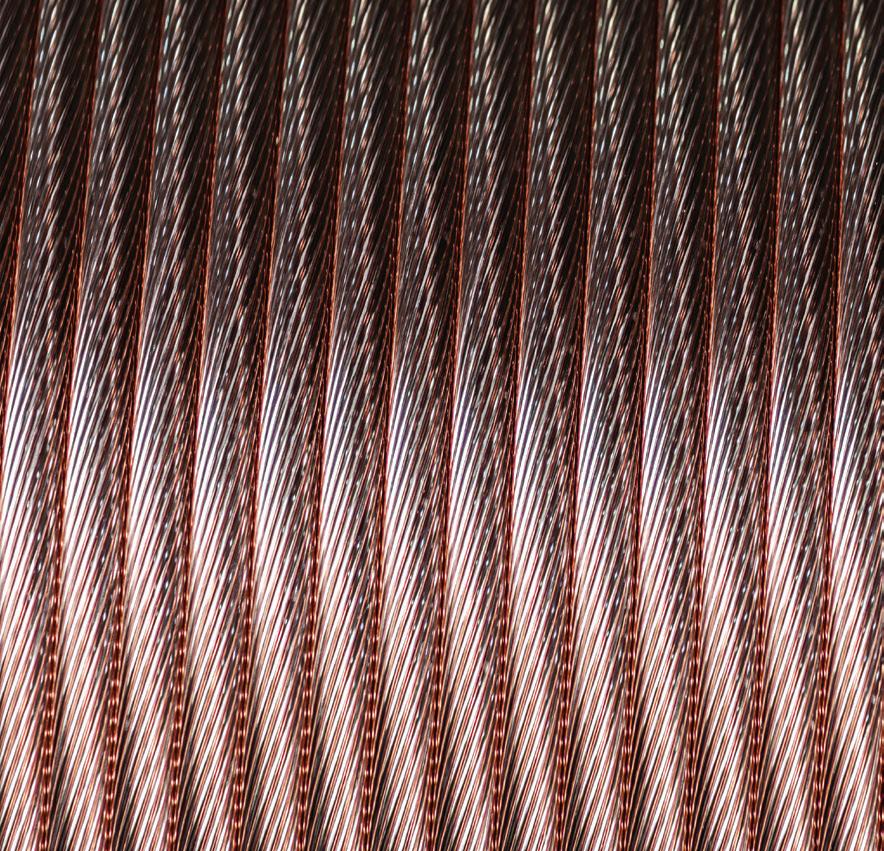

Our conductors are produced from pure copper, alternatively high conductivity aluminium according to European and international standards or to the specifications defined by our customers. And it’s a part of our mission to support our customers to develop new specifications and to optimize existing products. In that way we create significant opportunities to make products with outstanding characteristics made for specific purposes and targets.

QUALITY

Today we are a leading supplier in Europe, with our flexible and efficient manufacturing site in Helsingborg, Sweden. We installed all the test equipment and procedures needed to check fulfilment of most requirements of common wire standards and individual customer's specifications. Our activities, our business processes and structures are based on well-established management systems for quality ISO 9001:2015, environment ISO 14001:2015 and energy ISO 50001:2018 and we also meet the high requirements set by the automotive quality standard IATF 16949.

LOW-CARBON COPPER

Half of the carbon emissions over its production processes, compared to the global average footprint for standard copper.

Low-carbon Copper is made possible through production that has undergone a substantial transformation due to electrification and automation of various stages of the process.

The Low-carbon Copper has also been made possible by a very efficient ore concentration process, recycling of end-of-life materials and a world-class green energy mix. Resulting in new copper semi-finished products with low impact on nature and the climate.

The significantly lowe r CO2 emissions of the Low-carbon Copper are verified through several validation processes. The reporting protocol that is used for verification is the Greenhouse Gas Protocol – Product Life Cycle Accounting and Reporting Standard.

The product is also validated and reviewed against the general principles in ISO 14064-3 Standard.

Environmental declarations

Environmental declarations have been developed for Elcowire’s products, including Low-carbon Copper.

Our footprint is verified through mass balance-based self-declarations for Low-carbon Copper Wire Rod and Low-carbon Copper Profiles, as per the framework in ISO 14021.

This is a first important milestone for Elcowire and the next step is to perform calculations of the carbon footprint for drawn wire products.

Elcowire aims to be a sustainability leader in its business, and therefore the carbon footprint is strategically important.

For more information, please visit our website; elcowire.com

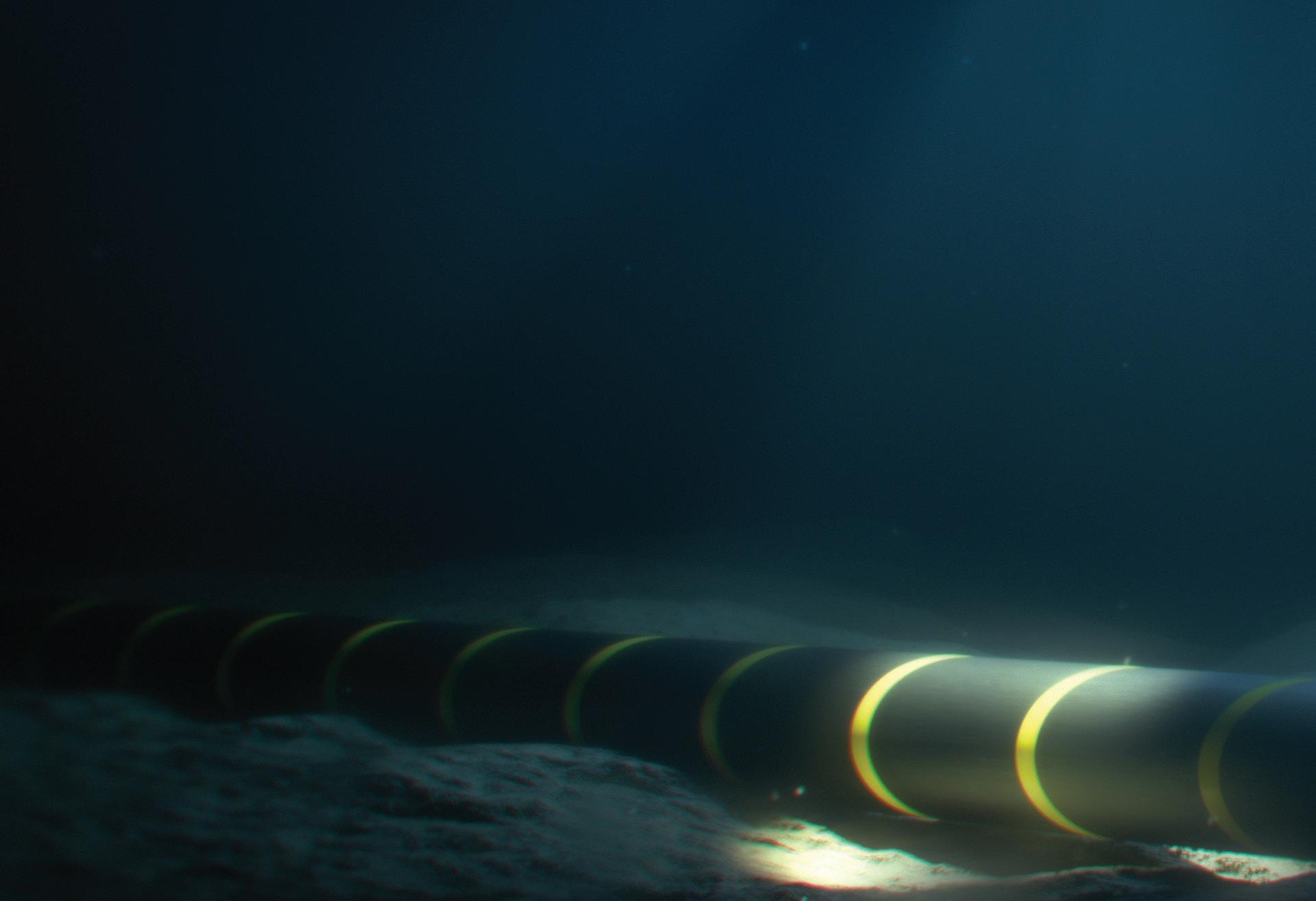

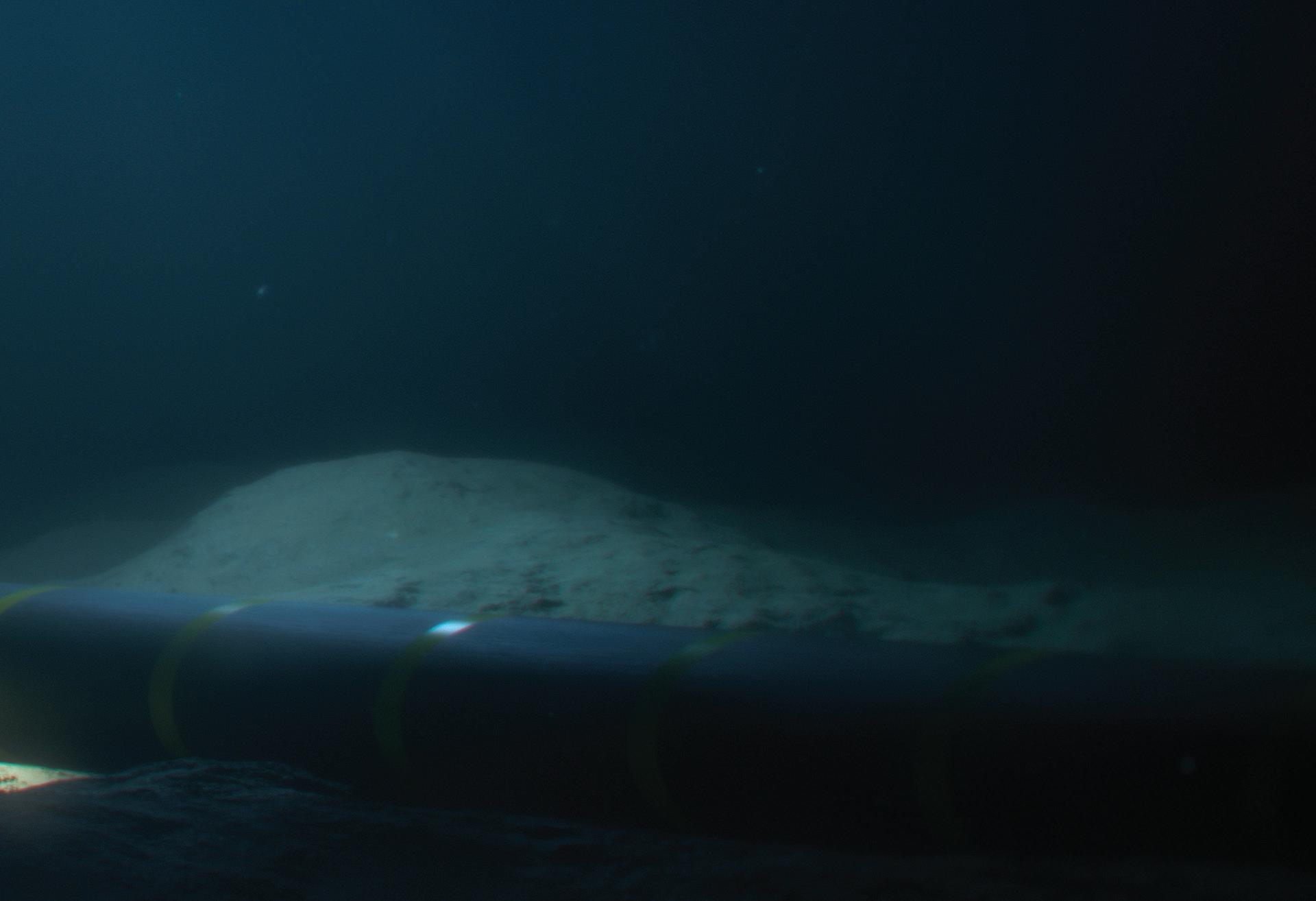

POWER CABLES

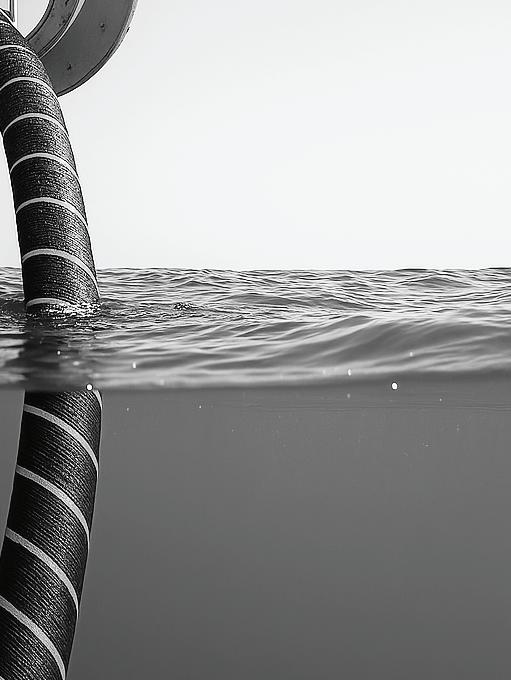

The high voltage cable market consists of overhead, subterrain and submarine cables. Elcowire Business Unit High Voltage targets the subterrain and submarine cable conductor market in Europe and other markets are considered in case to case basis.

The offered conductor solutions are either made of Copper or Aluminum in various alloys, qualities, shapes, sizes and compositions and are produced in either extruded or drawn processes.

The offering also includes customized logistics and packaging arrangements. Furthermore Elcowire proudly offers Low-carbon Copper products made from either Recycled or Primary copper, both categories significantly lowering the CO 2 emissions. Further to the conductor material and its insulation, the typical high voltage cable design differs in the conductor shape and arrangement.

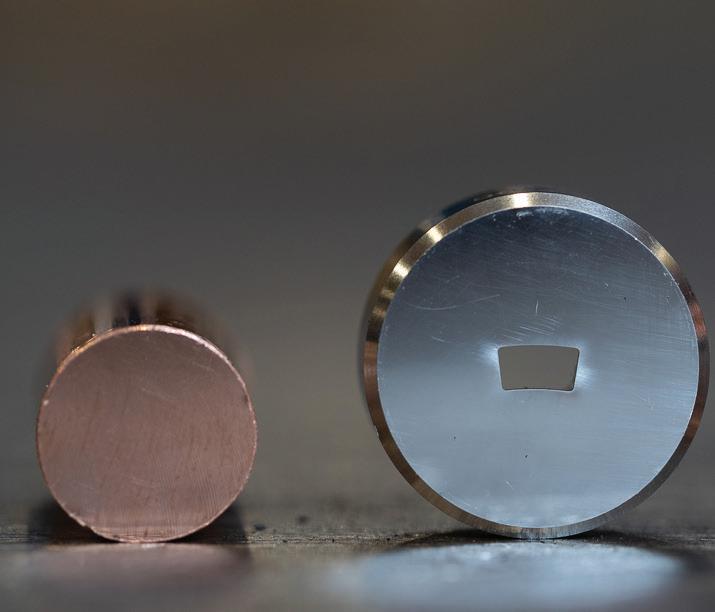

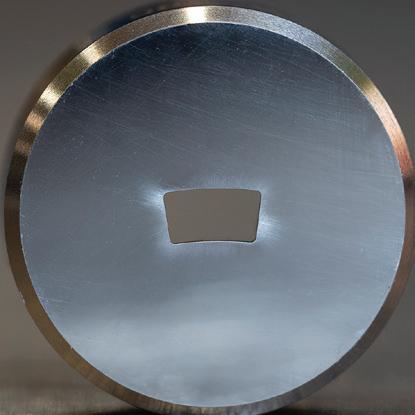

The conductor could either be based on trapezoidal profiles or compacted round wires.

A conductor made up of trapezoidal profiles arrange the profiles in a compact, layered configuration. These profiles are typically wound in a way that maximizes the packing factor, reducing the amount of unused space in the conductor area.

A conductor made of compacted round wires uses individual round wires that are compressed to reduce air gaps and improve packing density, and they are typically wound in a circular pattern.

Lower losses

Higher Packing Factor

MATERIAL EFFICIENCY IMPROVEMENT

Higher Packing Factor: couldresultin5-15% materialreduction.

Enhanced Mechanical Strength 8

Calculatedexample:a100kmcablethatrequires500MTofcopperwould(at5%materialreduction)nowonly require475MT.Withacopperpriceat9,500USDp/tonthesavingwouldbeapprox.237,500USDonthecopperalone.

Lower Losses: couldresultin5-10%reducedresistance(energyloss).

Calculatedexample:1,000A,500kV,100kmcable,copperresistivity1,68Ω·m,conductorcrossarea1000mm² (andforthetrapezoidalconductortheareais10%greaterduetohigherpackingfactor).

Powerlossduetoresistivityinthecaseofround-wireconductorwouldbe1,68MWandinthecaseofaconductormade oftrapezoidalprofilesitwouldbe1,53MW.

Forayearofoperation(8760h)andatanenergycostof30,00EURp/MWhtheoperationalenergylosssavingwould beapprox.395,000EURp/y.Forlongertransmissionlinesorhighercurrents,thesavingswouldbeevengreater.

BENEFITS OF USING TRAPEZOIDAL PROFILES

• Higher Packing Factor: Trapezoidal wires fit together more efficiently due to their shape, allowing for better packing density. This results in a conductor that occupies less space while maintaining the same electrical capacity. The increased packing factor can reduce the overall size of the cable for a given current rating or allow for higher current carrying capacity in the same space.

• Lower Losses: Due to the more efficient packing of trapezoidal wires, the conductor has a lower resistance for the same cross-sectional area, which leads to lower resistivity losses and improved efficiency.

• Improved Flexibility: Trapezoidal wires, when compared to compacted round wires, may offer better flexibility for installation in certain situations, especially in underground or underwater applications where bending radius and maneuverability are important.

• Reduced Skin Effect: The arrangement of trapezoidal profiles can potentially help reduce the skin effect, which is the tendency of current to concentrate on the outer surface of the conductor at high frequencies. The flatter shape can allow for better current distribution through the conductor, especially in HVDC systems.

• Enhanced Mechanical Strength: The trapezoidal profile provides better mechanical strength and structural integrity because the conductors interlock more securely, which can be critical for the durability of the cable under mechanical stress (e.g., vibration, tension).

• Long-Term Operational Savings: The enhanced efficiency and reduced losses of trapezoidal conductors often translate into long-term operational savings. Over the life of a high-capacity HVDC system, these savings can significantly outweigh the initial higher manufacturing costs. This is especially true in applications like underwater or underground cables, where space constraints and efficiency are critical.

Enhanced Mechanical Strength: couldresultin5-10%fewerdamagesorlowerrepaircosts.

Calculatedexample:IfthetotalinstallationcostofalargeHVDCcablesystemis100MEUR,andmechanicalstrength reducestheriskofdamageandreworkby5%,thiscouldresultinsavingsof5MEURinreducedrepairandreinstallation costs.

CONDUCTOR MATERIAL

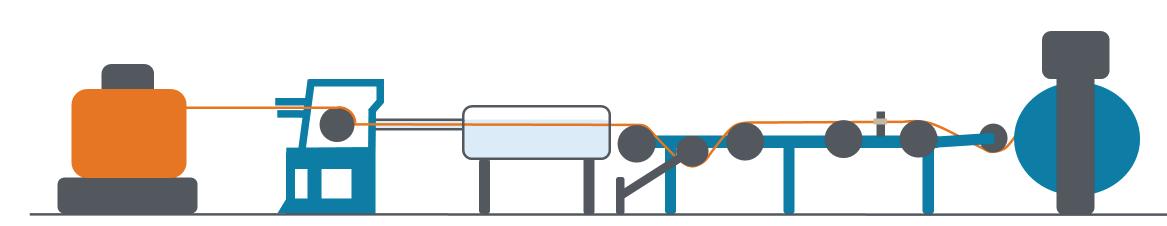

Elcowire Business Unit High Voltage specialises in designing and producing copper and aluminium conductors for high voltage cable manufacturers. Conductors are produced either by exrusion or drawn process.

Elcowire High Voltage’s conductor materials are used for advanced cables in interconnections, offshore wind parks, underground powerlinks and other applications.

In close collaboration with the customer, Elcowire High Voltage design and produce conductor solutions depending on external requirements, customer specification and installation environment.

The available market is dependent on design of conductor (AC or DC, insulation type, laying depth etc).

Regardless of cable design, Elcowire High Voltage has a suitable conductor solution.

The offered conductor solutions are either made of Copper or Aluminium in various alloys, qualities, shapes, sizes and compositions and are produced in either extruded or drawn processes. The offering also includes customized logistics and packaging arrangements.

Furthermore Elcowire proudly offers Low-carbon Copper products made from either Recycled or Primary copper, both categories significantly lowering CO2 emissions.

Elcowire has supported the High Voltage cable market with its conductor material for more than 50 years and our competence is deeply rooted in our people and our processes.

The extrusion process, which Elcowire view as one of its primary and core competences and where Elcowire both design and manufacture its own machines and tools, is highly flexible and versatile. This makes the extrusion process suitable not only for high volume production but also for small production series with extraordinary demands and specific customer requirements.

The conductor material produced by extrusion process is characterised by high tensile strength, low resistivity and being formable (soft).

EK SPEC 120 Cu-wire, Hard

CU-WIRE, HARD

1

2

3 Form of delivery

Other f orms of delivery and types of package can be made by agreement.

4 Requirements Copper Cu -ETP Density:

5 References EN 13602 Copper and copper alloys - Drawn. round copper wire for the manufacture of electrical conductors.

6 Miscellaneous Deliveries can also be made by the following specification: SEN 240102

Wrapping test and reverse bend test according to EN 13602 is not done.

References: EN 13602 - Copper and copper alloys, drawn round copper wire for manufacture of electrical conductors

Miscellaneous: Deliveries can also be made by the following specifications: SEN 240102

Wrapping test and reverse bend according to EN 13602 is not done.

EK 121 CU-WIRE, ANNEALED & MULTIWIRE

Dimensions: ø 0.19 - ø 0.41 mm (x max . 8 wires)

ø 0.42 - ø 0.52 mm (x max . 4 wires) ø 1.11 - ø 4.00 mm (single wire)

Tolerance of dimensions:

Form of delivery:

Other forms of delivery and types of package can be made by agreement.

Requirements: Copper Cu-ETP or Cu-ETP 1

8.93 g/cm3

1 7.24 nΩm

Strength: R m (min. 200) N/mm2

References: EN 13602 Copper and copper alloys - Drawn round copper wire for the manufacture of electrical conductors.

Miscellaneous:

EK 130 CU-PROFILE, SOFT

Dimensions:

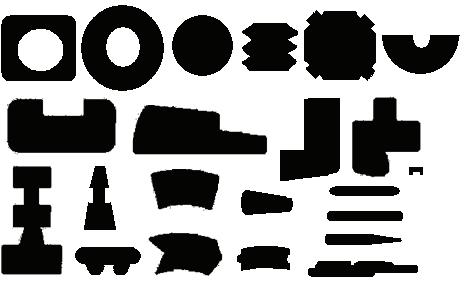

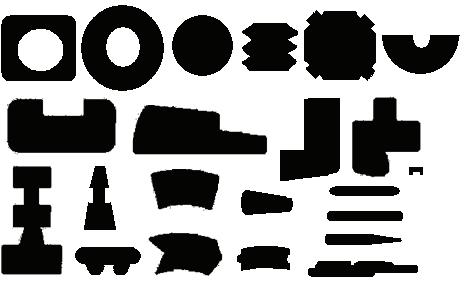

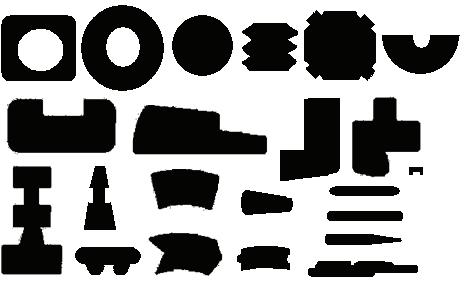

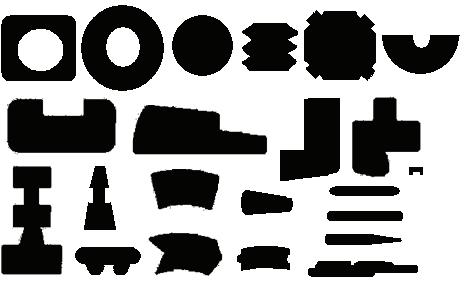

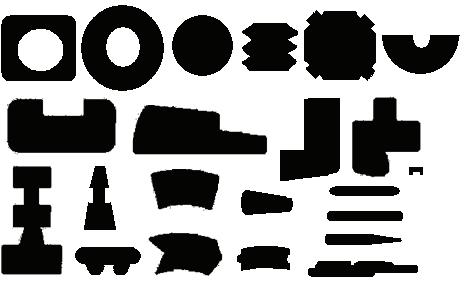

Examples of different types of profile:

Tolerance of dimensions: According to agreement

Form of delivery:

Other forms of delivery and types of package can be made by agreement.

Requirements: Copper Cu-ETP, R200

Density: 8.93 g/cm3

Oxygen: max 600 ppm

Resistivity: 1 7,241 nΩm

Tensile Strength: Rm 220-260 N/mm2

References: EN 13601 Copper and copper alloys - Copper rod, bar and wire for general electrical purposes.

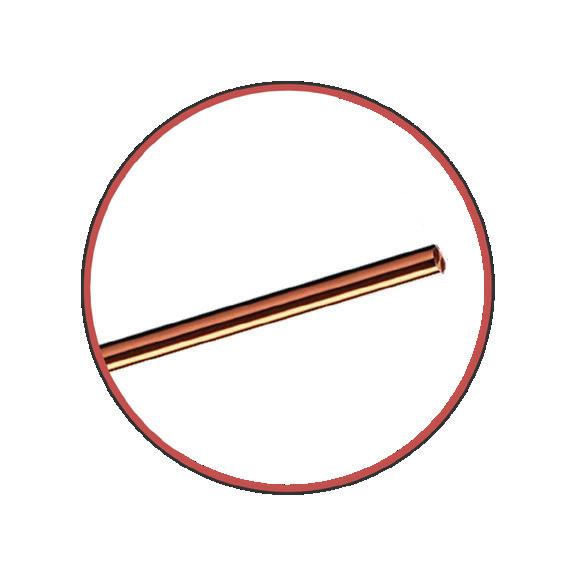

138 CU-WIRE, SOFT

Dimensions:

Form of delivery:

Deviation from circularity: max. half the tolerance of diameter

Other forms of delivery and types of package can be made by agreement.

Requirements: Copper Cu-ETP

Density: 8.93 g/cm3

Resistivity: 1 7,241 nΩm

Tensile Strength: Rm 220-260 N/mm2*

Elongation: L200 min. 35%*

* Can only be measured up to 22.5 mm.

References: EN 13601 - Copper and copper alloys, copper, bar and wire for general electrical purposes.

Miscellaneous:

An approx 15 meter long starting end is at the bottom of the drum, ie at the end of the length. There is a slightly discolored piece and a joint. It is recommended that the starting end is cut away since the tensile strength cannot be guaranteed. The profile is usually coated with a thin layer of white oil (paraffin oil), which facilitates uncoiling and reduces the risk of surface damage. Coarse dimensions can also be protected with a longitudinal crepe paper.

CUSTOMER REQUIREMENTS

NEW PICTURE

At Elcowire we believe that an open dialogue with our customers is key to guiding material choices, ensuring the selected solution aligns with performance demands, sustainability goals and long-term value.

HARD

Dimensions: ø 2.65 - ø 7.10 mm

Tolerance of dimensions: Other forms of delivery and types of package can be made by agreement. Requirements:

2

Form of delivery:

3

4 Requirements Aluminium EN AW-1350 or -1370 according to EN 573 -3

1) The Tensile Strength is not according to ASTM.

5 References SS-EN 573-3 Aluminium and aluminium alloys – Chemical compositions and plastic formed product types

ASTM B230M Aluminium 1350-H19 wire for electrical purposes

References:

6 Miscellaneous Production on reels (DIN 630) gives the following:

SS-EN 573-3 Aluminium and aluminium alloys - Chemical compositions and plastic formed product types.

- Dimensions up to Ø 5,3 mm running with automatic spool change and the inner end is pulled out.

ASTM B230M Aluminium 1350-H 19 wire for electrical purposes .

- Dimensions over Ø 5,3 mm is change manually, the inner end inserted into the hole in the center.

Miscellaneous:

Production on reels (DIN 630) gives the following:

-

-

up to ø 5.3 mm running with automatic spool change and the inner

is pulled out.

over ø 5.3 mm is changed manually, the

EK SPEC 230 Al-profile, Soft

Dimensions:

1 Dimensions

Examples

Tolerance of dimensions: According to agreement.

Form of delivery:

2 Tolerance of According to agreement. Dimensions

3 Form of delivery

Requirements:

4 Requirements

Other forms of delivery and types of package can be made by agreement.

Chemical Composition: EN AW-1370

Chemical Composition: EN AW-1370

Resistivity: max 28.0 nm

Resistivity:

Tensile Strength: Rm 60-90 N/mm2

Elongation: L200 min. 25 %

5 References

References:

EN 573-3:2019 + A1:2022 Aluminium and aluminium alloys – chemical composition and form of wrought products

DIN 40501:4 Aluminium for Electrical Engineering; Wires of pure Aluminium; Technical Conditions of Delivery

Miscellaneous: EN 573-3:2019 + A1:2022 Aluminium and aluminium alloys - chemical composition and form of wrought products.

6 Miscellaneous

DIN 40501:4 Aluminium for Electrical Engineering; Wires of pure Aluminium: Technical Conditions of Delivery.

An approximate 15 meter long starting end is at the bottom of the drum, ie at the end of the length. There is a slightly discolored piece and a joint. It is recommended that the starting end is cut away since the tensile strength cannot be guaranteed. The profile is usually coated with a thin layer of white oil (paraffin oil), which facilitates uncoiling and reduces the risk of surface damage. Coarse dimensions can also be protected with a longitudinal crepe paper.

An approximate 15 meter long starting end is at the bottom of the drum, i.e. at the end of the length. There is a slightly discolored piece and a joint. It is recommended that the starting end is cut away since the tensile strength cannot be guaranteed.

Author: Moses, Christian Approved by: Norlander, Zemka

Approved: 2023-01-19

The profile is usually coated with a thin layer of white oil (paraffin oil), which facilitates uncoiling and reduces the risk of surface damage. Coarse dimensions can also be protected with a longitudinal crepe paper.

EK 238 AL-WIRE, SOFT

EK SPEC 238 Al-wire, Soft

Dimensions:

1 Dimensions

Tolerance of dimensions:

2 Tolerance of Tolerance of dimensions: 1

3 Form of delivery

Other

by agreement.

Other f orms of delivery and types of package can be made by agreement

Requirements: Chemical Composition: EN AW-1370

Resistivity: max 0 nΩm

Tensile Strength: Rm 60-90 N/mm2 Elongation: L200 min. 25%

4 Requirements Chemical Composition: EN AW-1370 Resistivity: max 28 0 nm Tensile Strength: Rm 60-90 N/mm2 Elongation: L200 min. 25 %

References:

5 References EN 573-3:2019 + A1:2022 Aluminium and aluminium alloys – chemical composition and form of wrought products

EN 573-3:2019 + A1:2022 Aluminium and aluminium alloys - chemical composition and form of wrought products.

DIN 40501:4 Aluminium for Electrical Engineering; Wires of pure Aluminium: TechnicalConditions of Delivery.

DIN 40501:4 Aluminium for Electrical Engineering; Wires of pure Aluminium; Technical Conditions of Delivery

Miscellaneous:

6 Miscellaneous An approximate 15 meter long starting end is at the bottom of the drum, i.e. at the end of the length. There is a slightly discoloured piece and a joint. It is recommended that the starting end is cut away since the tensile strength cannot be guaranteed.

The profile is usually coated with a thin layer of white oil (paraffin oil), which facilitates uncoiling and reduces the risk of surface damage. Coarse dimensions can also be protected with a longitudinal crepe paper.

An approximate 15 meter long starting end is at the bottom of the drum, i.e. at the end of the length. There is a slightly discolored piece and a joint. It is recommended that the starting end is cut away since the tensile strength cannot be guaranteed. The profile is usually coated with a thin layer of white oil (paraffin oil), which facilitates uncoiling and reduces the risk of surface damage. Coarse dimensions can also be protected with a longitudinal crepe paper.

Author: Moses, Christian

EK SPEC 260

Solidal, circular and sector shaped

1 Dimensions

2 Tolerance of dimensions

Dimensions:

Circular conductor: 16 - 800 mm2

Sector shaped conductor 90̊: 25 - 300 mm2

Sector shaped conductor 120̊: 25 - 300 mm2

Tolerance of dimensions: Form of delivery:

3 Form

- 4,71

- 5,56 6,19 - 6,48 7,49 - 7,78 8,78 - 9,19 10,02 - 10,35 11,10 - 11,46 12,46 - 12,84 14,31 - 14,73 16,06 - 16,52

- 8,30 9,39 - 9,76

- 11,31

- 13,49 15,39 - 15,84

- 17,78 19,22 - 19,74 21,51 - 22,07

- 25,29

- 28,28 5,12 - 5,33 6,02 - 6,30 7,04 - 7,35 8,51 - 8,81 10,60 - 10,40 11,35 - 11,71 12,58 - 12,96 14,11 - 14,53 16,21 - 16,67 18,18 - 18,68 7,26 - 7,52 8,52 - 8,87 9,93 - 10,31 11,95 - 12,32 14,08 - 14,49 15,85 - 16,29 17,59 - 18,08 19,71 - 20,25 22,60 - 23,20 25,31 - 25,96

Author: Hill, Tony

Approved by: Hendess, Viktor Approved: 2024-10-28 Documentno: 179 Issue: 7.0

Requirements: Density: 2.70 g/cm3

Chemical Composition: EN AW - 1370

References:

Miscellaneous:

EN 573-3:2019 + A1:2022 Aluminium and aluminium alloys - chemical composition and form of wrought products.

DIN VDE 0295 Leiter für Kabel und isolierte Leitungen für starkstromanlagen.

EN 60228 conductors of insulated cables

BS 3988 Solid conductors for insulated cables

An approximate 15 meter long starting end is at the bottom of the drum, i.e. at the end of the length. There is a slightly discolored piece and a joint. It is recommended that the starting end is cut away since the tensile strength cannot be guaranteed.

The profile is usually coated with a thin layer of white oil (paraffin oil), which facilitates uncoiling and reduces the risk of surface damage.Coarse dimensions can also be protected with a longitudinal crepe paper.

DIN

Elcowire offers a variety of logistic and packaging solutions. The primary materials used for the packaging solutions (drums, spools and octabins) are steel, wood, polymere and paper. Steel, polymere and paper solutions are typically used in logistic loop set-ups and wooden solutions are typically used for one way delivery and at longer distances.

The choice of packaging solution is dependant on the customer requirement and which solution that is most suita -

The packaging solutions, particulary the steel and polymere solutions typically involves an investments and can be

The chart below shows the most common packaging solutions but many more are possible and for any product and

Part of the packaging solutions Elcowire offers different kind of delivery protections. Such protections can be plastic foil applied on each individual drum and spool or can be a plastic bag covering multiple drums and spools.

Further to the packaging solutions, and to ensure secure transport, the drums, spools and octabins are normally placed on a wooden pallet or a steel rack. There are multiple variants available and the most suitable one for each

Mb 560/760

Facts:

Tare:

Capacity (normal):

Mainly suitable for:

Dimensions:

& profiles

& profiles

the spools:

Form of delivery: We have 2 standard ways of packing - On special steel racks - On EUR-pallet with laths, max 3 pcs

Other info: The reels are the so-called Mossberg type

1 Facts Material: Tare: Capacity (normal): Capacity (max): Mainly suitable for: Type:

2 Dimensions Measuring point

DIN 630

Dimensions:

Material:

Steel

Tare: Appr. 90 kg

Capacity (normal): 450 kg copper

Capacity (max): 500 kg

Mainly suitable for: Fine wire, flexible cu-conductor, drawn cu and al-wire and cu- and al profiles

Type: Returnable

Measuring point

L1 = Overall width:

L2 = Inner width:

D1 = Flange diameter:

D2 = Barrel diameter

D3 = Centre hole: 25

1 Facts

Form of delivery:

2 Dimensions

Other info:

Form of delivery:

Note:

3 Form of delivery

Form of delivery:

D4 = Drive pin hole: 140

R1 = Drive radius (CC):

Material:

Steel

Tare: about 52 kgs

Capacity (normal): 215 kgs copper

We have 3 ways of packing the reels

Capacity (max): 250 kgs

- On EUR-pallet with laths

Mainly suitable for: Cu-wire

- On S2-pallet

Type: Returnable

- On small pallet with laths

Measuring point

L1 = Overall width:

L2 = Inner width:

The reel is according to DIN 46395 The wooden pallets are treated in accordance with ISPM 15

D1 = Flange diameter:

D2 = Barrel diameter:

DIN630/EUR-I

D3 = Centre hole:

- On a EUR-pallet

D4 = Drive pin hole:

R1 = Drive radius (CC):

One or two reels strapped on a EUR-pallet

We have 2 standard ways of packing the spools.

DIN630/S2

• On a small pallet.

- On S2-pallet

• On EUR-pallet with laths, max 4 pcs.

Note:

4 Other info.

One or two reels mounted on a steel pallet with size of a EUR-pallet

According to our drawing “reg 0355-KO”. Only center hole and flange diameter are according to DIN 46397.

Packing name Picture

EK560/1/fat

On a small pallet.

TRV 3

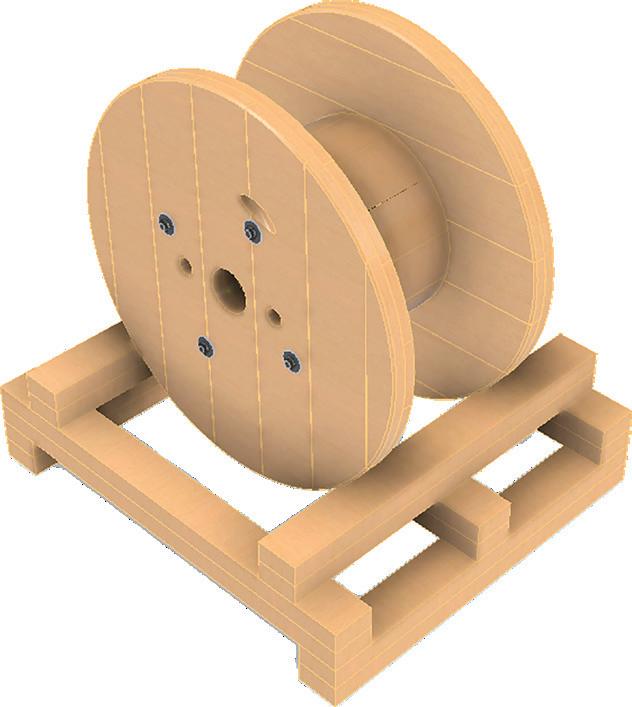

Facts:

Dimensions:

Material: Wood

Tare:

About 45 kg

Capacity (normal): 800 kg cu-strip, 500 kg cu-strand

Capacity (max): 1000 kg cu, 350 kg al

Mainly suitable for: Cu-strands up to 300 cm2, Cu-strips

Type; Returnable

Measuring point

= Overall

D1= Flange diameter

= Barrel diameter

= Centre hole:

1 Facts Material: Steel

D4 = Drive pin hole: 130

Tare: about 52 kgs

R1 = Drive radius (CC):

Capacity (normal): 215 kgs copper

Form of delivery: We have the following standard ways of packing the drums:

Capacity (max): 250 kgs

- On a small pallet, "eye-to-the sky

Mainly suitable for: Cu-wire

Type: Returnable

- On EUR-pallet, "eye-to-the sky"

- On EUR-pallet with laths, "eye-to-the wall"

2 Dimensions Measuring point mm

Other info:

- On Speedy -pallet "eye-to-the wall"

- In a cradle

L1 = Overall width: 324

L2 = Inner width: 280

- Lagged, placed in a cradle

D1 = Flange diameter: 560

- Loose. (See picture above.)

D2 = Barrel diameter: 305

The wooden drum and pallets are treated in accordance with ISPM 15.

D3 = Centre hole: 127

D4 = Drive pin hole: 25 R1 = Drive radius (CC): 127

Form of delivery: On a small pallet

3 Form of delivery

We have 2 standard ways of packing the spools.

Note:

One drum placed "eye-to-the sky"

• On a small pallet.

On a small pallet. No strapping

• On EUR-pallet with laths, max 4 pcs.

4 Other info.

Form of delivery:

On a EUR-pallett.

According to our drawing “reg 0355-KO”.

Note:

One drum or two drums placed " eye-to-the sky " on an EUR-pallet. No strapping.

Only center hole and flange diameter are according to DIN 46397.

Packing name Picture

EK560/1/fat

On a small pallet.

One drum placed “eye-to -the -wall” on a small pallet.Strapped

Form of delivery:

On EUR-pallet with laths

Note:

One or two drums placed and strapped "eye-to-the sky"

O n an EUR-pallet. Good solution for two drums with aluminium.

Form of delivery:

Note:

On Speedy-pallet.

One or two drums placed and strapped "eye-to-the wall" on an Speedy-pallet. Good solutions for two drums with copper.

Form of delivery:

Note:

In a cradle.

One drum placed "eye-to-the wall" in a cradle. Mp strapping.

Form of delivery:

Note:

Lagged, placed in a cradle.

Protected with wooden battens nailed to the flanges and secured with a plastic strapping.

The drums is then placed "eye-to-the wall" in cradle.

E 11FS

Facts: EK 560

Dimensions:

Material: Wood and steel

Tare: About 116 kg

Capacity (normal): 1500 kg

Capacity (max): 1700 kgs

Mainly suitable for: Copper conductor or profiles Type: One way

Cable drum with steel core and Plywood lined flanges.

Drive pin hole:

= Drive radius (CC):

1 Facts

Form of delivery:

Material: Steel

Tare: about 52 kgs

Capacity (normal): 215 kgs copper

Note: The drum is placed in a wooden cradle The drum is placed "eye-to the-wall

Capacity (max): 250 kgs

Mainly suitable for: Type:

2 Dimensions Measuring point

L1 = Overall width:

L2 = Inner width:

D1 = Flange diameter:

D2 = Barrel diameter:

D3 = Centre hole:

D4 = Drive pin hole:

R1 = Drive radius (CC):

3 Form of delivery

We have 2 standard ways of packing the spools.

• On a small pallet.

• On EUR-pallet with laths, max 4 pcs.

4 Other info.

According to our drawing “reg 0355-KO”.

Only center hole and flange diameter are according to DIN 46397.

DIN 1250

Facts:

Material: Steel

Tare: About 339 kg

Capacity (normal): 3200 kg copper 1050 kg aluminium

Capacity (max): 3000 kg

Mainly suitable for: Big copper and aluminium conductor dimensions Type: Returnable

EK 560

Dimensions:

1 Facts

Form of delivery:

Measuring point

L1 = Overall width:

L2 = Inner width:

= Flange diameter:

= Barrel diameter

D3 = Centre hole:

Drive pin hole:

R1 = Drive radius (CC):

Material: Steel

Tare: about 52 kgs

Capacity (normal): 215 kgs copper

Other info: One in a steel rack

Capacity (max): 250 kgs

Mainly suitable for: Cu-wire Type:

Material wrapped in plastic or optional crepe paper

2 Dimensions Measuring point

L1 = Overall width:

L2 = Inner width:

D1 = Flange diameter:

D2 = Barrel diameter:

D3 = Centre hole:

D4 = Drive pin hole:

R1 = Drive radius (CC):

3 Form of delivery

We have 2 standard ways of packing the spools.

• On a small pallet.

• On EUR-pallet with laths, max 4 pcs.

4 Other info.

According to our drawing “reg 0355-KO”. Only center hole and flange diameter are according to DIN 46397.

VKT 1500

Facts:

Material: Steel

Tare:

About 295 kg

Capacity (normal): 4500 kg copper, 1500 kg aluminium

Capacity (max): 5000 kg copper, 2000 kg aluminium

Mainly suitable for: Big copper and aluminium conductor dimensions Type: Returnable

Dimensions: mm Measuring point 920 L1 = Overall width:

L2 = Inner width:

D1 = Flange diameter:

D2 = Barrel diameter

D3 = Centre hole:

D4= Drive pin hole:

R1 = Drive radius (CC):

1 Facts Material: Steel

Tare: about 52 kgs

Capacity (normal): 215 kgs copper

Capacity (max): 250 kgs

Form of delivery:

Other info: One in a steel rack

Mainly suitable for: Cu-wire Type:

2 Dimensions Measuring point

Material wrapped in plastic or optional crepe paper

L1 = Overall width:

L2 = Inner width:

D1 = Flange diameter:

D2 = Barrel diameter:

D3 = Centre hole:

D4 = Drive pin hole:

R1 = Drive radius (CC):

3 Form of delivery

We have 2 standard ways of packing the spools.

• On a small pallet.

• On EUR-pallet with laths, max 4 pcs.

4 Other info.

According to our drawing “reg 0355-KO”. Only center hole and flange diameter are according to DIN 46397.

K 18

Facts:

Material: Wood

Tare: Approx 220 kg

Capacity (normal): 2500 kg cu, 2500 kg al

Capacity (max): 3000 kg cu, 3000 kg al

Mainly suitable for: Solidal Al and Cu conductors Type: Oneway

Dimensions: mm Measuring point

= Flange

= Barrel diameter

= Centre hole:

D4= Drive pin hole:

= Drive radius (CC):

1 Facts Material: Steel

Tare: about 52 kgs

Capacity (normal): 215 kgs copper

Form of delivery:

Capacity (max): 250 kgs

Note: The drum is placed in a wooden cradle The drum is placed "eye-to the-wall"

Mainly suitable for: Cu-wire Type: Returnable

2 Dimensions Measuring point

L1 = Overall width:

L2 = Inner width:

D1 = Flange diameter:

D2 = Barrel diameter:

D3 = Centre hole:

D4 = Drive pin hole:

R1 = Drive radius (CC):

3 Form of delivery

We have 2 standard ways of packing the spools.

• On a small pallet.

• On EUR-pallet with laths, max 4 pcs.

4 Other info.

According to our drawing “reg 0355-KO”. Only center hole and flange diameter are according to DIN 46397.

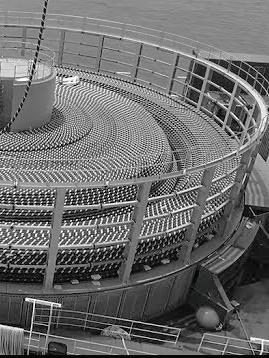

Tare: 1000 - 1250 kg

Capacity (normal): 10000 kg cu. 5000 kg al

Capacity (max): 21000 kg cu theoretical 6400 kg al

Mainly suitable for: Solid cu and al-conductors, Al-tubes Type: Customer owned

Form of delivery We have the following standard ways of packing the drums: - In a custom made steel rack - Loose.As per the illustration here below.

Facts:

Dimensions:

Material: Corrugated paper

Tare: 32 kg (incl. Oct-pallet)

Capacity (normal): 1500 kg cu

Capacity: 2000 kg cu/600 kg al

Mainly suitable for: Copper Wire/Aluminium wire Type: Oneway

Form of delivery:

We have 2 standard ways of packing the octabins:

- Normal packing

Seaworthy packing.

The octabin is placed in a plastic bag.

Other info:

The octabin is secured on the pallet with plastic-straps. Wooden boards are placed on the lid for safer and easier securing.

The wooden pallets are treated in accordance with ISPM 15.

COPPER ALTERNATIVES

OUR SOLUTIONS ARE AN ESSENTIAL COMPONENT IN THE ELECTRICAL AND INFRASTRUCTURE INDUSTRIES. WITH RESPECT FOR THE ENVIRONMENT AND FUTURE GENERATIONS, WE ARE DEVELOPING ADVANCED TECHNOLOGIES TO PROVIDE YOU WITH OUTSTANDING ENERGY-SAVING PRODUCTS WITH MAXIMUM CIRCULARITY.

STANDARD COPPER

Our copper is responsible sourced to prevent abuses of human rights, avoid contributing to conflicts, as well as safeguarding health and safety of miners in the supply chain. Our cathodes are LME Grade A and in accordance with the standard ASTM B115, or EN 1978.

LOW-CARBON COPPER

The Low-carbon Copper has less than half of the CO2 emissions per kg copper compared to standard copper. The reduced CO2 emissions of our Low-carbon Copper have been validated scientifically and will play an important role in the transition, to achieve the goal of net-zero CO2 emission by 2050 set by the EU. The carbon emissions reduction by using Low-carbon Copper is based on using copper mines with electrified production, Elcowire's lean prodution methods, very efficient ore concentration process and a world-class green energy mix.

Elcowire sets the example by producing semi-fiished and finished products that have a low impact on nature and climate.

RECYCLED COPPER

One of the most significant benefits of copper is its recyclability. Copper is a highly sought-after material in the recycling industry because it can be recycled over and over again without losing its quality or purity. This means that copper can be reused in new products, reducing the need for mining and extraction of new copper ore. Recycling copper also reduces energy consumption and greenhouse gas emissions associated with copper production, making it an environmentally friendly choice. Elcowire's waste management and processing of materials are focused on going from linear flows to circular flows, supporting the core of a circular economy.

End-of-Life materials can be sent back to smelters to be refined inseveralprocesssteps Metals are extracted withlowestpossible impactfrom suppliers' mines

Internalmetalscrap isrecycled

End-of-Lifecoppercanbesentbackto Elcowiretoberecycled

Processscrap from customers canberecycled at Elcowire

Elcowire's circularity process enables our customers to reduce their CO2 emissions.

End-of-Life - At the material end-of-life thereareseveralpossibilities forthematerialtogetanewlife

OUR COMMITMENT TO ENVIRONMENTAL SOCIAL GOVERNANCE & SUSTAINABILITY FOR THE EUROPEAN HIGH VOLTAGE CABLE INDUSTRY

Copper is a sustainable material with unrivaled efficiency and recyclability. As a leading copper processing company we recognize the critical role copper plays in the Green Energy Transition and thus the European High Voltage Cable Industry. Our mission goes beyond producing high-quality copper products – we are dedicated to ensuring that every step of our process contributes positively to the environment and the society.

Our journey towards sustainability begins with the responsible sourcing of copper. We collaborate with suppliers who meet the highest standards on environmental protection and social responsibility. Our commitment to ethical sourcing ensures that the copper we process is extracted and/or recycled with minimal environmental impact, preserving ecosystems and benefiting local communities. We apply the same level of responsibility throughout our own processing operations where we continuously seek ways to reduce energy consumption, water use and emissions. These efforts help to reduce the carbon footprint of the high voltage cables made from our copper, supporting the ambitious sustainability goals set by both our society and our customers. Through our green initiatives, we ensure that the copper used in high voltage cables contributes to a low-carbon, energy-efficient future.

We understand that sustainability extends beyond environmental impact, it includes the people and communities that make our products possible. Our CSR initiatives focus on supporting local communities, promoting fair labor practices, and contributing to social development in areas where we operate. By ensuring ethical business practices and transparency throughout our operations, we create long-term value for society, supporting both economic growth and social well-being.

Innovation is at the heart of our sustainability efforts. We continuously invest in new technologies and processes that improve the efficiency and environmental performance of our copper products. By embracing cutting-edge solutions, we help the European High Voltage Cable Industry to meet the growing demand for sustainable and renewable energy transmission while reducing its environmental impact. Our aim is to be a catalyst for the Green Energy Transition.

Elcowire Business Unit High Voltage is proud to contribute to the Green Energy Transition and the European High Voltage Cable Industry’s sustainability journey. Our products are more than just materials—they are fundamental to powering Europe’s Green Energy Transition, enhancing efficiency, and reducing environmental impact.

Through responsible sourcing, processing, and recycling, we are ensuring our part of the value chain in building a sustainable future.

CUSTOMER SERVICE CENTER HIGH VOLTAGE

CALLE CROONA

Sales Manager

Markets: Sweden, Denmark, Norway, Finland

Language: Swedish & English calle.croona@elcowire.com

Mobile +46 (0)705 300 696

CHRISTIAN MOSES

Sales & Application Engineer

Language: German, English & Swedish christian.moses@elcowire.com

+46 (0)730 894 765

LOUISE OLSSON

Helsingborg

Language: Swedish & English louise.olsson@elcowire.com

+46(0)42 19 53 15

ISABELLE PERSSON

Helsingborg

Language: German, Swedish, English & French isabelle.persson@elcowire.com

+46 (0)42 19 53 40

TONY HILL

Sales & Application Engineer

Language: Swedish & English tony.hill@elcowire.com

Mobile +46 (0)703 195 366

DÖRTE LÛTHJE-FRISTEDT

Helsingborg

Language: German, Swedish & English dorte.fristedt@elcowire.com

+46 (0)42 19 53 42

KAREN CARLSTRÖM

Helsingborg

Language: English & Swedish karen.carlstrom@elcowire.com

Mobile +46 (0)790 890 350

Withsustainabilityinmind,combinedwith widetechnicalknowledgeandexperience inestablishingnewareasofoperationand business,wearelookingforwardtogiveyou answerstoyourquestions...

ELCOWIRE TEAM

OUR PROMISE

- We work deliberately to earn and maintan our customer’s trust.

- We listen carefully to and do our utmost to live up to our customer’s wishes, demands and expectations.

- We act and do business in accordance with the Elcowire Code of Conduct.

- Our business and business relationships are managed to be long term sustainable.

- We shall continuously develop and strengthen our capabilities in order to stay competitve and relevant.

MIKAEL JOHANSSON

Helsingborg

Language: Swedish, English & German

mikael.johansson@elcowire.com

+46 (0)702 190 165

OUR REFERENCES

- North Sea Link: Norway-UK

- Viking Link: Denmark-UK

- Dogger Bank: Scotland

- Neu Connect: Germany-UK

- Sued Link: Germany

- SüdOstLink: Germany

- Champlain Hudson Express: Canada-USA

SUSTAINABLE RELATIONSHIP WITH OUR CUSTOMERS

The Group has expanded and this has added production capacity, but perhaps even more importantly, sales capacity, technical competence and experience. Capacity is important, but even more so is the knowledge of our Elcowire colleagues.

ELCOWIRE GROUP

OUR BUSINESS UNITS

BU Rod has an annual production capacity of 300 000 tons of pure and silver, tin- and magnesium-alloyed copper wire rod.

BU Rod is one of the largest manufacturers in Europe with continuous cast and upcast in rod dimensions 8–30 mm.

Our drawn wire products cover a diameter range between 4,6 mm and 0,05 mm. They are made from Elcowire continuous cast wire rod.

BU Wire & Strands manufactures our wires in compliance with European and international standards.

Profiles Center wires Round wires

BU High Voltage’s conductor materials are being used in cables for interconnections, off shore wind parks, underground power links and other applications.

BU High Voltage’s conductor materials are being used in cables for interconnections, off shore wind parks, underground power links and other applications.

BU High Voltage offers our extensive knowledge and products primarily to manufactures of high voltage and extra high voltage cables.

BU High Voltage offers our extensive knowledge and products primarily to manufactures of high voltage and extra high voltage cables.

BU Specials is a leading provider of drawn and extruded profiles used in various applications for energy transmission.

BU Specials is supporting our customers to build up renewable energy transmission systems.

BU Rail serves the worldwide market for overhead conductor material, including catenary and contact wires, feeder, stitch, jumper and earthing wires.

Our products are suitable for all speeds of operation and support sustainability in railway design.

ELCOWIRE GROUP

With an annual production of 300 000 MT

Elcowire is one of the largest manufacturers in Europe of copper wire rod, wires, stranded conductors, profiles and overhead catenary systems made from copper, copper alloys and aluminium.

ROD

WIRE & STRANDS

RAIL

HIGH VOLTAGE