India was the fastest growing market for Mercedes-Benz in 2022 and we expect the momentum to continue in 2023 as well

THE IMPACT OF EV MANUFACTURING ON THE ENVIRONMENT

FAME SUBSIDY WITHHELD: IMPACT ON THE INDIAN EV SECTOR

P O W E R I N G S M A R T , E L E C T R I C , E F F I C I E N T M O B I L I T Y F E B - M A R 2 0 2 3 | V O L U M E 4 | I S S U E 2

COVER

ED and Head of Operations, India Mercedes-Benz India Private Limited

STORY

06 RAGHAV BHARDWAJ Head – Strategy and Leadership, Bolt Earth Smriti Charan Sangeeta Sridhar advertise@firstviewgroup com Sadhana Raju Shenvekar Vaibhav Enterprises ADVERTISING CIRCULATION PRINTING Firstview Media Ventures Pvt Ltd Ashwini Chikkodi editorial@firstviewgroup com Sadhana Raju Shenvekar Rajarshi Sengupta Pallab Kumar publishing@firstviewgroup com Neha Barangali Radha Buddhadev design@firstviewgroup com PUBLISHING EDITING CONTENT DESIGNING CONTENT 10 12 FEATURED TALKS IN CONVERSATION OPINION KNOWLEDGE BYTES VYANKATESH KULKARNI KUMAR PRASAD TELIKEPALLI ED and Head of Operations, India Mercedes-Benz India Private Limited Co-Founder and Group CTO, Matter E Mobility Migration and Sustainability Software as a Service (SAAS) and Its Contribution to the Electric Vehicle Charging Industry 14 18 The impact of EV manufacturing on the environment The EV Lane-Way ahead in new age automotive manufacturing India's Electric Fleet Operator's Business Model 16 20 22 NEWS COMPANY FEATURE 04 07 INDIA NEWS BOLT EARTH 19 26 28 TECHNOLOGY INSIGHT POLICY DEBRIEF MARKET STATISTICS EMOBILITY+ RESEARCH 15 08 17 23 SPECIAL STORY COVER STORY CURRENT STORY CURRENT AFFAIR STORY FEATURED INSIGHTS COMSOL 09 PERSPECTIVE FAME subsidy withheld: Impact on the Indian EV Sector 24

FEB-MAR ISSUE 2022 | PG 03 | INDIA

LML Signs Up 50 Dealers Prior To The Launch Of Its Electric Two-Wheeler In India

LML announced that 50 dealers have been signed up in India as part of its initial phase of expansion prior to the launch of its electric two-wheeler Star According to the company, over 100 LML exclusive dealers pan India is the targets for the second phase in expanding the dealership network It stated that the expansion was planned and strategize on the Dealer-owned dealer operated (DODO model)

Goyal Aluminiums Receive Allotment Of Land To SetUup New EV Manufacturing Plant In Noida

Goyal Aluminiums informed the exchanges that it received a land allotment from the Greater Noida Industrial Development Authority or GNIDA to establish a new plant for electric vehicles The company stated in a regulatory filing that plot No 283 that measures around 4000 sq m and is available for lease for a period of up to 90 years The company will only manufacture electric scooters and low-speed vehicles for the domestic market

Omega Seiki Mobility And cKers Finance Sign MoU To Provide Financing For Electric 3-Wheeler Loaders

Omega Seiki Mobility, an Anglian Omega Group Company, and cKers Finance Private Limited, a non-banking financial company (NBFC) focused on financing climate-friendly businesses including electric vehicles in India, has signed a Memorandum of Understanding Through this tie-up, Omega Seiki Mobility customers for the e3W loader category can get their vehicles financed by cKers Finance

BYD India Partners With Evera To Deliver 100 All-New e6 Vehicles

The world’s leading new energy vehicle manufacturer BYD has partnered with Evera – an EV Cab service based in New Delhi to deliver 100 All-New e6 Evera provides app-based cab services in the national capital and has signed one of the largest orders for electric vehicle fleet operation with BYD India Evera comprises a network of sustainable energy solutions that come together to reduce carbon emissions being released into the environment by everyday travel Its services include a fleet of Electric Vehicles and an app-based cab service along with a network of energy-efficient charging stations to complement the journey

Gogoro Partners With Zomato And Kotak Mahindra Prime To Accelerate Adoption Of Sustainable Electric Vehicles In India

Gogoro Inc, a global technology leader in battery-swapping ecosystems that enable sustainable mobility solutions for cities announced a partnership with Zomato, one of the largest food ordering and delivery platforms in India, and Kotak Mahindra Prime Limited, a subsidiary of Kotak Mahindra Bank Limited The partnership is focused on accelerating the adoption of sustainable electric vehicles by delivery partners that are on board with Zomato offering them new, more favourable loan terms not available in India today Gentari, through its affiliated entity Amplus Power Supply Private Limited, signed a Memorandum of Understanding (MoU) with Tata Motors, India’s largest commercial vehicle manufacturer, in 2022, whereby the latter will deliver 5,000 units of Tata Ace EV – India’s most advanced, zero-emission, four-wheel small commercial vehicle, over three years The MoU includes the delivery of 1,000 units in the first year, for deployment in cities such as Delhi, Bengaluru, Hyderabad, Pune, and Kolkata

Gentari Partners With Tata Motors And Gati KWE To Deliver Electric Vehicles In India

| INDIA BUSINESS NEWS

FEB-MAR 2023

ROUNDUP>

FEB-MAR ISSUE 2022 | PG 04

INDIANEWS

Sun Mobility And Zomato To Power 50,000 Electric Two-Wheelers With Battery Swap Solutions

Sun Mobility, a leader in providing energy infrastructure and services to electric vehicles, has partnered with Zomato, an online ordering platform, and food delivery service, to power 50,000 electric two-wheelers across the country, over the next 24 months using its battery swap solutions

Gentari Signs MoU With MoEVing To Provide 1,500 Electric Cargo Vehicles On Subscription For Its VaaS Offering

Gentari further expanded its Vehicle-as-a-Service (VaaS) offering through an MoU with electric mobility provider MoEVing Urban Technology Private Limited (MoEVing) to provide 1,000 threewheeler and 500 four-wheeler electric cargo vehicles on subscription In 2023, Gentari aims to further grow its EV fleet to more than 4,000 vehicles across ten cities with a mix of threeand four-wheeler vehicles

Motovolt, A Kolkata-Based Electric Mobility Startup Invests Rs 9 Crores In eROCKIT Group

Motovolt, a Kolkata-based e-mobility startup, has invested Rs 9 crores in eROCKIT for an undisclosed stake It is notable to note that Motovolt raised Rs 16 crore in pre-Series A funding in November 2022 This will be used for product introduction, marketing initiatives, and expanding its India presence This is Motovolt’s first international expansion for its electric mobility solutions This initial investment will be used to strengthen the product development and production at eROCKIT’s Berlin manufacturing plant.

ARENQ Partners with RDL Technologies to Develop IoT Devices for Battery Monitoring

ARENQ India’s fast-growing manufacturer and distributor of storage batteries, has forged a five-year partnership with RDL Technologies, a renowned manufacturer of IoT products and software solutions As a part of the association, RDL Technologies will be responsible for developing the IoT devices that will upload data from the Battery Management System (BMS) to the cloud Through this collaboration, RDL Technologies will develop touchscreen displays, data loggers, vehicle navigation, and monitoring systems for ARENQ The IoT devices will allow ARENQ to remotely monitor and navigate the motor, controller, and battery while also providing customers with customised reports on the battery’s performance.

Mahindra Last Mile Mobility Rolls Out Its 50,000th e-Alfa Three-Wheeler From Its Haridwar Plant

Mahindra Last Mile Mobility (LMM), a division of Mahindra & Mahindra, has rolled out its 50000th e-Alfa from the Haridwar Plant LMM sells the e-Alfa Mini e-rickshaw as well as the e-Alfa Cargo. The milestone vehicle was a red e-Alfa Mini The -Alfa Mini is one of the highest-selling Mahindra electric 3-wheelers and was launched in 2017 Mahindra launched the cargo version in 2021

Tata Motors Receives An Order For 1000 XPRES T EVs From OHM E Logistics Pvt Ltd In Hyderabad

Tata Motors, India’s leading automobile manufacturer and the pioneer of India’s EV evolution received an order for providing 1000 XPRES-T EVs to OHM E Logistics Pvt Ltd in Hyderabad, for their electric cab transportation services

Kabira Mobility Secures $50 Million Investment For Expansion From Al Abdulla Group

Kabira Mobility is an EV startup that sells KM3000 as well as KM4000 electric bikes It announced that it had secured a $50 million investment from the Al-Abdulla Group of Qatar, at an undisclosed value The Goa-based company said that the funds raised would be used to improve its existing facility and set up a greenfield facility in Uttar Pradesh

CHARGE+ZONE Raises $54M Funding As A Part Of Series A1 Round led By BlueOrchard

CHARGE+ZONE, a leading EV charging company in India raises one of the largest rounds in equity and debt to expand the high-speed charging network in the country led by BlueOrchard Finance, a member of the Schroders Group and a leading global impact investment management firm along with existing and new institutional investors As part of Series A1, CHARGE+ZONE has raised $54M of which $8M is debt investment from an infrastructure strategy managed by Blue Orchard

IFC To Invest Rs 600 Crores In New Last Mile Mobility Company To Be Launched By Mahindra & Mahindra

In a bid to scale up electric three-wheelers and small commercial vehicles (SCVs) that are more affordable, IFC is investing INR 600 crores in a new last mile mobility (LMM) company – a wholly owned subsidiary of Mahindra & Mahindra that will be a newly incorporated (NewCo).

FEB-MAR ISSUE 2022 | PG 05 INDIANEWS FEB-MAR 2023

How has the year 2023 kickstarted for Bolt.Earth?

We jump-started this year making major headways in the EV space with 20K+ charging points installed across 500+ cities in India and serving over 100K+ users Apart from the major progress we have made within the country, there are several pilot projects that we are conducting in our neighboring countries

Moving from our charging business to our operating stack business, we are making a head start with 10K+ Bolt Earth-OS integrated vehicles scheduled to hit the roads in the next couple of months With real-time navigation updates, remote monitoring and tracking and the ability to offer Over the Air (OTA) updates, Bolt Earth OS is the next generation of innovation for EVs

Our aim for the rest of this year is to build a more robust EV ecosystem that supports the ever-increasing number of electric vehicles (EVs) on the road, make them smarter with our embedded OS technology and deliver reliable and efficient charging infrastructure to users across the country

What makes your company different from other players in the market?

Although we operate the largest charging network in India currently, Bolt Earth is not simply a charge point operator (CPO) unlike most other businesses in this market We like to think of ourselves as a hardcore tech-firm that happens to be in the EV space We have built a software stack that allows us to enable a two-sided approach to accelerating EV adoption – By making vehicles smarter with an OS and by embedding our firmware into charging products We also pride ourselves on having a strong data science and advanced analytics team With our software now on over 10k+ EVs and 20k+ chargers, we gain

RAGHAV BHARDWAJ

Head – Strategy and Leadership, Bolt.Earth

CONVERSATION HIGHLIGHTS

With our software now on over 10k+ EVs and 20k+ chargers, we gain real-time insights from both vehicle and charging station usage, allowing us to guide the EV ecosystem towards seamless user experiences

We have reached out to charging point manufacturers, fleet operators, and top EV makers to add their charging points to our ever-expanding network

In the upcoming years, we see ourselves emerging as a key EV ecosystem enabler and are committed to making electric mobility a viable and sustainable option for people across the globe

real-time insights from both vehicle and charging station usage, allowing us to guide the EV ecosystem towards seamless user experiences

Tell us about the key highlights of Bolt.Earth LITE EV charging sockets for homes

Bolt Earth LITE, our top-selling product, is a 15-Amp EV charging socket with a 3.3 kW AC output that offers multiple safety features for home charging What sets Bolt Earth LITE apart is the level of protection it provides compared to regular 15-Amp sockets such as:

In-built Surge Protection: Protects against sudden power surges

Auto Cutoff: Automatically cuts off power on completion of the charging cycle

Temperature Sensor: Automatically shuts down in case of elevated temperature.

In addition to these features, Bolt Earth LITE offers several advanced options that make it an ideal choice for EV users, including:

In-built meter for energy tracking

BLE (Bluetooth Low Energy) + Wi-Fi connectivity for local and remote control and monitoring

Ability to share your charging point with friends or the public to earn passive income

Designed for user ease, Bolt Earth LITE is simple to operate at home The device can be turned on/off using a single physical button for private charging, making it simply plugand-play charging Finally, Bolt Earth LITE is fully compatible with all EVs including 2-3-and 4 wheelers

Can you discuss any upcoming developments or innovations that your company is working on?

We have some exciting news to share! The launch of our Open EV Charging Platform is finally here, and we couldn't be more thrilled This platform aims to bring together country-

wide charging points onto a single platform to fulfill the increasing demand for charging points in India and make charging more accessible to everyone

By introducing this platform, Bolt Earth is now a one-stop-shop for EV users to locate and utilize charging points throughout India We have reached out to charging point manufacturers, fleet operators, and top EV makers to add their charging points to our ever-expanding network In addition, we have invited third-party app-based service providers to integrate our charging services within their own apps to facilitate EV charging for their users

Our initiative's goal is to address the demand for EV charging at home and in public spaces by aggregating charging points on a single app for users. The platform is also designed as a two-sided open engagement, allowing charging point hosts to tap into the demand for their respective charging points

What is Bolt Earth's strategy for the upcoming years to strengthen its presence in the market?

Bolt Earth was founded with the mission to revolutionize the future of electric mobility by offering solutions that enable the ecosystem Our innovative and revolutionary technology is driving this mission forward Our software stack powered by the Bolt Earth Operating system (OS) allows us to tackle the two critical elements that will change in the coming decade for mobility as a whole – Internal Combustion Engines (ICE) will be replaced with software-based upgrades in EVs and Fuel stations which will be replaced by decentralized energy distribution in charging

In the upcoming years, we see ourselves emerging as a key EV ecosystem enabler and are committed to making electric mobility a viable and sustainable option for people across the globe

Bolt.Earth was founded with the mission to revolutionize the future y offering solutions that enable the ecosystem.

FEATUREDTALKS

| INDIA FEB-MAR ISSUE 2022 | PG 06

BOLT.EARTH IS ACCELERATING THE EV ECOSYSTEM

WITH 20K+ CHARGING POINTS & 10K+ BOLT.EARTH OS-ENABLED VEHICLES ON ROAD

Who are we?

Bolt Earth is the leading EV ecosystem enabler in the country with 20K+ established charging points across 500+ cities and 10K+ Bolt Earth OSintegrated vehicles on the road We currently work with 8 of the top 10 2wheeler EV OEMs in India and are not only making major headway in India but conducting several pilot studies in other emerging economies. We have already equipped over 100K+ users with smart, safe, and simple engineered devices catering to EV charging needs With 500MWh+ energy dispensed, our charging infrastructure is a reliable and efficient network of charging stations to support the growing number of EVs on the road

Founded back in 2017, we began our journey with the aim of making EVs more accessible to everyone While addressing the challenge of poor EV infrastructure in the country, we are looking to scale the Bolt Earth ecosystem by introducing products and services to push emerging markets toward cleaner mobility

Our growth story:

Starting off with our operating system for 2 and 3 wheeler that helps make them Smart EVs, by 2020, we made major headlines with the launch of Bolt Earth LITE – a home charging solution and peer-to-peer charging network. In the last few years our progress has skyrocketed and reached new heights with the largest number of public charging points in the country, we are now India’s largest EV charging network

Presently, we are on a mission to build a robust EV infrastructure that will support the growing number of EVs on road by accelerating the EV ecosystem

Our ecosystem:

Today, we are EV ecosystem enablers with a strong portfolio of enabling India’s EV ecosystem through services such as charging networks, components (OTA), referrals, services, integrations & APIs/SDKs, E-commerce/marketplaces, financing & insurance, servicing with dealers, companion app & cloud portal, OTA updates, and speedometer OS+ with VCU We have also recently launched our Open EV Charging Platform with the aim of ensuring interoperability between different charging networks to pave the way for a more unified energy consumption structure for 2, 3, or 4-Wheeled EV users

While our innovative and revolutionary technology is driving our mission forward, we are constantly working to push emerging markets towards cleaner mobility.

EV Ecosystem Enabler

COMPANY FEATURE

| INDIA FEB-MAR ISSUE 2022 | PG 07

Bolt.Earth. is the leading EV ecosystem enabler in the country with 20K+ established charging points across 500+ cities and 10K+ Bolt.Earth OSintegrated vehicles on the road. We currently work with 8 of the top 10 2wheeler EV OEMs in India and are not only making major headway in India but conducting several pilot studies in other emerging economies."

J&K LITHIUM RESOURCE

Why Proper Mining And Keeping Socio-Environmental Balance Is Critical To Be Truly Atmanirbhar In Country's Energy Storage And Electric Vehicle Segment?

The Geological Survey of India announced, on February 9, that it had for the first-time established 5.9 Million tons of inferred resource (G3) of lithium within the Salal Haimana district of Jammu & Kashmir According to the GSI, the "lithium inferred resource" has been established This is based on a physical-chemical study of samples and the surface It was located in the Salal Haimana area in Jammu & Kashmir.The lithium found in Reasi has more than 800 ppm (parts per million) quality, which hints at a higher level of enrichment Any lithium mineral with more than 300 ppm quality is considered of good enrichment value According to the Mines and Minerals (Development and Exploration) Act 1956, "inferred" is the second stage of a four-step process G4 (reconnaissance), is where the mapping and exploration of resources takes effect. G3 (prospecting), is where quantities can be inferred This stage uses interpretations of geological, physical, and geo chemical data The deposit will then be targeted for further exploration G2 (general exploration) is the next stage More studies are conducted to determine the mineral's shape, size, grade Finally, the G1 stage (detailed investigation) determines the characteristics of the deposit with high accuracy

Potential Challenges

Strategic Challenges

China currently controls 77% of the global lithium-ion battery manufacturing capacity China is also way ahead in global lithium ore processing India's growing geopolitical rivalry is making security concerns more urgent, particularly in light of longstanding and recent escalating territorial and border conflicts with China According to the report of lithium import and production by the Ministry of Mine, India imported Rs 173Cr of lithium and Rs 8,811Cr of lithium-ion in FY 20202021 Geo strategic implications of the new discovery are more significant when you consider its larger geopolitical sensitivity Reasi may be in the more stable Jammu region. However, the Union territory in J&K has been the scene of past cross-border tensions between India & Pakistan, insurgency and terrorism Major involvement of local population in mining and processing of lithium ore, will ensure a stable socio-environmental effects of mining

The seismic zone map India shows that Jammu and Kashmir lies near the Himalayas and falls under Zone IV It is also ecologically fragile Large scale mining in this ecologically fragile region, could cause land slide or land sink like recent Joshimath event

Environmental Challenges

Li extraction from hard-rock mining, like the one proposed in J&K is done by open-pit-mining and then roasting the ore using fossil fuels Industry estimates shown that this process takes 170 cubic meters of water, and produces 15 tonnes of CO2 every tonne lithium These processes significantly degrade the environment They deplete and contaminate waterways, decrease biodiversity, and release significant air pollution Reasi, a district in J&K where lithium deposits were discovered, is home to rural households and vegetation The Chenab river and its tributaries are also close by the hills

India's ambitious goal to reach net zero by 2070 could increase lithium demand As India races to become a clean energy nation, the demand for lithium will rise as clean energy storage devices and electric vehicles (EVs), which are dependent on metal, is reduced

The Report on the Optimal Generation Mix 2029-30 has been prepared by Central Electricity Authority (CEA/MoP) According to the report, the 2029-30 installed capacity will include a Battery Energy Storage capacity equal to 27,000 MW/108,000MWh (4-hour storage) According to NITI Aayog the total EV sales could rise to 80 million by 2030 from the 1.3million sales reported until July 2022.

Lithium Resource Source https://sheetzohocom/sheet/open/8yvzrfc9ca2d599e5435797c5ef04badd 2d2b?sheetid=1&range=A1

The discovery would place India sixth in terms of lithium resources, just behind leading producer Australia and ahead of China, the largest raw lithium importer and producer of lithium-ion batteries.

GlobalLithiumResource(MMt) 0 5 10 15 20 25 Bolivia Argentina Chile USA Australia India China DRC

COVER STORY

| INDIA FEB-MAR ISSUE 2022 | PG 08

MODELING AND SIMULATION FOR MEETING THE

CHALLENGES OF BATTERY DESIGN

The biggest challenges for battery design are energy density, power density, charging time, life, cost, and sustainability Modeling and simulation are very efficient methods that can assist researchers, developers,anddesignersinmeetingthesechallenges

EdFontes,COMSOL

Energy density is limited by the battery’s chemistry, which even without losses limits the theoretical energy density The chemistry is defined by the electrode material and the composition of the electrolyte Lithium-air batteries get close to the energy density of gasoline, which is probably close to the maximum energy density for a battery However, the components required for thermal management and current collection contribute to the total weight of the battery system The design of these components can substantially influence the energy density of a battery system

Power Density and Fast Recharge

The power density of a battery is important for the efficiency of electric vehicles A high power density is required to recapture high amounts of energy in a short time during regenerative braking or fast recharge. This gives a difficult optimization problem, since the system has to cope with very high current densities during recharge and relatively low current densities during discharge It also relates to the design of the thermal management and the current collectors mentioned earlier In addition, the design of fundamental battery components such as the electrodes, separator and electrolyte are of great importance for power density.

combustion engines There is a larger potential in productivity gains and decreased costs by large-scale production in the manufacturing process for the battery components

Sustainability

The development of new batteries has to include the aspect of sustainability There has to be a strategy for mining, recycling, producing, and disposing of new battery types This is primarily a legal matter for governments, but also a commercial consideration for battery manufacturers and automotive companies.

Life, Reliability, and Safety

Life is a major consideration where safety and reliability are closely related Discharge, wear, and failure should occur slowly and in a controlled and transparent way This is not only an issue of the chemistry of the battery, but also of the design, since uneven current density distribution and poor control of discharge/recharge and of the thermal management system may accelerate wear and increase the risks of failure Short-circuits formed by metal deposition may be responsible for decrease in performance as well as an increased risk for runaway heating Technologies for state-of-health monitoring are required in order to continuously assess the state of the battery system and the risks of failure

Costs

The manufacturing process for high-power batteries and electric powertrains is not as optimized as for mechanical powertrains for

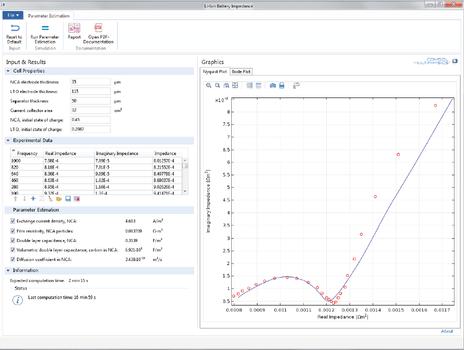

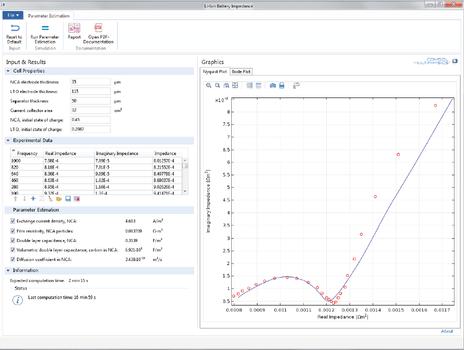

Figure 2 The goal with this application is to explain experimental electrochemical impedance spectroscopy (EIS) measurements and to show how you can use the model and the measurements to estimate the properties of lithium-ion batteries The application takes experimental data from EIS measurements as input, simulates these measurements, and then runs a parameter estimation based on the experimental data

The understanding and optimization of fundamental components of the battery; such as electrodes, electrolyte, and separator; can be accelerated using modeling and simulations The systems for thermal management, current collection, and state-of-health monitoring can also be developed with high-fidelity multiphysics simulations

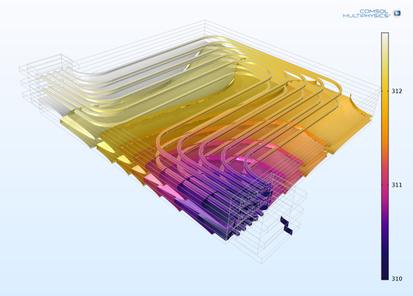

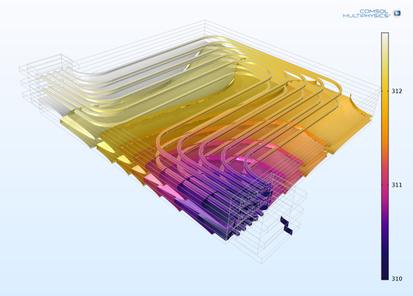

Figure 1 shows a model for the optimization of the channels in the cooling plates of a battery pack The is a common application in the automotive industry For example, Fiat Research Center uses mathematical modeling for studying thermal management of pouch cells for hybrid vehicles1

Fundamental studies of battery components as well as the development of state of health methods can be very efficiently carried out by combining experimental measurements of electrochemical impedance spectroscopy (EIS) with mathematical models, see the article from the French research institute CEA2 Figure 2 shows an app, where experimental data can be imported and used in a physics-based model of EIS. This allows for the estimation of parameters such as activity of the electrodes, surface area, electrical conductivities of the different components, mass transport properties of reactants and products, and state of charge of the electrodes

References

The Thermal Management of Li-ion Battery Packs Michele Gosso, Antonio Fiumara. Fiat Research Center, Orbassano, Italy. COMSOL News (2012), 48-49

Highly Accurate Li-ion Battery Simulation Mikael Cugnet French Atomic and Alternative Energy Commission (CEA), France COMSOL News (2013), 44-45

FEATURED INSIGHT

Figure 1. Multiphysics simulation of the temperature profile in a liquid-cooled battery pack. Fluid flow and temperature are modeled in 3D and a lumped 1D model of the Li-ion battery is used to calculate the heat source.

| INDIA FEB-MAR ISSUE 2022 | PG 09

India was the fastest growing market for Mercedes-Benz in 2022 and we expect the momentum to continue in 2023 as well.

Vyankatesh Kulkarni

ED and Head of Operations, India

Mercedes-Benz India Private Limited

CONVERSATION HIGHLIGHTS

At Mercedes-Benz, we forecast 25% of our total sales volumes in the next 4 years, will comprise luxury EVs India is a part of Mercedes-Benz global EV manufacturing network and first country to manufacture EQS outside Germany and amongst CKD network With a strong commitment to sustainability, Mercedes-Benz India runs the plant on 100% green energy. The plant generates 3.6 MW of electricity through solar energy

Mercedes-Benz is known for its luxury cars. How is the company adapting its manufacturing processes to meet the growing demand for electric vehicles?

At Mercedes-Benz India, we manufacture 14 ‘Made in India’ cars for the Indian market This ranges from the C-Class to right hand drive EClass, the S-Class and even AMGs and Maybach The growing acceptance of EVs in India reaffirms that the future is electric, and Mercedes-Benz is playing a leading role in EV transition in the luxury segment We retail four luxury EV models namely, EQB, EQC, ‘Made in India’ EQS 580 and EQS 53 AMG.

After Germany, India is the first base for Mercedes-Benz to assemble the pinnacle of luxury EVs – EQS 580 Our production lines at Mercedes-Benz India are flexible, which has a rare distinction of making both ICE and EVs Our made-in-India EQS 580 launched in 2022, has created a new benchmark in the EV segment in India, and its local manufacturing underlines Mercedes-Benz’s global manufacturing competencies developed in India

How is Mercedes-Benz approaching the challenge of ensuring the sustainability of its electric car manufacturing processes, and what measures are in place to ensure that the company's operations have a positive impact on the environment?

Mercedes-Benz is committed to reducing emissions throughout the whole vehicle lifecycle across the entire portfolio, developing an entirely carbon-neutral passenger car fleet by 2039 In India, we aim to Reduce, Reuse & Recycle, leading to a reduction in CO2 footprints through the design of our processes and initiatives At Mercedes-Benz India, we run our plant on 100% green energy The plant generate 3.6 MW of electricity through solar

panels and practices zero discharge of wastewater to public drains As a rare distinction, we maintain the ecological balance of our plant premises, which house 125 species of plants and animals, and afforestation is a key part of our CSR initiatives

Along with the manufacturing process, our cars also are built with keeping sustainability in mind All our vehicles are a minimum of 85 percent recyclable For example: the components in the EQS, are manufactured resource-efficiently using recycled and renewable raw materials The steel processed for the EQS at the Mercedes-Benz pressing plants consists largely of recycled steel scrap and the EQS has over 80%-recycled steel in its structure. Even the floor coverings are made of fishing nets and carpet scraps

How does Mercedes-Benz ensure that its manufacturing facilities maintain the highest standards of safety and quality control, and what measures are in place to prevent accidents and ensure worker safety?

Safety and Quality are the inherent and integral parts of Mercedes car; for which it is known in the entire world Same culture is inculcated when it comes to manufacture the safest cars Being ISO 45001 certified company in terms of Health and Safety, adopting the safe work practices by training all the employees providing appropriate PPE’s, maintaining 5S at the workplace and leaders leading the example by practicing highest standard of health and safety and thus setting the bench mark of safe work practices

With initiatives such as ‘Safety Week’, we create awareness ranging from safe driving for our carpool, safety practices at shop floor, safe equipment management among others For overall workforce, we conduct fire and natural disaster drills and we all believe “Safety is paramount” Additionally we are well integrated in “environmental & Safety Risk Management” processes n system at group owned production facilities

is

The manufacturing of EQS 580 4MATIC in India was a landmark moment and a strong testament to our state-of-the-art manufacturing prowess and our commitment to the vision of ‘Make in India’ For our journey of electrification, we had to adapt current infrastructure across mechanical, electric and other complex processes The plant evolved by implementing flexible assembly lines, which can produce multiple models and different drivetrains The assembly hosts multiple models at a time from E-Class, S-Class, Maybach EQS on the same line To complement complex battery set-up, our plant now implements innovative, safe and efficient Battery assembly process and delivers on philosophy of ‘First Time Right’ production and best quality assurance processes

INCONVERSATION

How important

innovation in the manufacturing process for electric cars, and how is Mercedes-Benz leveraging technology and new manufacturing techniques to improve efficiency and reduce costs?

| INDIA FEB-MAR ISSUE 2022 | PG 10

Mercedes-Benz academy introduced an industryfocused unique EV module in its highly popular Advanced Diploma in Automotive Mechatronics (ADAM) course. This initiative goes a long way in contributing to electric ecosystem of the country."

Can you talk about the role of R&D in the development and manufacturing of electric cars at Mercedes-Benz, and how the company is working to stay at the forefront of technological innovation in the industry?

In India, we have Mercedes-Benz Research and Development India (MBRDI), which is the largest R&D center outside of Germany India center is one of the biggest contributors of innovation for Mercedes-Benz globally Over the years, MBRDI has played an integral role in innovating and accelerating the future of sustainable mobility and we proudly say “There is bit of India in every Mercedes”

In recent years, there has been a significant shift towards digitalization and connectivity in the automotive industry. How is Mercedes-Benz leveraging these trends to improve the driving experience for customers, and what role is technology playing in this transformation?

Just like luxury, comfort, and safety, Technology and connected features have emerged as top buying criteria for today’s customers as they create something innovative, valuable, and intelligent for our customers These connected features and tech make the car more intelligent and personal, seamlessly integrating into customers’ lives Mercedes-Benz has been constantly pushing the boundaries in the domain of technology offerings and as a result, today, we have the largest carpark of connected luxury vehicles in the country, with over 79 000 connected Mercedes-Benz cars on the Indian roads

In addition, with the AI-enabled MBUX and now MBUX Hyperscreen in the EQS, our incar technology is miles ahead of any market offerings It is part of the Internet of Things and combines super-computing power with artificial intelligence to create a personalized user experience

With digitalization we are transforming manufacturing in various aspects of industrie 4 0 practices and with data driven decisionmaking, we achieve higher efficiencies in production & supply chains

INCONVERSATION

Finally, what role does India play in Mercedes-Benz's global strategy for electric car manufacturing, and how is the company leveraging the country's resources and talent to advance its goals in this area?

India is a part of Mercedes-Benz global EV manufacturing network and first country to manufacture EQS outside Germany and amongst CKD network Indian luxury Indian luxury EV market has showcased an upward trend and we are bullish on its growth At Mercedes-Benz, we forecast 25% of our total sales volumes in the next 4 years will comprise luxury EVs. Overall India was the fastest growing market for Mercedes-Benz in 2022 and we expect the momentum to continue in 2023 as well

Electric is the future, and it is imperative that we drive ahead with upskilling and re-skilling initiatives for our talent pool, making them industry ready and create a robust e-mobility ecosystem Mercedes-Benz academy introduced an industry-focused unique EV module in its highly popular Advanced Diploma in Automotive Mechatronics (ADAM) course This initiative goes a long way in contributing to electric ecosystem of the country

we

Mercedes-Benz has been constantly pushing the boundaries in the domain of technology offerings and as a result, today, we have the largest carpark of connected luxury vehicles in the country, with over 79,000 connected Mercedes-Benz cars on the Indian roads."

At Mercedes-Benz India,

manufacture 14 ‘Made in India’ cars for the Indian market."

| INDIA FEB-MAR ISSUE 2022 | PG 11

INCONVERSATION

We are working on all elements of technology in the EV ecosystem.

Kumar Prasad Telikepalli

Co-Founder and Group CTO, Matter

CONVERSATION HIGHLIGHTS

In November 2022, we launched AERA, India's first Geared electric motorbike Matter fits into multiple roles across the EV ecosystem, as we are not just limited to building our own vehicle but also providing cross platform solutions

Through vertical integration Matter has developed and built every critical component of AERA in house

What inspired you to start Matter, and how does the company fit into the broader landscape of electric vehicle manufacturing?

Matter was founded in 2019 with the goal of revolutionising India's electric ecosystem and with the mindset that the shift to electric vehicles would be aided by innovative technology Backed by this goal, Matter was founded with a vision to provide futuristic energy storage and mobility solutions to drive India to a sustainable future

Realising that the current products available in the Indian EV space are found wanting in certain aspects, our conversations narrowed down to four fundamental needs for an EVs: safety, security, reliability, and performance. Our discussions pointed in the direction of charting and developing one’s own technology as that would help us address the fundamental needs in an organic manner and also adapt faster Our company fits into multiple roles across the EV ecosystem as we are not just limited to building our own vehicle but also providing cross platform solutions We are working on all elements of technology in the EV ecosystem

Over the past few years, we have been working on multitude of disruptive cross-platform solutions, accelerating India’s transition to electric In 2022, we introduced India’s first liquid-cooled battery and motor in the 2W segment keeping in mind the Indian environmental and usage conditions Later in the year, we also launched India’s first geared electric motorbike Earlier this year, we exhibited innovative and disruptive future concepts: the Concept-EXE is for young executives, and the Concept-UT is for a diverse utility segment Both of which will be a both of which will be a combination of practicality and design We plan to continue down the path of ingenuity and innovation tailor-made for the Indian market.

How do you look at your current competitors? And what differentiates you from your from them?

The transition to EVs will be driven by innovation and technology, and it's exciting to see the fraternity growing because there are so many lessons to be learned from one another's efforts, and start-ups are carrying the innovation torch in India when it comes to electric vehicles

Matter has developed a highly modular technology platform to disrupt the electric ecosystem, ranging fromenergy storage solutions and mobility platforms What really sets our products apart is that they are built on the core principles of safety security reliability and performance Also, matter's vertically integrated approach has led to multiple patents which power Aera to be a world class product

Innovation is in the DNA of our organization, and this coupled with our indigenous development helps us move faster as newer technologies evolve We've invested a lot of effort into developing and building every critical component of AERA in-house. Our products are been subjected to comprehensive testing and validation and were built from the ground up, with over 95% of the vehicle content being indigenous

As an emerging player in the electric bike industry, how are you working to develop a skilled workforce capable of meeting the demands of the rapidly evolving electric vehicle market?

I truly believe that India has the necessary skill set and expertise to innovate and help in accelerating the EV development Engineers & Architects from our country have been providing technological solutions for several powertrain & energy challenges faced by the world over the last few decades It’s an open fact that countries look to India for the finest talent pool & India’s journey towards Energy independence needs to benefit from the same

It’s also necessary for automotive OEMs to step forward and collaborate with educational partners to upskill their present and prospective future workforce We have been working closely with Digital Simulation & Technology partners to collaborate with Accademia in solving some real-life challenges & accelerate Tech Road maps Matter’s internship programs are designed to build awareness & increase talent pool availability for the industry. Matter has also recently partnered with IIT Bombay Racing to provide internships in several aspects of electric mobility development, including hardware, firmware, simulation, and vehicle integration, for students get hands-on experience with cutting-edge EV technology & labs Beyond this there is a lot of work that Govt & industry bodies have been doing in ensuring skilled work force is available for manufacturing plants & test labs

While a lot has been done, a lot more must be done – especially in the areas of functional safety, cybersecurity which are very key enablers of robust, secure & safe EV industry

| INDIA FEB-MAR ISSUE 2022 | PG 12

We have been working closely with Digital Simulation & Technology partners to collaborate with Accademia in solving some real-life challenges & accelerate Tech Road maps."

One of the key challenges that the automotive industry faced in last few years has been with semiconductor supply chain & costs associated with change management due to related uncertainties. Matter has proactively built a robust relationship with key semiconductor players not just for the supply chain but also to accelerate our technology roadmap The symbiotic relationship & early involvement of key stakeholders in the development process has helped us to plan our supply chains better While this strategy has been very key for semiconductor supplies, the same has been followed for other key vehicle & energy storage systems

This robust supply chain strategy will help us reach our early-year target of selling 60,000 vehicles in 2023 & target 1 5 – 2 lakh units by 2024

Collaboration is often key to success in the rapidly evolving world. Can you talk about any partnerships or collaborations that Matter has formed to drive innovation and improve manufacturing processes for electric bikes?

I completely agree with you Collaboration brings together different perspectives, skills, and expertise allowing individuals and organizations to leverage each other's strengths and complement weaknesses It also fosters innovation by promoting the exchange of ideas and creating a culture of continuous learning and the key is to identify the right partners and establish clear goals and expectations for the collaboration At Matter, some of the collaborative examples are:

The Memorandum of Understanding between Matter and the Automotive Research Association of India (ARAI) aims to collaborate in the areas of functional safety, electronics reliability, and cyber security for nextgeneration mobility solutions

Matter is collaborating with Luminous Power Technologies to develop next generation stationary energy storage solutions and a smart home dock inverter that is digitally connected

Matter recently teamed up with IIT Bombay Racing to offer internships in hardware, firmware, simulation, and vehicle integration These internships will help IIT Bombay students get hands-on experience with cutting-edge EV technology

Matter is partnering with world class suppliers for electronics, cells, safety systems etc This enables us to access leading technologies while the suppliers get to integrate their components on an innovative end product

Through these collaborations, Matter has been able to incorporate diverse perspectives and expertise, that has helped the company to stay ahead of the curve in an ever-changing market

Finally,

We are a homegrown innovator brand that is catering to the unmet needs of the customers For electric vehicles to become mainstream, it is pivotal that we think new, decode the need for progression, and leverage technology for product development What makes me proud today is that our innovation culture has enabled key, core technologies in multiple domains of the electric vehicle be it drive, controls, battery management, drivetrain etc Our products are built on core technologies, developed in-house, that will usher in an era of new age mobility, connected experiences and shape the future of a sustainable and inventive India This innovation led approach helps us understand the technology curve and to ensure the newer products stay ahead of the technology curve while catering to the explicit and latent needs of the customer

what is Matter's vision for the future of electric bike manufacturing, and how do you see the company evolving and adapting to meet the changing needs of the market and the demands of consumers?

Can you talk about some of the key challenges that Matter has faced in scaling up the production of electric bikes, and how your team has overcome these obstacles?

INCONVERSATION

| INDIA FEB-MAR ISSUE 2022 | PG 13

The symbiotic relationship & early involvement of key stakeholders in the development process has helped us to plan our supply chains better. While this strategy has been very key for semiconductor supplies, the same has been followed for other key vehicle & energy storage systems."

Vivek heads Manufacturing Engineering Function for Tata Motors Passenger Vehicles Business unit He is a passionate automotive professional with 30 plus years’ of experience, 27 years in Auto OEMs- Honda Cars (5+ years), General Motors ( 15+ years), MG Motor (5 years) He has vast experience in Automotive technology – both for ICE and Electric Vehicles He has led New start ups sucessfully, has played key role in Honda Cars and MG Motor's success in India apart from having played crucial role in the Launch of more that 17 New vehicles with 4 auto Majors over the years He has played key role at Global level while working with General Motors and contributed significantly in bringing new Insights to ‘lean Manufacturing’ and formulating Modular concepts in Automation He has diverse experience in Plant operations, Manufacturing Engineering, Project Management, Advance vehicle development, Launch Management and Manufacturing finance

He has technical expertise in all Vehicle manufacturing and Quality processes and is hands on in Implementing Smart Manufacturing thru Digitalization (Industry 4 0), Autonomous/ electric vehicles and IoT based technologies. He is seasoned Speaker in Panel discussions within Automotive and New Technology domain He has authored various Articles in technology Managines. He is actively engaged with Mentoring Budding Managers of B schools on Management concepts, representing Corporate world

He is very passionate in sharing his views thru participation in Panel discussions, thru articles in e-magazinesbesides providing Mentorship to Young Engineers at various levels and Budding Managers of B schools

E MOBILITY MIGRATION AND SUSTAINABILITY

The Economic Survey 2023 has said that the “automotive industry is expected to play an important role in transition towards green energy India’s domestic electric vehicle market will be growing by almost 49% annually within next 7 - 8 years

It is literally a race against time for adoption of electric vehicles (EV) in India Despite the imperatives of cutting carbon emissions and reducing India’s dependence on crude oil around 80-82% of which needs to be imported, we have remained badly short of the stated adoption goals since our home-grown EV industry took its first steps 5-6 years ago.

In the past three – four years, the EV makers have collectively sold around 3 lakh EVs (majority of them three-wheelers and twowheelers) The traditional automotive sector, has managed to sell more than 8 million passenger cars and around 60 million two wheelers. Clearly far more fuel driven vehicles are selling compared to EVs

For consumers to shift to an electric vehicle (car or two-wheeler), affordability and mileage are the two main considerations, besides Charging infrastructure. Still, most of the EVs sold are ‘Second’ car for a buyer An Electric car with a starting Price range of 8 Lac, Charging time of 30 minutes, drive range of 400 km plus on one charge and Charging infra every 50 km on highways can be a strong influence in Customer preference migration towards electric vehicles

While migration from Internal Combustion Engine (ICE) cars to Electric Vehicles (EVs) have various environmental and societal benefits due to zero tailpipe emissions, which means they don't release dangerous pollutants like carbon monoxide, nitrogen oxides, and particulate matter, they also aid in the reduction of greenhouse gas emissions and the fight against climate change, yet, it is critical to evaluate the sustainability of EVs across their entire lifespan, including battery manufacture, usage and disposal, as well as the source of the power needed to charge them

It is important for EV manufacturers to adapt sustainability initiatives to Cut Greenhouse Gas emission, Use Renewable Energy in the form of Solar, Wind and Wind -Solar Hybrid, Reduce Energy and Water consumption and adapt Circular Economy in Automotive Eco system Recycle and reuse of the EV battery will play a crucial role in overcoming Sustainability concerns linked with Electric Vehicles

Additionally, in order to preserve society throughout the transition to EVs, it is critical to guarantee that everyone has access to the benefits of EV technology, even those who may not be able to afford their own EVs This may be accomplished through public transit, incentives for low-income people to buy EVs, and ensuring that charging infrastructure is easily accessible in all locations.

VIVEK GOSAIN

EXECUTIVE LEADER IN TATA MOTORS PASSENGER

EXECUTIVE LEADER IN TATA MOTORS PASSENGER

Overall, transitioning from ICE cars to EVs can have considerable environmental and societal advantages; however, it is critical to approach this transition in a responsible and sustainable manner that considers the whole lifetime of EVs and guarantees equal access for everyone.

O P I N I O N

| INDIA FEB-MAR ISSUE 2022 | PG 14

Special Story

India's draft battery swapping policy?

India had not yet finalized its battery swapping policy However, the government had released a draft policy in June 2021 for public consultation.

The draft policy proposed the creation of a regulatory framework for battery swapping infrastructure and services in India It aimed to address the issues of range anxiety and high upfront costs associated with EV ownership, as well as promote the adoption of EVs in the commercial sector

Under the proposed policy, battery swapping service providers would be required to obtain a license from the appropriate regulatory authority The license would specify the terms and conditions for operating battery swapping infrastructure, including safety standards, battery quality requirements, and service levels

The policy also outlined the technical specifications for batteries used in battery swapping, including their physical dimensions, electrical characteristics, and performance parameters These

specifications would ensure interoperability and standardization of batteries across different EV models and brands

In terms of financing, the policy proposed the creation of a battery swapping fund to provide financial support for battery swapping service providers The fund would be used to cover the costs of setting up and operating battery swapping infrastructure, as well as purchasing and maintaining batteries

The draft policy also included provisions for monitoring and enforcement, such as regular inspections and audits of battery swapping infrastructure and services, and penalties for non-compliance with regulatory requirements

Overall, the proposed battery swapping policy aimed to create a supportive regulatory environment for battery swapping in India, with a focus on promoting interoperability, standardization, and quality While the policy was still in the draft stage at the time, it signaled the government's commitment to promoting EV adoption through innovative approaches such as battery swapping

EM+ RESEARCH

FEB-MAR ISSUE 2022 | PG 15 | INDIA

Sandip Hazra, currently works as Deputy General Manager in Engineering Research Center, Tata Motors and has 21 years of work experience post his Master's degree from IIT, Varanasi, India, in 2002 He currently works in powertrain integration of ICE and EV vehicles in chassis engineering

He has credit for the entire range of vehicle development experience from concept to SOP, along with change management for many platforms and projects while working at Renault Nissan Technical and Business Centre (RNTBCI), Maruti

Suzuki and Tata Motors

He did his executive MBA from IIMK in 2010 and has hands-on experience in Program management, powertrain and Chassis system design on many platforms

His publications in international journals and patents testify his deep inclinations towards research and his technical competency His research interests are:

Product design

Electric and hybrid driving technology

NVH technology for BEVs and vehicle driving dynamics

THE IMPACT OF EV MANUFACTURING

ontheenvironment

The global campaign against climate change led to the market of electric vehicles, which has boomed worldwide in recent years The government's current initiatives and various subsidies aim to promote battery technology to achieve the vision for 100% electric vehicles by 2030 in the Indian vehicle market

Electric vehicles (EVs) are an essential option for reducing emissions of greenhouse gases Electric vehicles lessen the dependency on fossil fuels, diminish the impact of ozone-depleting substances, and promote large-scale renewable deployment Despite comprehensive research on the nature of their charging infrastructure, electric vehicle production and network modelling continues to evolve and be constrained The EV vehicles barrier is addressed from various perspectives, such as market, technical policy and infrastructure Vehicle-to-Grid is an essential aspect of energy security and renewable energy and significantly impacts dealing with global warming issues. The new concept of Vehicle-to-Grid has created an additional power source when renewable energy sources are unavailable

Critical barriers and insufficient charging facilities are addressed gradually for a developing country like India, which makes the study unique.

Since Lithium-Ion batteries are commonly used in electric power vehicles, a considerable amount of batteries will soon reach their end-oflife; how to recycle them to reduce environmental pollution and promote the sustainable development of the electric vehicle market has become an urgent challenge today. Implementation of the secondary reuse of used electric vehicle batteries is a valuable recycling strategy However, there needs to be more research investigating electric vehicle battery recycling network design at the enterprise level, the lack of which impedes the sustainable development of electric vehicles

In a country like India, most of our energy comes from coal burning, resulting in natural resource depletion

People are working on various sustainable battery technologies One option is to alternate Li-ion batteries Another option is to use solar power to recharge batteries; this will reduce energy consumption The recent news of a West Bengal businessman turning the Tata Nano into a solar car created a buzz about the umpteen opportunities to explore and tackle sustainability issues

The environmental profiles of the combustion engines and the vehicle platforms are based on the material mix and of comparable vehicle classes, which have been scaled according to the vehicle and platform mass The electric motor is based on the material mix of a permanent magnet synchronous motor (PMSM), scaled by the weight-to-power ratio

The power electronic components (e g inverters) are based on existing models of comparable elements The research on recyclable alternate materials is the topic of recent times

The policymakers can consider the socio-economic-environmental impacts of recycling retired EV batteries under the reward-penalty mechanism With the increasing demand for Electric Vehicles (EVs), many EV batteries are intensively reaching their end-of-life, which has posed a substantial challenge to ecological protection and sustainable development However, the traditional subsidy mechanism could be more effective in the current recycling market In addition, it could be more conducive to guiding the EV industry towards reduced dependence on governmental financial support

A feasible alternative policy to promote the recycling of retired EV batteries is needed to address the initiative on circular economy. Various models and studies by researchers on the life of lithium-ion (Liion) EV batteries are extended to incorporate the re-purposing and reuse in grid storage for a utility application application

O P I N I O N

Electric vehicles lessen the dependency on fossil fuels, diminish the impact of ozone-depleting substances, and promote large-scale renewable "

LTD

DIVISIONAL MANAGER AT TATA MOTORS

SANDIP HAZRA

| INDIA FEB-MAR ISSUE 2022 | PG 16

As the world shifts towards cleaner, more sustainable energy sources, the use of lithium-ion batteries has become increasingly common in a variety of applications, including electric vehicles, renewable energy storage, and consumer electronics However, as the use of these batteries becomes more widespread, the issue of recycling them is becoming increasingly important Lithium-ion battery recycling is a process that is critical to reducing the environmental impact of these batteries and maximizing their value.

The recycling process for lithium-ion batteries is complex and involves several steps The first step is to collect and sort the batteries based on their chemistry and size Once sorted, the batteries are dismantled, and the individual components are separated The cathode, anode, and electrolyte are separated, and any impurities or contaminants are removed

After separation, the individual components are processed and refined to recover the valuable metals and materials Lithium, cobalt, nickel, and copper are some of the valuable metals that can be recovered through the recycling process These materials can then be used to produce new batteries, reducing the demand for virgin materials and minimizing waste

The benefits of lithium-ion battery recycling are significant Recycling batteries helps to reduce the environmental impact of mining and manufacturing of virgin materials The recycling process also reduces the amount of waste that would otherwise end up in landfills or be

Current Story

Lithium ion battery recycling

incinerated By recycling batteries, we can recover valuable resources and reduce our dependence on foreign sources of raw materials

Moreover, recycling lithium-ion batteries can help to address concerns around the sustainability of electric vehicles and renewable energy storage With the increasing demand for these technologies, recycling lithium-ion batteries can ensure that they remain a sustainable and environmentally friendly option.

There are several challenges to lithium-ion battery recycling One of the primary challenges is the lack of a standardized recycling process While there are several recycling technologies available, they all have their advantages and limitations This makes it difficult to develop a universal approach to recycling lithium-ion batteries

Another challenge is the safety risks associated with recycling lithium-ion batteries These batteries can pose a fire and explosion risk, particularly when they are damaged or mishandled Therefore, it is essential to ensure that proper safety measures are in place when recycling these batteries.

In conclusion, lithium-ion battery recycling is a critical process that can help to reduce the environmental impact of these batteries and maximize their value While there are challenges associated with lithium-ion battery recycling, there is a growing need for a standardized approach to ensure the safe and efficient recycling of these batteries. As the use of lithium-ion batteries continues to grow, it is essential to invest in lithium-ion battery recycling to create a more sustainable future

EM+ RESEARCH

FEB-MAR ISSUE 2022 | PG 17 | INDIA

N O W L E D G E

SOFTWARE AS A SERVICE (SAAS) AND ITS CONTRIBUTION TO THE ELECTRIC VEHICLE CHARGING INDUSTRY

India's electric fleet operators have emerged as a promising business model, revolutionizing the transportation sector with eco-friendly solutions With the Indian government's push for electric mobility, the market for electric vehicles has witnessed exponential growth, providing an opportunity for electric fleet operators to thrive

The business model of electric fleet operators revolves around providing on-demand electric vehicles to consumers through ride-hailing, carsharing, and rental services These services offer a sustainable and cost-effective mode of transportation, reducing pollution levels and creating a cleaner environment

The key players in the electric fleet operator's market in India include companies like Ola, Uber, Lithium Urban Technologies, Blu Smart, and Yulu, among others These companies have adopted different strategies to cater to the diverse needs of their customers, including B2B and B2C services.

The primary revenue stream for electric vehicle fleet operators comes from charging customers for the use of their vehicles The charges are based on the distance traveled, time taken, and other factors such as peak-hour pricing and surge pricing Fleet operators can also generate revenue from advertising, partnerships, and collaborations with other companies

K

B Y T E S

| INDIA FEB-MAR ISSUE 2022 | PG 18

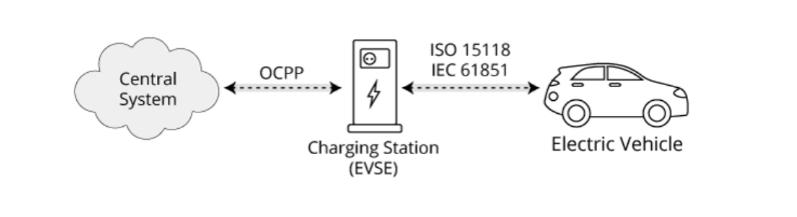

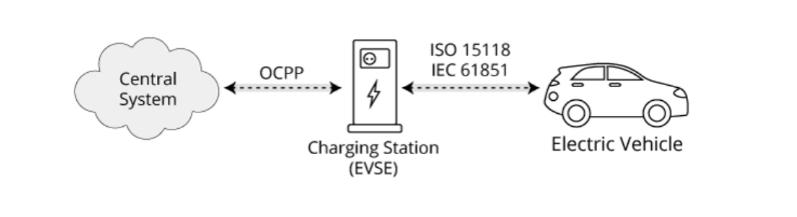

OCPP stands for Open Charge Point Protocol, which is a communication protocol that is widely used in the electric vehicle (EV) charging infrastructure industry. OCPP is an open-source protocol, meaning that it is freely available for use and can be implemented by any EV charging equipment manufacturer

The purpose of OCPP is to provide a standardized way for different EV charging equipment to communicate with each other and with back-end systems, such as charging network management systems and payment platforms This interoperability allows EV drivers to use different charging stations from different manufacturers with the same ease and convenience as they use different gas stations from different oil companies

OCPP is designed to be flexible and extensible, which means that it can support a wide range of use cases and functionalities For example, OCPP can be used to monitor and control the charging process, collect data on charging usage and energy consumption, and facilitate payment and billing for charging services OCPP also supports real-time communication between charging equipment and back-end systems, which allows for remote diagnostics and maintenance, as well as dynamic pricing and load management

In addition to its technical capabilities, OCPP is also seen as an important enabler for the growth and development of the EV charging infrastructure industry By providing a common language and set of standards for EV charging equipment and services, OCPP helps to reduce barriers to entry and promotes competition and innovation in the market

Overall OCPP is a key component of the EV charging infrastructure ecosystem, enabling interoperability, flexibility, and scalability for EV charging equipment and services

here are some examples of how OCPP is being used in the electric vehicle (EV) industry:

Interoperability: OCPP enables different EV charging equipment from different manufacturers to communicate with each other and with back-end systems, such as charging network

Technology Insight

What Is OCPP In EV Charging Infrastructure And Its Application?

management systems and payment platforms This interoperability allows EV drivers to use different charging stations from different manufacturers with the same ease and convenience as they use different gas stations from different oil companies

Remote monitoring and diagnostics: OCPP allows charging station operators to remotely monitor and diagnose charging equipment, which can help to reduce downtime and maintenance costs For example, if a charging station is not working properly, the operator can use OCPP to remotely diagnose the issue and potentially fix it without the need for a technician to physically inspect the equipment

Load management: OCPP can be used to manage the flow of electricity between charging stations and the grid, which can help to avoid overloading the grid during periods of high demand For example, charging station operators can use OCPP to set charging rates and schedules that balance the needs of EV drivers with the available capacity of the grid

Dynamic pricing: OCPP enables charging station operators to implement dynamic pricing models based on real-time data, such as the cost of electricity and the demand for charging services. This can help to optimize revenue and utilization of charging equipment while providing a fair and transparent pricing model for EV drivers

Data collection and analysis: OCPP provides a standard format for collecting and analyzing data on charging usage and energy consumption, which can help to improve charging infrastructure planning and management For example, charging station operators can use OCPP data to identify patterns in charging behavior, such as peak usage times, and adjust their operations accordingly.

These are just a few examples of how OCPP is being used in the EV industry As the industry continues to grow and evolve, it is likely that OCPP will play an increasingly important role in enabling interoperability, flexibility, and scalability for EV charging equipment and services

EM+ RESEARCH

FEB-MAR ISSUE 2022 | PG 19 | INDIA

GREENERG is a EV Technology Company started in 2020 focusing on Electric Powertrain, Connectivity Solutions and Digital Instrument Cluster The company has good presence in EV 2W and 3W market with its state of the art instrument clusters working on both single wire protocol & CAN The company has indigenously made IPM motor and controller which can work upto 10KW and has an unique integrated in wheel drive which can go from 1 5KW to 20KW

The total Business by 2030 in motor and controller alone constitutes roughly about 6Billion USD according to the numbers presented here. That’s a huge opportunity. So its time now for an Indian EV technology company to emerge. At least to start with cratering to local markets to begin with. As we know the FAME -II subsidy is given on the basis of make in india EV components, I feel this industry has been given the focus it really requires."

TheEVLane -Wayaheadinnewage AUTOMOTIVE MANUFACTURING

Where do we stand now

The Indian Electric Vehicle ecosystem is currently in inflection stage but has been gaining traction In 2021, EV registrations amounted to 330k units, a jump of 168% from 2020. The sales were led by 2- and 3-wheelers – 48% and 47%, respectively – followed by passenger vehicles at 4% E-rickshaw/e-kart category (top speed less than 25km/ hr) takes the major share among three wheelers with 45% Ebuses are included in others with a share of 0 36% The same has jumped to 2000 times in the 2022 and that’s the clear sign the industry is going to take the mainstream business With the current target to achieve 30 percent of EV penetration by 2030, considering the automotive industry is growing roughy about 30 percent YOY , the volume of electric vehicles will reach the current industry volume by 2030 Now the question , how much the industry has prepared to tackle the new requirements how much the ev ecosystem support this transition and what are the alternative methods to handle the challenges

Convincing the price-conscious Indian consumers about EVs will have to focus on two factors: the cost of ownership and vehicle quality Enhancing demand for EVs and better performing vehicles will be vital to accomplish the 2030 target Additionally, in the longrun, it is more economical to own and maintain an EV

Hence, consumers need to be made aware of the potential of EVs They need to be made understood that the technology to power an EV with solar power is already available and this investment pays off faster when the solar power is replacing much more costly petrol Also, many have the

The auto component industry–where does it stand?

Lets go back to the basic numbers again If we need to reach the 30AT2030 , 8 Million electric vehicles shall be manufactured and used in this country Let us divide this volume further town to the OEMs and their capacity of manufacturing, what is the possibility the supply chain from India meeting this requirement. How quickly we can scale the supply chain and the respective eco system including the battery production and charging units development As the powertrain is major change in electrification all the critical powertrain components to be developed and manufactured at all levels including Tier1, Tier2 and tier 3 there could be approximately 50 Million components at an average to be produced in an year. This is a long way to go At least we should try to start with import substitution

Now let us look at the Business opportunity The total Business by 2030 in motor and controller alone constitutes roughly about 6Billion USD according to the numbers presented here That’s a huge opportunity So its time now for an Indian EV technology company to emerge At least to start with cratering to local markets to begin with As we know the FAME -II subsidy is given on the basis of make in india EV components, I feel this industry has been given the focus it really requires Also the PLI scheme on battery production will certainly motivate the local manufacturing of EV components.

O P I N I O N FOUNDER &CEO GREENERG MOBILITY SOLUTIONS PVT LTD MANIKANDAN P | INDIA FEB-MAR ISSUE 2022 | PG 20

We also now a hear a great news that there is huge lithium deposit found in J&K I think our future battery story looks very strong from now on Of course we need to put the required efforts and investments to convert this demand into opportunity and profitable business model there by we can not only contribute at local level but also at global level

The EV Manufacturing ecosystem readiness

The main components in EV can be classified into:

Body parts

Structural parts

Powertrain

Power Electronics

Battery Systems

Charging Systems

DCDC Converters and Vehicle control system

How do we create the manufacturing facility to ensure all the above subsystems are seamlessly integrated, made to work together giving optimum performance and proved for roadworthiness In the process engineering there could be advanced manufacturing process can be implemented so that we shall increase the throughput to scale of the manufacturing at reduced cost of manufacturing In addition , we can also employ the digital manufacturing techniques to improve the overall quality, productivity and serviceability involving highest level traceability at different levels To enable this we need to have the ecosystem available close to the manufacturing plants, moving from the traditional automotive manufacturing to future automotive There needs to a highest level of coordinated transformation required the entire supply chain and value proposition The question is , most of these subsystems are currently imported in the new vehicle technology There needs a lot of focus. Some of the EV OEMs have started building this ecosystem with in their organization But is it sustainable and scalable We need to develop many clusters across the country to build the EV ecosystem OEMs , Suppliers and government should work together to achieve the same

The Technology Development

Future of mobility will be dominated by the following technology

Autonomous driving

Connected Mobility

Electric Mobility and Shared Mobility

This is called as ACES in short. Now what are technological breakthrough in all these areas How we as a country prepared for the same Its more than a century now the powertrain is changing from ICE to electric and we do not have home technology ready in every vehicle area on the same Last year alone more 800 Million USD worth of powertrain and batteries imported from China We need highest level of focus to develop such technological systems and solutions in India which will work effectively in Indian environmental conditions We have very unique environment and the component shall put on highest level stress so that it would work in all the situation. There are many Tier1 suppliers already started building such technology solutions But in my opinion it is not enough We need to focus these development as national level momentum involving multiple stakeholders together including research and educational institution If carefully analyse , every technology listed above has huge amount of software content in it We call ourselves as a software nation So we can play a strong global role if we develop the competency very quickly

The Skill development

I had an opportunity to discuss with one of the leading institution in India to develop an EV powertrain for a specific application together with their capacity The outcome of the discussion was a surprising fact for all of us It was told to me that , Indian engineering graduates have shifted their focus to new age Technologies like , Block chain, AI and ML There is no

focus on fundamental engineering subjects like motor design amongst the students On the other hand, the engineers and executives in the industry especially on the OEM side are need to be reskilled or upskilled in future mobility technologies The first step is to create the basic awareness with the automotive aspirants on what is really the opportunity in the industry and given them the confidence on the high potential availability for growth in mobility solutions. Secondly we need to develop specific contents so that they would become holistic mobility engineers with multidimensional skills We need kind of all-rounders at this stage apart from specialists in specific areas We need to develop not only the work force for the engineering for manufacturing also for technology development, service maintenance of electric vehicles The rough estimate of the requirements stand at 5Million engineers and technologies by 2030, in India The global numbers are mind boggling Also fundamental engineering needs focus along with digital technologies There are many initiatives taken by government in this line of thought In my opinion the stalwarts of the industry should come forward and work on a collaborative approach build the future skills. This is the need of the hour Needs immediate attention

Implementation of digital manufacturing

As we have discussed earlier, scaling up the production is inevitable to meet the growing demand of EV in India. One of the best ways to improve productivity and quality is implement digital manufacturing process using Industry 4 0 Thanks to the IOT in manufacturing sector and state of the art manufacturing equipment’s available to meet such requirements Also we digitally create the process in the lab , test run, make improvements and then implement them is the way forward quickly establish successful process than learn and improve. Making things first time right was yesterday’s challenge Today it is predictable process is what plays a major role This will be done thorough front loading of the key process items and spend enough time for the planning before start of implementation Once its done then the most of the critical process decision should be driven data. So data acquisition at various stages of the process is another key element Data analytics can happen if we can employ measurements Right measurement at time and quantity would be primary importance for the optimization So in conclusion the benefits of implementing digital manufacturing is countless So we need to focus on the same in EV manufacturing