Mobility means profitability

Maximising productive hours for your heavy equipment is the key to success.

This is where Sleipner comes into the picture –we are there to improve your equipment mobility and increase your productivity. At the same time, we help you to be more sustainable by cutting your CO2 emissions.

More working, less tramming

Sleipner dollies and lowbed trailers revolutionise the mobility of your existing drills, dozers and excavators.

Mobility means more Mobility means less

Productivity – more hours from the same fleet

Equipment lifecycle costs

CO2 emissions

Equipment uptime

Working efficiency

Fast transport

Controlled workshop repairs

Working safety

Undercarriage maintenance

Fuel consumption

Risky field repairs

Sick leave absences

PRODUCTIVITY TRANSPORT EMISSIONS

+12-20%

Better mobility, better utilisation rate.

less CO2 emissions in machine transport. -50%

“After a few months of use, the positive impact was already visible in maintenance. Together with the increased production time, the payback time was almost instant.”

- Sleipner user

EFFICIENCY FOR MINING

As mines operate in increasingly challenging locations, Sleipner dollies and trailers boost efficiency.

MOBILITY MEANS PRODUCTIVITY

Up to 85% less travel time, 12–20% more productivity.

LESS MAINTENANCE COSTS

50% less undercarriage maintenance, 20% less labour hours.

LOWER LIFECYCLE COST

Reduce your excavator LCC by 10–18%.

SUSTAINABILITY

Slow tramming produces emissions that can be cut significantly with improved mobility.

ADVANTAGE EVERYWHERE

Earthmoving sites, tunnelling, dams, road construction, wind parks, mine reclamations, pipelines… move 12–20% more tonnes with the same fleet.

THE BEST OF BOTH WORLDS

The new mobility enabled by Sleipner dollies and trailers lets you combine wheel loader mobility with excavator efficiency.

PRODUCTIVITY FOR QUARRIES

Combine wheel loader mobility with excavator efficiency and move more material per shift. Perform selective loading efficiently and blend your material without compromises.

OPTIMAL BLENDING WITHOUT COMPROMISE

Perform selective loading efficiently and blend your material without compromises.

Sleipner DB Series

Our lowbed trailers with advanced digital enhancements enable easy and safe mobility. Simple and quick loading and unloading, safe driving – with Sleipner DB Series trailers, your imagination sets the limits for mobility.

Sleipner E Series Holding it all together

Simulator-based training, remote support and on-site service – Sleipner makes sure your dollies and trailers stay productive and that your personnel can take full advantage of the mobility they enable. Wherever you operate, we are near you.

Our easily mounted, cost-effective mobility solution lets you transport most of excavators. Get on wheels in minutes and hitch a ride on a truck – no need for long tramming that wears out the machinery and produces emissions.

Sleipner DB Series

Versatile, agile mobility

Load your heavy equipment on wheels, get more done with fewer machines.

The Sleipner DB Series maximises productivity and minimises maintenance costs. INCREASE PROFITABILITY

In terms of mobility, safety, agility and rugged reliability, you can’t beat the Sleipner DB Series. UNBEATABLE MOBILITY

The Sleipner DB Series offers you fast loading, agile transporting, reliable braking and sufficient ground clearance. TRANSPORT EVERYTHING

Sleipner DB Series

DB130

FLEET SUITABILITY

Dozers up to D11T/D475A

Drills up to Atlas Copco PV 271/275

Drills up to Sandvik D75KS

Excavators up to 130 tonnes

MINIMUM PRIME MOVER 45 TONNES ADT

Bell B45

CAT 745

John Deere 460

Volvo A45

INCREASE DRILL/DOZER FLEET PRODUCTIVITY BY 12–20%

Less tramming equals more productivity –your equipment is where you need it to be.

OPERATE IN ANY TERRAIN

With its excellent ground clearance and manoeuvrability, the Sleipner DB Series can be used in previously unimaginable terrains.

EXPENSIVE UPTIME

Less tramming means longer undercarriage life. Improved mobility means less field repairs and a fast return to work.

EFFECTIVE FLEET USE

The possibility to quickly relocate your machinery makes your production planning more flexible.

SAVE ON DRILL FLEET

UNDERCARRIAGE MAINTENANCE BY 50%

Eliminating tramming can double or even triple the undercarriage service life.

IMPROVED WORKING SAFETY

The DB Series is designed for safety, featuring a tilting load bed, reliable braking system, onboard display unit, railings and steps for easy access.

Sleipner DB Series

DB80

FLEET SUITABILITY

Dozers up to D10T/D375

Drills up to Atlas Copco PV235

Drills up to Sandvik D45KS/D50KS

Excavators up to 80 tonnes

MINIMUM PRIME MOVER 40 TONNES ADT

Bell B40

CAT 740

John Deere 410

Komatsu HM400

Volvo A40

INCREASE DRILL/DOZER FLEET PRODUCTIVITY BY 12–20%

Less tramming equals more productivity –your equipment is where you need it to be.

OPERATE IN ANY TERRAIN

With its excellent ground clearance and manoeuvrability, the Sleipner DB Series can be used in previously unimaginable terrains.

EXPENSIVE UPTIME

Less tramming means longer undercarriage life. Improved mobility means less field repairs and a fast return to work.

EFFECTIVE FLEET USE

The possibility to quickly relocate your machinery makes your production planning more flexible.

SAVE ON DRILL FLEET UNDERCARRIAGE MAINTENANCE BY 50%

Eliminating tramming can double or even triple the undercarriage service life.

IMPROVED WORKING SAFETY

The DB Series is designed for safety, featuring a tilting load bed, reliable braking system, onboard display unit, railings and steps for easy access.

Sleipner DB Series

DB45

FLEET SUITABILITY

Dozers up to D8T/D155/1050K

Drills up to Epiroc SmartROC T36-T65/FlexiROC D35 - D65

Drills up to Sandvik DI450 – DI650/DX600 - DP1600

Excavators up to 35 tonnes

MINIMUM PRIME MOVER 40 TONNES ADT

Bell B40

CAT 740

John Deere 410

Komatsu HM400

Volvo A40

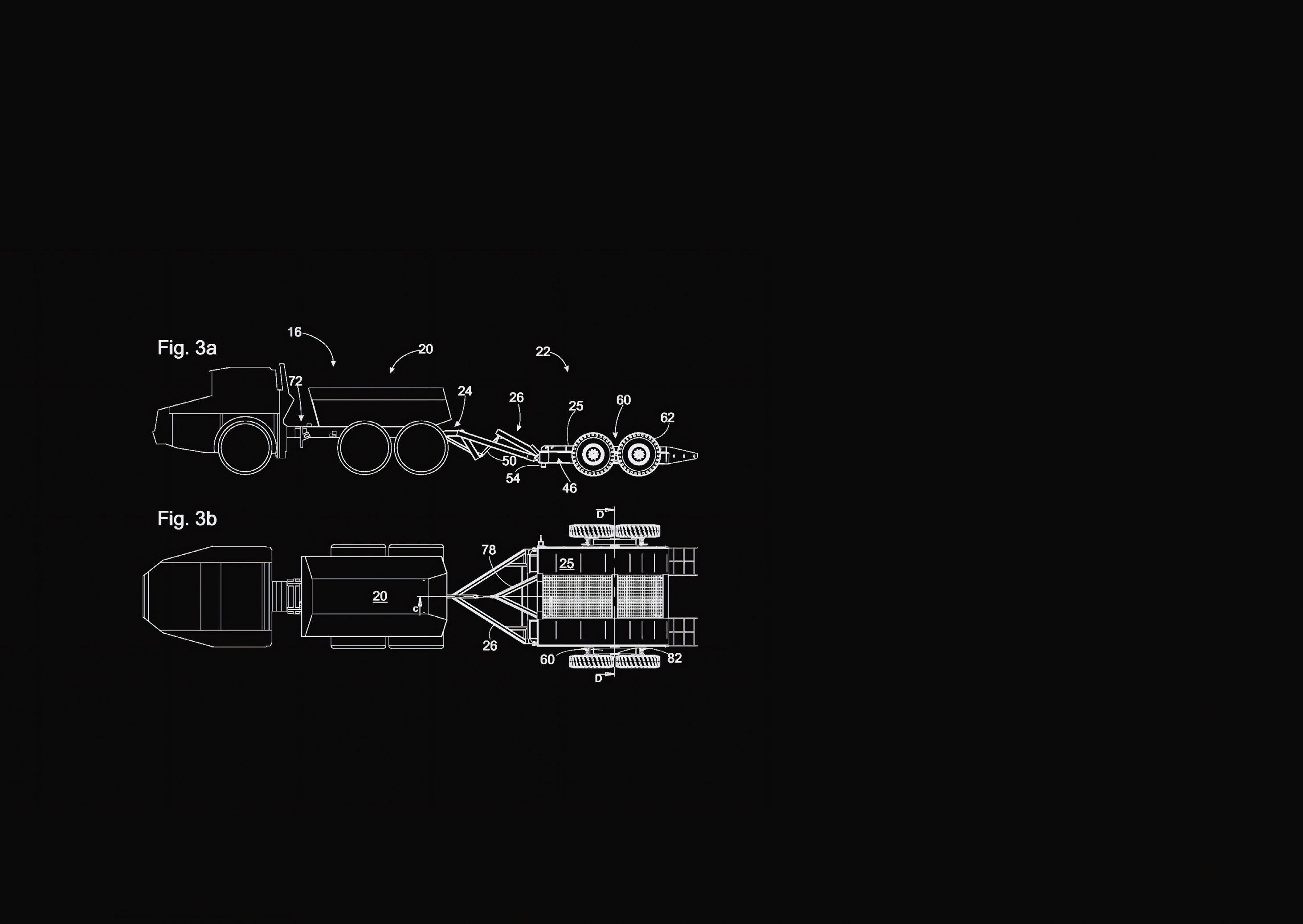

PATENTED OFFROAD TRAILER CONCEPT

The DB45 trailer offers excellent ground clearance and manoeuvrability, enabling it to carry surface drills and dozers across previously unimaginable terrains. Big wheeled ADTs offer outstanding performance compared to traditional truck trailers.

CONNECTS QUICKLY TO ADT

The trailer is easy and quick to connect to the ADT whenever the trailer is needed. When the trailer is not needed, the ADT can be used for normal jobs. The coupling hitch can be mounted to many different ADTs, increasing the flexibility of your operations.

IMPROVES FLEET USAGE

The possibility to quickly relocate your surface drills and small dozers makes your production planning more efficient and flexible.

Sleipner E Series

Rolling in minutes

Set up is easier and quicker than you can think.

SET UP

It takes less than two minutes to drive the tracks of your excavator onto a Sleipner E Series dollies.

PLACE THE BUCKET READY TO GO

Turn the upper carriage around and place the bucket on the bed of the truck.

Lift the tracks up by pushing the bucket down, and you are good to go.

E30 Sleipner E Series

EXCAVATORS TRUCKS

CAT 336

Hitachi ZX350

John Deere 345

Liebherr R 930

Komatsu PC360

Volvo EC300

Bell B20

CAT 730/770

John Deere 260

Komatsu HM300/HD325

Volvo A25

EXCAVATORS TRUCKS

CAT 352

Hitachi ZX530

John Deere 470

Komatsu PC490

Liebherr R 956

Volvo EC550 Bell B25

CAT 730/770

John Deere 260

Komatsu HM300/HD325

Volvo A25

4,0 tonnes (600 mm)

4,1 tonnes (700-800 mm)

4,2 tonnes (900 mm)

TYRE SIZE

16.00-25 32 PR WEIGHT PER PAIR (TRACK WIDHT)

Sleipner E Series

Sleipner E Series

CAT 374

Hitachi ZX690

John Deere 670

Komatsu PC650

Liebherr R 972

Volvo EC750

Bell B40

CAT 735/770

John Deere 410

Komatsu HM400/D325

Volvo A40

Sleipner E Series

EXCAVATORS TRUCKS

CAT 395

Hitachi ZX890

John Deere 870

Komatsu PC900

Liebherr R 992

Volvo EC950

Bell B60

CAT 773

Hitachi EH1100

Komatsu HD465

Volvo A60

MIN PAYLOAD MAX PAYLOAD

WEIGHT PER PAIR (TRACK WIDHT)

7,1 tonnes (600-700 mm)

7,2 tonnes (800-900 mm) 65 tonnes 98 tonnes

TYRE SIZE

18.00-25 40 PR

Sleipner E Series

EXCAVATORS TRUCKS

Hitachi EX1200

Komatsu PC1250

Liebherr R 9100

CAT 775

Hitachi EH1100

Komatsu HD465 Volvo R70

EXCAVATORS TRUCKS

CAT 6015

Hitachi EX2000

Komatsu PC2000

Liebherr R 9200 CAT 777

Hitachi EH1700

Komatsu HD785 Volvo R100

17,4 tonnes (800 mm)

18,2 tonnes (900-1000 mm)

WEIGHT PER PAIR (TRACK WIDHT) TYRE SIZE 113 tonnes

18.00-25 40 PR

Sleipner E Series

Sleipner E Series

EXCAVATORS TRUCKS

CAT 6020/6020B

Hitachi EX2600

Liebherr R 9300 CAT 785

Hitachi EH3500AC

Komatsu HD1500

2,90 m 800–1300 mm: 4,50 m

EXCAVATORS TRUCKS

CAT 6030

Komatsu PC3000

Liebherr R 9350

m 21.00-35 40 PR WEIGHT PER PAIR (TRACK WIDHT)

CAT 789

Hitachi EH3500AC

Komatsu 730E

Sleipner E Series

Sleipner E Series

EXCAVATORS TRUCKS

CAT 6040

Hitachi EX3600

Komatsu PC4000

Liebherr R 9400 CAT 793

Komatsu 830E

Hitachi EH4000AC

3,60 m 1300–1400 mm: 5,45 m 2,70 m

Sleipner E Series

EXCAVATORS TRUCKS

CAT 6060 (Gen 2)

Hitachi EX5600

Komatsu PC5500

CAT 797

Hitachi EH5000AC

Komatsu 960E

530 tonnes 570 tonnes

PAYLOAD MAX PAYLOAD 95,5 tonnes (1300-1400 mm)

WEIGHT PER PAIR (TRACK WIDTH) TYRE SIZE

27.00-49 54 PR

Sleipner Services

To guarantee the mobility of your mining equipment, Sleipner offers a range of services to keep you going and maximise the return on your investment.

TECHNICAL SUPPORT

With Sleipner telematics, our technical support can troubleshoot and solve problems faster, so your machine can return to productive work without any unnecessary delays.

TRAINING

To get the maximum benefit from your Sleipner products, as well as to ensure safe operation, we always provide comprehensive training for our customers with clear, uniform learning goals and practices.

ONSITE SERVICE

The telematics system of your Sleipner DB Series lowbed trailer features a built-in service reminder. Both planned maintenance and needed repairs are carried out smoothly onsite by our local team of experts.

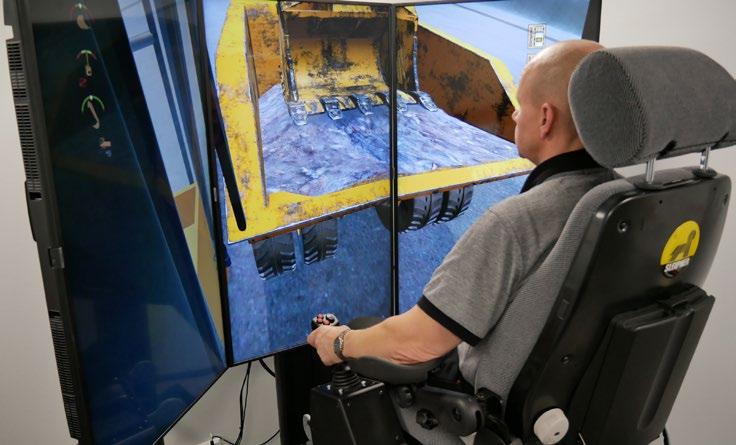

SIMULATOR TRAINING

Sleipner provides comprehensive training to ensure the safe and efficient use of our products. Our E Series simulator training keeps your dollies available for work during training.

SLEIPNER SPARE PARTS

Sleipner provides a full range of parts via our global service network. The wide compatibility of spare parts products reduces the parts inventory, while Sleipner online documentation provides service information or the parts number when you need it.

SLEIPNER SERVICES >

Since 1996

The idea of mobility Sleipner for every need Building the future

The first Sleipner products were built in 1996 – and most of them still perform flawlessly. What started as an idea for extremely robust yet easy-touse dollies for the heaviest excavators has since grown into a full range of Sleipner dollies and lowbed trailers.

We continue to develop our range of mobility solutions in close collaboration with our customers – making sure Sleipner products integrate seamlessly with your ways of working in more than 50 countries and on six continents.

We work together with our customers to build the future for the entire industry – efficiency through mobility. Wherever transport hours can be converted into working hours and the wear and tear of tramming into smooth rolling, we are there.

Sleipner is all about innovation

At Sleipner, innovation is in our DNA. We constantly improve our products, but we also rethink the concept of what our products and services could look like. We make use of data to maximise the positive effects our products. From more sustainable operations to maximised uptime and improved efficiency, we apply engineering to make the world run more smoothly.

Vision

Our sustainable innovations make us the global leader in mobility solutions for heavy machinery.

Values Customer success Passion for results Innovation Respect

Sustainability

Challenges such as climate change, population growth and urbanisation call for action – in everything we do.

ENVIRONMENTAL RESPONSIBILITY

Actions and products – our entire value chain has made a commitment to achieve our environmental goals.

HEALTH & SAFETY

Whether it is our own employees, customers, partner network or other stakeholders, our target is always uncompromised safety.

HUMAN RIGHTS

Sleipner is committed to respecting human rights in its operations in every possible way.

CODE OF CONDUCT

Our comprehensive Code of Conduct outlines the ethical principles for our operations.

RESPONSIBLE PROCUREMENT

Mutual trust and responsible collaboration help ensure the sustainability of our entire value chain.

SLEIPNER

SUSTAINABILITY >

DB Series combination examples

Technical details

Minimum prime mover

Epiroc FlexiROC D35 - D65

Epiroc SmartROC T35 - T65

Atlas Copco DM30/35

Atlas Copco DM45/DM50

Atlas Copco DML-SP

Sandvik DX600 - DP1600

Sandvik DI450 - DI650

Sandvik D254S

Sandvik D45KS/D50KS

Sandvik DR410i

Sandvik DR412i / DR413i

Sandvik D55SP / D75KS

OTHER EQUIPMENT

Notice: Some rotary drills may have some optional extras, like walkways or cable drums which can set limitations for physical suitability or operating weight. In order to ensure the equipment suitability to DB Series detailed fleet review is part of sales process.

E Series combination examples

CAT 336

Hitachi ZX350

John Deere 345

Liebherr R 930

Komatsu PC360

Volvo EC300

CAT 352

Hitachi ZX530

John Deere 470

Komatsu PC490

Liebherr R 956

Bell B20

CAT 730/770

John Deere 260

Komatsu HM300/HD325 Volvo A25

Volvo EC550 Bell B25

CAT 374

Hitachi ZX690

John Deere 670

Komatsu PC650

Liebherr R 972

CAT 730/770

John Deere 260

Komatsu HM300/HD325 Volvo A25

Volvo EC750 Bell B40

CAT 395

Hitachi ZX890

John Deere 870

Komatsu PC900

Liebherr R 992

CAT 735/770

John Deere 410

Komatsu HM400/D325 Volvo A40

Volvo EC950 Bell B60

Hitachi EX1200

Komatsu PC1250

Liebherr R 9100

CAT 6015

Hitachi EX2000

Komatsu PC2000

Liebherr R 9200

CAT 6020/6020B

Hitachi EX2600

Liebherr R 9300

CAT 6030

Komatsu PC3000

773

HD465 Volvo A60

775

EH1100

HD465

R70

CAT 777

Hitachi EH1700

Komatsu HD785 Volvo R100

785

EH3500AC Komatsu HD1500

Liebherr R 9350 CAT 789

CAT 6040

Hitachi EX3600

Komatsu PC4000

Liebherr R 9400

CAT 6060 (Gen 2)

Hitachi EX5600

EH3500AC Komatsu 730E

CAT 793

Komatsu 830E

Hitachi EH4000AC

Komatsu PC5500 CAT 797

Komatsu 960E

Mobility increases efficiency at an iron

ore mine in

Australia

An Australian iron ore mine used traditional transport methods for its excavators within its large geographical operations area. As a result, relocating the excavators often took a very long time – easily an entire working day.

With Sleipner E400 dollies, relocations today are done within one hour –the time saved is close to an entire shift. And while the constantly hot

Australian weather presents a special challenge, Sleipner E Series dollies are built to operate in any conditions.

The reduced traveling time resulted in improved excavator efficiency, more productive working hours, increased production and cost savings. This meant the break-even period for their Sleipner investment was just a couple of months.

Sleipner E400

Sleipner DB

Series reduces dozer loading time by more than ten times

Efficiency, manoeuvrability for getting into tight areas, and the ability to carry different sizes of dozers and structures were important factors in Dysart, Australia. But what really impressed our customer about the Sleipner DB120 was the amount of time it saved: loading a D11 dozer with a conventional float could take anywhere from 30 to 45 minutes. With the Sleipner, this time was reduced to just 3 minutes!

Investing in the Sleipner was a great thing – it has been in use now for around 3 years, and it has delivered every time we have needed it. The biggest benefit of using the Sleipner DB120 is the amount of time it saves.

Sleipners globally >

Mark Gravino, Head Operator, Billiton Mitsubishi Alliance (BMA)

Sleipner DB120

Sleipner E30

Sleipner

dollies Boost Equipment

Utilisation Rate

Significantly

Since getting two Sleipner E Series dollies (E30 and E50) in 2016, GeoTransport & Construction has been able to boost both production and the utilisation rate of its equipment. Transporting excavators by pulling them behind a tipper truck between distant sites improved the distance covered in one hour from 2 to 15 kilometers.

The Sleipner E Series improved the utilisation rate of our excavators by allowing us to move the equipment to where it is needed in an agile manner. When using the Sleipner E Series to move excavators, we save around 2 hours moving time, which means roughly 200 US dollars cost savings for us each time.”

Jacinto Gimena Pacino, Plant Manager, GeoTransport & Construction

Safe simulator training saves time

Boliden Kevitsa Mining Oy in Finland, benefitted from using a simulator when training the operators of its Sleipner E190 dollies, which is used for moving a Komatsu PC2000 excavator. Boliden’s training supervisor found the simulator to be extremely useful, especially in terms of safety and cost. Sleipner simulator

The Sleipner simulator is ideal for initial training, especially for operators who do not have previous experience with such excavator transport systems. The simulator provides a really good driving feel, software and physics. The machines respond almost like in real life – it couldn’t be better.”

Training supervisor, Boliden Kevitsa Mining Oy Sleipners globally >

What’s more, the simulator saved 1–2 days of training time. The training was faster as it allowed different operators to take the controls without any delay. Another advantage was that the training did not cause disruptions to operations at the mine due to traffic.

Globally local

From our Northerns origins, Sleipner has grown to be a global mobility expert.

Sleipner dollies and lowboy trailers have been delivered to more than 50 countries on six continents.

Sleipner provides the wheeled advantage to help our customers succeed.

59 countries delivered

6 continents

Sleipners representatives >