THE PLATINUM RANGE MAKES

MD Simon Cooper discusses the

Lights out operation Are we getting any closer to that goal?

Do

So, we enter a new era. I’d like to be totally upbeat about that, but minds much greater than mine will be grappling with the question we must surely all be asking - what impact will the appointment of a new prime minister and accession of a new monarch in such quick succession mean for a Britain in crisis? We’re at a turning point for sure. What we cannot be so sure about is how the future will play out. Taking control of what we can control in these shifting times may ease the angst. In this issue we cover a plethora of subjects that should help you do just that.

The Talking Point interviewee this time around is Solopress MD Simon Cooper on the decision to create a ‘head of business development’ role

That’s optimism for you. I asked him whether he thinks many PSPs are likely to take on someone in a similar role as we continue to see so much matter. And in keeping with the management theme you might want to digest the Top Tips article on how to make better decisions, and at the Zeitgeist piece on why it’s imperative to stay calm and carry on!

If technology is your thing, the What To Watch features this issue look at what’s being done to help you with lights-out working and at

Editor: Lesley Simpson lesley.simpson@imagereportsmag.co.uk

Production / Design: Alex Gold

Publisher: Wayne Darroch wayned@sjpbusinessmedia.com

Advertising Manager: Carl Archer carl.archer@imagereportsmag.co.uk Tel: 07723 079928

SJP Business Media, 2nd Floor, 123 Cannon Street, London, EC4N 5AU www.imagereportsmag.co.uk

For circulation enquiries contact: SJP Business Media Email: subscriptions@sjpbusinessmedia.com

Image Reports is available free to printers based in the UK. Register at www.imagereportsmag.co.uk/register.

To purchase a subscription please visit www.imagereportsmag.co.uk/subscribe –UK £54, overseas £84

Printed in Great Britain.

No part of this publication may be reproduced, stored in a retrieval system or transmitted by any means without the Publisher’s permission.

The editorial content does not necessarily reflect the views of the Publisher. The Publisher accepts no responsibility for any errors contained within the publication.

From Top: Lesley Simpson Alex Gold Wayne Darroch Carl Archer

p6 News

Keeping you abreast of all the latest news in relation to digital wide-format print.

Liyu UK’s Platinum range combines style with substance.

Digging below the surface with Industry Mole; Out and About events diary; Legal Eagle advice.

Why you need to trust yourself when all men doubt youand make allowance for their doubting too.

Go to www.imagereportsmag.co.uk for all the wideformat sector’s industry news, updated regularly online. Image Reports can also send a twice weekly enews bulletin straight to your inbox – register at: www.imagereportsmag.co.uk/ newsletter

Solopress MD Simon Cooper gives his thoughts on business development managers.

Taking a look at how you can make better management decisions.

A reminder of the key takeaways.

What printer manufacturers are doing to help you with remote working.

Bringing you up to speed with developments.

p23 Greenwashing: do you do it? Have you fallen foul of doing what you deplore others for doing?

BPIF hosts emergency energy roundtable

Platinum Q2 hybrid flatbed machine gets first UK showing 8% of businesses providing inflation-matching pay rises reveals research

Multi-million pound contract win for newly formed Astra Group

Dataline launches MultiPress Polaris

Beacon installs UK’s first Colorado 1630

Roland DG to build new HQ

KGK Genix nabs ‘Most Innovative Multidisciplinary Creative Agency 2022’ award

CMYUK adds Epson SureColor SC-R series to its portfolio

Papergraphics launches The Design Collection printable wallcoverings

Durst Kraftwerk opens to house spin-offs and start-ups

Shaun Holdom joins Fujifilm wide-format team

PDQ buys Gibson flatbed to bring work in-house

Cloud capabilities added to EFI Fiery Command Workstation

PFI appoints group business development director

Drupa data shows global print industry recovery and resilience

OneVision expands Automation Suites

Soyang Europe earns carbon neutral status

Perspex Distribution introduces 100% recycled acrylic Solopress appoints new head of business development

Soyang Europe takes on new Fujifilm product manager

Kitchen wrap demand prompts new William Smith training course

Oris packaging mock-up system extended FaberExposize UK and Northern Flags install Zund G3

Magnus Mighall joins Fespa UK board

MacroArt helps bring Newlife store to the high street

GIS makes key staff changes

Hybrid Software Group posts disappointing interim results

Three Point wins best family business gong Vanguard founder dies

CMYUK has launched a new division called Arkutex in which it is bringing together its surface textiles offering for the build/interiors environments. It is also developing a dedicated Arkutex showroom and contractor training centre in Bloxwich, home to its national logistics and distribution hub.

The centre - being designed by architectural and design practice KSS - will showcase multiple environments that simulate all target applications and markets for Arkutex surface textiles, which include ranges from Pongs, Kavalan, UFabrik and more.

Mick Crook, CMYUK business development director (materials) said: “Personalised interiors and décor using environmentally responsible materials is a high growth area and architectural textiles extend this trend even further. Creating new innovations both in design and installation, the scope and versatility that Arkutex offers, provides a compelling narrative with the potential to secure greater profitability and build more resilience into our customers’ business operations.”

Innotech Digital and Display has developed a fully biodegradable print medium. Once discarded and disposed of via the residual waste stream, Envirotech BIO250 PVC Free Biodegradable Print Media Grey Back 250g/m2 FR EN13501 will decompose within 9-12 months.

Made from 100% natural fibres, Envirotech BIO250 can be printed on Latex, UV-C or solvent machines. In Innotech’s own Eco Impact Score Tool, the material rates B. Though it breaks down quickly

in the right compostable conditions, it has a printed durability of up to two years

Derek Shedden, national sales manager UK, said: “This is a massive breakthrough for our industry. The pressure has been on all of us that make up the print industry to do something about our impact on the environment, and this is a massive stride in the right direction.”

Initially, the medium is available in 2.2m and 3.15m widths.

Banyan Software is to acquire the printIQ business in a move that is focused on R&D investment and business growth. Anthony Lew will remain at the helm as CEO.

Banyan focuses on a ‘buy and hold for life’ strategy for growing software companies. printIQ

Norwich-based CIM Signs and Graphics has employed five more people after a £54,200 grant from the LEP’s Growing Business Fund enabled it to buy a SwissQprint Nyala 4 that since its installation at the start of April has helped the company’s turnover jump 15% monthon-month.

MD Mark Baker said the new machine - CIM’s “first flatbed, and largest and fastest, costliest machine - has already increased our productivity

and turnover to the level where we’ve been able to take on a new person in general production, a specialist finisher, a designer and installer, plus an apprentice.”

Baker, who started the funding application process in December 2021, said “the grant meant I could look for something bigger than the 3m Agfa machine I had been looking into. The Nyala 4 lets us print materials up to 3.2m wide and rolls of any length, opening up new work

Perspex Distribution has brought out Palight Re-Nu, a 100% recycled PVC foam understood to be a first for the UK print market.

Palight Re-Nu is manufactured by Palram at its plant in County Durham, and has been developed to utilise recycled waste from the company’s production line and end users.

The new foam is produced as a co-extruded PVC, providing a white surface. The lightweight substrate is available in thicknesses of 3mm, 5mm and 10mm in a sheet size 3m x 2m.

PDL marketing manager Luke Martyn said: “We have been working with Palram to develop Palight Re-Nu and introducing a 100% recycled option for our PVC foam

has experienced significant growth over the past 12 months, and has recently made a number of appointments, including the promotion of former UK and EAMER sales manager Paul Bromley to global sales director. Rob Thurston has joined the company as UK sales manager following this move.

opportunities and enabling us to bring previously outsourced job in-house. We are now handling wider-width banner and printing onto some textiles that we couldn’t handle before. Plus, the speed is remarkable.”

The company, which also bought a sewing machine from the grant, has grown throughout the Covid period and had a turnover of £1.4m in 2021. It now has a staff of 24 and Baker anticipates further expansion.

customers. We tested the product at Sign & Digital UK this year and visitors were really excited to share this product with their own customers and delighted with the quality of the print tests taking place at the show. This new range demonstrates the strength of Palram’s UK manufacturing R&D being the first to offer a 100% recycled PVC foam solution.”

Dundee-based wide-format print specialist Tayprint has gone into liquidation, with all 21 staff having been made redundant. Seven of those staff have now been taken on by Tradeprint, which is also completing work in progress from when Ken Pattullo and Kenny Craig of Begbies Traynor were appointed as joint liquidators on 26 August.

Begbies Traynor said Tayprint’s financial difficulties had been exacerbated by the impact of the Covid pandemic and that it was in the process of realising any assets to provide the best return for creditors.

Tees Valley signage specialist Sign Design GB has brought a range of services inhouse, enhanced production capacity and is now exploring new application opportunities following the purchase of a SureColor SC-V7000, Epson’s first UV LED flatbed printer which was introduced earlier this year.

Ben Kennedy, commercial director at 2009 founded Sign Design GB, said: “We were sub contacting about £80,000 to £100,000 of direct-to-substrate work a year. We decided it was time to bring that in-house so we could ensure consistency, reduce turnaround times, cut our carbon footprint and also develop that part of the business. We can also explore other application possibilities, run samples, and show clients what is possible.”

The SC-V7000 was supplied by Perfect Colours and features a UltraChrome UV ink configuration including red, grey, white and varnish.

Anthony Rowell, sales and customer success director at Tradeprint, which is based on the same industrial estate as family-run Tayprint, said it was in talks with the liquidator about taking on some of the print kit, but pointed out that much of it was leased. The company already has other wideformat kit on order too.

“This is a sad situation for Tayprint, but it’s manna from heaven for us in that we are an expanding business and recruiting the right people was proving difficult. We have already taken on Tayprint staff across sales, pre-press, print production and finishing, and we’re still counting.

Rowell pointed out that Tradeprint had for some time been renting part of the Tayprint factory to house large-format HP printers and a Zund cutter it acquired from its sister company, and that the companies “were more than part of each other’s supply chain”.

“We have been working very closely together and are very pleased to be taking on Tayprint staff, and hopefully customers, as we expand our site and our offering,” said Rowell. He said the company expects to double its 1,860m2 site by the end of the year after earlier acquiring next-door premises that are currently being remodelled.

UK private equity fund Elaghmore has acquired Concept Group for its Hexcite Group.

Birmingham-based Concept provides sign and large-format LED solutions using traditional, bespoke and digital signage. Customers include Global Media Group, Open Media, and JCDecaux. The company, which has a workforce of 18, will continue to be run by managing director Sean Morrough and director Dave Neale, reporting to Wes Mulligan, CEO of Hexcite Group.

The Hexcite Group, formed in 2019 to provide specialist signage design, manufacturing, installation and aftercare services, has seen notable departures over the last year with Elaghmore having sold-off Kesslers and Gardners. The group now includes Blaze Signs, which has substantial signage manufacturing capability out of its sites in Broadstairs and Birmingham, and Cygnia Maintenance, a provider of sign maintenance services.

New branding and format changes have been unveiled for Sign and Digital UK (SDUK) 2023 (NEC, 21-23 March).

“After recent challenging years, the time was right to evolve the branding and introduce a new fresh and modern look for SDUK along with some new show

plans to meet the business needs of the industry,” said event director Jenny Matthew.

“We’ve created an SDUK working group to make sure we have our finger on the industry’s pulse. SDUK Explains will be back for 2023 focusing on the biggest challenges facing the sector, and creating

A new Amari Sustainable range has been introduced that comprises eight media made of at least 25% sustainable content, that are 100% recyclable, and that are produced in Europe in order to mitigate CO2 emissions.

There are five new products in the range alongside the existing Green Cast, Dispa and Smart-X offerings.

The products available within the Amari Sustainable range are:

• Altuglas R-Life Ex - an extruded acrylic sheet that

features 75% recycled content, has a high-gloss finish and is weather resistant.

• Exolon Eco - a solid polycarbonate sheet that features up to 40% recycled content and has been specifically designed for vandal-proof applications.

• VivakEco - a polyethylene terephthalate glycol (PETG) sheet manufactured with a minimum of 40% regrind from its own production. Fabricated from a lightweight material with extreme break resistance, it ensures low energy consumption and high durability.

• Foamalux Xtra - a lightweight foam PVC sheet made

The acquisition of Concept Group means Hexcite Group’s annual turnover is circa £35m with a customer base of more than 250 retailers, financial institutions, facilities management companies, and brands.

Concept is the twelfth acquisition made by Elaghmore from its investment funds worth £100m. Together, the businesses acquired by Elaghmore have a combined annual turnover of around £350m million and employ around 2,700 people across the UK and Ireland.

Mulligan said: “The digital OOH advertising market has great growth opportunities. Working closely with Blaze Signs adds substantial technical and manufacturing expertise to Concept, and our Cygnia business can help Concept accelerate its digital signage maintenance capability. We expect Concept to reinforce its position as one of the leading full turnkey system integrators in its sector.”

a programme of expert advice, case studies, and additional solution sessions from our exhibitors.

“Visitors also asked for better networking opportunities and we’re working hard on ways to do this to ensure SDUK remains an unrivalled meeting place for the industry.”

of up to 80% reclaimed post-production waste content.

• AkyPrint - a polypropylene bubble board made of at least 25% recycled material, for single and two-sided printing and suitable for indoor and outdoor use.

• GreenCast - a cast acrylic sheet made with 100% recycled materials and that looks, performs and fabricates like virgin acrylic - even after recycling.

• Dispa - a recyclable durable paper board that provides optimal flatness and dimensional stability.

• Smart-X - a recyclable lightweight polyester/HIPS foam board.

Maybe you’ve heard the name Liyu UK, or indeed talk of the Platinum range, perhaps when talking to industry colleagues who have installed a Platinum solution, or passed a machine in action at a trade show, or even seen the team’s fun and engaging social media presence. If not, it was only a matter of time before you become better acquainted with what they offer. Liyu UK is the central component of the Ultimatum Group, an organisation built on the passion of expert Inca Digital, Oce Arizona and Durst engineers who truly believed in delivering outstanding service at a better value for customers. After much exploration and analysis, they decided that leading European manufacturer Liyu was the right technology to centre the business around.

Managing Director of Liyu UK Eddie Tucker explains: “We knew we could shake things up and do things differently, while ensuring that customers are still getting reliable, world-class print technology. We took the plunge and formed Liyu UK, it was absolutely the right decision. We’re transparent and real with our customers, supporting them from the beginning of their journey and making sure we’re available for whatever they need from that point forward. We’re delighted to be at the forefront of what we call ‘The Printer Revolution’!”

It’s been a busy few years for Liyu UK as they establish themselves as one of the major players in wide-format print in the UK market, but there is no denying that things are ramping up even further. A busy few days as part of the wider European Liyu stand at FESPA Berlin earlier this year inspired a wider run of events as the standalone UK arm for the Autumn/Winter season. Hot on the heels of an outstanding Print Show in Birmingham in September,

Liyu UK has also partnered with the UK Graphic Awards, sponsoring the highly competitive Exhibitions category, and Liyu UK will also be putting its own stamp on the event calendar as it plans an exclusive Open House event, where visitors can see the printers and cutters live as well as connect with businesses who are already successful converts to the Platinum range. Tucker adds: “There’s a real buzz building around the Platinum range, so it’s the perfect time to invite people to see the equipment at work as well as enjoying a fantastic day out. We offer a fun, unique approach to business and so we will definitely make sure our visitors are wowed by our hospitality as well as our technology!”

Liyu UK’s Print Show presence was part of a new partnership with ADAPT – Amari Digital Printing Technologies, and saw the Platinum Q2, a 2.2m x 2m hybrid flatbed machine on display for the first time at a UK exhibition. Described by ADAPT’s general manager Dominic Bowen as an ‘incredibly good-looking piece of kit’, it was certainly a showstopper on the show floor.

The Liyu Platinum flatbed pairs sleek aesthetics with high-productivity, and is available in two sizes; the KC2512 and the KC3020. The Platinum KC builds on existing Platinum architecture to add even more efficiency and functionality through additional upgraded features including the maskless bed, reducing the need to use masking tape, the reverse vacuum for easily removing heavy or awkward materials from the flatbed, and electronic vacuum zoning. The beltless drive and LED UV liquid cooling ensures the Platinum KC is speedy,

sustainable, and affordable to run, and the choice of Konica Minolta or Ricoh Gen6 printheads means highquality prints are par for the course.

Owners of Gocre8 in Liverpool opted for the KC2512. Having explored the ‘usual suspects’ in terms of leading flatbed solutions, they found that the Platinum KC ticked all the boxes for their requirements: “After doing extensive research for our next flatbed printer we decided on the Platinum KC2512 with Varnish, what a superb choice and so affordable to run.

We do a lot of fine artwork as well as high production boards, this ticks all the boxes for us. The Maskless vacuum is so powerful which is ideal for awkward cardboard.”

Elsewhere in Liverpool, the larger version of the Platinum KC flatbed is also making a big impression. Peter Wilson, Managing Director of LWV Printworks, Liverpool, says: “We’ve taken delivery of the massive KC3020 Flatbed and its phenomenal in quality and speed, I didn’t know this type of flatbed was available at such a good price, we would highly recommend one.”

If a roll-to-roll solution is what’s needed, the Liyu Platinum range doesn’t disappoint. The Platinum PCT roll-to-roll printer is available with either UV LED or eco-solvent ink sets for environmentally responsible production. Once again putting operators at the heart of the design, the core Platinum technology has been upgraded with a range of user-friendly functionalities including an automatic media measuring system, LCD control panel, LED lighted printing area, and automatic pinch roller control.

The Platinum QR3 & QR5 are roll-to-roll UV LED printers that incorporate the familiar polished Platinum design with state-of-the-art technology. For businesses looking to explore new markets and revenue streams, the application possibilities of the Platinum QR combined with its production capabilities make it an attractive contender. The QR’s versatility handles materials such as leather (or vegan leather) and canvas, as well as being suitable for backlit applications, signage, adhesive vinyl and window stickers, and even packaging and prototypes.

On the hybrid front, the Platinum Q2 brings the ‘wow’ factor. It’s hybrid status means it’s a highly versatile machine, capable of printing on to a huge range of flat medias Including Foamex, Di-bond, glass, wood, and many more up to 50mm in height. Described as the ideal ‘all-rounder’, the Platinum Q2 boasts a heavy duty roll and take-up unit, Automatic head cleaning, Quadro vacuum ring motors for extra flatness for those awkward medias, and liquid cooled LED UV units. For an even more impactful solution, see the Platinum Q3 – this wider version accommodates larger media such as 3 metre boards.

Growth in the textile market continues, following a drop in demand during COVID, exhibitions and other events are back with a bang, making textile printing an attractive prospect for print service providers. Liyu’s Platinum FH Textile printer delivers a wealth of opportunities in the sector, offering a 3200mm print width and print speeds of up to 210 m2/h with 2880 dpi resolution and 3.5-13 picolitre droplet size, it’s possible to print with photographic quality on many types of fabrics such as bed covers, curtains, wall coverings, seat covers, flags, table clothes, and T-shirts.

On the finishing side, the Platinum Q Cut is a range of high-precision, flexible and automated cutters

equipped with an intelligent conveyor, automatic camera registration, a double beam cutting system, and speeds of up to 1.5m/s. The range consists of the Q Cut 3521, Q Cut 2516, BQ Cut 2516, Q Cut Offset, and DF Plotter. Platinum printer operators will find a match made in heaven with the razor-sharp accuracy of the Platinum Q Cut range.

It’s important to highlight the fact that sustainability is a driving force underpinning Liyu’s Platinum technology. As businesses across all sectors are aiming to work with print and signage partners that help them meet their sustainability targets, the Platinum UV printing inks are GREENGUARD GOLD certified, a prestigious certification that is awarded to products meeting some of the most exacting chemical emissions standards.

Tucker concludes: “It’s great to be expanding our presence in the market and showing PSPs what our equipment can do. We definitely encourage anyone with an interest in cutting-edge wide-format technology, particularly those that are looking for better value and more focus on their needs than they might be getting with their traditional manufacturer partners, just get in touch –we’re waiting to host you at our showroom!”

WE’RE DELIGHTED TO BE AT THE FOREFRONT OF WHAT WE CALL ‘THE PRINTER REVOLUTION’!

This summer Solopress took on Phil Foster as head of business development, a new role for the £32m turnover company (estimated sales for 2022), which expects to further expand its payroll, kit list and business premises within the year. I asked MD Simon Cooper about the decision to create this new role, and whether we’re likely to see many more PSPs follow suit as they continue to diversify.

Dare I ask - isn’t it the job of the MD to head up business development? Solopress has developed rather well since it was founded in 1999, especially since it joined the Onlineprinters Group in 2017. And you have been there as MD since February 2019, so when, and why, did you decide you needed someone else in that specific role?

Indeed it is. However, all elements of the business fall under my remit and so it’s difficult to spare the time needed to really support and onboard new customers. Additionally, when it comes to new service offerings we would like to add, like branded marketing portals, we need a dedicated resource to spearhead those initiatives.

Solopress has really ambitious plans to double the size of the business over the next five years and in order to do that we need experts like Phil [Foster] on board that can help us onboard new customers and launch new service offerings.

What’s your definition of ‘business development’ in respect to the new position - and have you clear objectives of what you want Phil Foster to deliver as head of business development?

Solopress has typically acquired its customers through online marketing channels and customers are then able to self serve, or deal with a human that can process their orders. However, many customers, especially larger resellers with high annual spend on print, aren’t happy to visit a website and start transacting - they need to have a personal relationship, someone they can build a relationship with and trust to ensure their projects go to plan. Phil will therefore proactively reach out to

print resellers to explain what the Solopro service (our programme dedicated to serving the trade) is all about, but also remain behind projects to ensure everything progresses smoothly.

Beyond that he will also be instrumental in launching our book printing service, which will enable us to service more of the publishing market, as well as launching our branded marketing portals.

Naturally, Phil has some sales targets as you would expect, but that’s between the two of us! However, for any business looking to have a proactive outbound sales team, my advice would be to ensure that the targets are heavily geared towards acquiring new customers and that any commission or bonus payments are related to incremental revenue gains and not servicing existing turnover. Therefore, if a sales person gains £1m of new business in year one, any commission payments in year two should not be related to servicing that existing business but rather focussed on gaining more new business.

Many large-format PSPs are diversifying and wanting to grow their businesses. Do you think it’s imperative that they all have a business development ‘leader’ of some description?

I wouldn’t say it’s imperative. I think it’s highly dependent on the size of the business and the areas they would like to expand into. I would say - and you would expect this of me - that it’s imperative that large-format PSP’s looking to expand consider partnering with a business like ours that can help them offer a wider range of products to their customers at really competitive prices with fast turnaround times.

Beyond that it’s imperative to have a long-term strategy - a clear understanding of where they would like to get to and what the growth strategy is. We’ve just been through this process within the Onlineprinters group, planning out our five-year strategy where our goal is to double the business. For us at Solopress in the UK that means we would like to achieve £60m by 2027. We’ve planned out a range of organic growth measures we will implement which entails adding new product and service offerings as well as a series of M&A activity.

What are your feelings on bringing someone into that role from outside the print industry - or, perhaps from within new target sectors/markets?

Personally, I would always strongly favour someone with print experience and would be highly unlikely to bring someone in from outside of the industry in a customer facing role. It’s essential the person talking to the customer is a real expert in their field. That said, I think people from outside of the industry can help us think differently and approach the market in new and unique ways, so in areas like marketing or software development a print background isn’t essential.

What knowledge do you think that business development leader needs to have to deliver the company the best outcomes? They need to be really knowledgeable about print in general and then specifically about the products and services we have on offer. They are the customers conduit into our business and need to make that as successful for the customer as possible. They need to be able to

think laterally, to identify where there is an adjacent market or opportunity we could easily be addressing with only minor alterations to our business model (in our case, publishing is a good example of this).

Whilst knowledge is important, it’s equally as important to have a couple of critical attributes, like trustworthiness and reliability, without those all the knowledge in the world will amount to nothing.

Do you think business development is becoming more difficult given the current economic/trading climate? I think this is highly dependent on the business you’re working within and the offering you have. Our business represents extremely good value and so in times of tough economic pressure, when buyers are looking to make a saving, they will turn to businesses like ours to find those savings.

It’s critical that you arm your outbound team with a powerful proposition - as a business leader you’re setting them up to fail if you send them out with a ‘me too’ offering. You need to have a point of difference and a way to grab the attention of the potential buyer.

For us, whilst we are an online printer, we are also prepared to take orders from customers through a human interface. This means that when customers need something off piste that’s not available on the website, they can achieve their requirements to speaking with one of our team. That’s just a small example but one of the ways in which we are able to differentiate our service.

Talking to Phil after just a couple of weeks in the business, his inbox is starting to fill up and it seems like the proposition he has is being well received. Long may it continue.

I WOULD BE HIGHLY UNLIKELY TO BRING SOMEONE IN FROM OUTSIDE OF THE INDUSTRY IN A CUSTOMER FACING ROLE

Business | Top Tips 12 | October / November 2022 People who are indecisive are pilloried as ditherers, tinkermen, procrastinators - and those are the kinder epithets. But is there something to be said for taking your time when it comes to making judgements in your business?

‘THE MANAGER’S INDECISION IS FINAL.’ WE’VE ALL WORKED WITH PEOPLE WHO THAT JOKE HAS BEEN AIMED AT. BUT IT’S BETTER TO BE INDECISIVE AND RIGHT THAN TO BE DECISIVE AND WRONG. THAT SOUNDS OBVIOUS YET IT’S ASTONISHING HOW OFTEN BUSINESSES RUSH TO JUDGEMENT - AND COME TO REGRET IT. HERE WE EXAMINE

HOW YOU CAN MAKE BETTER DECISIONS.

The most common flaw in decision-making is our complete failure to see ourselves as the rest of the world sees us. Management thinkers call this the ‘ego empathy gap’ - our assumption that everyone shares our values, assumptions and ideas. And guess what?

They don’t.

You’ve probably never heard of McDonald’s Arch Deluxe burger and there’s a good reason for that: it failed. The idea was to create a gourmet burger that would appeal to the sophisticated palates of Gen X consumers. The problem was these consumers weren’t interested. They regarded the idea as McCheesy. Worse, the upscale burger, created by fine dining chef Andrew Selvaggio, made the chain’s core customers wonder what had happened to ‘their’ McDonald’s. Multinationals have the resources to let data speak truth about the outside world to power. It is harder for SMEs but just listening to external influencers can make all the difference.

The ego empathy gap is reinforced by confirmation bias - our ingrained habit of only considering information that supports our opinion. We can also be quite lazy in our pursuit of information, content to focus on what is readily available rather than asking deeper, challenging - but potentially more rewarding - questions.

In the same vein, we often turn to the nearest available expert to resolve a debate. In some cases, the ‘expert’ isn’t very expert at all, they just happen to be someone the most powerful person in the room happens to know. I have personally been in a meeting where a multi-million pound investment was being assessed and one executive cited his son’s opinion in evidence. This is why many academics argue that having a dissenting opinion - even if it is held by an idiot - in a room improves the quality of the decision made.

‘When it is not necessary to change it is necessary not to change,” said Lord Melbourne, Queen Victoria’s favourite prime minister. He did have, shall we say, a relaxed leadership style but he had a point. More than 150 years later, a very different leader, Andy Grove, the dynamic founder of Intel, made a point of not making a decision until he was clear about what was at stake.

Often, we feel obliged to make a call even though there are many crucial factors we still can’t read. How will our competitors react? How reliable is the technology? Is the customer telling us the truth - or merely what they think we’d like to hear? Once a decision has been taken, we are hard-wired to resist a U-turn, even if that is the most sensible decision. Kodak could have saved itself a lot of grief if, after inventing and rejecting digital photography - mainly because its engineers assumed that the public shared their technical expectations - had done what ‘Private Eye’ calls a “reverse ferret” and invested in the technology. Killing the best idea Kodak had had for decades was a decision that didn’t need to be made and all but killed the company.

WE ARE HARD WIRED TO RESIST A U-TURN, EVEN IF THAT IS THE MOST SENSIBLE DECISION

The one advantage SMEs have over such giants as Kodak is that they can open up debate to everyone who has a stake in a decision. There is no excuse - other than old fashioned hierarchical, autocratic thinking - for small businesses to have decision-making silos. Sony’s failure to capitalise on the launch of the Walkman was a textbook example of siloed thinking. The company developed the world’s first portable music player in 1979 - 22 years before Apple unveiled the iPod - and also had, at that time, some of the world’s best-selling music artists on their record label. But the divisions never talked to each other, which created the space into which the visionary Steve Jobs launched the iPod and iMusic. By 2025, analysts predict, Apple Music will be generating revenues of around $7bn.

Are you asking the right questions? In 1986, regional newspaper publisher Eddy Shah did a very brave thing: he launched ‘Today’, the first British national newspaper to print in full colour. In Shah’s view, computerised typesetting had reduced production costs so dramatically he could afford to compete with such established titles as the ‘Daily Express’, ‘Daily Mail’, ‘Daily Mirror’ and ‘The Sun’. He was half-right. National newspapers could be produced much more cheaply but his competitors put their hands in their much deeper pockets and invested in the same technology. They ploughed those multi-million pound savings into marketing campaigns and circulation-boosting promotions which Shah could not afford to match.

His failure to consider how aggressively his rivals would defend their patch - and to understand the importance of marketing - cost him dear. Within four months, he was forced to sell the title which was later acquired by Rupert Murdoch and closed in 1995. Shah’s vision had forced the newspaper industry to adopt colour but he discovered that, although there was a gap in the market, there wasn’t a market in the gap.

How you frame a decision matters. When you boil it tight down, the Watergate burglary that undid Richard Nixon was simply an attempt by three middle managers trying to get one over on the competition and impress their bosses. The question at the crucial meeting where Gordon Liddy presented his bonkers plan was not ‘Should we do this? But ‘How should we do this?’ Only Liddy was genuinely enthused by the scheme but as he had scaled down the original proposal (which would have cost $1m and involved the hiring of prostitutes) his colleagues felt obliged to make what negotiation experts call a reciprocal concession. One of the White House officials left the crucial meeting saying to himself: “It’s only a third-rate burglary, what can possibly go wrong?”

Many businesses fall foul of what theorists call the ‘planning fallacy’ in which we fall so deeply in love with our new ideas and innovations we make unrealistic assumptions about how they will be received. “If you build it he will come” worked for Kevin Costner in the classic baseball fantasy ‘Field of Dreams’ but it’s no guarantee of success in the real world. We would do better to be realistic, accept uncertainty and consider how we could survive a worst case scenario.

The ‘planning fallacy’ is often exacerbated by what theorists call the ‘endowment effect’ in which we get so attached to our pet projects that we resent any suggestions - even sensible ones - that might improve them. To be fair, it can be hard to distinguish between the ’endowment effect’ and the kind of resolute defence of an innovation that Jobs showed when developing the iPod with Apple designer Jonny Ive.

The defining managerial trait of the 21st century will not be decisiveness, it will be curiosity. Change is happening so fast, and in so many different dimensions, that it will be hard to keep up. The tried and trusted formulas will soon become the tried and rusted formulas. We need to think with breadth and depth about the decisions we take - and hire people who can do the same.

HAVING A DISSENTING OPINION - EVEN IF IT IS HELD BY AN IDIOTIN A ROOM IMPROVES THE QUALITY OF THE DECISION MADE

Two trends fundamental to the long-term growth of the UK print industry were centre stage at this learning and networking event. Firstly, how businesses can increase their environmental sustainability ahead of significant changes to legislation in the next few years and rapidly changing print purchasing priorities. And secondly, how to ensure they are protecting the productivity and health of their teams through implementing wellbeing practices at work.

A supplier expo ran concurrently at the event too, with Antalis, BCR Associates, Canon, Duplo, Fujifilm, HP , Imprint MIS, Konica Minolta, printIQ, Tharstern, Vivid, Worksthing, Xerox and Xmpie all in attendance, and whose collective support/sponsorship made the conference affordable and on-point for delegates.

The day kicked off at 8.45am with networking over coffee before the speaker sessions started at 10am, which then ran through until 5pm.

Lawrence Green, from Greens the Signmakers and Digiprint, was the first speaker of the day, discussing his journey with sustainability in his session ‘Walking the Walk’. The man is a passionate advocate for sustainability and over the last few years has completely transformed the way his business operates, inspired by family and through extensive research.

Marcus Timson from FuturePrint, then discussed wellbeing and ‘Taking Back Control in a Time of Great Uncertainty’, giving his opinion of what wellbeing is and focussing on some observations from personal struggles with mental health. His talk ended with a number of practical ideas for thriving.

Andy Place from RPM Digital focused on ‘A Sustainable Path to Business Growth’ by highlighting how embracing the ‘sustainable’ message within the company has played out as

a success story - for customers and for his own business.

Rob Pink and Tom Charles from Sku-Driver helped with ‘Parting the Sea of Greenwash’ in relation to sustainability initiatives. Sku-Driver has made some inspiring innovations and these experts provided insights of how to operate sustainably through business operations.

Next, Marianne Steel and Neil Lovell from The Printing Charity discussed exactly ‘Why Wellbeing Matters’. Having handled a number of cases among individuals within the industry that need emotional, financial, and practical support, they explained several ways employees could be supported to improve wellbeing.

John Conroy from Claremon, then talked about sustainability and particularly why ‘You Need to See it, to Be it’. He has put sustainability at the heart of his business operations, ensuring Claremon runs efficiently through sustainable initiatives, and also talks his customers through the power of sustainability. At the conference he discussed his partnership with the Resea project.

Finally, Chloe Thompson from Harrison Scott Associates, discussed how businesses can ‘Build a Platform to Attract Top Talent’. As a recruitment consultancy, Harrison Scott is aware of various company cultures and Thompson outlined how a commitment to staff’s physical, mental, and financial well-being attracts top candidates to roles.

IPIA general manager Brendan Perring says on the topic of sustainability, one of the two key topics of the conference: “It’s becoming ever more critical that print businesses and our entire supply chain understand what it really means to be sustainable. The conference educated delegates and provided tangible tools to help them make informed decisions about how to reduce their carbon footprint, get ahead of impending Government legislation and affect positive change within their organisation.

“Proposed legislation, cultural changes and the significant shift in corporate social responsibility priorities being shown by brands will all have an impact. The result will be print buyers that increasingly require print service providers to demonstrate their sustainability credentials - and that of their products or services when tendering for business. This in turn will drive PSPs to require their material and technology suppliers to do the same.

“It will become a key defining factor ultimately affecting the competitiveness of businesses in our sector. The conference guided delegates on decisions about sustainability that not only protect natural resources, but also make good business sense.”

On the second key conference topic, the agenda was all about how to maximise wellbeing at work with the Covid-19 pandemic having triggered a real cultural shift in how people see their work-life balance and what motivates them and influences their productivity.

Another critical trend is how recruitment is also being significantly influenced, with the best talent increasingly weighing up a range of criteria in regards to their quality of life, not just how much they will get paid. Speakers advised on how to create a healthy environment where workplace stress is reduced, productivity is increased, and employees feel valued and supported.

THE INDEPENDENT PRINT INDUSTRIES ASSOCIATION (IPIA) HOSTED ITS AUTUMN CONFERENCE IN SEPTEMBER UNDER THE BANNER ‘PRINT IN BALANCE - SUPPORTING PEOPLE AND OUR PLANET’. WE ASKED FOR AN OVERVIEW OF THE KEY POINTS MADE DURING THE DAY TO HELP SPREAD THE MESSAGE.

THE CONFERENCE GUIDED DELEGATES ON DECISIONS ABOUT SUSTAINABILITY THAT NOT ONLY PROTECT NATURAL RESOURCES, BUT MAKE GOOD BUSINESS SENSE

Remote diagnostics, better analytics, and of course automation, are the friends of any PSP wanting to reduce on-site, hands-on production time and expand lights-off operation. There’s a long way to go before that becomes anything like mainstream - if it ever will - but we’ve also come a long way in turning what was once a mere daydream into reality and systems manufacturers continue to build on that.

Rainer Ganter, product development manager at Fujifilm, says the company is currently doing a lot on remote diagnostics for instance, pointing out that “the Acuity Prime and Acuity Ultra R2 presses provide some excellent examples of our progress in this area.” Both have detailed analytics dashboard that splits data into three categories - for the operator, production manager and for Fujifilm. It means performance issues can be identified early and addressed remotely if needs be.

Ganter also points out that “the ability to remotely send and receive data - often through on-press cameras - is key in order to anticipate potential breakdowns, forecast whether any spare parts or inks are required, and be able to know exactly what needs to be addressed by engineers so that up-time is maximised and disruption kept to a minimum.”

“Automation is another critical aspect of lights off operation,” acknowledges Ganter, who believes that the labour requirements of wide-format PSPs and current recruitment challenges across the sector are going to drive even more investment in automation technologies.

“Automatic sheet feeders are one example, and

another, which we are seeing more of, is the use of jumbo rolls - up to 800m long - which can be left on the machine to run. Not only does this speed up production, it lowers the carbon footprint, reduces waste and boosts efficiency. Fewer changeovers mean less need for human intervention - and the economies of scale can mean much more profitable work. Automated handling, including the use of robotics for pallet-to-pallet loading and unloading and the lifting of heavy rolls (up to 1 tonne) is speeding up production and reducing the need for human involvement.

“Ink refills ‘on the fly’ are also important heremaintaining constant production and ensuring that every machine is working as long as there is work for it to do. In fact, the seven-litre tanks found within the Acuity range ensure the efficiency of this process.

“Fujifilm is not yet at the point of total unattended lights off printing, but with every advance in remote diagnostics and handling automation, we are getting closer and closer. At Fujifilm we want to make our machines as productive as they can be, and continued development of remote diagnostics, automated two-way systems communication, and automated machine handling will all play a critical role,” says Ganter.

Jane Rixon, business development manager, HP Large Format, continues with the remote diagnostics theme.

“HP PrintOS is a print production operating system built into all modern HP large-format printers. As a free-of-charge software its usefulness might have been underestimated, however PrintOS can be accessed anywhere at any time, via the Web or the dedicated mobile app, making it an

WITH HP PRINTOS PRINT BEAT PRODUCTION MANAGERS CAN MONITOR THE STATUS OF THEIR MACHINES AT ANY NUMBER OF SITES, WITHOUT HAVING TO PHYSICALLY BE THERE

AS REMOTE OPERATION BECOMES MORE WIDESPREAD WE ASK MANUFACTURERS WHAT THEY ARE DOING IN REGARDS TO PRINTER DIAGNOSTICS AND OTHER TECHNOLOGICAL ADVANCES TO KEEP DEVICES RUNNING AND HELP LARGE-FORMAT PSPS OPERATING LIGHTS OFF.

essential tool for diagnostics,” she says.

“Service partners can use PrintOS to have a real-time view of any issues on the machine and look at upcoming maintenance tasks. Error notifications are sent straight to users’ phones or computers, meaning users can see where and when materials or ink need replacing.

“With HP PrintOS Print Beat production managers can monitor the status of their machines at any number of sites, without having to physically be there. At a glance, they can see the proportion of the fleet that is printing, preparing to print, disconnected or suffering an error.

“Additionally, the HP Print OS Configuration Centre allows PSPs to easily monitor their printers in case of calibration needs or additional alignment of printheads. It also notifies the product manager if there is a new update for the firmware and has it ready to be installed when available. The printer can also report to the supplies partner to let them know when the inks or media is running low, so they can ship out replacements before they run out.”

Rixon continues: “With each update to our product portfolio, we strive to mitigate issues and ensure the user experience is as seamless as possible. We are heavily investing in improving our applications and tools to optimise and automate print operations with the ultimate goal to grow new business for PSPs. With HP Print OS and HP PrintOS Print Beat, HP Click and HP Smart Stream we make sure to offer PSPs the right tools in order to ensure a seamless printing experience.”

InkTec MD Joey Kim, flags up the company’s work on remote diagnostics too, saying: “Our use of virtual remote diagnostics has become more prevalent as the number of Jetrix printers installed both in the UK and across Europe has increased. As a result, InkTec is considering further investment in a more involved remote support diagnostic tool to enhance the existing remote access we have to the Jetrix GUI software. In addition, the software could enable both parties to review images, documents or print outs that are being discussed and shared as part of a video conference.”

He adds: “Offering remote support for our customers has always been part of our service. However, as we move forwards, the sophistication and depth of detail we now want to offer remotely means we are investing in even more superior technology. To achieve this, we have to expanded our team of Jetrix technicians as it makes no sense to have the infrastructure available without the people to actually offer that support. As a result of reducing the need for non-essential travel, means we can help more customers and contribute towards reduce our carbon emissions too.”

Duncan Smith, production direct sales director, Canon UK and Ireland, says it is also “focused strongly on automation technology through our R&D. This helps us to ensure that we are offering customers technology that will allow them to keep their production workflows running 24/7”. He points out that at Fespa Global earlier in the year Canon launched the Prisma XL Suite to support workflow automation, adding: “Our Prisma remote app enables unattended printing, allowing Colorado customers to run their printers overnight, see the status of their devices and receive alerts about any errors or warnings via their smartphone or tablet.

“Through Prismaservice our engineers are able to

remotely collect, analyse and evaluate print data to help maximise uptime at the customer’s site. We also work with One Vision to support large-format PSPs or print factories that receive daily print jobs from multiple sources.

Smith highlights too: “We work closely with technology partners such as Zund and Fotoba so that we’re able to provide complete end-to-end solutions that will help allow 24/7 production 365 days a year - one result of that collaboration being the UVgel Wallpaper Factory, which provides a fully automated solution for print factories that specialise in digital wallpaper production. The entire production process is supported from printing to shipment, offering maximum output whilst maintaining flexibility in finishing options.”

At Roland DG Peter Waelkens, product manager software, acknowledges the increase in remote working seen across many industries over the last couple of years, saying that “print shops have adjusted their processes and workflows and, alongside Teams and Zoom, have also leveraged remote repair, maintenance and printing functionality that - until Covid-19 - was a largely underutilised feature set. This includes remote VPN logins, hot folders in Rip software as well as tools like Roland DG’s OnSupport which allows users to quickly access machine usage metrics, firmware updates and product information through a PC or smartphone.”

He enthuses: “Within Roland we see great benefits of bringing devices online so have developed a cloud-based service, Roland DG Connect, which allows users to monitor the print status while away from office. When partnered with a compatible device (currently select TrueVis and VersaUV models) Roland DG can help solve or prevent many of technical issues which can slow down or halt production.

“The software, available on mobile or desktop, can monitor printer status and condition - recognising patterns in production and printer state to identify potential problems before they happen. It can also send notification of when key maintenance should be performed and give an overall health status of the connected device. What’s more, through Roland DG Connect users can grant their authorised dealer access to their machine, who can monitor and analyse online the machine’s status and even plan pro-active support based upon the collected information, keeping the machines online for longer.”

Waelkens also points to other features found on Roland printers to aid PSPs aiming for lights off operation, such as the adjustable take-up unit included as standard on the TrueVis VG3, plus an optional new dryer/blower to support media drying for TUC even in high-speed mode, allowing for long runs with a controlled print length to be left unattended. Moreover, when the take up unit is combined with the printers Perfcut and separation cut functions, the post-print finishing process is minimalised.

“In the future, we expect to see more manufacturers offering additional smart device integrations to offer services such as help and support directly from the printing device screen or remotely via an app rather than calling a helpline, prompts to order supplies allowing PSPs to minimise stock and ensure they never run out of key materials even when not on-site - and voice control, which will allow them to talk to their printer like you do with domestic smart devices,” adds Waelkens.

PRINTERS HAVE LEVERAGED REMOTE REPAIR, MAINTENANCE AND PRINTING FUNCTIONALITY

THAT, UNTIL COVID-19, WAS A LARGELY UNDER-UTILISED FEATURE SET

“We see resellers still having to spend time convincing print users to move to more automated finishing processes.” So says John Draycott, marketing manager at ArtSystems, which together with its partners is one of the biggest suppliers of large-format print finishing systems in the UK, so having him say that PSPs still need to be convinced to automate their finishing departments may be somewhat surprising given that for so many production efficiencies are a key focus, and as Draycott stresses, “the print finishing workflow is logical place to improve as it reduces waste and time dramatically”.

He adds: “The whole print workflow is under constant review, and many print companies have invested in software to help manage print from start to finish, so automating the final print finishing is the next step.

“Also, the pressures to reduce waste and to have full life cycle visibility means that print finishing has be more automated and manageable. All manufacturers are looking to make their finishing devices easier to use and to integrate into the full workflow, and that will accelerate over next few years.”

Earlier this year Josero received Summa Cutter Partner accreditation, enabling it to offer consultations and advice on the full range of Summa products. Sarah Winterbottom, group sales director at Josero, builds on Draycott’s message: “As wide-format print technology evolves, with print speeds advancing all the time and automation reducing production downtime, the finishing department can often be the bottleneck when it comes to moving jobs through and out of the building efficiently - even more so if you outsource some or all of your finishing. Everyone’s focus is now on efficiency and lean manufacturing as

The Elitron DL45

maximising capacity and profit is crucial. The finishing technology in wide-format is also progressing, but perhaps not on a par with the print itself, so further R&D investment would be welcome to ensure the entire production process is optimised.”

Elitron says it will continue to invest in automation surrounding both printing and finishing in order to present new automated systems at Fespa Global 2023, and that: “Our focus is very much on automation in order to give our customers maximum flexibility. Not only does automation allow for greater productivity, but integration between both the printer and the cutting system and the printer and the loading/unloading system means that operator time is freed up to concentrate on specifically manual tasks.”

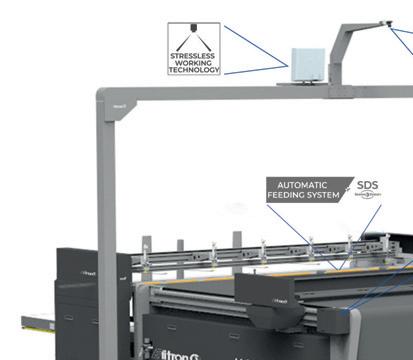

Fespa Global 2022 this spring meanwhile saw Elitron launch in-line automation for the large-format, multi-function Kombo SDC (3200mm width) conveyor cutting system, for roll and rigid media. The automatic feeding system not only seamlessly feeds the Kombo cutting system but it also incorporates a new vision system, the SDS Seeker System. This compliments the patented dual camera system to add further camera underneath the tabletop, to scan the materials directly from the underside.

All printed materials can now also be cut and creased with the print side facing downwards, without any operator intervention, as all images are all centred and aligned automatically, prior to being cut. This is in addition to the patented Seeker System Pro which scans, aligns, cuts and creases from the top side, using the two digital cameras - one on the cutting head and the other on the overhead frame.

In addition, Elitron also introduced the Digital Multi Degree (DMD) module with both motorised giant circular blade and V-Cut blade options, and a new DL45 tool and a new automatic bit changer for the milling module at Fespa Global 2022.

The new DMD module promises to take creativity to the next level. Using either the giant, motorised circular blade of up to 200mm in diameter, or the V-Cut tool, both make light of cutting all honeycomb materials, with the possibility to digitally set the angle of the tools to suit the job in hand. The new, twin 45 degree blade tool is the latest, patented tool from Elitron. In one single pass, a clean 90 degree cut is created, thus cutting V-cut production times in half! It’s possible to start V-cutting anywhere on the sheets, as the independent blades are electronically controlled. The same DL45 tool can also be used in the traditional V-cut mode, with only one single blade, for maximum flexibility and complete creativity.

Fespa Global 2022 visitors also got the chance to see the fruits of a new collaboration between Kongsberg Precision Cutting Systems and OneVision Software. The pair have developed an integrated automation system that

THIS HAS HARDLY BEEN A YEAR OF MAJOR INNOVATION WHEN IT COMES TO LARGE-FORMAT FINISHING SYSTEMS, BUT IN A BID TO BRING YOU UP TO SPEED WITH THE ADVANCES THAT HAVE TAKEN PLACE IN 2022 WE ASKED SUPPLIERS TO FLAG UP WHAT THEY’VE ADDED TO THEIR OFFERING, AND ALSO WHERE THEY FEEL THERE IS STILL THE MOST NEED/SCOPE FOR FURTHER DEVELOPMENT?

at the show was used to demonstrate how an end-to-end workflow delivering consistent data can maximise digital finishing efficiency.

“Every converter wants their table to be running as close to 100% of the time and have as little downtime as possible,” says Koen Van Reybroeck, product manager at Kongsberg PCS. “They also want quality end products every time, regardless of who is operating the machine. The key to achieving this is consistency in the data sent to the machine and standardisation based on the materials being produced.

“To get the best performance from our i-cut Production Console (iPC) and the table, the user wants to send additional metadata with the cut file,” Koen explains. “For example, the name of a substrate that will be used for producing the job. By focusing on the material, we can then standardise and optimise, automatically applying tools and settings that give the best cutting result. We refer to this as our ‘material is key’ way of working, ensuring a consistent file input quality, correct material and tooling presets and full unattended machine production.”

OneVision business development manager Sacha-Vittorio Paolucci adds: “The OneVision software can be easily integrated to automate and standardise all production steps from entry to finishing. With the smart connection to the Kongsberg cutting table, print and cut files are automatically checked and optimised. Market-leading nesting technology and cut line management prepares the files optimally for further finishing. This means that manual interventions thus become unnecessary, and processes are more efficient due to a substrate-saving production.”

Koen says that the focus of the integration is automation, both in file preparation and also on the cutting table itself. “With the Kongsberg-specific output formats and the integration of the Connect to Kongsberg module, OneVision users can now automatically push

Salary according to age and experience.

Apply by mailing CV and salary history to: kam@etcltd.co.uk

No Agencies.

files to iPC and import them in a consistent way onto the cutting tables.This also enables an operator to perform full, unattended production, freeing their time and further boosting efficiency and productivity.”

OneVision’s software solution also allows barcodes (QR) to be automatically added to the print file, helping speed up the production process as iPC can then load, prepare and start the different jobs automatically on the table, whether roll or sheet-fed production.

“This smart workflow offers standardisation in iPC based on materials and tooling presets, delivering consistent cut quality independent from operator experience, as well as a more economical production for print service providers,” stresses Koen.

Also new to the UK in 2022 is the Moditech EWS Electronic Work Station, Swedish designed and manufactured by EWS and introduced here by Your Print Specialists in August.

With a working width of 1750mm and three available lengths, the Moditech flatbed is available in two models, the X2 and X4. Both models feature electronically controlled legs allowing the height to be adjusted at the touch of a button, which makes it easier to achieve a comfortable working position which in turn can have a positive impact on operator wellbeing. The table can also be tilted up to 25 degrees depending on the task at hand and, with a foldable glidebeam, the full table space can be utilised.

The EWS is user friendly and ergonomic with a range of features to aid the user. The electronically controlled pressurised roller ensures an accurate and even pressure along the entire length of the roller. This allows the operator to work anywhere on the table without the need to stretch towards the middle. Storage shelves and recessed grooves for cutting are on both sides of the table for added ease. With optional extras such as an LED backlit surface, remote control and heated roller, the EWS can be built completely to specification. Each EWS is packed and delivered vertically with just a 78cm width and 190cm height, making installation into small spaces easier.

YPS MD Georgia Brown concludes: “As soon as we saw this product we knew we wanted to offer it. From the quality of work and reduction of waste to the overall health and wellbeing of operators, this is a bit special.”

Vivid flags up the Zip Core Design Pro CAD/CAM packaging software that has been developed to enhance the use of the Veloblade Nexus range of wide-format digital die cutting systems. It offers a library of parametric models and packaging designs, including ECMA, FEFCO, corrugated Board and more - plus a library of FSDU displays designs which includes POP and POS.

Position now vacant at Electro Tech Colour Ltd. Established in 1994 we are based in London N7 (www.etcltd.co.uk). We are Looking for an experienced print Finisher, with Production experience. Must be able to use Seal Image 42 plus and Seal 62 Pro. Cold/hot sealing. Energetic and enthusiastic candidate with Previous experience in Hoarding graphics, portable displays, canvas wraps and cut vinyl graphics. Opportunity to work on site and Surveys with installation experience an advantage. Ideal candidate has a proven industry track record, maybe looking to progress into production. Liaising with the print department and clients to ensure jobs are tracked finished and delivered to a high standard.

ALL MANUFACTURERS ARE LOOKING TO MAKE THEIR FINISHING DEVICES EASIER TO USE AND TO INTEGRATE INTO THE FULL WORKFLOW, AND THAT WILL ACCELERATE OVER NEXT FEW YEARSThe Moditech EWS Electronic Work Station

THIS SECTOR IS TO BE APPLAUDED FOR THE EFFORTS IT’S MAKING IN BECOMING MORE ENVIRONMENTALLY CONSCIENTIOUS, BUT PERHAPS WE NEED TO ASK OURSELVES SOME DIFFICULT QUESTIONS BEFORE WE START CLAPPING OURSELVES ON THE BACK. WALTER HALE CONSIDERS...

Climate change is like the sun - you can ignore it, but it isn’t going away. Although the the passing of QEII, the cost of living crisis and the war in Ukraine have knocked global warming off the front pages, and governments - especially the UK’s - are prevaricating about what they know needs to be done, the threat posed by catastrophic climate change is growing.

It has to be said that celebrities are hardly setting a great example. Kylie Jenner’s infamous 17 minute flight was rightly condemned as showing “absolute disregard for the planet”, but various studies have suggested that the CO2 emissions from her private jet were lower than Taylor Swift’s who has, in the first seven months of this year, emitted the same amount of what, on average, 1,184 people do in a year. All of which provokes the inevitable thought: why should I bother?

And yet a university study says that is nonsense. Even as individuals, if we make a series of lifestyle changes, we could reduce carbon emissions by 25%. The key changes we need to make vary from the problematic (living without a car) to the eminently manageable (using renewable energy, encouraging staff to use public transport, taking one less long-haul flight a year).

That is not a bad outcome in itself but what’s more, such changes can help generate momentum, encouraging peers, competitors and customers to make sustainable choices. As David Kester, managing director of the strategic design consultancy DKA, says: “This is an existential crisis for humanity that will not be solved by a single innovation but by a thousand innovations. What we need is an army of innovators with solutions to resolve this.” So, no matter how insignificant your individual actions might seemwhether it be collecting and recycling customers’ waste or ensuring that your printer supplier is reclaiming yours - it really is making a difference.

As Friends of the Earth eloquently puts it: “Individual action doesn’t detract from systemic and structural change. It deepens and expands it. In other words, individual action can be part of the behaviour change process.” The charity goes on to say that we shouldn’t let other behaviourwhether by celebrities or companies - make us apathetic, for “time and time again, caring, protest and campaigning has led to significant social and structural change”

So how do print service providers make a difference? A good start, as Friends of the Earth indicate, is by avoiding the language of ‘greenwashing’. The word was coined back in 1986 by American environmental activist Jay Westerveld in an essay on the hotel industry. Westerveld was distinctly unimpressed by the increasingly common practice in the industry of encouraging guests to reuse towels to protect the planet when, in reality, the real goal was to reduce laundry costs. This eco-friendly attitude was not, he noted, reflected in the minimal efforts to reduce energy usage.

ENVIRONMENTALLY AWARE BUYERS WILL ASK THEMSELVES WHETHER A PSP IS COMMITTING ONE OF THE SEVEN DEADLY SINS OF GREENWASHING

So, if you are not to be accused of similar hypocrisy, terms such as ‘green’, ‘eco-friendly’ and ‘sustainable’ need to be backed up with facts. The evidence could be the appropriate certification or a link to your website, and your mission statement in sustainability, so that customers can make a judgement for themselves. In a nutshell, the more specific you can be about your present carbon impact, how you try to minimise your environmental impact and what your future goals are, the better.

Environmentally aware buyers will ask themselves whether a print service provider is committing one of the seven deadly sins of greenwashing, as identified by the consultancy Terra Firma. These comprise vagueness, lack of proof, hidden trade-offs (claiming a product or service is green based on a very narrow set of attributes and ignoring all others), false labels (of which more later), irrelevance (quoting an impressive sounding statistic that really has no bearing on a product’s environmental impact), declaring that something is the lesser of two evils (a car using unleaded petrol may be greener than one running on diesel but it is not eco-friendly in any real sense) and outright lies (which, fortunately, are less common than they used to be.)

While achieving net zero emissions by 2050 is a laudable aim, businesses - especially large public companies in, for example, the retail and fmcg sectorsare looking for something more compelling that doesn’t feel like greenwashing. Many net zero strategies fail to convince because, when you look beyond the headline pledge, the company concerned seems to talk a lot about offsetting and less about reducing emissions (the oil and gas companies are particularly bad at this).

Ideally, according to America’s Sustainable Green Printing Partnership, your statement should cover six key areas: energy efficiency (which, if you broadened the definition somewhat to ‘resource efficiency’ could also include water), waste reduction and recycling, environmental compliance, responsible labour practices, process efficiencies and operational excellence. It’s probably worth exploring a couple of these areas in more detail.

Traditionally, sustainability has been all about the environment but, during the pandemic and lackdowns, a broader agenda called ESG (Environmental and Social Goals) gained momentum. The public became critical of companies that failed to look after their staff in difficult times and that attitude has persisted.

There are plenty of examples of companies continuing with irresponsible labour practices - P&O Ferries being the most notorious example - but these employers are more likely to suffer a backlash from consumers, brands and, as we have increasingly seen, regulators and governments. Whether you think the British government was really as tough on P&O as it claimed to be or not, the fact that a Conservative administration felt obliged to make the effort

is emphatic proof of a change in the public mood.

And what of operational excellence? This is basically the bit where you talk about your ongoing commitment to sustainability and outliner future plans and commitments. Many wide-format print service providers have already begun this journey with some simple steps - environmental accreditation, carbon auditing, electric vehicles, recycling materials and waste. As part of this process, it is imperative that printers identify, interrogate and use the right suppliers.

What, for example, are the likely lifetime emissions of that new wide-format printer you’re eyeing up? (And by lifetime, we mean including the emissions produced during manufacture.) Some suppliers are better at providing the information than others but the more often they are asked, the more likely they are to seek some answers. Many printer suppliers, notably HP , offer schemes to take back printer waste, not just used cartridges but the machine itself. This is exactly the kind of detail that adds authenticity to your environmental stance, persuading clients that you aren’t just saying the right things.

There is a visual dimension to greenwashing too. One of the most egregious corporate examples is BP which still, in its marketing campaigns, has tried to rebrand itself with the slogan ‘Beyond Petroleum’. In 2000, this repositioning was symbolised in a new logo in which the traditional shield was replaced with a sunburst, an emblem that had long been used by the German Green Party. This exercise seemed a little cynical - especially when ‘The Guardian’ revealed, in 2015, that many of the group’s investments in low carbon technology and green energy had been sold off. Yet more recently, BP has sold some major fossil fuel operations leading some analysts to conclude that it is finally getting serious about renewable energy.

To be fair to BP , the group’s greenwashing looks pretty mild when compared to the likes of Volkswagen (which once assured us that “Diesel has really cleaned up its act” even while it was cheating emissions tests. The American bedding company Moonlight Slumber was in a class of its own when it came to greenwashing, promoting its mattresses with a Green Safety Shield icon it had invented itself! Funnily enough, the regulators took a dim view of this practice, and ordered the firm to drop the label.

This is one reason why print service providers may eschew the obvious colour when trying to emphasise their environmental strategy. Let’s face it, turning your logo green is not exactly subtle is it? Instead of emphasising your commitment, it may lead more discerning print buyers to conclude that you are protesting too much.

The best way to avoid being accused of greenwashing is not to make claims that you can’t substantiate, be clear about your goals and admit where you have to do better. Customers will find that far more credible than the kind of over-promising that has, over the past decades, eroded our faith in politicians. So let’s all get to work - we have a planet to save.

IT IS IMPERATIVE THAT PRINTERS IDENTIFY, INTERROGATE AND USE THE RIGHT SUPPLIERS

Authored by former print professionals, Image Reports provides intelligent news coverage which targets those that produce and sell wide- and grandformat digital print.

Dedicated entirely to the digital print provider rather than the manufacturer or supplier, Image Reports presents information via three main filters – business, technology and the environment.

Also part of the Image Reports family is Widthwise Report, an annual survey and report on the state of the UK and Irelands wide-format print sector which is packed with facts, figures and features.

www.imagereportsmag.co.uk @imagereports

Please contact Carl to discuss advertising and sponsorship opportunities: Tel: 0791 606 7589 Carl.Archer@imagereportsmag.co.uk

Leeds-based Imageco and client Syn Retail worked together on POS and interior branding for the new interactive Dr Martens test and learn concept store on Carnaby Street in London. Imageco has relatively recently become a certified carbon neutral printer, helping Dr Martens meet the sustainable brief set out for the store.

Antalis made the finals of the World Exhibition Stand Awards 2022 with its ‘Sustainable Street’ stand (used at the VM & Display Show), for which every element was made using substrates from within the company’s eco-friendly substrates portfolio.

MacroArt and sister company Aluvista delivered the design, print and framework production for the Pokémon World Store at this year’s World Championships in London’s ExCel, as well as the installation and derigging pre- and post-show.

Artworks Solutions worked alongside Claremont Group Interiors to deliver a variety of graphics for key walls and lightboxes in communal areas throughout the seven storey Flutter HQ in Dublin.

Universal Graphics picked up the brief for this lift wrap at the UPMC Sports Medicine Clinic in Thurles.

please to

When?

EVENTS1 November, 2022

Where?

Stationers’ Hall, London

Cost?

£199 for the seminar, £299 including dinner

Every October, the senior leadership team at Mole Graphics - all four of us - force ourselves to contemplate what the year ahead might bring.

For 2023, there will probably be a Coronation ceremony - which ought to be organised by the team behind ‘Downton Abbey’ - that might give Britain’s mood and economy a much needed lift. We certainly need something to look forward to. The UK economy is forecast to grow by a meagre 0.2% next year, bouncing back - to use the phrase quite wrongly - to expand by 1% in 2024. That is a fraction of the growth predicted in those European economies - such as France and Italywe like to be so condescending about.

For the past few years, running a business in Britain has felt like being repeatedly bludgeoned over the head. While you recover from one blow (like the pandemic) you get hit again (Brexit-related chaos) and again (runaway energy bills). There is also, at the back of my mind, a nagging fear that the pandemic-induced recession may have tipped the balance against print. The shift has nothing

to do with the environment, it’s all about saving money. If a supermarket can print fewer signs in-store, why wouldn’t they? These cutbacks could exacerbate the shrinkage caused by shop closures.

I went back to the ancestral seat the other day and walked around the town centre for the first time in years. One of the main streets was so dilapidated it looked as if the Luftwaffe had returned recently and tried to finish the job they started in 1941. Store closures are lower than at any time since 2017 - 34 a day, on average apparently - but it’s rare to find a high street without ‘To Let’ and ‘Closing Down Sale’ signs.