Editor: Lesley Simpson

lesley.simpson@imagereportsmag.co.uk

Production / Design: Alex Gold

Publisher: Wayne Darroch wayned@sjpbusinessmedia.com

Advertising Manager: Carl Archer carl.archer@imagereportsmag.co.uk Tel: 07723 079928

SJP Business Media, 2nd Floor, 123 Cannon Street, London, EC4N 5AU www.imagereportsmag.co.uk

For circulation enquiries contact: SJP Business Media Email: subscriptions@sjpbusinessmedia.com

Image Reports is available free to printers based in the UK. Register at www.imagereportsmag.co.uk/register.

To purchase a subscription please visit www.imagereportsmag.co.uk/subscribe –UK £54, overseas £84

Printed in Great Britain. No part of this publication may be reproduced, stored in a retrieval system or transmitted by any means without the Publisher’s permission. The editorial content does not necessarily reflect the views of the Publisher. The Publisher accepts no responsibility for any errors contained within the publication.

New Sign Awards announced for 2023

Xaar has “most significant product launch in recent years”

Fujifilm Europe appoints workflow and solution consultant

Hybrid shows off major upgrade to its SmartDFE

William Smith brings out new PVC-free digital print film

New Screen innovation centre to open spring 2023

Vanguard Europe unveils new headquarters

PrintFactory enters technology partnership with AVA

Serif brings out Affinity Version 2 creative software

SAi extends Sign Design Elements image library

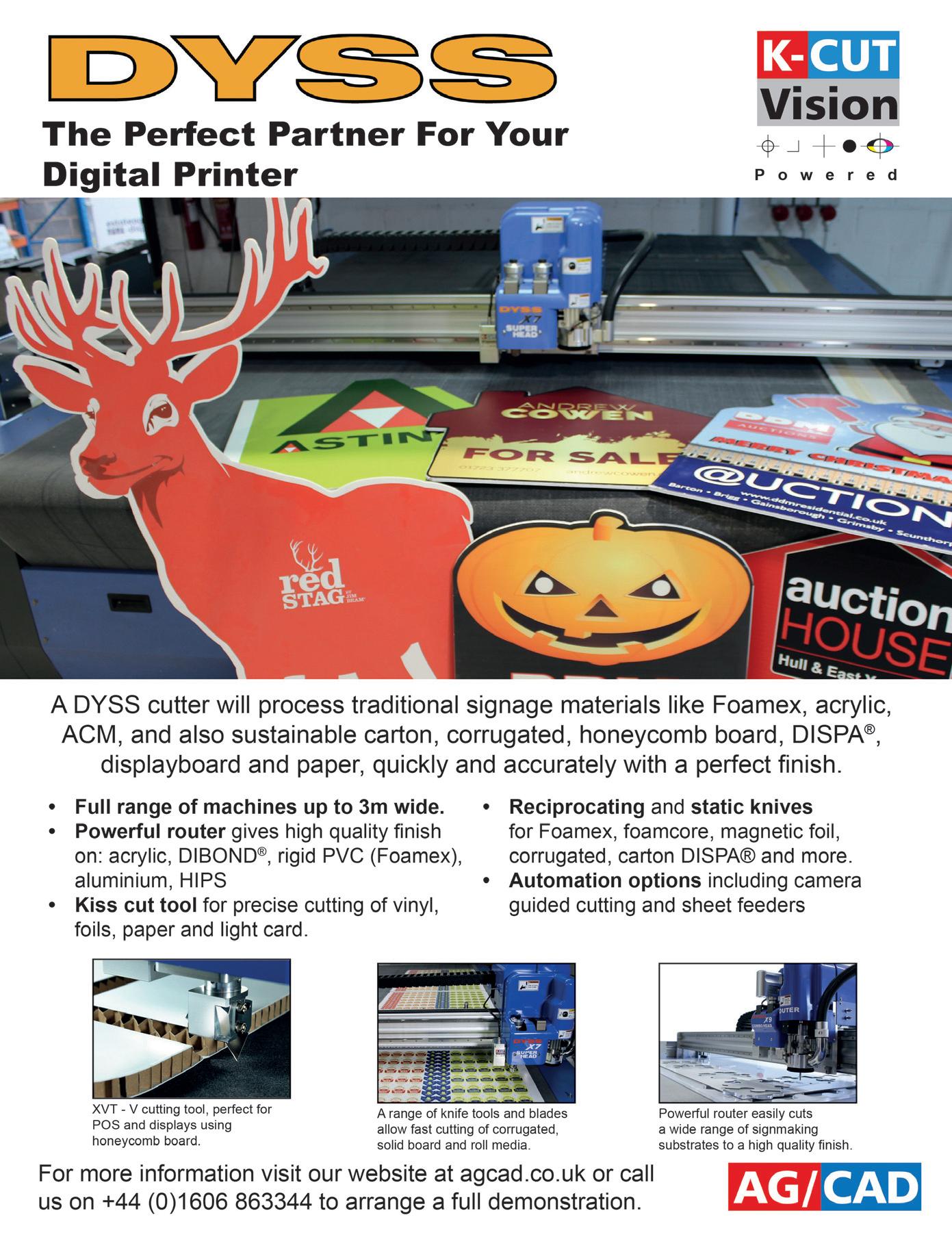

EFI launches corrugated media management for Vutek h5

KGK Genix waste recycling plan helps local school

Expectations for Q4 have deteriorated shows BPIF research

First EFI Vutek XT installed at US company IES

Soyang appointed distributor for Meevo sewing machines

ESMA to run ‘Digital Textile Printing’ courses

Spandex UK now stocking ImagePerfect EverGreen films

Soyang to distribute InkTec’s Jetrix LXiR320

Colorado 1650 UVgel ink approved for 3M MCS Warranty

Color-Logic certifies Vanguard VK300D-HS flatbed printer

Acorn Press expands POS offering

Mimaki brings out 3l ink supply for the JFX600-2513

WTTB sets up personalised merchandise service

New solvent Nazdar inks for Mutoh ValueJet printers

MacroArt accelerates its apprentice drive

GIS adds drive electronics support for Epson S800 Series

ColorGate hires focus on packaging and textile business

UPM gets closer to its ambitious environmental target

Shabby storefronts turn off customers says Roland poll

Screen shows water-based inkjet packaging printer

New inkset from Mutoh

David Preskett takes up leading role at Kongsberg Antalis adds categories to its interior design awards

Made Smarter, a programme that has backed 2,500 SME manufacturers to adopt new digital technology and skills to create growth and jobs, has secured £6.1m funding to continue for three more years.

The initial adoption programme in the North West has helped small and medium-sized companies start their digital journey by providing them with specialist advice and a digital roadmap to help them select the right approach, level of investment and tools for their business. More than 250 of them - including several in the print and packaging sector - have invested in new technology, ranging from software and sensors to robotics and extended reality, to become more efficient, build resilience, increase their productivity and

grow sustainably. As a result, Made Smarter said the companies it has supported are set to create 1,250 new jobs, upskill almost 2,300 existing roles, deliver an additional £176m in gross value added to the region, and help the UK meet its net zero target by 2050.

Now with a further £6.1m funding from the government, Made Smarter can accelerate its drive to support hundreds more SME manufacturers to embrace the industry 4.0 movement.

Following on from the work in the North West, the national roll out of the Made Smarter adoption programme now includes the West of England and East Midlands as well as the North East, Yorkshire and the Humber, and the West Midlands regions.

Epson has brought out its first 6-colour 44in-wide dye-sublimation printer, the SC-F6400H. At the same time it launched the 44in-wide, 4-colour SureColor SC-F6400, said to be 20% more productive than its predecessor, the SC-F6300.

The SC-F6400H provides an extended colour gamut by offering the use of CMYK, plus a choice of

either fluorescent pink and fluorescent yellow, light cyan and light magenta or orange and violet.

Both the new machines - designed for low to medium-volume printing - use 1.6l ink packs to minimise replacement frequency and waste. The printers also feature a new 4.3in touch screen. The SC-F6400H includes a bundled take-up reel too.

South Korean-based Inktec is expanding its European operations with dedicated fulfilment hub in the Netherlands.

Working in partnership with the Busan Port Authority (BPA), a new logistics warehouse occupying 30,000m2 in the Port of Rotterdam has been built.

Preston-based Optimum Signs is to launch a new division that will involve the exclusive distribution of key products primarily aimed at the events and hospitality sectors. The company - which in the first six months of this year surpassed last year’s figures, making this its eighth year of growth - is expanding its large-format services which it aims to be 50/50 trade services.

The moves come on the back of investment in staff and kit - a new general manager will allow senior

swissQprint presented the Karibu 2 roll-to-roll printer at the Printing United Expo 2022 in Las Vegas. It can achieve up to 1350dpi, accommodates rolls up to 3.4m wide and uses flexible, NVC-free and Greenguard Gold certified UV inks.

“We took proven and popular features from the first generation and have now augmented them with the

project manager Darren Watt to step back from production and focus on R&D and sales, and there’s a new Canon Colorado 1650, supplied by CMYUK.

Prior to the installation of the Colorado, Optimum was running six older Mimaki printers, three of which (2 x solvent and 1 x UV) have been replaced by the Colorado. Other equipment in the company’s plant list includes a Kongsberg digital cutting table, Mimaki JFX 500 flatbed and Mimaki UJV 55-320.

The purchase of the Kongsberg digital cutter in

The new hub is a BREEAM sustainable, meaning it has been constructed as sustainably as possible and reduces its impact on the environment.

As a result of the relationship with the BPA, InkTec can now bulk distribute its solvent, aqueous and sublimation inks across Europe.

2019 helped Optimum respond to opportunites created during Covid, when it started promoting its Alfresco range of outdoor products (café barriers, parasols, planters, awnings, canopies etc). This line is expected to become turbo charged with the launch of the new division.

The future of Optimum Signs will see a business of two distinct parts. It has always manufactured traditional neon and has a department dedicated to the bending of glass for this portfolio.

latest printhead technology”, said Carmen Eicher, chief of sales and marketing officer.

swissQprint offers a dual roll option for the machine, capable of handling two rolls each up to 1.6m wide. The roll holders are split into two sections with each half of the shaft driven individually to ensure optimum web tension.

The Karibu vacuum plate is divided into 136 individually operable segments. Within four seconds, the vacuum can be selectively adjusted, whatever the roll width.

A light box is based next to the printing area and a mesh kit is also integrated beside this. For media that needs to be printed front and back, swissQprint offers an automatic double-sided printing function.

Fujifilm and Barberán are working together to bring a high-speed, single pass inkjet printer to market in late 2023.

A number of sign and display businesses have already signed agreements to take the first machines, which will print up to 1.6m wide at speeds of up to 6,000m2/hr.

Following extensive talks over two years, Fujifilm has agreed terms for a joint development with Spanish manufacturer Barberán, which has established its credentials for high productivity

Fespa UK Association is seeking a print company to take part in a trial to remove foamboard from landfill and be processed for granulation then delivered for re-manufacturing.

The participating printer must have a considerable amount of waste Foamboard to take part in the trial, which is intended to extend the association’s recycling programme that it is running in partnership with Reconomy. The aim is to build a network of printers and suppliers that will enable more sustainable processing options for printed materials. Solutions for several difficult to recycle waste streams have already been established, with one UK supermarket chain being able to recycle an estimated 346 tonnes of used banner waste - equivalent to 2,175 1100 litre wheelie bins.

industrial presses for the corrugated market over the last ten years, with 30 customers in North America alone.

This new partnership combines Barberán’s manufacturing expertise with Fujifilm’s knowledge of inkjet integration, ink chemistry and its experience in the sign and display market.

The 30m long printer will use a new Fujifilm ink and primer - developed at its factory in Broadstairs, UK - making it suitable for printing to onto all typical sign and display substrates,

including plastic and particleboard, up to up to a width of 1.6m.

David Burton, business and commercial director at Fujifilm WFIJ HQ, said: “We’ve been in close talks with Barberán for more than two years because they have a huge amount of expertise in industrial print manufacturing. They already have a single pass product that is proven in the corrugated sector, and we have the expertise to help them adapt it for the very different requirements of the sign and display market.”

Mutoh Europe has unveiled the XpertJet 1682SR Pro (64in/1.6m) sign and display printer. The new machine carries two AccuFine HD printheads (each with 3200 nozzles drop mass range 3.4417.71pl), a new weaving algorithm and Mutoh’s VerteLith Rip software to deliver high quality output at speeds up to 35m2/h.

The new printer uses a new Mutoh MS51 quick dry CMYK inkset, which is gBL free, Greenguard Gold certified, and said to deliver excellent gloss preservation and weather resistance, abrasion and chemical resistance with UV durability up to three years without lamination.

Manufactured in Japan, the XPJ-1682SR Pro is an addition to Mutoh’s XPJ-1341SRP and XPJ-1641SRP single-head models released in January. Product highlights include: nozzle area select, which allows the disabling of nozzle areas

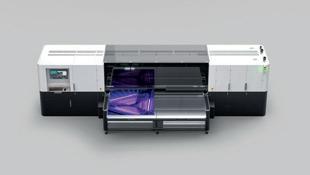

A new HP Latex 2700 3.2m wide printer range has been unveiled, the HP Latex 2700W including what the company is calling its ‘whitest white’. A range of HP Professional Print Service Plans have also been introduced to help PSPs improve workflow monitoring.

The new printers run at up to 89m2/hr via symmetrical double printheads, which come equipped with automatic printhead cleaning technology.

All devices in the series run on fourth generation HP Latex ink - bringing UL Ecologo certification, while also meeting UL Greenguard Gold and Toy Safety requirements. The HP Latex 2700W printer includes white, and runs at up to 54m2/hr.

The whole portfolio takes HP Eco-Cartoncardboard-based ink cartridges that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop recycling process. Automatic ink recirculation and white printheads that can be stored in an offline rotating chamber eliminates waste between white jobs.

The HP Professional Print Service Plans - Basic and Plus - each contain new and enhanced features:

- Print Beat Live Production - gives users a realtime view of all jobs queued and in production across multiple sites.

- Print Beat Jobs API - makes printer data available to businesses’ external ERP/MIS systems.

on the head to continue printing; new generation i-screen weaving technology to suppress banding; new VerteLith Clear Tone Screening to deliver the better gradients and skin tones; ICC substrate profiling; soft proofing; workflow efficiency and finishing tools; and companion workflow software for print-to-cut applications.

There is motorised take-up (30kg, 40kg, 100kg), automated bi-directional alignment, automated media feed adjust and media roll length management (through bar code print/ scan).

Options include an automated nozzle check unit, whereby missing nozzles will be automatically detected, attempt recovery via cleaning and, if needed, automatically activate the Nozzle Area Select feature to continue production, without the need of an operator intervention.

- HP Learn - a digital learning platform with free and premium training modules depending on the service plan PSPs choose

- Enhanced HP Service Center - proactive troubleshooting to improve uptime, including smart diagnostics that alert service representatives when action is needed

Meanwhile, UPM Communication Papers is collaborating with HP to pilot a new generation of digital printing papers specifically designed for highspeed inkjet printing technology.

The new ColorPro portfolio includes four treated, coated grades compatible with all existing HP inkjet printers, including the newest generation Latex machines.

Mimaki has added the TS330-1600 sublimation transfer inkjet printer to its portfolio. It’s capable of printing 69m2/hr in high speed mode, with its fastest mode reaching up to 135m2/hr.

The printer costs £23,995, which includes Mimaki’s TxLink4 dedicated textile Rip software, along with a

standard MBIS bulk ink system. Add-on options include a 10kg ink tank and a mini jumbo roll unit.

The TS330 is one of three models that make up the Mimaki 330 Series, the others being the JV330 solvent printer and the CJV330 printer/cutter. All three feature ‘Mimaki Weaving Dot Technology’

(MWDT), a Core Technology that changes the order of ink droplet placement depending on the printing conditions. ‘Mimaki Remote Access’ (MRA) is also incorporated across the series, improving ease of use by allowing users to remotely access the machine and check the operation status.

Being present online is just one part of a wider digital transformation that is changing the printing industry as we know it. It’s time to say goodbye to print, and hello to print 4.0.

The evolution of the print industry is largely down to the rise of digital technology that supports a more connected world. An industry that makes smarter decisions based on big data. For example, HP printers can now collect much more data than they did 10 years ago. Now, all that data can be processed into powerful insights that help our customers make the right decisions at the right time.

The printing industry has focused on one aspect of print 4.0 which is ‘automation’. This is to better connect printing technology and allow for a more seamless transition from when a customer places an order to its delivery. This will ultimately lead to a better customer experience, both for print providers and end customers.

Environmental policies and safety regulations are getting stricter, as well as the rising demands of eco-conscious customers. Sustainability has gone from being a “nice to have” to a key purchasing driver for consumers. The 2022 EU Directive, which came into play earlier this year, has also meant large companies will need to conduct thorough environmental and human rights due diligence throughout their value chain.

According to a study by NielsenIQ, consumers are actively seeking companies that care about environmental issues. 81% of global consumers believe that companies should help to improve the environment. And a further 85% of consumers say their purchasing behaviour has

become more sustainable in the last five years. As a result, brands are reacting to this increased demand for sustainability, as well as to investors’ sustainability concerns and new regulatory requirements, by bolstering their sustainability credentials.

In the next year, we will continue to see the industry develop large-format products and consumables designed with sustainability in mind. Current initiatives include the new HP Latex 2700 portfolio, which can improve margins without compromising on sustainability or print quality. The whole Latex portfolio takes HP Eco-Carton - cardboard-based ink cartridges - that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop recycling process, including post-consumer beverage bottles and U-validated oceanbound plastics.

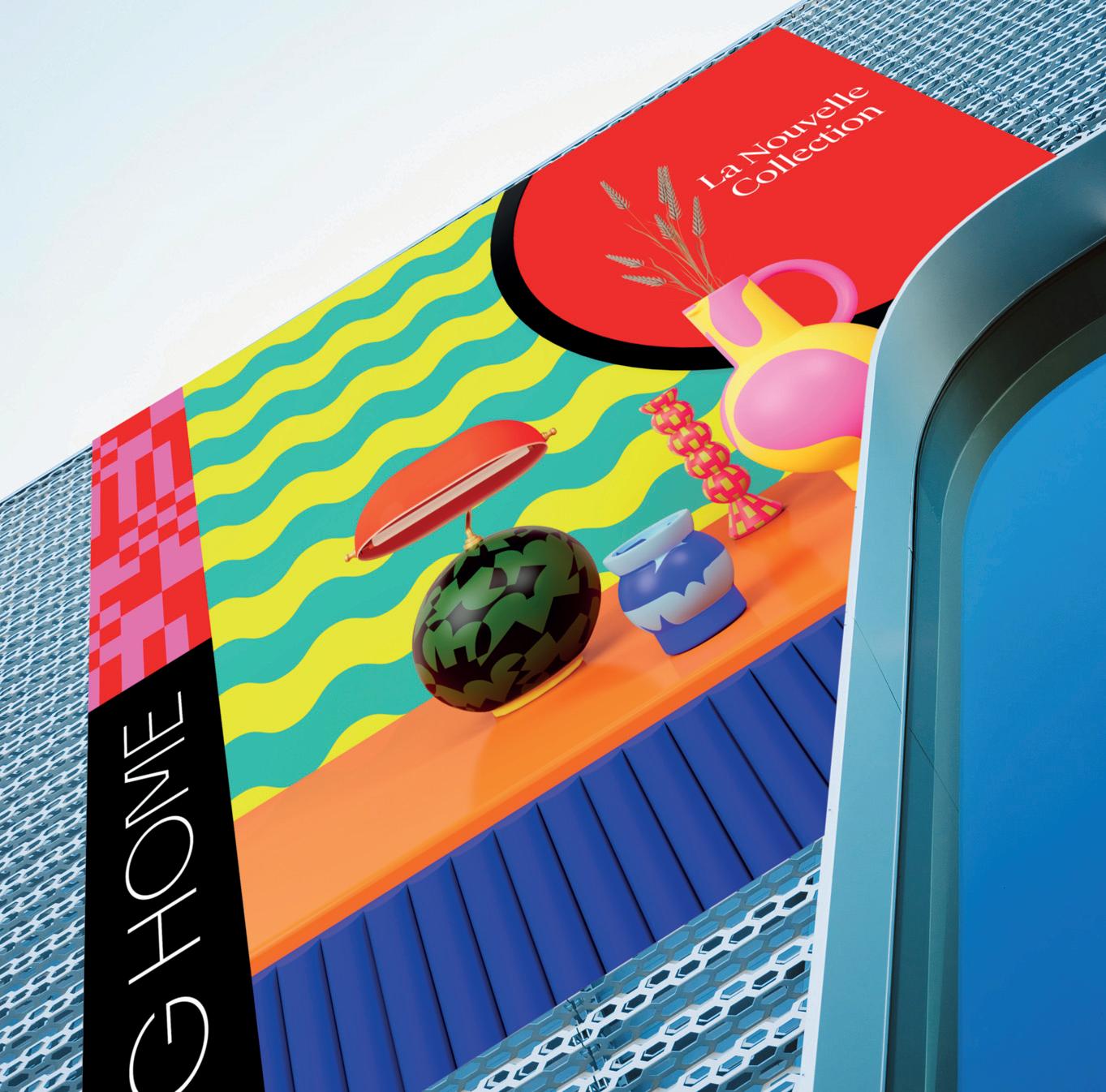

As well as stepping up their sustainability credentials, brands are also seeking to build stronger connections with consumers by creating impactful and immersive experiences in the real world. The return to offices has meant employers are also looking to reinvent their workplaces with fresh new decorations — which creates new opportunities for large-format PSPs who can meet this hybrid demand. Décor applications are set to grow 6% year on year from 2021 to 2026. As a result, we’re seeing a rise in printed décor applications and demand for high-impact campaigns

Nearly half of PSPs see diversifying their products and services as the key to future-proofing their business, according to research conducted by HP . Moving to digital

The rise of Print 4.0 in the age of digital transformation

81% OF GLOBAL CONSUMERS BELIEVE THAT COMPANIES SHOULD HELP TO IMPROVE THE ENVIRONMENT

WHAT WILL MOST IMPACT THE LARGE-FORMAT PRINT SECTOR IN 2023 AND BEYOND?

print technology will enable this transformation. PSPs must be able to deliver innovative offerings efficiently and quickly. That agility is only possible with the flexibility and speed provided by digital workflows.

We’ve seen the megatrends shaping our industry, and by combining these powerful insights, we have developed a roadmap for the future of HP Large Format Printing.

Limitless application opportunities: Our customers want limitless application opportunities. So, we promise to help them grow easily into new business premium/ high-value applications by providing key technology assets and experiences through HP Latex technology.

Streamlined production and confident delivery: Our customers want streamlined production, and the confidence of knowing that they can deliver on time. So, we promise to give them smart, connected production, with no disruptions and optimized control, through solutions that are labourless and remotely controlled, always on, and part of a digital ecosystem that enables our customers to grow and scale effortlessly.

Sustainability edge: Finally, our customers want a sustainable advantage over their competitors. So, we will ensure that every signage decision is also a sustainable decision. And everything we innovate will be safe to use, and contribute to the circular economy, protecting operators and the planet.

The new HP Latex 2700 portfolio and HP Professional Print Service Plans can improve margins without compromising on sustainability and ticks all of the above boxes.

The new 3.2m (126-in) wide HP Latex 2700 printers take production efficiency to the next level, offering vivid colours at up to 89 m2/hr (958 ft2/hr) via symmetrical double printheads, which come equipped with automatic printhead cleaning technology. Users can take on high-margin jobs with 30% wider gamut at high speed, preserving media gloss and feel across a range of signage and décor applications –including thin films, vinyl and paper.

“With the investment in the HP Latex 2700, the increased white ink capabilities allow us the opportunity to go after so many new layers and finishes which offers us new techniques,” says John Mark Watson, MD of John Mark Ltd. “We have been blown away by the results we are getting and have been showing those to designers who have been impressed by the outcome. The new white ink changes the game and takes digital wallpaper printing into a whole different dimension.

In the long term, we see that this will lead to a new trend in design, and it accelerates our position in offering quality digital printed wallcoverings. The machinery and the ink that HP supplies are not only eco-friendly but are leading in the market which also gives us a competitive edge.”

Meanwhile, the HP Latex 2700W printers offer the whitest white ink[ ] on the market at speeds of up to 54 m2/hr (581 ft2/hr), allowing PSPs to produce high-margin applications on pre-coloured and transparent media. Automatic ink recirculation and white printheads that can be stored in an offline rotating chamber eliminates waste between white jobs.

All devices in the Latex 2700 series run on fourth generation HP Latex ink - bringing UL ECOLOGO® certification, while also meeting UL GREENGUARD GOLD and Toy Safety requirements. This allows PSPs to embrace jobs in even the most sensitive environments. Additionally, the whole portfolio takes HP Eco-Carton - cardboard-based ink cartridges that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop recycling process, including post-consumer beverage bottles and U-validated ocean-bound plastics.

HP Professional Print Service Plans are designed to enable business agility, maximize uptime and productivity, and to provide learning opportunities and support.

PSPs have a choice of two different HP Professional Print Service Plans – Basic and Plus – with each containing a portfolio of service and software solutions tailored to business needs. New and enhanced features include:

• Print Beat Live Production – giving users a single, realtime view of all jobs queued and in production across multiple sites. This helps monitor work, anticipate issues, and save precious time

• Print Beat Jobs API – making printer data available to businesses’ external ERP/MIS systems. Monitor HP printers alongside non-HP hardware, automate processes and combine with other operational data for richer business insights

• HP Learn – a digital learning platform with free and premium training modules depending on the service plan PSPs choose, allowing users to upskill and keep ahead of challenges

• Enhanced HP Service Center – proactive troubleshooting to improve uptime, including smart diagnostics that alert your service representative when action is needed

Get in touch with your HP sales representatives who can advise you on the best printer to suit your needs. Call +44(0)8004084348 or send an email to: andy.white@hp.com

85% OF CONSUMERS SAY THEIR PURCHASING BEHAVIOUR HAS BECOME MORE SUSTAINABLE IN THE LAST FIVE YEARS

HAS MUCH CHANGED DURING THE COURSE OF THIS YEAR - AND WHAT DO WE EXPECT 2023 TO BRING? THAT’S WHAT PSPS AND SECTOR SUPPLIERS DEBATED IN TWO RECENT VIRTUAL DISCUSSION GROUPS HOSTED BY IMAGE REPORTS TO ADDRESS THE ISSUES PLAYING OUT IN THE UK’S WIDE-FORMAT PRINT SECTOR. HERE’S WHAT KEY STAKEHOLDERS HAD TO SAY…

At the start of this year Image Reports conducted its 15th annual Widthwise Survey of domestic PSPs operating in the wide-format print space. 201 companies responded to that, allowing us to produce a Widthwise Report that provided a real grassroots snapshot of how the sector was performing and feeling. And at that time things were looking quite positive. Almost three quarters of those polled said they were optimistic about their businesses over the next couple of years - even though half had seen a drop in turnover in 2021 and 40% had suffered a drop in margin. Maybe the optimism had something to do with the fact that two-thirds said they expected the UK’s wide-format print market to grow in 2022/23.

But time has marched on, and I’m really pleased that we managed to get a good cross section of print providers to discuss whether much has changed, what it’s like doing business in today’s landscape, and how they think the sector will fare as we move forward. Here’s a taste of what they had to say - the full video interviews can be found on the Image Reports website.

Firstly, have things changed for better or worse in your own business since the start of 2022? And what have been the most major impacts?

Spencer: We’ve had a lot of change within the business because we replaced one of our 5m printers which meant we couldn’t do as much work as the switchover was going on. It also impacted us costwise - having to find the deposit, put new electrics in etc. We had a better turnover last year too because we were involved in a big roll-out last year. As we’re a trade company we don’t always know what’s coming up, which can be very difficult, so we just have to plan for best and worse case scenarios and hope we’ll fall somewhere in-between.

Pitts: Since the start of 2022 business has boomed considerably. About 80% of our clients are retailers and having no Covid restrictions has been positive as footfall has increased. Customer surveys and our own indicate there’s still a desire to spend in physical retail, so while the cost of living crisis is a concern, you could argue that some retailers might actually spend more to gain market share in difficult times. As many of them trust to look after their flagship stores we think the spend with us will stay relatively stable.

Rider: Obviously 2021 was Covid affected as was Q1 of 2022. Since then we’ve found the taps have been turned on again. Events that had been cancelled have been brought into this year etc., so last year and this has been like night and day for us. Also coming out of furlough has meant bringing in more staff, and we’re thinking of investment as well having sorted out repayment of

Covid-related Government grants etc., so it’s really been a year of restabilisation. With the political and economic landscape as it is we’re just being very cautious.

Baker: We feel quite fortunate. We got quite a lot of work during Covid and since then we’ve found a lot of our customers are being very positive. Our markets are very spread so that’s helped - we’ve seen a huge influx of work for vehicle graphics and from retailers too who are taking over other stores. We didn’t expect 2022 to be as buoyant as it has. We have a few storms ahead I feel, but 2022 has been the biggest since our incorporation.

Wheeler: I think any business that’s come through Covid is a bit stronger than before. We’ve certainly learned how to be a bit tighter in what we’re producing. Power and energy is obviously currently a big topic and it will affect margin, but on a positive note, we’ve moved into new areas and are looking at services to boost the more profitable parts of the business. I think that generally the outlook is good, though somewhat tainted by what’s going on in the world.

What needs to happen/change to increase your profitability? What are your biggest worries going forward - and can anything be done on an individual or industry-wide level to improve things?

Wheeler: Well, we can’t have much of an impact on politics, but canvassing our MP is good option and we use that. In terms of what’s going on in business day-to-day we just look for where margin is best and invest in that area.

Rider: Traditionally, the market we’re in is very time and service driven - price almost tends to be secondary. We garner clients that are loyal to us and will almost give us a pipeline of work. So we are looking at things like machine efficiency. Fortunately, we’ve capped our energy costs for the next three years so I don’t have to worry on that front. But what is worrying is that practically every week we’re getting price increases on media, so there is pressure on being able to deliver the levels of output and service clients demand at a price that’s justifiable. You don’t want to get caught into competitive tender situations where it’s all about price cutting. We don’t want to be busy fools. It’s about growing business with those that are becoming increasingly reliant on us.

Pitts: I suppose it’s about being more picky in regards to the jobs you take on - and not chasing turnover is really important. For us, our full-service offering is where our clients see the real benefit as their own teams have been shrunk. We’re finding more are touching every part of our business so we don’t have to focus on one specific area to earn the money, so sometimes we can be a bit more competitive.

Mark: What Graham and Antony have said is exactly what we’re about too. We’ve built our reputation on being

I AM GIVING SOME 10% PAY RISES TO RETAIN STAFF. WHAT IS THE INDUSTRY STANDARD FOR PAY? IT’S SOMETHING WE DON’T DISCUSS ENOUGH

able to deliver and with a lot of the work we have we don’t even price it until we’ve done it! But I do feel that now we’re getting a bit more nipped - the overheads are larger and when it comes to staffing we have to be aware that there are a lot of other opportunities out there. We have the work coming in, but the sign industry isn’t known for being particularly well paid so we have to look at that to retain good staff.

Spencer: We’ve definitely taken a hit on margins due to rising materials costs. They keep going up all the time, and we can’t keep changing our pricing to reflect that - a lot have already put tenders in etc. So we’ve been

looking internally at how we can improve things and cut costs. One of the reasons we’ve replaced our 5m printer is that the old one was using a lot of electricity. The new one uses less, the service contract is cheaper, plus the inks are a bit cheaper and you don’t waste so much material. It’s 4-colour rather than 8-colour but because the technology has moved on the print quality is actually better than that we were getting before, while we’re saving money. Also, we’re putting in new offices, and we had a cool design with high ceilings etc but we’ve changed that to one with a suspended ceiling that will make heating a lot cheaper. Even small things like only emptying the waste bins twice day rather than keep opening the shutters and letting in cold air makes a difference.

Do you think the UK wide-format print market as a whole is expanding or contracting?

Spencer: A lot of our trade customers have put in their own wide-format printers now and we have a couple

that used to spend a lot of money with us and don’t any longer. It’s most noticeable at the smaller end of the scale - we find our 1.6m machines aren’t as busy as they used to be. Also, a lot of non-specialist wide-format print companies have now invested in the bigger machines, and I think that’s because the market is growing.

Pitts: I definitely think the market is growing. It’s still recovering from the pandemic so it’s hard to gauge as many of us are still getting back to where we were, and in the retail sector there is still the threat from digital marketing, but I’m convinced there will always be a need for large-format printed graphics.

Rider: Post Covid we saw a market contraction because companies that had been around weren’t any more, and other companies have been buying their own machines as Nicole said. But I think that generally there is growth in the sector with people spending again, but then we’re hearing of things slowing up again for Q1 and Q2 of 2023 so it’s a wait and see situation I think.

Wheeler: At this point in time we’re very busy but I don’t think we’ve really felt the pinch yet. I think next year traditional wide-format print areas such as retail, exhibitions and display will contract a bit, but saying that there are other areas that are growing, so it’s about finding those and adjusting your business accordingly to service them.

Baker: Yes, I think it’s all about keeping your eyes open. There are certainly opportunities out there if you’re prepared to flex and bend.

So where do you see potential for growth within your own business?

Baker: For us it’s about creating relationships with those working with bigger companies and offering new solutions that aren’t bland. We’re making a real effort to get them to come in so we can show them possibilities they may not realise are available, such as printing onto glass - jobs that are a bit more profitable for us.

Wheeler: We’ve established that looking after clients is key so they stay with us, then it’s about growing our offering - not just graphics - to those clients via all of our business areas.

Rider: Well, clients for whom sustainability is coming very much to the fore is increasing. It’s ironic that a lot of ‘eco’ products that are recyclable not as usable as others so they need replacing more often so there’s opportunity there! Also, where people are reusing stands and things like that they made need services which we can bolt on that make us more margin. So I think the whole eco-landscape focus will important as we go forward.

Pitts: In the past we’ve grown through acquisition, and that’s proven a good investment. Though growing rapidly in times of uncertainty can be a bit of a risky strategy we are looking at other new relationships - the reality is that there are decent businesses up for sale for good prices most certainly.

Spencer: I echo much of what’s already been saidit’s about looking after clients and constantly seeing if there’s anything else we can offer them. For years now we’ve not really been out to see people because of Covid so we’re focussing on really getting to see them face-toface and having deeper chats with them. It’s important to

sometimes take a break from the day-to-day stresses and focus on the longer-term.

What about investment - are you making any? If so, where are you making it and why?

Spencer: As I’ve said, we’ve replaced one of our 5m machines due to efficiencies. And as I also mentioned, we’re putting in new offices, something we’ve been talking about for years. It’s not just about space for kit, but about retaining staff - you can’t expect people to want to come and work in the ones we have now! We’ve also spent some money on things like a bailer to help us recycle more - our own and maybe some from customers as well.

Baker: Out biggest issue is space. When we moved into our unit there where eight or nine of us and now there are 24, so we need to increase the space then we’ll add a 3.2m Zund as our current finishing table is running eight to ten hours a day. But the questions is how much more work do you have to turn around to pay for the extra space and machinery? But the buzz around the place is great when people can see you’re in growth mode.

Pitts: This year we took delivery of the EFI Vutek h5 because it made sense to make use of the government’s super tax incentive, plus it’s great in terms of productivity and energy efficiency. And it made sense from a space saving point of view. We took out two machines and replaced them with the h5 - which was faster and better. But there aren’t really any further investment plans through the next year.

Rider: We too are looking at replacing a 5m machine due to quality, speed and economies. We need to make sure we have enough work to feed it or it’s no improvement.

Wheeler: Our number one investment is always in our staff, and it’s not always financial, but time and effort. We have been heavily investing in bringing on a younger team and have brought down the company’s average age considerably. You always have to look at your production kit though too and we’ve made a modest investment to keep work in-house that we previously subbed-out. And you have to think about opening new doors - we bought a large-format 3D printer about six years ago that took us into areas we knew little about and now it’s a thriving part of the business.

What’s your take on staffing issues as that’s been mentioned quite a bit? How big an issue is the cost of living crisis and pay rise expectations.

Baker: Two weeks before this meeting I’d have said it wasn’t an issue but you’re always only one conversation away from that changing. Bullying is the long and short of it and some tough decisions have had to be made. Trying to keep everyone happy and onboard without always dangling carrots can be difficult. To be honest I am giving 10% pay rises to some of the seniors who have seen the company through thick and thin but you can’t do that with everybody. It’s tough to absorb but you need to keep your good people on board. What is the industry standard for pay? It’s something we don’t discuss enough.

Rider: A lot of people disappeared in the industry in Covid and didn’t come back so that pushed wages up. The flip side, is that perhaps companies had dead wood that they could get rid of. We are finding the jobs market more fluid now and more people are available and less wage pressure.

BUSINESSES AREN’T CHARITIES. WE HAVE A LINE IN OUR QUOTATIONS NOW THAT SAYS, IF YOU WANT TO RECYCLE IT WILL COST YOU £X

Wheeler: I don’t see staff retention is a problem here. We did do a cost of living payment to all our staff though. And we do things that that are fun too - it won’t stop them leaving for an extra ten grand, but it does help if you’re working with people that you’re actually friends with.

Pitts: We run an apprenticeship scheme to help futureproof the business but I think recruiting at the higher level is still difficult at the moment.

Spencer: We have a history of taking on apprentices too but we’re also looking for people with a bit of background experience in signage or graphics as a whole because while we’ve had some really good apprentices, to have them out of the business for a day a week is not always that great for us. We’d rather have someone not on an apprenticeship and learning on the job full time.

Overall, are you optimistic about the future? What are your key concerns going into 2023?

Spencer: Given we’re a trade printer, for us it’s about more customers taking wide-format print in-house. Also, increased prices are of course impacting our customers as well as us, and we do wonder if they are all still going to be around once the full force of the economic situations hits them. We have already seen a couple of really well established companies going bust on us this year so there is a worry there’s more of that to come - just because they’re busy doesn’t necessarily mean they’re making money by being busy.

Pitts: Rising costs and inflation are always going to be a concern. The production staff tend to be the ones towards the lower end of the pay scale so making sure they can actually afford to come to work is an issue because wage rises add to the cost of the business, but we need those people. There’s a lot happening outside of our control, and not being in control is not something I feel comfortable with.

Rider: Yes, business needs certainty and we haven’t got that. We can plan for certain things - we know what events are coming up next year etc. - and we can make efficiencies, such as via a new MIS we have installed, but we can’t control the economic situation.

Baker: For us the biggest issue is just making sure we get paid. It’s great having nice work coming in but we need to make sure customers pay their bills, and pay them on time as some have been stretching their luck a little bit. We could sink at the hands of others who have been overspending.

Wheeler: Ensuring the supply chain is a big issue for us. Yes, our suppliers have got to increase their prices, they’re suffering as we all are, but more important than price is ensuring we have materials. We are having to explore new avenues to ensure we have what we need. And we are also pushing our suppliers for more information on things like carbon footprint because that’s another concern.

What do you think needs to happen to ‘green-up’ this sector as the focus falls increasingly on sustainability?

Spencer: I think it’s about what happens to print once it’s gone to the end user. It’s all well and good printing onto more recyclable materials, but if it’s all going into mainstream waste what’s the point? But it’s very difficult to change that. We’re giving the print we produce to

someone else, who’s giving it to someone else etc. There’s been a lot of investment into recyclable product, and we’ve invested a lot into recycling our own waste, but better information needs to be fed down the chain to end of life. It’s not about just our industry, it’s about educating everybody and it’s a massive project.

Pitts: There’s a lack of infrastructure in the UK in terms of recycling. A lot of those PVC-free materials that are taken for recycling can’t be recycled in the UK and have to go to mainland Europe. If you’re talking about selfadhesive materials for instance which tend to volume up but don’t weight a lot, the eco-footprint and economics of sending it to somewhere like Spain to be recycled just don’t make sense. I think cardboard and paper-based products are key to our offering, because everyone knows how to handle those. It would also help to print in a corner of the graphic produced whether or not it can be recycled, and if so, where it needs to go.

Baker: Doing a lot of vehicle wrap a lot of our material waste is for landfill and though we’d like to put it somewhere else we just don’t have the mass. We need a couple of things: one is education so people know what to put where, then we need some clever people to come up with ways of reusing that product and make a business of doing that, but what that could be I don’t know.

Wheeler: I agree that communication is key - from supplier down through all the groups print materials impact. We recently had a client who wanted to close loop recycling on some graphics - they are collected after the promotion at a modest cost to, which the client pays for indirectly.

Rider: We talk a lot about how we can get end-users on board with recycling. Hopefully, we’ve just recently got to cracking how we recycle PVC-based products in the UK and we hope that will be commercially viable very soon. It will need us to invest and it will change how we manage our waste internally but, also as others have said, there’s all that print which we never see again and how do we control the recycling of that? And if there’s a cost to the printer regarding recycling, will the client pay for it as that affects our margin and we can’t just absorb that at the moment. Businesses aren’t charities. We have a line in our quotations now that say, if you want to recycle it will cost you £X.

This is a difficult ask, but where do you think the sector will be in five years’ time? Will you still be in the sector?

Spencer. It’s difficult to know where we’ll be next week! But yes, I think it is a sustainable sector. I do think digital advertising is something we need to look at, especially in the signage market. I have seen supermarkets close to us putting in digital frames for instance, but they are still alongside regularly changing printed campaigns.

Pitts: I agree with Nicole, and I’d also like to think we will all be better at recycling.

Rider: I think as long as we keep pace with the environmental demands of clients there’ll always be wideformat print requirement. It’s just about staying relevant.

Baker: I’m going to be hopeful and say yes, we’ll still be here and doing well.

Wheeler: There are far too many invested in this industry for it to disappear. We as businesses need to be agile and maneouvre to meet changing circumstance, and in Covid the sector on a whole proved it could.

WE ARE PUSHING OUR SUPPLIERS FOR MORE INFORMATION ON THINGS LIKE CARBON FOOTPRINT BECAUSE THAT’S A CONCERN

Having heard from PSPs we held a second discussion, this time with two of the Widthwise sponsors, for their take on the state of the market.

Firstly, how would you describe the state of the wide-format printing market in the UK over the past year? And how do you see the year ahead shaping up?

Argent: I’ve sold a lot of lower-end equipment [1.6m wide printers] and I’d say that over the last year that has slowed down massively as the situation for oneand two-man bands has become more challenging. At the top end it’s still very buoyant.

Rixon: I agree with James. We have seen consolidation in the market and people are sweating their assets as finance gets tighter. I think the mid- to high-end market is much more buoyant than the low-volume. The secondhand machine market also seems to be buoyant. On the whole I’d say the larger wide-format companies are doing better than commercial print companies.

The 2022 Widthwise survey shows that the cost of supplies is a prime concern for print service providers. What have the cost pressures been like for you? Have you raised prices? And do you expect the pressures on supply chains, costs and prices to ease in the year ahead?

Rixon: I think supply chain challenges are going to be present everywhere for some time to come. We don’t discuss pricing for competitive reasons, but in my area of the business we haven’t raised our prices in the last two years. We’re trying to help customers with their current struggles, and with HP being so large and diverse it’s perhaps a bit easier than for some others to try and absorb some of the rising costs. But who knows what the future holds?

Argent: We have pretty good supplies coming through - I think we’ve been able to get on top of that. We too wouldn’t discuss pricing too much, but we’ve only had one consumables rise in the last year because we’re aware of how difficult it is for printers to pass that on to their customers.

With more organisations making net zero pledges, sustainability remains a critical issue. How are you ‘greening-up’ your own business? Where do you think the sector as a whole needs to be making bigger, quicker ecological advances?

Rixon: I could speak all day on this from a HP perspective - it had a social responsibility charter back in 1956. It’s not just about ‘greening-up’ in terms of water-based inks or whatever, it’s a much, much bigger issue and commitment. For instance, it’s pledged to become the world’s most sustainable and just technology company - and we align our goals to the UN’s sustainable development goals. I suppose the elephant in the room is ‘Is print sustainable?’. There are things

companies can do at no cost to them. We run a free-of-charge recycling scheme but it’s amazing how many of our customers don’t use it. We also do eco-audits for printers to help them become more sustainable but again, it’s probably underutilised. Maybe it’s because these are free so they don’t see the value in them! Because we’re so careful not to greenwash, and don’t want to come across as sanctimonious, perhaps we don’t flagup all we’re doing but we’re now making sure our channel partners pass on the information.

Argent: We’re trying to work more closely with our larger customers to reduce the carbon footprint as much as we can. For instance, we’re always working on our ink technologies to reduce the amount used/ wasted etc. In terms of recycling programmes we’re working very closely with media manufacturers. And as Jane said, there are a lot of programmes already out there and I don’t think printers use them enough. But also, we have to look at the end-user. At the end of the day many of them are not willing to pay the higher price for a product to be recycled and that’s a mindset that has to change.

The consensus among PSPs is that the major technological shifts in wide-format are behind us. Do you envisage any transformational technologies emerging in the next five to ten years - and if so, where?

Rixon: It’s 14 years since we first introduced Latex ink and we’ve recently launched new Latex printers of course with a new generation of those inks. And we’ll continue to see everybody continue to develop new inks. In terms of the wider picture I think we need to pay attention to how we manager print fleets, so I think we’ll see more in terms of automation and in terms of printers being able to see remotely what’s going on across their whole production process. We have printOS already that does this, but a lot of people aren’t using it, again, probably because it’s free.

Argent: We have things we’re working on that we can’t talk about, but what I can say is that with the

acquisition of Inca we have single-pass technology coming for packaging.

With a more hybrid world of work, do you see Industry 4.0 playing a greater role in the wideformat sector?

Rixon: Obviously HP provides technology across many industries, and I’d say the wide-format print sector is the slowest to adopt I4.0. We have JDF capability built into all of our printers - it’s been there for many years - but when you talk to a lot of companies they don’t even know what it is. I think that perhaps as more young people come through these businesses that will change. I think the technologies are out there, but adoption is very slow.

How optimistic do you feel about the large-format print market in the UK?

Argent: Talking to our customers I’d say we’re certainly on our way back to pre-Covid levels of business, but there are still a lot of end users not spending like they used to. But we’re finding that where that’s the case, print companies have replaced lost or reduced business with something else through diversification. Looking at the next 12-18 months, given the UK economy, I think requirements will actually grow because people will need to advertise more.

Rixon: The companies we’re talking to are currently busy. I think it’s a shorter term market now, with PSPs operating more on a month-to-month basis rather than having a longer term work pipeline. Everyone I talk to seems to be confident about the lead up to Christmas, but 2023 is more of a concern.

Videos of the Widthwise Round Tables in full can be found at: www.imagereportsmag.co.uk/image-reports-videos

In spring 2023 we’ll be doing the Widthwise survey all over again - but in the meantime, if you haven’t already done so, you can download the 2022 report from the Image Reports website at: www.imagereportsmag. co.uk/widthwise

If you don’t know Olga Munroe it’s time you did. She became chair of the BPIF POS Display Group this autumn, where she is likely to make a real impact given her various professional guises, not least as head of the Retail Institute. So, what is she bringing to the table, and what does she hope you’ll put on it?

Your LinkedIn profile says that as head of the Retail Institute your role is to enable knowledge sharing and create an environment where academic research can act as an enabler for businesses. In September you also became chair of the BPIF POS Display Group. Can you elaborate on how you see the two roles marrying?

I always feel very privileged in my role to be working with practitioners, people who are passionate about their industries, and connecting them to academic knowledge that makes their decision making easier. Through the research of the Retail Institute, I often work with global brands, retailers and packaging supply chain, and the print sector fits nicely into this mix.

The core function of my role is problem solving, often on a strategic level and for people who lead innovation or organisational growth. How to best solve problems? For me, it is to understand it from multiple perspectives, across disciplines. For example, take the plastic problem. Plastic pollution is one of the most emotive environmental issues industries have had to deal with - it changed the way people purchase goods, and it changed the way retailers and brands want their products to be packaged or sold. The real problem here is our troubled relationship with waste - not seeing the value in protecting natural environments from leakage of toxic substances or pollutants. We now know that the challenge to solve plastic pollution lies in economics of plastic recycling and an inadequately funded waste infrastructure that makes it cheaper to ship waste abroad. One could also argue that the fault lies with the socio-economic system that thrives on excessive consumption. This is just one example of how complex those issues can be.

When I offered to chair the POS Display group, BPIF colleagues kindly connected me with some of the leaders in this sector. They helped me to understand some of the aches they’re experiencing. Issues with recruitment or aging workforce, disruptive print technology or increased operational costs. I am a big advocate of collaboration, and I believe groups, if they engage the right people, can bring about change and improvements to the whole sector by generating accessible knowledge. That is what we will do.

The retail sector is a core market for my readers and they are continually trying to improve their relationships with clients in that sector to build business. Are they missing any tricks - and can you help them learn them?

I think business leaders who deal with their clients dayto-day know exactly what the market demand is and how to respond to the needs of their clients. It might, however, be harder for them to react and adapt to socio-economic changes depending on their business size or monitor their market as a whole.

Perhaps, one ‘trick’ I would flag up to print companies is this balancing act of reactiveness and proactiveness in business contingency planning. Many businesses say they do long-term strategic planning, but the figures for SME survival tell another story. There are techniques you can apply as a company leader to help you keep the focus on the future, anticipate change and plan for the unexpected - we can teach you how to do that.

For large organisations my tip would be keep on top of climate emergency regulation. Support your supply chain in the green transition. You will be required within scope 3 emissions to report and work with environmentally minded entities. Prepare your partners for this now, for the good of your organisation and healthy network. I know many large players in the large-format print sector already do that, and it’s great to see such good practice. But it’s a continual learning journey. I do hope that through the life of the BPIF POS Display Group this something we can grow our knowledge on and share with others.

You mentioned to me earlier that you also head up a Government funded programme ‘Help to Grow: Management’ that could benefit print chiefs. What’s that all about?

Yes, I am glad you mentioned that. I am a director of a ‘Help to Grow’ programme (*) at Leeds Beckett. This is a 12 weeks’ executive leadership programme, which is 90% funded by Department of Business and Industrial Strategy (BEIS). Our current prime minister, during his time as a chancellor, secured £520m investment into this provision, delivered by UK’s top business schools. This is

an exceptional course for anyone who wishes to improve their business performance, and worth taking advantage of if you meet the criteria.

Also, it’s easy to navigate and undertake - no assessments, no tests. You work on the growth plan for your own business - which is the key output plan you will implement within your company. Most modules are online, with only four face-to-face, so you get to network with your group. You also get ten hours of free consultancy from a professional mentor, and you can pick their area of expertise.

The programme is highly practical and aimed at personalised growth with tangible business results. At Leeds Beckett all your lecturers will be academics who are also business people, so they can relate to your realities. We have so many case studies on how successful it’s been for leaders and how it led them to growth, new capabilities, or new initiatives. It’s a great opportunity to become part of a huge regional business network - the alumni network. We meet regularly and many friendships are born this way - after all, leadership can be lonely, and it’s good to see people providing peer support to each other, irrespectively of their sector.

The programme covers topics such as management and strategic capabilities, growth plans, building resilience, innovation, digital technologies, value proposition, employee engagement, responsible business practices and sustainability.

Businesses with more than ten employees can put two leaders onto the programme, businesses with five-nine employees can put one leader forwards - each person would need to register separately. The next cohort will be starting in February 2023.

Information sharing is key to developing the BPIF POS Display Group roadmap, and industry actions key to project delivery, but I know there are internal frustrations that things aren’t happening fast enough. Where are the main sticking points, and what can print companies do to help move things forward?

Business knowledge is often seen as a ‘nice to have’. Companies prioritise here and now, and that is

understandable. If you need new knowledge, you hire expertise with years of personal experience. However, there’s another way to approach such needs, so that you get this holistic viewpoint on where your business fits in the overall retail sector and what are the crosslearnings across segments. This can be achieved through collaboration.

For example, look outside of your immediate sector to find how packaging companies had to adapt to new market realities during recent turbulent years and how they are innovating with bio-feedstocks. You can also grow research capabilities within your own organisation, or in collaboration, to jointly gather market intelligence in your sector. After all, anticipation of obstacles and overall future focus is critical to any organisation.

The BPIF, as a trade organisation, plays such an important role to support you with this. Being a knowledge driven organisation is about thinking differently about how you gather market intelligence. It is about how everyone in your organisation can play a part in contributing to your shared values. It creates engagement and purpose for individuals too. If you are already doing this, that is great. If you prioritise day to day over long term, you might wish to reconsider this approach to ensure your business becomes sustainable in the long term. Make time for working on your business, not just in your business.

What is your overall message to those providing professional print services in this sector?

Let’s work together. Bring passion for your business to the table. Tell your story - your viewpoint to enrich ours. Share successes but, more importantly, also share challenges so that we can support you in finding solutions together. Collaborative platforms are highly effective. Become one of those people who drives change across your sector, and you will stay ahead of your competition.

*For more information please visit: https://www.leedsbeckett. ac.uk/business-services/support-for-small-and-medium-sizedbusinesses/help-to-grow-management/

Head of the Retail Institute and chair of the BPIF POS Display Group

I AM A BIG ADVOCATE OF COLLABORATION AND I BELIEVE GROUPS, IF THEY ENGAGE THE RIGHT PEOPLE, CAN BRING ABOUT CHANGE AND IMPROVEMENTS TO THE WHOLE SECTOR. THAT IS WHAT WE WILL DO

and the other on the overhead frame.

in as little as two months.

SWITCH ENFOCUS and production preparation processes.

CARBON FOOTPRINTING TOOL CARBONQUOTA/THARSTERN and the carbon tool in addition to each quote and a whole.

ACUITY ULTRA HYBRID LED FUJIFILM 2/hr rolls of different diameters the same time.

JFX600-2513 MIMAKI

We’re learning to take what’s thrown at us and use it to our benefit, but 2023 is looking challenging. Working on the assumption that a little insight can make a big difference in terms of preparedness, here’s what we should expect in terms of technological impacts according to some of this sector’s key system manufacturers.

Let’s start with Duncan Smith, production sales director at Canon UK and Ireland, who believes the UK’s economic situation will naturally see print providers (PSPs) “reassessing their technology and putting measures in place to ensure that their devices are working as efficiently as possible. Automation is set to rise in importance as it helps to deliver reduced waste, as well as lower energy use through the streamlining of workflow processes.” Sounds spot on so far.

He adds: “One of the continuing impacts that the print industry will likely face in 2023 is sustainability, as consumers, brands and print buyers increasingly seek out environmentally friendly solutions. 2023 is likely to see PSPs looking for technologies with highly sustainable credentials, whilst remanufacturing, field-upgradeable technology and environmentally friendly processes are also set to remain of high importance.

“Due to the rising cost of energy and the drive for energy-efficient solutions in light of the climate crisis we’re seeing an uptake in technologies that use less heat and ultimately, less energy. For example, we’re seeing an increase in interest for UV LED curing, which is used in both our Arizona family of flatbed printers and our Colorado roll-to-roll printers with its UVgel technology.

“We’re also seeing PSPs investing in long-term solutions to futureproof their businesses, such as with Prisma automation software which helps to deliver fewer errors, better efficiencies and reduced waste.”

Smith continues: “AI is a very broad topic but clever use of data continues to offer a great opportunity for the large-format sector too. It can help PSPs to support their clients with better targeted print communications through personalisation, mass customisation and even geotargeting, whilst better measuring the results of advertising campaigns.

“i4.0 seems to have been absorbed into a number of other topics in recent times, taking in automated solutions at all levels of a process, connectivity for remote servicing and process management - as well as the use of data. This may be because the ‘internet of things’ is still an untapped opportunity in the print industry - with only a few PSPs using real-time, trigger-based, customised print to its full potential.”

Phil McMullin, pro graphics sales manager at Epson (UK) thinks there are a number of factors that will shape the large-format print sector in 2023 and beyond, pointing out that “a major influence on everyday business has been the

acceleration of digital transformation that supports hybrid and remote working while also driving greater automation in systems and solutions.

“Technologies such as artificial intelligence (AI), the internet of things (IoT), virtual and augmented reality (VR/ AR) and cloud computing are all impacting connectivity, responsivity, and flexibility. They help create systems and processes that manage time consuming and repetitive tasks in the most efficient way possible. They also support more effective sales and marketing, better customer service, improved supply chain efficiency and streamlined manufacturing processes. Products and services can also be more aligned with customer needs.

“Digital transformation is also helping address another market trend set to dominate 2023 - a shortage in skilled workers - as employers are under pressure to ensure they are providing attractive careers in a nice working environment with the flexibility of hybrid work.”

McMullin also points out that greater workplace automation “can help with reskilling and up-skilling as well as with recruiting by simplifying processes. Intelligent setup and operation on large-format systems can ensure ease of use for repeatable and consistent high quality while intelligent planning can streamline throughput, maximise output and deliver cost and time savings.”

He too comments on how ‘green’ considerations are going to impact PSPs: “With the looming climate crisis businesses and partners are looking to work with likeminded organisations that have the right environmental and social credentials. 2023 will see companies ensuring their environmental, social, and governance (ESG) processes are central to their strategy. Epson is targeting around 770m Euro at its sustainability transformation over the next decade. Internally this will see investment to decarbonise and close resource loops while externally innovation will reduce the environmental impact of customers and develop new products that are inherently sustainable.

Jane Rixon, business development manager, HP large format, says “it’s time to say goodbye to print, and hello to print 4.0.” She explains: “The evolution of the print industry is largely down to the rise of digital technology that supports a more connected world. An industry that makes smarter decisions based on big data. For example, HP printers can now collect much more data than they did ten years ago. Now, all that data can be processed into powerful insights that help our customers make the right decisions at the right time.

“The printing industry has focused on one aspect of print 4.0 which is ‘automation’. This is to better connect printing technology and allow for a more seamless transition from when a customer places an order to its delivery. This will ultimately lead to a better customer experience, both for print providers and end customers.”

Rixon continues: “Our customers want streamlined

WHAT WILL MOST IMPACT THE LARGE-FORMAT PRINT SECTOR IN 2023 AND BEYOND? THAT’S THE QUESTION WE PUT TO A BROAD RANGE OF SUPPLIERS TO THIS SECTOR. HERE’S WHAT THEY IDENTIFIED.Phil McMullin, pro graphics sales manager at Epson (UK) Duncan Smith, production sales director at Canon UK and Ireland Jane Rixon, business development manager, HP large format

production and the confidence of knowing that they can deliver on time. So, we promise to give them smart, connected production, with no disruptions and optimised control, through solutions that are labourless and remotely controlled, always on, and part of a digital ecosystem that enables our customers to grow and scale effortlessly.”

She too believes sustainability will climb up the agenda, saying: “Sustainability has gone from being a ‘nice to have’ to a key purchasing driver for consumers. The 2022 EU Directive, which came into play earlier this year, has also meant large companies will need to conduct thorough environmental and human rights due diligence throughout their value chain.

“In the next year, we will continue to see the industry develop large-format products and consumables designed with sustainability in mind. Current initiatives include the new HP Latex 2700. The whole Latex portfolio takes HP Eco-Carton - cardboard-based ink cartridges - that reduce plastic by using 100% recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closedloop recycling process, including post-consumer beverage bottles and U-validated ocean-bound plastics.”

Peter Bray, managing director, Durst UK and Ireland, echoes the above messaging, saying: “The need for automated and highly productive systems has never been more important and will continue to influence the large-format print sectors in 2023 and beyond in a major way. Customers will also increasingly look to sustainable solutions.”

Joey Kim, MD InkTec Europe too thinks that the key focus for the large-format print sector will be on environmental initiatives and practices moving forward. “This will mean increasing energy efficiencies, reducing carbon footprints, using less plastic/opting for PVC-free, and more recycling of both printer hardware and finished printed applications.”

Kim continues: “The industry is rapidly moving away from the use of mercury lamps, which has naturally reduced energy costs by utilising LED curing technology. This is probably now the standard preference for flatbed and roll-to-roll printers. In addition, roll-to-roll units that run using single phase as opposed to three-phase are also preferential to reduce energy consumption.

“GUI software in large-format printers is also responding to the demands for more efficiency, with features such as a ‘resume print function’ on flatbeds helping to avoid wasted print materials. So, if a job is cancelled or the heads accidentally crash when printing, the print can resume where the stop occurred. If the media has not been moved or damaged, there is a strong chance the image can be saved, as well as the media, eliminating unnecessary wastage. There is also the X/Y skip function, which reduces needless head movement, saving energy and wasted time. For example, if you have large portions of an image with no image data, i.e., a big gap between printed parts, instead of the head moving pointlessly left and right, mimicking printing, the head pauses, processes until it is due to move, then starts printing where needed. Little techniques like this when multiplied are improving the general overall efficiency of LED UV printing.”

Combined with rising overhead costs, PSPs will be keen to see reduced energy consumption of large-format printers, lower service cost for machinery (with potentially more remote support) and lower cost for extended

warranties. Kim points out: “Effective ways to reduce their costs are through the use of alternative inks at reasonable prices, efficient and versatile printer choice and committing to extended warranties, so they have transparent, upfront fixed costs from a reliable service provider.”

He expects there will also be more of a focus on a circular economy approach with it becoming increasingly important for manufacturers to work with resellers and customers to look at opportunities to sell-on printers, offer refurbishment, or recycle where possible with new owners.

Erskine Stewart, managing director of swissQprint UK, confirms “there are three key topics that our customers continue to prioritise and ask for our support with. First, efficiency, and especially energy efficiency given the state of the costs facing businesses. Secondly, productivity, they need to produce more with less. Finally, versatility - their customers’ needs are changing. We continue to prioritise these points in our R&D. Our new UV-LED flatbed printerthe energy efficient Kudu with 10 configurable ink channels and a top speed of 300m2/hr - is a good example of how our this translates from customer priorities into a solution.”

Rob Goleniowski, head of sales, UK and Ireland at Roland DG thinks software integration as well as system automation will play a big part in the large-format print sector in 2023. “We are seeing an increase in connectivity across all areas of our lives, and I think we are about to see a surge of that within the large-format print sector. We have only started to see this becoming prevalent in the industry over the last few years, but print professionals are increasingly looking for ways to increase their productivity and return on investment.

“At Roland DG, we’re working on improving how our hardware talks to software. For example, we launched Roland DG Connect, a cloud-based service, which allows users to monitor the print status when away from the office, receive notifications of when key maintenance should be performed, and give an overall health status of the connected device.

“On top of this, this connectivity allows hardware manufacturers to improve the level of after-sales service and support offered, allowing customers to utilise their machines more and as a result have less downtime. For example, the Roland Care team uses these technological advances to provide AI repairs and remote monitoring, which allows for proactive support based upon the collected information keeping the machines online for longer - more production time equals higher revenue potential.”

AI, IOT, VR/AR AND CLOUD COMPUTING ARE ALL IMPACTING CONNECTIVITY, RESPONSIVITY, AND FLEXIBILITYRob Goleniowski, head of sales, UK and Ireland at Roland DG Erskine Stewart, managing director of swissQprint UK Joey Kim, MD InkTec Europe Peter Bray, managing director, Durst UK

are also under pressure from their customers to do the same. We have a passionate team here that has taken on the company’s sustainability strategy in addition to their day-to-day role, and that team wanted to start getting indicative figures together for the environmental impact of our standard printed products.

“We’d been aware of Sustain from POPAI for a while and we knew that would be our next investment - not an investment in terms of money, as its very reasonable [a six-month licence is £850 for non-POPAI members] - but an investment in terms of time. We signed up to Sustain in the summer and we’re really pleased with it so far. The customer service team is really responsive - happy to look at getting new products into the system - and a new improved version has recently been released which we’re working through at the moment,” says Furness.

He explains: “We’re currently using Sustain to benchmark different variations of the same project, whether that is the recycled content within the material, the way we package it up for delivery, or how we get it delivered. We always have a good idea of how the results will look, but it’s great to get them in black and white from an industry standard tool.

“We’re also using the results to show our customers the benefits of switching to more sustainable products. It doesn’t look much when you show the environmental savings of one poster, but when you multiply it by thousands the carbon saving moves from grams to tonnes each year.”

“2022 has seen the rise in requests from prospects, customers and stakeholders asking us if we can provide the carbon footprint of the products we produce. Retailers, brands and media agencies are all under pressure from consumers to take responsibility for their impact on the environment and we’ve come to know we need to lead and guide our supply chain to help in this drive for change.” So says Shane Furness, commercial director at Cestrian.

Sustainability has been a key focus at the Cheadlebased, Carbon Smart certified, PSP for a number of years “and we’re constantly thinking of new ways to make improvements,” stresses Furness, pointing to one of its most recent initiatives - signing up to POPAI’s Sustain Global Eco-Design environmental impact measurement tool that has been specifically developed for the POP industry. It lets you measure as many projects as you need and up to six versions of a project to help discover their environmental impacts, with assessments carried out in accordance with ISO 14067-1 and the GHG Protocol Product Life Cycle Accounting and Reporting Standard.

“Like many companies, we recognise the impact that our business has on the environment and that it is imperative that we do the right thing. In addition to our own drive to be more sustainable, our customers

Furness says Cestrian is working with Sustain every day and is also in regular communication with POPAI on how it can be made to work even better for the company. And he’s keen to point out that the tool is just one of the sustainability elements it is using to reduce its environmental impact.

“For us it’s about manageable achievements - there’s no point saying you’re going to be PVC-free next year if you haven’t got a plan to actually get there.

“One of our proudest achievements is when we set ourselves a challenge to reduce the amount of nonrecyclable packaging and components we were using on a daily basis. 100% of our packaging for all our customer deliveries is now fully recyclable and PVC-free, and that includes component parts such as paper-based tape, bubble wrap, tubing, strapping and cable ties too.

“This is also our seventh year of being zero-waste-tolandfill, something we are extremely proud of. Through this initiative, we have produced 5,449 traffic cones using waste diverted away from EfW. And our materials are being recycled into more paper-based or sporting equipment from PVC and PE waste material.

“We’re also busy getting ready for our next ISO auditwe’ve held the accreditation for 11 years now.

“We are incredibly proud of the work we have done to date on reducing our environmental impact. There’s lots going on behind the scenes and we’re very excited about some of the initiatives that will come to fruition over the coming months.”

WE WANTED TO START GETTING THE INDICATIVE FIGURES TOGETHER FOR THE ENVIRONMENTAL IMPACT OF OUR STANDARD PRINTED PRODUCTS

CAN YOU COUNT THE COST OF THE ENVIRONMENTAL IMPACT YOUR PRINT HAS ON THE ENVIRONMENT? CESTRIAN CAN, THANKS TO THE POPAI SUSTAIN MEASUREMENT TOOL.

If you haven’t seen the movie ‘Network’ you really ought to. This savage satire stars Peter Finch as a suicidal news presenter who encourages viewers to open their window and shout “I’m as mad as hell and I’m not going to take this anymore!” That seems like an appropriate slogan for what we’ve all been through doing business in the UK this year. Here are just a few of the things that have enraged me…

1. Younger people (be they Millennials or Gen Z) who think print is environmentally unsustainable, even as they rush to the Apple store to snap up the new iPhone, oblivious to the fact that each new model is responsible for 64kg of carbon emissions - 80% of which occur before they have even used it. It is amazing how many intelligent people assume that digital technology magically transcends environmental science whereas, according to the UN, the IT sector already accounts for 2-3% of global emissions. We’re never going to achieve net zero - or anything like it - if all we do is to blame the crisis on a few pantomime villains, such as print and aviation, and ignore reality.

2. Vladimir Putin and Donald Trump - the Tweedledee and Tweedledum of turmoil

3. The government. I can understand why the Conservatives ditched Liz Truss, described by Private Eye as the ‘Lady Jane Grey of prime ministers’, but now we’re back to ‘normality’, for which read spending cuts and higher taxes, the same wrong-headed strategy that has given us the slowest growing economy in G7. Funnily enough, Truss had half a point - you can’t cut your way to prosperity, you have to create an environment in which businesses have the confidence to invest. And, although I have nothing against Rishi Sunak, I don’t think a multi-millionaire public schoolboy telling nurses we can’t afford to give them a pay rise is a good look.

4. Banks for talking the talk about helping business but not walking the walk. Many of our smaller customers miss not being able to go to a branch and say that trying to get help online is like wading through a digital quagmire.