Project

Studio: Craft + Future = ?

Faculty: Prof. Rishav Jain

Teaching Assistant: Ar. Teja Payapalle

Graduate Project Sem: 4

Location: Multiple locations, Gujarat

Concept: D.I.Y (Do It Yourself)

There is a sense of loss in this internet age where mass production is rampant. It leads to the apparent irony, meaning that the better connected we are, the lesser connected we feel in an absolute sense.

Nowadays, personalization is everywhere because of the raised awareness amongst everyone and increase in the sense of creating- content, works, entrepreneurships etc.. It creates emotions, and eventually, emotions take over the future.

So this is the proposition Craft + Future= Makers Movement 2.0, where people will make and personalize their interior environment through the craftspeople. A collaborative approach wherein the designer and everyone else will be a maker. The designer will give a system, and the maker will use it to personalize their environment. Craftspeople will be the catalysts for this change.

8 | Design Portfolio

01

Initial Perception of “Craft”

How do you imagine the future and its impact on craft practices?

Personalisation being the future whose evolving roots can be seen in every other aspect of our day to day life, be it the apparels choices or online shopping. Design practices will be personalised while making craft as a medium through the techniques getting evolved which will help in retaining the practices that are becoming obsolete along with helping them evolve overtime.

Manifesto for Craft + Future = ?

What is your idea of Craft?

Craft is about Technique. Changing the technique from for eg. handmade to 3D printing can help in changing the outcome of the craft along with providing more opportunities to explore it further.

Abstraction of Craft Cube Explaining the Argument for “Your Idea of Craft” so as to create a “Personalised” cube Using one joinery made of screws and laser cut acrylic sheet to make multiple options for assembling a cube of size 12”x12”x12” using crafted surfaces. Crafts used are Mata ni Pachedi being laser cut on acrylic sheet, Cross Embroidery done on Plywood with Lacquered finish & Wood Turning used for Wooden planks

2013- 2023 | 9

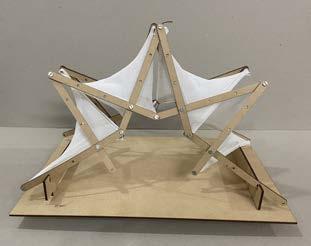

3- Axes Bamboo Joinery Inspired by Ar. Kengo Kuma

Making and Makers

Zones Requirement for the Program

User Groups

Existing Anganwadi spaces typologies

10 | Design Portfolio

Nomadic makerspaces have been proposed where the designer (Architect/ Interior designer) will devise a system which will help the user to personalise their space with the help of the local craft in that particular location. Craftspeople will arrange a setting using those design systems in order to showcase their skills where user can come, visit and learn from the craftspeople diectly, leaving room for innovation andgrowth for the craft.

2013- 2023 | 11

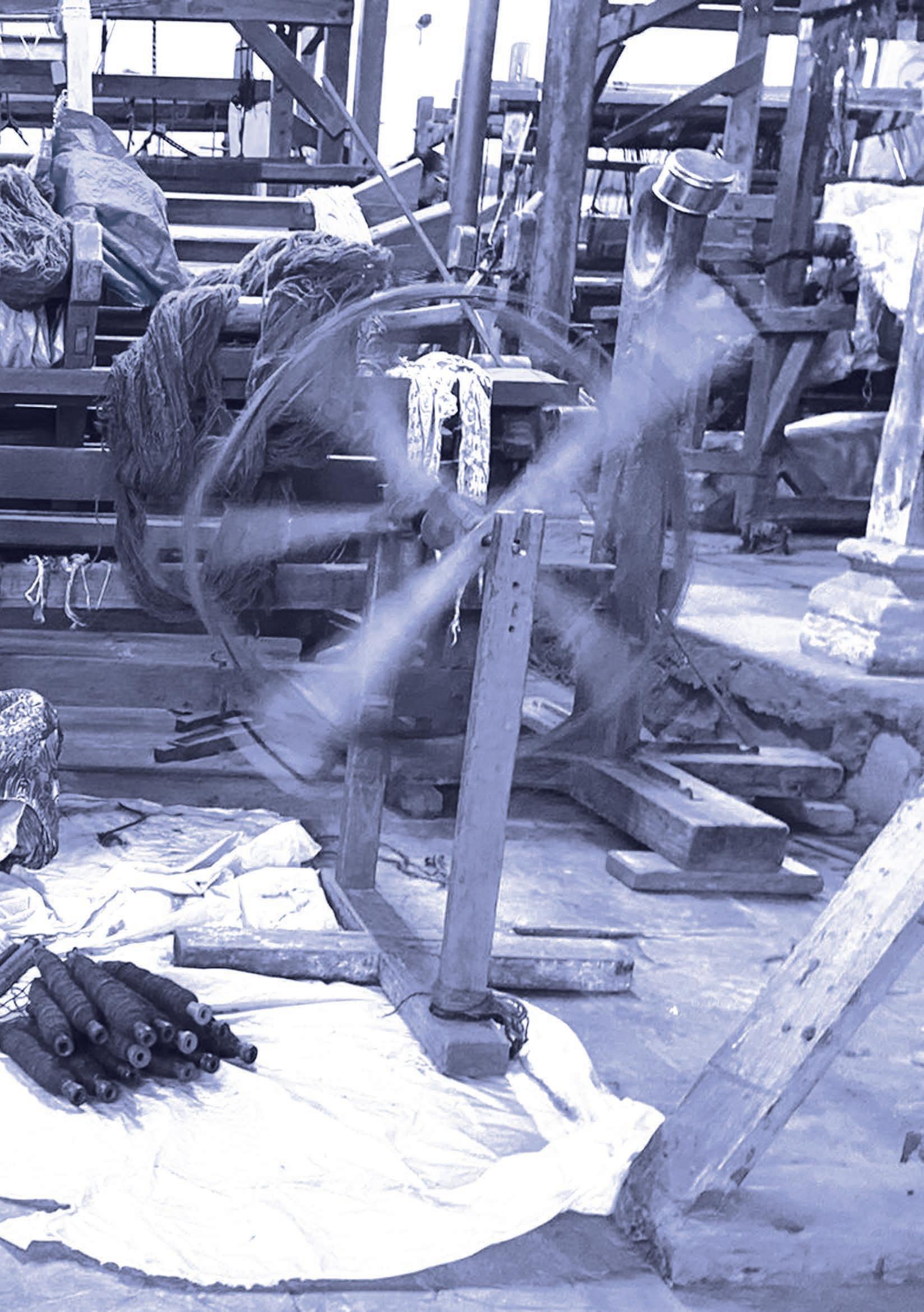

Proposal plan for maker space in Patan, Gujarat Craft identified: Patola Weaving

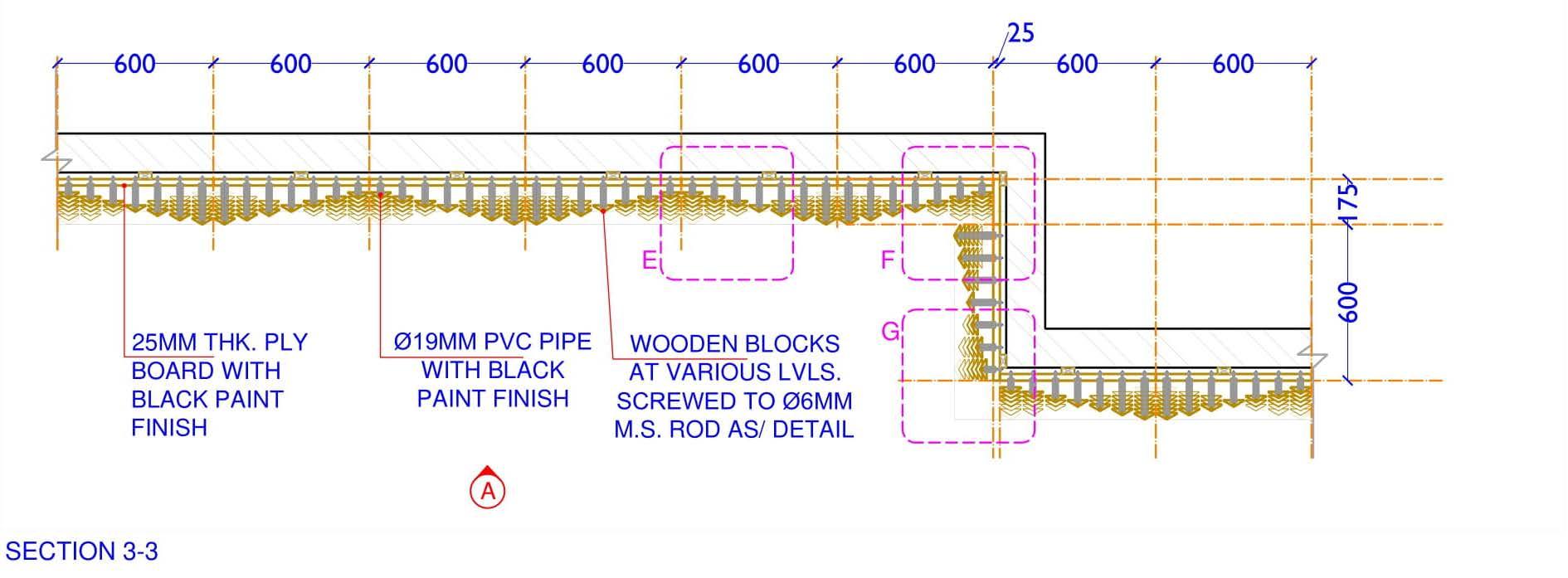

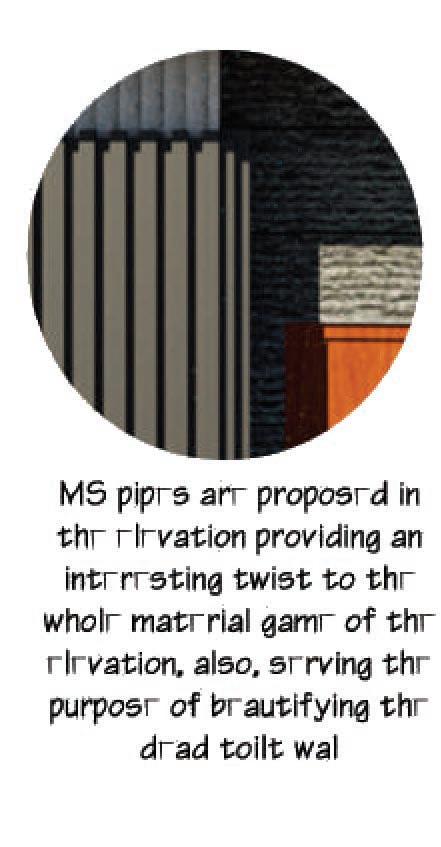

Longitudinal Section through the space

Transverse Section through the space

Project: Sahyogyashala

Year: 2030

Location: Patan, Gujarat

Crafts Used: Patola Weaving

“The artist is not a special kind of man, but every man is a special kind of artist.” – Ananda Coomaraswamy.

12 | Design Portfolio

The proposed project looks at all the people as makers with the instinct to connect to their environment through personalising their space by learning from the indigenous makers i.e. the craftspeople. The designer helps in empowering makers by catalysing the whole process by providing easy-to-install D.I.Y. systems that help in evolving crafts by challenging AND complimenting the old ways of making crafts.

Rural migrants that have migrated to urban areas in seach of better employment opportunities have the crafting skills which are overlooked because of the type of jobs available. But these skills can be used and taken forward in collaboration with the urban population who have technical know hows which will generate the need for experimentation and also keep people attached to their roots.

Proposal plan for maker space in Waghai, Gujarat Craft identified: Bamboo Weaving

2013- 2023 | 13

Element 1

Element 2

Element 3

Transverse Section through the space

Manual for Bamboo Panel DIY construction

Prototype for Bamboo joinery

Manual for Storage units DIY construction

14 | Design Portfolio

2013- 2023 | 15

Longitudinal Section through the space

Studio: Biomimetics Computational Design

Faculty: Ar. Arpi Maheshwari & Ar. Radhika Amin

Teaching Assistant: Ar. Ayushi Agarwal

Graduate Project Sem: 3

Location: Goa

Concept: Deployability

This studio focused on identifying the problems in the chosen location which have been hindering the lifestyle of people living in the area. The study had been made for the beaches of Goa where shacks are found for catering the tourist inflow which is increasing year by year.

Due to heavy precipitation during the months from June to August, the shacks are removed from there respective positions on the beach due to increase in water line because of high tides during rainy season.

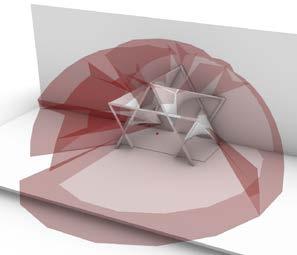

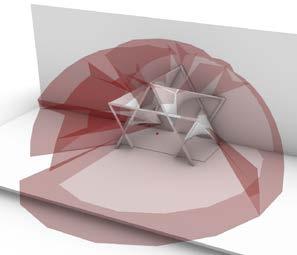

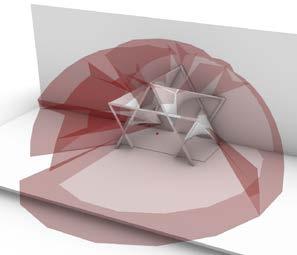

Because of which, the shack owners have to spend money every year contributing to the cost of erection of structure, materials used and environment. So further experiments had been made by identifying the issues that are being observed in the location and catering to the problem by creating a deployable shack structure and keeping in mind the visibility and thermal comfort based upon solar radiation for the visitors.

Conclusions made through the experiments

16 | Design Portfolio

Project 02

8 m

Site: Beach Shack Location: Calangute, Goa

Size: 18 X 8 m

Materials Used: Fabric, Bamboo & Dried Leaves

2013- 2023 | 17 Goa

LOCATION

Problem Statement

Since shacks get dismantled every year from June to September, during dismantling, some of them are left abandoned resulting in non reusability of materials and expenditure of money on rebuilding every year.

EXPERIMENTS

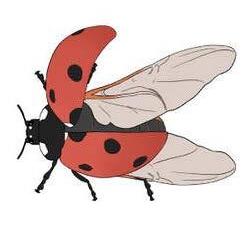

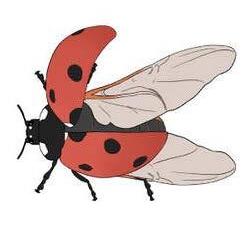

Learning from ladybug wing’s mechanism, further experiments were conducted in order to develop a system for deployable shack.

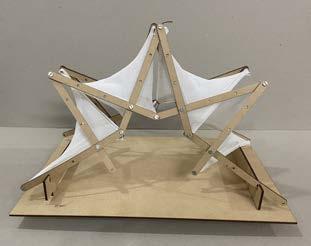

Scissors mechanism has been used because of its deployability and fabric membrane has been provided in transverse direction in order to provide the visual connection with the surroundings of the structure while keeping in mind the thermal comfort of the user by analysing it through radiation analysis.

To create a Deployable System which is well connected visually from the surroundings while minimising the amount of radiation entering the site.

Fitness Criteria

Maximise Deployability

Maximise visual connectivity- 50%-90% minimise Solar Radiation- 0-2 KWh/m2

Natural System

First few experiments concentrate on trying to achieve the maximum width and height through changing pivot points of scissors, anchor points, pivot point with fabric.

Further experiments focus on understanding the role of fabric in the whole system which provides visual connection, controls radiation entering inside the building, the deployability of the whole system and the amount of time a system takes to fold and unfold.

LADYBUG holds the second set of wings under their visible set of wings which open once the ladybug pulls the upper setof wings up.

The wings underneath hold elastic potential energy within them which is stored during the folding which was done the previous time, so when the upper wing is picked up, the under wing opens up directly.

The wing underneath is deployed and when unfolded becomes double its size, this is the idea which has been used to create the module for proposing the deployable Shack structure system.

Elastic Energy saved inside the wing artery

Wing Unfolds

Due to elastic energy wing starts to unfold

18 | Design Portfolio

Aim

Outer Shell

EXPERIMENT 01

CONSTANTS:

1. Length of Module

2. Number of divisions

3. Point of Contact of scissors

4. number of scissors in one module

EXPERIMENT 02

CONSTANTS:

1. Length of Module

2. Number of divisions

3. Point of Contact of scissors

4. Number of scissors in one module

5. Tensile Membrane Point of Contact

6. Anchor Point

EXPERIMENT 03

CONSTANTS:

1. Length of Module

2. Number of divisions

3. Point of Contact of scissors

4. Number of scissors in one module

5. Tensile Membrane Point of Contact

6. Anchor Point

EXPERIMENT 04

CONSTANTS:

1. Length of Module

2. Number of divisions

3. Point of Contact of scissors

4. Number of scissors in one module

5. Tensile Membrane Point of Contact

6. Anchor Point

VARIAIBLES: Pivot Poin for Scissors

INPUT PATTERN: length of one stick= 16 cm

VARIAIBLES: Point of Pivot for sticks

INPUT PATTERN: length of one stick= 16 cm

Fabric size = 12X12 cm

VARIAIBLES: Anchor Points of Module

INPUT PATTERN: length of one stick= 15 cm

Fabric size = 12X12 cm

VARIAIBLES: Point of contact of fabric

INPUT PATTERN:

length of one stick= 15 cm

Fabric size = 12X12 cm

2013- 2023 | 19

A B D C A B D C

A B C D

20 | Design Portfolio A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D Deployed Geometry Deployed Geometry Experiment Experiment Side View open Geometry Side View open Geometry Front View open Geometry Front View open Geometry

2013- 2023 | 21 A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D A B C D Experiment Experiment Isovist Volume Isovist Volume Visibility Analysis Visibility Analysis Radiation Analysis (winter) Radiation Analysis (winter) Radiation Analysis (Summer) Radiation Analysis (Summer)

Conclusions

-The proposed module can be used for creating a deployable structure for the places where it has to be mantled and dismantled frequently

-The fabric used for the mechanism can help in generating the amount of sunlight and radiation entering the structure

-The movement of each module depends upon the pivot point of the scissors mechanism giving a curved surface for the structure

-The placement of fabric can regulate the opening of the scissors according to the point of contact

-The anchor point for the system is crucial in order to enclose the amount of volume that is required for the structure

-with the decrease in number of divisions for pivot point of scissors, there is an increase in span and height achieved for the system.

22 | Design Portfolio

Interior View of deployable shack structure