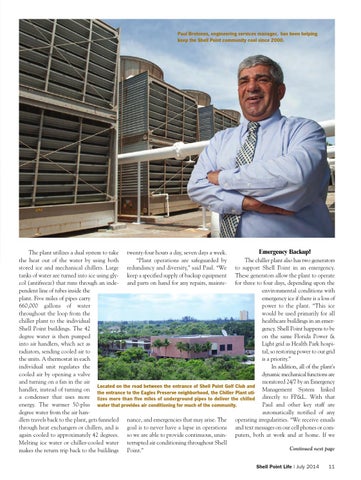

Paul Bretones, engineering services manager, has been helping keep the Shell Point community cool since 2000.

Emergency Backup! The plant utilizes a dual system to take twenty-four hours a day, seven days a week. “Plant operations are safeguarded by the heat out of the water by using both The chiller plant also has two generators stored ice and mechanical chillers. Large redundancy and diversity,” said Paul. “We to support Shell Point in an emergency. tanks of water are turned into ice using gly- keep a specified supply of backup equipment These generators allow the plant to operate col (antifreeze) that runs through an inde- and parts on hand for any repairs, mainte- for three to four days, depending upon the pendent line of tubes inside the environmental conditions with plant. Five miles of pipes carry emergency ice if there is a loss of 660,000 gallons of water power to the plant. “This ice throughout the loop from the would be used primarily for all chiller plant to the individual healthcare buildings in an emerShell Point buildings. The 42 gency. Shell Point happens to be degree water is then pumped on the same Florida Power & into air handlers, which act as Light grid as Health Park hospiradiators, sending cooled air to tal, so restoring power to our grid the units. A thermostat in each is a priority.” individual unit regulates the In addition, all of the plant's cooled air by opening a valve dynamic mechanical functions are and turning on a fan in the air monitored 24/7 by an Emergency Located on the road between the entrance of Shell Point Golf Club and handler, instead of turning on the entrance to the Eagles Preserve neighborhood, the Chiller Plant uti- Management System linked a condenser that uses more lizes more than five miles of underground pipes to deliver the chilled directly to FP&L. With that energy. The warmer 50-plus water that provides air conditioning for much of the community. Paul and other key staff are degree water from the air hanautomatically notified of any dlers travels back to the plant, gets funneled nance, and emergencies that may arise. The operating irregularities. “We receive emails through heat exchangers or chillers, and is goal is to never have a lapse in operations and text messages on our cell phones or comagain cooled to approximately 42 degrees. so we are able to provide continuous, unin- puters, both at work and at home. If we Melting ice water or chiller-cooled water terrupted air conditioning throughout Shell Continued next page makes the return trip back to the buildings Point.” Shell Point Life | July 2014

11