ONE THAT PROVIDES.

Time-tested Agribusiness banking.

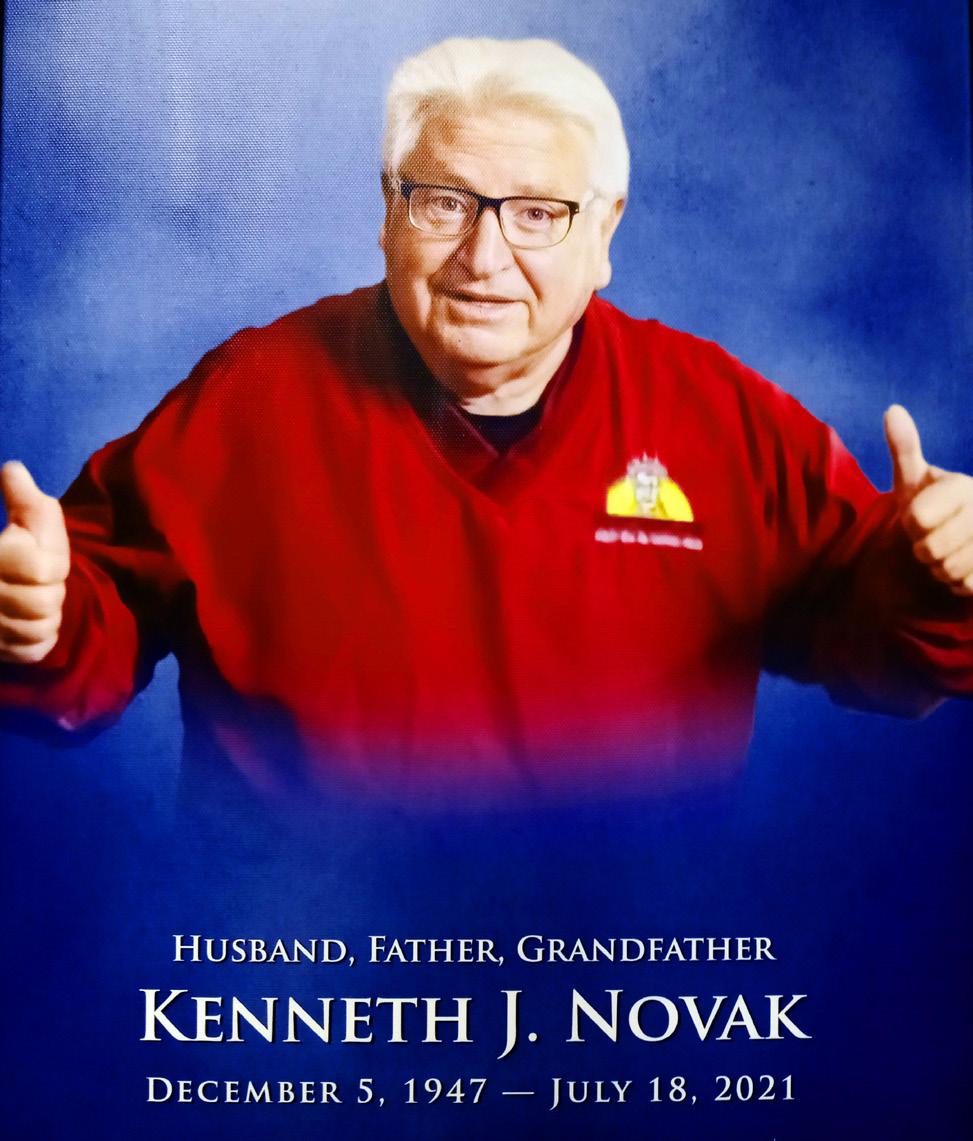

Remember Ken? You do if you’re someone who did business with Ken Novak, or maybe you just remember the caricature with the Krazy hair. Novak was well-known to his customers as “Krazy Ken, the Farmer's Friend” when he owned Farmchains.com and C&N Supply. Novak opened C&N Supply in 1986 and Farmchains.com in 2008. He died in 2021, and the businesses passed to his son-inlaw Doug Hicks.

The customer base reflects that specialization. In addition to older farmers, Amish and Mennonite farmers from the Midwest and Northeast also are frequent callers, relying on older equipment and valuing someone who understands it. Hicks also gets the occasional antique tractor owner looking for steel detachable chain for display or demonstrations.

And when those customers call, they don’t get routed to some remote call center queue; the call goes right to Hicks’ pocket — his cellphone that he carries with him. Customers can also text photos, send measurements and troubleshoot outside normal business hours. It’s that kind of commitment to customer service and attention to details that makes a big difference, especially when a piece of equipment is down.

The mindset of helping first and selling second traces back to Hicks’ earlier career.

“It’s not necessarily selling to them, it’s more about helping them,” Hicks said. “Coming from law enforcement, that’s what you kind of do, to help people. That’s what Farmchains does, it helps farmers get their old equipment back up and running again.”

Farmchains.com began in 2008, but its story stretches back even further, when things first started getting a little “Krazy” at a downtown Dixon storefront.

Ken Novak, Hicks’ father-in-law, founded C&N Supply in 1986 as an industrial supply store. At the time, northern Illinois still had a strong manufacturing base, and C&N did a lot of business with industries throughout the Rockford area. Novak — whose shtick was being “Krazy Ken, the Farmer’s Friend” — knew his products, especially chain. Before opening his own business, he sold for Allied-Locke, where he learned the ins and outs of farm chain applications, knowledge that would later become the backbone of Farmchains.com.

But as industry dried up and factories shut down, the industrial side of the business took a hit. Farming, however, endured, and in 2008 Novak launched Farmchains.com as a way to serve a different kind of customer, one who still relied on equipment built long before onboard computers and dealerexclusive parts. Today, C&N Supply is still part of the operation — selling drill bits, end mills, caps, bandsaw blades, cutting tools and Herschel tillage parts — but it’s Farmchains.com that takes up most of Hicks’ focus these days.

In its first year, the online experiment did even better than expected, generating enough sales for a solid start for a niche business.

“Farmchains is mostly an online business, and it’s grown ever since,” Hicks said. “I would say 85 percent of sales is online or by calling, so I don’t get a ton of walk-in business.”

Back when Farmchains began, Novak was still the face of the operation. He traveled — a lot. Farm and trade shows across the country, roughly 10 a year, were among his destinations. As technology advanced and the online world grew, the business became less about the storefront being at the forefront and more about the website being there.

“With that side of business, you once had to do it to get the name out there in the beginning,” Hicks said. “Now, the world operates around a cell phone and a search engine, where you can see who comes up first. Customers will search for what they need on their cell phone or computer, and you have to be right at the top of that search engine.”

CHAINS

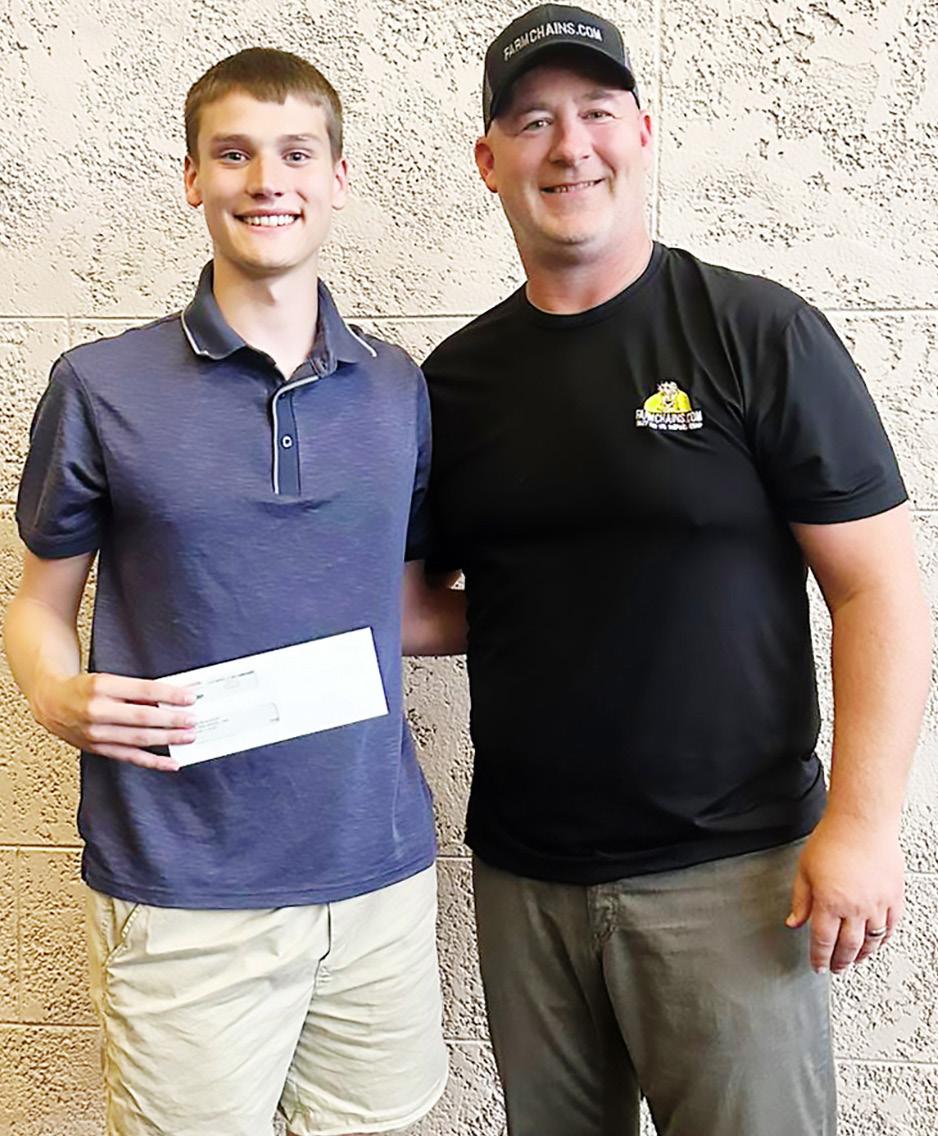

2025 Dixon High School

graduate Cullen Shaner (left) was awarded the “Krazy Ken The Farmer’s Friend” memorial agriculture scholarship this past summer by Farmchains.com and C&N Supply owner Doug Hicks. The scholarship is in honor of the former owner of the businesses, Ken Novak, who died in 2021.

Then came a turning point for Hicks, both personally and professionally. There had been some uncertainty about the future of the business when Novak was diagnosed with esophageal cancer, but in 2019 Hicks took on a different duty. He retired from the Lee County Sheriff’s Department and joined the business full-time, initially running the Farmchains side. When Novak died in 2021, he took over ownership of both Farmchains.com and C&N Supply.

“It didn’t seem like anyone was interested in the business within the family,” Hicks said. “I left [the sheriff’s department] kind of early — I had 21 years in — and decided to take the chance and come work for Ken.”

Hicks grew up on a family farm south of Harmon and attended Amboy schools. He met his wife, Amanda, in high school; the two married in 2002 and have three children. “Having grown up on a family farm, it was kind of a no-brainer to come in and run Farmchains,” he said.

After taking over the businesses, Hicks embraced the internet in a way that his father-in-law was hesitant to adapt to, and it’s paid off. From 2021-25, business has grown roughly 30 percent, he said. Even during the coronavirus pandemic, which disrupted so many operations, the business turned into an unexpected high-water mark.

The shift from show floors to search engines didn’t happen overnight. Novak was reluctant to lean too hard into online marketing at first, hesitant about search engine optimization strategies and a heavy digital presence. The results, however, were hard to ignore: Hicks hired an online marketing firm to help manage the shop’s digital footprint, and he stopped doing farm shows altogether.

The phones kept ringing anyway.

“We have grown every year since then,” Hicks said. “We

had a record year last year. We had a record month, and we had a record back-to-back month.”

Another pivotal moment for the business came in 2023: A cracked structural beam in its old building in downtown Dixon forced Hicks’ hand. He could either invest money in an aging building or find a new home. He opted for the latter, and in the summer of 2023 began work on a new building south of town along state Route 26, opening it in spring 2024. The building offers more space to work, room to handle deliveries and a location closer to farms.

Along with keeping C&N Supply in business, Hicks has also found another way to honor Novak’s legacy, beyond the balance sheet: He established the “Krazy Ken The Farmer’s Friend” memorial agriculture scholarship, first awarded last summer to Dixon High School senior Cullen Shaner, who is attending University of Illinois in Champaign to pursue a degree in finance in ag business.

As for the future, Hicks is realistic. Right now, none of his children are interested in taking over the business, but, he added: “We’ll see what happens.”

Today, Hicks runs the operation largely on his own. He streamlined the ordering process after taking over, making it easier for customers to get exactly what they need without unnecessary back-and-forth. It’s a one-man show built on experience, availability and product knowledge. That knowledge matters, Hicks said, because the customers are not calling about new equipment.

CHAIN STORE

Go to farmchains.com to order chains or for more information. Contact: 815-973-2648 or info@ farmchains.com. The shop, along with C&N Supply, is located at 1546 state Route 26 in Dixon. Hours vary; call ahead.

“It’s a unique business because I sell a lot of chain that not a lot of dealers want to deal with,” Hicks said. “My typical customer is a 50-to-80year-old farmer who farms a few hundred acres and has really old equipment. When they call their dealer, they don’t have any parts for them — they have all new equipment. That’s where I come in: They find me and I’m willing to talk with them and get them the part they need, or identify the chain that they need, and get it out to them quickly.” n

Shaw Media reporter Cody Cutter can be reached at 815-632-2532 or ccutter@ shawmedia.com.

CHAINS cont’d from page 9

SAUK VALLEY MEDIA By

Eighty years ago, when a trio of brothers put their minds together on their farm, they were just looking for a better way to change the look of the landscape, but what they created would end up changing the business landscape, both at home and around the world.

Today, their name lives on in the company they built, along with their commitment to innovation.

Woods Equipment is known today as a leader in its field — and yards and everywhere else its products are used — manufacturing rugged, durable tractor implements and attachments from its Oregon plant. But behind all that steel and hard work is a rich history and a wealth of people whose ideas, relationships and pride have helped build a brand that’s celebrating 80 years in business this year.

The company’s products are used in a host of jobs — agricultural, landscaping, grounds maintenance, construction and more — helping landowners, farmers, contractors and municipal workers tackle tasks and chores with increased efficiency and reliability. The company also has a parts plant in Rockford.

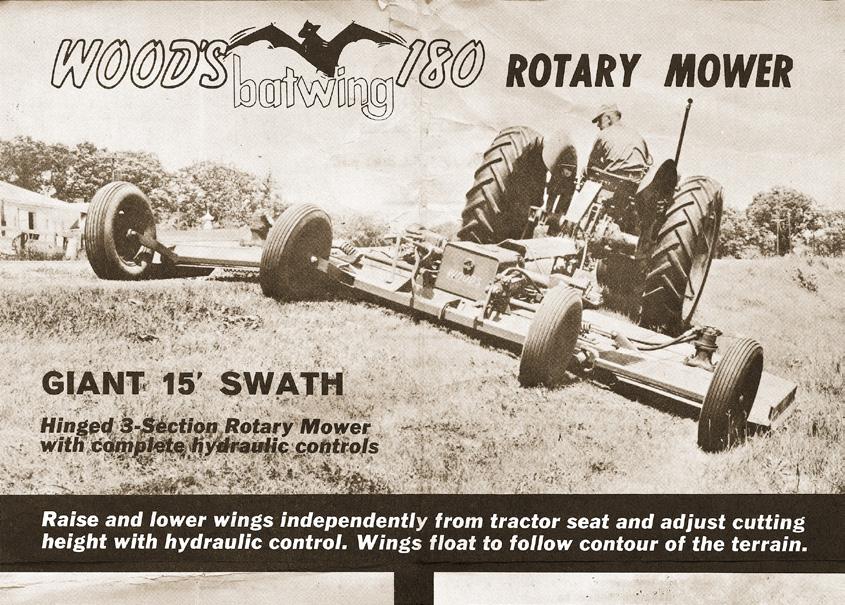

Its product range includes various types of rotary cutters — from heavy-duty rigid models to flexible “Batwing-style” cutters — that are engineered to clear brush, mow fields or roadside vegetation, and shred crop residue. In addition to cutting tools, the company builds finish mowers to manicure turf, seeders for planting plots large and small, tillage equipment for preparing soil, and backhoes for digging and earth moving tasks.

WOODS cont’d to page 14

Woods also offers a wide selection of landscape attachments and accessories, from hitches and loader tools to snow removal gear, designed to expand the capability of tractors and loaders for a variety of jobs. Together, those machines reflect a company focused on people who are focused on the land, with tools designed to last.

Woods Equipment traces its roots back to a 4,000-square-foot metal Quonset hut in 1946, when three brothers — Leonard, Keith and Mervel Wood — built and introduced the first successful tractor-mounted rotary cutter, revolutionizing how land was mowed and maintained. This invention helped create an entirely new category of implement that soon became standard on farms, roadsides and other large tracts of land.

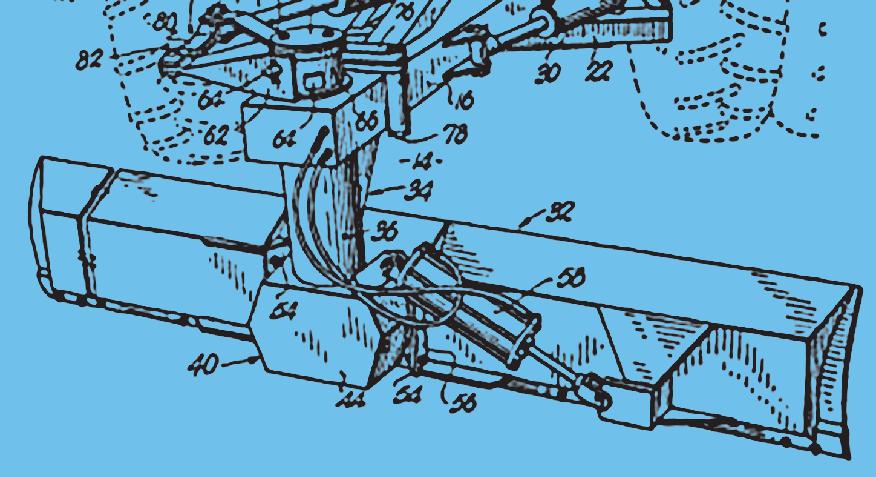

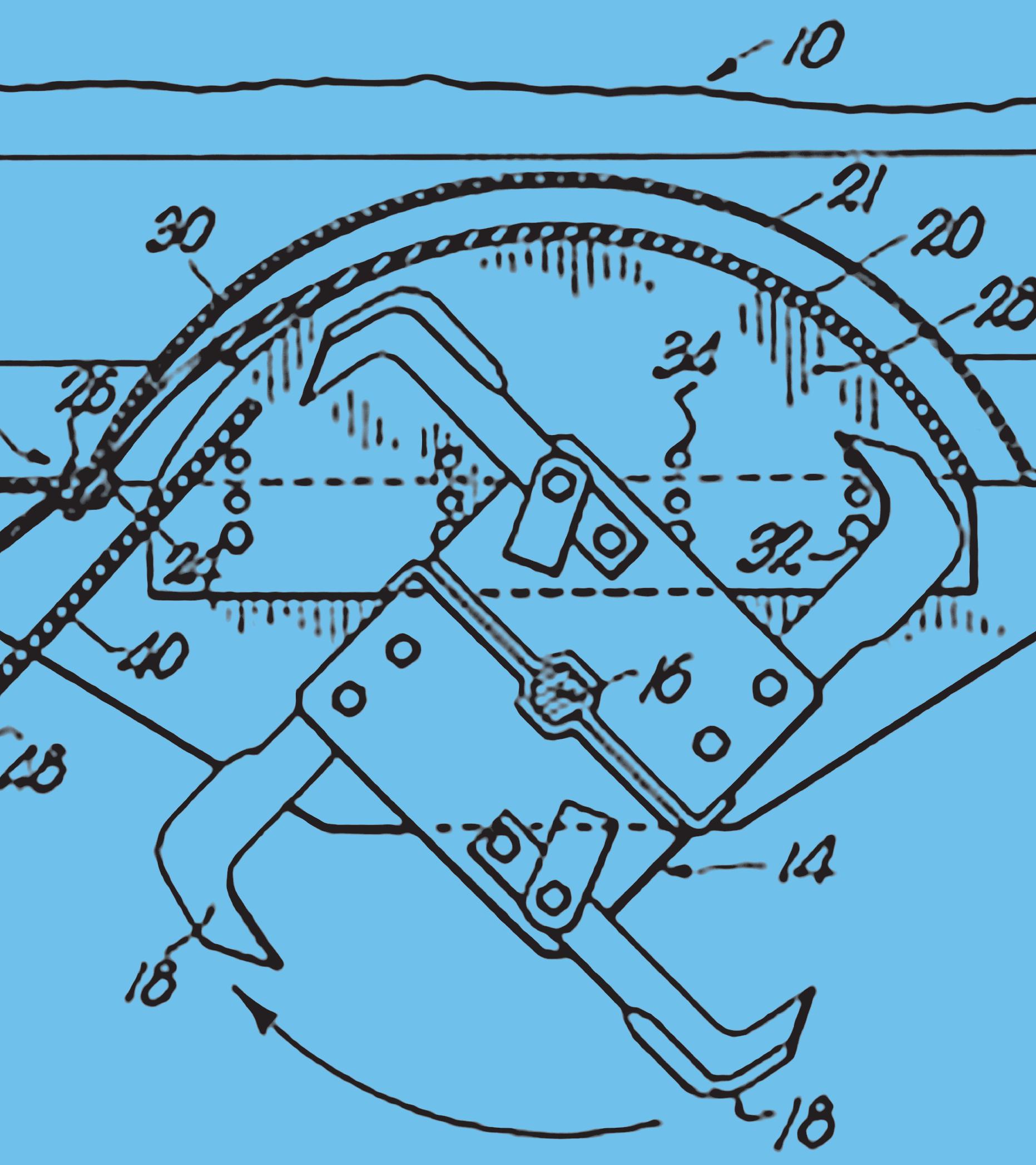

Over the next few decades, Woods introduced and patented a steady stream of design improvements, including its “Batwing” cutters and numerous drive- and hookup systems. The history portion of Woods’ website (woodseequipment.com/our-story) details

these patents with original sketch drawings of what would soon come.

In 2011, Woods became a division of Blount International, a global manufacturer of professional-grade tools and equipment, expanding its global distribution while maintaining its Midwestern manufacturing base. Blount rebranded to Oregon Tool in 2021 — a name that honors the lineage of companies under the former Blount umbrella founded in the state of Oregon, not the town Woods is based in.

As Woods marks its 80th anniversary, the story of its longevity is best told by the people who have been part of it, sharing their memories and everyday experiences. From assembly workers to office workers, technicians to truck drivers, sales team to management team, they’re all part of Woods’ legacy.

Among them, Vice President and General Manager Derek Paulsen, who’s taking time to look back on Woods’ past while keeping an eye on its future. He and fellow company leaders see the anniversary not only as a milestone worth celebrating, but as a launching point for where Woods is going.

When it comes to favorite moments in Woods’ history, Paulsen is experiencing his now.

“Our 80th anniversary, here in 2026, is my favorite,” Paulsen said. “It is incredible to see the evolution of an idea of a rotary cutter grow into a substantial business. It further mushroomed into the Batwing product category, in which our branded product has long been the industry standard and moniker. Even better, our team is hungry to make the next 80 years even better.”

WOODS cont’d to page 15

Paulsen

WOODS cont’d from page 14

For senior test technician John Becker, Woods has been both a career and a classroom. Over nearly four decades, Becker has worked closely with engineers to build first-run machines from the ground up, pushing them to their limits before they ever reach customers.

Becker’s favorite chapter in the company’s evolution came with the development of zero-turn, front-mounted mowers, products that took patience and persistence to perfect as designs improved over time. The process, he said, reinforced the value of learning, adaptation and passing knowledge forward.

“The development department has been great to work in because I am able to build the first new pieces of equipment from scratch, test and modify as needed so they may be produced and sold,” Becker said. “It is very rewarding to drive around the country and see all the products that Woods has manufactured over the years.”

Gallentine says Woods’ appeal has always felt personal, familiar for a company rooted in a region where land management is part of everyday life.

“It’s been a great, stable place in our community,” he said. “With this area we live in with a lot of agriculture, there’s a lot of land management to get done, and I think it’s neat to work for a company that helps with all of that.”

Greg Gallentine, who has spent 32 years at Woods and now manages daily plant operations, recalls 2000 as a defining moment: Demand for the BrushBull single-spindle rough-cut mower surged, pushing the Woods team to produce an impressive of 15,000 units in a single year.

“The commitment, hard work and teamwork from everyone in our organization to build those 15,000 units in that year was pretty awesome,” Gallentine said. “The sales on it really took off.”

On the sales and dealer side, Pamela Turek has spent 45 years nurturing relationships that extend far beyond transactions. Working closely with a dealer network of roughly 1,500 across the U.S. and Canada, she credits Woods’ long-standing reputation and people-first culture for those connections — even when the conversations turn from work.

“We’ve built good relationships, whether it’s with inside employees or outside employees, and you keep those relationships forever,” Turek said. “It’s a real good, closeknit community.”

WOODS cont’d to page 17

Turek

Gallentine

Becker

Mervel Wood inspects a new model of the company’s heavy duty all-purpose cutter (date unknown).

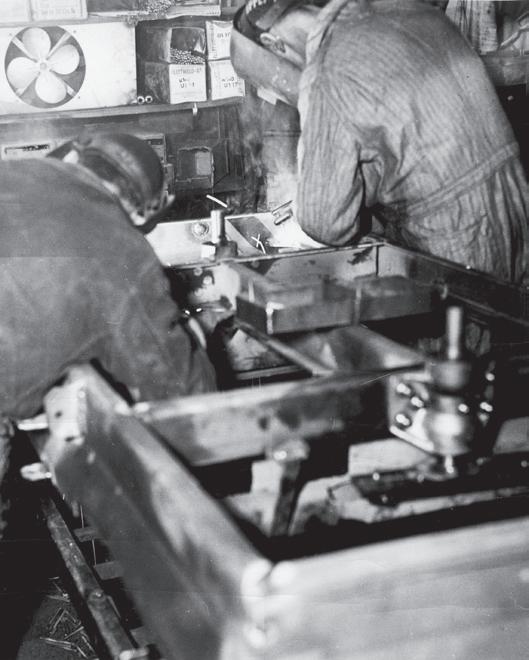

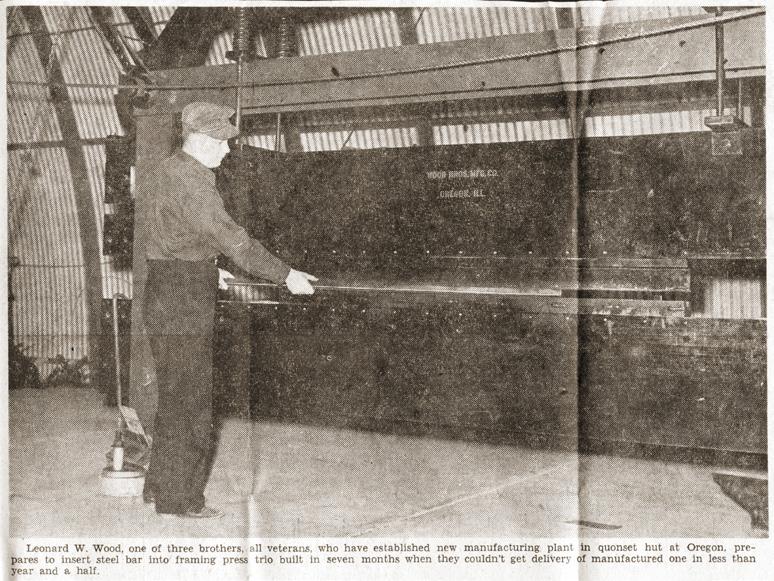

Leonard Wood is seen in a newspaper clipping inserting a steel bar into a framing press. According to the caption, the Wood brothers built the press in seven months when they couldn’t get a manufactured one delivered in less than a year and a half.

Woods Equipment employees and executives pose for a photo taken in the late 1940s in front of its first facility: A metal Quonset hut in Oregon (seen also above left).

The Wood brothers, (from left) Keith, Leonard and Mervel, are seen here in 1951.

Workers weld a main frame (date unknown).

Black is the new orange ... Woods is celebrating its 80th anniversary by rolling out limitededition Batwing (shown here) and BrushBull rotary cutters with commemorative matte-black designs. Proceeds from their sales will support Woods’ new “Your Land, Your Legacy” scholarship program, which will fund future leaders in ag, conservation and land management from schools in and around Oregon.

Those relationships were shaped most during a pivotal shift in how Woods connected with dealers: a mid-1990s zone concept sales reorganization under former CEO Tom Laird that brought the company closer to the people selling its equipment. Turek’s zone was in the Southeast U.S.

“He set up zones all over the U.S. and had district managers,” Turek said. “I was able to meet dealers and put a face to the name, and work oneon-one with the sales force. I like to talk, and that worked out well. We worked closely inside our own little zone; you knew what products were the ones they were most interested in and could sell best.”

Rob Dewey, who started as an engineer and now leads product development after 38 years with the company, sees that culture reflected in how Woods approaches innovation. He describes the company’s design-to-value philosophy as deeply rooted in listening to loyal customers of both Woods and other brand products. New products are tested extensively, both on Woods’ 30-acre test plot near the plant and on private land owned by area farmers.

2606 S. state Route 2, Oregon

Contact: woodsequipment. com/contact/, 1-800-319-6637, or woodsinfo@OregonTool.com Online: woodsequipment.com and on Facebook.

“When we release a new product, we have confidence that it’s the best product that we can produce and that it outperforms the competition,” Dewey said.

One moment that crystallized that confidence for him came in 2018, when a Kentucky dealer hosted a side-by-side mowing comparison against competing brands. Watching a Woods mower outperform the others — and hearing a longtime horse farmer explain why so many in the region relied on Woods — was validation years in the making.

Proceeds from these anniversary model sales will support Woods’ new “Your Land, Your Legacy” scholarship program, which will fund future leaders in agriculture, conservation and land management from schools in and around Oregon. Love said she enjoys working for a company that gives back to the community. In 2023, Woods designed an “Old Glory” Batwing cutter, decked out in red, white and blue to award to a farmer involved with the Farmer Veteran Coalition, which provides assistance to veterans starting a farming or ranching career. Aspiring recipients sought it through an application process, and it was awarded to Texas farmer and Army veteran Joseph Burdulinski. Many veterans work at Woods, something the company is committed to and takes pride in, Love said.

“When we have an opportunity to support veterans, we always try to find a way to do that,” Love said. “That was a very cool initiative that we had.” Moments like that, employees say, reflect a company whose impact extends well beyond its equipment, and the community sees it, Turek said.

“I wanted to see it first-hand because I had worked on these machines,” Dewey said. “That was my favorite day. I worked in the engineering department most of the time I’ve been here, designing these products and testing them. It just was proof that we’re doing the right thing.”

To mark its 80th anniversary, Woods will celebrate throughout 2026 under the theme “Quality for Generations,” which highlights company milestones, customer stories and its long-standing focus on performance-driven engineering, Marketing Manager Jillian Love said.

The celebration includes limited-edition Batwing and BrushBull rotary cutters with commemorative matte-black designs, to be unveiled at the 2026 National Farm Machinery Show in mid-February in Louisville, Kentucky.

“Woods has always been the place to work in Oregon and Ogle County,” Turek said. “It has a great reputation, treats their employees well, and I can’t think of a better place to work. It’s always been a part of Oregon’s history, 80 years.”

For many at Woods, those moments of pride are woven into a workplace that has shaped careers, relationships and a shared sense of belonging across generations.

“Woods has a family culture where we experience wins and challenges together. We treat our external partners like family, and how we want to be treated. It’s all about people.” n

Shaw Media reporter Cody Cutter can be reached at 815-632-2532 or ccutter@shawmedia.com.

Dewey

Love

WOODS cont’d from page 16

PHOTOS COURTESY WOODS EQUIPMENT

It turns out both are right — the challenge, though, can be finding the right balance.

That’s where an experienced loan officer can help. They can navigate the numbers and help find the right plan for planters, and finding that plan is about more than just crunching numbers; it’s about coming up with a way to help borrowers from feeling the crunch.

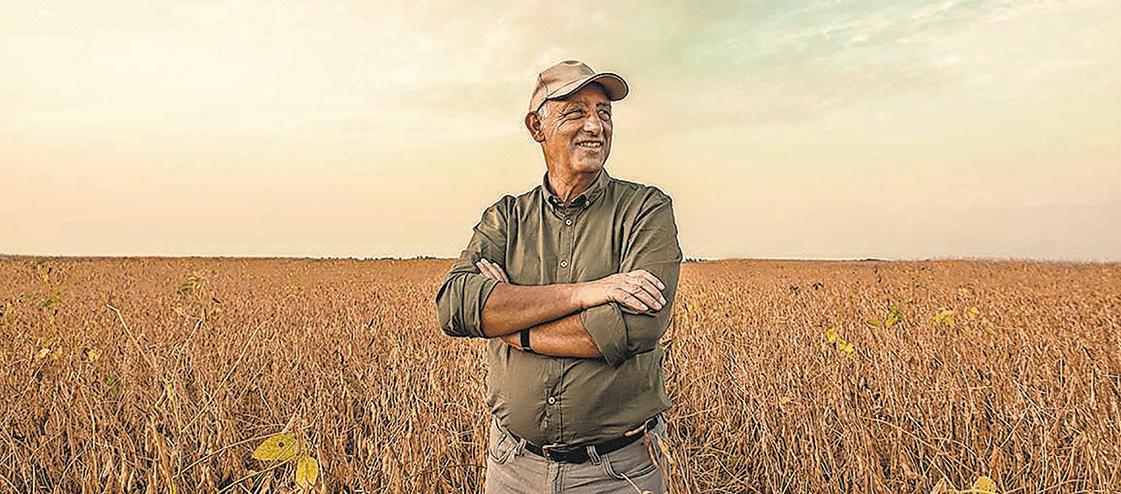

For Sarah Wiersema, an agricultural loan officer with The First National Bank in Amboy, her days are shaped by conversations with producers, long-term planning discussions, and helping farm families make decisions that can ripple across years and generations.

At its core, Wiersema says, agricultural lending is about relationships, trust and walking alongside producers as they make decisions that shape not only their operations, but also the future of rural communities across northwest Illinois. It’s a role that acts less as a gatekeeper and more as a partner invested in long-term success. In an industry where margins can be tight and variables are often outside a producer’s control, lenders understand both the land and the people working it can be as important as access to capital itself.

Sarah Wiersema (center) of The First National Bank in Amboy, works with her team of lenders to help borrowers with their financial needs. The team also includes Susan Gomez (top), and (from left) Chas Cross, Todd Muur and David Lloyd. PHOTO:

“As an agricultural lender, I get to see firsthand each producer work toward their goals and achieve them one step at a time,” Wiersema said. “On top of that, you won’t find a better group of people to carry on a conversation with than our local producers.”

The First National Bank in Amboy, headquartered in the namesake central Lee County town, also has branches in the county in Dixon and Franklin Center, as well as Monroe Center in northeast Ogle County. Wiersema works out of the Amboy office, but also stays in touch with her fellow ag lenders at the other branches to better understand what producers are experiencing across the region.

Those connections — with both farmers and fellow lenders — is what makes the job fulfilling, Wiersema said, taking pride in getting to know the producers behind the loan applications; leaning more about their families, their long- and short-term plans, what makes each operation unique. It’s a familiarity that allows her to serve not just as a lender, but as a trusting financial partner at pivotal moments in a producer’s life.

“As their financial partner, I get to help fund that first farm purchase, the farm they’ve had their eye on for years, that piece of equipment they’ve needed, or provide resources to cash rent more ground for the upcoming year,” Wiersema said. “It truly is fulfilling to be able to share those crucial parts of their lives with them.”

Engaging in a relationship-based approach becomes even more important when viewed through the lens of rural community health. Wiersema believes local access to agricultural credit plays a critical role in keeping farming viable — and keeping rural traditions alive.

cont’d to page 22

Providing farmers with quality coverage is what we do. With Farmers Mutual Hail at Hugh F. Miller Insurance Agency, Inc., your livelihood will be protected, just as it has been for generations.

PEACE OF MIND FOR

YESTERDAY,

& TOMORROW

Providing farmers with quality coverage is what we do. With Farmers Mutual Hail at Hugh F. Miller Insurance Agency, Inc., your livelihood will be protected, just as it has been for generations.

www.hughmillerinsurance.com 801 1st Ave, Rock Falls, IL (815) 626-1300

•

•

•

“Local producers are the backbone of our rural communities,” she said. “They pass on traditions, guide the younger generation and act as role models to others.”

For those producers, having a lender who understands their specific operation, and is available when needed, makes a big difference. Strong ag lenders take the time to research individual operations and remain engaged throughout all phases of a farm’s life cycle, Wiersema said.

Consistency in the role can help ensure land remains in the hands of farmers or landlords who share a commitment to strengthening rural communities and preserving the agricultural way of life, rather than becoming disconnected from local stewardship.

“Whether it be year-after-year operating transactions, retirement or next generation transitions, a good lender will be with them every step of the way,” Wiersema said. “It’s all to keep land in the hands of farmers or landlords with the same goals to improve the rural community and keep the agricultural lifestyle alive.”

Recent years have brought added complexity to farm finances, including market volatility, rising input costs, and the presence — or absence — of government assistance.

One example is the recently announced $12 billion farmer bridge payments, introduced by the United States Department of Agriculture in December 2025. It’s a federal support

measure designed to provide short-term financial relief to producers facing cash flow challenges. The payments are intended to help offset income gaps caused by market disruptions, high production costs or delayed program assistance. They offer temporary stability as producers plan for the upcoming season.

While those payments can provide some relief, Wiersema said they are just one piece of a much larger financial picture.

“Government payments over the last few years have been sporadically able to help fill in cash flow gaps when markets, trade or inputs are volatile,” she said. “They do slightly reduce the risk going into the next year.”

Still, Wiersema emphasized that ag lending decisions are not built around any expectation of stimulus. Regardless of whether government payments are available, she said lenders remain committed to supporting producers and helping them make informed decisions.

“If there are government stimulus payments or if there aren’t, we will still stand behind each producer and their operations to help guide them,” Wiersema said.

Such guidance often begins with the loan application process itself, a situation where education and communication are key. Evaluating a farm loan starts with gathering the right financial information, which includes recent years’ tax returns, a current financial statement and a crop plan.

LOANS cont’d to page 23

Reflecting on her role in supporting agriculture and helping it thrive, Wiersema sees it as more than just approving loans: It’s about providing steady support through changing markets, life transitions and generational shifts in keeping agriculture strong at the local level.

For her, the reward lies in watching producers move forward, one decision at a time, with someone in their corner who understands both the business and the people behind it. One of the most important steps in the ag lending process, she added, is helping producers understand their own numbers. Completing accurate and thorough financial statements isn’t just a requirement for the bank, it’s a tool for the operation’s success. Anything for a better peace of mind.

“When we collect the appropriate financials, we try to make the loan application process as easy and seamless as possible,” Wiersema said. “We help our producers to have the ability to fill out accurate and complete annual financial statements and really dig into their own numbers. Understanding what their financials mean to the operation is so significant to their success.” n

Amboy

• 220 E. Main St.; 8 a.m.-4:30 p.m. Monday through Friday, 8 a.m.- noon

Saturday

• 301 E. Joe Drive; 8 a.m.-4:30 p.m. Monday through Friday, 8 a.m.-noon

Saturday

Dixon

• 1314 North Galena Ave.; 8 a.m.4:30 p.m. Monday through Friday, 8 a.m.-noon Saturday

• 728 S. Crawford Ave.; 8 a.m.-4:30 p.m. Monday through Friday, 8 a.m.-noon Saturday

Franklin Grove

• 108 N. Elm St.; Monday, Wednesday and Friday 9 a.m.-5 p.m., 9 a.m.-noon Thursday and Saturday

Monroe Center

Shaw Media reporter Cody Cutter can be reached at 815-632-2532 or ccutter@shawmedia.com.

• 5558 N. Clark St.; Monday, Tuesday, Thursday, Friday 8:30 a.m.-4:30 p.m., Wednesday and Saturday 8:30 a.m.- noon

RUSTY SCHRADER/SVM ILLUSTRATION

he pages of a textbook aren’t the only place students turn to for their lessons. Sometimes they find them beneath polycarbonate panels in a pot of dirt.

At least that’s where they are for Morrison High School students who are doing some house work (green, that is) along with their homework.

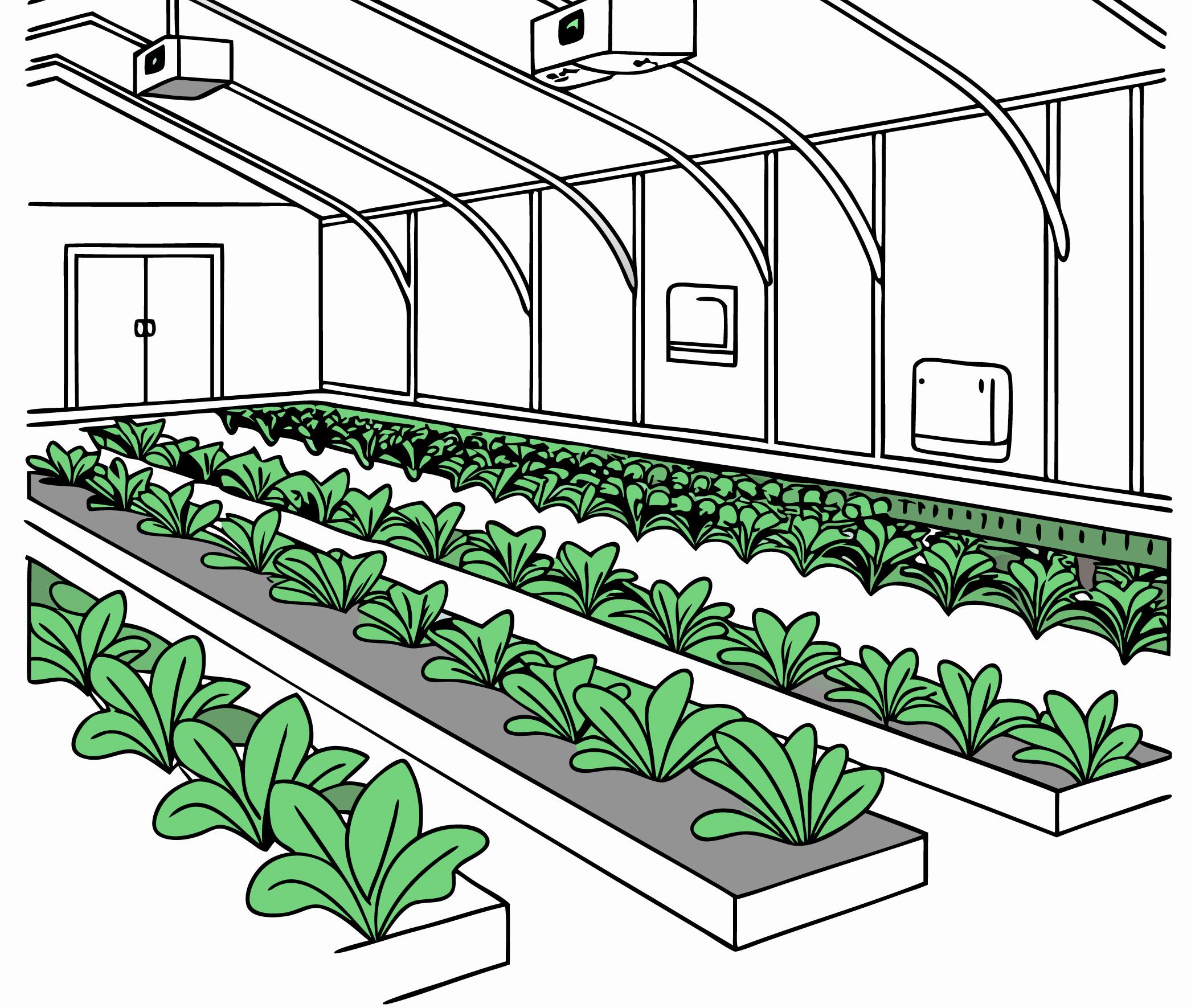

Through labs, learning and lessons, the school’s new greenhouse is helping students learn about seeds, soil and science — as well as patience, research skills and, perhaps most importantly, where their food comes from. Since the campus classroom opened in November 2024, students have grown flowers, vegetables and herbs – tomatoes, zucchini, green peppers, carrots, broccoli, kale, lettuce, and more.

Built to expand hands-on agricultural learning, the greenhouse hums daily with experiments, leadership, and even some trial and error. It’s what agriculture teacher Tonia Prombo hoped the space would become.

“The learning experience is that they not only learn the importance of growing their own food, but how the food, the soil and how everything goes together,” Prombo said. “Knowing how to fertilize and why we fertilize, how plants respond to different stimuli, and the different physiological processes of plants as well, and learning the scientific process.”

The idea for the greenhouse on the south end of Morrison High School’s property was planted back in 2023, pushed forward by the school’s FFA alumni. Since then, Prombo, now in her eighth year at Morrison High School, has watched the greenhouse evolve and grow into a living laboratory.

The 14-by-48-foot Educator Series greenhouse, purchased from FarmTek in Dyersville, Iowa, was designed with intention: polycarbonate panels for durability, eleven growing tables, adjustable hanging racks, a large sink, filtration, heating, ventilation and space to grow. A small single-gutter rainwater collection system is in place, with plans to expand it to two gutters in the near future.

GREENHOUSE cont’d to page 26

GREENHOUSE cont’d from page 25

“They kind of get to learn what it’s like maybe working at a research facility, so it goes beyond just being a greenhouse,” Prombo said. “They’re able to see what other careers may be available in the field of agriculture other than just growing plants. They’re learning that it’s not just as simple as growing something in some soil and watering, there are certain things that you have to do in that process to assure that you get a good crop.”

That broader view is intentional. Prombo has long argued that agriculture education is as much about purpose as it is production, particularly for students who may not initially see themselves in the field.

“Research shows that most students, as a general rule, learn better by doing and being able to apply what they are learning,” Prombo said. “It gives them a purpose. You get some students who go, ‘Why does it matter?’ I try my best to show them why this matters. We have a lot of students who didn’t think they’d really enjoy this type of stuff, and my hope is that over time they’ll enjoy getting into career areas like floriculture or landscape design.”

GREENHOUSE cont’d to page 27

Tonia Prombo (left), Morrison High School ag teacher, and Noah Icenogle, Morrison High School sophomore/greenhouse supervisor

The greenhouse is student-run. Prombo oversees the curriculum, but daily operations are largely left to students, including sophomore Noah Icenogle, who is the greenhouse’s supervisor. His role inlcudes watering schedules, maintenance, systems checks and helping other students learn their way around the space.

“It’s a learning experience and it gives me a hands-on opportunity to let me see what all goes into a building of this size,” Icenogle said. “It’s learning about what it takes, and it’s a cool responsibility to have.”

For Icenogle, the greenhouse offers something classrooms cannot replicate: a real connection to food and what it takes to grow it, along with the responsibility that comes with it, and the consequences if they don’t live up to that responsibility.

“Out here, it gives them a hands-on experience,” Icenogle said. “It gives them a chance to work with their hands, and it gives them a connection. It’s different to learn from a book, and this gives them a connection to their food and what goes into it. It’s experience right here.”

Some things are trial-and-error: Students tried growing poinsettias last school year, but those were hard to get growing, Prombo said. Another lesson they learned — and quickly: Aphids really like mums.

What did grow well grew well in numbers. Last year, the greenhouse housed around 1,000 plants — more than expected — which they grew for the school’s first plant sale in May 2025. The sale generated about $2,400, a number the school hopes to surpass during this year’s sale, again in May. Combined with profit from foods grown in the greenhouse last year, the funds cycle directly back into the program.

“The spring sale went really well,” Prombo said. “We didn’t sell all of our plants, but were able to donate to the local nursing homes, Homestead and Resthave. Some of the plants we planted over in the community garden. The money that we raise allows us to buy plugs for certain flowers for them to do transplanting and learning that process, and to pay for soil for the next year. It’s eventually self-sustaining.”

The greenhouse has also become a point of outreach. During last year’s Ag Day in May, elementary students toured the facility and planted seeds to take home, extending the greenhouse’s reach in the community. This year’s Ag Day is scheduled for mid-April, Prombo said.

For Icenogle, the potential still feels wide open.

“It’s amazing just how much you can do in here,” Icenogle said. “It’s a smaller greenhouse, but you can grow a lot in here. It’s a learning experience figuring out what’s best and what’s not, but it’s amazing how much you can do in here.”

Prombo knows firsthand how important a greenhouse can be for students. At one of the schools she taught at before Morrison (Dowling Catholic High School in West Des Moines, Iowa), there was no greenhouse when she was there and she would often hear students, many of whom lived in urban areas, tell her where they thought food came from

“So many kids, especially in urban areas, have no connection — unless they have family — to what agriculture is and what it entails,” Prombo said. “Most of them, if I asked them where their food comes from, they literally tell me ‘Hy-Vee.’ Then I’m like, ‘Then where do they get it?’”

With a greenhouse, teachers can at least show them where stores get it — and hopefully students will get it, too, building an understanding that food, science and sustainability begin long before a grocery store aisle, she said.

It’s a first step that will become increasingly important in the coming years, Prombo said. Even schools far removed from farmland, she says, have something to gain by investing in a greenhouse and agriculture education.

“Nearly everywhere needs to consider themselves an agriculture community,” she said. “As we move forward to 2050 and a population of possibly 10 billion, those people are going to take up more space that we won’t be able to grow food on.” n Shaw Media reporter Cody Cutter can be reached at 815-632-2532 or ccutter@shawmedia.com.

Find Morrison FFA and Morrison CUSD Greenhouse on Facebook for projects, events and more regarding Morrison High School’s greenhouse and agriculture program.

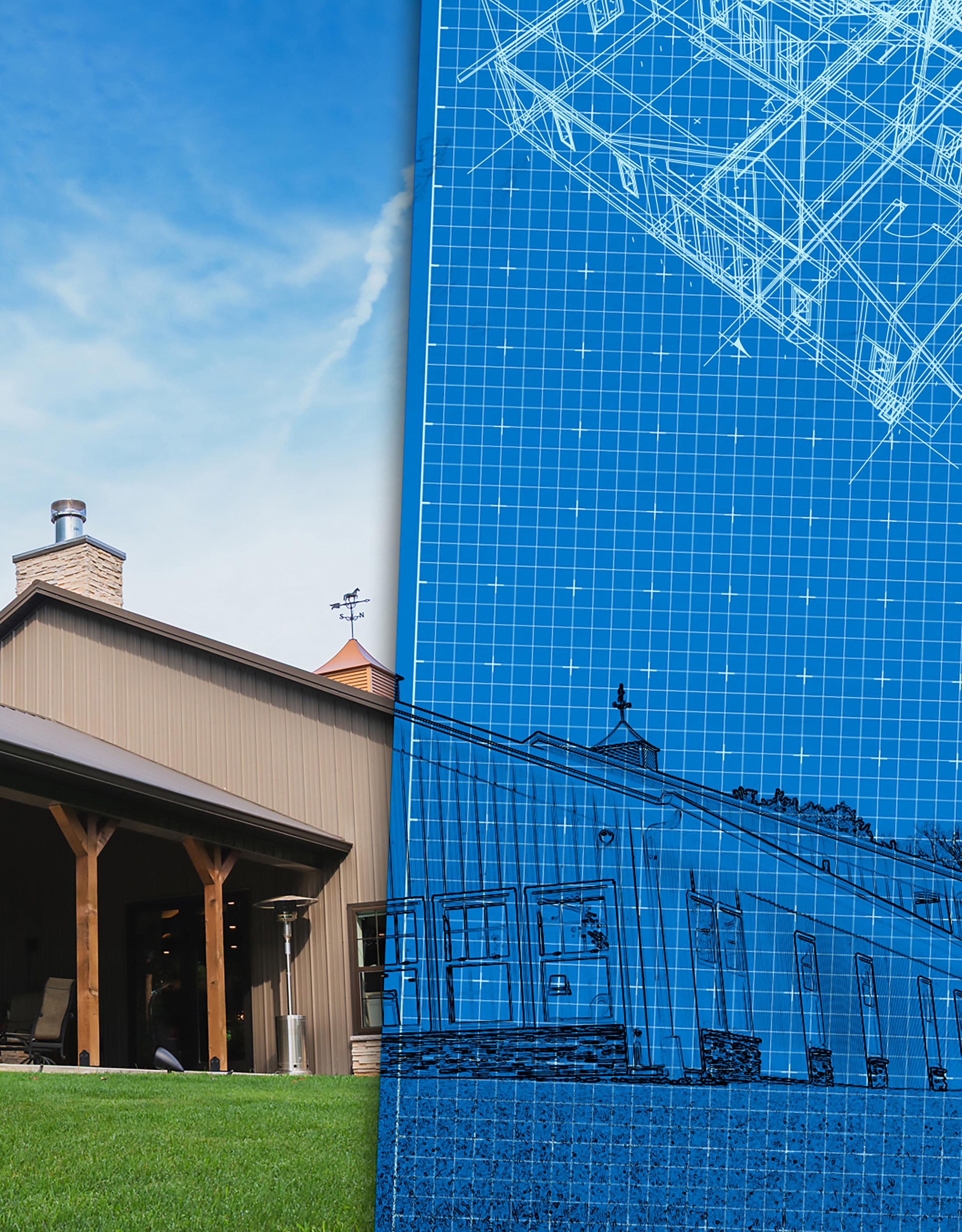

BUILD SMART. DEDUCT MORE .

FBi Buildings deliver the solutions that protect the long-term

Since barndominiums often resemble pole barns, people may assume that the cost of building one can be significantly less than a traditional home, but “that’s not entirely the case.” Dobson says. While there can be some savings from their more open floor plans, “You’re still finishing out the interior with all of this.”

While post-frame construction can offer efficiencies in materials and speed, the interior of a barndominium still includes all the same elements as a conventional home: plumbing, electrical, insulation, drywall, flooring and finishes. While the post-frame shell can be erected quickly, interior finishes still require a time and investment similar to a conventional homes. There can, however, be some savings realized from the reduced long-term maintenance that comes with owning a barndominium.

Whereas a traditional home may have vinyl siding and a shingle roof that will need replaced, barndominiums often feature steel exteriors and metal roofing, known for their durability and longevity. For many homeowners, that means fewer repairs and less upkeep over time, Dobson said.

The buildings come in a variety of styles, with plenty of room for a variety of different floor plans to suit buyers’ desires. Current trends include longer porches and more windows.

Dobson

With their flexible layouts and open floor plans with space to spare, barndominiums after plenty of room to include everything from a living space in a cozy corner of the house to a large workshop to a “great room,” (a large room that plays various roles; a sort of family room/living room/study).

PHOTOS: FBi BUILDINGS INC. FACEBOOK PAGE

Once the buyer has lined everything up for their new home — land, permits, etc. — the building can go up in a relatively short amount of time.

“What we’re seeing on our end is that people like the simplicity of post-frame construction,” Dobson said. “Depending on how large the building is going to be, we can easily have it up by 6 to 8 weeks from when a customer signs a contract.”

Go to fbibuildings.com/ barndominiums to learn more about barndominiums and to view floor plans. Find FBi Buildings on Facebook, X or Instagram, email info@ fbibuildings.com, or call 1-800-552-2981 for more information.

FBi Buildings will build the structure, but the interior work is taken care of by a general contractor. Buyers can line up their own, or FBI can help with connecting them one from their network of trusted general contractors.

In 2025, FBi partnered with Back Forty Buildings to help customers turn pole buildings into homes. Through that partnership, homeown-

ers can choose from several barndominium floor plans — including the Remington, Lakeside and Mad County designs (more plans are available on FBi’s website) — or use them as starting points for customization. While many plans feature two-story layouts, Dobson said onestory living also has become increasingly popular, particularly among older homeowners.

Others enjoy hybrid spaces that combine living quarters with workshops, garages or hobby areas under one roof. Those larger garagefocused designs are “shouses,” blending shop and house into a single structure.

“Maybe they’re a farmer or someone who has a hobby and works on cars; they’ll include a larger shop space attached to their house,” Dobson said. “Just one building to go to and from with.”

As with any home build, barndominiums come with considerations beyond just design. Zoning regulations, permit requirements and financing can vary by county and lender. Not all banks are familiar with post-frame homes, so that makes early conversations with lenders and local officials essential. But once all the t’s have been crossed and the i’s dotted, homeowners can look forward to a rustic and roomy residence that they can call home for years to come.

Demand for barndominiums continues to grow, Dobson said. Only a short time into the new year, the company had already received more inquiries in January 2026 than the same month last year. It’s becoming a market that’s building on its own success. The more barndominiums go up, the more people see them, and the more people see them, the more they become interested in one.

“All it takes is a couple of designs and people see that and go, ‘That’s what I want to have,’” she said. n

Shaw Media reporter Cody Cutter can be reached at 815-632-2532 or ccutter@shawmedia.com.

AMBOY Leffelman & Associates

Amboy 815-857-2125 lisa@leffelmanassoc.com BYRON

132 W. 2nd St., Suite 10, Byron (815) 234-3211 office@byronins.com

DIXON

Sauk Valley Insurance, Inc.

109 6th Street, Dixon 815-288-2541 www.saukvalleyinsurance.com

Stenzel Insurance Agency 102 N. Elm, Franklin Grove 815-456-2319 office@stenzelinsurance.com

LAMOILLE

Leffelman & Associates LaMoille 815-638-2171

lexi@leffelmanassoc.com LEE CENTER Baylor Insurance Agency Lee Center 815-857-2716 rbaylor1@gmail.com

Eckburg Insurance Group, Inc.

604 N. Main, Rochelle 815-888-3030

info@eckburg.com

ROCK FALLS

lsandrock@2cornerstone.com

ROCHELLE

Miller Insurance Group

427 N. Main Street, Rochelle 815-561-9911 fax: 815-561-9912

insure10@frontier.com

Query Insurance Agency

330 May Mart Drive, Rochelle 815-562-4152 tbecker@crumhalsted.com

Adami Insurance Agency

712 First Avenue, Rock Falls 815-625-6220

tracey.adamiagency@gmail.com

Hugh F. Miller Insurance Agency, Inc. 801 First Avenue, Rock Falls 815-626-1300

hughmillerinsurance.com

SUBLETTE

Leffelman & Associates

Sublette 815-849-5219

chris@leffelmanassoc.com