What a Year and Hello 2026

As we wind down and get ready to close the book on 2025, I want to take this time and share with you a point I made to the audience who attended our Open House in September. Perhaps coincidentally, it’s an especially good time of the year to talk about Gratitude.

Since becoming part of the SOMIC family in 2014, I’ve experienced professional gratitude on several different occasions. First, it is a privilege to lead the great group of people working at SOMIC Packaging here in Minnesota. We’ve come a long way in a relatively short amount of time since our early days.

I am deeply grateful to our German and American colleagues, whose shared passion for engineering, innovation, and service drives this company forward.

I am deeply grateful to our customers, who have trusted us with their production goals and allowed us to grow alongside them.

I am grateful to the mayor and city council here in Inver Grove Heights, and to the German-American Chamber of Commerce, for welcoming us into this community and supporting our journey.

And I am forever grateful to the Bonetsmuller family for entrusting me with the leadership of SOMIC Packaging, a privilege and responsibility I honor every day.

September 25, 2025 will always be one of the most special days in my life. It marked a pinnacle two years in

Retail-Ready Magazine is published by SOMIC Packaging, focusing on the Retail-Ready industry. We manufacture advanced mechatronic case-packing systems that collate, unitize and load cartons, trays, retail-ready packages, and wraparound cases.

See how SOMIC can bring new efficiencies to your packaging line.

the making as we welcomed guests from around the world into our new home. You can read all about it in this issue, but I do want to repeat a vitally important comment I said that day.

In my remarks I mentioned how SOMIC simplifies the complex in today’s packaging world. Our machines are a culmination of thousands of parts and the organization functions the same way. We are made up of many parts and each one must operate together in order for us to maximize our performance.

I talked about the influence of SOMIC’s DNA and how it strengthens our bond like a link on a chain. As we are about to usher in a new year, I can assure you we have very strong links that are getting stronger every day.

Three days after the Open House, we marked another new chapter in our history with the wildly successful debut of the 434 SuperFlex platform at PACK EXPO Las Vegas. You can read more about it in this issue, which include stories about the expansion of our partnership with Weber, Inc., and two terrific new employees who recently joined the company.

From our family to yours, I wish you happy holidays and all the best in the new year.

Respectfully,

Peter Fox, Chief Executive Officer

8270 Courthouse Blvd. Inver Grove Heights, MN 55077

+1.651.419.6050 us.somic-packaging.com

info@somic.us

Follow us on our Linkedin page:

linkedin.com/company/ somic-packaging-usa

Newcomers Roy Hoke and Joshua Larson add valuable packaging experience

Strengthening Sales & Service

Ahead of the 434 SuperFlex Rollout

Welcome to our newest team members, Roy Hoke and Joshua Larson. Combined, they have over 50 years of successful experience in the packaging industry. This expertise will be critical as SOMIC prepares for increased market demand around the new 434 SuperFlex platform.

Roy joins Rosann Bagin, Stacy Schmeiser, and Scott Welker on the Sales side in the newly created position of Southeast regional sales manager. Joshua has taken over as the after-sales and service manager, and both have ambitious plans in store for the months ahead.

“SOMIC manufactures impressive machines,” he continued,“ and I wanted to be part of a growing and innovative company. That made my decision easy, and my goals are to start developing the territory and booking orders, while continuing to learn and grow within the company.”

Building the Service Framework for the SuperFlex Era

Larson brings to SOMIC valuable cartoning and case packing experience over the same amount of years. He began as a machine assembler and moved up to field service positions before taking on field director roles at various Minneapolis area companies. He is now planning new processes for his team, which he had success with in the past.

“As SuperFlex expands, our service must scale with it. My job is to build the systems that keep customers running at their best.”

Josh Larson

Roy has spent 28 years in the packaging industry working with food and beverage, water, home care and personal products. Based in Sarasota, Fla. and responsible for a 10-state territory stretching from Oklahoma to the Carolinas, he believes his previous success and knowledge of SOMIC equipment will play an instrumental role in building his customer base.

“At my last job, I took a negative margin product line with minimum sales and transformed it into one of the company’s most successful product lines with an average 42% gross margin. I also helped create three new machines and product improvements to expand the company portfolio towards customer needs.

“I like to build solid teams who have a connection with our clients, and a desire to make sure they are taken care of at each opportunity,” said Joshua about supporting customers by better understanding their needs. He will soon be introducing new improvement programs.

“I plan to develop strong processes and implement new systems, which can be challenging but very rewarding. In the past I introduced CRMs that have improved service tracking, billing, reporting and other functions. Some processes here are now being changed for the betterment of our customers.”

“SuperFlex gives customers the flexibility they’ve been waiting for. My goal is to help them see what’s now possible.”

Roy Hoke

A WARM WELCOME

Open House dazzles global Visitors

On a picture perfect day, we welcomed more than 120 guests from around the world to our Open House event in Inver Grove Heights, Minnesota on September 25.

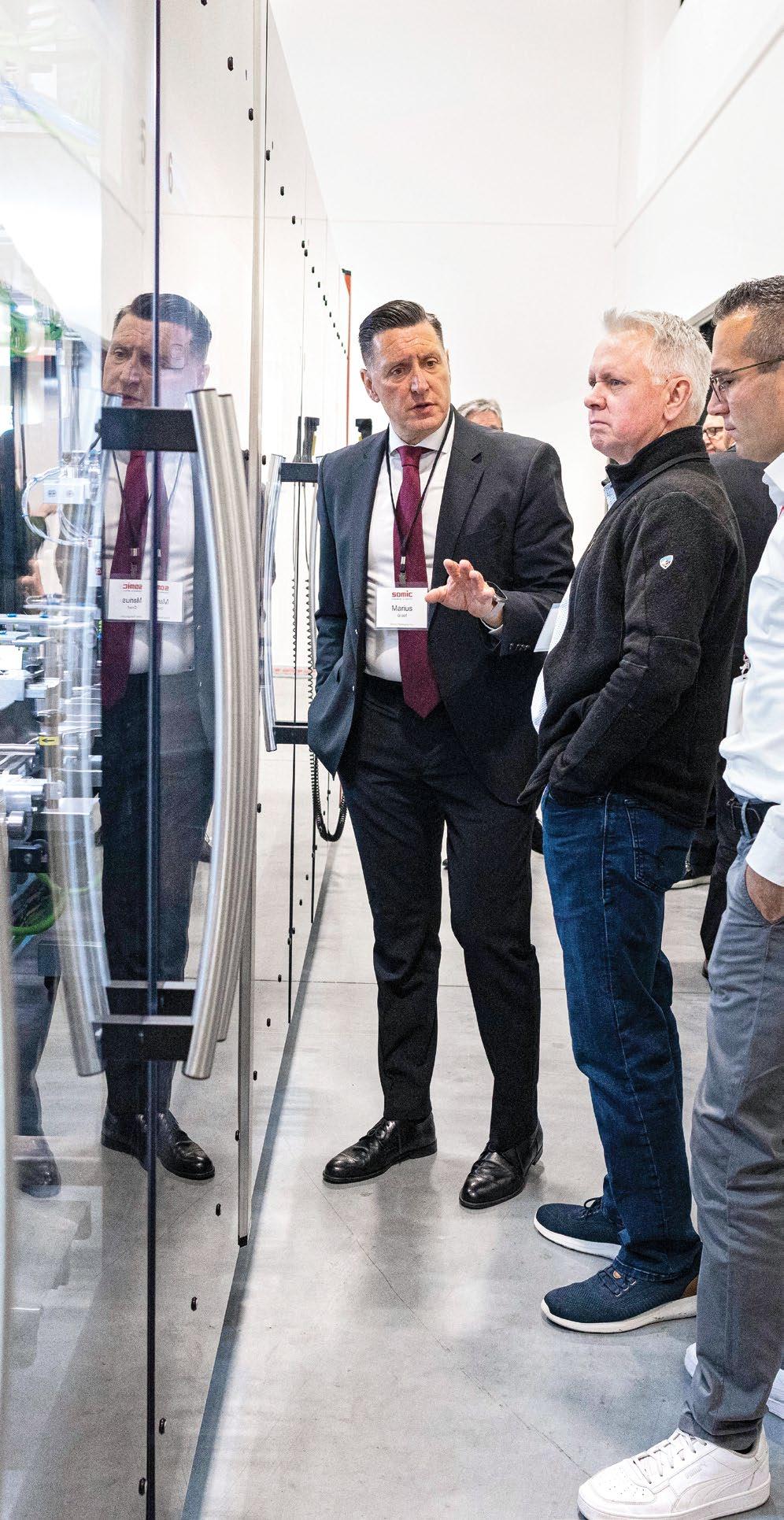

Several SOMIC officials were joined by local dignitaries who spoke to the crowd. Their speeches were followed by a formal ribbon cutting ceremony and tours of the sparkling 48,000 square-foot facility with demonstrations of various equipment.

A

First Look at the 434 SuperFlex

One machine that impressed everyone was the new 434 SuperFlex case packer. Our most revolutionary, end-of-line packaging machine ever, this next generation machine made a lasting impression with all just three days before it was formally introduced at PACK EXPO Las Vegas.

From a Small Office to a National Home

SOMIC Packaging CEO Peter Fox served as the master of ceremonies and set the tone for the day with his initial remarks. Thanking all involved, he recalled the small leased space the company operated from in Chicago when SOMIC entered the North American market in 2014 before relocating to Eagan, Minnesota in 2018.

“We’ve come a long way since the early days. This building gives us four times the capacity of our prior facility and brings under one roof all the functions that support innovation, engineering, project planning, assembly, commissioning and testing, spare parts logistics, sales delivery, and service.”

“The passion, pride and craftsmanship I saw was tangible; you could feel it.”

Peter Fox, SOMIC CEO

The Pursuit of Perfection

Fox shared that when first introduced to the company in 2014, he had never heard of SOMIC. After a trip to Germany, he soon understood how the commitment to excellence is part of the company’s DNA and explained why the sun never sets on SOMIC.

“The passion, pride and craftsmanship I saw was tangible; you could feel it. I discovered the SOMIC DNA,” he said. “It begins with a fundamental pursuit of perfection. There is nothing manufactured in the world that is 100% perfect, but it is the pursuit of perfection that is at the core of our SOMIC DNA.”

After expressing his gratitude for SOMIC’s deep passion for engineering, innovation, and service and how it drives the company forward, Fox introduced Patrick Bonetsmuller, chairman of SOMIC Verpackungsmaschinen GmbH & Co. Mr. Bonetsmuller looked around the room, talking about the spacious new headquarters while pointing to all of its natural lighting, and said it was a grand day for a celebration.

He was followed by heartfelt remarks from James Schollett, president of the German American Chamber of Commerce Minnesota chapter, and Brenda Dietrich, the mayor of Inver Grove Heights.

Commitment to U.S. Operations

Dr. Gerhard Huber, CEO of The SOMIC Group, discussed the company’s commitment to operations in the United States and future investment. Chief Operating Officer Tim Haase spoke directly to the customers in the room and provided them with insight about future plans. Fox returned to the podium and shared his final thoughts about the machines and the organization.

Simplifying the Complex

“The mark of true genius is to simplify the complex. Anyone can make the simple complex, but to break down complex problems – or, in the case of our machines the functions – and make them simple, efficient and repeatable, that is genius,” he said.

“You will find these ingenious functions and devices throughout our machines. The harmonic coordination of many functional devices working in concert, efficiently and effectively. That is the SOMIC DNA.

“We do this so we can be the leader in providing our customers with the best and most efficient way to automate their packaging operations. This makes them more competitive and efficient in the marketplace, and when they succeed, we succeed. This is why at SOMIC, we proudly say we are engineered to perform. And now we are made in the USA.”

Inside the New Headquarters

Visitors then began touring the building which opened in October 2024 and is located only 10 minutes from the Minneapolis-Saint Paul International Airport. Besides the 434 SuperFlex, they saw machine demonstrations including the 434 with CORAS® collating and grouping technology.

Made in Minnesota

As Fox explained in an interview with the local ABC-TV station, all North American machine installations are now being assembled in Minnesota.

A Celebration to Remember

After the tours, a catered lunch was served outdoors, giving guests an opportunity to mingle and enjoy the sunshine. Later in the day, many visitors continued the celebration in nearby Stillwater for an evening of dinner and entertainment, bringing a memorable close to a landmark event for SOMIC.

On stage for the ribbon cutting ceremony was, from left to right: Peter Fox, SOMIC CEO; James Schollett, president of the German American Chamber of Commerce Minnesota chapter; Patrick Bonetsmuller, SOMIC Chairman; Brenda Dietrich, the mayor of Inver Grove Heights; Dr. Gerhard Huber, CEO of The SOMIC Group; and Tim Haase, COO of The SOMIC Group.

A NEW STAR IS BORN

“We had a great response from the people who saw the machine demonstrated in the booth, and they now have a better understanding of how we streamlined our design-to-order process.

Peter Fox, SOMIC CEO

In its early years over a half century ago, Las Vegas was the entertainment destination for the stars of Hollywood. When those famous names of screen, song, and stage lore needed to unwind, they made the 300 mile trek to the desert mecca.

Some would stay for long weekends or longer periods. A few enjoyed the nearby escape so much, they would mix business with pleasure

and perform at casino properties like today’s stars do with residency agreements.

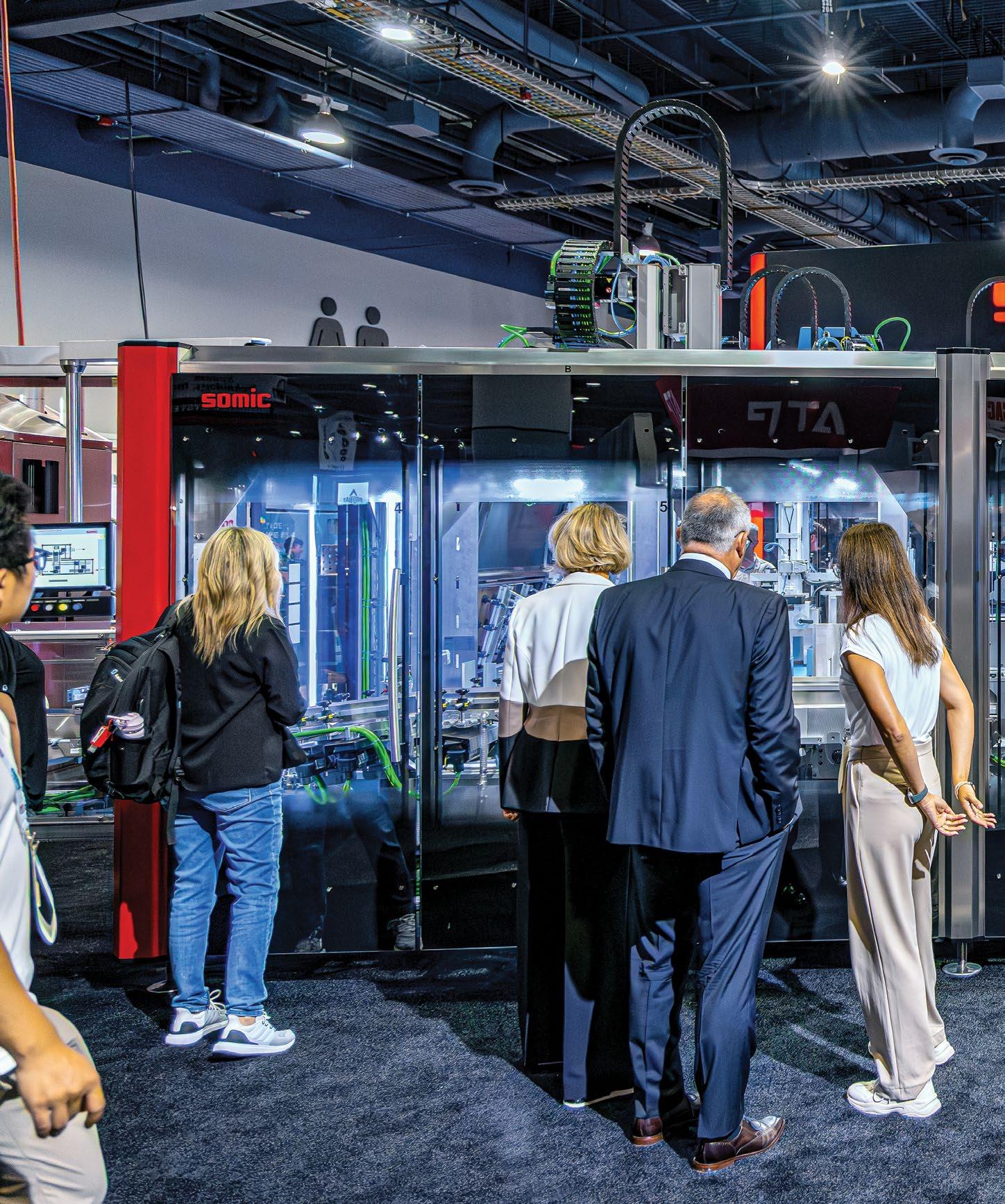

The stars still shine in Las Vegas and on September 29, a new one was created in the South exhibition hall of the Las Vegas Convention Center. SOMIC’s new 434 SuperFlex case packer received stunning reviews from an overflow crowd that packed our booth at PACK EXPO Las Vegas.

“The majority of the integrated platform is designed with standardized architecture, so it can meet the needs associated with end-of-line automation now, next month or next year.”

Peter Fox, SOMIC CEO

“We were talking to people as soon as the show opened. Everyone we spoke to was impressed with the 434 SuperFlex. It received so many compliments, and one person called it the Ferrari of case packers,” said CEO Peter Fox, who indicated the final results far exceeded expectations for the show.

“Our booth was very busy all three days of the show. The number of people who visited was very good throughout, and we recorded much greater scan numbers compared to the last show in Las Vegas. We registered half of our total scans on the very first day.”

A do-anything machine

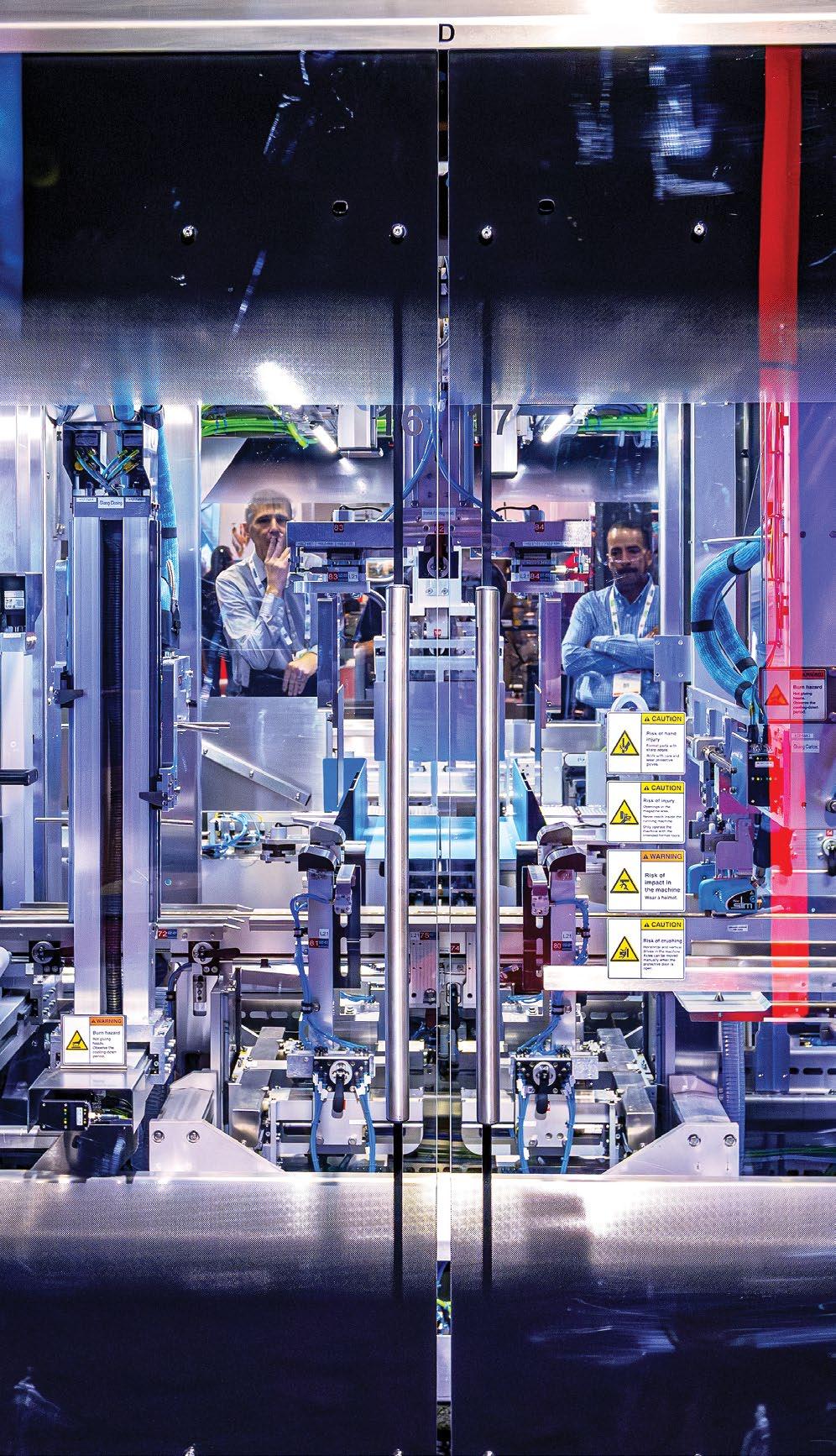

As everyone who visited the booth quickly discovered, the 434 SuperFlex is capable of producing nearly every possible major retail packaging configuration. Designed to handle upright, stand-up pouch displays and wraparound cases, or two-piece tray-and-cover formats, flat nested orientations and other needs, the options are endless.

“The majority of the integrated platform is designed with standardized architecture, so it can meet the needs associated with endof-line automation now, next month or next year,” said Fox.

“We had a great response from the people who saw the machine demonstrated in the booth, and they now have a better understanding of how we streamlined our designto-order process. With 80% of the machine pre-engineered and only 20% requiring customization to match a customer’s specific packaging application, they saw first-hand how we can deliver it much faster. We can have it to them in a fraction of the time, especially now that all North American machine installs are being done in Minnesota.”

Compact, fast and future-proof

Fox said this is important because it offers customers strategic value and other benefits.

“Built to scale and being a compact machine, the 434 SuperFlex requires up to 50% less space than traditional, multi-component systems,” he acknowledged. “Since we engineer it with precision servo controls, integrated product conditioning, and proprietary mechanisms for handling pouches and imperfect blanks, this machine gives CPG brands, co-packers and others more options.”

He indicated that success in Las Vegas is boosting momentum going into the new year.

“We spoke with many decisionmakers and I’m very encouraged with the depth of the conversations. We have taken the next step by following up and arranging in-plant visits to evaluate their operations and see what works best for them.”

“Built to scale and being a compact machine, the 434 SuperFlex requires up to 50% less space than traditional, multi-component systems.”

Peter Fox, SOMIC CEO

A Seamless Slice-to-Shelf Solution Weber + SOMIC:

PACK EXPO Las Vegas also served as the stage for SOMIC and Weber to showcase their respective machines that combine efforts to make retailready convenience meal case packaging easier for grocery stores and others.

Peter Fox and Weber CEO, Jarrod McCarroll, met with the media and spoke with customers about their company’s relationship that was formed in 2021. Weber systems for packaging ready-made breakfast sandwiches, snack trays, wraps, and dinner kits have included SOMIC machines such as a 424 T2W case packer with four case formats.

“The days of long runs of the same product are gone.”

Weber has also invested in the SOMIC 434 platform and plans to utilize the 434 SuperFlex. At the show, Fox and McCarroll explained how the partnership can open more doors. For Weber, it will help gain access in the dairy industry, specifically the cheese segment given SOMIC’s established footprint. At the same time, Weber can help SOMIC in the protein processing market.

“The days of long runs of the same product are gone,” emphasized McCarroll, who has led Kansas City-based Weber since 2014. He believes the partnership can provide a competitive advantage in emerging markets as meal assembly kits and sandwich processing lines.

“When you show a customer their product flowing from slicing to portioning to assembly, then straight through to a retail-ready carton that is fully-automated, it really clicks. They see how they can scale up, launch new SKUs, and still meet tight retailer requirements without adding square footage or people.”

Fox notes that the partnership works because both companies think the same way about technology and uptime. SOMIC and Weber share similar servo platforms and data architecture, which eliminates the integration headaches processors face when mixing equipment from different suppliers.

“SuperFlex is built to future-proof operations,” said Fox. “Mediumsized processors we spoke with at the show are the ones leading the charge. They’re nimble, they’re proactive, and partnerships like ours give them the technology needed to seize new opportunities before competitors do.”

With automation reshaping the ready-meal and fresh-food landscape, the SOMIC–Weber collaboration continues to demonstrate what’s possible when two engineering-driven companies align around customer needs and deliver a seamless, retail-ready solution from the first slice to the finished case.

“They see how they can scale up, launch new SKUs, and still meet tight retailer requirements without adding square footage or people.”

Jarrod McCarroll, Weber CEO

From an Open House to endless possibilities, the future is exciting.

In the fall of 2024, SOMIC Packaging relocated to a larger North American headquarters in Minnesota. Since this move, we've expanded our services to the packaging equipment industry, and future-ready innovation inspires our way forward. We're assembling our own equipment here to get our customers up to speed faster. We’re hiring more technicians and service staff to shorten periods of downtime. And all this is just the beginning. Not only are we anticipating the future in our new home, we’re creating it.

Look inside this issue of Retail Ready to learn more about the Open House and the equipment featured at it. 651.419.6050 • somic.us.