DESIGNING LIFE SCIENCE BUILDINGS

FOR A LOW CARBON FUTURE

Authors:

David Hilditch Scott Brownrigg

Fiona Grieve Scott Brownrigg

Steve Jell Scott Brownrigg

Introduction

Opportunities to create carbon savings

A data-driven design approach

Case studies

Carbon offsetting

Conclusion

INTRODUCTION

Life science buildings tend to be complex, resource-intensive environments and therefore present numerous design challenges that need to be addressed to work towards a low carbon future.

A holistic, integrated design approach that considers the entire lifecycle of the building, from material extraction and manufacturing, to construction, operation, and eventual decommissioning is required. Collaboration between architects, engineers, material experts, and sustainability experts is essential for striking the balance between meeting the functional requirements of laboratory buildings and ensuring carbon efficiency during construction and in operation.

This paper outlines the key considerations when designing life science buildings for a low carbon future and uses three case studies to detail the viability of retrofitting another building typology for life sciences, designing a new build ‘best in class’ laboratory, and achieving cost-effective low carbon laboratory design.

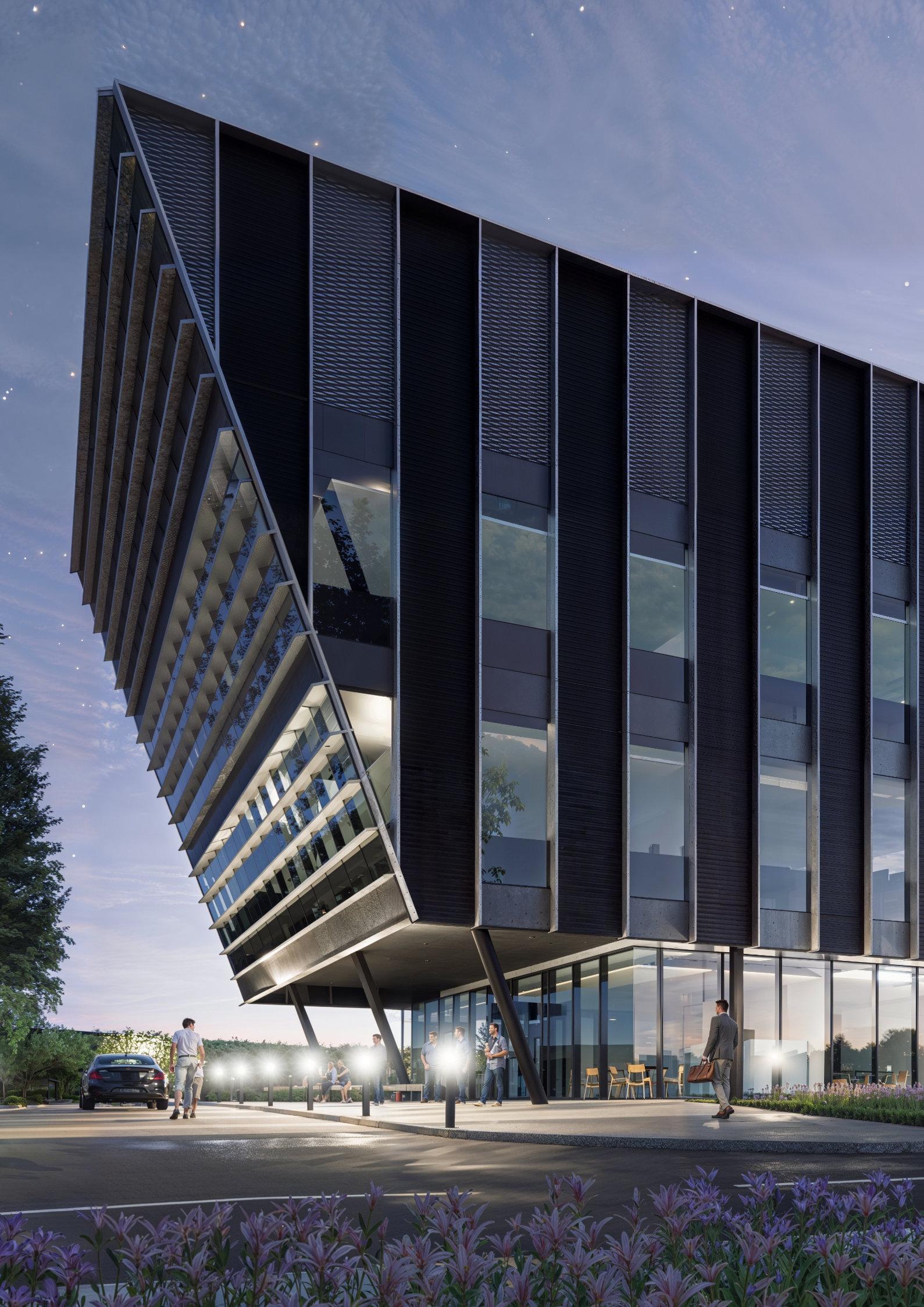

Proposals for a new landmark R&D facility at Southampton Science Park © Scott Brownrigg

OPPORTUNITIES TO CREATE CARBON SAVINGS

Life science buildings require robust structural systems and are extremely energy-intensive in use, however there are many opportunities to reduce both the carbon associated with these buildings during design, construction and in operation. Key areas to consider are:

DURING DESIGN

Structural frames

Laboratory buildings require extensive structures to meet the strict vibration and loading criteria for experiments, equipment and research. A hybrid solution which integrates a concrete structure for laboratory spaces and a pre-manufactured timber structure for offices presents opportunity to significantly reduce embodied carbon.

Flexibility and futureproofing

Ensuring the building can adapt to future needs is very important, as the life science industry is an ever-changing field. Embracing circular economy principles in laboratory design and planning for the entire lifecycle can significantly reduce whole-life embodied carbon emissions in buildings. By maximising resource efficiency, and minimising waste, designers can play a crucial role in mitigating environmental impact.

Building envelope and insulation

High-performance building envelopes require good u-values, tailored glass specification and a careful balance between solid and glass – user comfort is vital. Specifying higher quality materials with greater insulation may increase embodied carbon but could help significantly reduce operational carbon by minimising need for additional heating and cooling systems.

Material selection and sourcing

Laboratories require the use of durable, highperformance materials which often results in the use of concerete, vinyl and blockwork. The challenge is to find equally robust sustainably sourced or recycled materials with significantly lower embodied carbon.

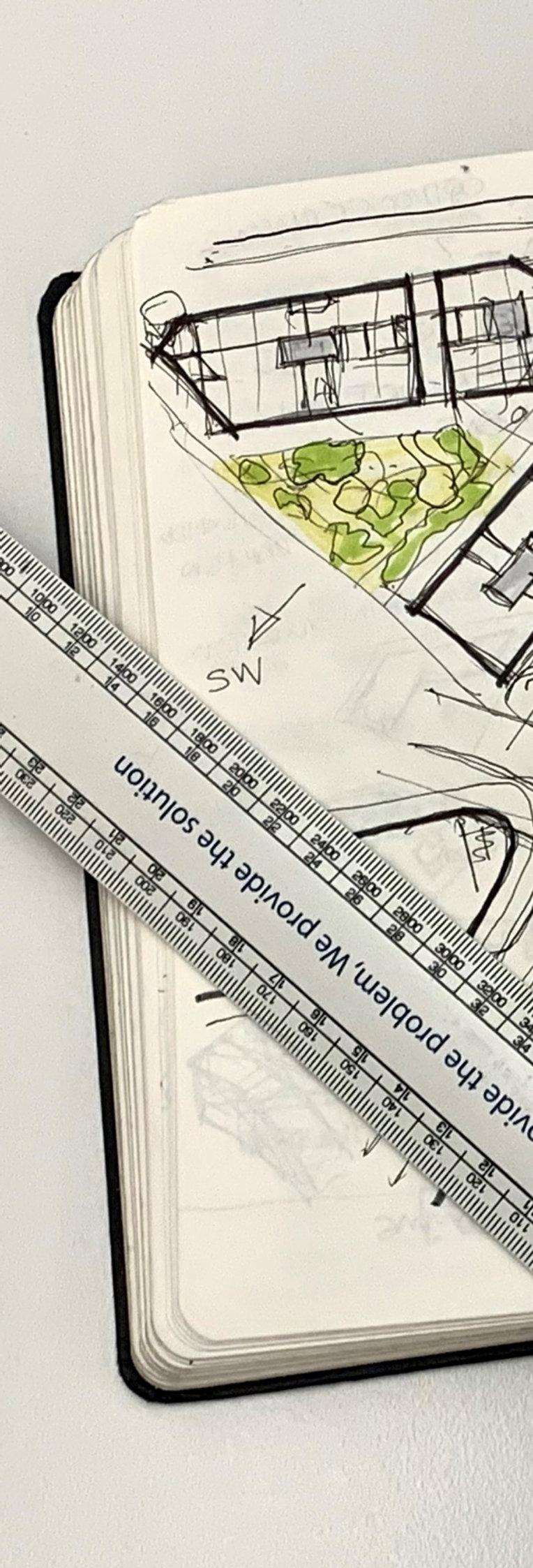

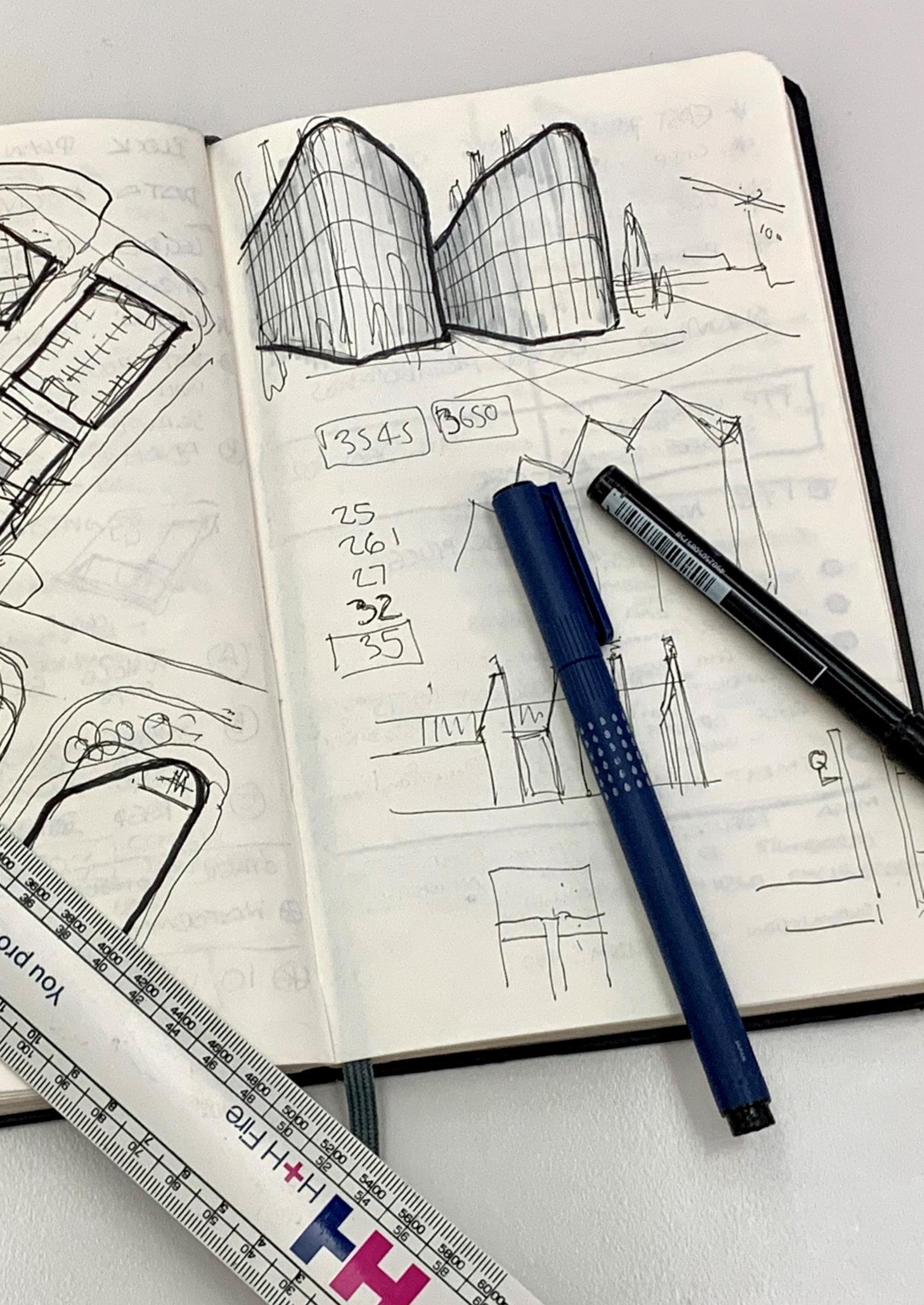

Life sciences sketches © Scott Brownrigg

© Scott Brownrigg

Cambridge International Technology Park © Scott Brownrigg

DURING CONSTRUCTION

Certification and compliance

Targeting initiatives which require a commitment to government net zero targets, such as RIBA 2030, promotes a more holistic approach to sustainability and provides embodied carbon targets to align with. More clients are also seeking or setting their own sustainability targets for projects.

Construction waste and practices

Minimising waste during the construction phase is crucial, prioritising prefabrication, locally sourced materials and recycling of existing materials. Minimising waste from the highest spending carbon elements such as the façade and structure should be prioritised alongside the application of circular economy principles to the design.

IN OPERATION

Integration of renewable energy

Using renewable sources of energy and systems for energy storage is important to lower operational carbon, however analysis of the operational carbon savings payback time should be assessed and taken into consideration.

Economic and operational constraints

Operational savings should be compared to the embodied carbon cost; it may be worth spending embodied carbon to reduce operational carbon by a greater amount over the lifetime of the building. It should be noted however, that as the grid continues to decarbonise, embodied carbon will become a more significant proportion of the whole life carbon cost.

A DATA-DRIVEN DESIGN APPROACH

Adopting a data-driven approach and undertaking carbon calculations as part of the design process allows us to minimise the impact of our projects by identifying opportunities for carbon saving and testing different designs in an iterative process. Data driven from carbon testing is a valuable tool in providing informed decisions, so that we can be sure we are embedding low carbon design in all our work.

To measure quantities, we extract information from an up-to-date and accurate Revit model, following the RICS guidance for measuring and classification of building components. We input this data into OneClick LCA which uses certified Environmental Product Declarations (EPDs) to give us a whole-life embodied carbon breakdown. We can then use this to test different iterations and replace components to test their impact, repeating the process throughout the design stages to refine and improve wherever possible.

We recently analysed the carbon associated with three different approaches to life science projects as shown in the following case studies.

OneClick LCA © Scott Brownrigg

Urban Labs © Scott Brownrigg

CASE STUDIES

3.1 Case study: Urban Labs

Converting a retail building into laboratories

Urban Labs is a concept for transforming disused retail units across the country into spaces for science centres, currently focussed on a test project at The Fitzroy in Cambridge. Converting these spaces into flexible co-working science hubs can help to reinvigorate the high street whilst giving tenants ease of access to wider town and city centre amenities. This approach involves taking an existing building and retrofitting it to meet laboratory requirements. The primary advantage is the significant reduction in embodied carbon by reusing the existing structural frame. Key considerations include:

• Building typology and constraints: Feasibility studies to explore the existing building’s structural, service and spatial constraints to ascertain suitability to house life sciences which typically require high ceiling levels and access for deliveries and servicing.

• Structural adaptation: Ensuring the existing structure can support the necessary load bearing and vibration control requirements for laboratory equipment, or have the opportunity for reinforcement without major intrusion.

• MEP system integration: Upgrading mechanical, electrical, and plumbing systems to meet the stringent environmental controls required for laboratories, without adding excessive embodied carbon.

• Material selection: Careful material selection for refurbishment to maintain low embodied carbon while achieving better performance standards.

Urban Labs © Scott Brownrigg

The current total estimated embodied carbon for retrofitting and adding a top floor extension to Fitzroy Street to shell and core standard is approx. 618 tonnes @ 220-250 kg/m2. An equivalent new build would be over 600-850 kg/m2, which illustrates a significant carbon saving associated with re-using the existing building. In the graph below we can see where the carbon is being spent. Most of the carbon is associated with the structure, as well as the roof and walls for the top floor extension. There is also significant spend on upgrading existing curtain walling for better thermal performance, which is important to meet current standards and will reduce operational energy/carbon.

There was desire to use a timber frame instead of steel for the extension, however this was not possible due to height restrictions and the increased size of timber members to meet structural loading requirements. Our steel frame, assuming the worst-case scenario where 0% steel is recycled, cost 130 tonnes of carbon. It would cost over six times this in carbon to create a concrete structure and foundation for a new build of equivalent size. The existing building’s structure, including foundations and steel frame, would have cost over 1200 tonnes of carbon initially, which we have saved by retrofitting the existing retail building.

Retrofit is not, however, a one-size-fits-all solution for life sciences. The use typically requires high ceiling spaces and good quality building access for servicing. The form and quality of the structural framework may also impose limits on the type of science that the finished building can accommodate, due to greater vibration measures. The potential need for extensive strengthening and stabilisation works could reduce carbon savings. The Urban Lab project involves reuse of a retail building which offers ample ceiling height and natural light, but the building’s location and structural constraints present their challenges.

As a vital part of a holistic approach to site selection and development, retrofit can offer fantastic opportunities which should be explored and seized where appropriate. The Urban Lab project aims to demonstrate that the volume of vacant and struggling high-street retail space could present a real opportunity for the burgeoning life science sector to make real change in communities.

3.2 Case study: Eastpoint

Creating a new ‘best-in-class’ laboratory

Eastpoint is the transformation of an underused business park in Oxford into a new flagship life science campus. The scheme will bring an additional 200,000 sq ft much needed life science space to the Oxford-Cambridge Arc and provide a focal point for interaction with STEM and educational outreach within the local community.

This scenario explores carbon testing and design iterations undertaken in the early stages of a new-build project. Where the typical stringent load, vibration, and energy performance criteria are required in tandem with a design brief that targets a high-quality best-in-class facility with wellbeing provision beyond the typical.

Developing this sustainability strategy focuses on creating a balanced and enduring scheme where the human aspects of sustainable design are addressed equally to low carbon design, to ensure the wellbeing of current and future generations. The key issues included in this study are:

• High-performance materials: The need for durable and resistant materials to meet laboratory standards, which often come with higher embodied carbon.

• Advanced structural systems: Designing robust structures to support heavy equipment and control vibrations, typically involving materials with significant embodied carbon.

Our approach for Eastpoint was to get a baseline for our design and then investigate where we could make carbon savings. Initial findings shown in this graph are for a shell and core and do not include MEP equipment. The team explored potential reductions in some of the largest areas responsible for carbon spending: the structure, façade and floor build-up.

One of the first high carbon areas the design team tackled was the structure. A lab typically requires a vibration criterion of 1 or less, putting stringent requirements on the structure that naturally drives a concrete solution. On this project the limitation of space for plant on the roof stipulates a maximum capability of 55% laboratories across any one floorplate. The first step was to assess the brief, establish the best location for the laboratories, and reduce the remaining structure to a vibration criteria fit for

office and write up use. The first option explored was a hybrid timber and concrete structure. With a concrete laboratory structure and timber office structure, carbon could be reduced by 8%. Issues with insurance and added costs made this solution unviable. Waterman’s calculations and research into concrete use and how we could reduce carbon, established a potential to save over 17% of the total buildings carbon by using a high percentage of GGBS cement

replacement, and allowing the extra curing time for added strength. Furthermore, the design required an estimated provision of 110 tonnes of steel for secondary framing and the Photovoltaic (PV) panel supporting frame. With the use of 90% recycled steel, an additional saving of 5% of the building’s total carbon could be made. This is an area the team are looking to explore at the next stage of design.

Visualisations of Eastpoint Business Park © Scott Brownrigg

Eastpoint courtyard © Scott Brownrigg

The second highest carbon spending was in the façade. Testing undertaken through the design process focused on creating a balance that would address the embodied carbon spent against healthy environments, biodiversity net gain, and mitigating operational carbon spent later in the project’s lifecycle. With careful consideration to form, orientation, user wellbeing and the holistic performance of the fabric, a kit of modular components was developed. Each piece a carefully considered and highly functional piece of the puzzle that brought biodiversity, air quality mitigation, and user wellbeing into the façade design through planters, terraces and openable windows. These pieces were then composed across the façade through daylight and solar gain testing undertaken by Hoare Lea to address long term operational carbon and user comfort. Once the composition of the façade was established, the team investigated material selection. Glass Reinforced Concrete (GRC) was the preferable feature material selected for its low-carbon properties, versatility in form making, and durability. With the support of Colorminium, the façade carbon spending was analysed to determine the best construction method for the solid areas (SFS), glazing installation (punch hole windows) and feature bands (GRC panels hung on steel frame). Tested against three other options, this construction method reduced embodied carbon by 20% from the original design intent. It also provided a substantially better U-value, with a betterment of 0.2W/m2K against the previous.

Next, we looked at the floor build-up zone (right). A typical life science building floor build-up contains a 150mm raised access floor to the office area and a 75mm screed with 55mm void former to the laboratory side. Through initial calculations, we found this 150mm zone accounted for 10% of the building’s total carbon. Beyond carbon saving, the omission would save money, reduce waste and dead load on the structure, and provide a positive carbon saving benefit; attracting tenants who care about sustainability and carbon impact.

By implementing these best-case scenario changes, shown in the Design Development graph (left), we could save 46% of the total carbon from our initial design, producing a leaner, ‘best in class’ life science building.

OPTION 1: NO FLOOR ZONE

FLOOR FINISH ZONE

FLOOR BUILD UP ZONE

OPTION 2: SCREED

FLOOR FINISH ZONE

SCREED

VOID FORMER

FLOOR BUILD UP ZONE

OPTION 3: RAISED ACCESS FLOOR

FLOOR FINISH ZONE

RAISED ACCESS FLOOR

FLOOR BUILD UP ZONE

Southampton Science Park © Scott Brownrigg

3.3 Case study: USSP Gateway Building

Cost-effective, low carbon lab design

The USSP Gateway Building is a new three storey 3,400 sqm multi-tenancy research and development building at the entrance to The University of Southampton Science Park. Space within the curved design is optimised to provide tenants the flexibility to adapt the layout to suit their needs, with a sleek glazed facade providing exceptional levels of natural light and views out over the surroundings.

This case study explores how a new build life science building with a CAT B lab fit out can be designed to minimize carbon in a cost-effective way. This study emphasises the importance in understanding carbon reduction throughout the building’s lifecycle, especially in material selection. Typically, a more sustainable project is seen as requiring a greater fiscal cost, but this isn’t necessarily true. Key issues include:

• Material optimisation: Selecting materials with the lowest possible embodied carbon that still meet performance criteria and with a good design life, while ensuring sustainable sourcing and minimal waste during construction.

• Design cost: A lot of projects have a restricted budget, and it is important to understand this constraint whilst ensuring that cost saving doesn’t lead to large increases in embodied carbon.

From initial testing, it was clear our upfront carbon was mostly in the façade and finishes. Please note this study does not consider structure and servicing. Material selection was carefully considered and tested to allow the data to inform savings. As a speculative CAT B project, we were able to expand our testing and interrogate expenditure on internal finishes, floors and ceilings and the large impact caused by these items.

When looking at the façade we focused on creating a lean design, which brought benefits on carbon and cost savings for the project. Two equal sized sample areas on different elevations of the façade were tested in OneClick LCA to identify carbon savings. On the more visually

prominent east façade, the design included protruding caps, which provide shade and form a key part of the architectural rhythm of the design. On the west façade these caps were removed, with daylight testing undertaken for confirmation, saving around 30% of the façade’s carbon for that area. When expanding the testing to analyse the wall construction systems for these sample areas, curtain walling prevailed in the carbon saving. When adding in the impact of using aluminium with high recycled content, the saving was even greater and not proportionate. Going from a UK average of 31% to 70% recycled aluminium content can halve the embodied carbon. With this change, the project would save 4% of the entire building’s carbon without impacting the building design.

Southampton Science Park © Scott Brownrigg

Our analysis also looked at the impact of floor finishes, primarily the replacement of carpet tile for vinyl in the write up areas. Although the materials have a similar upfront carbon cost (acknowledging this can vary greatly with specific product specification), long-term analysis shows that vinyl is more durable and can last twice as long. If both products are used for their full life, the choice of vinyl would halve the embodied carbon spent on the floor finishes. It is worth noting that this calculation is dependent on tenant behaviour as often the lifetime of finishes is shorter than manufacturer recommendations due to excess attrition, changes in fashion, or new tenants wanting to update the space. We also reviewed the end of life for these items to understand how we would recycle or directly re-

use. An adhesive free vinyl would make removal for re-use easier, further reducing the future embodied carbon impact. Furthermore, the embodied carbon can vary greatly between similar products, especially if there are products available with high recycled content or high biogenic content. It is important to find EPDs for specific products, as early as possible so that the design team can utilise the data to make informed choices and avoid changes to products in later stages, which may greatly increase the carbon.

CARBON OFFSETTING EQUIVALENCE

One alternative way to push for a ‘net zero’ carbon building is by using carbon offsetting schemes such as tree planting. Shown here are the areas of new UK woodland required to be planted and maintained in order to offset the entire building’s upfront embodied carbon. This data is created using the Woodland Trust estimate of 300 tonnes of carbon sequestered per hectare over 100 years.

Overlaying the offset onto the project’s site plan illustrates that the area required for offset treeplanting is much greater than the site footprint, even for best-case low carbon scenarios.

With a high demand for land in the UK, and significant shortage of land available to be converted to woodland, finding the necessary land for carbon offsetting is not a simple or longterm solution to achieving net zero.

When outsourcing offsets internationally, there can be issues with ensuring accountability and guarantees over forest management. Do we know how many trees are planted, and how many live long enough to lock in the required carbon?

Offsetting, if used, should be undertaken to the Gold Standard which was developed to ensure the offsetting of projects are reliable and sustainable. If they are not gold standard, there is a risk of carbon offsetting credits being a false economy.

It is imperative to reduce the embodied carbon before offsetting is considered as a part of a project’s credentials.

CASE STUDY 1: RETROFIT

Would require approximately 2 hectares of Woodland to offset upfront embodied carbon.

An equivalent newbuild would require approximately 3 times the area of woodland for offsetting.

CASE STUDY 2: BEST IN CLASS LAB

The baseline design case would require 50 hectares of woodland to offset embodied carbon.

Our best-case scenario reduces this to 28 hectares.

CASE STUDY 3: COST EFFECTIVE LAB

For our current design it would require approximately 7 hectares of woodland to offset embodied carbon.

The Daubeny Project at The Oxford Science Park © Scott Brownrigg

CONCLUSION

Life science buildings have specific requirements, limiting factors and varying briefs, however there are always opportunities to create leaner, lower carbon life science facilities. Each of the cases studies explored in this paper face numerous challenges and require careful design, collaboration, and support for ambitious innovative solutions. Testing throughout the design process allows us to identify opportunities for meaningful reduction in embodied carbon with data driven evidence.

Ultimately the best opportunity to create a low carbon design is through retrofit, however the conditions required for a life science building do not always permit this typology to easily operate within the conditions defined by existing building stock. Carbon emissions are a critical component in the path to a better future, however sustainability extends far beyond these issues and other areas must be considered. It is important that each project takes a balanced and holistic approach to ensure it provides good social and economic value with low carbon spending.

Addressing climate change requires a multifaceted approach, creating a balance that integrates various aspects in the design decisions, project strategies and consequential behaviours of building users. Creating buildings that people want to use is crucial in achieving a low-carbon building. Without tenant engagement and satisfaction, even the most energy-efficient buildings will fail to meet their sustainability goals.