Positive IMPACT

Predictions

Minimizing disruption and maximizing opportunities in the supply chain

Integration

A strong digital backbone can fix vulnerabilities and deliver agility

Resiliency

The need to predict and be ready to manage Black Swan events

Vol 9 - Issue 12 - 2022

Why it makes sense to increase sustainability when looking to cut freight costs

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Consultant Tom Vince Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Steven Dobinson

Editorial Administrator Amy Gilks

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork Administrator Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors Philip Monument, Joy Francesconi Head of Content Management Adam Blanch

Client Sales Executives Chloe Allman, Mark Cawston

Project Managers Lewis Bush, Jo-Ann Jeffery, Lauren Proulx, Ben Richell, Basil Sharpe

Content Managers Mark Cowles, Valentina Forero, Jeff Goldenberg, James Page, Richard Saunders, Tarjinder Kaur De Silva

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

US Office

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Hello and welcome to the December issue of Supply Chain World. I’ve been looking back over the year and thinking about the number of fascinating people we’ve been lucky enough to interview. I am so grateful for the insights they have shared and the generosity with which they have discussed the strategies behind their success. I extend a warm thank you to all those companies we have spoken to, as well as the other contributors who have created features for us. I am really looking forward to working with you again, as well as bringing in a new host of interviewees and authors – 2023 could deliver the best content yet!

Hammond, Editor

lh@finelightmediagroup.com

Integration A strong digital backbone can fix vulnerabilities and deliver agility Minimizing disruption and maximizing opportunities in the supply chain Resiliency The need to predict and be ready to manage Black Swan events Why it makes sense to increase sustainability when looking to cut freight costs Positive IMPACT

of the magazine are strictly copyright, the property of

and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents

Finelight Media Group,

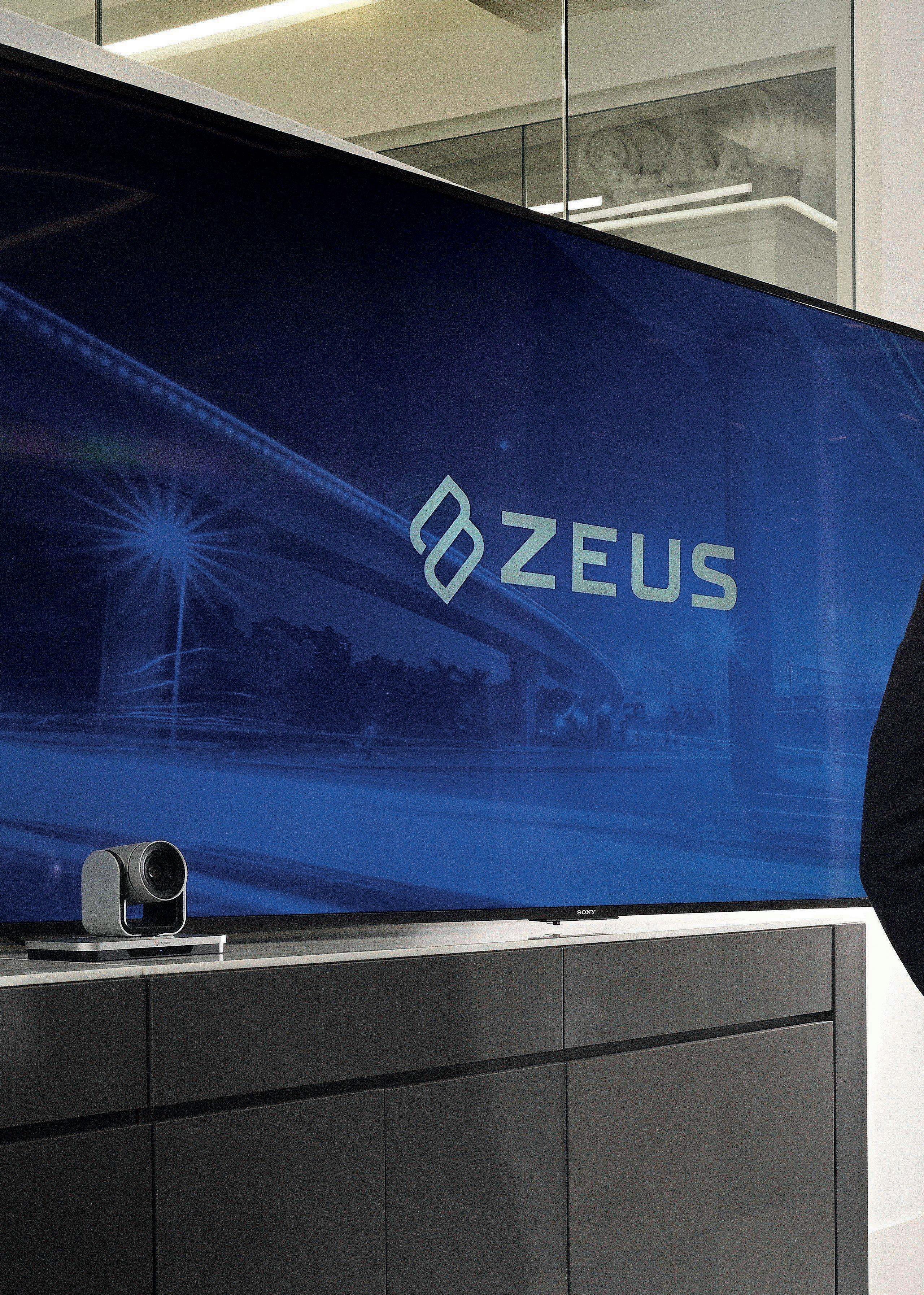

Our cover story from the founders of digital log-tech start-up Zeus, explains why a drive to implement new efficiencies needn’t be a race to the bottom. Revealing how technology holds the key to success, it’s worth a read on page 4.

@SCWmag supply-chain-world-magazine Follow supply chain world at Welcome scw-mag.com 1

Libbie

2 Inside this issue Freight Predictions Cover Story Resiliency 4 8 14 18 Integration Contents

scw-mag.com 3

American Welding & Gas Conagra Brands 24 52 36

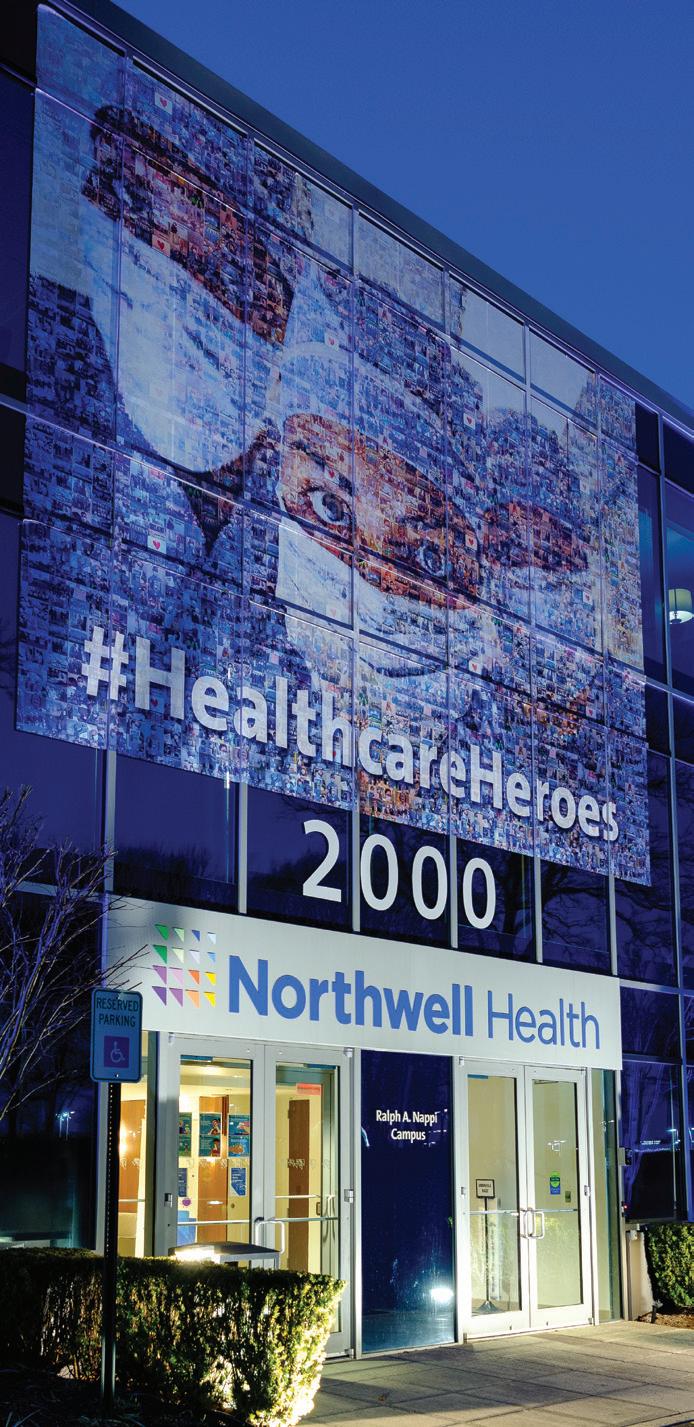

30 Northwell Health 56 supply chain world

Troy UK

Tenneco

Positive IMPACT

It’s time to get moving with sustainable freight.

By Jai Kanwar and Clemente Theotokis

By Jai Kanwar and Clemente Theotokis

2022 has been a great year for volatility – a bad year for business planners, procurement teams and sustainability. Political chaos and ongoing economic instability have made 2022 stand out for all the wrong reasons. The war in Ukraine, record fuel prices, record inflation, the continued fall-out from Brexit and Covid, plus a new UK recession, have converged to create a unique set of challenges.

4

Freight 5 scw-mag.com

Shippers – be they manufacturers, growers, or retailers – are grappling with navigating these challenges, while also trying to implement ESG drives, net zero strategies, and sustainability initiatives. And – though they can’t publicly admit it – ‘the good’ is losing out to margins and growth.

With cost reductions front of mind, it’s easy to see why investing in green infrastructure and solutions might not be a priority for many businesses. And, with the spiralling cost-of-living crisis, suppliers are understandably reticent to help reduce costs.

But the truth is, a drive to implement new efficiencies needn’t be a race to the bottom. In fact, it makes sense that a drive to cut costs in the supply chain should also be a drive to increase sustainability. The two can go handin-hand, and technology is the key to enabling this symbiotic and systematic relationship.

The world cannot wait

There are some innovators out there – like Henkel, P&G, and Zara – who are making bold progress on sustainability across their value chain. Henkel has committed to a 65 percent reduction in the carbon footprint of their factories by 2025 and intend to be ‘climate-positive’ by 2030. An ambitious plan. However, across the board, when it comes to the movement of freight, this is lagging quite far behind other initiatives. Even though getting products into stores is the single most important step before selling them. We see that manufacturers across the UK and Europe are floundering when it comes to finding ways to execute their sustainability wishes in their distribution and supply chains. But this doesn’t need to be. Digital transformation is already making it easier for shippers to streamline their middle mile distribution. Freight management technology is eliminating intermediaries, increasing automation of repetitive tasks, and cutting out empty admin hours. Combine this with load optimization, route

planning, new fuels, advanced telematics, and mobile logistics and there is also a significant impact on carbon emissions too. Road freight is still the most significant generator of carbon emissions, even with the application of new technologies and efficiencies. Net Zero can only be achieved with zero emissions technology. However, HGVs based on battery electric or clean hydrogen still have a number of substantive hurdles to get over.

But the climate science is clear – the world cannot wait. And our economy cannot wait. Commitments made with the Paris Agreement need to be adhered to – and though COP27 was a restatement of this desire, there is evidence that we will exceed the 1.5-degree increase. In fact, according to the UN, current climate plans could lead to an increase of almost 11 percent in global greenhouse gas emissions by 2030, not a reduction.

Governments need to play a bigger part than they do now – the private sector cannot do this alone. Unfortunately, the current approach is more stick than carrot, with potential fuel duty hikes and the phasing out of diesel vehicles overly clumsy and uncoordinated. This approach is shortsighted and could even stall infrastructure roll-out and vehicle development, as many companies opt for a ‘wait and see’ approach. Change is challenging, but there is a risk associated with leaving it too late: for the environment and for business. However, it’s not all negative news. Investing in green technology, including electric HGVs, is a big commitment. But there is another way to make real reductions in CO2 emissions right now – HVO fuel. This drop-in replacement ‘bio-diesel’ is made from waste, is renewable, and can be used in any diesel truck or car straight away.

Other good news? The production of it is not affected by fossil fuels or the war in Ukraine. Lab tests show that HVO can

6

reduce carbon emissions by up to 90 percent compared to diesel. It does cost ten to 15 percent more than diesel, but the benefits are huge. The Global Logistics Emissions Council is currently reviewing HVO – we just hope that they complete this with speed! This intermediate fuel is a great way for businesses to cut emissions today and, combined with a digital freight management platform, make double-digit savings in delivery costs too.

The consumption economy is here to stay. What we need to do now is combine science, technology and the will to drive forward. Sustainability is about sustaining economic needs and building a future for freight that is good for people and planet.

Investing in upgrading our freight infrastructure, supporting freight providers of all sizes, and investing in the acceleration

of new market technologies and ways of working is essential, and will have a tangible, positive impact on the long-term health of our consumer-driven economy. ■

For a list of the sources used in this article, please contact the editor.

Zeus www.yourzeus.com

Jai Kanwar and Clemente Theotokis are co-Founders and joint-MDs of digital log-tech start-up Zeus. The two-year-old freight-matching platform, used by 40+ enterprise-level clients including Primark, Decathlon, Nestle, Kellogg’s, and AB InBev, is driving change across the sector through service-first solutions to middle-mile distribution that deliver substantial reductions in CO2e

Freight 7 scw-mag.com

The supply chain in 2023

Getting used to the unpredictable.

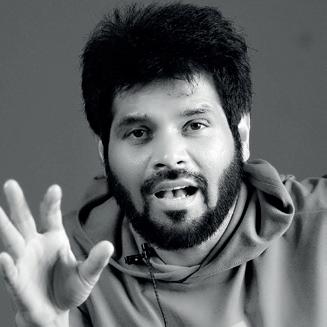

By Bart de Muynck

I’m writing this article around Halloween and while trick or treating is fun for kids in the neighborhood, for those involved in supply chain operations the words ‘trick or treat’ could take on a more ominous tone. Certainly, if you take a step back and think about all the challenges supply chains have faced in the last few years, it would be enough to frighten off the more faint-hearted from considering a career in the industry. Indeed, if you work with supply chain colleagues and they appear to have a somewhat haunted look, that is not just the Halloween spirit, there are real issues now and ahead in 2023 which must be addressed.

As my colleague Josh Brazil said recently: “We are living through a unique convergence of economic, environmental and social challenges, and the supply chain, which was fundamental in keeping the world moving during the pandemic, is being tested like never before…”

So, if you are in the supply chain profession, or a company waiting at the end of a supply chain for goods that might be critical for your business, how do you get your head around these obstacles? And more importantly, how do

you minimize disruption and maximize the potential opportunities that effective management of your supply chain can offer?

Fundamentally, we must get used to operating in a state of permanent uncertainty, which is nothing unusual for the supply chain industry, but perhaps the level of unpredictability around economic, geopolitical and natural disruptions is what makes this even harder.

Surviving the scary season for supply chains

There are any number of real headaches facing both those operating in the supply chain industry and their end customers. Inventory build-up is a very real issue, because companies stockpiled goods in response to supply chain difficulties during the pandemic or due to late arrival of products that were ordered previously. This is now leading to surplus stock. In our October Ocean report, Nike was referenced as having $9.7 billion of goods on its balance sheet in the first quarter, up 44 percent on the same period last year. Amazon and Walmart faced similar inventory woes. Total retail inventories in the US set a new record in July at $731.6bn. With the

8

Predictions 9 scw-mag.com

prospect of a global recession on the horizon, retail inventories in the US are 46 percent higher than they were before the financial crisis in 2007.

From a supply chain planning perspective there is a real concern companies will miss revenue opportunities as they have not been able to clear existing stocks. With inflation hampering consumer demand and consumers’ knowledge of these high stockpiles, consumers are waiting on product clearances before being able to focus on Christmas. In our Global Insights analysis we reported that “as warehouses in both Europe and the US are full, the sizeable inventory levels resulting from the disappointing earnings reported by

“ “ “ “

nearly all major retailers will continue to prompt mark-down sales and a cut-back on excess inventories.”

And Christmas peak season is not the only headache for retailers, who are already planning Spring Collections. In some cases, we have seen clothing retailers ordering next year’s collections back in the first half of the year. With shipping transit times coming down, it means product is getting to its destination quicker, but then dwell times in ports start to add unnecessary costs which may have to be passed on to already cash-strapped consumers.

That is not great when we already know inflation is clearly having an impact on consumer demand. While inventory has grown by 30

From a supply chain planning perspective there is a real concern companies will miss revenue opportunities as they have not been able to clear existing stocks

10

to 40 percent consumer demand has only grown in single digits. It means consumers are becoming more discerning about where and when they spend, so in turn, B2C companies are forced to offer more sales and discounts to shift inventory.

This creates another big headache for supply chains. Logistics does not like multiple peaks. All these supply chain issues create capacity inconsistencies. For example, reductions in the amount of time ships are berthed in port has led to greater capacity which has weakened spot rates and seen a dramatic increase in blank sailings. In the October Ocean report, blank sailings were highest on the Asia to Europe trade lane in September with an average of 41 percent compared to an average of 27 percent in October. The average for blank sailings on this trade is forecast to rise again to 31 percent in November.

The biggest problem these supply chain issues are causing for operators and their customers is cash flow uncertainty. Companies need cash more than ever in the current economic climate to be able to save. If they’re stockpiling goods, not shifting them, cash is not flowing. And we all know that cash has become more expensive with rising interest rates.

Outlook for 2023: Welcome to a world of unknown unknowns 2023 will bring other cost considerations. There will be more changes to regulatory requirements with scrutiny on sustainability reporting. IMO2023 (Oceanside) will mean older ships must slow down to reduce emissions with a knock-on effect for capacity as ships will reduce the number of trips. Combined with the rising cost of oil and bunker fuel there could be even more incentive for carriers to run slower steaming services to save on rising transportation costs.

Capacity issues will impact rates as demand is still strong. Supply chain operators

and their customers will have to build this consideration into their budgeting.

Labor costs will also escalate as staff demand salary increases to cope with the cost of living crisis. We have already seen this impact on where goods are shipped as companies worry about fulfilling peak demand this Christmas. In the most recent Ocean report, New York has become the number one box port in the US, overtaking Los Angeles due to fears about strikes by the International Longshore and Warehouse Union. In our recent Global Insights report, it was estimated the eight-day strike at Felixstowe port impacted some $4.7 billion in trade.

Extreme weather events are also on the rise. Experts are warning about the social and economic impacts of extreme weather events, such as drought on the Mississippi and the Rhein which in the last year has impacted key transportation routes. In our most recent Global Insights report we flagged that this summer’s record low water levels on the Rhine forced many containers to use rail networks and trucks for shipping adding unexpected intermodal costs and delivery headaches. Such unpredictable changes have a knockon effect for other ports as well, making it essential to have real-time visibility of supply chains so that logistics routes can adapt.

Supply chain professionals always cope with change and black swan events but given how central the performance of supply chains has become to the global economy there is even more pressure on the sector to reassure businesses they can handle not just the uncertainty, but the increased unpredictability of geopolitical, economic and weather factors.

What is clear from our data is that supply chain performance is an early warning system for potential softening in economic performance, underlining the strategic value to the business of having better visibility of what is happening. For example, in the October Ocean report Twenty-foot

11 scw-mag.com

Predictions

Equivalent Unit (TEU) volumes from Asia to North America were down eight percent in August on a year-on-year basis whereas Asia to Europe were down seven percent It also pointed to a similar reduction year-on-year with four percent less deployed vessel TEU capacity in September and a two percent decline in the number of vessels in the same period. With this visibility, companies can plan how they adjust production to reflect where demand is slipping and equally identify where it is increasing. Spotting these opportunities early, particularly in the current economic climate, will be critical to driving new revenue opportunities.

End-to-end visibility requires collaboration

Given so much uncertainty and unpredictability companies must manage their supply chains in such a way that they can be more pro-active or at the very least react in an informed way. End-to-end visibility is key, but that can only be achieved with collaboration. The best companies today in the supply chain eco-system are collaborating more and that should include the technology vendors providing the software to run these supply chains. It is absolutely crucial they work together to share data and collaborate more effectively, because ultimately the more visibility built into a supply chain the more it will have a positive impact on cashflow.

For example, in the October Ocean report carriers posted reductions in shipment delays of more than 40 percent year-on-year in September. Asia-Europe experienced a 19 percent reduction in shipment delays in September when compared to the previous month. On the surface this appears a positive development reflecting improvements in the processing of goods in ports, but equally it indicates a softening in demand simply because less goods are being processed.

The good news is that if companies get their approach right, there are opportunities to

be had. The companies that were brave during the 2008 Financial Crisis came out ahead.

Make supply chain insights digestible

If a company can achieve end-to-end supply chain visibility through collaboration with its partners, it means they have invaluable data that can have a direct impact on business decision making and performance.

For example, everyone in the industry needs to have a wary eye on what dwell times might mean for Christmas sales. In the most recent Ocean report the number of vessels waiting to berth on the Eastern seaboard of the United States and Gulf Ports has jumped notably since July, particularly in the ports of Savannah and Houston, which experienced a 208 percent increase yearon-year in the number of vessels waiting to call at the ports in September. Savannah had the highest average with 37 vessels waiting to berth in September. New York and Houston had 25 and 24 vessels waiting to berth, respectively. Any delays to accessing stock could have a real consequence for those retailers on 5th Avenue hoping for bumper Christmas sales. With newer vessels carrying up to 24,000 TEUs, a single vessel delay could impact millions of consumers.

A complete and single view of supply chain data means businesses can be forewarned. In the Global Insights report terminal dwell times increased in European ports largely due to labor shortages and congestion. Limited trucking and rail availability also continue to impede the movement of goods at the ports, where most storage space is occupied to its full capacity.

Deciphering supply chain data and the lingo is not straightforward so it must be a priority to make data consumable for everyone in the organization. To get to that point companies must ensure they have all the data on one platform from ocean, road and rail routes. This gives confidence they

12

“ “

“ “

have a complete picture. It also makes the user experience better, as users can adapt the data to their specific requirements.

Start small and build Global supply chains are huge. It would be too disruptive to try to integrate all insights from every aspect of the supply chain in one go. It is better to start with one mode. Decide where to start by identifying where the biggest opportunity for improvement lies. For example, ocean visibility is easier in some senses as it is a less segmented market than road haulage.

Then adopt a step-by-step process and ensure the software provider is willing to be a partner on that journey. Every customer should be asking its vendor to help find value in the supply chain not just in the short term, but continuously monitoring for future opportunities. What we have seen work is setting up a center of excellence which encourages collaboration and enables customers and partners to constantly look at how to improve capabilities.

One aspect that should not be overlooked is talent, as developing a more integrated digital supply chain platform also requires very different skills. Given that every sector is facing huge challenges to find the right skills organizations need to think about how

they attract the talent that will help their businesses in the next five to ten years.

Here too, there is a role for the vendor to be supportive. Next generation AI and automation tools can automate mundane tasks easing the burden on employees and allowing them to focus on more interesting, challenging tasks. Building a reputation as an innovator in supply chain technology will make a business more attractive to top talent.

Hopefully, this hasn’t put readers off a career in the supply chain industry. If anything, it should reinforce that it is probably one of the most exciting and fast moving career choices out there. Let’s face it, you will never be bored! However, as supply chain professionals we must also be realistic about what lies ahead. There is a real opportunity for data emerging from supply chains to offer strategic insights to critical business decisions in the year ahead, but access to that information will only be possible with end-to-end visibility and increased collaboration between everyone in the eco-system. Insights will have to be delivered in near real-time to keep companies ahead of the uncertainty and unpredictability. Get that right and the supply chain can demonstrate critical value to the business. ■

For a list of the sources used in this article, please contact the editor.

project44 www.project44.com

Bart de Muynck is Chief Industry Officer at project44. As the supply chain connective tissue, project44 operates the world’s most trusted end-to-end visibility platform that tracks more than one billion unique shipments annually for over 1,200 of the world’s leading brands, including top companies in manufacturing, automotive, retail, life sciences, food & beverage, and oil, chemical & gas. Using project44, shippers and carriers across the globe drive greater predictability, resiliency and sustainability.

A complete and single view of supply chain data means businesses can be forewarned

Predictions 13 scw-mag.com

Is your supply chain ready?

The next Black Swan event is already out there say John Ferguson and Ken Koenemann

The next Black Swan event is already out there say John Ferguson and Ken Koenemann

14

Like one-hundred-year floods, Black Swan events, a term used to describe unforeseen occurrences with a severe impact, have become increasingly common with consequences for global supply chains. Covid and Russia’s invasion of Ukraine are two such events that derailed the global movement of goods and parts for finished products, affecting a wide range of manufacturers and distributors. Now, the threat of a US freight railway worker strike and heated tensions over Taiwan are two more ‘outlier’ events that should remind business leaders to regularly anticipate, and plan for any unforeseen disruptions to the global supply chain

Key to resiliency is de-risking and diversifying

A conflict with the People’s Republic of China over Taiwan or a strike by US freight railroad workers each brings with it its own permutations of challenges, but a key to resiliency in a supply chain is de-risking and diversifying by building a broad pool of suppliers across geographic regions. Managers should now view the supply chain as one with many hidden fault lines where there never is zero risk of disruption. For many manufacturers, changes in the geopolitical landscape and other factors may spur a push to find suppliers closer to where a final product is produced – a refinery or assembly plant. Also, manufacturers may forgo low-cost suppliers for sources that safely assure uninterrupted delivery of essential parts and raw materials.

A conflict over Taiwan is sure to impact global trade, disrupting supply chains. Published reports offer varying theories on how China may try to seize the island nation, with some

analysts suggesting that Taiwan’s ports could be blockaded and undersea communications links could be severed. Any conflict would impact the shipping of goods from Taiwan and nearby markets via sea or air. Goods and raw materials sourced from the entire region are diverse, but Taiwan is home to more than 90 percent of the manufacturing capacity for the world’s most advanced semiconductors, a critical building block of modern industrial economies. Meanwhile, the implications of a disruption to US rail traffic are evident when considering weekly data measuring goods delivered by rail: each week, nearly half a million carloads and intermodal units move motor vehicles and parts, nonmetallic minerals, farm products, grains, chemicals and metals.

Conduct top-down review of all aspects of production to map out vulnerabilities

Managing geopolitical risk now means that companies should not rely on a particular supplier or a region and watch for political flashpoints that could disrupt supplies. If you rely on one primary supplier for 80 percent of your goods and 20 percent from a secondary source, you may want to change that mix. While maintaining strategic alliances with suppliers is important, if you want to de-risk and build a resilient supply chain going all-in with one supplier may no longer be feasible. For some businesses, adopting this strategy may be easier said than done. Within healthcare, for example, you can readily shift sources of masks or syringes, but the pivot to a new supplier of Magnetic Resonance Imaging machines may be tougher because of their size and weight. Sometimes, weaning yourself off a region and its suppliers – for example,

Resiliency 15 scw-mag.com

Taiwan’s semiconductors – cannot be accomplished overnight because shifting production is complex and involves a long-term effort.

Faced with a rail strike or tensions in Asia, companies looking to ensure resiliency in supply chains should take a strategic look at what goes into the production of finished goods and what may impact their ability to fill customer orders. Such a topdown review involves examining all aspects of a manufacturing process to see what raw materials or parts are essential ingredients that could be cut off by a disruption in rail, air, or trucking tied to geopolitical or labor issues. Ideally, this cataloging of key ingredients is carried out regularly, and managers routinely review component families and inventory classifications to map out vulnerabilities in a supply chain,

assigning a risk score to each part. Can a mold for a product be moved to another location, and how quickly will machinery need to be retooled to fulfill orders at another location?

Increasing your safety stock to weather unforeseen challenges

In some cases, managers will want to reconsider how they view ‘safety stock’ and increase inventories of essential parts or ingredients for their manufacturing process to mitigate risk. For example, companies dependent on freight rail for plastic pellets or resin – used in seat belts and cell phones – will want to keep an extra railcar or two on site to ensure a strike doesn’t slow plant production. Companies may have become more complacent after the end of the Cold War when geopolitical

16

tensions appeared to abate, however, since the pandemic, conversations about supply chain risk are routine. Many business leaders are feeling exhausted like smoke jumpers that have been putting out fires since 2020. Each new unforeseen event brings its own set of challenges.

As these high-impact events become more prevalent and predicting when or where they’ll occur becomes more challenging, it’s imperative that business leaders find a way to manage them by assessing risks to their daily processes and diversifying to build more resilient supply chains. Managers should get into the practice of reviewing their business’s vulnerabilities ahead of any actual crisis. That means adopting a business culture that looks to identify risks to their supply chain before unanticipated calamities

and introducing a Chief Resiliency Officer or CRO, whose sole role is to oversee a regular strategic review of supply chains and their durability. ■

For a list of the sources used in this article, please contact the editor.

TBM Consulting www.tbmcg.com

John Ferguson is Chief Executive Officer, and Ken Koenemann is Vice President, Supply Chain & Technology, at TBM Consulting. TBM Consulting is an operations and supply chain consulting firm that works with manufacturers, distributors, and private equity firms to accelerate productivity, improve profitability, and grow enterprise value. The firm’s supply chain capabilities include inventory optimization, supplier management, talent development, integrated business planning and S&OP, and network/warehouse optimization.

...companies looking to ensure resiliency in supply chains should take a strategic look at what goes into the production of finished goods and what may impact their ability to fill customer orders

Resiliency 17 scw-mag.com

“ “ “ “

MODERN alternatives

Siloed operations make businesses vulnerable to disruption, and poorly placed to respond when issues do occur, and are often caused by operational challenges such as acquiring competitors in new geographies or changes in legislation. It is clear that businesses of all sizes must ramp up digital transformation efforts to ensure end-to-end integration remains a

priority, says Arjun Khanna, Chief Technology & Innovation Officer at Kallik. Critically, that must include the pivotal but regularly overlooked artwork and labelling processes –it is essential that ‘what it says on the tin’ is accurate in every detail.

When disruption occurs, the ability to react quickly and effectively to avoid a ripple effect throughout the supply chain is vital. But a recent survey of manufacturers found

Make supply chain woes a thing of the past with end-to-end digitization – and that includes packaging and labelling

18

that up to 90 percent struggle with integration challenges that are essential to maintain smooth supply chain flows. Despite the much-publicized threats to business continuity, many firms continue to operate a patchwork of core systems with either little to no integration with each other. They are often developed piecemeal with inhouse fixes or manual workarounds. While this may help maintain the status quo of day-to-day operations, it is highly vulnerable to disruption and far from agile compared to more digitally mature competitors.

Disparate data predominates legacy systems

Thankfully, the latest wave of digital transformation has placed an increased focus on the safety of cloudbased solutions and customizable implementations for core platforms such as ERP systems. However, other, more legacy systems or manual processes are equally critical to operational success –yet often neglected in the grand scheme of ‘digital transformation’ projects. This lack of integration is especially noticeable among businesses operating in highly-regulated industries such as pharma, medical devices or chemicals, despite these being prime candidates for short-notice impactful disruption.

Integration is critical to artwork, labelling and packaging

The disconnect is particularly noticeable in siloed product assets, where labels, artwork and symbols are often subject to minimal version control or global insight, and where integration with print requests and data flows from the ERP system, for example, are yet to be embraced as part of an integrated system. But these label and artwork management systems play an increasingly critical role in ensuring product consistency, consumer safety and regulatory compliance. As a result, having these operations and assets siloed is non-negotiable. Integration with other platforms such as regulatory systems is a must.

Underestimate it at your peril

Take a label for a simple medical device intended for the EU market. This must pass through extensive review and approval processes to

Integration 19 scw-mag.com

ensure medical, marketing and regulatory information – including various symbols and markings – are all present, correct and consistent. To be sold broadly throughout the EU, this device label would in theory need be translated into 24 different languages.

This upstream process is therefore very delicate and susceptible to disruption or human error. If an incorrect version of a regulatory symbol is used, or some medical information is changed in one language then not updated across all other language versions, this could introduce a major error – potentially even threatening the health of the end-user and triggering a costly product recall.

If the systems involved in this workflow are not fully integrated into other critical business systems, processes and databases, the risk of recalls can rise significantly.

company’s digital maturity project. That means finding proven, feature-rich solutions that can be deployed across all necessary department and locations worldwide, with full integration capability to ensure seamless operation with other core systems.

Label and artwork management platforms are no exception. Indeed, these must be able to integrate with other critical software as standard – from Regulatory Information Management (RIM) systems, Enterprise Resource Planning (ERP) platforms and Product Lifecycle Management (PLM) solutions.

Consolidation and integration is key when it comes to rationalizing and standardizing systems and processes as part of a

Business leaders would also be welladvised to opt for a cloud-based solution that can be readily deployed and accessed in any location by any department, adding a new level of scalability.

As businesses connect and integrate critical IT infrastructure, the benefits of truly unified operations and visibility become apparent.

Choose a digital artwork and labelling system that suits integration

Go the extra mile – establish a single source of truth with integration in the cloud

20

For example, if a specific product asset or symbol must be replaced or updated at short notice, users can tap into the ‘Where Used’ functionality within a fully integrated management solution to identify every instance of the existing asset actively being used worldwide – and effortlessly make a bulk update in turn. No manual searching of data siloes, no piecemeal updates across multiple teams – this is all easily accessible and actionable in a ‘single source of truth’.

The benefits of integration are all encompassing

This unlocks powerful end-to-end audit and version control capabilities – allowing any users with relevant permissions to make changes and flag comments in a clear, actionable format. By integrating a solution with further powerful features, such as automated artwork generation, businesses can significantly reduce the risk of human error in asset creation, updating and positioning.

For artwork and label management solutions, a cloud-based end-to-end platform is an ideal candidate focus for any integration-

minded business – providing a standard set of APIs out the box as a tried-and-tested ‘blueprint’ to follow during implementation. From a security perspective, shifting to a single artwork and label management platform also brings fresh benefits –with a single sign-on and corporate login enhancing system security, user management and data protection.

The race to digital transformation is on – keep pace with innovative rivals

The ability of integration to ensure enduser safety in highly regulated industries, and reduce artwork and labelling errors is immense. From distributing new products to exploring new geographies, businesses can be agile, adaptable and resilient with integration providing a robust digital backbone. With supply chain disruption set to continue, there’s no time like the present to assess legacy IT stacks and equipment for either heavy integration, or replacement with modern alternatives. ■

For a list of the sources used in this article, please contact the editor.

Kallik www.kallik.com

Kallik, the enterprise labelling company, provides regulated industries with a definitive, end-toend artwork management and label management platform they can trust. Medical device, pharmaceutical, chemical, manufacturing and cosmetics companies use Kallik to deliver trust in their labelling, integrity in their process and confidence in their brand. Kallik’s cloud-based labelling platform, Veraciti™, enables compliance and delivers supply chain efficiency for all the artwork and content assets that make up product packaging, labelling and instructions for use (IFUs).

Integration 21 scw-mag.com

stop us Troy and

In 1986, a collective of independent businesses joined together as a buying group to bolster a position from which they could negotiate better terms from their supply chain. Over the last four decades, the company, Troy UK Ltd (Troy), has expanded from its base in core-engineering tools to a wider range of maintenance, repair and operations products, cutting, power and hand tools, PPE, hygiene and janitorial equipment, and fasteners. All of the above are provided by some of the biggest brands in the industry, such as Stanley, Makita, DeWalt and Bosch. Besides its extensive range of products, the company also offers vendor managed inventory solutions.

Troy champions proactivity, over reactivity, in terms of evolving market trends. This approach is facilitated by its shareholder-owned status, which allows for swifter decision-making and greater agility as a business model. In order to provide the best possible service, the company treats its members as individuals, with individual’s needs.

By forming partnerships with them, as it does with suppliers, it succeeds in forming long-term relationships built on trust. This methodology has brought it over 400 independent members who are able to access over 400 suppliers as part of the Troy supply chain.

How Troy overcomes challenges to support independent businesses and bring people together

24

Troy UK scw-mag.com 25

26

Since the company last sat down with Supply Chain World, a year ago, it has continued to evolve, regardless of the current market climate. Keira Park, Head of Marketing, details this further: “Over the last 12 months, we have continued to invest in the ways we can offer support to our network, especially given the turbulent time that everyone is working through. We have pursued further development of our market-leading platforms to complement our team of specialists, employed to cater to our members’ needs across a broad range of topics. Additionally, in collaboration with industry leaders such as Microsoft, Insight Works and Open Door Technologies, our team has designed, built and implemented a successful Enterprise Resource Planning system. The enhanced functionality of which, has been created with our members in mind.”

As well as becoming the main sponsors of the Exeter Chiefs, this year Troy has made four acquisitions, with Applegate being the most recent. Thus far, the move has proven to be a huge asset; by working in partnership, the two businesses have developed the industry’s first carbon emissions reporting tool. This will enable members to provide an estimate on the combined emissions for all products sold through the group to end users. There is a new dedicated business-to-business wholesale portal, in addition to the recently launched myTroy platform – which allows suppliers and members far more than just communication. It stands as the single location where the company’s network will be able to access technologies such as dashboards and data insights driven by machine learning.

Troy supports its members in competing against the larger national firms. The company works as an extended team to the entire network, to amplify suppliers’ brands among its members to maintain the strength of the supply chain. In turn, the members provide a passionate, personalized service, teeming with product knowledge, to end users.

“

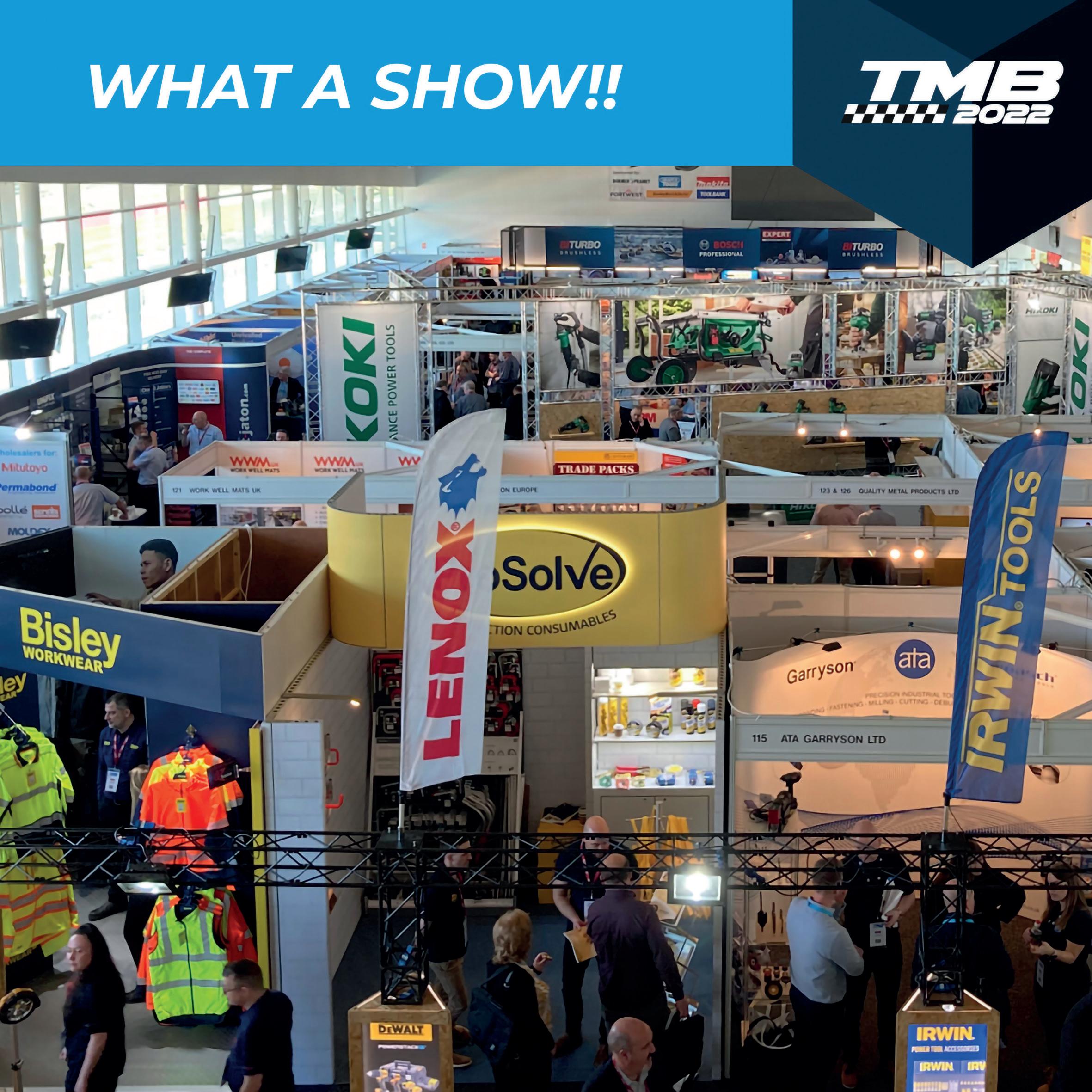

This year alone, Troy has welcomed 35 new suppliers to the group, providing ever-growing opportunities for member to access diversification of products, services and opportunities to enter new markets. Due to the restrictions regarding social distancing throughout the last couple of years, this year also marked the first face-to-face Troy Means Business (TMB) trade show since before the pandemic.

“ “

Despite our enormous growth, it has always been important to our CEO, Paul Kilbride, to keep the family-feel at the top of the company’s agenda

“

scw-mag.com 27 Troy UK

In light of this, Richard Pymm, Group Sales Director, says: “The foundation of our business has always been connecting people with people. That’s why it was so great to be able to host our TMB trade show at Silverstone again, followed by our industry-acclaimed evening gala. It really is a fantastic event, with suppliers and members alike often saying it’s the highlight of the year. Sadly, we haven’t been able to host for the past two years, but we were certainly back with a bang! We saw record numbers in attendance generating unprecedented amounts of business, around

£8 million in total being done on the day, and the networking on the evening going well into the next morning. It was a fantastic, circusthemed extravaganza! The date for next year’s, in March, is already in everyone’s calendars.”

Coming out of such difficult times, into further supply chain issues and now the problems caused by inflation, Troy has worked hard to maintain the working environment for its staff, members and suppliers. By working closely as a team and introducing digital channels for communication, both in conjunction with the family-oriented

28

“ “

sensibilities of the network, the overall supply chain has come out stronger. As Keira details further: “We’re a family business supporting family businesses. Despite our enormous growth, it has always been important to our CEO, Paul Kilbride, to keep the family-feel at the top of the company’s agenda. It’s certainly a family-affair for him, with his wife, Lexi, and two sons, Alex and Oz, also working at Troy.

“The coming months and years are going to be very exciting for the Troy network. After significant investments this year, we are excited for the upcoming additions to the range of tools and services we offer our members and suppliers. We are always

looking to the future and will continue in developing the ways in which we can offer support to independent businesses. There’s never been a more important time to support independents. Small and medium enterprises provide 60 percent of all private sector employment and put more money, pound for pound, back into local economies. The societal benefits of retaining independent businesses across the country are huge, that’s why we do, what we do, here at Troy,” she concludes. ■

“ “

www.troyuk.co.uk

The coming months and years are going to be very exciting for the Troy network

scw-mag.com 29 Troy UK

30

Make tomorrow better

One organization, four business groups, four values; Tenneco’s secrets to success, under the hood

In 1999, Tenneco emerged from a conglomerate that had previously consisted of six businesses. Through a variety of sales and spin-offs, its peers in shipbuilding, packaging, farm and construction equipment, gas transmission and chemicals had all started to separate from the early 1980s. The entities that remained under the then-named Tenneco Automotive, included an Original Equipment Manufacturer (OEM) and Monroe and Walker, a wellknown and widely loved aftermarket brand. Both organizations had been established for over 100 years, and provided the significant experience and expertise that makes Tenneco the company it is today.

Moving forward into the early noughties, Tenneco dropped the ‘Automotive’ in 2005 to reflect the broader spectrum of markets it had come to serve. Throughout this decade, the company sought to expand its global footprint, by becoming one of the earliest

automotive suppliers to establish operations in China. This both supported the growth of its light vehicle production, as well as the business’ involvement in developing cleaner air solutions. Through enhancing its engineering and manufacturing capabilities, Tenneco was soon considered the leader in helping its customers meet the varying emissions-control regulations across the globe.

One of its most notable achievements, to the wider markets, was the commercialization of diesel particle filters in Europe in 2000, however Tenneco also leads the industry in a number of aftertreatment products, including selective catalytic reduction, gasoline particulate filters, and hot and coldend exhaust systems. Its Monroe Intelligent Suspension portfolio features both adaptive and semiactive electronic suspension systems, and its noise, vibration and harshness product range caters to both the light and commercial vehicle markets.

Tenneco scw-mag.com 31

“ “

“ “

Tenneco has acquired two businesses within the last four years, in a tactic to further the enormous growth it’s experienced since the millennium. This has primarily been resultant of the expansions to its products range and global reach. In 2018, it acquired Federal-Mogul, another automotive supplier with over 100 years of experience, with which came a further 25 aftermarket brands and another OEM, doubling the size of the business overall. In 2018, it was the turn of Öhlins Racing, a Swedish company famed for its advanced suspension systems and affiliations to the racing industry. Tenneco had previously collaborated with Öhlins on a number of projects involving electronic valve technologies and the first CES shock absorbers.

Since a restructuring initiative in 2020, the Tenneco of today is a global automotive tier one supplier comprised of four equally diverse, whilst complementary, business groups: performance solutions, motor

Tenneco has acquired two businesses within the last four years, in a tactic to further the enormous growth it’s experienced since the millennium

32

parts, clean air and powertrain. Whilst encompassing 30 of the industry’s most respected automotive brands, the business collectively employs 71,000 people across six continents, in its 196 manufacturing sites, 38 engineering and technical facilities and 29 distribution centers. In providing the utmost in driving advancements in global mobility, Tenneco currently serves the likes of General Motors, Cat, Ford, BMW, Volkswagen, Volvo, Toyota and many more.

Earlier this year, international adventure driver, Rainer Zietlow, set out armed with a Volkswagen ID.4 GTX crossover that had been equipped with Tenneco’s Monroe Intelligent Suspension CVSAe System (MISS), in an attempt to break a world record. The challenge in question was to achieve the

highest altitude reached in an all-electric passenger vehicle, for which Zietlow’s team had to scour through a number of South American mountain ranges, in order to find a trail that would beat the previous record of 18,933 feet. They settled on the stratovolcano, Cerro Uturuncu, in the Sur Lípez province of Bolivia.

The path, or lack of, follows an unpaved mine road up to an elevation of 19,081 feet, which Zietlow successfully climbed and thus set a new world record. The vehicle’s CVSAe semi-active suspension continuously adapts to changing road conditions, using data captured by multiple onboard ride control sensors. The MISS equipped ID.4 model was also named 2021 World Car of the Year. Henrik

scw-mag.com 33 Tenneco

Johansson, Vice President and General Manager of Advanced Suspension Technologies at Tenneco, was quoted as saying: “CVSAe technology elevates the driving experience, whether in a city environment or on more adventurous terrain – and it doesn’t get more adventurous than climbing a volcano.” Tenneco’s drive for sustainability is a key part of the company’s core principles, with one of its main values being to ‘Make Tomorrow Better’. Under the banner of Environmental, Social and Governance initiatives, the business focuses on the efficient management of its energy and water consumption, emissions, and operational waste, as ways to improve its carbon footprint in line with its targets. These are to reduce its scope 1 and 2 greenhouse gas emissions by 30 percent, decrease its operational energy demand by ten percent and to source 15 percent more renewable energy by 2030, all whilst cutting its waste to landfill by 20 percent in the meantime.

In recent years, Tenneco has worked closely with CHEP – a circular business model based on the concepts of sharing and reusing. As a member of the CHEP pooling system, a company is able to obtain its pallets, IBCs and industrial containers on a rental basis, a simple principle that ensures greater sustainability for all parties involved. Since August 2015, Tenneco has been using CHEP’s Foldable Large Containers (FLCs), designed for the transportation of larger products such as catalysts, radio grilles, transmission and engine parts, and batteries. The cube utilization and pack density of the FLCs vastly increases the optimization of trucks, sea-freight containers and warehouses.

The business’ social goals are driving greater diversity amongst its employees; with targets of increasing the number of females and US

34

minority group members in managerial roles and above, by a third, by 2030, and to achieve 100 percent certification with IATF 16949, ISO 9001, or similar, by 2025. In terms of governance, Tenneco’s code of ethics is represented by its commitment to accountability, integrity and compliance in its operations. By the end of this year, the company is aiming to have 100 percent of its strategic partners reaffirm their commitment to the Tenneco Code of Conduct, as well as to have received completed selfassessment questionnaires from all of its high-risk or high-impact suppliers.

The company’s efforts are regularly acknowledged by its industry peers. This year alone, Nissan named Tenneco as a sustainability partner, on account of its demonstration of sustainable and socially responsible business practices, and Ethisphere listed it as one of the

world’s most ethical companies too. On top of these, Newsweek also included the business in their Top 500 most responsible companies in the United States.

Besides ‘Make Tomorrow Better’, Tenneco’s values include ‘Integrity Always’, under which it believes in doing the right thing the right way, speaking up and owning whatever you’ve accomplished. ‘One Team’, instills the ideas of taking care of one another, embracing the differences of others and succeeding as one, and finally, ‘Will to Win’ encompasses the drive to always seek flawless execution, create customer fans and ultimately, make a difference. Tenneco has grown spectacularly thusfar and possesses the means to keep on going. It’s with bated breath that we wait to see its next big move. ■

www.tenneco.com

Conduent is proud to partner with Tenneco to help increase savings, reduce costs and drive visibility across all categories of spend.

Learn more at conduent.com

Conduent salutes Tenneco for making their working capital work harder.

scw-mag.com 35 Tenneco

Fuel for growth

Ihave been in the consumer goods industry for almost three decades,” begins Alexandre ‘Ale’ Eboli, Executive Vice President and Chief Supply Chain Officer at Conagra. “My career began back in my home country of Brazil, then Latin America and Europe, until I arrived in the US and joined Conagra. I have spent the last 27 years working and travelling across different geographies.

“The beauty of Conagra is that we are a highly focused company in terms of our portfolio,” he goes on. “By concentrating on the North American market and consumer brands, we have created a strong sense of team spirit and commercial agility, allowing our employees to collaborate in an inventive way. We do things quickly, both in terms of connecting to customers as well as expanding and maintaining the brands they love.”

Conagra is the manufacturing force behind household brands such as Birds Eye, Slim Jim, Gardein, Duncan Hines, Healthy Choice, Earth Balance, Reddi-wip, and Orville Redenbacher’s – just to name a few. In the last 15 years, Conagra has made a concerted effort to modernize its portfolio, creating fresh products – and revitalizing iconic ones – to reflect the needs of customers and consumers alike.

In today’s highly competitive marketplace, it has never been more important to stay relevant and up-to-date with the latest trends. Consequently, as Ale details, the food giant has grown even bigger in stature, garnering substantial returns for its shareholders and investing back into the business and its portfolio of iconic brands.

Why supply chain is the beating heart of any organization, according to Conagra Brands

Conagra Brands 36

scw-mag.com 37

“ “

“Simply put, our intent is to continue to serve our customers and consumers with high quality food and innovative products – each and every day,” says Ale. “Our products fall into three main categories. First is our frozen food, which has gone through a resurgence in recent years as we’ve introduced new products into the frozen aisle that are more aligned with consumer preferences. By premiumizing our frozen portfolio, we’ve been able to offer consumers convenience, affordability and nutrition, and also a means of reducing their waste through the use of sustainable packaging.”

Fresh food spoils. That is not new. With frozen food, we take out what we need when we need it, and the rest is saved until another day. Less ends up in the bin. But Conagra is taking this aspect of sustainability and waste reduction one step further. Evol, a Conagra-owned brand focused on making tangible steps towards the protection of the environment, recently became the first manufacturer to introduce Carbonfree Certified Carbon Neutral frozen meals. In addition, these products are produced in a TRUE certified Zero Waste facility.

To earn this accolade, plants must have diverted an average of 90 percent or greater waste from landfills or made other equivalent waste reductions in the last 12 months. The eco-friendlier range, which includes the all-new Five Cheese Alfredo Mac with Chicken

We are the metaphorical heart of the company

“ “

Conagra Brands 38

as well as eight other certified singleserve offerings, utilizes fully recyclable paperboard cartons and paper bowls to slash the carbon footprint of packaging across the line.

Small changes make big environmental savings. Indeed, across its Healthy Choice Power Bowls range, a significant carbon saving has been made by Conagra. By using plant-based fibers instead of plastic, the carbon footprint of manufacturing select product lines has been reduced by up to 70 percent, helping to decrease the company’s overall carbon footprint by 34,117 metric tons – the equivalent to avoiding greenhouse gas (GHG) emissions produced by driving 84 million miles.

Ale continues his overview of Conagra’s three distinct product

categories: “The second is snacks, so we produce meat sticks, popcorn, sunflower seeds, puddings, and more. We continue to innovate in places that see new or growing consumer demands. If you think about it, a popular meat stick like Slim Jim is free from carbohydrates, and that is really well-received by consumers. Similarly, popcorn offers a healthier option than, say, regular potato chips. These snacks form what we like to call an ‘acceptable indulgence’ for our consumers, and we are growing quite a lot in that space.

Another example is keto-friendly cake mixes from Duncan Hines, a versatile option for those following a ketogenic diet but wanting to still get that sweet fix. Addressing this particular consumer need has stimulated significant growth for us.

Conagra Brands 40

YOUR ADHESIVES SOLUTIONS PARTNER Indirect Supplier of the Year 2022 Award Recipient by Conagra Brands PROUDLY SERVING CONAGRA Driving innovation Facilitating sustainability Prioritizing service Since 1887, H.B. Fuller has provided adhesives, coatings, and tapes to packaging makers and CPG brands. hbfuller.com/packaging

“Finally, we have our staples category, which are ingredients and enhancers, and shelf-stable meals and sides,” he goes on. “This portion of the business is all about keeping brands available, profitable, and serving consumers according to their evolving needs. It is always imperative to identify and match changing trends: ten percent of turnover comes from innovation and delivering products that directly respond to market analysis. It is a core component of our strategy,” asserts Ale.

Beneath the brands, however, is a rigorous supply chain strategy and program that keeps the wheels turning at Conagra. Without it,

particularly in these current times of geopolitical and economic turmoil, names like Slim Jim and Birds Eye might not be available on grocery store shelves.

To prevent that, Ale spearheads a robust supply chain division that focuses on building from a strong base with an experienced and capable team to ultimately drive gross margin and customer service through an aggressive end-to-end productivity agenda. According to Ale, investments in people, assets, and technology make that happen.

Driving forward with an agile and resilient end-to-end supply chain is part of Conagra’s ambition

42

of delivering $1 billion in cost savings over the next three years and becoming the best supplier in the food industry. Yet, for Ale at least, it goes much deeper than that. “There are two things in supply chain that allow me to wake up happy each morning,” he reveals. “The first is that we are responsible for the livelihoods of 15,000 people across a total of 42 factories in the US, Canada, and Mexico. These factories are responsible for approximately 80 percent of the food that we sell; the rest is produced by core manufacturers that operate as an extension of our manufacturing footprint. We ship products from 21 distribution centers across the entire country.

“If, on average, each one of those 15,000 employees has a family of four, then you can imagine the number of people we are impacting – and that is not counting suppliers, their workers, and their workers’ families,” he aptly points out. “We are one of – if not

Devro

Devro is a leading global supplier of edible collagen casings and gels for the food industry. We have over 1000 customers in over 100 countries, including many of the top meat snack and sausage companies in the world, and we are particularly proud to count Conagra Brands among them. We boast a modern manufacturing footprint that includes operations in six countries across four continents. Our wide product portfolio enables productivity enhancements and provides sausage products with the superb bite and texture consumers love. Our 85-plus-year history of unparalleled service and operations creates and maintains outstanding relationships with our customers.

Devro is a leading global manufacturer of Edible Collagen Casings and Gels, supplying a wide array of products and providing technical expertise to many of the top sausage and meat snack companies around the world.

Devro, Inc / North America Customer Service Toll free (United States and Canada): 1 800 637 5343

FOR

EXPERIENCE THE DEVRO DIFFERENCE FOR YOURSELF!

devro

Delivering the Added Layer of Value

OVER 25 YEARS AS A PROUD PARTNER WITH CONAGRA BRANDS

www

com

Conagra Brands scw-mag.com 43

the – biggest employer in this wider network of communities; thus, we see it as our duty to conduct business in a responsible way and also give back to the communities. We treat people with respect as we truly have a tangible impact upon their lives.

“The next special aspect of supply chain management is how it relates to and interacts with the wider business,” he says. “We are the metaphorical heart of the company; we make the blood pump through the system every day, despite the challenges and obstacles that are bound to arise. This is particularly special here at Conagra because we have a uniquely strong partnership with sales, marketing, and finance – all of whom are driven to find creative solutions. Indeed, we approach the supply chain holistically

as an orchestrator of specialties, meaning our network of suppliers depends on us to open commercial channels and facilitate the flow of imaginative ideas.”

To expedite that process, Conagra has reorganized its supply chain management, leveraging the integration of end-to-end

Sonoco

Sonoco is a proud partner of Conagra Brands, and together, we work to improve the quality of products for people worldwide. Sonoco has a rich history of helping brands achieve their sustainable packaging goals, and our solutions, services, and programs support our corporate purpose of better packaging, better life.

44 Conagra Brands

scw-mag.com 45

46

procurement, manufacturing, logistics, product quality, and service. Suppliers become intertwined with the customer as part of that network.

Key to Conagra’s strategy is its Fuel for Growth program. Ale explains: “The Fuel for Growth program is made up of five pillars and one core, foundational element. The first pillar is Network Optimization, which is not just limited to logistics. In that area, we are centralizing our network and expect to reduce 50 percent of shipping locations within the next three years. Regarding the manufacturing side, we are reviewing opportunities for either

Burd & Fletcher

Burd & Fletcher continues to meet the food packaging needs of Conagra. For well over a century, Conagra has counted on us for speed-tomarket, package quality, plant efficiency and process improvement. As integrators of its packaging needs, we’re honored to make Conagra’s products stand out on store shelves. From concept to consumer, our role is to protect the company’s brand and supply chain through innovation and continuous process innovation.

Conagra Brands scw-mag.com 47

consolidation or outsourcing (if they are needed), and finding new capabilities that we can leverage.

“The second pillar is Integrated Margin Management, which is basically our productivity program,” he adds. “The focus, here, is on identifying opportunities on mostly a cost basis across the entire supply chain, so we have a strong team of people always looking at how we can optimize formulations, integrate better, reduce waste, increasingly automate, and digitize our supply chain. All this is part of a wider company effort to be more efficient and lean in our manufacturing and distribution processes.

“The third concerns End-to-End Planning and the retooling of related processes,” comments Ale. “This area is utilizing data science and has successfully implemented artificial intelligence to aid that reconfiguration; consequently, thousands upon thousands of models have been created to find the right weekly location for item combinations. Another concrete example we have used to bolster this pillar is a tool called Blue Yonder – a software that allows us to be much more agile in terms of supply and long-term capacity planning.

“Finally, we have pillars four and five,” he notes. “Talent Management is a pillar that reflects how we attract, maintain, and develop our people and offer them a pathway to a successful future, and the final pillar is Sustainability, which can be broadly summarized by improving our operations through five areas of priority: decarbonization, packaging, agriculture, waste, and water. For each of these, we are building programs that mirror our commitment to the environment.”

Ultimately, each pillar underpinning the Fuel for Growth program is sustained by a core element: Conagra’s continued investment in technology. This includes, for instance, Connected Shop Floor, an innovative program that will neatly digitize and standardize all of the food giant’s manufacturing sites, and Oracle Transportation Management (OTM), a logistics service used to upscale a range of execution capabilities.

On a larger scale, Conagra has also recently opened a new, 245,000-square-foot vegetable processing plant in Waseca, Minnesota. The state-of-the-art facility processes fresh vegetables – taking them from harvest to frozen in just five hours – to support Conagra’s frozen division and Birds Eye brand. The

48

Waseca site was built to the company’s own specification, maximizing automation to generate greater operating efficiencies and enhance food safety measures. Water usage per pound of product produced will be cut by upwards of 25 percent and Conagra will operate with a 20 percent higher throughput capacity, leading to a better overall yield.

It is worth pausing on the sustainability aspect of Conagra’s operations once more. Reduced water usage is an important factor across plant processing sites; however, the company aims to embed more

environmentally-friendly methods across its entire supply chain.

Indeed, supply chain sustainability initiatives have not only reduced Conagra’s carbon footprint by 215,000 metric tons and waste by 122,700 tons, but also saved the company $280 million since 2009. Environmentallyminded moves such as this are driven by Conagra’s overarching green agenda: the food company has committed to reducing Scope 1 and 2 GHG emissions by 25 percent by 2030 and will slash Scope 3 emissions from purchased goods and services by up to 20 percent per metric ton of material sourced within that same timeframe.

Conagra Brands scw-mag.com 49

As mentioned previously, Conagra has already begun to implement plant-based serving bowls across select product lines, which have avoided an estimated 23 million pounds of plastic, while also driving $1 billion in sales. Another example Ale is keen to highlight is the transformation of Swiss Miss’ Coco Powder packaging.

“We were the first major hot cocoa brand to move to a cubical shape instead of the conventional cylindrical one,” he says. “The shape of a product affects everything – how you build and stack pallets, space utilization in transport, and the amount of stock that can be stacked on shelves. By altering the shape of the packaging, we managed to completely change the carbon footprint of the product, making Swiss Miss better for the environment and more profitable.”

The new Swiss Miss easy-to-grip container is made of recyclable plastic and features a space-efficient cube design that is said to reduce the carbon footprint associated with manufacturing and transportation by 15 percent – the same as avoiding emissions expelled by driving 243,176 miles.

“Each sustainability initiative makes sense for both the planet and the business,” concludes Ale. “That interconnection is powerful, and we will continue to invest in this dynamic space going forward. But we will also continue to play the game we are currently winning, and that means continuing to innovate, grow, and listen to consumer demand. Everything comes down to digitizing and improving operations across the supply chain.” ■

50 Conagra Brands

www.conagrabrands.com

World-class service

Headquartered in Raleigh, North Carolina, American Welding & Gas, Inc. (AWG) is one of the largest independent, fullservice suppliers of industrial, medical, beverage and specialty gases, propane, safety supplies, and welding supplies. A family-owned company, AWG traces its history to Valley Welding Supply in Billings, Montana, and Scott-Gross Company in Lexington, Kentucky – both of which began operations in 1949.

Today, over 600 employees work across AWG’s 70 retail locations and 18 gas fill plants. It’s a footprint that spans Montana, across the upper Midwest and Great Lakes to Pennsylvania, and down through Texas and Florida. Underpinning AWG’s operations is a fleet of more than 300 trucks and trailers, used to pick up and distribute products across the country. Palletized cylinder trucks make up the bulk of this fleet, used specifically

to deliver compressed gas and welding supplies to AWG’s customers. Cryogenic transports, meanwhile, deliver bulk quantities of medical and industrial oxygen, food grade and industrial carbon dioxide, nitrogen, and argon, while the company’s tube trailers transport bulk quantities of compressed nitrogen, helium, and hydrogen.

According to Stuart Williams, AWG’s Vice President of Supply Chain & Product Management, this range of products is a “key differentiator” for the company. He comments: “We have the capability to produce and deliver packaged gases and bulk gases for almost any customer need, and have the flexibility to identify new and safe ways to do so – for example, bulk delivery of liquid argon, nitrogen, or oxygen to bulk tanks at customer sites, EPA protocols for research applications, beverage CO2 or argon-CO2 75/25

American Welding & Gas is a supplier with a difference

52

American Welding & Gas scw-mag.com 53

twelve-pack cradles for metal fabrication. As for welding supplies, we distribute filler metals for all types of fabrication, welding consumables, plasma consumables, abrasives, safety supplies, welding machines and various industrial supplies from a variety of leading brands, as part of an inventory that’s regularly refreshed in line with customer demand.”

Much of AWG’s success comes down to an ethic of continuous improvement. “Our most recent investment includes the introduction of smartphones, as an alternative to

handheld scanners,” Stuart explains. “With this comes the additional customer service benefit of being able to provide emailed invoices at the time of delivery, as well as accept electronic signatures. We’ve also been implementing delivery and route optimization to reduce our miles driven while improving our delivery service.”

Amid a volatile time for the energy sector, these investments have proved key. “Fuel has been and continues to be a challenge for our industry because our distribution model is predicated on delivering to

54

our customers doorstep,” Stuart insists. “Since launching our route optimization strategy, we’ve been able to reduce our miles driven while increasing the number of cylinders we deliver. That in turn has prolonged our fleet life, reduced the need for maintenance, mitigated risk, and elevated our customer service.

Challenging norms

“Other ongoing capital asset expenditures include cylinders, bulk tanks, or new rolling stock,” Stuart adds. “We recently completed a significant investment in our Indianapolis fill plant and specialty gas lab, including facility upgrades, expansions, and capability improvements. That in turn has given us the opportunity to expand our specialty gas offering, and provide a higher degree of service and product mix for our customers.”

But AWG doesn’t work alone. For Stuart, it’s important to emphasize the need for robust sector relationships. “On the gas side of the business, our customers demand a consistent supply across a wide-ranging geography,” he points out. “Without great relationships, we’d be unable to deliver the service that makes us such a great partner. Similarly, within welding supplies, the bulk of our customer base is engaged in some form of metal fabrication –so there has to be a high degree of confidence in the materials in use. We also have to trust our suppliers to make joint sales calls to bring on new customers, or help customers with technical issues so they can perform to their own expectations.”

To deliver on these requirements relies on a motivated and dedicated team. Accordingly, AWG undertakes a number of initiatives to cultivate an open company culture, such as its partnership with the Gas and Welding Distributor’s Association (GAWDA), to sponsor Women in Welding scholarships. “Our industry is male-dominated, and we want to increase the opportunities for women,” Stuart says. “By focusing on the educational aspects to give women that training, we believe it will diversify

our workforce and provide broader perspectives to challenge the norms of our industry.”

AWG has completed three acquisitions in the last nine months, as it looks to improve its operational reach and service new customers. And it’s not done yet. “We’ll continue integrating our acquisitions into the overall fabric of the business throughout the remainder of the year,” Stuart concludes. “We’ve also opened two greenfield locations in the last six months, and expect to focus on growing those businesses. Over the next five years, we expect our productivity initiatives to continue helping us improve our efficiencies and bottom line, and keep us at the forefront of delivering world-class service.” ■ www.awggases.com

scw-mag.com 55 American Welding & Gas

Healthcare behind the scenes

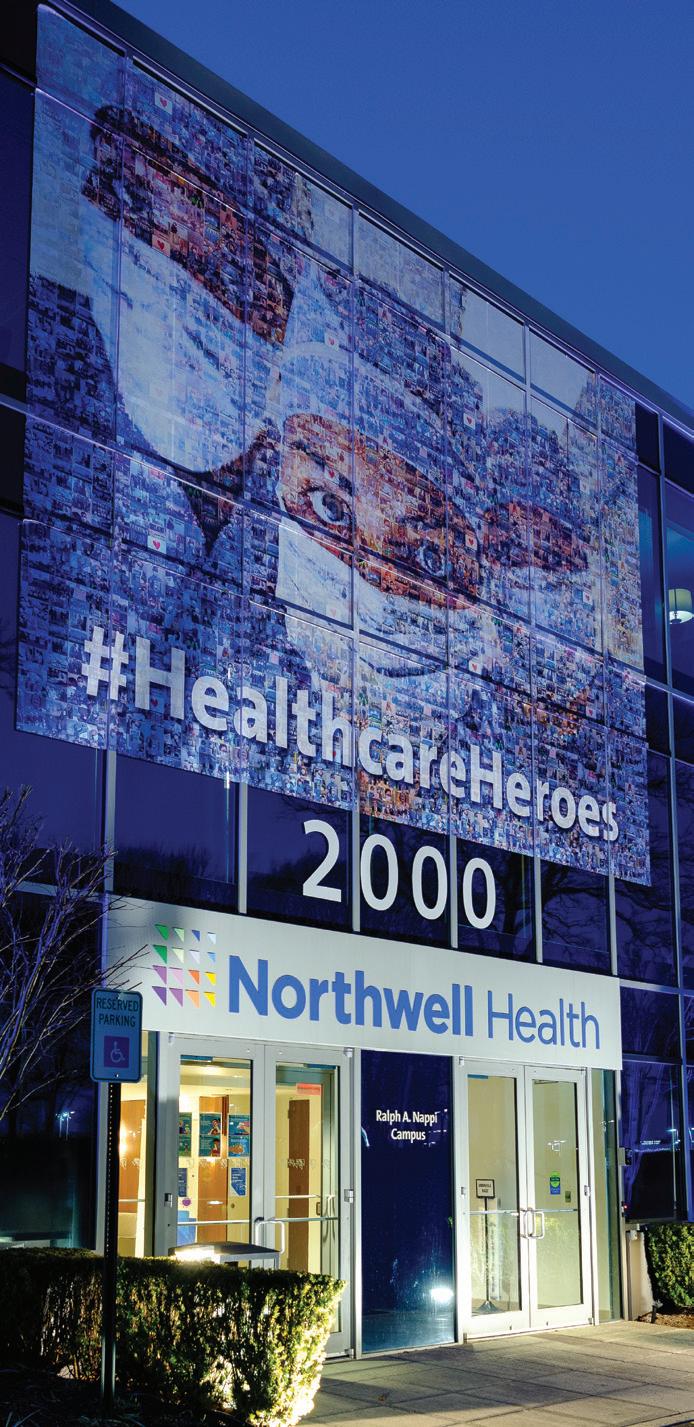

Northwell Health: the $5 billion supply chain supporting New York’s largest healthcare provider

56

Northwell Health (Northwell) is more than just a healthcare system. As the largest private employer in New York, the company employs more than 12,000 credentialed physicians, including approximately 4900 doctors and 18,900 nurses. With a combined footprint of 21 hospitals and more than 850 outpatient facilities, Northwell provides care to two

million patients annually – including approximately 19,000 new cancer patients – more than any other healthcare provider in the state and delivers more than 30,500 babies annually, accounting for 15 percent of all the births in New York. Northwell also boasts one of the largest medical residency programs in the US and operates the largest hospital-based laboratory in North America.

Northwell Health scw-mag.com 57

58

“ “

Supporting all the above is a $5 billion supply chain managed by the Supply Chain department at Northwell. The department is headed up by Phyllis McCready, Senior Vice President and Chief Procurement Officer for the entire Northwell system, and Executive Director and Chief Operating Officer of Northwell Health Alliance Inc., Northwell’s in-house group purchasing organization. The Supply Chain team operates its 85,000-squarefoot distribution center, delivering approximately 3000 SKUs 24/7 to Northwell’s facilities throughout New York, Long Island, and Westchester. It delivered over $200 million of goods in 2021 alone and turned its inventory approximately 14 times within a calendar year.

From the perspective of spend management, Northwell operates a centralized supply chain encompassing everything within the clinical and non-clinical space, including all pharmacy, research, IT,

engineering, facilities, and more, spanning from supplies to service contracts and capital equipment. Category management, which includes value analysis and integration into the clinical space, is essential to the work of Northwell Alliance’s procurement team. “Having the centralized structure that we do, along with the team’s deep industry knowledge, is a key success factor in our GPO’s ability to provide value to Northwell,” explains Phyllis McCready. Supplier management, procurement to pay operations, and master data management all fall within the scope of the Supply Chain department, as does the digital solutions group responsible for all technologies, data, and analytics. “Keeping the technology group embedded in the operations, along with the autonomy to create processes and solutions, has been instrumental in successfully advancing our mission,” explains Vikas Balani, Vice President, Supply Chain at Northwell, when speaking to Supply Chain World

“ “

In this new global climate, a fundamental shift in how risk is identified and monitored is required

Northwell Health scw-mag.com 59

Operating its distribution center proved a good fortune for Northwell in recent years when the Covid-19 pandemic uprooted healthcare and associated supply chains. Reflecting on the period when a disruption became next-to-unavoidable, Phyllis McCready notes that the company began activating its disaster management plans as early as January 2020.