Daring to be

Krispy Krunchy

The story behind the growth and popularity of Krispy Krunchy chicken

Agriculture

Four of the largest upcoming agro-informatics trends that are driving change

Labelling

Food allergen labelling and the need to protect the safety of consumers

Issue 192 - 2023

Rachel Cope, Founder & CEO at 84 Hospitality, on filling a gap in the market, and in the community

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Consultant Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Annabelle Crook, Steven Dobinson

Editorial Administrator Amy Gilks, Afiya Lucombe Davis

Creative Lead Lee Protheroe

Managing Art Editor Fleur Daniels

Art Editors David Howard, Charlie Protheroe, Amy Robertson

Artwork Administrator

Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors

Philip Monument, Joy Francesconi

Head of Content Management

Adam Blanch

Project Managers Lewis Bush, Michelle Fontaine, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Basil Sharpe, Laura Thompson

Content Managers Johanna Bailey, Victoria Burke, Mark Cowles, Valentina Forero, James Fuller, Jeff Goldenberg, Melanie Joyce, James Page, Wendy Russell, Richard Saunders, Kieran Shukri

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division

Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

© 2023 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

US Office

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Hello and welcome to the February issue of Food Chain. In this month’s magazine, technology takes a front seat, as we look at a variety of areas where the right solution can pay dividends. These include sustainability, frozen food supply chain, and agriculture. We also cover ‘lean manufacturing’ – once believed to be the pinnacle of efficiency, our author Marcel Koks analyzes the theory through the lens of recent events and asks: ‘In pursuit of greater efficiency and reduced costs, have we changed the equation to such an extent that the risk/ reward ratio has become significantly out of balance?’ Find out the answer in his feature on page 14.

If it’s insights from business leaders that interest you, for the inside scoop on what makes their business’ tick – these start on page 52.

Libbie Hammond, Editor

LH@finelightmediagroup.com

Our cover story looks at 84 Hospitality, a prime example of entrepreneurship and business foresight. Rachel Cope, Founder & CEO, shares what sets it apart on page 52.

publication

Agriculture Labelling Rachel Cope, Founder & CEO at 84 Hospitality, on filling a gap in the market, and in the community Daring to be Please note: The opinions expressed by contributors and advertisers within this

do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Follow Food Chain magazine today at @foodchain_mag food-chain-magazine

Welcome foodchainmagazine.com 1

Inside

issue Mars Wrigley Lean Frozen food manufacturing Agriculture Digital technology Main Interview 14 26 22 18 8 Contents 2

this

Restaurants Allergen labelling Sustainability Functional ingredients Waste 34 30 38 46 42 foodchainmagazine.com 3 food chain magazine

84 Hospitality

Krispy Krunchy Kevin’s Natural Foods Cookies-n-Milk

Cover Story 58 64 78 72 52 Contents 4

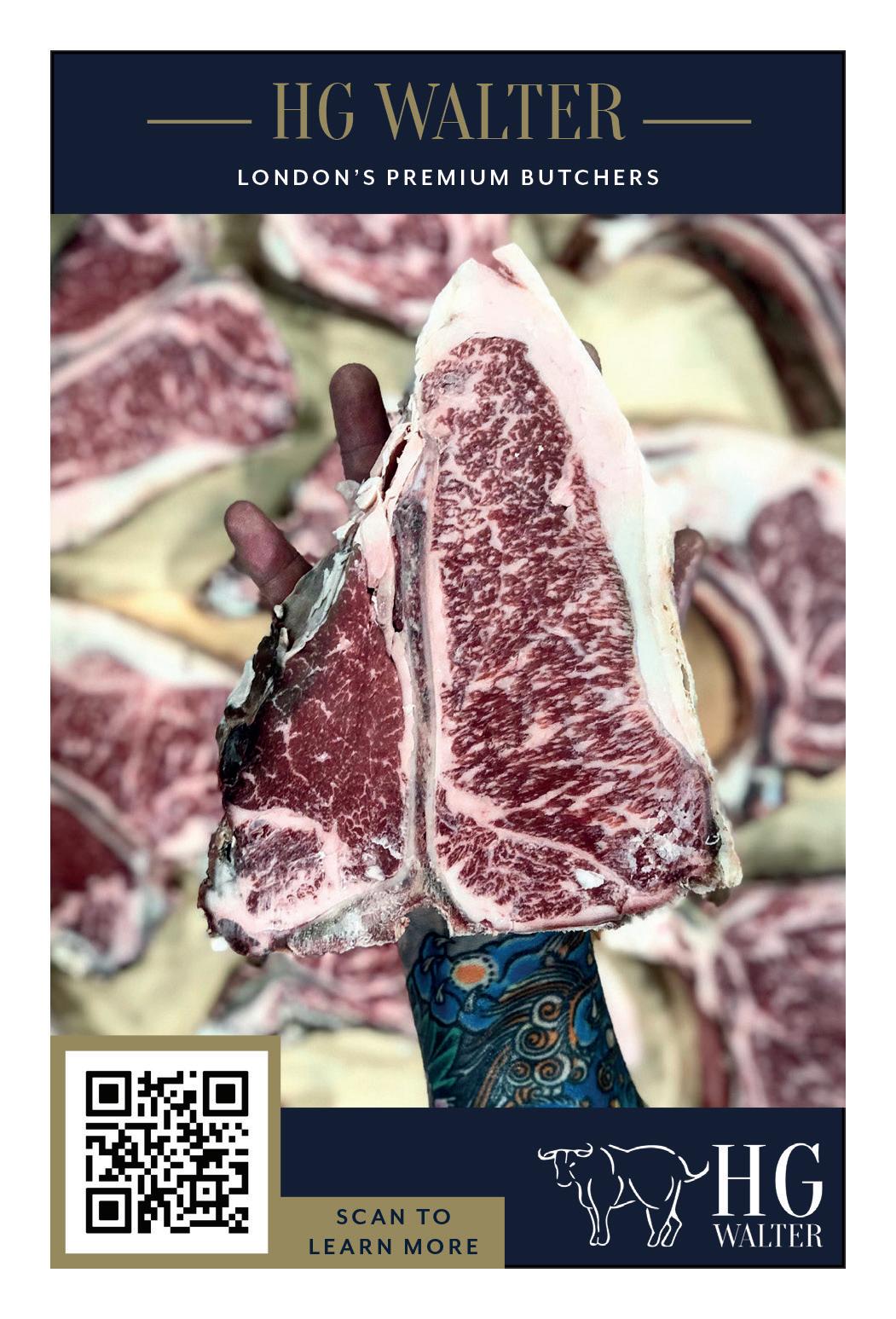

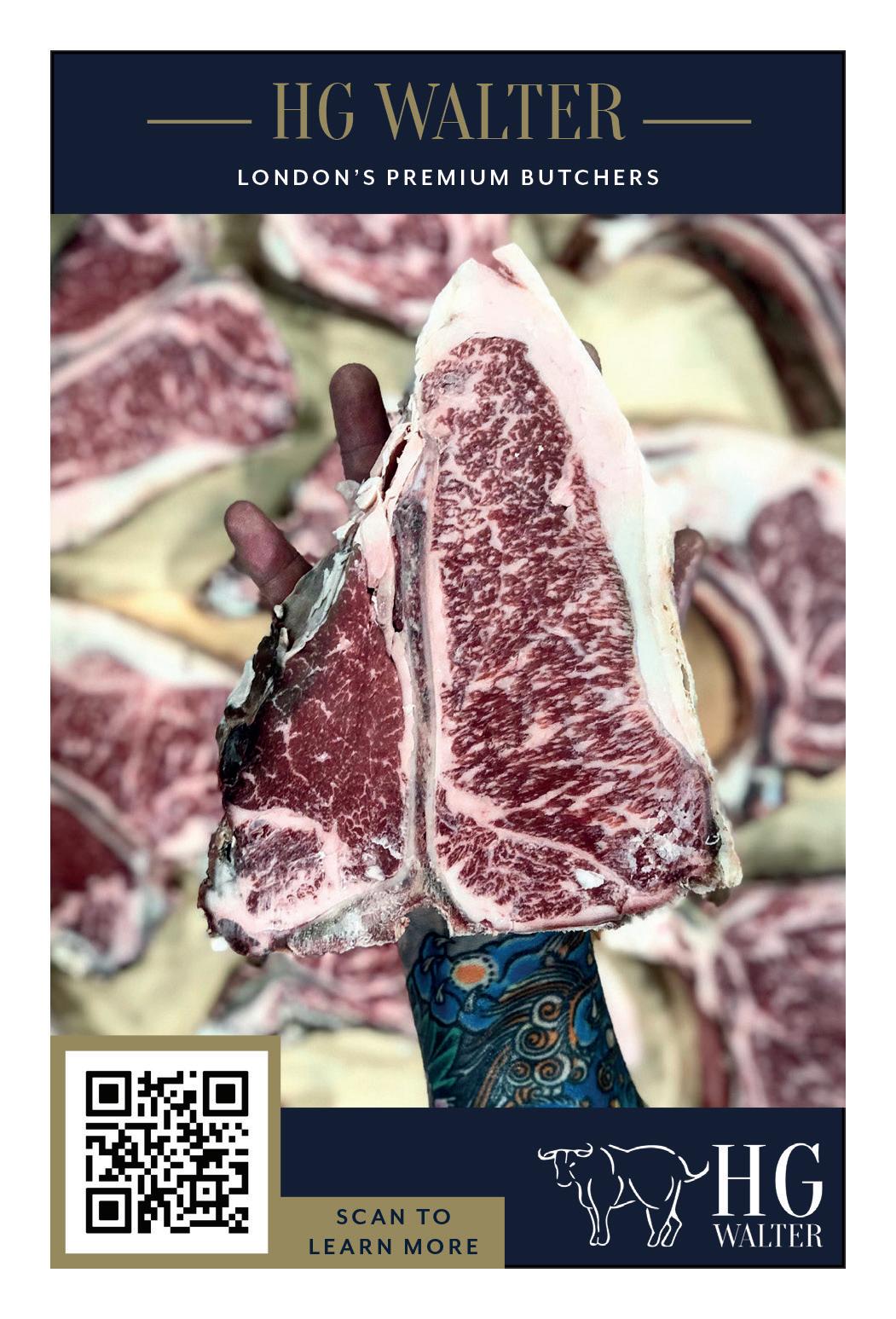

Donald Russell

Tomahawk Steakhouse Hoogland Restaurant

Rhubarb Hospitality Collection S&L Companies Heart of America Group Nathan’s Famous 116 94 106 100 82 88 foodchainmagazine.com 5 food chain magazine

Group

127 Wall/ Yellow Banana

Lone Star Bakery, Inc.

127 Wall/ Yellow Banana

Lone Star Bakery, Inc.

OH SNAP! Camerican

Casino Del Sol

122 130 142 136 152 148 Contents 6

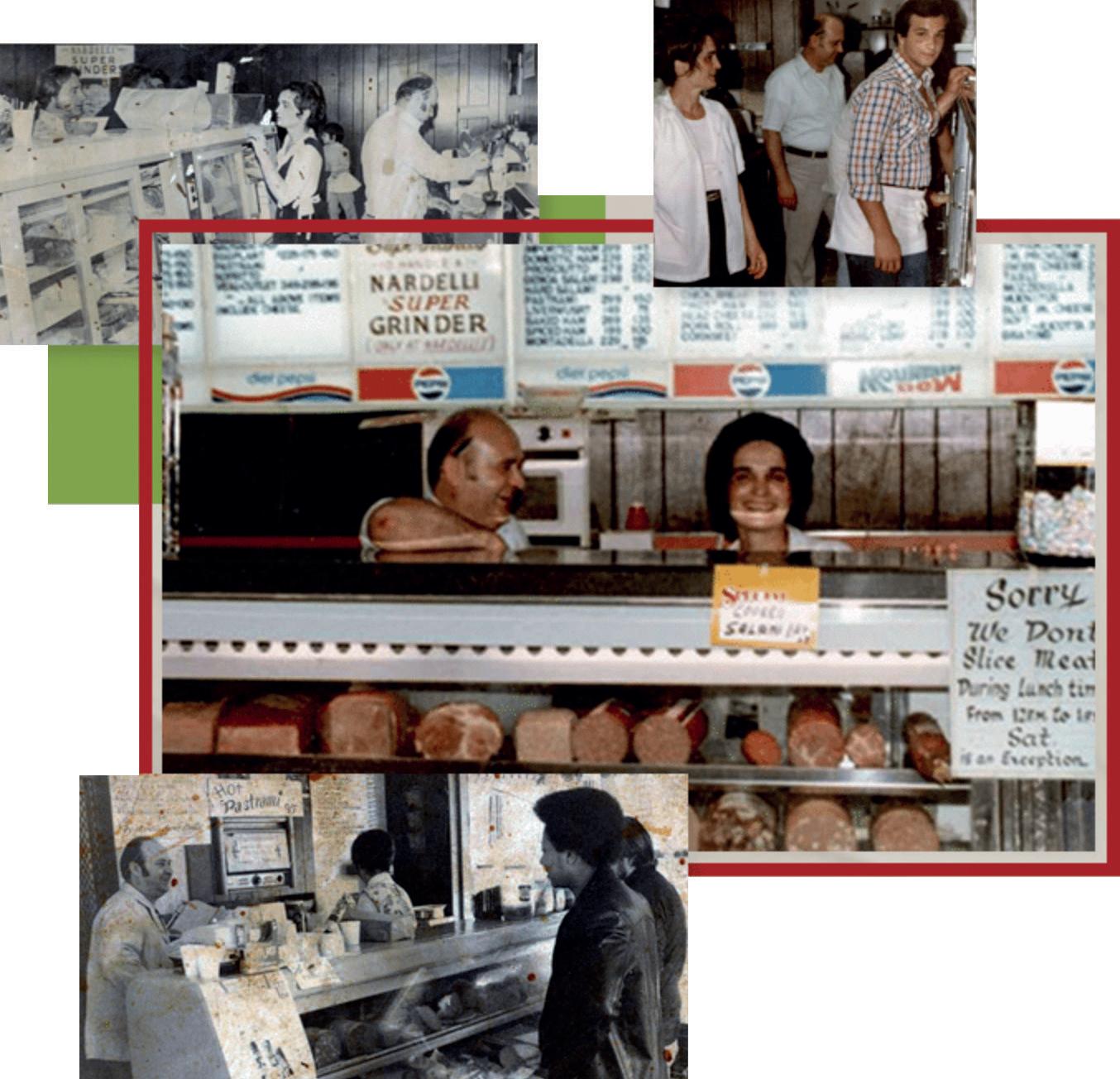

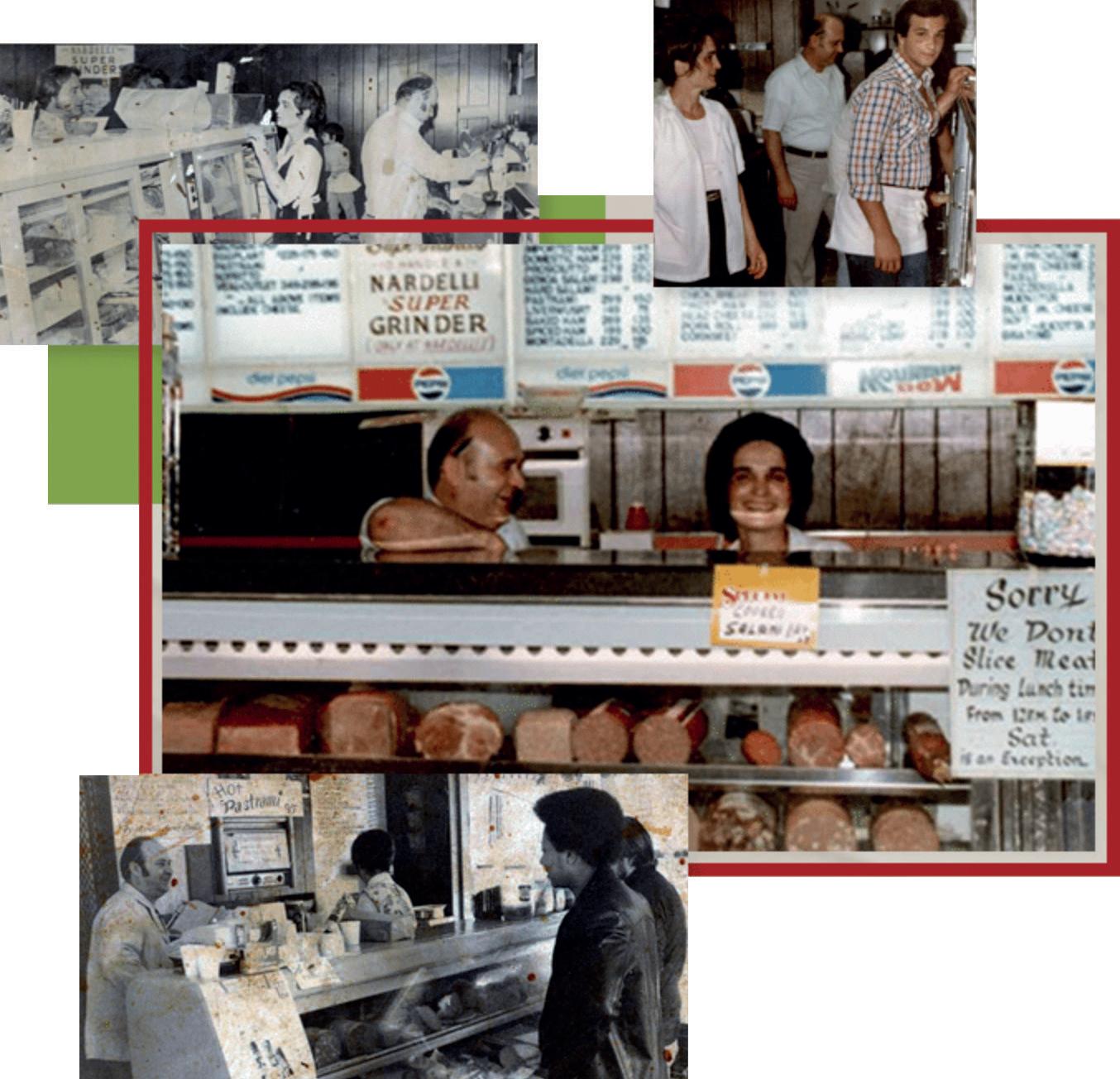

Monday Night Brewing

Wen JAI Palermo’s Pizza Nardelli’s Brothers Drinks The Hershey Company Soreen 184 168 180 174 156 162 foodchainmagazine.com 7 food chain magazine

Pleasure you can measure Pleasure you can measure

Marc Carena of Mars Wrigley discusses the organization’s impressive commitment to people, product and planet

From Skittles and Snickers to M&M’s, and Marc Carena’s personal favorite, Maltesers, Mars Wrigley (Mars) boasts a wealth of wellloved brands. For generations, people, and their pets, have enjoyed Mars’ products and services, and the organization’s ‘Associates’ (how Mars refers to its employees) work hard to consistently evolve and deliver on customer expectations.

Earlier in 2022, Mars announced the appointment of Marc Carena as Regional President for Europe, Central Eurasia, Belarus and Turkey, which accounts for around one third of the business’ entire activity. Marc is excited to be part of an organization that has a positive impact on people’s lives across the world. “At Mars Wrigley, we inspire moments of everyday

Marc Carena, Regional President for Europe, Central Eurasia, Belarus and Turkey

Marc Carena, Regional President for Europe, Central Eurasia, Belarus and Turkey

9 foodchainmagazine.com

Mars Wrigley

happiness for our consumers. This is a wonderful reason to go to work. I’m lucky enough to work with some of the biggest and best-loved brands in the world, and having the opportunity to grow them further is a challenge I’m excited to be tackling.”

Marc joined the organization from McDonald’s Russia, where he spent almost four years as Managing Director. In this role, he maintained full responsibility for the

Russian market, including over 850 restaurants and 65,000 employees. Before joining McDonald’s, he spent six and a half years in senior general management and marketing positions with the German retailer, Metro Group. He has also held several senior general manager, marketing and sales positions at Nestlé, across Europe, Asia and Africa.

Marc brings his extensive experience in retail, foodservice and Fast-Moving Consumer Goods (FMCG) to help enhance and drive Mars’ strategy for purpose-led growth across Europe, Central Eurasia, Belarus and Turkey. He provides a unique understanding of the industry, its value chain, and consumer and customer needs. His experience of managing in over 30 countries, from developed to developing markets, across three

“ “ “ “ 10

There is a real emphasis on talent, continuous development, and collaboration

continents, will help him to successfully lead his current portfolio of countries. Passionate about championing employees and their development, he is keen to engage with the Mars ‘Associate’ concept.

Lasting impact

“There is a real emphasis on talent, continuous development, and collaboration. Everyone has a voice, and a progression plan. I really don’t think this is true of many companies. Mars nurtures an equalitarian culture; it is informal and far from hierarchical. Even the CEO doesn’t have a separate office,” explains Marc.

Associates at Mars are ‘everyday heroes,’ united by an inspiring purpose. They take pride in Mars’ unique way of doing business, and everyone is empowered to learn, expand, dream and develop. Mars is proud to be ‘family-owned, futurefacing, and purpose-driven.’ Embedded within its culture is the mantra: ‘the world we want tomorrow, starts with how we do business today.’ As a global company, with the footprint of a small country, the organization has the responsibility, and the opportunity, to leave a lasting impact on the world. Indeed, Mars challenges its people, partners and suppliers to transform the way it does business, every day.

“As a private company, we have the luxury of thinking in generations rather than quarters,” continues Marc. “So, we have a chance to make a real impact. Mars is strongly led by its purpose, and tries to achieve holistic value creation, incorporating positive societal impact. It is a trusted partner to stakeholders as well as a strong performer, financially. Our

remuneration structure helps us achieve near-term results without compromising on the world we want tomorrow.

“Mars is led by a set of strong core principles, one of which is mutuality, which means working together with customers and suppliers to find the win-win outcome in every situation. From people and R&D to sustainability and packaging, our approach is underpinned by our global purpose, thereby ensuring that we take a principled, purposeled approach to all decision making.”

Indeed, this principled approach is threaded throughout the organization’s operations, and particularly so, in terms of attitude and approach to sustainability. Mars’ ‘Sustainable in a Generation’ plan includes working to create a healthy planet and thriving communities. One such commitment in action is accelerating its progress to achieving net zero Greenhouse Gas (GHG) emissions by 2050.

“I am excited about our sustainability agenda. We are mobilizing our suppliers on climate action. Since joining the Supplier Leadership on Climate Transition (LoCT) program last year, Mars has engaged over 85 suppliers to enrol, representing roughly 25 percent of our total carbon footprint. We are focused on engaging and mobilizing our largest 200 suppliers to maximize impact, and catalyze change through our broader supply chain,” enthuses Marc.

An additional commitment is evidenced by Mars’ dynamic relationship with CARE, an organization that saves lives, defeats poverty, achieves social justice, and fights for women and girls. “Via our Women for Change Program,” Marc explains, “we have been investing in community-

Mars Wrigley 11 foodchainmagazine.com

based initiatives to empower women through finance, skills and networks. In September 2022, we exceeded our target by reaching more than 77,000 Village Savings and Loans Association members in Ghana and Cote d’Ivoire, more than 75 percent of which are women.”

Partnership approach

The target to be net-zero, not only as a business but also with a scope-3 supply chain, by 2050, is an incredibly exciting ambition, one that will be driven, in part, by Mars’ desire to contribute to a circular economy. This model of production and consumption involves sharing, reusing, refurbishing and recycling existing materials and products for as long as possible.

2050

Indeed, Mars’ ice-cream factory in Steinbourg, France, was the first in its global network to run entirely from renewable energy. It no longer uses energy from fossil fuels, but rather from renewable wind, hydro and solar sources. “We now hope to roll this measure out across additional sites, as it is a crucial step in our global commitment to achieve carbon neutrality throughout the supply chain by 2050,” elaborates Marc.

“We are also striving to ensure our packaging material, for example, never becomes waste, but rather, is recycled, reused or composted. To address the

issue, we are investing hundreds of millions of dollars in the reimagining and redesigning of our packaging. This includes redesigning more than 12,000 packaging types across our diverse portfolio to fit with the recycling infrastructure that either exists today, or is likely to exist in the near future. Today, almost half of our packaging portfolio is undergoing redesign or elimination.

“In 2020, we introduced our new gum bottle, changing the material from High Density Polyethylene (HDPE) to Polyethylene Terephthalate (PET), a more popular recyclable plastic material. Then in 2021, in the German market, we launched a further improved gum bottle featuring 30 percent recycled PET. Furthermore, our new M&M’s pouch is designed to be recyclable, according to the existing local packaging waste collection and sorting system. By simplifying the design and structure of our flexible packaging formats, we are significantly improving their chances of being recycled. To reinforce these measures and organizational accountability, Mars’ top 300 executives now have remuneration linked to delivering against these packaging targets.

“Our business can only be successful if our partners, including the communities, suppliers, customers and planet we depend on, are also thriving. This isn’t altruism, it is sound, mutual business,” reinforces Marc. “Over recent years, we’ve seen how important our partners are to our operations, which is why we will continue to prioritize our partner and supplier relationships.”

One crucial component of the Mars supply chain is cocoa. Marc explains: “We have committed $1 billion over ten years as part of our ‘Cocoa for Generations’ strategy. Launched in 2018, it aims to

12

deliver real, lasting positive change across the supply chain for future generations. The strategy focuses on the critical issues that need to be addressed for cocoa farming families to thrive, taking action to help protect children, preserve forests, and improve farmer income. In October, we announced that from 2023, 100 percent of the cocoa purchased for Mars’ direct factory operations across Europe will be responsibly sourced. This is a huge milestone for the business, and one of which I’m immensely proud.”

Sustainability focus

In Marc’s relatively short tenure to date, he has relished getting under the skin of the business. From market visits and factory tours to meeting colleagues and exploring the full product portfolio, he has had the opportunity to learn about the strong foundations of the business, potential areas for development, and reflect on plans for the future.

“We’ve made huge leaps forward in recovering ground lost during the pandemic due to reduced footfall in retail stores. We’ve worked closely with our retail customers to ensure that the right products from

the right brands are in the right locations in store, to make sure they are available and noticeable for consumers. In fact, our gum brands are leading the charge in this respect. With exciting new formats and flavors, we are working hard to maximize distribution and display across the region. Consumers love our gum and we want to make sure they can find it wherever they go.

“Without a doubt, post-induction, I’m aware that the biggest challenge we face, not just as a business but as a global community, is sustainability. However, we do already have a great foundation for this with our ‘Sustainable in a Generation’ program, and our ambitious targets. We know that we must act now; deadlines in the future cannot be an excuse for inaction and delay. We have already cut our full value chain GHG emissions by 7.3 percent since 2015 despite business growth. We’re committed to delivering this by having robust internal governance to ensure we hold ourselves accountable to our ambitions,” he concludes. ■

www.mars.com

Mars Wrigley 13 foodchainmagazine.com

When is LEAN too LEAN ?

Marcel Koks asks if lean, rigid supply chains are still a

option for food and beverage manufacturers

Supply chains everywhere have become too lean - and not just in the food and beverage industry. This trend was highlighted by pandemic-driven shortages in virtually everything - medicines and medical equipment, construction supplies, even toilet paper. These shortages show no signs of stopping either. UK supermarkets are still seeing empty shelves due to a lack of truck drivers and because of manufacturers struggling to source ingredients. The ongoing war in Ukraine is causing a noticeable lack of availability of wheat and sunflower oil, amongst other products, and growers are putting the brakes on the cultivation of certain produce because of the excessive energy costs involved.

viable

14

Lean 15 foodchainmagazine.com

The current situation has led the UK’s National Farmers Union (NFU) to warn that the UK is sleepwalking into a food supply crisis, which is not actually that surprising given that current shortages show no signs of abating. If the last few years have taught us anything, it is to always expect the unexpected and never say never. For the food and beverage sector in particular, this is what makes risk management not only important but difficult too.

So how did we get here?

Since the early 1980s, product portfolios and customer choice in supermarkets have exploded. For example, in the past you only had fresh produce during the local harvesting season, but now you can eat any fresh produce the whole year round because there is always somewhere in the world where it is being harvested. Smaller pack sizes are more prevalent, to cater for those who live alone, and convenience foods are now a major feature of any supermarket. On the sourcing side, a great deal of complex new ingredients are now available to manufacturers, and new varieties of crops have been developed.

All this leads to longer, increasingly complex supply chains. For the food and beverage sector, this has seen the establishment of rigid supply chains, many of which have grown out of long-standing relationships. In times of stability, these rigid, tried-and-tested supply chains worked well but, as we have seen more recently, in times of turbulence and unpredictability, a different approach is needed.

As has become all too evident, certain food and beverage supply chains are precariously extended around the globe, making even the slightest hiccup ripple through like a destructive shock wave. Over-extended supply chains and a reliance on single sourcing, in combination with trying to run leaner manufacturing operations, have all played a role in the current situation. While these can all contribute to more efficient manufacturing, could it be that this approach has been taken to risky extremes? In pursuit of greater efficiency and reduced costs, have we changed the equation to such an extent that the risk/reward ratio has become significantly out of balance? With this in mind, perhaps a little fat in the supply chain diet may not be such a bad idea, after all?

A careful balancing act

Of course, adding a little ‘fat’i.e., buffer - into the supply chain comes with increased financial impact as well as potential risk of obsolescence, depending on the item in question. Hence, this course of action needs to be balanced against the potential benefits to be reaped in terms of resilience and maintaining those all-important customer commitments. Better demand forecast data, visibility deep into supply tiers, hedging and buffering - these are all tools that can be deployed. But, ultimately, it all boils down to this: food and beverage businesses need to constantly and consistently assess and adjust their supply chain strategies to respond to changing demands and changing market dynamics.

16

This could involve a variety of factors. So, more local sourcing and the ability to switch easily to other ingredients and suppliers, taking into account any knock-on effects on product formulations and product quality. At the same time, if sourcing is to be brought closer to home, perhaps consumers might have to accept that there will be less choice of fresh produce? The growth in popularity of veg boxes, with seasonal produce delivered direct to the door, is testament to the fact there is an appetite to shop seasonally. From a sustainability point of view, this would certainly be helpful too, as would a reduction in packaging, something else that could simplify the sourcing process.

A cultural shift

Industry culture also bears some responsibility for the inflexibility of supply chains. Typically, large retailers have wielded enormous power to force suppliers to operate on the thinnest of margins, because they themselves have had to fight hard for every pound of profitability. They have also not permitted suppliers to pass any unexpected cost increases on to them, further tightening the vice-like grip on the suppliers. What has resulted is a cascade of brutal cost pressure throughout the supply tiers, with major suppliers also guilty of similarly pressurizing their own suppliers. With the current cost of living crisis, this situation is only set to get worse.

If any good can come out of the current situation, perhaps it is that it has forced customers and suppliers to realize their mutual interdependence, working towards greater collaboration and trust, leveraging innovative technologies to facilitate this.

Lessons from the past

While there is reason to hope that some of the lessons learned from the current shortages, in terms of supply chain strategies and supplier relationships, will become institutionalized in the food and beverage

industry’s culture, an extra dose of vigilance is recommended to avoid falling back into old ways. But this could very well change if companies and consumers have to pay for the true cost of the environmental footprint of extensive, complex supply chains. It is all a very careful balancing act but one which the industry needs to perfect if it is to continue to thrive in our ever-changing world. ■

For a list of the sources used in this article, please contact the editor.

Marcel

Marcel Koks is Infor’s food industry strategy leader. Infor is a global leader in business cloud software specialized by industry. Infor’s mission-critical enterprise applications and services are designed to deliver sustainable operational advantages with security and faster time to value. Over 60,000 organizations in more than 175 countries rely on Infor’s 17,000 employees to help achieve their business goals.

Koks www.infor.com

Koks www.infor.com

Lean 17 foodchainmagazine.com

18

TIME TO ADAPT

The three essentials to satisfy the consumer appetites of 2023 and deliver more sustainable and meat-alternative products

By Laura Gilbank

The UK food market is expected to be worth £241.3 billion by 2027, with the plant-based protein market alone forecasted to reach £565 million by 2025. With research showing some 7.2 million adults in the UK are now following a meat-free diet - meaning they are now vegetarian, pescatarian, or vegan - the UK food industry is under increasing pressure to cater for more sustainable lifestyles.

This new environment will require food businesses to take a good look at their manufacturing processes and introduce a strong digital ecosystem to meet the demand for meat alternative products and help food businesses introduce more sustainable operations.

I believe that there are three essential ingredients to a digital ecosystem that will help food businesses achieve sustainability success in 2023.

1. Sustainability is crucial to satisfy food concerns

It will be crucial for businesses to address food waste in 2023. The UK alone produces around 25 million tons of CO2 each year from food waste, but significant change is coming. With the United Nations initiative to reduce food waste by half before 2030 and with 55 percent of consumers adopting lifestyle changes to reduce their carbon footprint, many food businesses will follow suit. But it doesn’t stop with sustainable food options. Consumers want greater transparency surrounding the food they buy, and recent legislative changes around allergens, such as Natasha’s Law, are making traceability a musthave factor in all food operations. A foodspecific Enterprise Resource Planning (ERP) system can tackle food wastage and food safety concerns around allergy management, as its high-quality tracking and inventory

Digital Technology 19 foodchainmagazine.com

management capabilities allow businesses to follow products through their entire lifecycle. This insight can highlight areas where businesses need to reduce their carbon footprint and prevent issues such as crosscontamination along the supply chain.

It’s important that businesses remember to provide and display information about the product’s lifecycle and how products can be reused to their consumers. If a business can become more transparent with its product origins, it will unlock a larger pool of conscious consumers and play a major role in solving environmental challenges within the food industry.

2. Customer experience (CX) becomes a critical differentiator to support healthier lifestyles

CX will be crucial for businesses to excel in 2023, with customers wanting their buying experience to replicate

their personal ones. Customers want to be able to research information online, compare offers, and request prices on products at their own leisure. I believe with the increase in digital marketplaces, it makes it even harder for businesses to be able to differentiate themselves from the rest. But an innovative way that businesses can stand out is through their customer experience – with 86 percent of buyers willing to pay more for better CX. This is where a Customer Relationship Management (CRM) system will allow for the forward-thinking business to explore this CX opportunity.

A CRM system gives businesses visibility of their potential customers, with buyer insights, order history, and preferential analytics. This can be taken to the next level through incorporating a CRM system with a food-specific ERP system to gain real-time accessibility and data sharing capabilities. This allows for

20

businesses to fulfil customers’ needs and wants – turning prospects into customers.

3. Sustainable products at a sustainable price point

Throughout 2023, more people will turn to plant-based diets, not just vegans. Animal welfare, environmental concerns, and reducing personal carbon footprints are the driving forces behind this market trend, as a recent study shows that 31 percent of consumers consider moving to a plant-based diet will have a positive impact on climate. So where does this leave food businesses?

It’s time for them to embrace this trend, and already some companies are leading the way. Birds Eye have released their ‘Green Cuisine’ range, and small start-up, Meati, produces less processed products to satisfy both meat lovers and non-meat-eating consumers. However, vegans in the UK spend on average £14 a month more on vegan products compared to meat eaters. With food prices at their highest in 40 years and the recent cost-ofliving increases, it’s crucial for forward-thinking businesses to keep their prices reasonable.

Food-specific ERP software can help with long-term savings and reduce the cost of manufacturing products. For instance, QR code scanners can gather information about recalls, which can help with product quality checks to ensure food is not wasted once it’s ready to be used. Warehouse management tools can also automate procedures along the supply chain, making it more efficient. Together, these additional features soften the cost burden that comes with product recalls and products being wasted due to being out of date.

Food for thought in 2023 with sustainable meat-alternatives and improved CX

As we head into 2023, it’s clear that the food industry’s landscape is changing, and businesses need to adapt to meet these changes. Food companies must look to change their outlooks on sustainability for both the product and their pricing strategies. Improved CX will help businesses gain their share of these lucrative opportunities - and this is where a strong digital backbone upheld by industry-specific ERP systems can help food companies adapt to changing consumer eating habits in 2023. ■

For a list of the sources used in this article, please contact the editor.

Laura Gilbank www.columbusglobal.com/en-gb

Laura Gilbank is Business Development Manager at Columbus UK. With more than nine years of sales experience, much of it in Outsource IT, ERP and CRM platforms, Laura’s success is built on a clear and documented understanding of client needs as well as encouraging success with internal stakeholders. Columbus is an expert in helping ambitious companies digitally transform, maximize assets and futureproof their business operations.

Digital Technology 21 foodchainmagazine.com

SUCCESS GROWING

Agro-informatics trends transforming the food industry in 2023

By Ron Baruchi

Driving the food industry forward from the ground up, the agricultural industry looks much different today than it did hundreds of years ago. Mechanization changed agriculture’s reliance on human labor and horsepower. The Green Revolution harnessed selective

breeding allowing more grain to be produced per acre, helping to feed the growing population and enabling food producers to create new products. Over the past few years, this change has continued, with an increasing focus on sustainability worldwide, as a result of consumer demands

22

and changing production policies. A large part of this is also driven by the agricultural industry, where sustainability improvements are fed throughout the production chain.

In 2023, we’ll see an increasing number of familiar challenges being addressed with new technologies. While mechanical technologies continue their development, it’s the digital technologies we will see driving the most

change within agriculture. Below, I’ll dive into four of the largest upcoming agro-informatics trends I see pushing sustainable change in food production in 2023 and beyond.

A focus on increasing production to meet growing global needs

The Food and Agriculture Organization estimates that by 2050, we will need to produce 60 percent more food to feed a world population reaching nearly ten billion. Even if we hit that mark, 300 million people will still be grappling with food scarcity.

Developing countries will play a key role in this global food supply. Today, countries like the Philippines and Colombia are setting records for US exports. In 2023, developing countries will continue to account for most of the growth in US agricultural exports.

As indicated by the US Farm Service Agency, there will be 1.2 million fewer acres dedicated to corn production in the United States. As a result, farmers will need to have significantly higher yields from their land in order to meet the food needs in the face of a growing global population. For the food industry, this represents a significant supply chain risk.

In the past few years, extreme weather events, Covid-19 supply chain disruptions, and worldwide economic concerns have severely impacted food and beverage supply chains. These factors will continue, and more will join, carrying the potential to shift the reality of 2023 from these projected outlooks.

An increased use of AI-based digital tools

As technology adoption grows, the digital age continues to thrive. In farming, adoption has the potential to mitigate the previously mentioned supply chain risks. From measuring soil nutrient levels to monitoring irrigation and using drone imagery to map and estimate disease presence, Artificial Intelligence (AI) will become a constant

Agriculture 23 foodchainmagazine.com

presence in agriculture, enabling more efficient, predictable food production and higher quality raw ingredients.

Global spending on smart technology and connected systems in the ag space is projected to triple in revenue by 2050. With it, the capabilities of these technologies will grow, in turn enabling food producers to benefit. For food producers who own the farms

from which they harvest raw ingredients, investing in such digital tools could be revolutionary.

Closely related, synthetic data is often used to validate AI models. Based on real-world data, and created by a model that uses the parameters of real-world datasets, it can be used to create a digital twin. This synthetic digital twin could be used to more accurately

24

predict and even impact the amount of raw ingredients a food and beverage company will receive, improving planning capabilities. With so much potential, use of this will increase, with Gartner predicting it will outpace real data in AI models by 2030.

A larger use of precision agriculture, primarily to decrease production costs

Precision agriculture harnesses smart, connected technology systems to improve grower outcomes. Growers can save time, money, and resources – all at a premium in today’s world – with tools that support crop monitoring and targeted crop nutrition plans. This makes producing the raw ingredients cheaper, with cost benefits being passed to food producers.

In 2023, using precision AgTech tools for precise fertilizer application will be more important than ever, driven by rising fertilizer costs. Fertilizer costs increased the most of any input in 2022, with projections that this will further increase over the coming year. With no other way to recoup the costs, farmers have been raising the price of their produce, making profit margins smaller for food and beverage companies. The improvement of precision agriculture means farmers input costs will be reduced, creating a positive knock on effect.

A continued focus on sustainability

Sustainability isn’t a new trend or topic in 2023, but it’s a safe bet that companies will double down on their efforts. To do so, they’ll need to quantify their impact on sustainability. To consumers, a highly sustainable product is a great selling point, and food producers can significantly improve their sustainability ‘scores’ by sourcing sustainably grown ingredients.

Along with positively impacting the environment, financial benefits of environmental sustainability also exist.

As well as the numerous carbon markets available for US producers, the USDA’s Natural Resources Conservation Service is offering technical assistance and financial support for improving air quality, conserved ground and surface water, soil health, improved or created wildlife habitats, and more, encouraging farmers to grow sustainable ingredients for the food industry.

Staying abreast of all the industry changes can be a challenge. However, with pressures from a changing climate and growing population, adapting is necessary.

Quickly understanding the impact of new technologies or production practices on raw ingredient supply and quality is critical in driving profitable and sustainable change. Reviewing available research can help to predict plant growth and development. In turn, this allows food and beverage companies to predict their supply of raw ingredients, an invaluable foresight for planning. Ultimately, it pays food companies to consider the stage before the factory - the growing of raw ingredients. ■

For a list of the sources used in this article, please contact the editor.

Ron Baruchi www.agmatix.com

Ron Baruchi is CEO of Agmatix, an agro informatics company that develops data-driven solutions for ag professionals worldwide. Its cutting-edge technology platform uses agronomy data science and advanced AI technology to convert agronomic data into actionable insights at field level. The SaaS platform aggregates, standardizes, and harmonizes agronomic data from trials and experiments, unlocking a significant new layer of knowledge. With a revolutionary approach, Agmatix aims to solve the lack of data standardization to dramatically improve agricultural practices, crop yields, and nutritional quality, and to promote sustainable agriculture.

Agriculture 25 foodchainmagazine.com

Keep your COOL

Increase confidence in supply chain predictability through smart manufacturing

By Jim Bresler

By Jim Bresler

26

Food and Beverage (F&B) manufacturers are under increasing scrutiny and pressure. Problems with empty grocery store shelves have mostly subsided since the pandemic, but F&B manufacturers still have plenty of challenges to contend with today. Key challenges include environmental volatility that can impact production, ingredient availability and transportation as well as labor shortages that impact productivity across an enterprise’s supply chain operations.

Frozen F&B suppliers face an added hurdle in the industry - guaranteeing that their goods stay frozen during transportation. Logistical efficiency is essential for making sure products reach customers unscathed and at peak quality, thus cementing a successful supply chain process.

27 foodchainmagazine.com

Frozen food manufacturing

Labor shortages and environmental disruptions are expected to continue or worsen in the coming years. In response, F&B manufacturers must leverage smart manufacturing technologies to enable supply chain and production predictability. Accurate demand and inventory forecasts produce insights that enable F&B companies to develop strategies that minimize food waste and adhere to regulatory requirements. In addition, better predictability enables enterprises to circumvent disruptions caused by natural disasters and labor shortages.

Advanced inventory & logistics management challenges

The F&B industry is facing increasing demand for longer product shelf life. At the same time, regulatory agencies are examining food manufacturers through a critical lens following the events of the pandemic and the recent national baby formula shortage across the US. Further complicating operations are challenges surrounding ingredient sourcing, production planning and logistics management.

In contrast to other manufacturers, F&B manufacturers - especially frozen F&B producers -

cannot depend on an easily predictable level of supply or demand. Trends in consumption and ingredient availability change over time and are subject to seasonal fluctuations in the F&B industry. Variability in ingredient quality and shipping times can also impact production planning. While frozen F&B manufacturers produce a shelf-stable item, so long as the finished product remains frozen, the ingredients used in production are still subject to degradation and potential damage.

To overcome these challenges and meet fluctuating demand, frozen F&B manufacturers must be able to scale production up or down as indicated by data-driven insights. Agile scaling of production enables F&B companies to meet demand when it rapidly fluctuates while reducing the risk of revenue lost through food waste and expired products.

Successfully executing advanced inventory and logistics management requires elevating operations beyond paper documents, which are still used for inventory and production planning by many manufacturers. Paperbased approaches to inventory sourcing and production management leads to significant obstacles in the volatile supply chain reality of today: slow internal communication, uncoordinated efforts and misaligned priorities between departments (sales, order processing, customer care and plant floor operations) and a lack of visibility into realtime updates. To get through communication bottlenecks, overcome labor shortages, effectively manage third-party suppliers and enable visibility across supply chains, which leads to predictability and traceability, manufacturers must digitize their operations.

Digitizing inventory & logistics management

Smart manufacturing technology adoption, and the digitization of processes that accompanies

28

a smart manufacturing approach, elevate procurement and production planning and lead to maximizing revenue generation and reducing waste. It’s simply impossible to overcome the F&B supply chain challenges of today through paper processes, which cannot provide automated tracking capabilities or integrate with critical manufacturing systems such as Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MESs).

F&B manufacturers that digitize operations can leverage the Industrial Internet of Things (IIoT) and industrial automation systems to collect and analyze supply chain information. Analyzing this information generates data-driven insights to guide strategic decision-making as well as internal and external communications with stakeholders and partners. However, if insights are to be accurate, this data must be holistic - i.e., collected from across the enterprise’s various departments and systems - which is impossible to confidently achieve with a paper-based approach.

F&B companies must compare historic customer purchasing information against relevant inventory procurement data to optimize supply chain planning. But enterprises that leverage insights derived from incomplete data run the risk of basing key business decisions on faulty information. This risk is best avoided by deploying supply chain planning software, which aggregates end-to-end enterprise data into a single source of truth for analysis. Advanced analytics capabilities offered by supply chain planning software automate the generation of actionable insights based on historical data and help F&B manufacturers easily identify optimal strategies to circumvent logistics challenges. Further, the automation of data analysis and insight generation reduces the strain on human workers and frees up time to solve other challenges throughout the enterprise that cannot be solved by advanced data analytics.

Predictability is the core benefit of a smart manufacturing approach to supply chain planning. Increasing predictability of outcomes by analyzing historic procurement, shipping, purchasing and production data, enables decision-makers to visualize supply chain timelines and ingredient availability more accurately than would ever be possible with a paper-based approach.

Inventory & logistics management optimization benefits all stakeholders

Supply chains are essentially a giant collaborative project. Multiple stakeholders work together to construct and manage a supply chain from beginning to end. Partners, suppliers, distributors, freight companies and raw ingredient suppliers can all gain increased predictability, reduced waste and optimal revenue-generating strategies based on insights provided by the digitization of supply chain planning. Suppliers can receive accurate orders farther in advance, logistics providers can better plan shipping operations due to more accurate estimates of reserved freight capacity, and manufacturers can feel more confident in their partners’ ability to meet demands. These benefits will be key to ensuring business continuity when frozen F&B manufacturers must overcome the next challenge - whatever that may be. ■

For a list of the sources used in this article, please contact the editor.

Jim Bresler www.plex.com

Jim Bresler is Director of Product Management, Food & Beverage, Plex. Plex Systems, Inc., a Rockwell Automation Company, is a leader in cloud-delivered smart manufacturing solutions, empowering the world’s manufacturers to make awesome products. Its platform gives manufacturers the ability to connect, automate, track, and analyze every aspect of their business to drive transformation.

Frozen food manufacturing 29 foodchainmagazine.com

REMAIN VIGILANT

Developments in food allergen labelling and what to expect in 2023

Global efforts are constantly underway to evolve and harmonize product labelling in a bid to improve the safety of consumers with food allergies – a group estimated to equate to between 1.1 percent and 10.8 percent of the population worldwide. But with new changes comes additional pressures on businesses to adapt their labelling, ingredients, and product information. Experts at the product information people, Ashbury, explain that due to the current pace at which the regulatory market is evolving, food allergen labelling is resulting in many cases of costly product revisions, product recalls, reformulations, and redesigns for those businesses failing to keep up.

Joanna

Becker-Hawkins, Senior

allergen labelling in 2023, how these changes vary around the world, and how businesses can best prepare to ensure they remain compliant.

“Food labelling provides information to individuals about the products they buy and consume. As anyone with a food allergy will know, it’s crucial that what’s on the label is accurate – even trace amounts of an allergen can lead to serious reactions, including anaphylaxis.

“And yes, using an EpiPen can counteract an allergic reaction after it’s occurred, but it’s certainly not an appropriate or long-term preventative solution for food allergy sufferers.

Regulatory Advisor

at Ashbury, explores what changes we can expect for

“Instead, the best way that the industry can protect and support consumers with allergens is to remove the ingredient from the production and supply chain process altogether – which is why solid data and allergen management

30

processes are crucial. Or, where complete removal isn’t possible, ensure the potential risk is clearly communicated.

“Whilst in theory, this sounds simple and easy to implement, it’s in fact a challenging task for brands and retailers to achieve, as we’ve seen in recent high-profile cases.”

What’s the current UK legislation?

All ingredients contained in an item should be listed on a food label in a clear and concise ingredients list, with allergens being highlighted – in most cases they’re listed in bold and accompanied with a statement: ‘For allergens, see ingredients in bold.’

The 14 mandatory allergens in the UK are: milk, mustard, celery, sesame seeds, cereals containing gluten, crustaceans, fish, lupin, mollusks,

peanuts, soybeans, sulphur dioxide acid (at concentration of more than ten parts per million), sulphates and tree nuts. But these differ worldwide - the US has nine, Australia ten and Canada 11.

How is allergen management handled worldwide?

Allergens differ around the world. Vulnerabilities to allergens vary depending on each population, and can be affected by factors such as diet, culture, history of food consumption and the environment.

But globally, the management of allergens is comparable, as a regulatory approach has been established by the World Health Organization (WHO) through Codex, which outlines that each country must manage food allergies within a local context.

Nationally, or even on a smaller local scale, foods that are considered

Allergen Labelling 31 foodchainmagazine.com

problematic must be established and their presence clearly communicated to consumers. Plus, each country is continually working to understand and determine acceptable threshold levels.

For brands and manufacturers, it’s essential that they entirely understand their product and extensively research the market in the country they’re trading within. With this knowledge, what must be included on the label (or alternative means of providing such information, which also varies by country) will be understood, and must be upheld.

What changes are currently taking place?

In a report issued by the NHS in September, it found that allergy and anaphylaxis hospital admissions have increased by 15.6 percent in the past 12 months for adults aged 19 and over. Therefore, it’s unsurprising that much is being done globally to change and evolve the allergen labelling industry. But these changes aren’t harmonized, and do vary worldwide.

For example, changes in the US were implemented from January 1st 2023. The Food and Drug Administration (FDA) introduced a regulatory requirement for packaging labels to detail foods that contain sesame as an ingredient. However, following this statement, some restaurant chains were found to purposefully add sesame to foods that didn’t previously contain it, possibly in order to bypass some of the cross-contamination risk management processes.

What are allergen threshold levels?

Back in 2015, the Australian VITAL programme began researching crosscontamination risk, with a mission to establish levels of allergenic food in small enough quantities to prevent triggering an allergic reaction. Since then, this has been further developed and refined by WHO, and when these levels are exceeded, a warning message must be printed on a product label. But these threshold levels aren’t yet universally agreed. And only levels for Gluten and Sulphur Dioxide are recognized to date. Due to this, it’s likely that we will see further advancements within this arena over the coming months and years.

What challenges are being faced regarding allergen labelling?

The introduction of certain legislation can be problematic. For example, it’s been argued that ‘may contain’ warnings or Precautionary Allergen Labelling (PAL) could be used by manufacturers where not needed, with the view that it’s easier to state this than to ensure the appropriate controls are in place to remain compliant. But, when used loosely in this manner, the number of foods available to affected consumers drastically reduces, and can create confusion with regards to the genuine risk of a product.

Plus, the wording used for PAL is under review worldwide, due to its lack of standardization across the board. It’s been suggested that ‘product is not suitable for X allergy sufferers’ would be more

“

32

“ The food industry is rapidly evolving, especially with regards to the declaration and labelling of allergens “ “

suitable, than the current ‘may contain X’ or ‘produced in a factory where X is used’, but this is yet to be determined.

Novel foods, and up-and-coming sectors such as plant-based or alternative proteins, can also be considered challenging regarding allergen labelling. Currently, when a novel food is assessed by UK or EU authorities, its allergenicity and likelihood of causing an allergic reaction in the said population is reviewed and scientific evidence researched.

As of 31st December 2022, all insect foods in the UK are required to undergo a novel foods application through the authorities – a process that could see a huge increase in insect-based ingredients being used. However, several scientific opinions and studies have been unable to conclude the allergenicity of such ingredients, with some insects being cited to have caused allergic reactions in shellfish or crustacean allergy sufferers. As novel foods are increasingly used in products and are becoming more common within the UK market, these will need appropriate monitoring.

What other influences are impacting product labels?

Oftentimes, legislation is influenced by errors reported within the industry. Take, for example, the recent inquest into Celia Marsh, following her death after consuming a wrap from sandwich chain, Pret-A-Manger, which contained undisclosed dairy that she was allergic to. This concluded in a proposed testing regime to prevent risks of cross-contamination.

Testing, although part of a reasonable and robust process, can also pose further issues, as it’s highly dependent on the overall checks and balances in place, as well as being reliant on the remainder of the supply chain also meeting regulation.

Many consumers are having an increasing and conscious awareness of the Environmental, Social and Governance (ESG) of products, which impacts their purchasing habits. Disclosing this information is voluntary, but they are insights that consumers are regularly seeking – especially for allergy and asthma sufferers who might buy products based on how ‘healthy’ they appear to be. In the US, the Allergy Standards Limited (ASL) promises to make the indoor environment a healthier space for these consumers.

The food industry is rapidly evolving, especially with regards to the declaration and labelling of allergens. There are many suggested changes that are likely to be reviewed and enforced over the coming months, and many more obstacles that need to be addressed and overcome. Brands, retailers and manufacturers need to be vigilant to ensure they remain compliant regardless of the changes that are brought into effect. ■

For a list of the sources used in this article, please contact the editor.

Joanna Becker-Hawkins www.ashbury.global

Launched in 2011, Ashbury is a UK leading consultancy service provider, helping businesses navigate the complex world of product information regulations for food and non-food products. Its expert regulatory team guides clients from a place of uncertainty to complete reassurance, helping them to understand, apply, and comply with domestic and international regulations, and empowering them to help their customers make safe and informed choices.

Download Ashbury’s Behind the Label: Protecting Allergic Consumers guide: https://mailchi.mp/ ashbury.global/protecting-allergic-consumers.

Allergen Labelling 33 foodchainmagazine.com

Set the mood

What the color of your restaurant means

As a restaurant owner you’ll no doubt have put a serious amount of time, energy, and money into the interior design of your establishment. But what does the color of your restaurant mean? And, more importantly, how does it make your customers feel?

Color psychology is the study of how colors can affect people, and the different subconscious associations we have with each shade and tone. So, hospitality and catering suppliers Alliance Online have looked into color psychology to determine what the color of your restaurant may be telling your patrons about your business.

34

Red

Red is perhaps the most stimulating color you could choose to decorate your restaurant with. It is very eye-catching, and it is often associated with physical energy and alertness — which is probably why it is so often used in fast food and takeaway branding. However, there are romantic connotations to the color red, too, which make it the ideal option for cozy dining rooms, and it is also the color most associated with stimulating appetite. So, in many ways, it is the perfect choice for restaurants!

The downside to using red in your interior design is that too much of it can sometimes lead to subconscious feelings of aggression, so it’s best used as an accent color rather than your primary shade.

Orange

Orange is a color that is said to encourage teamwork and openness, so if you’re looking to create an atmosphere of friendliness among your staff and customers, this is the right color for you. It’s best used in tapas or small plates restaurants, or simply those with a more laid-back feel. Warm and joyful, it can invoke feelings of sociability and encourage

conversations in your restaurant, so it’s more suited to a room with dining tables than fast-food counters.

However, as orange contains the color red, it could similarly be perceived as overwhelming to some people if overused.

Yellow

Yellow is said to stimulate serotonin (the ‘happy’ hormone) in our brains, so it’s a great color for fun restaurants such as burger bars or family-style eateries. Use yellow wherever you want to promote cheeriness and laughter — if you specialize in fine dining, you can opt for a pale yellow to provide an upbeat atmosphere while keeping your design sophisticated.

As with red, there is a downside to doubling down on yellow décor. Studies have shown that too much yellow could have almost the opposite of the desired effect, including hyperactivity and becoming overly emotional. So, you might want to consider a yellow feature wall rather than painting all the walls of your restaurant, or to try decorating with yellow accents.

Restaurants 35 foodchainmagazine.com

Green

Green is a color of harmony, neutrality, and balance, so it’s always been considered a safe option to decorate a restaurant with. However, more recently, it has even more potential to be beneficial for your business. Healthy eating, veganism, and sustainability are more on trend now than they have ever been, so if your restaurant ticks any of those boxes, it makes sense to advertise that to potential customers with a green color scheme. Another great thing about green is that there are so many shades to choose from, from bold

emerald to pale mint, olive, and seafoam — though it’s best to stay away from ‘sickly’ yellow greens that might remind people of illness. Plants, living walls, and herb gardens are a particularly safe way to bring green into your establishment, especially for vegan or eco-friendly restaurants.

Blue

Blue is an extremely popular color in interior design as it promotes rest and calm, making you feel safe and even sleepy in the right circumstances. As a result, restaurants tend to shy away from it and choose more upbeat, stimulating

36

colors instead. This is probably for the best, as it has also shown potential to be an appetite suppressant.

That’s not to say that blue should never find its way into restaurant décor, however. If you want to create the kind of establishment where people go to unwind and relax, it can help relieve their stress and evoke feelings of trust — perfect for encouraging repeat custom.

A bright, fresh blue can also remind people of being on holiday as it is reminiscent of the sea and clear, sunny skies, so if you’ve chosen blue for your restaurant, you shouldn’t necessarily reconsider you decision.

Consistent branding

“It’s interesting to know that you can use color schemes to influence the way people perceive and respond

to your hospitality business. When decorating, think about the USP of your restaurant and the mood you want to create, then choose colors that reflect those,” said Rachael Kiss, Marketing & Online Manager at Alliance Online.

“Your brand colors should be a jumping off point to ensure consistent branding — but remember that each color can also have a negative association when overused. Bold colors, such as red, may be better off incorporated as accent colors.

“Opportunities to include accent colors include feature walls, artwork, and furniture, but also your crockery, cutlery, and napkins can be used to provoke the mood you want to.” ■

www.allianceonline.co.uk

Alliance Online specialises in catering and kitchen equipment selling both to trade professionals and the public.

Founded in 1999, Alliance Online works with a vast range of suppliers to deliver high quality equipment to professionals in the hospitality industry and to those at home. Alliance Online has a dedicated fleet working across the country to ensure quick and efficient delivery options.

“

“

“ “ Restaurants 37 foodchainmagazine.com

...you can use color schemes to influence the way people perceive and respond to your hospitality business

38

Vital links

Organizations worldwide are facing increasing regulatory pressure to provide greater traceability of their products. This pressure is two-fold, stemming from the need to protect consumer health and safety, and develop more transparent, future-proof supply chains.

These drivers for change could be viewed as a necessary evil – a stick enforcing the adoption of new solutions and processes to provide additional data – however, this is not necessarily the case.

As Lee Metters, Group Business Development Director, Domino Printing Sciences, explains, traceability and transparency require little more than a humble, serialized code – the vital link that joins a product to its online data, provenance, and history. Moreover, organizations can use the data afforded by serialization to achieve much more than compliance.

Spotlight on security

The last decade has seen a marked increase in the number of governments and regulators requiring a greater and more stringent exchange of data to protect patient and consumer safety. Often this is achieved via 2D codes and serialization – assigning an individualized or variable code to items so that they can be uniquely identified, tracked, and traced throughout their lifetime. Regulatory serialization requirements* have been restricted to pharmaceuticals, medical devices, and tobacco until recently. However, as global demand for more transparency within supply chains increases, we see the requirement expand into other industries, particularly food and beverage. For example, Russia’s Chestny ZNAK track and trace system was inaugurated in 2017 for prescription and OTC medicines and has since been expanded to include

The variable data behind sustainable food supply chains

Sustainability 39 foodchainmagazine.com

bottled water and milk. In addition, it is anticipated that the next update of the FDA’s Food Safety Modernization Act will require the serialization of certain food and beverage products in the US.

Supply chain opportunity

Typically, compliance obligations come at a cost to brands, with little commercial gain. While the prospect of new regulatory serialization requirements might, therefore, seem daunting, the reality is that the serialization of products can provide significant benefits to brands. For instance, enabling visibility on how products move through supply chains. As the pharma industry has found, the end-to-end traceability of products via scannable, serialized 2D codes can present an opportunity for brands to run their supply chains more efficiently and drive out potential causes of waste. These same benefits apply to the food and beverage industry, and with the spotlight on global food waste reduction, arguably, the opportunity for change has never been more significant.

Variable code scanning at each step in the supply chain – from the initial raw material supply all the way through to retail sales data – can allow supply chain partners to access information on the provenance and journey of each product. This increased visibility can provide opportunities to identify issues and sources of waste at each step of a product’s journey, providing the insights needed to run supply chains more efficiently.

Sharing data across supply chains can also provide insight into supply and demand levels in different regions, presenting an opportunity for manufacturers to produce in a way that matches downstream and upstream needs. The benefits of improved supply chain efficiency help reduce waste and drive out inefficiencies and enable brands to offer a greater variety of fresh food products, with increased shelf life, to their consumers.

The push for transparency

The benefits of this kind of deep, granular supply chain data extend far beyond the brand level – as it is now widely recognized that more transparency in food supply is key to sustainable growth and development.

Indeed, amongst the 17 UN Sustainable Development Goals is a focus on ensuring sustainable consumption and production patterns (UNSDG 12), with a commitment to halve, per capita, global food waste at the retail and consumer levels and reduce food losses along production and supply chains, including postharvest losses, by 2030.

In the UK, the National Food Strategy – an independent report for government – has recommended creating a National Food System Data programme to collect and share data to improve the nation’s health, wellbeing, and the environment. It advocates that the programme should include data from beyond the farm gate: “on food production, distribution

“ “

“ “

The first and simplest step towards greater supply chain efficiency is through the adoption of variable 2D codes to facilitate data exchange

40

and retail, and the environmental and health impacts of that food.”

Similarly, other governments are looking at solutions to provide an audit trail of data on the supply chain of food products.

In 2020, the US Department of Agriculture proposed implementing blockchain technology to trace the supply of organic food products. The Food and Drug Administration of the Chinese Chongqing Yuzhong District has tested blockchain in facilitating traceability and quality assurance in food and drug supply chains. Indeed, China is one of the world’s most rapid adopters of blockchain solutions, with the central government expected to release a national blockchain standard later this year.

In addition, organizations such as TagOne, WholeChain, and IBM also offer blockchain-enabled solutions for the food and beverage industry to improve traceability, with the underlying goals of reducing food waste – improving food freshness and safety – and increasing sustainability and supply chain efficiency.

Is blockchain the answer?

For many businesses, the concept and understanding of blockchain remain vague. Yet every food and drink manufacturer will be familiar with variable data labels and serialized codes – the underlying product codes that provide traceability, and transparency, by linking physical products to the online world.

The first and simplest step towards greater supply chain efficiency is through the adoption of variable 2D codes to facilitate data exchange. Unique to each product, serialized codes will provide the greatest level of data, but even batch-level identifiers can provide a certain degree of transparency.

An additional step is to have a background system that collects data

at each stage of the supply chain and stores the information to be instantly accessible. A blockchain-enabled system could then provide additional, immutable assurance that the information is correct.

The variable 2D code is the vital link that joins a physical product to all its online data at each step.

Conclusion

Through regulation, corporate ESG initiatives, and consumer demand, the world is on a journey to provide better identification and faster sharing of data which can have significant benefits in supply chain efficiency. Some organizations can help provide the back end too i.e., blockchain-enabled solutions or supply chain systems. For these solutions to work, a link to the physical product is required, which means manufacturers need to ensure their systems are equipped to provide that link.

The good news is that embracing serialization does not need to be challenging. The underlying variable data coding technology is already in place to provide traceability and authentication – to provide the missing link between manufacturers’ physical products and the online world and enable genuinely sustainable food supply chains. ■

For a list of the sources used in this article, please contact the editor.

*Regulations include the EU Falsified Medicines Directive, first adopted in 2011, which introduced harmonized measures to ensure that medicines in the European Union (EU) are safe and that trade in medicines is properly controlled; the US federal Drug Supply Chain Security Act (DSCSA) enacted in 2013 for the identification and traceability of certain prescription drugs; and China’s National Drug Administration’s (CNDA) new serialization guidelines for pharmaceuticals.

www.domino-printing.com

Sustainability 41 foodchainmagazine.com

42

PREVENTING FOOD LOSS

The need to prioritize food safety and effective decontamination practices throughout the food life cycle

By Larry Clarke

Waste not, want not. That axiom couldn’t be farther from the truth when it comes to our love affair with food. Did you realize that 40 percent of all food is thrown away in the USA? Did you know that more than one-tenth of American households were deemed ‘food insecure’ before the pandemic even hit? What are the causes behind this problem, and what are the solutions?

Educating the masses is one important place to start. Consider the widespread disposal and disregard of ‘ugly’ food by the buying public. Teaching consumers

about imperfect food shapes and expiration dates is a major step toward the reduction of food waste. Imperfect foods have become a focus of innovative startups by bringing them to market with campaigns that support consumption. And expiration dates can also be extended in the FFV (fresh fruit and vegetable) markets by decontamination processes. The processes themselves are under question due to the residuals left on the FFV during the process, but the standardization of FFV has improved with better seed technology, therefore improving the processing capabilities and efficacies.

Waste 43 foodchainmagazine.com

Beyond that, a continued improvement in supply chain management and cold storage traceability and tracking is crucial for saving perfectly good food from ending up in landfills. The tighter the supply chain and the better the tracking capability, the higher the likelihood that fresh produce will make it to the grocery store with the consistency

and confidence that consumers are requiring. The same goes for food processors, who see consistency

and product quality as part of their requirements for suppliers.

So fresh and so clean

Prioritizing food safety and effective decontamination practices early in the food life cycle can be incredibly impactful in limiting food waste. The farmer community carries the burden of having to harvest when the produce is ready and when the weather is willing. This does not always match with the requirements of food processors or distributors. Any misalignments create waste. This is the area of focus for the vertical farming industry, which can match the readiness of the crop and harvest much more closely to the consumer demand.

Early decontamination creates a positive virtue cycle. Clean products create less contamination in the processing and handling

“ “

Much of this waste occurs once products are harvested and introduced to the world of bumps, bruising, and contamination... 44

“ “

equipment across the supply chain. Also, cleaner products are less likely to have detrimental microbial impact in the given time to market from harvest to consumer. The longer that molds, fungi, and pathogens remain on the product, the greater the foothold they take and the larger the negative impact they have on the product’s value (in both appearance and nutrition).

To be sure, the impact of clean (or decontaminated) processing and handling facilities cannot be overstated. Not to place it on an equivalency, but it is the same reason that hospitals must work tirelessly to combat bacteria. If a negative microbial contamination is found, it will likely be spread by the general nature of the handling and, like the produce being shipped, the microbial will be spread with each load that moves around the country.

Providing an oasis

In wealthy countries — and, more specifically, wealthy ZIP codes — food insecurity is not much of an issue. We can afford the higher-margin items, which promotes a higher likelihood that markets can have higher returns on investment. These higher margins tend to offset the losses of products (food waste) that are simply seen as a cost of doing business. If we can systematically reduce the losses that occur in the supply chain to the market, we can also look for ways to reduce the losses that occur at the market and once the product has been taken home for consumption.

The general rule of thumb is that about one-third of food is destined to be ‘wasted.’ Much of this waste occurs once products are harvested and introduced to the world of bumps, bruising, and contamination in the normal handling to get the product to market. Over time, this natural decline in wholesomeness

is inevitable, but a sustained focus can delay the process; that is what ‘shelf-life extension’ is all about.

If we can add further steps to the tracking and tracing of food that has become so valuable in the improvement of food waste reduction, we can make strides. The focus should now be about a curative impact on the problem, not just identifying the contaminated product. We have seen new technologies coming forth working on the dehydrating reality of post-harvest FFV, but not as much on the reduction of molds, fungi, and pathogens. Done at an early stage in the supply chain, and maybe yet again as it gets closer to the consumer, decontamination of food has been shown to reduce waste and improve the safety aspects of the product.

As we see food deserts continue to be an issue in low-income neighborhoods (as well as low-income countries), any improvement in the shelf life — and therefore improvement in supply chain margins — will help provide more food for those going without. It only stands to reason that less waste equals more food for consumption. Waste not, want not. ■

For a list of the sources used in this article, please contact the editor.

Nanoguard Technologies www.nanoguardtechnologies.com

Larry Clarke is the CEO of NanoGuard Technologies, a company that prevents food and feed waste and improves food safety by eradicating harmful pathogens and mycotoxins through its Airilization technology. He brings more than 30 years of experience in agribusiness, including global business management, trading, and international assignments. Larry graduated with an agriculture degree and a business degree from Mississippi State University, as well as the Advanced Management Program at Harvard Business School.

Waste 45 foodchainmagazine.com

Botanical fanatical

Ingredients for label-conscious consumers

By Alessio Tagliaferri

By Alessio Tagliaferri

Interest in botanicals is growing, for both their intriguing flavor profiles and consumer-associated functional attributes. In fact, 71 percent of consumers state that they are aware of at least one botanical, and the global market for plant extracts is anticipated to grow with a CAGR of six percent between 2021-2026. Botanicals with the most recognition include green tea, aloe vera, lavender, ginger, peppermint and cinnamon. Additionally, consumers are taking a more proactive approach

to their well-being, with many seeking out foods and beverages that contain ingredients with multifaceted attributes to meet their individual health and wellness goals. Beyond their associated health halos, botanicals are in demand as a source of exciting taste experiences with added appeal as ‘kitchen level’ ingredients derived from natural sources. Whether in dietary supplements or functional foods and beverages, botanical ingredients have great potential to attract and hold consumer attention.

46

Ingredients 47 foodchainmagazine.com

Functional

Holistic health and wellness

Foods and beverages with certain botanical ingredients may have consumer associations with better-foryou characteristics, such as immune function, sleep, digestive health, stress relief and emotional well-being. These are important areas for many consumers, especially as people associate food choices with their physical and emotional well-being. In addition to the more familiar herbs and spices, several botanicals are emerging as champions for holistic well-being.

Lemon balm is widely associated by consumers with relaxation, rest and recovery and combines beautifully with fruity flavors like finger lime and mango, as well as refreshing mint. Lemon balm works well in teas, biscuits and lemonades.

Flavor impact

New flavor experiences are a driving factor in the growing popularity of botanicals in foods and beverages. Many botanicals deliver unique flavor notes that may help consumers satisfy a desire to experience new taste profiles as a form of adventurous exploration. Research shows 43 percent of consumers believe botanical ingredients are tasty, and they don’t feel they have to sacrifice flavor for nutrition.

For instance, guarana, green coffee and yerba mate all contain caffeine and are linked by consumers to reduced fatigue and improved mental focus. These ingredients pair well with energy drinks, snacks and supplements.

Blending acerola and camucamu can provide a source of vitamin C, which is often recognized by consumers to support immune function. Consumers may also associate acerola extract with support for energy, metabolism and exercise performance. Acerola can be added to functional juices, gummy confections and more.

What’s more, botanicals can bring a complex combination of flavors to categories including dietary supplements, snacks, confectionery, bakery and beverages. The beverage category is particularly ripe for opportunity for developers to leverage botanical ingredients, with consumers showing curiosity for new and inventive flavor profiles. Cocktails and mocktails are a popular space to experiment with intriguing botanical flavors, such as a gin fizz spotlighting juniper’s piney and fruity notes with citrus and a hint of pepper. Nutty maca tea finds balance with floral cardamom and spicy ginger. Ready-to-drink (RTD) coffees also lend themselves well to botanical flavors, from purple ube lattes to ‘cinnamint’ cold brew.

Flavor is also critical for an enticing sensory experience, and it plays a role in consumers’ emotional engagement with a product. As people feel more

“ “

“ “

Today’s conscientious consumers frequently scrutinize packaging for ingredients that they consider natural for authentic taste, appearance and benefits

48

connected to their purchases through flavors, many are also more motivated to share with their networks through social media, creating an even larger buzz around trending botanical ingredients and flavors.

Clean and green

Today’s conscientious consumers frequently scrutinize packaging for ingredients that they consider natural for authentic taste, appearance and benefits. Many shoppers associate botanical ingredients with qualities like sustainable, natural, better-for-me and trustworthy. Label-conscious consumers are paying particularly close attention to ingredients associated with ‘close-to-nature’ attributes and sustainability, especially as they increasingly tend to shop based on their values. For example, consumers say that simple, recognizable ingredients impact their purchasing decisions. On top of that, shoppers are seeking options that can benefit themselves, their communities and the planet.

Functional Ingredients

Botanicals are multi-faceted ingredients that can help meet consumers’ evolving needs, including associations with wellness attributes, exciting flavor profiles and clean label cues. Brands that work with a global partner to craft the right combination of botanicals, functional ingredients and flavors will find success and meet the market demands of today and tomorrow. ■