SR

Sustainability Report

Sustainability Report

Frame the QR Code and watch the video

1. From a mechanical industry to a leader group at an international level

1.1 Profile

Our values and our history pag. 14

1.2 Transparent management of our business

Governance, Ethics and Compliance pag. 26

1.3 The creation of value

Economic performance pag. 30

1.4 The relationship with the territory

Local communities pag. 32

What sustainability means for Sambonet

2.1 The commitment to sustainability

A long-term vision pag. 40

2.2 Our interlocutors

The strategic role of Stakeholders pag. 44

2.3 What is important

Materiality assessment pag. 48

2.4 Biodiversity pag. 54

3. Creating value within Sambonet Paderno

3.1 Us

People at the heart of the company pag. 58

3.2 From raw materials to shipping

The production process pag. 76

3.3 Higher productivity, lower environmental impact Natural resources throughout the process pag. 84

4. Product responsibility and customer orientation

4.1 Focus on the product From quality to innovation pag. 98

4.2 Focus on the customers Their satisfaction pag. 104

5. Attachments

5.1 Methodological Note pag. 110

5.2 Summary of Performance Indicators pag. 112

5.3 Perimeter table of material topics pag. 125

5.4 GRI Content Index pag. 127

Hospitality is in our DNA — and so are the table and good food. Through our brands, we enter homes and the finest hotels and restaurants around the world. For this reason, it is essential for us to always work with the utmost respect for the people who choose us every day.

The year 2024 was a significant one for our company: we consolidated the achievements reached in recent years and set new improvement goals. We also overcame challenging situations caused by extreme weather events that tested our production site — events that make us see firsthand the urgent need to continue reducing our environmental impact, year after year.

Sustainability has now become an integral part of the values that define our brands — excellence, quality, and the proudly Italian ingenuity that goes into our products and underpins our strategic positioning.

In full alignment with our Group’s global strategy, Sambonet Paderno Industrie continues to lead this long-term journey, positioning sustainability as a distinctive and essential asset.

Among our achievements, we are proud to have received, for the third consecutive year, the Silver Medal from the EcoVadis assessment project — an important milestone that places us among over 13,000 virtuous companies worldwide, recognized for their commitment to the environment, labor practices, human rights, and ethics.

The year 2024 also marked the awarding of the “Historical Trademark” seals for Sambonet, Paderno, and Arthur Krupp — a result that celebrates the tradition, strength, and value of our roots, while projecting them toward an increasingly innovative and responsible future.

We wish to contribute to fostering responsible consumption by offering our customers high-quality and increasingly sustainable products — not only for their renowned durability. It is through our products that we express our philosophy, our commitment, and our vision of hospitality, as well as the art de la table at its best.

It is a universe nourished by culture and design, craftsmanship and innovation — one that evolves with the times and with our customers, protecting and supporting them. We look to the future with confidence and determination, ready to continue this journey together — bringing the excellence and warmth of Italian hospitality to every table, every home, and every experience.

Giovanni Coppo CEO, Sambonet Paderno Industrie

The

PRESENT IN OVER EMPLOYEES

WASTE DESTINED FOR RECOVERY 81%

PERMANENT CONTRACTS 94%

FEMALE EXECUTIVES 67%

PIECES PRODUCED 4,5 MLN

TOTAL REVENUE

€ 77 MLN

COPYRIGHTS

EXPENDITURE ON LOCAL SUPPLIERS

31% RENEWABLE ENERGY

100%

Sambonet Paderno Industrie S.p.A analyzes and examines the corporate context day by day to integrate improvements into all internal processes

Through certified management methodologies, a coordinated and punctual flow, dedicated teams and the constant consulting of accredited bodies, it makes the impact of every choice tangible and it always identifies new improvement goals.

The Company has already achieved numerous goals but every day it is committed to continuous improvements by setting itself new challenges and goals to share with its stakeholders.

In 2023, on the strength of its long-established practices, obtained certification for Gender Equality according to the UNI guidelines PdR125:2022.

Sambonet Paderno Industrie is one of the most important realities of cutlery, tableware, cookware and accessories for the luxury kitchen in Italy, controlled by the families of the brothers Pierluigi and Franco Coppo through the Arcturus Group holding.

With more than a century of history behind them, Sambonet and Paderno, the two souls of the Company, represent the best practices of the sector serving both the Horeca sector and final consumers.

The attention to the quality of the product combined with a strong interest in its aesthetics, have made the two brands of the Company, Sambonet and Paderno, award-winning and internationally recognized brands

The Vision of Arcturus Group

We want to spread innovation, culture, design, starting with our products. Inspire and enhance every positive experience in the kitchen, at the table and in the home living.

In 2024, Sambonet, Paderno, and Arthur Krupp were recognized as “Italian Historical Trademarks of National Interest”, obtaining their registration in the special register of Enterprises and Made in Italy dedicated to them.

The Historical Trademark of National Interest is reserved for Italian companies with at least 50 years of history, which have become symbols of Italian excellence and style worldwide.

The recognition of the Historical Trademark for all three brands that are part of Sambonet Paderno Industrie makes us even prouder and more enthusiastic to spread our concept of hospitality worldwide, through our products and the uniquely Italian know-how that distinguishes them.

Since 1856, Sambonet provides products for tableware and kitchen, to supply homes, hotels and restaurants.

Every day our products renew the love for hospitality all over the world. Sambonet wants to spread innovation, culture, art, starting from the table

These topics are connected to our savoir-faire, that we are going to show to everyone has keen eyes and an eager mind.

Paderno offers kitchen products and supplies for hotels and restaurants, and is distinguished by the excellence of its stainless steel cookware production

With 100 years of history, a widespread presence worldwide, and more than 10,000 products in its catalog, Paderno is a benchmark for the professional catering sector and for every cooking enthusiast.

1.1 Profile

Our identity and our history

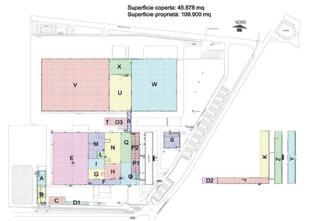

Sambonet Paderno carries out its activities in a plant that stands in an area of 110,000 square meters with eco-friendly architecture, harmoniously inserted in nature, between Vercelli and Novara.

The entire site has been imagined, as a whole, as a design object integrated within the context of the Piedmont countryside. The plant project, followed by the Frigerio Design Group studio, has been able to harmonize forms and functions with the image of the surrounding territory characterized, in some ways, by great contradictions: pervaded on one side by the rhythms of production and trade, but on the other side, marked by the secular rhythms of the agricultural world.

The culture and traditions that distinguish the surrounding area become the inspiring elements of the architectural project, which precisely arises from the recognition of the peculiar and constitutive characteristics of the surrounding landscape: from the geometries of the road layouts to the subdivision of patches of paddy field according to Cartesian forms, to the courses of irrigation channels.

• Horizontal layout for maximum integration with the landscape

• Glass window measuring 100 m x 8 m for natural light and transparency

• Large green areas designed with local agricultural elements

The philosophy of Slow Architecture according to the Frigerio Design studio.

“We are committed to not leaving footprints: we want to reduce the ecological footprint and make more coherent and conscious use of materials and resources. To do so we follow the lesson provided by nature in whose circular processes nothing is wasted, and by the past. We aim to be sustainable from the outset. Because the energy consumption of the building is only the final phase of a process that has already started from the energy used in the production of the architectural pieces and components that we have chosen to use”.

Sambonet is committed to creating a work environment for its employees that pays attention to artistic detail. For this reason, the ownership has furnished the Company with the aim of creating a welcoming and inspiring place for all employees and, at the same time, promoting the Italian savoir-faire that the Company itself represents. The Novara headquarters boasts a collection of around 30 works of art, including paintings and sculptures both indoors and outdoors, created mainly by Italian artists such as Alfonso Borghi, Mauro Staccioli, and Antonio Paradiso.

Our identity and our history

Undoubtedly the distinctive trait in Sambonet’s work and design is given by its autonomy in realization, from the concept and the design phase to the production phase, thus giving all products a clear connotation of craftsmanship: 90% of the products are in fact signed by the style center of the company. This has always helped to strengthen the brand identity, making it exclusive and unmistakable in the international panorama. Collaborations with renowned external designers are linked to specific projects and enrich the wide “home-made” offer.

PESCIERA RST

HANNAH

TAILOR

TAILOR MADE

NEUTRA

The company originates from the Officine Meccaniche Giovanni Coppo firm, born in 1978 in Milan. The brothers Pierluigi and Franco Coppo started an entrepreneurial success story with the acquisition, in 1979, of Paderno, a Group founded in 1925 in Milan, a world reference point for professional cookware,

1997 saw the acquisition of Sambonet, a historic Piedmontese cutlery and tableware company, founded in Vercelli on May 15, 1856 by Giuseppe Sambonet, a goldsmith and graduate of the Institute of Fine Arts. Between 2000 and 2002 the new headquarters were built, a success in eco-friendly architecture, harmoniously integrated in nature, designed by Novarabased architect Enrico Frigerio.

In November 2004 the two brands merged and the company changed its name to “Sambonet Paderno Industrie”.

Since 2005, Sambonet Paderno Industrie has undertaken a path of acquisition of certifications in different fields, which highlight a growing attention to ESG issues.

Confindustria Awards for Excellence

In 2006 the company received the Confindustria Awards for Excellence from Confindustria, an honorific created to reward excellent companies that have distinguished themselves in Made in Italy, innovation and enhancement of the territory.

This acquisition, together with the skills acquired by Sambonet in the hospitality industry, marked a fundamental point in the international development of the Group, guaranteeing it a leading role in the table top Home, Ho.Re.Ca. and Contract.

Group

The portfolio of the Holding Arcturus Group, parent company of Sambonet Paderno Industrie S.p.A , expanded in 2013 with the acquisition of the German porcelain brand Arzberg and in 2015 with the acquisition of the historic French porcelain excellences of Limoges Raynaud and Ercuis silver cutlery. The result of this corporate strategy, aimed at growth and acquisitions, is the establishment of a leading reality in terms of quality, diversification and complementarity of the table and kitchen offer, which ranges from medium-high level to extreme luxury thanks to the different identities of its brands.

Arcturus is introduced to the market. Thanks to its ten brands, the Group becomes a reference point for the entire tableware business worldwide

1.1 Profile

Our identity and our history

Sambonet Paderno Industrie, present in over 30 countries, mainly Italy, Germany and United States, offers its high quality and refined products to a wide range of players.

What sets us apart in the market is the meticulous and continuous attention to those who choose us. Every day, the company makes available to its customers the expertise of its sales network and specialized collaborators, to help them design tailor-made solutions and achieve the desired result, supporting them from selection to purchase, and through to after-sales service.

The company’s main customers are companies or third-party resellers. In particular.

Ho.Re.Ca.

Hotel chains, hotels, restaurants, public establishments, and every other type of accommodation facility.

69%

Resellers

Stores and retail businesses offering premium tableware accessories and home décor items for living spaces.

22%

Direct channels

Sambonet and Paderno online shops, and locally, brand corners at Rinascente in Milan and Rome, as well as the company outlet at the Orfengo headquarters.

8%

Our identity and our history

Sambonet, an international leader in the manufacturing of stainless-steel eating utensils and tableware and items in electroplated nickel silver, is divided more or less equally between the Ho.Re.Ca. and retail sectors. In addition to its own tableware lines, Sambonet offers an exclusive selection of top-quality objects for serving, home living and an essential kitchen collection. A practical and functional series of cooking utensils that combines the brand’s style with the latest technology.

Paderno mainly operates in the professional sector and stands out for the excellence of its production of cookware in stainless steel. The brand also produces and distributes over 10,000 items intended for chefs and gourmet foodies: knives and other utensils to recreate state-of-the-art kitchens.

Arthur Krupp is one of the leading Italian brands of tableware, catering both to professional dining and home. Thanks to the versatility and style of Arthur Krupp — which includes stainless steel cutlery and tableware, porcelain and stoneware collections, as well as buffet and service items — every table setting becomes a unique experience.

The values of a responsible business

Fairness and transparency guide every decision and activity of Sambonet Paderno Industrie, which has always pursued its objectives with respect for the law and fundamental human rights. A modus operandi marked by clear and shared rules, in harmony with the goals of its stakeholders.

SAMBONET

Since 2015, conceived to share the guidelines and conduct of the Company, Employees, and all external stakeholders.

Expressed through the company’s commitment to ensuring a safe, comfortable, and inclusive workplace. In this context, we place the UNI EN ISO 45001 certification, regarding Workplace Health and Safety, and the UNI/PdR 125:2022 certification on Gender Equality.

Fairness

Sambonet Paderno Industrie’s attention to its Employees and Customers is concretely expressed through:

VOLUNTARY CERTIFICATIONS

Obtained spontaneously over the years in different areas and, above all, aimed at improving the effectiveness and efficiency of its business processes, starting from the certification of its integrated system according to international standards:

• UNI EN ISO 9001 Quality

• UNI EN ISO 14001 Environment

• UNI EN ISO 50001 Energy

• UNI EN ISO 45001 Occupational Health and Safety

• UNI EN ISO 22000 Food Safety

SHARED INTEGRATED POLICY

Consistent with its activity and scale, it is aimed at the continuous improvement of environmental performance, as well as the protection of workers’ health and safety. This policy, signed by the Management and disseminated internally, represents a real and shared commitment.

CORPORATE SOCIAL RESPONSIBILITY

Integrated into every decision-making and operational aspect of the company, it carefully considers social, economic, and environmental dimensions in its business development. This rooted vision evolves year after year, as proven by significant achievements such as the SR10 and UNI/PdR 125:2022 certifications for gender equality.

QUALITY AND FOOD SAFETY

Certified for over 10 years through Aseclab – Alimentary Security Control Laboratory, a highly specialized internal laboratory accredited UNI EN ISO 17025:2018. Here, products, internal production processes, and environmental analyses are examined to protect both users and the environment.

Sambonet Paderno Industrie is the business that brought to life the current Arcturus Group, an Italian holding that includes well-known international porcelain and silverware brands of the highest quality.

A success story the Coppo family embarked on, transforming the company in its early days 1978 from “a mechanical workshop in Milan to an international leader in prestige tableware”.

CEO Giovanni Coppo, chaired by Franco Coppo, along with a Board of Statutory Auditors.

Sambonet relies on a leading independent auditing firm for the review of its financial statements, ensuring the proper application of national and international accounting standards.

related initiatives, monitor its compliance with new regulations and, ultimately, coordinate tasks regarding sustainability reporting.

Starting from the end of November 2021, the Company has adopted its own Organization, Management and Control Model pursuant to Legislative Decree 231/01 (hereinafter Model 231 or M.O.G.) for the management of environmental risks and those related to the health and safety of the individual.

This initiative was taken in the belief that the adoption of the Model can be a valid tool for raising awareness among all those who work in the name and on behalf of the company, so that they adopt correct and linear behavior in carrying out their activities, such as to prevent risk of committing the offenses provided for by the Decree itself.

In particular, through the adoption of the Model, the company aims to pursue a thorough and periodic monitoring of the areas of activities at risk and to intervene promptly to prevent or counter the carrying out of the crimes themselves.

The Organizational Model, however, has been completed with the establishment of a Supervisory Body that, as required by the Article 6 of Legislative Decree n.231/2001, has the function of overseeing the functioning, effectiveness and compliance with the Organizational Model, taking care of its constant updating.

Since July 2023, the company has set up a platform for whistleblowing in accordance with Legislative Decree of March 2024.

During the year 2025, specific training sessions on the Model and the application of the Code of Ethics will be provided to all Sambonet employees; the training will also take into account the extension of the Model.

As part of its commitment to responsible risk management and climate resilience, the Company commissioned an assessment based on Zurich Insurance Group’s Cat Risk Insights hazard data.

1%

Distributed to capital providers

15%

Distributed to employees

7%

Distributed to the Public Administration

77%

Distributed to suppliers

In general, the largest share of the total value distributed was distributed to the Suppliers category, for a total of 77%: the item includes the purchases of raw materials and other operating costs such as goods and services, third-party assets and management costs.

The other category to which a significant share has been distributed are the Employees, to whom through wages and salaries, severance pay, social charges, various benefits and other personnel costs was distributed about 15% of the total value distributed.

The remaining portion of the distributed value, about 1% in total, is allocated to Capital Suppliers, Public Authorities (through payment of current taxes and various other levies) and to the local communities for which the Company has registered donations, including LILT Novara and Fond. Com Novarese for membership in the “Sociali e Sportivi in centro” project.

Sambonet has always been committed to supporting and engaging with local communities; the bond between the company and the surrounding area is reflected in activities that maintain active relationships with young people, citizens, associations, municipalities, and other local and national institutions.

VIRTUOUS RELATIONSHIPS

CNVV Confindustria Novara Vercelli Valsesia

ANIMA Confindustria Meccanica

FEC Federation of European manufacturers of Cookware and Cutlery FIAC Associazione fabbricanti italiani articoli per la casa, la tavola ed affini

YOUTH EDUCATION

University UPO and local Technical and Commercial Institutes

PROFESSIONAL TRAINING

Chef Associations and Professional Culinary Schools

CULTURE AND ART

Local cultural and artistic institutions and associations

CHARITY

Charitable and volunteer organizations in various fields

Some initiatives that have characterized the involvement of Sambonet in the local community during the 2024 are listed below.

1.4 The relationship with the territory

communities

The training of tomorrow’s chefs begins locally. The company supported the Luparia High School in Rosignano on the occasion of the inauguration of the new professional program in Services for Food and Wine and Hospitality. A technical kitchen sponsorship to introduce young people to a quality-oriented approach to the equipment used in culinary laboratories.

Valuable partnerships to support virtuous chefs and young professionals from around the world, in Italy to learn the culinary traditions of our country.

Slow Food’s Chef Alliance and ICIF are the established professional organizations with which the company collaborates to further connect the excellence of Italian cuisine with the quality of the tools being used. A

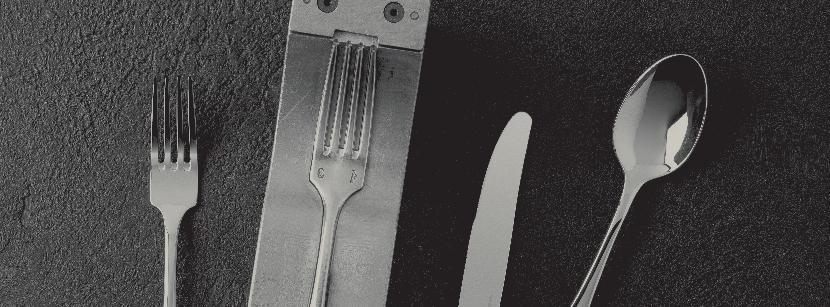

Over 1,500 visitors discovered the design, production, and distribution processes of an industry that brings Italian design, quality, and ingenuity to the world.

An opportunity to showcase to the public the brand’s heritage through the archive of its more than one thousand molds, but above all, the technological evolution behind every object that reaches our tables, our homes, and also renowned restaurants and hotels.

2.1 The commitment to sustainability A long-term vision pag. 40

2.2 Our interlocutors The strategic role of stakeholders pag. 44

2.3 What is important Materiality assessment pag. 48

2.4 Biodiversity pag. 54

Sambonet Paderno Industrie has consolidated and increasingly strengthened over the years its commitment to the integration of the principles of environmental, social and ethical sustainability in every business activity.

Sustainability, transparency and awareness are the key words of the Company’s way of acting. This approach has guided the industrial growth of recent years, growth accompanied by the implementation of a responsible, sustainable and respectful policy towards people and the territory.

Sustainability Report for more than 11 years

Photovoltaic system and 100% certified energy from renewable sources

Paper reduction and digital archiving

Monitoring of consumption and discharges

Well-being of employees and attention to the territory

Use of recyclable materials and waste reduction

Prepared in accordance with the GRI Standards, this Report reflects the Company’s commitment to achieve the highest levels of transparency and accuracy in the data disclosed.

This analysis focuses on Stakeholders and material sustainability issues, with which Sambonet engages and through which the Company can further strengthen its positive impact.

Sambonet’s corporate culture is founded on ESG principles, with particular reference to the 17 Sustainable Development Goals of the 2030 Agenda.

• Respect and enhancement of people.

• Protection and preservation of the environment.

• Responsible consumption and production.

• Technological innovation.

• Virtuous partnerships.

The results of Sambonet Paderno’s management, increasingly attentive to sustainability, have also been confirmed by the rating received from EcoVadis, one of the world’s leading providers of business sustainability ratings.

In fact, the company was assessed across a number of areas, and in 2024 it again earned a percentile ranking of 86 in the cutlery, hand utensils and hardware production sector in general, demonstrating its alignment with the industry’s benchmark companies.

Undisputed protagonists within the sustainability journey undertaken, Stakeholders inspire the corporate strategy of Sambonet Paderno Industrie.

With full transparency, Sambonet is committed to their engagement and to the inclusion of their priorities and perceptions in the Company’s strategic definition.

Thanks to the requirements pursued over the years in the field of Corporate Social Responsibility and the commitment required also to suppliers and intermediaries with whom Sambonet Paderno Industrie collaborates internationally, the Company is now able to offer objective guarantees to the various categories of interlocutors, from employees, to customers, to the market, to the community, to bodies and institutions.

A more exhaustive overview of the Stakeholder categories with which Sambonet Paderno Industrie Spa interacts frequently is provided below.

TRADE UNIONS

CUSTOMERS

FINAL CONSUMERS

SUPPLIERS

PROPERTY

EMPLOYEES

ASSOCIATIONS AND NGOS

MEDIA

PARTNERS LOCAL COMMUNITIES

INVESTORS AND BANKS GOVERNMENT ENTITIES, INSTITUTIONS AND PUBLIC ADMINISTRATION

SCHOOLS, UNIVERSITIES AND RESEARCH CENTERS

The involvement of the identified interlocutors takes place mostly within the framework of normal business activities and is based on a constant and transparent communication that allows to establish a constructive dialogue.

The following table summarizes the main ways of involvement for each category of Stakeholder:

B2B CUSTOMERS

FINAL CONSUMERS

SUPPLIERS

PROPERTY

EMPLOYEES

INVESTORS AND BANKS

LOCAL COMMUNITIES

SCHOOLS, UNIVERSITIES

Press reviews, social media, website, questionnaires, online and offline advertising, publications (price lists, catalogues, etc.), PoS materials, newsletters, conferences/visits and factory tours, sector fairs and roadshows.

Social media, website, questionnaires, online and offline advertising, publications (brochures, catalogues, etc.), PoS materials, newsletters.

Website, conferences/visits.

Press releases, press reviews, website, internal meetings.

Press reviews, social media, website, questionnaires, newsletters or internal emails, company bulletin boards, internal meetings.

Press releases, website, meetings and gatherings.

Website, online and offline advertising, conferences/visits and Open Day.

Website, conferences/visits and Open Days, Scholarships. AND RESEARCH CENTERS

ASSOCIATIONS AND NGOs

TRADE UNIONS

GOVERNMENT ENTITIES, INSTITUTIONS

Website.

Newsletters, corporate bulletin boards, conferences/visits and Open Days, internal meetings.

Website. AND PUBLIC ADMINISTRATION

PARTNERS

MEDIA

Website, publications (price lists, catalogues, education or training, sector fairs and roadshows).

Social media, website, publications (price lists, catalogues), sector fairs and Roadshows.

The materiality analysis is the tool with which the definition of “material” issues is made; this concerns those aspects of economic, social and environmental responsibility that are of significance for both the Company and its Stakeholders.

The process of defining these issues has been conducted gradually over the years; it initially called for benchmarking analyses and company workshops and later for the random involvement of various internal and external stakeholders.

The data acquired have made it possible to finalise Sambonet Paderno Industrie’s materiality matrix in which the issues that the organisation must consider and the intersection of the levels of interest that they exert on the various stakeholders are represented.

Governance, Ethics and Integrity

Economic responsibility

Product responsibility

Diversity and inclusion Wellness of staff

Training, attraction and

Stakeholders

Corporate governance

Responsible packaging

Protection of human and workers' rights

Environmental responsibility

Responsibility towards personnel

Social responsibility

Worker's health and safety

Energy management and climate change

Quality, sustainability and product safety

Customare satisfaction

Research, development and product&process innovations

Waste management and circular economy

Management of water resources

Compliance and risk management

Value creation

Below, a description of the 18 material issues:

MATERIAL TOPICS

GOVERNANCE

COMPLIANCE AND RISK MANAGEMENT

CORPORATE DESCRIPTION

Definition of a governance structure that includes criteria of social and environmental responsibility. Transparent communication on the organization’s good governance practices and adherence to international best practices/regulations.

Integrity and transparency in business activity that includes the adoption of a Code of Ethics, policies and procedures to support compliance with current regulations. Adherence to national and international principles and guidelines that include areas of social and environmental responsibility. Identification, assessment and management of present and potential economic, social and environmental risks to which Sambonet is exposed.

VALUE CREATION

RESEARCH, DEVELOPMENT AND PRODUCT

Ability of the Group to create and distribute value between the different categories of stakeholders. Pursue economic and financial results and ensure socio-economic and environmental balance in medium-long term.

Research and development activities aimed at the design AND PROCESS INNOVATIONS of innovative and more sustainable products, with particular attention to the integration of new technologies in production, or the continuous improvement of processes.

QUALITY, SUSTAINABILITY AND

Development of products and services that comply with PRODUCT SAFETY high quality and safety criteria aligned with national and international standards and industry best practices.

CUSTOMER SATISFACTION

Offering products and services that meet customer needs and monitoring their degree of satisfaction to pursue continuous improvement.

TERRITORIAL PROTECTION AND

Support to local communities through sponsorships, DEVELOPMENT OF LOCAL COMMUNITIES donations and partnerships aimed at creating a sustainable and cultural development in the areas close to the reality of Sambonet (Province of Novara and Vercelli). Promotion of the conservation and/or creation of habitats conducive to the maintenance of native flora and fauna.

MATERIAL TOPICS

RESPONSIBLE SOURCING

Selection and monitoring of suppliers according to social and environmental criteria and promotion of social responsibility behaviour also through selection of certified raw materials.

ENERGY MANAGEMENT AND

Reduction of carbon dioxide emissions and compensation of CLIMATE CHANGE those that cannot be eliminated. Focus on energy efficiency and the use of renewable energy sources.

MANAGEMENT OF WATER RESOURCES

SUSTAINABLE PACKAGING

Conscious and efficient management of water resources and definition of efficiency strategies in water use. Monitoring practices for the chemical, physical and biological quality of discharges.

Attention to the sustainability of product packaging, to minimize non-recyclable materials, promote the recovery of materials and prefer the compostable and biodegradable, derived from plant products (for example tissue paper or Kraft paper without plasticization).

WASTE MANAGEMENT AND

Responsible management of waste related to business CIRCULAR ECONOMY activities. Promotion of circular economy activities and waste recovery.

WORKERS' HEALTH AND SAFETY

Policies, procedures and management systems that promote the protection of health and safety in the workplace in full compliance with the related regulatory requirements, which also include periodic monitoring activities.

ENHANCEMENT AND WELL-BEING

Promotion of initiatives to improve the well-being of OF STAFF employees and the right balance between private and working life. Ensure learning and training paths to improve employee skills and attract talent.

DIVERSITY, INCLUSION AND PROTECTION

Promotion of equal opportunities through the development OF HUMAN AND WORKERS' RIGHTS of inclusion policies and the enhancement of diversity. Ensuring respect for human rights for all people involved, through Code of Ethics, Management Systems and adhesions to international charters and principles.

MATERIAL TOPICS

TRAINING, ATTRACTION AND RETENTION OF TALENT

STAKEHOLDERS ENGAGEMENT & RELATIONS

CORPORATE DESCRIPTION

Guaranteed education, learning and training to improve employee skills and attract talent, making the Organization an attractive place to work.

Maintaining a high ethical standard and adhering to fundamental international rights throughout the entire supply chain, ensuring dignity and respect for human rights for all individuals involved. Ensuring transparency in all business operations and across the supply chain (e.g., regular publication of public reports containing sustainability metrics and progress toward goals). A fair and moral code of conduct for the strategic and operational management of affairs, in compliance with relevant laws, policies, and regulations.

Support to local communities through the distribution of generated value (e.g., salaries, purchases from local suppliers, contributions to sociocultural development initiatives, etc.). Partnerships with local, national, and international associations and organizations aimed at fostering sustainable socioeconomic and cultural development in the areas near Sambonet's operations (Province of Novara and Vercelli). Promotion of the conservation and/or creation of habitats conducive to the preservation of native flora and fauna, especially in areas where Sambonet has its production facilities.

The results of the analysis made it possible to define our Sustainability Path, resulting in an ESG - Environmental, Social, Governance - Sustainability Strategy, aware of the path we have taken and the road we still have to travel.

The foundations laid in recent years by management systems, projects and collaborations have enabled the company to focus on the main issues of social and environmental responsibility, working towards both employees and the region. (Creation of Value within Sambonet Paderno - Chapter 3)

In this context, always aiming at excellence for our products, we have kept the quality of the products themselves and customer satisfaction at the centre of attention (Product Responsibility and Customer Orientation - Chapter 4)

Biodiversity is present within the Company, supported by 3Bee – the climate tech company leading in biodiversity protection and implementing regenerative projects through advanced technologies.

Five hives equipped with 3Bee Hive-Tech™ technology provide a safe home for as many as 1,500,000 bees, which feed on the pollen of wildflowers surrounding the Company’s premises. By monitoring the health of the bees and adding shelters for other pollinators, the Company takes responsibility for fostering their connection with the ecosystems that characterize its local territory.

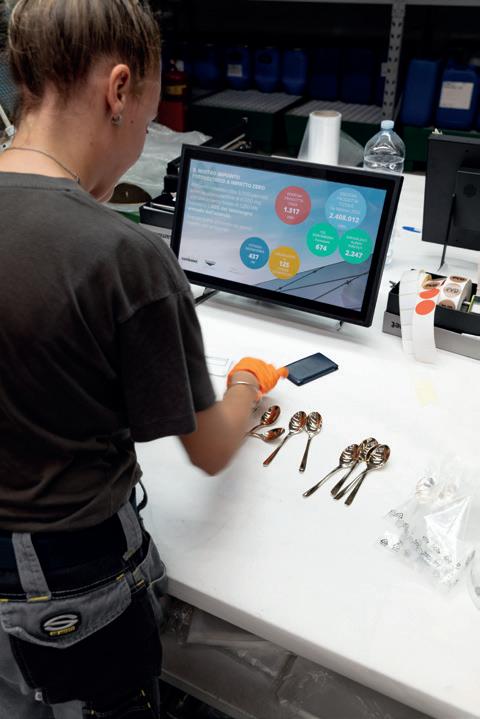

It is thanks to the skills of the employees, the quality of the raw material and the increasingly innovative production process that Sambonet produces excellent products.

Sambonet is aware of how these factors influence the success of the Company and every day tries to invest in its people, in responsible procurement and in the continuous efficiency and modernization of its production process.

Sambonet is fully aware of the strategic role that its people have in the success of the Company and the valuable contribution that they make day after day.

For this reason, the Company values and protects the human heritage:

• Inclusion of young people into the world of work

• Equal opportunities

• Respect of diversity, in all its facets

People at the heart of the company

Specifically:

Selecting staff on the basis of CRITERIA OF OBJECTIVITY, COMPETENCE AND PROFESSIONALISM, ensuring equal opportunities and avoiding any favoritism and aiming to ensure that the Company has the best skills in the job market.

Maintaining an internal environment that PROMOTES THE INVOLVEMENT OF THE STAFF in the achievement of the organization’s objectives

COMBATING FORCED AND CHILD LABOUR

CREATING A SAFE WORKING ENVIRONMENT in accordance with national and international directives on the matter and with the voluntary standard UNI EN ISO 45001.

Complying with the REQUIREMENTS ON CONFIDENTIALITY of personal data contained in the Data Protection Code in accordance to EU Regulation 2016/679.

RESPECTING WORKERS’ RIGHTS of unionisation and of collective representation.

Establishing a REMUNERATION POLICY that supports a dignified lifestyle.

Respecting all SOCIAL PROTECTION RIGHTS (sickness and accident, pension, unemployment insurance, etc.), to protect the stability and quality of jobs.

Investing IN UPDATING KNOWLEDGE AND SKILLS that could improve their career prospects and productivity as well as the competitiveness of the organization.

Aiming for AN ADEQUATE WORK-LIFE BALANCE.

Encouraging RESPECT FOR HUMAN DIGNITY.

The attention to the staff begins the same day you become part of the Sambonet Paderno family, in fact, during 2021, the Company has drawn up a “Welcome Book”, structured document that from 2022 will be provided to all new hires with the aim of making the on-boarding and integration process more fluid and effective in the company.

In fact, with this document, the new entry immediately gets to know the values, practices and policies of the Company

Within the Welcome Book, in fact, there are the most important information in this field, such as the rules of conduct in the Company, the values described in the code of ethics, the procedures for safety and prevention, the presentation of the existing certifications and management systems that characterize the path towards sustainability at 360°

282

EMPLOYEES

9% Company headcount on 31 December 2024

During the reporting year Sambonet recorded a hiring turnover of in decline with data for 2023 in decline with data for 2023

Outgoing turnover of

13%

To complete the total staff, Sambonet has 2 working relationships with workers who are not employees, all interns introduced in collaboration with high schools and Universities of the surrounding areas. The internship collaboration is realized with the aim of creating value for local communities: young talents of the territory are given the chance to increase their technical skills, not only at school but also directly on the field, approaching the reality of Sambonet, and, potentially, to find work immediately after graduation*

Sambonet pays particular attention to diversity in the company and carries out daily the commitment to achieving gender equality in the composition of the staff, which today is made up of 45% of female staff. The Pdr 125 certification obtained in 2023 naturally placed itself in this context. For the same reason, the company is committed to ensuring female representation even in high-level jobs, in fact 67% of Sambonet executives are female Moreover, in 2024 Sambonet employees belonging to protected categories are 17 (11 in 2023). The Company takes great care in the integration of this group with other employees, in the protection of their rights and health and safety at the place of work.

* Regarding the type of contracts, 94% of the employees are employed with permanent contracts, underlining the Company’s desire to consider and invest in its own people. In addition, the Company hires all its employees in compliance with national and regional regulations. All employees are employed with the C.C.N.L of the Metal-mechanical companies, while for interns, curricular and extra-curricular, specific agreements are made involving the training agency or the certified body.

People at the heart of the company

Sambonet Paderno Industrie wants to preserve the excellent craftsmanship of which the Company has become a landmark through the years keeping up with technological innovation and emerging industry trends.

Conscious of how much these factors influences the success of the company, Sambonet seeks every day to invest in its people, in responsible sourcing and in the continuous development of its products.

For the Company, the fundamental key of its corporate strategy is the development of its employees, indeed it invests in training and in updating the skills of its human capital precisely with this perspective: innovating tradition

From the very first day, a new hired becomes part of the Sambonet Paderno family, being accompanied in a path of professional and personal growth, aimed at retaining talent and encouraging the development of specific skills.

Each employee, according to their role and positioning within the Company, is accompanied by training courses that aim at its growth and specialization. Starting from 2021, in the Performance Management activities, the Company included an assessment of the training needs of groups of employees that, starting from the analysis of the performance of the previous year, includes the types of courses to be provided the following year. The mapping is done through collaboration with the managers of each area and is not implemented for each employee, but for working groups (depending on their function). Sambonet also cares about the support of employees who change roles within the Company, designing specific training courses from case to case.

The Company guarantees multiple training courses, internally managed for the Hard Skills (for example specific training for the factory workers), instead managed through third-party companies regarding the Soft Skills. The compulsory courses focus on Health and Safety in the company (e.g, first aid, toxic gas licenses, etc.), while the non-compulsory training courses focus on languages, administrative updates, technical courses for the use of specific machinery and effective communication with its stakeholders (course implemented from 2021 mainly addressed to managerial figures).

To crown Sambonet’s commitment to the formation of its human capital, there is the intention to implement increasingly structured plans for the evaluation of the effectiveness of the training provided, developing targeted gap analysis and considering employee performance. In this way it will be possible to formalize specific targets for the training of all.

During 2024, Sambonet provided

5.596

In particular, hours of training. In 2023 there were 7,174.

81% of the scheduled hours are non-compulsory training courses, to highlight the Company’s sincere interest in educating and keeping its employees always up to date, investing time, resources and capital.

3.1 Us

People at the heart of the company

Sambonet Paderno Industrie, to encourage the professional growth of all employees has activated an annual performance assessment mechanism, designed to bring to light virtuous behaviours in the performance of activities/projects and to give the possibility to make defined, clear, shared and measurable the objectives and expectations of each role for the period following the assessment.

Moreover, for about 20% of employees there is also an incentive system MBO (Management By Objectives), a method of evaluation of human resources based on the achievement of objectives: currently, in fact, this system is applied to commercial and managerial figures. The Company does not exclude the application of this system to a greater number of employees in the coming years.

Finally, Sambonet is proud to share its annual result with all employees, in fact all employees are entitled to an annual award linked to the result achieved by the Company.

The Company has joined Valore D, Italy’s first business association promoting diversity, equity, and inclusion. By participating in this network of over 400 companies, the Company strengthens its commitment to fostering gender balance, inclusive leadership, and equal opportunities.

Sambonet Paderno Industrie has joined the Istituto per i Valori d’Impresa (ISVI), an organization committed to promoting responsible entrepreneurship and openness to innovation. The mission of ISVI is to develop and spread an advanced concept of enterprise and its role in society, emphasizing the importance of entrepreneurial values that are ethical, sustainable, and future-oriented.

Welfare is a key expression of appreciation and recognition for the people who, every day, contribute to the Company’s success.

The designed welfare structure offers the following benefits to staff:

• Supplementary Health Care Assistance Metasalute, a form of contribution prescribed by the CCNL (national collective labour agreement) of the category (i.e., the metalworking industry);

• Agreements of various kinds through understandings with local shops/restaurants and specific agreements for specific employees;

• Extra discounts for purchases at the company outlet;

• Company gym;

• Company restaurant;

• Free supply of drinking water in the entire establishment;

• Flexible working hours and remote working and the offering of part-time contract types that meet employees’ needs. In 2024 the Company individually acceded to new requests for part-time contracts and the extension of remote working hours for certain workers, reconfirming its commitment and vision.

In addition to providing preventive measures for accidents and illnesses in the workplace, the company is proactively working to offer employees with opportunities to improve their individual and family status, from conventions for the purchase of goods and services to facilities for work from home and reconciliation between professional and personal life.

All the initiatives promoted by Sambonet are aimed at achieving a balanced lifestyle with respect to nutrition, sports and emotional context and thus ensure the well-being of its employees.

3.1 Us

People at the heart of the company

The importance of making people’s time at work more and more agreeable is reflected not only in the services offered but also in the improvement of the company premises. At year’s end the company conducted a project to redevelop the entire employees’ service area, a project involving the total refurbishment of the canteen and the adjoining relaxation area, fitting out a large recreation space equipped with table football.

Under the company’s Creative Management, the premises were designed by Studio Frigerio so as to interpret the taste and the new image of the company’s brands. Inaugurated just before Christmas, the company restaurant was named “Trattoria Americana” in memory of the establishment the Coppo family had run before starting their own metalworking business

In 2023, under the general coordination of the Piedmont Regional Council, the WHP project was launched again; the project envisages the creation of a Network that will support companies in helping to improve workers’ state of health and well-being, encouraging, notably in the workplace, actions and organisational and behavioural changes through the implementation of interventions recognised as recommended practices.

Sambonet, which has been present in the project since 2018, has again joined the network, which is coordinated locally directly by the Novara ASL and Confindustria Novara Vercelli Valsesia (CNVV).

Sambonet adopts an integrated system of management and development of human resources that offers all its employees equal opportunities and professional development, based on merit criteria, avoiding any type of discrimination (gender, racial, sexual, etc.).

The Company not only leads personnel management (e.g, hiring, promotions, etc.) avoiding any form of discrimination, but is also committed to promoting an inclusive working environment by banning, within the Code of Ethics, any behavior of verbal, physical or psychological violence by an employee to any individual inside or outside the Company. In 2022, the Company’s commitment to these issues resulted in zero discriminations

In particular, with respect to the subject of remuneration, the Company is working to eliminate the gender pay gap (pay gap between male and female employees in the same role).

This is how Sambonet promotes an inclusive work environment: countering all forms of discrimination in company policies and practices and ensuring psycho-physical well-being and employees satisfaction.

Sambonet cares about the health and safety of its personnel and for this reason seeks to create safe and comfortable working environments, spreading the “culture of prevention” accompanied by concrete measures, formal procedures, monitoring systems, and periodic training.

As proof of the Company’s attention to ensuring safe working conditions, in 2024 there were 7 cases of injuries related to the workplace. The Company believes that security, by its nature, is a “status” that implies the participation of all resources and is attainable through acknowledge of risks and their prevention and therefore it develops through:

• Dissemination of culture of prevention.

• The ongoing risk assessment by those who work “in the field”.

• Detecting the trend of the elements of distress.

• The risk analysis.

The safety management system is based on following pillars:

Employees training and involvement; Assessment and risk management; Monitoring and management of accidents.

In partnership with ASL Novara and Confindustria Novara Vercelli e Valsesia (CNVV), Sambonet promotes initiatives to improve workers’ health and wellbeing. Each year, preventive actions and organizational changes are introduced to guide recommended practices and behaviors among Sambonet employees.

In 2024, on the occasion of LILT’s Percorso Azzurro for Men, Sambonet also hosted its first series of

Sambonet focuses on the widespread awareness among workers of the risks related to work activities as a form of prevention. The Company, to root the sense of awareness in all the staff, promotes countless training and education courses in health and safety, provided by qualified personnel, sometimes internal, sometimes external:

• Compulsory training courses for the entire company population;

• First aid courses for competent personnel;

• RSPP and RLS refresher courses;

• Fire training;

• Specific courses on the use of certain machineries.

The active involvement of employees is an important element in the process of raising employees’ awareness toward health and safety risks. Indeed, Sambonet encourages all the workers to report any situation of danger occurred or that may occur (near miss).

For this reason, the Company has implemented the PS009, a specific procedure on internal communication of near miss. This procedure outlines the ways in which it is possible for an employee to make a report:

• by special mail;

• using the boxes in the canteen and reception;

• through its supervisor, SGM, MSW and/or RSPP or ASPP.

After the report has been made, the security team in charge reviews the cases and the preventive actions to be taken. Sambonet then prepared the Risk Assessment Document pursuant to Legislative Decree 81/06 and s.m.i., periodically revised and integrated according to the evolution of the business environment. The evaluation methodology was set up without neglecting any relevant aspects and giving order to the information collected, developing the following operational objectives:

• Identification of workplace dangers

• Justification of the method and the technical choices adopted for the risk assessment in order to draw up a report, as motivated as possible, concerning machinery, equipment and products;

• Monitoring the adequacy of the measures taken;

• Establish a priority list if further measures are needed;

• To demonstrate that all factors relating to work have been taken into account and this has allowed a valid and reasoned assessment of the measures taken;

• Ensure that the measures taken, as a result of the risk assessment, are effectively improving the level of protection of workers.

The main categories of risk are related to the machinery used in the technical/production departments and industrial activities.

Accident management is supported by written procedures, which comply not only with laws and regulations but also with ISO 45001. The procedures define the roles, responsibilities, actions to be taken to report accidents (both actual and near-miss) by employees and, finally, the activities to be implemented once the report is received: specific investigations with recognition of any non-compliance and corrective and preventive actions.

During 2024 there were 7 accidents, and, therefore, the accident frequency index is 2.55, up compared to 2023 where it was 2.39. The increase can be also attributable to the hours worked in 2024.

With a view to prevention and continuous improvement, the company has always invested in education, information and training in order to improve the level of awareness of the risks and dangers associated with each tasks.

NUMBER OF EMPLOYEE ACCIDENTS IN 2024

To preserve the value built over time through the quality and design of its products, Sambonet adopts a responsible approach throughout the entire value chain: from the careful and sustainable selection of raw materials to production processes driven by innovation, efficiency, and the reduction of waste and consumption.

The quality of Sambonet products stems from the choice of excellent metallic raw materials, which account for 99.9% of the materials used, including stainless steel and aluminum. Each material is selected with the utmost care, in full compliance with European food safety regulations. The steels employed, such as AISI 304 and AISI 420, are included in the positive lists of the Italian Ministry of Health and are analyzed with high-precision instruments, such as X-ray guns, to ensure the perfect conformity of their composition.

All materials used are 100% recyclable. Steel, in particular, can be regenerated infinitely without losing its properties. Even production scraps are recovered and reintroduced into the production cycle, turning into new resources ready to be enhanced.

The high quality and reliability of the products that distinguish Sambonet are guaranteed, among other things, by the management of the production chain that contributes to the realization of the finished product.

The Company establishes strong, lasting relationships based on mutual trust with its suppliers.

To ensure the excellence that has always characterized its products, Sambonet selects the entities with whom to collaborate, following strict criteria both in the ethical and environmental field

From raw materials to shipping

The production process

Almost all the raw materials used by the Company are metals (in particular stainless steel, aluminium, nickel silver and brass). The totality of the suppliers is constituted from resellers, of which 76% placed in Italy, while the remaining part coming mainly from Germany, France, Hungary, Turkey, India and U.S.A. To these last ones, Sambonet asks the declaration of absence of “Conflict Minerals1” both in the qualification phase and in the subsequent period, annually, as a guarantee of the responsibility of the entire downstream supply chain of its supply chain.

The company buys semi-finished products and components that, subsequently, through techniques and maximum experience, are reworked or, in the case of components, assembled to the body of the product

Sambonet relies on third parties for processes that require specific technical skills, such as surfaces finishing treatments or heat treatments. The Company, committed to enhancing its territory, collaborates with local contractors, located in the province of Verbano Cusio Ossola or in the Po Valley. This brings out an attention from the company to favor, where possible and preferable, relationships with suppliers located near the plant and the operating area, for better organizational capacity, to avoid emissions due to unnecessary movements and to contribute to the economic support of the territory

The list of suppliers, for 2024, is composed of almost for a total expense2 of ONE THOUSAND

companies

34,340,487 euros

1 Conflict Minerals are natural resources mined in conflict zones and sold to perpetuate hostilities. Various armies, rebel groups and external parties profit from mining, while contributing to violence and exploitation during wars in these regions.

2 In this context, “total annual expenditure” means how much Sambonet has spent in the course of 2024 towards the totality of the suppliers. The total of suppliers includes the following categories: retailers of raw materials, contractors, suppliers of semi-finished products, consumables, goods and services, packaging and packaging materials. For further details on the expenditure towards suppliers incurred by Sambonet in 2024, refer to the GRI 204-1 performance indicator Proportion of expenditure to local suppliers -Table No. 16.

For Sambonet Paderno, the awareness of the entire supply chain on ESG issues is a priority. The company, with its integrated management system for quality, environment, energy, social responsibility and safety, wishes that its employees also feel strongly about these issues.

To empower the entire supply chain, the Company has introduced the so-called “Qualified Suppliers List”, a list drawn up on the basis of the responses to an assessment questionnaire to which suppliers are subjected

Sambonet, as a socially engaged organization, feels the responsibility to develop a business model that allows it to transmit its values through the production chains: for this reason, since 2015 it has implemented the Code of Conduct for manufacturers and suppliers

The Code includes principles and standards for the correct development of relations between the Group and its suppliers and has been formulated through three fundamental criteria:

• ALL OPERATIONS MANAGED BY THE GROUP AND ITS EMPLOYEES MUST BE DEVELOPED FROM AN ETHICAL AND RESPONSIBLE PERSPECTIVE.

• ALL PEOPLE WHO HAVE, DIRECTLY OR INDIRECTLY, ANY KIND OF EMPLOYMENT, ECONOMIC, SOCIAL OR INDUSTRIAL RELATIONSHIP WITH THE GROUP MUST BE TREATED IN A FAIR AND HONOURABLE MANNER.

• THE DEVELOPMENT OF THE GROUP’S ACTIVITIES MUST BE CARRIED OUT IN THE MOST ENVIRONMENTALLY FRIENDLY MANNER

The aim of this document is to raise awareness of these interlocutors on purely ethical, social and environmental issues, so as to ensure, apart from quality, reliability and safety of products processed and distributed on the markets, the protection of the environment and health, compliance with ISO standards, a remuneration that guarantees a dignified lifestyle, and finally, fairness in business activities.

Once arrived, the raw material is stored in the warehouse and, subsequently, prepared for use in production processes. The process to produce an article is composed of multiple phases whose nature and sequence varies significantly according to the final product (pots vs cutlery vs tableware...). Once finished with the final cleaning, an object can be subjected to further processes such as silvering and the galvanic gilding or PVD, before being assembled/packaged. ARRIVAL

production process

A visionary approach to production technology has always been close to the heart of the company. Over the years, Sambonet has constantly invested in new technologies and kept all its machinery running at a high level of efficiency, as well as making particularly large investments in Industry 4.0 in recent times. The company has always made decisions that put efficiency alongside the sustainability of internal processes.

Profoundly artisanal processes, which remain relatively untouched by the technological boom of the 21st century, have been improved and made sustainable through investments that do not affect the method of operation

For example, torch welding is a manual operation dating back to antiquity that is still used today at Sambonet for the production of fine tableware and coffee pots. For more than a decade it has used water electrolysis technology to produce hydrogen gas (and oxygen) to feed the flame, and has stopped using the acetylene cylinder altogether, since it not only presented a risk factor from pressurised gas, but also released oxidation products such as carbon dioxide (CO2). In contrast, the hydrogen flame reacts with oxygen in the air and turns into water vapour, closing a sustainable circle with zero carbon dioxide emissions.

The material cutting technologies currently in use (with laser and with water) enable the company to carry out its production while minimising waste of raw materials, which are used to full potential.

In recent years Sambonet has dedicated numerous resources (both human and financial) to innovating and renewing its processes, introducing new technologies and implementing automation and efficiency in the manufacturing of eating utensils, saucepans and tableware.

The new technologies introduced have consolidated the practice of experimentation in the creation of new products, stimulating creativity and enhancing the professional skills of the people involved.

Sambonet has always been committed to reducing environmental impacts and promoting process efficiency: the entire plant is designed for the optimization of water and energy consumption and over the years the investments on the plant have allowed to optimize waste management too and mitigate emissions into the atmosphere.

Sambonet is committed to researching environmentally friendly materials or materials with a reduced environmental impact to be used in production processes, such as production processes such as, for example, material of vegetable origin for drying the parts produced by the galvanic plant or recycled materials used for the vibratory finishing plant. The company constantly monitors not only the quantity of withdrawals and discharges, through meters installed in 2019, but

3.3 Higher productivity, lower environmental impact

Natural resources throughout the process

Sambonet is aware of the fundamental importance that careful energy management has both internally and for the community and the environment

For several years, in fact, having an integrated policy that responds to ISO 50001 certified management systems, it annually implements monitoring activities such as:

• Energy analysis carried out by the Energy team;

• Energy Diagnosis carried out by third parties;

• Punctual systems for monitoring energy consumption through meters also installed on the various production lines;

• Calculation of specific KPIs in the field of energy performance.

The set of these monitoring actions allows the Company to identify the most significant areas of energy consumption, possible inefficiencies or problems, which cause for example losses and general malfunctions, and opportunities to improve performance in order to define objectives, targets and action plans

In 2024, the photovoltaic system, built in several phases starting in 2022, became fully operational. Over 5,000 solar panels on an area of over 6,000 sq. m. The plant is able to generate 2,250,000 kWh annually, covering approximately 40% of its average consumption, thus considerably reducing CO2 emissions into the environment: the equivalent of planting 7,500 trees in the space of just five years. A small but significant contribution for our planet.

Sambonet uses natural gas for heating the plant and the warehouse on the one hand, and for the operation of washing machines located in the various production departments on the other, in this case, in fact, methane is necessary for heating the solutions to 50 and 60 degrees and for drying the pieces, as well as to feed the furnace for welding some products.

The Company uses electricity mainly to power its production processes and to supply energy offices. The Company believes in renewable energy and has shown this in the choice of electricity suppliers. Since 2014 Sambonet uses electricity 100% covered by certificates of Guarantees of Origin

The company uses Diesel fuel exclusively for the movement of a limited fleet of vehicles. Instead, it doesn’t have heavy vehicles because the logistics is entrusted to a network of couriers

In particular, the fleet of sambonets is structured in this way:

8 vehicles for business use

3 trucks 16 vehicles assigned to employees

3.3

Higher productivity, lower environmental impact

Natural resources throughout the process

In 2024 Sambonet recorded, overall, energy consumption, for production activities, equal to

22,355 GJ (6,210 MWh)

with a decrease of 4% compared to the previous year, in which consumption was 23,225 GJ (6,174 MWh).

3,433 MWH 12,357 GJ

More specifically, most consumption consists of the use of electricity, which amounted to 12,357 GJ (3,433 MWh) in 2024, while natural gas consumption amounted to 227,198 Sm3 in 2024

In addition to the above consumption, and referring to production activities, should be considered the consumption of the car fleet whose consumption was recorded for Diesel 34,635 l in 2024 (27,887 l in 2023).

The data show that the decrease in consumption reflected the decline in production. However, 2024 consumption levels remain at a historical low compared to the series available since 2017, with the exception of 2020, a year influenced by the Covid-19 pandemic, while the number of units produced is in line with the average for the period.

Natural Gas

227,198 SM3 8,752 GJ

34,635 L 1,246 GJ Diesel

To improve and make the Company more efficient from an energy point of view, Sambonet has invested in energy efficiency activities over the years through, for example:

• Intelligent lighting systems that provide sensors for automatic adjustment compared to the natural light in the environment;

• Energy saving measure such as the prohibition to turn on the lights in the “daytime” area from 23:00 until 6:00;

• Replacement of machinery or parts of the same that led to waste or poor efficiency;

• Energy consumption monitoring system thanks to the installation of meters on all production lines in a uniform manner, to ensure completeness in monitoring.

• Installation of pulse relays and remote reading of analog meters. This implementation enables the automated collection of readings, increasing both the frequency and the level of detail regarding hourly withdrawals.

One of the additional goals on which Sambonet works is to improve environmental culture with systematic education, information and training, in order to increase the level of awareness of hazards and risks, and knowledge of techniques for the prevention of environmental problems, correct application of laws and regulations.

(Gas Methane)

0,03 0,57 0,05 0,77

The energy intensity indicators were calculated as the ratio between energy resource and pieces produced during the year 2023 (6,824,821 pcs) and 2024 (4.484.251 pz).

The indicators show that between 2023 (the best year in the 2017–2024 historical series) and 2024 there was an increase in energy intensity per unit. This aspect is reasonably attributable to the sharp decline in production in 2024 compared to the previous year. Nevertheless, the figure recorded in 2024 remains among the best in the historical series.

3.3 Higher productivity, lower environmental impact

Natural resources throughout the process

Sambonet Paderno Industrie has chosen technological solutions that optimize the quality and quantity of emissions into the atmosphere;

The emissions are low air pollution and are authorized in compliance with the emission limits and requirements indicated, for the type of processing carried out, in the D.D. of the Piedmont Region n. 145 of 2 May 2011 and in accordance with the current national legislation on environmental protection (Legislative Decree 152/06, Environmental Code).

For Sambonet, the commitment to this important issue translates not only into the monitoring of direct and indirect emissions of GHG, but also in the monitoring of further significant emissions that some production plants produce mainly in the departments of:

• mechanical production;

• galvanic.

In this regard, the Sambonet plant is in possession of a Unified Environmental Authorization (SEA) relating to emissions into the atmosphere and water discharges

For Sambonet, self-monitoring analyses are not a mere fulfilment prescribed by the single environmental authorisation (Autorizzazione Unica Ambientale - AUA), but a useful process for periodically monitoring the environmental impact of the production process, with a view to analysing risks and opportunities for the continuous improvement of environmental performance.

The data collected to date have not shown any exceedances of the limits established by current regulations

459 tCO2

INDIRECT GHG EMISSIONS SCOPE 2 (MARKET BASED)

DIRECT GHG EMISSIONS SCOPE 1 0

INDIRECT GHG EMISSIONS SCOPE 2 (LOCATION BASED)

1,009 tCO2

2024 Direct emissions (scope 1) corresponds to the amount of CO2 stored from about 4.490 trees in a year5

5 The amount of CO2 stored by a tree is very variable and depends on the species, size and many other parameters. In this case reference was made to a turkey oak tree, considered excellent as CO2 storage, equal to 155 kg/year (ref. Calculation of the carbon footprint for the reduction of emissions by planting - Polytec Technology Srl).

Water is of crucial importance for the planet and its ecosystems, as well as for humans. At the same time, water is at the heart of Sambonet Paderno’s production processes. Sambonet is aware of the value of water and is committed to using it in the most rational and ecological way possible

The water withdrawal takes place mainly through two wells owned by Sambonet, authorized for industrial use for water supply and for a residual part, through the aqueduct of the Municipality of Casalino. Sambonet can also boast a purification system, which allows, in part, the recirculation of water, thus contributing to the overall reduction of water withdrawal.

The company uses the water resource for civil uses, but especially for industrial uses during some specific stages of the production process. In particular:

• For silver plating treatments;

• During the extraction and pickling phases, where the pieces of pottery and cookware are treated in water with nitric and sulphuric acid;

• During the moulding of the pottery through water-jet plants that allow the product to take on rounded shapes;

• In the final washing phases where the products through treatment tanks and washing tunnels are cleaned for several years with aqueous solutions of detergents, and no longer with chemical solvents, to minimize water pollution.

WATER WITHDRAWAL AND DISCHARGE

110 thousand m3

91 thousand m3 OF WATER WITHDRAWN IN 2024 (124 IN 2023)

OF WATER DISCHARGED IN 2024 (91 IN 2023)

3.3 Higher productivity, lower environmental impact

Natural resources throughout the process

After the chemical-physical treatment of industrial water, and clarification of domestic water, the wastewater is sent to the Busca irrigation channel. The discharge activity is conducted by Sambonet in accordance with the Legislative Decree 152/06 as well as the provisions contained within the SEA that authorizes Sambonet to discharge into surface water.

The chemical-physical treatments performed by a purifier owned by Sambonet, allow to purify the water through operations such as oxidation of cyanides, reduction of organic substances and metals, sand filtration to ensure the quality and compliance with all the parameters required by the above-mentioned provisions.

Overall, in 2024, there was a constant discharge withdrawal compared to 2023.

Inside the Sambonet Paderno plant, there are five washing machines located in different departments. The operation of these systems fully corresponds to the Company’s philosophy of using water as a resource not to be squandered, with the aim of achieving the lowest possible consumption.

For this reason, the washing tunnels provide rinsing ramps with adjustable and measurable flow through flow meters; the power supply of each ramp is controlled by a level switch placed in the tank of that washing section and if necessary, a water flow from the next section comes into operation. In this way, the solutions of the cleaner rinsing tanks feed the previous rinses thus providing a mechanism of “re-use”.

Responsible waste management is part of Sambonet’s commitment to increasingly sustainable production. Through a process of continuous improvement, the Company optimizes the use of raw materials and minimizes waste, investing in efficient technologies and advanced production solutions.

In addition to preventive measures aimed at reducing waste, the production site strongly promotes the separate collection of materials such as paper, plastic, steel, aluminum, wood, iron, toner, and neon tubes. This concrete focus involves employees on a daily basis, encouraging them to actively contribute to the

WASTE FOR DISPOSAL (t) 2024

167 Liquids/ washing water

17,52 Sludge

10,84 Coal/sand

8,56 Abrasive material

5,1 Oils/emulsions

1,1 Packages

achievement of environmental objectives In 2024, civil and industrial activities led to the production of a total of 620 tonnes of waste, of which 76% was non-hazardous (they do not have any of the hazardous characteristics pursuant to Annex III of Directive 91/689/ EEC).

The composition of the waste is mainly of materials derived from production processes such as metals, cardboard packaging and, to a lesser extent, sludge produced by washing. All waste (both those destined for landfill and those destined for recovery) is managed externally through local companies specialized on waste treatment. Most of the waste (about 65% in the year 2024) is destined for recovery. Paper, cardboard and metals are completely managed through recovery.

WASTE FOR RECOVERY (t) 2024

233,1 Metals

122,0 Paper and cardboard

32,4 Electronic materials

Sambonet has joined the BACK TO WORK project, promoted in collaboration with ESO – Ecological Services Outsourcing, with the aim of giving a second life to end-of-cycle Personal Protective Equipment (PPE) such as clothing, shoes, gloves, goggles, and safety helmets.

Through this program, worn-out PPE is collected and sent to recovery and recycling processes, avoiding landfill disposal and transforming them into materials used for the construction of flooring in playgrounds and recreational areas. A daily action that translates into value for both the environment and the community.

The dynamic balance between tradition, craftsmanship and innovation is the basis of the Company’s work. The idea of modernity of Sambonet Paderno in the table and kitchen is born from the awareness of its history and its excellence, to be preserved, but also to be reinterpreted in the light of contemporary trends and customer needs.

Create integrated solutions of quality, design and functionality.

Anticipate and satisfy the needs of our customers, in their professional life or in their families, through a portfolio of distinctive but complementary products. Pursue an ethical and sustainable path of continuous innovation that is born from our tradition, interprets contemporary trends and creates new ones.

Tableware, kitchen products, and home décor items crafted with meticulous attention to detail, rigorous quality, and constant focus on customer needs. This standard is ensured by the company’s ongoing commitment, which takes shape through precise manufacturing processes, structured policies, efficient quality monitoring systems, and a strong focus on the needs of end users.

In the field of food safety, Sambonet can boast an SGSA certified by an external body EN ISO 22000:2018 since 2013. Periodically, the Management is subject to internal audits and external audits that certify the maintenance and adaptation of the production process to meet the requirements of the standard.

The certified Quality Management System allows the company to act in compliance with the strictest production quality criteria; it clearly and systematically sets out the steps to be followed so that the plant’s production complies with internal and external regulations and is in line with the agreements made with customers.

Carried out by Quality Control personnel and the Production function, as well as by subcontractors when required.