CARDINAL EXPANSION

Arch 348 Wells Concrete Competition

Project Site: Iowa State College of Design

Program Type: Studios, Review Areas, Fabrication Shop

Spring 2024

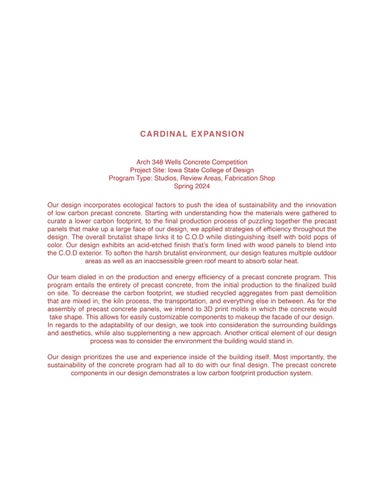

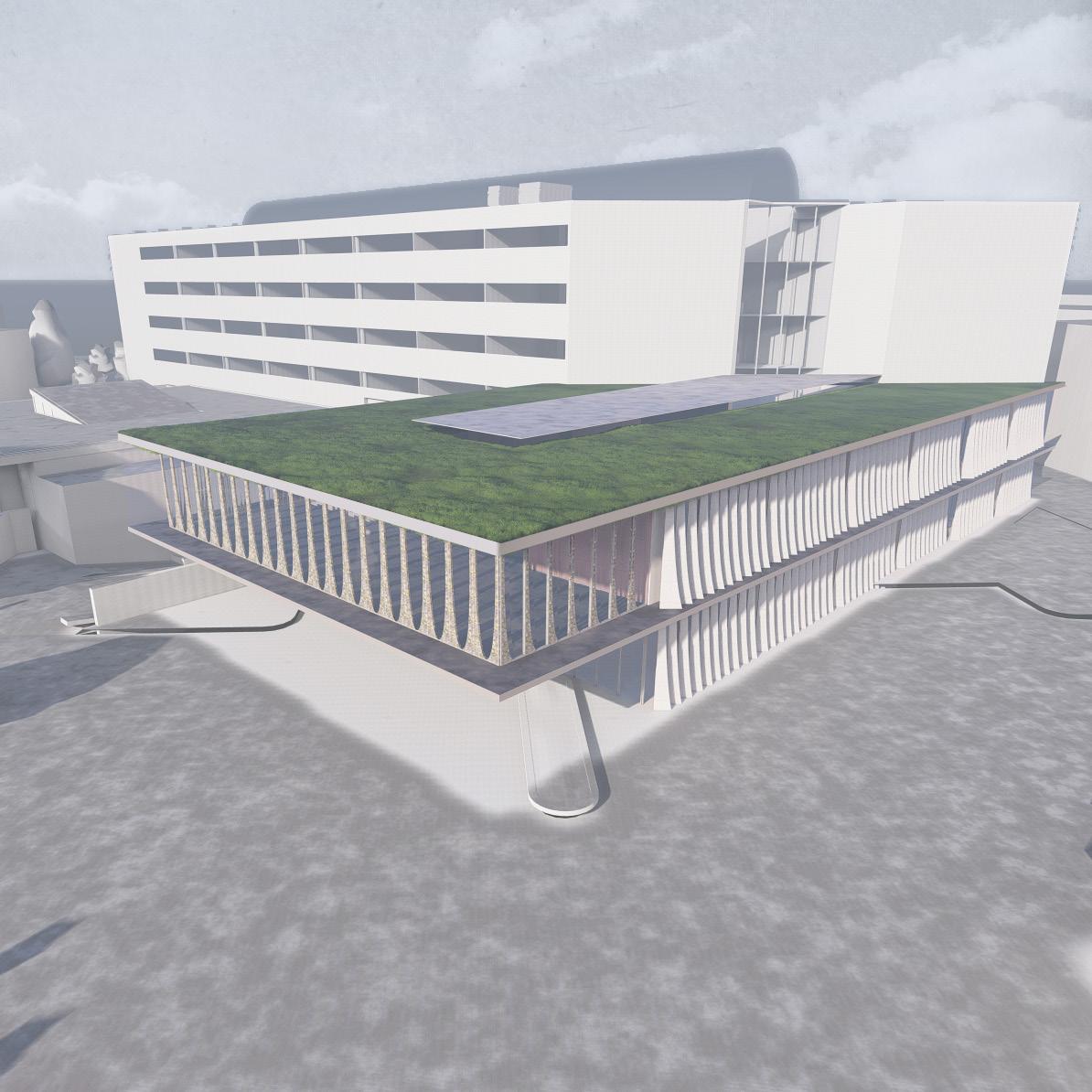

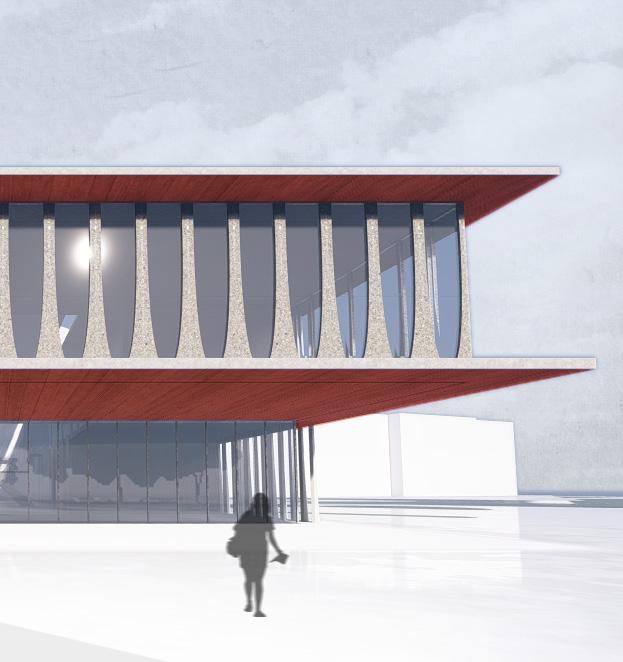

Our design incorporates ecological factors to push the idea of sustainability and the innovation of low carbon precast concrete. Starting with understanding how the materials were gathered to curate a lower carbon footprint, to the final production process of puzzling together the precast panels that make up a large face of our design, we applied strategies of efficiency throughout the design. The overall brutalist shape links it to C.O.D while distinguishing itself with bold pops of color. Our design exhibits an acid-etched finish that’s form lined with wood panels to blend into the C.O.D exterior. To soften the harsh brutalist environment, our design features multiple outdoor areas as well as an inaccsessible green roof meant to absorb solar heat.

Our team dialed in on the production and energy efficiency of a precast concrete program. This program entails the entirety of precast concrete, from the initial production to the finalized build on site. To decrease the carbon footprint, we studied recycled aggregates from past demolition that are mixed in, the kiln process, the transportation, and everything else in between. As for the assembly of precast concrete panels, we intend to 3D print molds in which the concrete would take shape. This allows for easily customizable components to makeup the facade of our design. In regards to the adaptability of our design, we took into consideration the surrounding buildings and aesthetics, while also supplementing a new approach. Another critical element of our design process was to consider the environment the building would stand in.

Our design prioritizes the use and experience inside of the building itself. Most importantly, the sustainability of the concrete program had all to do with our final design. The precast concrete components in our design demonstrates a low carbon footprint production system.

PROJECT DATA

Iowa State University College of Design Expansion

PROJECT PROGRAM Studios

Fabrication Shop

Monumental Stair

Review Space

PROJECT FLOOR

Two Stories Above Ground Level

One Basement Level Construction

PROJECT HEIGHT

36’-0”

BUILDING FOOTPRINT

21,408 SF (223’-0” by 96’-0”)

PROJECT AREA + PROGRAM

Total Project Gross Area: 61,248 SF

Level 01: Approx. 21,408 SF - Studios, Lecture Space, Exhibition

Level 02: Approx. 18,432 SF - Studios, Pinup Space

Basement: Approx. 21,408 SF - Fabrication Shops, Flex Spaces

Massing Diagram

Bird Eye View

Massing Diagram

Bird Eye View

Program Strategy Diagram

Program:

4 Super Studios (10 Studios Total)

Lecture Space

Exhibition Space

Fabrication Shop (Photography Room, Wood Shop, Metals Shop, Spray Room, Comms Room)

Flexible Study Space

Studio View

Facade Design

The southwest side of the addition is highly vulnerable to solar heat gain, so we’ve implemented vertical louvres that are motorized to shift as the sun travels through the sky. This sun shading system will improve the interior experience by limiting direct glare, in addition to preserving the initial priority of sustainability by minimizing solar heat gain in the warm months. The shape of these louvres is carried through the rest of the facade, creating a hollistic and dynamic design. They are multi-colored, with one side featuring a red pigment.

9 AM, June 21 Noon, June 21 3 PM, June 21 6 PM, June 21

Shadow Study

Kinetic Louvre Design

The vertical louvres will be made of precast concrete. We plan on running a stiff metal cable through the middle of each concrete panel (the precast form will create a tube of space for this), then placing a motor system at the top and a bearing at the bottom, allowing the device to spin on its axis. The motor will be programmed to follow the sun studies in the area. In the winter it will be shifted to allow the most sun in, and in the summer, it will run to block as much direct sunlight as possible (shown in diagram above).

Southwestern Elevation

Exploded Axonometric View

Exploded Axonometric View

Construction Process + Module Assemblage Diagram Strategy

The building’s structure and facade consists of modular pieces to increase efficiency in the construction process. Precasting modular forms offers a streamlined production process, improved consistency of each piece made, and accelerated assembly/ installation. This approach optimizes production workflows, ensures uniform quality and dimensions, and enables swift on-site integration, leading to efficient construction timelines and cost-effectiveness.

Form-liner like curvature

Base mold (same used for both casts)

Resulting panels

Precast Concrete System Diagram

Innovative Precast Concrete System

The intent to design modularly persists in our facade design. We use one modular shape to create the shading panels on the Southwest facade, and another for the panels lining the windows on the Northeast and Northwest facade. Both panels maintain the same height and depth, with only their inner curvature distinguishing each one. This similarity allows for simplified production and transport of each piece.

We intend on 3D printing molds to cast each panel. Because a 3D printed form is computer generated, it can ensure a high degree of accuracy. We plan on creating one large mold fitting the shared dimensions of each panel, featuring slots which will allow for many panels to be produced out of this singular base form. In addition, we will cast two other molds which will be laid on top of the base mold, to form the respective curvatures of both the shading panel and the mullion panel.

3D printed molds shown above.

We anticipate the transport of these panels to shoulder a very low carbon footprint due to the small-scale size of each panel. Because of their modest dimensions and their ability to be stacked, only one trip would be required to deliver all facade panels on site.

Pinup Space View

Pinup Space View

Low Carbon Footprint Strategy Diagram

A low carbon footprint is achieved through a number of design strategies.

Our structural bays that are 32’ x 32’ allow for modular prefab structural elements to be transported and efficiently constructed with the minimum amount of energy used. The elements have been made more efficient in our design by using carbon-press technology that strengthens the tensile properties of prefab elements so that less material is used.

Recycled materials from demo sites like aggregate or slag can be used to produce prefab modules.

3d-printed molds can be used to create molds with a high-level of accuracy, minimizing the amount of material used to reduce carbon impact.

Our design implements passive strategies like green roofs and kinetic shading devices to reduce the overall energy use of our building during the summer monrths, leaving a long lasting impact post-construction.

Finally, the structural system we propose utilizes the modularity of prefab concrete to create bays with different elements of columns, beams, slabs, and shear walls. This strategically puts material where it is needed programatically and saves costs.

Brutalism is wasteful with monolithic concrete elements; instead, we use strategically designed bays that achieve the dramatic architectural expression while using the minimum amount of material.

Plan Design Strategy

Our ground floor functions as an extension of the C.O.D that shifts the access point to the parking lot. An axial relationship is established between the atriums of our extension and the C.O.D to create an expressive flow

Through our plan, we want to encourage natural movement and filtration between the different buildings on the site. Open bays towards the entrance featuring flexible lecture and exhibition spaces highlights the work of design students to passerbys. Super-studio spaces placed on the peripherals allow for natural light to filter in the space, and acoustic partitions between encourage unique educational configurations.

Level

Our basement level creates a flow between different fabrication needs so that students can see their project develop from start to finish in our addition alone. This floor is dedicated to ideation and development, with an array of makerspace as well as collaboration desks in the central area. The different areas of craft highlight the variety of resources the C.O.D offers to students, as well as the boundlessness of the creative process. Basement

Our second level features a cantilevered pinup space that showcases students work, as well as natural light supplied from both the front facade and the clerestory roof above. An X-shaped stair leads students up to either side filled with collaborative studios. This floor is directly accessible from the C.O.D itslef. Beyond each pinup space on the west end is a wrap-around balcony lined with greenery meant to rejuvinate the students when needed.

Conclusion

In conclusion, our design embodies the principles of eco-brutalism, emphasizing sustainability and innovation in precast concrete construction. Every step was carefully considered to minimize environmental impact. Our approach includes utilizing recycled materials, 3D printing, and modular forms to increase construction efficiency. Ultimately, our focus on sustainability extends throughout the project, offering a dynamic design that prioritizes both the creation process and the user experience within the building.