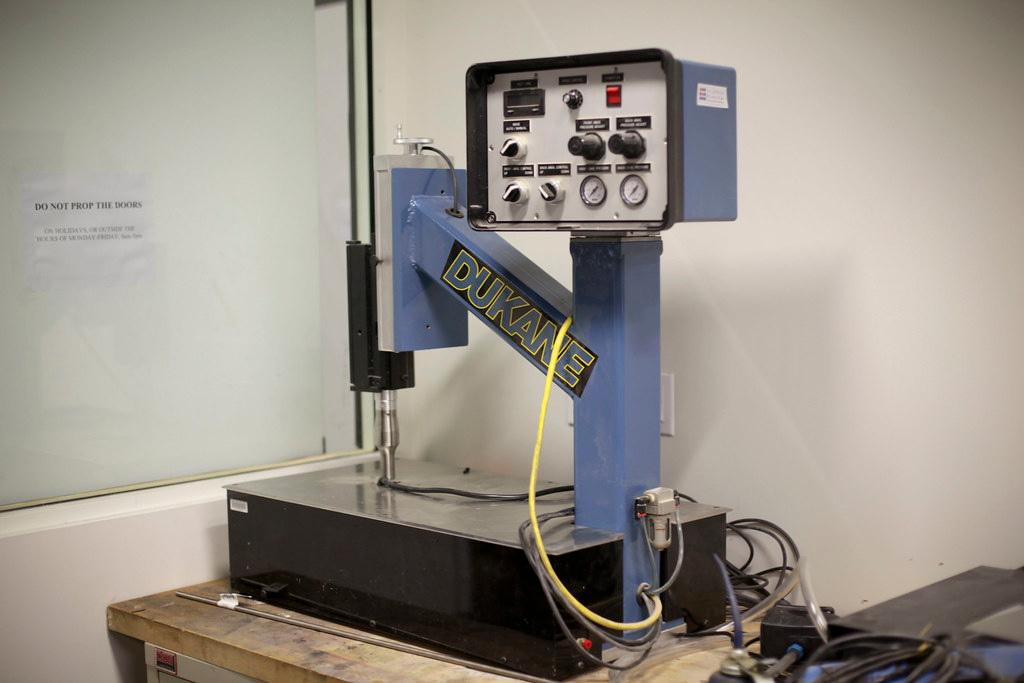

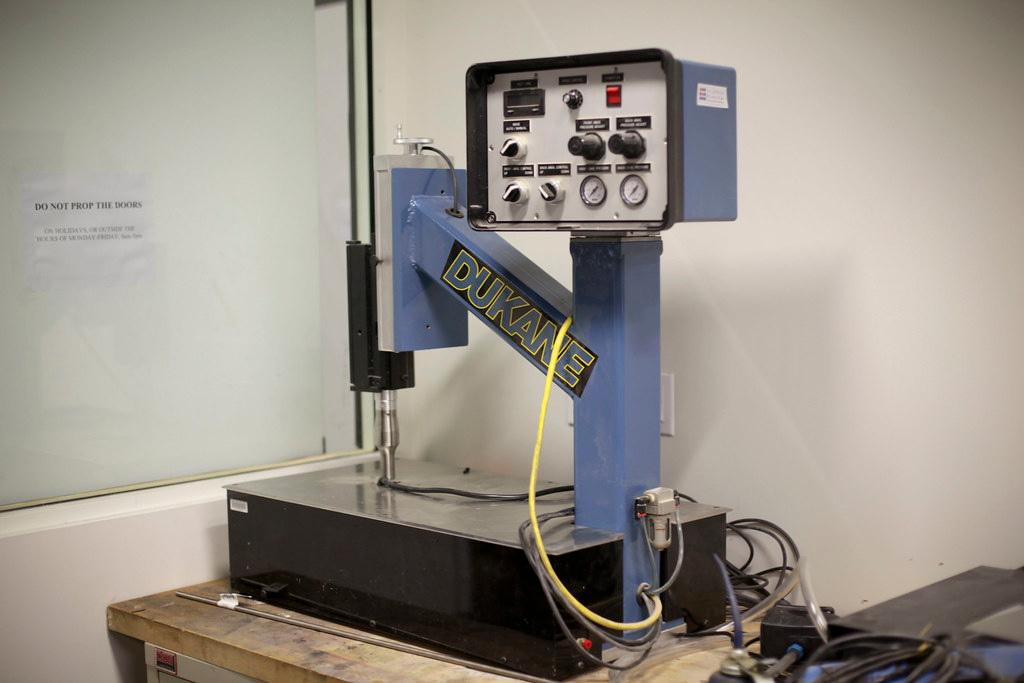

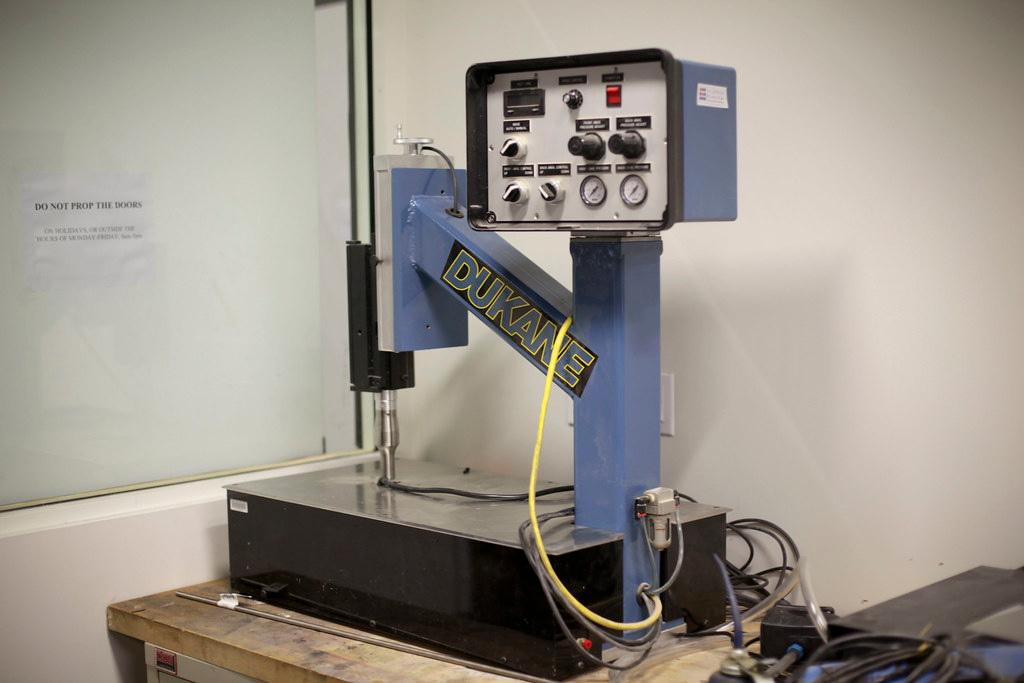

SONIC WELDING

High frequency (ultrasonic) sound waves are used to fuse two or more workpieces together into a single piece during the process of ultrasonic bonding, sometimes referred to as Sonic Weld. Ultrasonic welding, which is frequently used to join plastic parts, especially those composed of several types of plastic, firmly welds the individual workpieces together without the use of adhesives or mechanical fasteners.

The most common method of welding employs ultrasonic energy to produce heat and a weld by causing surface and intermolecular friction. The majority of thermoplastics are acceptable for ultrasonic welding.

Semi-crystalline polymers, on the other hand, are usually more challenging to ultrasonically weld than amorphous polymers, which are normally the best h transfer high frequency vibration determines its applicability for ultrasonic welding. Therefore, stiff materials are preferable than flexible ones. Melting behaviour is crucial as well. The ideal materials are those that melt over a wide temperature range

The two main types of ultrasonic bonding are continuous rotational drum welding and singlestrike, or "plunge", welding. The most frequent applications for single-strike ultrasonic bonding are spot welding, strap attachment, and the creation of smaller, more localised joints. Continuous sonic welding is frequently employed for longer welds and/or those requiring special geometries.

Although it can also be used to connect larger parts for automobiles, aircraft equipment, and other high-tech applications, sonic welding is most frequently employed to combine smaller plastic parts, such as those in portable electronics or medical devices. To get the optimum results for the given application, the ultrasonic bonding procedure might be changed.