People Right Partner"

People Right Partner"

Designing a product is just one part of the manufacturing process. Once you have created a design, the next step is to ensure that it can be produced efficiently and cost-effectively.

This is where the concept of design for manufacturing (DFM) comes in. DFM is the practice of designing a product with the manufacturing process in mind, in order to minimize production time, reduce costs, and improve product quality.

In this article, we will discuss how to optimize your product's production process by designing for manufacturing.

To design a product that is optimized for manufacturing, you must have a good understanding of the manufacturing process. This includes understanding the materials used, the manufacturing equipment and processes, and the assembly and testing procedures. By understanding the manufacturing process, you can design a product that is both functional and manufacturable.

One of the key principles of DFM is to keep the design as simple as possible. A simpler design is easier and less expensive to manufacture, assemble, and test. By reducing the number of parts and simplifying the design, you can also reduce the number of potential failure points and improve product quality.

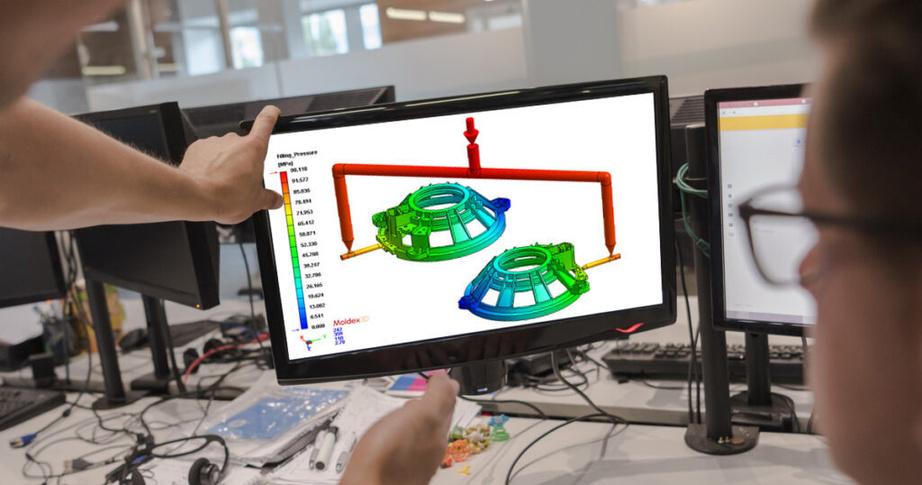

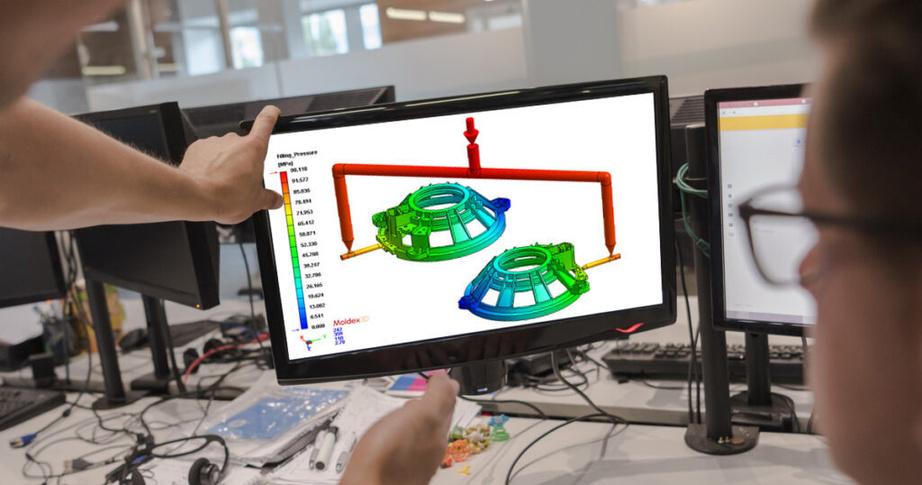

Choosing the right materials is another important consideration in DFM. The materials you choose should be both suitable for the intended use of the product and compatible with the manufacturing process. For example, if you are designing a product that will be injection-molded, you should choose a material that is suitable for this process and can be molded easily.

In addition to designing for the manufacturing process, you should also consider the assembly process. The design should be such that the assembly process is as simple as possible. This can be achieved by using standard components, designing parts with easy-to-use features, and designing for easy access and visibility during assembly.

Finally, it is important to test the design before moving to production. Testing can help identify any potential manufacturing or assembly issues and allow you to make any necessary changes before mass production begins. This can save time and money in the long run by reducing the number of defective parts and minimizing production downtime.

Designing for manufacturing is an essential step in the product development process. By designing a product with the manufacturing process in mind, you can optimize your production process, reduce costs, and improve product quality.

Rutland Plastics is a leader in plastic injection molding, offering design and prototyping services to ensure that your product is optimized for the manufacturing process.