New

Brown

chair

“We

Farmers and rural communities are invited to join Prime Minister Christopher Luxon, Agriculture Minister Todd McClay and Federated Farmers President Wayne Langford for a public meeting about how we can restore farmer confidence.

Tuesday 26 November

Mystery Creek Events Centre, Waikato, 12pm – 2pm

Friday 29 November

Ashburton Event Centre, Canterbury, 12pm – 2pm

Wednesday 4 December

Southern Field Days Site, Southland, 12pm – 2pm

Throw on your gumboots, jump in the ute, and we’ll see you there.

SUDESH KISSUN sudeshk@ruralnews.co.nz

NEW DAIRYNZ chair Tracy Brown says bipartisan agreement among political parties on emissions pricing and freshwater regulations would greatly help farmers.

Brown, the first female chair of the industry-good organisation, says farmers need certainty around what future regulations may look like.

“Farmers cannot plan or invest if they don’t know what you are up against,” she told Dairy News.

Agriculture sector leaders are engaging more with National, Labour and Greens to understand their positions and help allay farmer uncertainty around emissions and water regulations.

DairyNZ was part of He Waka Eke Noa (HWEN), set up by the previous Labour government and made up of the pastoral sector, farmer groups, Ministry for Primary Industries and Maori, to look at emissions pricing. However, the current Government disbanded HWEN in June this year.

The Government has since established a Pastoral Sector Group to tackle biogenic methane and take agriculture out of the New Zealand Emissions Trading Scheme (NZ ETS). The group is likely to meet in the coming months.

Brown says the Pastoral Sector Group’s challenge is to work out how we can meet our climate change obligations while keeping

kiwi farmers in business.

“That’s why bipartisan agreement with major political parties is critical. We’re spending a lot of time talking to National, Labour and the Greens as well as Act and NZ First,” she says.

“The challenge is how can we meet somewhere in the middle and keep the economy going and giving certainty to farmers which is not crippling.

“If change needs to be made then it needs to be over a reasonable timeframe and with reasonable expectations.”

Brown notes that the world we operate in is changing, with an increased focus on sustainability. She says it’s not going to go away, and the dairy sector needs to keep

moving on this.

“Our markets are demanding it, we hear from our milk producers that they are coming under scrutiny, being questioned around what farmers are doing, and [asked] to provide evidence,” she says.

HWEN is credited with bringing the pastoral sector together to discuss solutions. Brown says while HWEN involved some good work, it “didn’t quite land”.

“We’re now in a different space with a new Government.”

Brown wants regulations that are practical and workable to all parties.

“However we operate going forward, it must be practical and workable to all parties. It must be a system that farmers understand and where their efforts are recog-

nised and rewarded.”

She notes that since 2001, 96% of farms have got a greenhouse gas emissions profile and 60% have a plan to manage emissions, that’s up from only 15% three years before in May 2021.

“Our knowledge and understanding is growing all the time,” she says.

“But farmers need certainty. Right now, the target reviews are going on, farmers don’t know what they need to do, so there’s quite a lot of uncertainty.”

And Brown adds that regardless of where that lands DairyNZ will remain focused on delivering the on-farm solutions farmers need to meet their obligations, and continuing farming sustainably and profitably into the future.

CHINESE BUYERS are returning in force to replenish stocks and helping send global dairy prices higher.

China significantly reduced its imports of dairy products over the past two years compared to previous years, due to softening demand at home and a surge in their own production.

However, Westpac senior economist Michael Gordon says it’s becoming more apparent now that the pullback in their imports has left them significantly understocked, especially for milk powders.

Gordon notes that

China’s dairy industry is still struggling with an oversupply of liquid milk, some of which is being dried into powders in order to be able to store it – but it appears they don’t have the capacity to make up for the extent of the shortfall in imports.

“For whole milk powder (WMP) in particular, China has few options for increasing its supply. New Zealand is by far the dominant supplier on the global market, and Fonterra has tilted its product mix away from WMP in the last couple of seasons, in response to the fall in Chinese demand.

“So, the only real way to secure more WMP is to divert it away from other markets. Conse-

quently, we’re seeing buyers from North Asia (largely China) take up an increasing share of the product sold at the Global Dairy Trade auction.”

The last GDT saw the price index jump 1.9% to US$4089/metric tonne,

its highest point since July 2022. WMP prices rose 3.25% to US$3826/ MT.

Westpac has revised its forecast milk price for the season to $10/kgMS. If achieved, it would be the highest milk price on record and the first dou-

ble-digit one. However, he cautions that’s not quite the case once we account for the general rate of inflation.

“It’s certainly above average, but there have been four previous years where the milk price was higher in inflation-

adjusted terms. It should also be noted that none of those previous highs were sustained, and in some cases were followed by sharply lower prices in the following season.”

Adjusting for general inflation also understates the degree to which onfarm costs have risen in recent years.

DairyNZ currently estimates a breakeven price of $8.15/kgMS for a typical dairy farm, up from $8.01/kgMS last season.

“That said, a $10 milk price would leave substantial room for farmers to spend and invest more, even after catching up on maintenance and other costs that might have been deferred during the previous tougher season,”

says Gordon.

“A $10/kg milk price, along with an increase in milk volumes that is shaping up to be in the order of 2%, would mean around $3.5 billion of additional revenue for Fonterra’s suppliers compared to last season (and $4.5b in total if this experience is repeated across the other dairy companies).

“After allowing for an increase in costs, this suggests about $4b of extra discretionary income for dairy farmers this year, equal to around 1% of GDP.”

Another factor pushing dairy prices up is production constraints, especially in Europe and the US – two of the world’s biggest milk producers.

FEDERATED FARMERS dairy industry group chairperson Richard McIntyre says farmers in Southland have done much to reduce bad practices around winter grazing.

His comments follow criticism of what’s happening in Southland by Listener writer Dr Andrea Graves whose article was headed ‘Stuck in the mud’.

The article showed a photograph of cows standing in mud up to their hocks. Graves has a PhD in animal behaviour, and did her doctoral research on chickens.

Her article was followed by comments by animal welfare expert and veterinarian Dr John Hellstrom who

noted that every time a photograph like the one in the Listener appeared in the media it was seen overseas and was bad for NZ. He noted that winter grazing had a place in Southland but only if it was properly managed.

McIntyre says one of the problems farmers faced is that some photographs of cows in mud are taken out of context.

“We have seen time and time again where people walk up to the road and cows wander over to the muddiest bit and get photographed there and that gets presented that the whole paddock is muddy. If that was how cows looked day in and day out then there is an issue, but more often that is not the case.”

A NET zero pilot dairy farm, set up in Taranaki two years ago to help reduce on-farm emissions, is showing promising results.

The farm is owned by Fonterra and is located next to its Whareroa plant. With one of its biggest global customers, Nestle, Fonterra aims to create New Zealand’s first commercially viable net zero dairy farm within ten years. The farm is run with Dairy Trust Taranaki.

Since 2022, the Fonterra-owned 290ha farm has achieved an approximate 27% reduction in absolute emissions and a 5.5% reduction in emissions intensity.

Fonterra director

of sustainability Charlotte Rutherford says the reduction is promising, though results may vary seasonally.

“We’re pleased with our progress so far but still have a lot more work to do to make further improvements.

“We are trialling different tools and approaches to see what works and what doesn’t, and while some trials have shown promising early results, others have provided valuable insights and lessons.”

The reduction in absolute emissions over the last two seasons was coupled with a decrease in milk production.

Over this time, the herd decreased from 600 to 550 cows and was switched to ten milkings across seven days rather than two milk-

ings a day. This improved staff morale and reduced farm operating expenses, but resulted in an 11-12% decrease in milksolids production per cow. The farm has returned to twice a day milking this season.

The focus over the next three seasons is to reduce emissions inten-

sity, targeting a 30% reduction by the 202627 season. This will be achieved through a focus on breeding and reproduction, calf-rearing, nitrogen use efficiency and the use of novel technology.

Over the last two seasons, the farm has used crossbred sexed semen

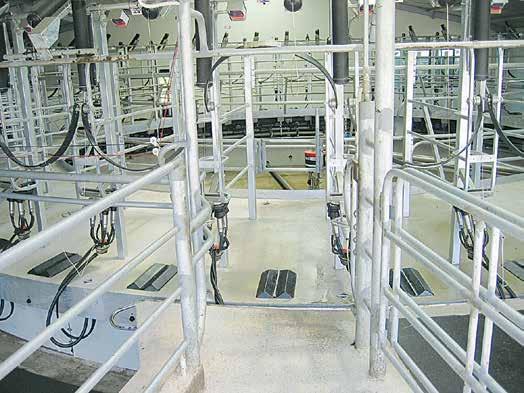

Book a dairy shed rubberware review today

Scan the QR code or visit skellerup.co.nz/dairy

tion in May. The EcoPond team are currently developing a method to treat the whole pond.

Other novel technology includes the use of a milk cooling system via New Zealand-owned Coolsense, which is expected to reduce dairy shed power consumption by up to 30%.

with Fonterra to provide direct support to farmers to help them reach the co-operative’s target of a 30% reduction in on farm emissions intensity by 2030, from a 2018 baseline.

on the top 60% of cows, based on their genetic merit, which has led to significant genetic gains, although challenges in conception rates remain.

The trial of novel technology EcoPond has shown promising results reducing methane emissions from the effluent by 93% since its installa-

Native trees, Kapuka and Kanuka, have been planted in 12m or 16m spacings to test two different densities and learn about silvopasture, the practice of integrating trees with grazing animals.

The trees will grow to 10-15m in height, with the aim to balance the carbon, shade and shelter benefits and minimise negative effects on pasture growth.

In addition to the farm, Nestle is partnering

It includes Nestle funding an extra payment for farmers who achieved The Co-operative Difference for the 2023-24 season, which was in the vicinity of 1.44c/kgMS. This payment to Fonterra farmers who achieve The Co-operative Difference will be offered again for the 2024-25 season.

Nestle New Zealand chief executive Jennifer Chappell says the initial results are promising.

Fonterra board members and management visited the farm before the co-op’s annual general meeting in New Plymouth this month.

Our national team of Technical Specialists are here to help, whether you’re facing a tricky issue or just need a second opinion on your rubberware setup.

Troubleshoot and resolve issues in the dairy shed

Tailored rubberware recommendations to suit your herd and equipment

Expert advice to optimise milking efficiency, milk quality, and cow health

Issue a rubberware maintenance plan

Hewett

Rob

told Dairy News

A WORK in progress is how Farmlands chair Rob Hewett describes the rural trader’s 2024 annual results.

The farmer-owned cooperative announced a net loss of $14.3 million, which includes a one-off adjustment for previous tax losses of $12.3m. Last year the co-op reported a net loss of $700,000.

“While the $12m taxrelated loss doesn’t make it any easier to swallow the disappointing result, it’s an annual result that’s in line with a promise and strategy to deliver greater value to Kiwi farmers and growers and to invest in strengthening the co-operative itself, while also managing through a tough market environment,”

The annual results include some highlights like the $92m rebate delivered to its 79,000 shareholders.

“The reason Farmlands was set up as a co-op was to be the buying group for NZ farmers and the rural community,” says Hewett.

“What our shareholders have received through shelf and card purchase discounts over the year shows the value of being part of a co-op.

“Despite a tough operating environment and reduced revenue, we’ve given more in rebates back to our shareholders.”

Farmlands’ turnover topped $2.5 billion, 3% down on the previous year while revenue was down 8.4% to $740m.

The co-op has completed the first two years of its three-year supply chain transformation.

Hewett notes that while it’s been a challenging year, the results show the strategy is working.

“We are seeing significant organisational and customer benefits:

the right product range – concentrating buying power – is leading to price reductions.

“In less than 12 months we completed a business-wide range reset and roll-out to ensure we can meet the widest range of customer needs, while also providing us

maximum buying power to support better pricing.

“We know that when our farmers and growers have a tough time, we are likely to feel the impact. It’s been one of those years. We recognised this early and adjusted our short-term strategy quickly.”

Farmlands also reviewed its buying strategy: to better source essential rural supplies with greater efficiency and at the best price, while continuing to deliver quality products.

It also launched AgStar –its first own-label range of direct-sourced agricultural chemicals, aimed at providing customers more choice and a better price.

Hewett says Farmlands has been testing the waters with the own-label range and the results are encouraging.

Farmlands chief executive Tanya Houghton points out that its efforts to improve pricing on rural supplies have put an additional $6.9m back in hands of farmers and growers.

“This has been made possible through efficiencies gained from our

supply chain transformation, careful inventory management, supplier negotiations and tight operational cost controls.

“Farmlands is becoming a much stronger cooperative than it was 2-3 years ago because of deliberate decisions we’ve made. Other examples of this growing underlying strength are an improved cash position year-onyear, acquisitions like SealesWinslow and new partnerships such as Fern Energy.”

Fern Energy, 50% owned by Farmlands, is the leading bulk fuel provider for the rural sector.

The business generated $647m in revenue, $3.3m in Farmlands profit and a $2.75m Farmlands share of dividends – a significant increase from last year.

@dairy_news

facebook.com/dairynews

Our portfolio of powerful, proven products has helped farmers from one end of the country to the other create and maintain thriving businesses, and has earned us an excellent reputation as pasture protection and brushweed specialists. Our extensive suite of herbicides provides farmers everything they need to win the war against weeds and brushweeds. Visit corteva.co.nz to view our online pasture and brushweed resources.

DEPARTING FONTERRA

director Leonie Guiney is urging the next generation of co-operative farmers to step up and be there to lead in future.

Speaking at the co-op’s annual meeting in New Plymouth this month, the Canterbury farmer notes that Fonterra’s future is dependent on the efforts of its farmer shareholders.

She also urged Fonterra leaders to be humble or risk losing the good work done in the past few years to turn the co-op around.

“I will flag a risk, to both board and management. Recent performance has been very good. Often success is the hardest thing to manage forward.

“The day any of us considers ourselves individually responsible for good outcomes, we risk running aground,” Guiney says.

She points out that domestic competition shouldn’t distract the co-op from a focus on its global exposures and opportunities.

“The competition will eat our lunch if our overheads aren’t further reigned in, and if farmers don’t retain their ability to ride the cycles with a competitive position on the global cost curve.

“But enough good brains with business acumen and experience and the right reasons for being there – which is to serve – will help management get the most important decisions right for the owners.

“To that end I encourage the next generation of farmers to step up and be there to lead in future. Fonterra’s future is dependent on its business-savvy suppliers, with skin in the game, being prepared to determine your own future.”

Guiney, who served nine years on the board, is the first and only incumbent in Fonterra’s history to be removed by any means other

than a farmer vote. She served between 2014 to 2017 but then failed to gain approval to stand again through the co-op’s selection process. However, the following year, she stood again and was elected by farmer shareholders. Guiney finished her tenure at the coop’s annual meeting this month.

Guiney says she’s not worried about Fonterra’s future.

“Not in this wonderful temperate climate that enjoys outstanding comparative advantage in the production of very highquality sustainable protein. Complemented by our sharemilking system that attracts entrepreneurs to our industry and our scaled co-op with genuine advantage in ingredients innovation, foodservice and market access. I am personally so very happy to be a NZ dairy farmer.”

Guiney says she’ll miss the privilege of steering something that is so important for the outcomes of farmers and NZ.

She thanked farmers from Northland to Southland for backing her and trusting her intent.

“I will also miss every one of my colleagues. I am so very happy for Fonterra that I can say that, because it speaks of a culture that will keep delivering for all our stakeholders.”

Guiney says Fonterra is in a good position today.

“The growing confidence in Fonterra that I observe from farmers and the business community, I consider to be well placed.

“It’s been a journey to get Fonterra to that place, and it is imperative that Fonterra has learned where we went wrong in the past.

“A focus on the appearance of value at the expense of actual value was at the root of our poor past outcomes.

“Add to that a strategy misaligned from our core advantages, and an absence of risk-adjusted thinking in investment, made for expensive

errors.

“Most businesses will make some poor decisions. Good governance owns its errors in a timely manner thereby minimising further damage to shareholders’ equity.

Fonterra did not do that in the past and that was a governance failure we cannot repeat.”

Guiney also thanked her husband Kieran and children for their sacrifice and support.

“IT WAS awesome to see not only where our milk goes but to find out more about the range of ways it’s used.”

That’s the reaction from Mid-Canterbury farmer shareholder Jay Schmack after a recent visit to the co-op’s Te Mātāpuna Innovation Lab in Singapore with her husband Wayne.

Fellow farmer shareholders Dave and Karen Ellis were also part of the visit, organised by Fonterra’s Southern Central Canterbury regional manager Tom Munro.

“We got talking to Tom at a local event and mentioned that we had a day layover in Singapore on our way back from South Africa for the All Blacks’ matches in Sep-

tember,” says Jay.

“He suggested a visit to the innovation lab which sounded like an exciting opportunity.”

The Innovation Lab, which opened in February, is one of several similar co-op facilities around the world, the others being in Melbourne, Amsterdam, Chicago and six in China. They act as

an in-market extension of the Fonterra Research and Development Centre in Palmerston North and the teams work on a range of innovative applications using the co-op’s NZMP ingredients, such as bakery products, beverages, dairy foods and snacks, to suit the local trends, tastes and cultures. The Singapore lab

is focused on Fonterra’s Southeast Asian markets and regularly hosts customers and suppliers to develop products tailored to that region.

Dave says the lab team was very welcoming and knowledgeable, able to give them a greater understanding of the opportunities that exist in Southeast Asia as well

as the rationale behind the potential divestment of the co-op’s Consumer business.

“They gave us a great presentation on the different markets and applications and we were able to sample some products,” says Dave.

“It was very interesting to see what they do there and learn

LIC FARMERS are set to benefit from a genetics collaboration with US company, Sexing Technologies (ST).

LIC chief scientist Richard Spelman says this is part of their focus to breed the best cows to improve the national herd.

“Collaborating with ST to access their genetics means that we’ll be bringing in genetic diversity and traits of interest, such as improved udder conformation. The genetics will be

available for New Zealand LIC farmers in 2026.”

ST chief executive Juan Moreno says that working with LIC to access its herd genetic diversity is an exciting opportunity for ST.

“We have a vision to help create the best animals and the collaboration will mean that LIC, and therefore New Zealand farmers, will have access to US elite breeding heifers.”

Last year, LIC generated embryos

for specific traits using elite LIC sires and a number of ST’s elite female donors.

These were implanted at ST to create a first progeny of calves (F1) – these first animals are half US, half NZ bred.

The resultant sires will have semen collected and will be available to LIC New Zealand farmers in 2026. The heifers born in USA will then be used to generate embryos with elite

more about the growing demand for New Zealand dairy and proteins across the region.

“We didn’t know much about the scale of the market across Southeast Asia and other regions. When you look at the world markets compared to our small domestic market it puts into perspective the value that can be created by focusing more on the Foodservice and Ingredients areas.”

Jay says seeing the experts in action was a unique opportunity.

“We’ve done the Understanding Your Cooperative Programme at Fonterra’s head office in Auckland and while that was informative, learning first-hand about the enor-

LIC sires utilising cutting-edge US technology and skills. The male sexed embryos will be sent to NZ to provide future LIC semen for breeding, supporting continued genetic improvements.

“This multi-year project is part of LIC’s core business to invest in breeding programmes and research so we can offer the genetic diversity to our farmers,” says Spellman.

“We’ve listened to our farmers –

mous amount of work that goes into creating value for shareholders is at another level,” says Jay.

“The staff were really open about how they’re working to expand the markets for our milk and create demand for highvalue products and ingredients.”

Tom Munro says he was pleased that the farmers got a lot out of the visit.

“It’s great to be able to offer these unique experiences for our shareholders. We’re always looking for ways that can help farmers build a deeper connection to the co-op,” says Munro. “Jay, Wayne, Dave and Karen are really engaged so it was a pleasure to be able to give them this opportunity.”

they’ve been asking for greater diversity in our cow population, as well as improvement in udders to support the greater production per cow.

“We’re excited to leverage off US cutting edge technology, as well as fast-tracking access to superior udder traits.

“Signing the contract with ST technologies USA marks an exciting step in the future of our genetic diversity,” says Spellman.

AUCKLAND MANUFAC-

TURER and distributor of colostrum-based supplements, New Image International, celebrated its 40th anniversary this month.

About 200 local and international guests, including David Seymour, Minister of Regulation and Judith Collins, Attorney-General & Minister of Science, Innovation and Technology, attended the event at the Ellerslie Event Centre.

Overseas guests included delegates from Australia, Malaysia, South Africa, Taiwan and Vietnam. The event was livestreamed in four different languages - English, Mandarin Chinese, Bahasa Indonesia and

Greek - reaching 230,000 people online across the world. The event also coincided with a group of 220 Taiwan based New Image distributors who had qualified for travel to New Zealand.

Reflecting on the past four decades, executive chairman and founder Graeme Clegg said he is proud to see New Image contributing to and improving the health and financial outcomes for large numbers of people around the world.

“The company started from humble beginnings in Masterton back in 1984. To see New Image grow into a global leader in the nutrition and supplements industry with customers and distribu-

With a diverse portfolio of over 30 products catering to large numbers of customers globally,

New Image has expanded beyond supplements and nutrition. This includes the acquisition of skincare and cosmetics company ‘Nutrimetics’ and the acquisition of Food Innovation Waikato and its major milk powder drying facility to enhance New Zealand colostrum production. The company is also working with the University of Waikato to manage a range of research projects around the health and wellness benefits of milk products.

New Image chief executive Rod Taylor said the company continues to be driven by innovation and research and is ready for its next stage of growth.

“The New Image team has always been

guided by our mission to improve people’s quality of life. I am immensely proud to be part of a team that is one of the leading direct selling companies in the world and to see the positive impact we’re creating for so many people.

“As we look ahead to the next 40 years and beyond, we will continue to expand and grow in new markets such as Europe and South Korea, investing further into our research and development programmes in New Zealand to continue to create high-quality colostrum, nutritional products, supplements and skin care that enhances people’s health and wellbeing.”

FONTERRA HAS introduced a new UHT bakery cream for its booming foodservice business in China.

The new Anchor Easy Bakery cream was revealed at the China International Import Expo (CIIE) in Shanghai this month.

Foodservice is a high-value channel for Fonterra – including top selling products such as cream cheese, UHT cream and mozzarella – and is a key part of the co-op’s strategy.

Teh-han Chow, Fonterra Greater China chief executive officer, says innovative products like the Anchor Easy Bakery cream is key to maintaining and growing the co-op’s market share in China.

“We have a strong Foodservice business in China and tapping into new markets with products like this is key to maintaining our leadership position in this competitive market and expanding our footprint into new cities,” says Chow.

Made with 100% New Zealand dairy, the Anchor Easy Bakery cream is designed for the mid-tier market in China, which is the fastest growing

segment of the UHT cream market. Demand for UHT cream continues to increase in China, driven largely by a growing middle class, urbanisation

and increased awareness of the nutritional value of dairy.

“The Anchor Easy Bakery cream aims to attract new customers who

want a full dairy bakery cream with good functionality at a competitive price. Together with our Anchor Whipping Cream, this new product

will consolidate our leadership position in the UHT market,” says Chow.

Aside from the new UHT cream, Fonterra showcased several other innovative and sustainably produced dairy products at its booth at CIIE this year.

“CIIE is a great platform for Fonterra to showcase our high-quality dairy products and demonstrate our strategic focuses on sustainability, nutrition health and locally driven innovation,” adds Chow.

Fonterra has six application centres in China, allowing it to work closely with customers and technical experts to co-create new product applications using the co-op’s dairy products.

Fonterra’s booth this year also showcases the co-op’s progress in sustainability with innovations such as the Carbon Footprinter, a tool created to help customers calculate the emissions profile of products which in turn helps them manage their carbon footprint.

@dairy_news

facebook.com/dairynews

WHAT A difference a year can make. Twelve months ago, Fonterra shares plummeted to $2 on the New Zealand Stock Exchange.

Compare that to seven years ago, when it was hovering around $6.50. Last week, shares were trading around $4.50. In the last financial year, Fonterra’s market capitalisation is up $4.3 billion to $7.7 billion.

The shift in share price reflects performance, and the returning confidence farmers have in Fonterra. And credit for this must go to Fonterra’s management team and staff.

Koru-koi

CALL IT what you want, a hikoi, a car-koi or a koru-koi, the recent protest march against Act’s Treaty Principles Bill has been exposed now for what it was – a publicity stunt for and by the Maori Party. The fawning media have presented it as a popular uprising, over-reporting the crowd sizes and not reporting at all who was really running and funding the show. The Taxpayers Union (TPU) claims it has confirmed that the leader of the protest, Eru Kapa-Kingi, is on the Parliamentary payroll as a full-time, taxpayer-funded staffer of the Maori Party. TPU says the party is using Parliamentary resourcing to keep it secret. “If this was a Ministerial staffer, the activity would be covered by the Official Information Act.” So, not so much a ‘grassroots movement’ as a party-political stunt, funded by us!

GREENPEACE TRIED its best to disrupt Fonterra’s annual meeting at a hotel in New Plymouth earlier this month, but they were outflanked by a formidable team of Fonterra staff, security officers and Taranaki police.

The activist group hired a truck and adorned it with anti-Fonterra messages, however the police were onto them. The truck was stopped and searched by police 100 metres from the meeting venue. A couple of activists, one carrying a video recorder, mingled near the meeting venue before they were sent packing by Fonterra staff. Security staff hired by Fonterra were given strict instructions not to let anyone not registered for the meeting, including hotel guests, near the meeting hall.

The meeting, attended by 120 farmer shareholders, went ahead without any hitch.

THE NEW Labour Government in the UK is facing the wrath of farmers. Last week thousands of farmers and their supporters converged in London protesting changes to inheritance tax for farmers announced in the Budget.

From April 2026, inherited agricultural assets worth more than £1m, which were previously exempt, will be liable to the tax at 20% - half the usual inheritance tax rate.

However, many farmers argue that while they are asset rich, in terms of land and livestock, they are cash poor and the changes would mean they would have to sell up to be able to pay the tax.

The Government is not budging, saying it understood farmer concerns, but claiming that the vast majority would be unaffected. The farmers are not done yet, so Londoners can expect more fireworks.

A GROUP of University of Auckland academics claim a carbon tax is the most effective way for New Zealand to cut emissions while supporting a stable economy.

The follows a study comparing the effects of three environmental policies: carbon taxes, emissions trading schemes and emission intensity targets on the economy. It also explores environmental impacts on the economy by factoring in how pollution spreads across regions. They admit that carbon taxation may increase the cost of living, particularly by increasing food, transportation and energy prices. Relying on the ETS for emissions reduction is ineffective in terms of meeting NZ’s environmental goals, and agricultural emissions pose a considerable challenge, they say.

No right-minded Government would back a carbon tax that causes more pain than gain, especially for the agriculture sector that remains the backbone of the national economy.

It’s been a tough few years for the co-op’s farmer shareholders. Rising costs, interest rates and below par milk price have been taken a toll on dairy farming.

Thankfully, on-farm costs are easing and a potential $10 milk price on the cards this season means many farmers will be either breaking even or making a profit after a tough period. For these farmers, a rejuvenated co-op with a healthy share price puts the icing on the cake.

At Fonterra’s annual general meeting this month, the board and management expressed confidence in its revised strategy and the potential to create further value for shareholders.

The co-op has lifted its target average return on capital to 10-12%, up from 9-10%. There’s also a commitment to return more of the co-op’s earnings to shareholders, with an enhanced dividend policy of 60-80% of earnings, up from 40-60%. And the co-op is committed to maintaining the highest sustainable farmgate milk price.

With the co-op in a healthy state and the farmgate milk price heading towards $10, there’s renewed confidence among farmer shareholders. They can say Fonterra is in a strong position today and has a strong future.

Head Office: Lower Ground Floor, 29 Northcroft St, Takapuna, Auckland 0622

Phone 09-307 0399.

Postal Address: PO Box 331100, Takapuna, Auckland 0740

by: Rural News Group

by: Inkwise NZ Ltd Contacts: Editorial: sudeshk@ruralnews.co.nz

material: davef@ruralnews.co.nz Rural News on-line: www.ruralnews.co.nz

Subscriptions: subsrndn@ruralnews.co.nz

Publisher: Brian Hight Ph 09-307 0399

General Manager: Adam Fricker Ph 021-842 226

Editor: Sudesh Kissun Ph 021-963 177

Machinery

Editor: Mark Daniel Ph 021-906 723

markd@ruralnews.co.nz

Reporters: Peter Burke Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech Ph 021-190 3144

Production: Dave Ferguson Ph 027-272 5372

Becky Williams Ph 021-100 4831

Digital Strategist: Jessica Marshall Ph 021 0232 6446

AUCKLAND SALES CONTACT: Stephen Pollard Ph 021-963 166 stephenp@ruralnews.co.nz

WAIKATO & WELLINGTON SALES CONTACT: Lisa Wise Ph 027-369 9218 lisaw@ruralnews.co.nz

SOUTH ISLAND SALES REPRESENTATIVE: Kaye Sutherland Ph 021-221 1994 kayes@ruralnews.co.nz

THE FIRST insight is our global operating context, which continues to change.

And the second is risk – how we manage risk on your behalf and the way we treat your capital.

We are and always will be a New Zealand farmerowned co-op, but we are also a global export business.

When considering our strategy, we need to challenge ourselves to look beyond the back fence, and past the here and now.

The world is changing. We are moving out of an era of trade liberalisation and co-operation and into a world that is more

expensive, competitive and volatile. Expectations are evolving and New Zealand milk is becoming scarce.

Customers are increasingly calling on us to partner with them to improve their sustainability and innovation capabilities. And there’s even more focus on sustainability from banks, regulators, and from a market access perspective.

The cost of capital has increased, and many industries – including agriculture and our bankers – face higher capital requirements.

advantages, simplifying the business to meet that, and then aligning our people to achieve that singular vision.

cial settings and a risk appetite that is now more appropriately aligned to that of our farmer owners. As you’ve seen from our recent financial performance, this approach has served us well in recent years and has set a strong platform for this next phase in Fonterra’s evolution. Fonterra adds value for all dairy farmers by creating stability for the industry and de-risking the onfarm investment.

That all sounds inherently negative, and it’s certainly not without risk, but the opportunity for us still absolutely exists.

In this new global context, Fonterra also faces increasing competition for both milk and capital here at home.

Demand for dairy continues to grow and, in a rapidly changing world, we are uniquely positioned to capitalise on any shifts. We have high quality New Zealand milk which is becoming more scarce.

And most critically, we have scale. That gives us great confidence in the future of our co-op. Success will come by focusing on our comparative

The second insight we consider is risk. Fonterra is an extension of your farming businesses. It exists to provide certainty and manage risk on your behalf, while also maximising returns via a competitive and sustainable milk price, and a respectable return on the capital you invest in the co-op.

We govern Fonterra through a set of finan-

You and your bank manager know that your milk will be collected and you’ll be paid on time each month – not every industry can say that. We add value through the milk price, delivering a return on the $50 billion invested in on-farm capital. And by generating a return on the $12 billion worth of capital you have invested in the co-op.

To be in this special report contact your advertising representative now to promote your products and/or service to all NZ dairy

IN MY last article, I covered factors affecting the marginal returns from growing maize on-farm.

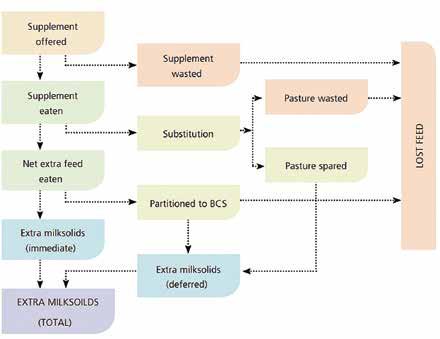

While yield and costs are often focal points, how maize silage is fed within a dairy system effects milk response and, ultimately, has a big impact on economic returns. During my dayto-day work, I’ve had the privilege of observing how top dairy farmers achieve milk responses as high as 100 grams of milksolids (MS) per kg of dry matter (DM) fed. These farmers pay attention to feed-out management and feeding accuracy to minimise wastage, they understand how substitution works, and they design their systems to maximise the utilisation of additional feed. Figure 1 below illustrates how feed can be partitioned within a system and shows why not all feed is converted into additional milk.

Minimising wastage

Wastage is an inevitable challenge when offering supplementary feeds to grazing cows.

Losses occur at the stack (heating and spoilage) as well as during feeding out (feed left uneaten in the paddock or feed bin). The extent of this wastage depends on the management practices, feeding methods, and infrastructure in place.

Top operators take specific measures to mini-

mise these losses:

Precision feeding: Understanding the pasture supply curve and feed budgeting helps to ensure they have sufficient feed to maintain a consistent supply throughout the season. This helps prevent under or over feeding at any time during the season.

Silage quality: Highquality, well-preserved silage means that more of the energy is retained in the stack. Farmers using proven ensiling techniques, such good compaction, covering completely with tyres and applying inoculants, often see fewer losses and better overall feed quality.

Infrastructure: Investing in feed pads or troughs reduces feed wastage significantly. Feeding on a pad can keep wastage as low as 10%, even in challenging weather, while feeding directly in paddocks, especially in wet conditions, can increase wastage to as much as 40%. It can also create pasture damage which impacts pasture yields especially

when ground conditions are wet.

Understanding substitution

Substitution occurs when cows reduce pasture intake in response to increasing supplementary feed. This effect can have both positive and negative impacts. On the downside, cows may

leave good-quality pasture uneaten, leading to wasted drymatter and/or a loss in feed energy as pasture quality decreases. However, substitution can also create opportunities. For instance, using supplements to manipulate rotation length and achieve optimum pre and post grazing covers

can lead to extra pasture grown or “saved,” contributing to a deferred milk response. Top farmers using maize silage leverage positive substitution while minimising negative effects: Maintaining pasture grazing pressure: These farmers carefully manage animals and feed. They

adjust stocking rates (typically higher), calving dates (early and/or split calving), and drying-off dates to achieve high cow days in milk each season. These strategic decisions also create larger pasture deficits that can be filled with maize silage while maintaining consistent grazing pressure and minimising substitution.

Strategic supplement type and timing: Timing and type of supplements influence substitution rates. For example, during high-substitution periods like during the peak of spring pasture growth, top operators often lean towards supplying concentrate feeds over forage feeds, as they create less substitution. However, typically these feeds are more expensive, so they are often fed for short periods and then replaced with typically cheaper forage-based feed.

Adjusting seasonally: Substitution rates tend to be highest in spring and lower in the summer and autumn. Having stored maize silage to feed as part of the diet in summer and autumn helps to achieve pasture and BCS targets that contribute to achieving a deferred milk response.

Optimising feed partitioning for milk production

Ensuring that supplementary feed is converted efficiently into milk rather than maintenance

is another priority for top operators. Achieving high production per cow and minimising body condition fluctuations throughout the season ensures the energy from supplements contributes more effectively to milk production rather than maintenance and replenishing body reserves.

Maintaining consistent body condition score: Farmers who meet body condition score (BCS) targets before calving and maintain them through lactation limit the energy losses associated with gaining and mobilising BCS.

For example, a lactating cow requires 50 MJME to store one kg liveweight (LWT); however, mobilising one kg LWT only supplies the cow with 37 MJME. Leveraging high genetic merit cows: Highgenetic merit cows tend to prioritise milk production over building body reserves. This makes them more efficient at converting supplementary feed into milk.

If you would like to understand how to get more production from the supplements you are feeding, feel free to give me or my colleague Matt Dalley a call. Our contact details can be found at pioneer.co.nz.

• Wade Bell is Genetic Technologies farm systems manager. Contact him at wbell@genetic.co.nz

• Fits plastic and concrete tanks • Rugged and long lasting • For Water Storage Tanks • Adjustable levels from 50mm-2.5m • Minimises pump operation •Available in 20/25/32/50mm

• Stainless steel bracket and Shaft

AS TEMPERATURES

rise, our cows face the challenge of maintaining production and health while battling the heat.

Heat stress doesn’t just affect cows’ comfort – it directly impacts milk yield, reproduction, and overall wellbeing. One of the most effective ways to prevent the worst effects of heat stress is ensuring cows have the right balance of minerals before the hottest months arrive.

Effects of heat stress

Cows begin to experience heat stress when temperatures reach around 20°C, especially in high humidity. Cooling themselves down causes their metabolic and nutrient demands to increase, leading to changes in mineral requirements.

Heat stress causes cows to sweat more, lose electrolytes, and reduce their feed intake, which results in lower intake of essential nutrients. If these losses are not replaced, cows will struggle to maintain milk production, fertility, and overall health.

Key minerals to manage heat stress

Many farmers reduce mineral supplementation over summer, but this can be harmful to the cows’ health and performance. There are several minerals cows need to be able to effectively manage heat stress and maintain productivity.

Sodium and potassium

Sodium and potassium, two of the most important electrolytes lost through sweat, help regulate fluid balance and maintain proper nerve and muscle function. As

cows sweat more, they lose more sodium and potassium, which can lead to dehydration and reduced milk production. Supplementing these minerals in the weeks leading up to summer prepares cows for higher electrolyte losses.

Magnesium

During heat stress, magnesium requirements increase, especially if they are consuming more grass, which may already be low in magnesium.

Ensuring cows have adequate magnesium before summer helps maintain proper muscle function, including the muscles involved in digestion and milk production.

Zinc

Zinc is known for its role in maintaining skin integrity and supporting immune function. This is especially important over the hotter months when cows are more prone to hoof problems and infections due to the stress of heat and walking longer distances to graze. Zinc supplementation before the onset of summer means cows will have adequate stores to support immune function, reducing the risk of infections and helping maintain production under stressful conditions.

Selenium

Selenium works to protect cells from oxida-

tive damage, particularly during times of stress. Selenium deficiency can be an issue during heat stress, as selenium supports the liver and the liver works much harder in heat stress conditions. Because our soils are naturally low in selenium, it’s important to supplement well ahead of summer to build up reserves in cows’ systems.

Other additives:

Ingredients such as seaweed extract, toxin binders, chromium propionate, and live yeast have all clearly shown in trial work to reduce the effects of heat stress in dairy cattle.

Pasture grasses under dry and heat stress are prone to build excessive toxin levels on the leaf. These toxins further exacerbate heat stress in animals. Using a very basic toxin binder can be

a game-changer.

Under heat stress, cows struggle to maintain good rumen balance and function. A live yeast can make a big difference in these conditions.

Timing mineral supplementation

Farmers who start and continue mineral supplementation before and during the hottest months give their cows a better chance at maintaining health and productivity.

Assess mineral levels: Testing bloods and livers will identify any deficiencies early on. Starting mineral supplementation two to three months before the peak heat stress period will give cows time to build up adequate reserves.

Use targeted supplements: Choose mineral blends that are specifically formulated for

summer conditions and dose consistently, especially when pasture quality is low.

Monitor regularly: Monitor cows closely for signs of heat stress and adjust supplementation if needed. Make sure cows always have access to cool, fresh water, as hydration plays a significant role in how well cows can utilise minerals like sodium and potassium during heat stress.

With summer fast approaching, the risk of heat stress becomes a major concern. Getting ahead with mineral supplementation has several long-term benefits for dairy herds, including improved milk production, better reproductive performance, and stronger immune systems.

• Chris Balemi is Agvance Nutrition founder and managing director.

Your milk is your life and your livelihood. You have an entire team to support you to make the most of every drop, and you have the rest of your Co-op behind you. You own this Co-op. You live this Co-op. You are this Co-op.

RENOWNED AS market leaders in the self-propelled forage harvester sector, Claas has used its experience of chopping a wide range of crops on farms worldwide to improve the heart of the machine – the chopping cylinder.

The new cylinder, known as V-Flex, claims to mark a new milestone in chopping cylinder technology.

Initially available on 900 and 900 Terra Trac Series machines as an alternative option to the V-Classic and V-Max cylinders, it is said to offer greater versatility when it comes to knife configuration. In combination with the new knives that it comes equipped with, Claas maintains that it has set new standards for smooth running and knife service life and enhanced chopping quality.

The new design enables higher throughputs, reduces noise levels and ensures smoother running with more consistent crop flow, especially for chop lengths over 12mm. The V-FLEX chopping cylinder is available in four versions, using 20, 24, 28 or 36 knives and can be configured as a full set of knives, half or one third the number of knives, to extend the length of cut, from 3.5 to 53mm.

High knife stability and the triple bolt fastening offers high knife stability, while also allowing the clearance between the cylinder and the shear bar to be reduced to achieve better chopping quality.

Meanwhile, Claas has also reconfigured the knife sharpening operation to make it more user-friendly with the control options for sharpening and shear bar adjustment, able be combined, with the cycle reduced to around one minute. The improvements are said to deliver greater efficiency with further reductions in fuel consumption per tonne of throughput. – Mark Daniel

WHILE ELECTRIC vehicles, despite subdued sales at present, seem to be finding converts in the car industry, one wonders if they have a place in agriculture.

Italy-based telehandler manufacturer Merlo seems to think so. It used the recent EIMA event held in Bologna to showcase the latest concept for its Generation Zero range – the TFe43.7.

Like the currently available e-Worker, the key points for consideration are zero carbon fuel consumption, no noise or vibrations and, of course, no polluting emissions.

It received an Honorable Mention

Award in the event’s Technical Innovations competition, and like its ICE equivalent, the new machine offers a maximum load capacity of 4300kg, combined with a maximum lift height of seven metres, and a road speed of 33km/h.

Featuring a battery pack that is said to offer up to eight hours duration, complemented by a 3.5 hour recharge time, the manufacturer is says the total cost of ownership (TCO), which encompasses the purchase price and total service costs across its lifetime, is significantly lower than the comparative traditional model.

COWS INGESTING metal objects in conserved feed is typically going to end in tears, quite often with a trip to the knacker’s yard.

Fitting a magnet to a mixer wagon auger can help extract these foreign bodies, but bring with them the task of removal, where operators must enter the mixing tub where they are exposed to sharp cutting blades. Additionally, some magnets are so powerful that they run the risk of erasing a chip in a credit card or do damage to a mobile phone. German mixer wagon manufac-

turer Siloking has developed a heavy-duty magnet concept that allows metal objects to be safely removed from outside the tub.

The company suggests this has made the job safer and easier, which seems to have the backing of judges at the recent Eurotier Show in Europe, who awarded the idea a silver medal.

Compared to existing solutions, the magnet is permanently secured to the base of a mixing auger, then shrouded by a stainless-steel housing.

The magnet is said to be

so powerful that nails, mower blades and even tedder tines, adhere to this housing.

In operation, an integrated tool is used to slide out the housing, that when pulled away from the magnet, sees metal objects simply fall off to be collected. When used in a twice-daily feeding regime, the company recommends checking and clearing the magnet once a week.

The option can be fitted to all the firm’s trailed and self-propelled machines, costing around $4,000.

BRITISH BASED JCB recently celebrated the milestone of producing one million engines.

Chairman Anthony Bamford acknowledged the company’s teams around the world, noting that to have made one million engines in 20 years was a major achievement and a significant moment for the business.

“The JCB engine is very well

respected around the world for its reliability and very well appreciated by our customers,” said Bamford.

“Our machines work in dirty, hot and cold climates, and from the moment they go to a customer, they are working hard and doing a full day’s shift. The engine really is the beating heart of that reputation for reliability.”

The first JCB engines were

designed by Lord Bamford’s father, who passed away in 2001 and did not live to see the engines go into full production. Engine production commenced in 2004 at JCB Power Systems in Foston, Derbyshire, in the UK, followed in 2010 by the site in Ballabgarh, Delhi, India. Currently, the company produces a total of around 500 engines daily.

Never far from the record books, JCB engines have featured in a series of world records, including the dualengined Dieselmax Streamliner that still holds the record for the fastest diesel-powered car, reaching a speed of 350.092 mph in 2006 at the Bonneville Salt Flats in Utah. Meanwhile, a JCB Fastrac tractor broke the record for the fastest tractor in 2019,

Introducing the Landquip Lanerotr R1

equipped with a 7.2-litre six-cylinder Dieselmax engine to hit a top speed of 135.191 mph.

More recently, alongside the diesel engines, the company continues to develop a hydrogen internal combustion engine, with around 120 units manufactured, fitted to a variety of machines and currently undergoing long-term evaluation.

The Lanerotr R1, designed with input from dairy professionals, clears laneway edges efficiently, improving drainage and reducing herd lameness. Built tough in Hawke’s Bay, it operates at 1.5 km/h, clearing up to 5 km per day with a quick 5-minute setup. The R1 easily mounts to any tractor with a standard Eurohitch and requires a 50L/m hydraulic flow. Its durable, all-welded construction and American hydraulic motor, with built-in protection, ensure long-lasting performance.

Available now - sales@landquip.co.nz