MOZZ KING

It makes a lot of cents.

Trusted by farmers for effective worm control with NIL MILK withholding periods and improved R.O.I

Studies in NZ dairy cows have shown the potent effects of EPRINEX® on parasites resulted in more daily milk, more milk protein and more milk solids.1,2

A$2b bid for Fonterra’s Oceania assets?

SUDESH KISSUN sudeshk@ruralnews.co.nz

AN A$2 billion bid for Fonterra’s Oceania business would be great news, according to Forsyth Barr senior analyst, equities, Matt Montgomerie.

He told Dairy News that this would imply a higher enterprise value to earnings before interest and taxes (EV/EBIT) ratio - a metric used to determine if a stock is priced too high or too low in relation to similar stocks and the market.

“This would be great news if the valuation is true for Fonterra,” says Montgomerie.

“The issue we have is that Fonterra hasn’t disclosed earnings for Australia and New Zealand – only gross profit and revenue, so this makes it hard for us to have an informed view on the valuation.

“If you pro-rata the $2.2bn based on gross profit share it implies an19x EV/EBIT multiple or 15x EV/EBIT multiple based on revenue share. Both of which are supportive for the top-end or greater of our valuation range for Mainland Group of NZ$2.5bn to NZ$3bn.”

Media reports out of Australia say Bega Cheese and a European dairy co-operative, possibly FrieslandCampina, have made a A$2b bid for Fonterra’s Oceania business.

Montgomerie says Fonterra has a clear preference for selling the entity in one piece.

“At this stage, Bega is only interested in Oceania, but it would be interesting if Friesland Campina is interested in the rest. From the outside, it seems like Lactalis is the front runner, but this is hard to call.”

Fonterra farmers, who will have the final say to approve any sale, are watching the divestment process unfold from the sidelines.

Fonterra Co-operative Council chair John Stevenson says the council doesn’t have any insight into this process.

“So unfortunately, I can’t make any comments at this stage. Fonterra will be best placed to provide answers,” he told Dairy News.

Fonterra’s portfolio in Australia includes the country’s top butter brand, Western Star, and popular cheese brands, Perfect Italiano, Bega Cheese, and Mainland. Lactalis Australia has Paul brands of fresh milk, yoghurt and cream plus several top selling brands of flavoured milk and cheese.

The Bega bid means there could be a three-way battle for Fonterra’s assets. The world’s largest dairy company, Lactalis cleared a major hurdle last month when the Australian Competition and Consumer Commission (ACCC) indicated that it would not oppose Lactalis’ proposed acquisition of Fonterra’s con-

sumer, dairy ingredients and food service businesses. The third player making a bid is Japanese food company Meiji Holdings.

However, the green light from the ACCC puts Lactalis Australia at the front of the queue.

Lactalis and Fonterra both currently acquire raw milk from dairy farmers in Victoria and Tasmania, as well as processing and supplying a range of dairy products across Australia. The ACCC decision means there are no regulatory hurdles for the acquisition.

“We looked very closely at the transaction as it will combine two of the largest buyers of raw milk in Victoria and lead to some further consolidation in Tasmania,” ACCC deputy chair Mick Keogh says.

“While we acknowledge the concerns raised by some representative bodies after careful consideration, we have determined that the acquisition is unlikely to result in a substantial lessening of competition.”

The ACCC found that across Gippsland, the Murray and Western Victoria, alternative buyers of raw milk would continue to constrain Lactalis if the acquisition proceeded.

“We found that while the industry in Tasmania is already concentrated, Lactalis has a limited presence and the acquisition would not substantially alter the market dynamics. If the acquisition proceeded, Lactalis would continue to be constrained by Saputo and, to a lesser extent, Mondelez,” Keogh says.

Fonterra explains why butter prices are high. PG.07

Matt Montgomerie, Forsyth Barr.

Fresh is best, says awardwinning cheesemaker

MISSING FRESH moz-

zarella cheese made at home in Bari, southern Italy, Massimo Lubisco and his wife Marina decided to bring a taste of home to New Zealand.

In 2010, the couple rented a small, licensed cheesemaking facility in Auckland to churn out fresh, authentic Massimo’s Italian cheeses.

Lubisco recalls that it was all about making small batches of mozzarella and selling them on weekends at farmers’ markets around the city. The fresh cheeses, uncommon in New Zealand at the time, were turning heads. Soon restauranteurs and retailers were asking him for cheese.

Sensing a market for fresh Italian cheeses, Lubisco set up a cheese factory at Dairy Flat, north of Auckland, and decided to focus on mozzarella.

“Because I didn’t have many customers and orders for big volumes back then, I had more time to play with the milk and do different things,” he told Dairy News.

“I was doing other cheeses, like Provolone or Blue: then I stopped,

because my business was growing.

“I decided to concentrate only on the mozzarella because you can’t mix cultures: if you do blue cheese, you can’t do mozzarella. Also, there’s a risk of contamination. Mozzarella is quite a delicate cheese, so it can’t be done together with other cheeses.”

Massimo’s is the country’s only supplier of fresh cow milk mozzarella. Today, the business employs 12 full-time staff and its product range includes the 1kg mozza-

rella log, burrata, ricotta and bocconcini. About 50% of the products are sold through retailers while the rest is sold directly to the food service sector.

The company has picked up NZ Champion Cheesemaking Awards medals every year since 2012, when it won a gold for its ricotta and a bronze for its mozzarella. This year it won gold medals for burrata, burratina, mozzarella, bocconcini, cheery bocconcini, stracciatella and ricotta. Mossimo’s quality

has also garnered recognition on the international stage. Last year it won gold for mozzarella log at the International Cheese and Dairy Awards in Staffordshire, UK. This year, Massimo’s picked up two gold medals – for the log and burrata – and a bronze for tub mozzarella. Over 9000 cheeses entered the competition.

Lubisco says he was pleasantly surprised by the medals won in the UK this year. Mozzarella is best served fresh and with entries taking 10 days to reach the UK, he

wasn’t sure about the flavours being retained.

“We submitted three entries. I was confident of the mozzarella in brine, but the log doesn’t sit in water, so I was worried that it might lose its flavour.

“However, even after taking 10 days to reach the UK, winning the gold medals was a good surprise for the team.”

Lubisco says the medals is a testament to pure NZ milk and the hard work of Massimo’s team.

“We have no preser-

FROZEN IMPORTS

MASSIMO’S SOURCE milk from Fonterra under the Dairy Industry Restructuring Act (DIRA), where the coop is required to sell raw milk to smaller processors.

Fonterra tankers deliver the milk to Massimo’s plant in Dairy Flat, north of Auckland.

The milk is pasteurised and turned into mozzarella cheeses and delivered to retailers within 48 hours.

Massimo Lubisco says fresh, not frozen, is the biggest point of difference between Massimo’s products and competing imported products.

Lubisco says with high production and labour costs, NZ fresh cheeses are unable to compete with frozen overseas products.

He says there’s a need to highlight the difference between fresh local cheeses and frozen overseas ones.

“But you don’t see anything on the shelf - it’s not written that it’s frozen, you buy without knowing.”

vatives in our product, no additives, no fat, only pure milk.

“So, it’s recognition of local milk and our hard work, and our good recipes. It also shows us that we are on the right track and delivering excellent products to New Zealanders.”

From the early days of selling small batches of cheese at farmers’ markets to becoming NZ’s fresh cheese specialists is a great achievement, something Lubisco says wasn’t easy and something he had never dreamt off. He adds that educating NZ consumers about fresh cheeses has been part of the journey.

“It’s a good achievement; I always knew that

if you do a good job, you get results.

“However, at the beginning, everybody was saying, ‘you know, this is New Zealand, it’s not like in Italy’. When we started selling at the farmers’ markets, fresh mozzarella was new to the country,” he says.

“People were not accustomed to this delicate, milky flavour. New Zealanders are used to stronger flavours like cheddar and blue cheeses. After tasting mozzarella, people were saying, ‘oh, there’s no flavour in it’.

“It was a long process to educate people, pointing out to them the similarities between fresh milk and fresh product we make.”

Massimo’s Italian Cheeses owners Massimo and Marina Lubisco.

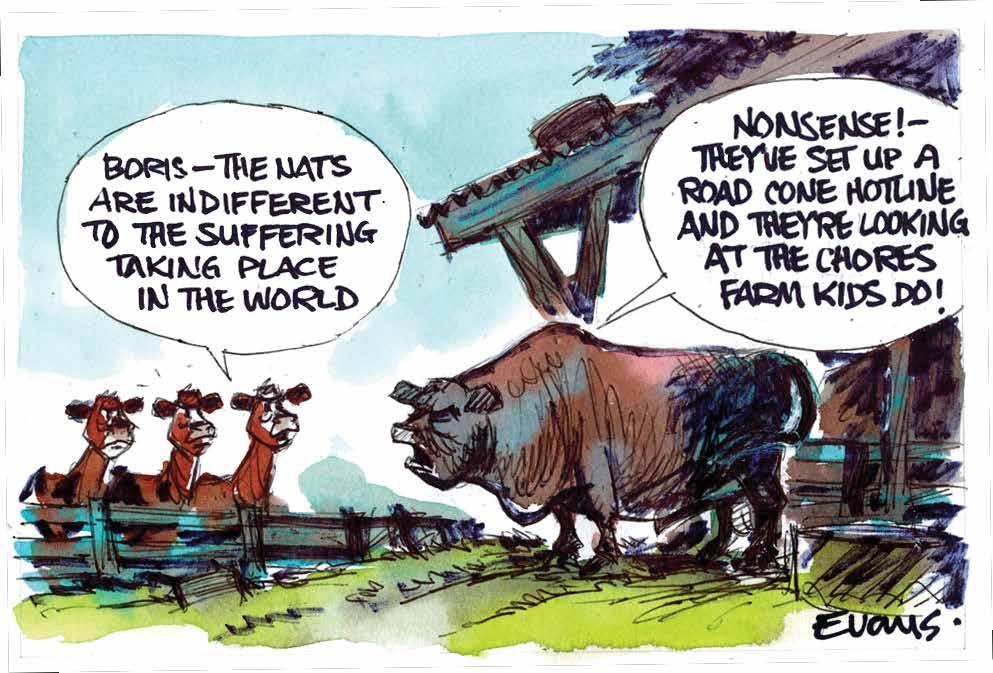

Farmers welcome ‘practical farm safety reforms’

FARMERS ARE welcoming new Government proposals to make farm health and safety rules more practical and grounded in real-world farming.

The Government last week announced targeted consultation with farmers and the wider agriculture sector on health and safety rule changes.

Many of the proposed changes reflect what Federated Farmers and its members have been calling for, health and safety spokesperson David Birkett says.

“We’re really pleased the Minister has announced a raft of changes, and that she’ll be consulting directly with our sector to make sure any new rules are fit for the realities of farm life.

“This commitment to targeted consultation is a good sign farmers will be properly heard.”

Workplace Relations and Safety Minister Brooke van Velden says she’s consulting with rural Kiwis in the agriculture sector on changes that will ensure health and safety requirements are workable and practical.

“Farmers know their farms and the risks that come with farming life better than anyone. They’ve told me the law needs to recognise that the farm is often both their workplace and their home. That includes making space for children to safely learn and contribute to farm life in ways that are safe and age-appropriate,” says van Velden.

Rural Women NZ says the consultation recog-

nises what rural families have been saying for years – farms are not just workplaces, they are homes and family businesses too.

“The Government’s review reflects the real lives of many rural families and the fact the farm is a home where children grow up immersed in the rhythms and responsibilities of farming life,” says Rural Women New Zealand national president Sandra Matthews.

One proposed change is to amend the General Risk Regulations to make it clear that young people can safely take part in light chores on family farms.

“We’ll be consulting with farmers and the agriculture sector on the thresholds for light chores children can do on farms, like collecting eggs, feeding small animals and watering plants, while ensuring safety is not compromised,” she says.

“I expect higher-risk activities such as being near heavy machinery like a hay baler will remain off-limits. As children grow older, they’ll be able to undertake more complex tasks with supervision and training, such as driving a tractor.”

WorkSafe will be developing an ACOP on roles and responsibilities in agriculture to help farmers navigate work activities. In particular, it will provide clearer guidance on overlapping duties and PCBU responsibilities in agriculture.

“Farmers and other businesses coming on to the farm need to know what health and safety duties they are each responsible for

and how they can best work together to manage the risks. For example, if a fencing contrac-

tor is working on a farm, both the contractor and the farmer will need to manage risks relating to

their work, like moving vehicles or the use of agricultural sprays,” says

Real gains come from insights you can action all year

Insights to identify at-risk cows early

Tools to get them back on track

Data to make sure your season’s moving in the right direction

“Great mating results don't happen in isolation. It's understanding how cows recover, and feeding them well consistently. Every day you can look at your numbers in Halter and if they’re not on track, you can do something about it.”

John Glass, Northland | 380 cows Lifted 6-week in-calf rate from 70% to 81% in 2 seasons with Halter M Milkers 11 kg DM/cow

van Velden.

Workplace Relations and Safety Minister Brooke van Velden.

When dairy does well, NZ does well

DAIRYNZ CHAIR Tracy Brown has waded into the debate around soaring butter prices, pointing out that the demand for dairy overseas dictates the price to farmers and at the supermarket.

In an op-ed issued by DairyNZ, Brown says it’s unique New Zealand story – when an export does well, it’s good for the economy but unfortunately tough for locals.

“Cyclical food price stories are a reminder that 95% of our dairy products are exported, which means we pay international prices locally,’ she says.

“I buy butter too, so I can appreciate that double edge very well, as can every dairy farmer across New Zealand. Every farmer can also appreciate the increasing cost of farming inputs, which puts pressure on

our margins as well.”

Butter prices have dominated news headlines with Fonterra under pressure to explain why New Zealanders have to pay exorbitant prices for butter produced locally.

Brown says while these stories come and go, they remind us of what we’re good at as a country.

“We earn our living on exports – mostly food and fibre and of those, mostly dairy. $27 billion over the past year alone.

“That’s income for the Government in tax take, which gives us the public services we rely on like our schools, our hospitals, and our roads.

“We received a cheeky thank you from an MP at our Farmers Forum recently for the extra addition to their tax coffers this year as the

“We earn our living on exports –mostly food and fibre and of those, mostly dairy. $27 billion over the past year alone.”

sector delivers well for the country,” she says.

New Zealand’s economic recovery is being led out of the regions, by the 360,000 people working in the primary sector, of which 50,000 work in dairy, in a country of over 5 million.

Brown says that’s been the case before and it will be the case again.

New Zealand dairy farmers have tackled

Save on growing cost. Gain on yield.

Located in Korakonui some 20 km south of Te Awamutu, Chris and Jude Stacey, alongside their children Tom and Stella, farm this top performing 155 hectare dairy platform with 450 crossbred cows.

To ensure they have enough feed for the summer, the Staceys grow a range of crops, including fodderbeet which is a perfect supplementary feed late in summer and early autumn.

Like many farms, the main challenge with growing fodderbeet is the weed burden and gaining control of it. And this is where the CONVISO® SMART System impresses Chris.

Chris explains:

“I’ve been very impressed using the CONVISO SMART System. There’s no need for plant checks after the spray. It’s been very simple to use the two post-emerge sprays. The crop has been very clean, and has yielded very well, so I’m very happy with it.”

challenges head on over the past decade, including biosecurity incursions, more extreme weather events and regulatory uncertainty.

Over the past decade too significant strides have been made on reducing environmental footprint to ensure we remain competitive

When it comes to weed control, Chris reckons the CONVISO SMART System performs well at the initial knockdown and the residual weed control.

“We’ve been able to control Amaranthus or Red Root, which in the past we’ve had issues with that weed in our crop. I’ve only had to spray it three times with this system and at a reduced cost.”

The herd also loves the beet and they find the grazing easy, getting the beet out of the ground with little effort and leaving very little behind –with 95% utilisation.

While this is just his first year using CONVISO SMART, Chris is pretty sure it’s already paying dividends.

“The system is fairly priced, with the seed and the chemistry. I think we’ve definitely saved money on our growing costs, and we’ve gained yield, so our cost per kg of dry matter grown, is lower.”

among the most sustainable and low-emissions farmers on the planet.

All of this equals demand for NZ dairy on the world stage, Brown says.

“It also ensures we benefit from a growing global appetite for more natural and nutritional food and fibre that comes from responsible sources.

“I recall it wasn’t that long ago that butter was very unfashionable and deemed unhealthy, and so it follows that the swing back to more natural products has driven the increased demand and subsequent increase in price.

“While the world shouts for our butter, let’s remind ourselves at home the reasons why New Zealand dairy is a world-class exemplar and so in demand:

■ We export most of

what we produceso we are exposed to world trade and must be customer focused.

■ We are primarily family businesses and farmer-owned cooperatives - and that drives values-led innovation.

■ We have a temperate climate where we grow pasture welland that is the ultimate starting point for this story.

■ We are unsubsidised. We have to make a living at world prices competing against the best.

“Therefore, our pasture-based dairy farming system delivers highly nutritious milk, with a comparably low environmental footprint, and happy cows who graze outdoors.

“A story that has clearly spread around the world,” says Brown.

Chris Stacey, Dairy Farmer - Korakonui, Waikato

SCAN TO LEARN MORE ABOUT CHRIS STACEY

DairyNZ chair Tracy Brown says she buys butter too and appreciates that double edge very well.

Fonterra explains why butter prices are so high

Kiwis love their butter, and that’s great because New Zealand produces some of the best butter in the world. But when the price of butter goes up, it’s tough for some, particularly when many other grocery staples have also gone up and the heat goes on co-operative Fonterra, the country’s main butter maker. Here the co-op explains why butter prices are so high right now.

THE MAIN driver of the price consumers ultimately pay for butter is global prices.

Now, these prices are the highest they’ve been in more than five years. Strong global demand is one of the factors influencing the wholesale price of butter.

Retailers ultimately set the shelf price, but companies that sell to them buy butter at a wholesale price driven by the globally traded price from Fonterra and other suppliers.

So, who sets the global price? The global price of butter reflects demand from around the world, from China to the Middle East, and also the supply from butter exporters, not just in NZ but globally. Like other globally traded products – like coffee – global dairy prices go up and down. Why doesn’t domestic demand set the price?

New Zealand exports 95% of all its dairy products and sells products like butter to all its customers – whether they’re based in New Zealand or offshore – largely at the same price. This means the international market for dairy sets our price in New Zealand.

In some countries larger than New Zealand, where their dairy products are largely consumed domestically rather than exported, the price of their products is determined by domestic demand rather than global demand. Why can’t we sell it to New Zealanders for less?

As a farmer owned cooperative, Fonterra’s role is to collect, process and sell farmers’ milk to customers here in New Zealand as well as globally, working to get the best

price they can for their farmers. Selling it for less would mean a business choosing to sell at a loss or giving a subsidy. That’s not a sustainable model for any business long term, particularly when they compete in global markets.

Is butter cheaper in supermarkets overseas?

It’s not always. And it’s really important that when prices are compared, currencies are converted so we’re looking at like for like. It’s also important to consider if the butter is in the same size format for example, in some other countries, 250g blocks are more common than the 500g seen in New Zealand.

The difference in price can be driven by a number of things, including whether the price is set by the international market or domestic market.

Tax is also applied differently in different markets. For example, in Australia they don’t have GST on butter. If you take GST off the New Zealand price and convert it to New Zealand dollars, a similar block of butter is often cheaper in New Zealand than in Australia. How is the cost of NZ butter made up?

Fonterra is focused on keeping the costs they can control as efficient as possible.

The cost of butter varies between different brands and formats. However, if we take a 500g block of butter that’s being sold for $8.60 around 80% of this cost comes from the global butter price, and the cost to cut, wrap, store and distribute the product to the retailer.

Then there’s the margins added by producers,

distributors and retailers, plus all the costs to get the product from the distribution centre and onto

the retailer’s shelf, and finally GST is added onto this to come to the final selling price.

Take control of your mating season.

CIDR® Cattle Insert. NZ’s #1 repro device*

Take control of your mating season and maximise your herd’s reproductive efficiency with the trusted, Kiwi-made CIDR® from Zoetis. It’s the cost-effective, vet preferred tool proven to tighten calving spread and produce more days in milk.

Talk to your local vet about boosting your productivity and profitability.

New Zealand sells products like butter to all its customers – whether they’re based in New Zealand or offshore – largely at the same price.

Time to rein in Greenpeace

FEDERATED FARM-

ERS is renewing its call for Greenpeace to be stripped of its charitable status immediately, following the activist group’s latest publicity stunt.

In the early hours of July 22, members of Greenpeace used a cherry picker to hang cartoon crosses over the trout statue in Gore and hung a sign over the town’s ‘Welcome to Gore’ sign, adding ‘Where Dirty Dairy Wrecked The Water’.

This was after a do not drink notice was issued on July 18 after nitrate levels in the water supply exceeded legal limits, which Greenpeace blames on the effects of dairy farming in the region.

Southland Federated

Farmers president Jason Herrick said that Greenpeace needed to be held accountable “for their repeated illegal activity and the spread of harmful misinformation” - not just limited to the recent actions in Gore.

Charitable status in New Zealand is intended to support organisations that advance public benefit through education, relief of poverty and other recognised charitable purposes.

Under the Charities Act, organisations must operate for the public good and not primarily serve political or advocacy purposes.

Herrick says he sees Greenpeace’s ongoing activities as clear evidence that it no longer meets these criteria for charitable status.

In April,, Federated Farmers called for the

Government to strip Greenpeace of its charitable status after the group’s occupation of Port Taranaki.

At the same time, Federated Farmers lodged a formal complaint with the Charities Services requesting an inquiry into Greenpeace’s conduct and eligibility for chari-

table status, focusing on Greenpeace’s ‘repeated involvement in premeditated unlawful protest activity’.

This included a 2024 protest at Fonterra’s Te Rapa dairy factory where seven individuals were arrested, and last year’s occupation of Straterra’s Wellington office where

five were arrested during a staged lockdown.

“Storming offices, intimidating people who thought they were in a safe workspace, defacing public property… a charitable organisation should not be behaving in the manner that they’re behaving,” said Herrick.

“How can they be recognised as a charity under the requirements of the Charities Act 2005 when they’re breaking all kinds of laws? It sends a poor message that anyone who wants to deface public property can plead that they’re protesting as an example.”

Herrick says Greenpeace’s vandalism was a “shameless attempt” to divide the small rural community, which relies heavily on the economic impact of dairy farming, and to spread anti-farm-

ing propaganda.

“Farming plays a huge role in not only our local economy, but in our social fabric too. Misinformation can cause disruption and mistruth out there by targeting a specific group like dairy farmers – that can have a flow on effect by the public perception. We’ve heard enough of that over the last 3-4 years.”

Although no permanent damage was caused to the statue and sign and no-one was hurt, Herrick explained that there was easily room for things to go wrong, with materials used to stick protest signs up having potential to cause damage and the use of cherry pickers at height without supervision could have led to injury.

“There’s no proof that dairy farmers were the cause of the high nitrates

in the well that was affected.

“There are opinions out there and protest, no two ways about that, but Greenpeace overstepped the mark while threatening livelihoods with misinformation about farming.”

However, Herrick says it’s not just Greenpeace that needs to be held accountable for how it’s operating as a charity, with the Charities Services and the Government needing to be held accountable too and answer some “tough, but fair, questions about how this is being allowed to continue”.

A copy of Federated Farmers’ complaint has been sent to Community and Voluntary Sector Minister Hon Louise Upston and Minister of Internal Affairs Hon Brooke van Velden.

BIRDS WRECKING

• Nationwide Firestone trained and accredited installation contractors.

• Future proof - dependable performance, 50 year life expectancy even when exposed, 20 year Firestone material warranty

• Over 120 million square meters installed worldwide.

• 30 years in the NZ lining business.

Jason Herrick

Experts highlight need to restore Waikato lakes

WAIKATO IS home to a diverse range of lakes, and experts say they urgently need better management and restoration.

University of Waikato freshwater scientist Dr Deniz Özkundakci says “a lot, if not most” of the hundreds of lakes in the region are significantly degraded and in urgent need of action to protect and restore their health.

“At the same time, we have some truly hidden gems – lakes that rank among the best in the country. The region includes the full spectrum of lake condition, from outstanding lakes to some of the most degraded,” he says.

The findings are part of a newly released book, a joint venture by the University of Waikato and the Waikato Regional Council.

Lakes often hold strong emotional value for people, whether it be childhood memories of learning to swim, fishing or water skiing to summer holidays with family, Özkundakci says.

However, farming and urban development has resulted in several lakes being much smaller and shallower than they were in the early 1900s.

Water quality remains one of the biggest concerns.

“Most of the lakes are all enriched in nutrients, particularly phosphorus and nitrogen from farmland runoff, causing algae bloom and turning the water a bright green and making it smell bad,” he says.

“In some lakes, aquatic plants have disappeared entirely. Where plants remain, they’re often overrun by invasive species. We’ve also lost many lake birds that relied on native plants and the food they provided.”

But it’s not all doom and gloom, says Özkundakci, who noted that many community groups have started to get involved in restoration efforts.

However, he says that “while promising efforts are underway, scaling

them up will be essential to deliver the widespread impact that is urgently needed”.

Özkundakci also notes that many of Waikato’s hidden lake treasures are tucked away on private land and far from major roads or access points, making them largely unknown and inaccessible to the wider public.

“People often don’t even know these lakes

exist, and many of the really beautiful ones are located on private property,” he says.

“This makes it very difficult to access them and work on protecting these valuable ecosystems.”

Özkundakci says there are examples where lake health has improved when the right work has been done.

“Improvements are always possible if enough resources are put in. But often the limiting factor is the lack of resources like people power and money. At some point though, we need to have honest conversations about priorities.

“Every time we come to a lake, and we talk to the local community, they say that giving up is not an option for us – I know that” he says. “At the same time, several contributors to this book have made it clear just how difficult it will be to restore all of the lakes.”

He emphasised the importance of ongoing dialogue and collaboration, while also acknowledging the challenges.

“There is recognition that restoring ecosystems requires both scientific insight and inclusive governance,” he said.

University

Dr Deniz Ozkundacki

of Waikato freshwater scientist

Dr Deniz Ozkundakci says many waterways in Waikato are in urgent need of protection.

DISCOVER GENETICS FIT FOR YOUR PURPOSE.

nProve makes it easier to find the best genetics for your herd. Using a series of buttons and slider scales, the free online tool finds beef stud breeders who rank highly in the traits important to you.

The Beef-on-Dairy (NZ$BeefxDairy) index created by Beef + Lamb New Zealand is designed for mating beef bulls with dairy cows to produce beef-cross calves.

It prioritises calving ease and gestation length to ensure dairy cows can safely calve beef calves and maintain a calving period that fits the dairy herd’s schedule. It also promotes the production of calves that grow well and meet beef market specifications.

Getting started is easy, you can jump straight in and you'll find helpful tips to guide you along the way

give farmers a reliable system that works for their farm, saves them money, and sets them up for the future.

“Most farms can expect a payback time of around 2.5 years, depending on their current energy use and system setup,” says Papa.

“The Government’s new Investment Boost tax incentive could also help farmers invest in technology like this.”

Unlike traditional electric systems, Eco2Energy’s CO₂ technology gets more heat from less power, delivering up to 3.9kW of heat using just 1kW of electricity.

It runs on natural CO₂

Donovan spent 26 years dairy farming and 18 years with Ecolab helping farmers improve milk quality through better hygiene systems. He knows just how critical reliable hot water is to maintaining milk quality.

“If your plant or silo wash doesn’t reach the right temperature, you risk leaving behind residues or bacteria that can compromise the next milking. That can lead to costly milk quality downgrades.”

“Getting it right helps protect milk quality, keeps things running smoothly, and takes one more pressure off during a busy time like calving.”

Right supplements help smooth calving

THE CALVING season brings with it significant nutritional demands on the herd.

And mineral supplements manufacturer C P Lime says meeting these demands with effective and targeted mineral supplementation is key to reducing clinical issues and enhancing productivity.

It says the use of its product Vitalise — a pelletised mineral supplement — is proving to be an innovative and practical solution for supporting herd health throughout this critical period.

The company says conditions like milk fever (hypocalcaemia), grass staggers (hypomagnesaemia), and facial eczema are prevalent across New Zealand dairy herds.

“Most farmers will

experience at least one of these each season. While emergency supplementation during calving is standard practice, prevention is always preferable.

“Good mineral supplementation doesn’t just address visible health issues — it also supports cows at a sub-clinical level, helping maintain production and fertility even in the absence of outward symptoms. Waiting until blood tests reveal a deficiency often means the damage to milk production and long-term health has already been done.”

Vitalise provides more than just calcium and magnesium – it provides comprehensive nutritional support. It can be custom blended with essential trace elements like copper, cobalt,

iodine zinc and selenium, depending on specific herd requirements and seasonal challenges such as mating or facial eczema risk periods.

For herds on fodder beet diets, Dicalcium Phosphate can be added

to prevent low calcium and phosphate levels, a common risk.

Biotin can also be a useful addition for skin and hoof health, and yeast cultures to improve rumen health.

Monensin, another

23 Triangle Road, Waimate - “Mariposa Farm”

additive option, improves rumen function and supports optimal cow condition, reducing issues like ketosis and bloat while enhancing in-calf rates and protein production.

The company says Vitalise’s pellet form

pellet form ensures every cow receives an accurate dose, reducing waste and cost.

ensures every cow receives an accurate dose, reducing waste and cost.

Its versatility — from standard to custom blends — and seamless integration into in-shed systems make it an ideal tool for modern dairy

farming, it adds.

“It is 100% utilisable, ensuring accurate dosing either via a mineral dispenser or by pre-blending with your local feed supplier. Our ethos is “little and often,” with easily adjustable dose rates to meet seasonal herd needs.

“Whether you’re preparing for calving, navigating mating, or simply maintaining optimal herd health year-round, Vitalise delivers the right nutrients at the right time.

“With over 10 years of proven performance, Vitalise is more than a mineral supplement; it’s a proactive solution to improve animal welfare, reduce stress during calving, and optimise farm productivity all season long,” the company says.

On offer is an outstanding dryland dairy farm totalling 466 hectares (approx.). Located beneath Mt Studholme, 10 minutes out of Waimate in the renowned summer safe area of Hunter. This property was converted in 2009 by the Vendors to a very high standard with excellent infrastructure. It’s on 3 titles and is flat to easy rolling contour with some steeper back sidlings. Soils are predominantly Claremont Silt Loams. Supplying Oceania Dairy, the last six seasons average production totals 330,000 KG/MS from an average peak milk cow numbers of 800. Historically the cows have been wintered on farm and young stock off the property after weaning. Cow number have been increased to 860 wintered for the current season. The farm is well laid out with a central 54 bail rotary shed with cupremovers and auto drafting and a 600 cow rectangle yard. A central loop lane to all paddocks, which all have 2-3 troughs makes management easy. The farm includes a renovated 3 bedroom plus office main homestead, 4 bedroom second home and 2 other staff houses. Improvements and features include a 54 bail rotary shed, 40T wheat silo and crusher, in-shed molasses and PK feed system, covered palm kernel bunker, 7 robotic calf feeders capable of rearing 200 calves, cattle yards, numerous hay sheds and calf sheds, pine plantings on ineffective back faces and halter towers and collars. Retiring Vendors have set the farm up well and will allow a walk in walk out, going concern. A viewing will confirm the quality and opportunity on offer. Call the Sole Agents Ian or Greig Moore for a viewing and the price expectation.

Greig Moore 027 205 9702 greig@redhotrealestate.nz

Vitalise’s

Cynical politics

THERE IS zero chance that someone who joined Fonterra as a lobbyist, then served as a general manager of Fonterra’s nutrient management programme, and sat on the board of Export NZ, a division of lobbyist group Business New Zealand, doesn’t understand that local butter (and milk and cheese) prices are set by the international commodity price.

So, Finance Minister Nicola Willis’ little game, implying that the co-op might be cranking the domestic price up, and that she was going to meet with CEO Miles Hurrell to discuss it, was pure political theatre – and cynical politics, at that.

This led to the ridiculous spectacle of TVNZ’s lightweight ‘political editor’ trying to doorstop Hurrell on the 6 o’clock news about why butter costs so much. Everyone uses dairying as a whipping boy. It’s deeply disappointing to see Willis doing the same thing.

Taxonomy talk

IS THE Government’s taxonomy proposal dead in the water?

ACT won’t back making the proposed sustainable finance taxonomy – a classification tool giving banks and investors guidance on how farms are delivering on sustainability – mandatory.

As ACT agriculture spokesman Mark Cameron says: “the whole idea is about of slapping farms with a red, amber or green label so the banks know which ones tick the ‘right’ boxes, according to Wellington-approved definition of what’s ‘sustainable’.”

Cameron says it might sound harmless if it stays voluntary.

“But the proposal spells it out: the plan is to make it mandatory down the track. That’s where ACT says no.”

Synlait snag

CANTERBURY MILK processor

Synlait’s recovery seems to have hit another snag.

The listed company, majority-owned by China’s Bright Dairy, says manufacturing challenges at its Dunsandel plant are going to hit its full-year bottom line.

However, newly appointed chief executive Richard Wyeth remains upbeat. He says the 2025 full-year result would be a “marked improvement” on last year. The net loss for the year to the end of July is now forecast to be between $27 million and $40m, as opposed to a $182m net loss last year.

However, manufacturing challenges at its Dunsandel facility across a range of product segments will result in one-off costs in FY25.

Synlait has faced a slew of problems – from manufacturing overcapacity to a costly spat with its second largest shareholder and key customer a2 Milk Company.

Wyeth, an industry veteran, is leading Synlait’s recovery. He started in the role 10 weeks ago.

Fatberg

SYDNEY HAS a $12 million milk disposal problem. Figures reported by the Sydney Morning Herald show Sydney Water has spent A$11.7m ($12.8m) to manage more than 11,000 clogs in its network in the past year, caused by the buildup of fats. As a result, Sydney Water is asking people not to pour milk down the sink. The fat in milk is the problem, as it can combine with other material to form ‘fatbergs’ – a large, congealed mass of solid waste found in sewer systems. Ben Hodgson-Armstrong of Sydney Water told the Sydney Morning Herald that fats in dairy products, such as milk, solidify and can end up sticking to the walls of pipes. Stuff reports that in 2022, Water New Zealand estimated that people flushing what they shouldn’t, cost New Zealand at least $16m a year to unblock pipes.

THE GOVERNMENT has been seeking industry feedback on its proposed amendments to a range of Resource Management Act (RMA) national direction instruments.

And from submissions received from the main players – DairyNZ, Federated Farmers and Beef + Lamb NZ – the proposals are getting qualified support from farmers.

However, the devil is always in the detail. While proposals like updates to Te Mana o te Wai, simpler wetland rules, a review of nitrogen limits, and more flexible ways to set freshwater objectives could reduce red tape, farmers are hoping that for rules that are practical and workable on farm.

DairyNZ is advocating for change that reflects on-farm realities and builds confidence for the future. DairyNZ has spent the past year preparing to provide a workable replacement to the existing policy. It says its team has developed an alternative freshwater framework to support a constructive, science-led response.

Federated Farmers is signalling broad support for the Government’s proposed direction. It says New Zealand’s freshwater rules have become too complex and are completely unworkable - a nightmare not just for farmers, but also for local councils tasked with the unenviable job of trying to untangle a bureaucratic bird’s nest of rules - and implement them.

“Rules like the fertiliser cap, wetland definitions and the application of Te Mana o te Wai should be on the chopping block for repeal or major amendment.”

Beef + Lamb NZ says a community-driven, targeted, and risk-based approach is crucial to balance the economic viability of farming businesses with environmental sustainability.

It’s critical the Government get these proposals right – farmers desperately need robust, inexpensive and uncomplicated frameworks for freshwater and the wider environment that deliver enduring, but also reasonable and affordable, outcomes.

Head Office: Lower Ground Floor, 29 Northcroft St, Takapuna, Auckland 0622

Phone 09-307 0399.

Postal Address: PO Box 331100, Takapuna, Auckland 0740

:

by: Inkwise NZ Ltd Contacts: Editorial: sudeshk@ruralnews.co.nz

material: davef@ruralnews.co.nz Rural News on-line: www.ruralnews.co.nz

Subscriptions: subsrndn@ruralnews.co.nz

Publisher: Brian Hight Ph 09-307 0399

General Manager: Adam Fricker Ph 021-842 226 Editor: Sudesh Kissun Ph 021-963 177

Machinery Editor: Mark Daniel Ph 021-906 723

markd@ruralnews.co.nz

Reporters: Peter Burke Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech Ph 021-190 3144

Production: Dave Ferguson Ph 027-272 5372

Becky Williams Ph 021-100 4831

Digital Strategist: Jessica Marshall Ph 021 0232 6446

AUCKLAND SALES CONTACT: Stephen Pollard Ph 021-963 166

Methane campaign is 100% politics

WE ARE endlessly told that livestock are responsible for half of New Zealand’s total emissions. Despite research showing the warming impact of livestock methane is so small it cannot be measured; the widespread perception remains that our livestock are dangerously warming the planet. So where does this belief come from?

Ask our industry lead-

Even if they manage a 6-month version, each 30-month steer would need four doses, its mother two. At $20 a capsule—an estimate not denied by officials—that’s $120 per steer, before on farm costs. They claim it might improve productivity by 5%. A 300 kg steer would need to fetch $8/kg just to cover the capsule cost, never mind everything else. The only guaranteed result? More food inflation, already a growing crisis.

The question no one

There is no science in this methane reduction campaign. It’s 100% politics, —part of a long-term agenda to consolidate global control.

ers or processors how much warming our livestock cause, and they’ll often quietly admit: “not much.” Press them further - Then why do we need to act - and the reply is always the same: trade pressures or customer expectations, usually meaning supermarket buyers seeking to meet their Scope 3 emissions targets. Ask why they don’t push back, and the excuses roll in: “It’s too hard” or “It would cost too much.”

In other words, it’s easier to throw farmers— their suppliers and shareholders—under the bus than it is to defend the truth. These same leaders are happy to cosy up to Government and commit millions of farmer money to AgriZero, chasing ‘tools’ to reduce livestock methane—emissions which cause no significant warming.

One of these technologies received a funding boost back in May. It involves daily feeding— completely impractical for New Zealand’s freerange, grass-fed systems. In other words, it would hand our competitors an advantage based on solving a non-problem. A monthly delivery version is in development, which would mean wrestling large cows 12 times a year. Are any farmers going to buy into this nightmare?

global control.

If you value your land, your freedom and your future, then you must stand up to our industry organisations, our processors and banks and demand they stop giving

has answered is this: how can we use these synthetic interventions without compromising the integrity of our worldleading, natural, grassfed product? At least one processor won’t accept cattle for a premium brand if they’ve grazed on oat crops that have begun to head—because that counts as grain-fed. So how will consumers respond to chemically dosed animals?

We already know. Look at Europe’s backlash against Bovaer. Consumers aren’t demanding methane cuts, despite what the hysterical media say. So where are these ‘customer demands’ really coming from?

The answer? The global elite. Let’s step back. To bring in a One World Government, you need to control three things: money, people, and food. The money supply is already in global hands. The COVID-era showed just how easily people can be controlled. That leaves the food chain.

This methane narrative is an ideal tool to make natural, nutritious food unaffordable and unavailable to ordinary people.

There is no science in this methane reduction campaign. It’s 100% politics, —part of a long-term agenda to consolidate

into political correctness while our industry, our nation and the farming communities that underpin them slowly die.

• Neil Henderson is a founding member of Methane Science Accord.

NEIL HENDERSON

The methane narrative is an ideal tool to make natural, nutritious food unaffordable and unavailable to ordinary people.

Reproduction starts in the liver

THE LIVER doesn’t often get the attention it deserves.

Tucked behind the rumen and largely invisible to farm-level observation, it quietly carries the burden of converting nutrients, detoxifying metabolites, and producing energy in the form of glucose to fuel lactation. But during early lactation, when energy demands are highest and intake is lagging, the liver is often overwhelmed. When this happens, fertility can suffer.

It’s time we looked at ketosis not only as a milk production or animal health issue, but as a reproduction issue too. Without a functioning liver, you won’t get functioning ovaries. The hidden chain reaction

During early lactation,

the cow enters a state of negative energy balance. She can’t eat enough to support her output, so she starts mobilising body fat. This fat is converted into non-esterified fatty acids (NEFAs) and sent to the liver for processing. In a well-functioning cow, the liver turns NEFAs into usable energy or exports them as fat. Reductions in liver performance are a common problem across many herds during early lactation when maximum liver capacity is of utmost importance. In cows where the liver is not fully functional, NEFAs are not efficiently utilised, leading to the production of ketone byproducts such as betahydroxybutyrate (BHB) and acetoacetate. This is ketosis in action.

When this imbalance continues, the cow’s immune system weakens, milk production drops,

and ketosis, either clinical or subclinical, can set the cow up for fertility issues later on. Ketosis interferes with calcium metabolism and disrupts insulin signalling, which can lead to suppression of ovarian function, delayed estrus,

and an increased risk of early embryonic loss. Ketosis isn’t one thing

Not all ketosis is created equal. Ketosis can be categorised into three nutritional causes:

• Type 1: Poor nutrition – Often from low

propionic acid or amino acid intake. These cows are not getting enough nutrients from their diet to meet glucose requirements.

• Type 2: Fat cows –Over-conditioned cows which have mobilised too much fat, overwhelming the liver.

• Type 3: Bad silage –High butyric acid from poor silage risks higher ketone levels due to higher butyric acid, a precursor for the ketone BHB.

In all cases, the liver’s ability to oxidise fat and fuel the cow is compromised. But each type requires a different nutritional strategy to resolve it.

Fertility fallout

Why does this matter for mating? Because reproduction is an energy-intensive process. The cow must not only

resume cycling but also produce viable follicles, ovulate, support embryo survival, and maintain a pregnancy. All of that depends on glucose and, by extension, on a liver that is in good working order.

Insulin resistance, triggered by elevated NEFA and BHB levels, blocks ovulation and can delay return to oestrus. Progesterone levels are affected, conception rates fall, and early embryonic death becomes more likely, leading to apparent failures to conceive or early pregnancy loss.

What you can do now

So, how do we set cows up for better liver function and reproductive success?

Feed for the liver, not just the rumen

Focus on propionic acid precursors (e.g.

maize, molasses, protected starches) and bypass amino acids to support gluconeogenesis in the liver. It’s not just about energy, it’s about the type of energy.

Use DCAD strategically Consider a controlled negative DCAD (dietary cation-anion difference) approach pre-calving to improve calcium availability and reduce metabolic stress. Stable calcium levels in the blood support uterine recovery and ovarian function.

Target minerals that support the liver

Selenium, cobalt, and zinc play important roles in antioxidant activity and enzyme function. Liver health depends on it.

Test, don’t guess Monitor BHB levels in fresh cows to catch subclinical ketosis before it cascades into something worse. A cow with BHB levels above 1.2 mmol/L might look fine, but her liver is under strain, and her reproductive future is at risk.

Watch your silage

Don’t assume goodlooking silage is harmless. High butyric acid can depress appetite and spike BHB production, which are hallmarks of Type 3 ketosis.

When your cows aren’t getting in-calf, it might not be about bull management, synchrony, or timing. It might be about the liver.

• Chris Balemi is founder of Agvance Nutrition @dairy_news facebook.com/dairynews

CHRIS BALEMI

Without a functioning liver, you won’t get functioning ovaries.

Probiotics help tackle SCC, cows begin cycling faster

MILTON DAIRY farmer

Chris Wills says he began using probiotics in spring 2023 to address somatic cell count (SCC) grades when cows transitioned from their winter barn to lush spring pasture.

While the SCC issue was resolved, an unexpected benefit emerged - cows began cycling significantly faster.

In the second season on the program, Halter data showed cows were returning to heat just 24 days after calving—far below the national average of 42 days.

“The first season I used Rumicell just to the milking herd, cycling premating was phenomenal,” says Wills.

“There was no need for Metrichecking or

“There was no need for Metrichecking or CIDRs, and our 3-week submission rate rose to 93% - a 5% increase.”

CIDRs, and our 3-week submission rate rose to 93% - a 5% increase.”

Wills had tried various products to fix his SCC issues but switched to Probiotic Revolution’s Rumicell after reading about another farmer, John McCarty, who went antibiotic-free using probiotics. Rumicell com-

bines live yeast with carefully selected bacterial strains to support digestion and immunity.

He began with autumn calvers and carryovers

in May 2023. With 480 cows, most calving in spring, the cost of switching from a live yeast product was negligible, and the usual spring SCC

spike was greatly reduced, avoiding any grades.

Probiotic Revolution’s Chris Collier points to research showing that feeding cows three

strains of probiotics 21 days pre calving as well as post-calving helped improved production as well reducing sub-clinical ketosis, which is strongly linked to several early lactation issues such as mastitis, calving difficulties, milk fever and post calving cycling.

Consequently in 2024, when Wills added SuperStart Lead Feed to his springer mob, his cows were cycling on average just 24 days post-calving, compared to 40 days for other farms in the district.

Collier emphasises that rapid post-calving cycling depends on cows avoiding metabolic issues.

“We’re using nine targeted probiotic strains in SuperStart Lead Feed. If

cows have ketosis, milk fever, or retained membranes, cycling gets delayed but with these probiotics we must be firing up cows’ production and intake to get them cycling so quickly.”

He shared cases where farmers under work pressure stopped feeding SuperStart to late-calving cows.

While early calvers cycled in under 30 days, the late ones blew out past 30 days and bore the brunt of calving and mastitis problems.

“It’s easy to use in transition diets or water troughs, giving nearly every farmer the chance to improve mating outcomes.”

Probiotics not only solved a SCC issue but helped cows begin cycling significantly faster.

Synchrony programme finds better heifer production

THE TEAM at Totally Vets, led by Dr Peter Aitken, have worked with Zoetis to test a new synchrony programme on Manawatu dairy farms, with their study finding real-world improvements in heifer reproductive performance.

Aitken presented this information to New Zealand dairy veterinarians at a national conference in 2024, and the findings have since been published as a research paper in a major international scientific journal, Theriogenology.

Synchrony programmes allow groups of dairy heifers to be put up for artificial insemination (AI) on a single day. Calves bred from heifers

by AI are normally higher value than those bred by natural mating as they are often of high genetic merit, but use of synchrony programmes also improves outcomes in the current heifer group.

Synchronised heifers calve earlier in the calving season, giving them more time to recover before the mating season, and resulting in higher milk income for the farm as these heifers are milking for more days during their first milking season.

Over the years international researchers identified differences between heifers and adult milking cows in how they respond to synchrony drugs, then used this knowledge to design specific synchrony

programmes to suit heifers. However, these findings had never been tested in New Zealand, so Peter and the team at Totally Vets wanted to explore whether a similar effect would be found in our pasture-based seasonal dairy industry.

to evaluate reproductive performance. Synchronisation with the new CIDR Heifer Plus programme resulted in significantly more heifers getting pregnant as a result of the AI mating, and for the entire first 6 weeks of the mating season.

The

increasing availability of genomic testing is now enabling farms to identify genetically superior animals early in life, select them for entry into the dairy herd, and target them for breeding of future dairy replacement heifers.

CIDR Heifer programme. Most of this economic benefit was found to be derived from the additional milk income that the farm would receive from their heifers calving earlier and therefore being milked for more days in their first season.

POWER UP SPRING‑CALVING COWS FOLLOW WITH START WITH

BOOST PRODUCTION AND HEALTH

THE AVERAGE TIME FROM CALVING TO FIRST HEAT WAS 24 DAYS WHICH WAS 16 DAYS QUICKER THAN THE DISTRICT AVERAGE. CHRIS - OTAGO

LAST AUTUMN I DITCHED ANTIBIOTICS. TREATED 25 HIGH SCC COWS WITH BOVINE BOOST AND RUMICELL — DROPPED FROM OVER 900,000 TO UNDER 250,000 BY MAY. MASTITIS CASES FELL FROM 20% TO 5% WITH 90% CURE RATE AFTER A SECOND DOSE!

IMPROVE PH BALANCE - TO REDUCE ACIDOSIS (SARA)

ENHANCES RUMEN FUNCTION AND FIBRE DIGESTION

SUPERIOR HEALTH SUPPORT WITH 8 STRAINS OF PROBIOTIC BACTERIA

NIL MILK WITHHOLD

At the start of the 2023 spring mating season, 565 rising two-year-old heifers from four dairy farms were randomly allocated to be synchronised for AI with either the current CIDR Heifer programme or the new CIDR Heifer Plus programme (also known as a modified 5-day Cosynch programme). Both programmes used the same drugs, but the CIDR Heifer Plus programme had different treatment timings and used some additional injections to align the treatments better with the activity of heifer ovaries.

After AI on a fixed date, the heifers were mated as normal for the rest of the spring mating season, then aged pregnancy testing was carried out using ultrasound

If a mob of 100 heifers were synchronised with the new CIDR Heifer Plus programme, compared to the standard CIDR Heifer programme, these study results show that this would, on average, result in:

• 17 additional heifers pregnant following artificial insemination.

• 13 additional heifers pregnant after the first 6 weeks of mating.

• 10 extra days in milk for the heifer mob during their 1st season.

Once both the costs (drugs, yarding, feed, etc) and benefits (extra milk, higher value calves) of the new CIDR Heifer Plus programme were calculated, this improvement would be worth around an extra $98 per heifer at a $10 milk payout compared to the standard

The increasing availability of genomic testing is now enabling farms to identify genetically superior animals early in life, select them for entry into the dairy herd, and target them for breeding of future dairy replacement heifers.

Using the CIDR Heifer Plus programme to AI heifers would permit further acceleration of dairy herd genetic gain by breeding replacements early from their highest genetic merit animals.

Aitken and his team are grateful to the farmers who allowed their heifer groups to be included in this study. They also thanked Zoetis for their support with study design and supplying CIDR devices, and to Parnell Animal Health for supplying injectable hormones.

Vets led by Dr Peter Aitken worked with Zoetis to test a new synchrony programme on Manawatu dairy farms.

World’s widest mounted mower

MARK DANIEL markd@ruralnews.co.nz

WITH MOST forage harvester manufacturers offering machines touching 1000hp, the logistics puzzle has always been ‘dropping” grass and pulling injto a swath big enough to feed the “beast”.

French manufacturer Kuhn appears to have taken up the challenge in the world of high output mowing, with the recent release of the GMD15030.

The fully mounted unit, with a working width of 14.5metres features four 3.1metre, seven-disc equipped cutter-bars at the rear and combined with a 3.1m wide GMD plain or FC-F conditioner equipped front mower. The company notes that the latter allows the cut grass to be placed in a narrower swath, rather than be driven over.

Tipping the scales at 3.8 tonnes, which the

maker says is comparable with a 6.2m butterfly seup equipped with groupers, the rear unit folds to only 3.0m wide and just under 4.0m tall.

The narrow transport width is achieved by

wing assembly features a hydraulic break-back system, alongside friction clutches on each side to protect the driveline.

Power requirement is said to be around 230hp, resulting in an output of 20ha/hr at a typical forward speed of 15km/hr, less any turning time on headlands, with an overlap between the two machines of 300-500mm.

manufacturer has also announced an augerbased merger on a new butterfly mower, aimed at bulky forage crops up to 2.0m tall.

using the gearbox housings of the two outer mowers to form a 180degree hinge. In addition, mechanically driven throughout, the two mowers are synchronised, rather than being offset, so there is no need for an additional overlap.

A ram between the two beds limits the amount of movement when in-work, limiting the range to between -4.0˚ to +6.0˚. Each

Cutter-bar ground pressure is controlled hydraulically using the manufacturers well known Lift-Control system, with overall control via a dedicated KFA12 control box or through an ISOBUS integration kit, which allows mower control through the in-cab joystick and tractor terminal.

In other news, the

The GMD 9530RV features a 500mm diameter auger, mounted rearwards of each mower unit, rotating at up to 900 rpm, to deliver a central swath of 1.60 to 2.20 metres wide. 50cm of hydraulic side-shift on each of the mowers on each mower is partly used to set the swath size. The augers feature replaceable wear edges made of Hardox steel, while primarily protected by a cam clutch and a shear bolt, as the last line of defence against any foreign objects.

WATER SOLUTIONS FOR SMALLER MOBS

WELL-KNOWN FOR its K-Line irrigation pods, RX Plastics has taken inspiration from that design and carried over some key learnings into the K-Trough Series.

Offered in 75 and 150-litre capacities, individual K-Troughs are ideally suited to service mobs of up to 25 cattle or 150 sheep. The company notes that the smaller capacitiesobviously well suited to lifestyle situations-also allows larger blocks to be split into smaller areas, for improved pasture management and to reduce congestion.

RX Plastics also points out that the smaller troughs offer the benefit of more frequent replenishment of fresh, cool water, which encourages animals to drink more, resulting in increased growth rates, alongside meat and milk production. Interestingly, husbandry experts suggest that ideally replenishment rates for fresh water

should be up to three times per day. Featuring a wider, thicker base to encourage location, strength and

durability, the upper edge is rolled inwards for rigidity, resistance to inquisitive cattle rubbing, alongside the benefit of reducing the volume of water to direct sunlight, so keeping it cooler.

The Philmac- EasyPHIL float valve and the water supply elbow are fully recessed into the body of the trough for general protection, with a convenient inspection window on the upper face of the trough that also serves as a drain aperture for cleaning.

From an operational point, smaller troughs also allow the creation of multiple access points compared to a large volume, single troughs, which are often subject to erosion or pugging, so needing regular maintenance.

Smaller troughs also help discour-

age algal blooms and bacterial growth.

During development, durability testing was undertaken with multiple species and breeds, confirming that the inwardly rolled upper edge performed better than conventional designs that typically saw upper edges rolled outwards to impart rigidity, but creating a purchase/rubbing point, from where cattle could destabilise the trough.

Indeed, clever design details and the durability they impart, have been reinforced by the findings of a horse owner -animals known to be hard on water troughs-who had one belligerent animal that could destroy a new water trough in around three weeks. A switch to a K-Trough has resulted in no damage of 18 months of use.

www.rxp.co.nz

The smaller capacities also allows larger blocks to be split into smaller areas, for improved pasture management and to reduce congestion.

The fully mounted unit comes with a working width of 14.5m and features four 3.1m, seven-disc equipped cutter-bars at the rear.

Claas unveils new Cerex

700 RC round baler

MARK DANIEL markd@ruralnews.co.nz

WITH THE biennial

Agritechnica Event just a few months away, manufacturers are offering sneak peaks at new innovations, with Claas recently highlighting its new Cerex 700 RC round baler.

Said to complement and offer greater output and density above the existing Variant 500 Series, the new Cerex also offers maximum versatility in silage, straw, hay and hemp.

Up front, a 1,000 rpm PTO input,

The MultiFlow HD pickup offers a working width of 2.10 m, with five tine bars rotating at 146 rpm, allowing high forward speeds and a constant flow to the chopping rotor.

combines with a 5-row HD Multiflow pick-up and spiral feed rotor, said to be capable of producing up to sixty high-density bales per

hour. At the heart of the new series, a new variable bale chamber concept with separate hydraulic system, features two endless Heavy-Duty belts and door clamps, to achieve bale densities of over 135 kg/m³ in straw. Claas suggests that using two wider, rather than multiple narrower belts, makes the bale forming chamber dimensionally stable and due to the almost complete enclosure of the bale, means losses are significantly reduced even in short crops. The Cerex 760 RC offers bale diameters from 0.90 to 1.60 metres, or 0.90 to

1.83 m from the larger Cerex780 RC, while a soft-core function is standard to enable targeted core pressure when baling hay and silage.

The Multi-Flow HD pick-up offers a working width of 2.10 m, with five tine bars rotating at 146 rpm, allowing high forward speeds and a constant flow to the chopping rotor. The innovative cam track, carried across from the existing Rollant 630RC, offers stability with a 70mm central support shaft, while removeable, durable plastic stripper bands allow easy access

for maintenance work.

Rearwards of the pick-up, the proven heavy-duty Roto-Cut feed rotor uses 8 mm thick, spirally arranged double tines made of doublehardened boron steel. Four rows of tines feed the crop at up to 13,800 cuts per minute through the 25-blade cutting rotor, achieving a theoretical chop lengths of 44 or 63 mm. Knife groups can be switched to 25, 13, 12 or zero, vis electro-hydraulic control. In the event of irregular lumps or foreign objects, the knife frame can open by up to 30mm to adapt to crop flow. Should a blockage occur, the cutting frame can be actively lowered hydraulically at the touch of a button on the ISOBUS terminal.

The Cerex 700 RC utilises a new wrapping system, with a so-called “duckbill” that ensures that the net can be inserted quickly and precisely thanks to its pre-positioning, saving time when changing rolls, as there is no need for any threading. A hydraulic net brake ensures optimum net tension, saving up to 15 per cent material. Net storage allows three rolls to be stored on the machine during use.

ISOBUS operation of the new Cerex 700 RC is via the familiar, clearly laid out Cemis 700 terminal with a 7-inch colour display with touch function, ten direct access buttons and a rotary pushbutton in the programme. Alternatively, the round baler can be operated via other suitable ISOBUS terminals.

Promoting maximum operating comfort, sees work lights, an unobstructed view of the pick-up, integrated camera for bale monitoring, even in the dark, alongside a moisture sensor for crop condition and a sensor on the bale ramp to ensure vit is safe to close the tailgate.

The new Cerex 700 RC round baler offers greater output and density. Below: The heavy-duty Roto-Cut feed rotor uses 8 mm thick, spirally arranged double tines made of double-hardened boron steel.

New 5M tractor series offer more horsepower, comfort

excellent visibility, an upgraded, optional air conditioning system offers increased air flow and distribution around the operator.

MASSEY FERGUSON has announced the introduction of the MF 5M Series, offered over six horsepower steps from 95 maximum hp, to a new 145hp model, with 14 unique variants depending on the cab and transmission type.

Building on the existing MF 5700, MF 5700 Dyna-4, and MF 6700 Series, the model range, offered as cabin or platform configurations, is powered by an AGCO Power four-cylinder, 4.4 litre engines. Complemented by a 24% larger fuel tank, holding 198 litres, said to be the largest in the sector, allowing for more work between refills.

Transmission choice is 12x12 on the entry 5M.95 model, with 12x12 or Dyna-4 configurations with the remainder of the range, excluding the flagship 5M.145 model, which is only available with the latter. Dyna-4 transmission, which provides clutch-free control of 16 forward and 16 reverse speeds with a 40km/h Eco top speed.

The optional AutoDrive system offers automatic shifting in Power or Eco modes, along with Brake-to-Neutral as standard, to automatically disengage drive when the pedal is pressed, ensuring precision, comfort combined and smoother operation.

At the business end of the tractor, an open-centre, 100 litre/min hydraulic system is fitted as standard, complemented by lift capacities of 4300kg up to the 5M.115 and 5200kg for the three larger models.

Decked out in the latest MF family styling sees a diamond grey cab with new striking sabre style, a new model logo design on the side of the bonnet, with a black, ribbed grille.

Said to offer high levels of comfort and

1.3 metres wide, the cabin has a flat floor and car-style pedals and large glass areas. The Visio Roof option allows improved visibility and safer handling operations.

Those operators using front-end loaders have the choice of mechanical or electronic joysticks, while benefitting from a 4.65 turning radius.

Comfort can be improved further with a new cab suspension system option on all Dyna-4 models, while meanwhile LED work-light options, in addition to the halogen lights, provide increased illumination, especially at night, with a choice of either two LED front and rear work-lights, or two mid-mounted units. Externally, a new PTO switch, for remote engagement, is located on the rear of the nearside fender.

For control, precision and comfort all 5M tractors can be equipped with full MF Guide, including the Fieldstar 5 terminal or, as MF Guide ready. MF Guide provides fully automatic steering and is offered with a Trimble®, or a choice of other receivers that provide a range of positioning accuracies.

Fieldstar 5 provides access to several Massey Ferguson Smart Farming options, including ISOBUS, while also offering a range of features including Section Control to automatically switch up to 96 different sections, Rate Control to automatically vary application rates and MF Connect telemetry providing near real time data transfer.

Completing the package, a comprehensive range of MF services, includes MF Care extended warranty, personalisation options and MF Always Running courtesy fleet, for total peace of mind.

Clipping dairy Solutions

MARK DANIEL markd@ruralnews.co.nz

An open-centre, 100 litre/min hydraulic system is fitted as standard, complemented by varying lift capacities for each model.