The Case for COTS in 5th Generation Warefare

Using Carbon Fiber Structures for Energy Storage

The Case for COTS in 5th Generation Warefare

Using Carbon Fiber Structures for Energy Storage

14 The Case for COTS in 5th Generation Warefare

By Aaron Paseur, a retired U.S. Navy SEAL and Jared Febbroriello, an Industry expert in security and government contracting.

By John Reardon, , Editor-in-Chief, COTS Journal

Cover Image: Combat Capability

Louisiana National Guard soldiers conduct platoon tactical movements during Exportable Combat Training Capability at Camp Shelby near Hattiesburg, Miss., May 21, 2024. Exportable Combat Training Capability is a series of training exercises between an active-duty Army brigade and an Army National Guard brigade intended to increase the skills and readiness of National Guard units.

COTS (kots), n. 1. Commercial off-the-shelf. Terminology popularized in 1994 within U.S. DoD by SECDEF Wm. Perry’s “Perry Memo” that changed military industry purchasing and design guidelines, making Mil-Specs acceptable only by waiver. COTS is generally defined for technology, goods and services as: a) using commercial business practices and specifications, b) not developed under government funding, c) offered for sale to the general market, d) still must meet the program ORD. 2. Commercial business practices include the accepted practice of customer-paid minor modification to standard COTS products to meet the customer’s unique requirements.

—Ant. When applied to the procurement of electronics for he U.S. Military, COTS is a procurement philosophy and does not imply commercial, office environment or any other durability grade. E.g., rad-hard components designed and offered for sale to the general market are COTS if they were developed by the company and not under government funding.

6 The Inside Track

EDITORIAL

EDITORIAL SUBMISSION AND RELEASES

johnr@rtc-media.com

PUBLISHER/CEO

John Reardon • Johnr@rtc-media.com

CONTRIBUTING EDITORS

Tom Williams, Glenn ImObersteg Buck Biblehouse

ART AND PRODUCTION

CREATIVE DIRECTOR

David Ramos • drdesignservices@ymail.com

DIGITAL MARKETING MANAGER

Scott Blair • Scott@blair-media.com

AD TRAFFIC

Vaughn Orchard • Vaughno@rtc-media.com

FINANCE AND ACCOUNTING

Paige Reardon • paiger@rtc-media.com

ADMINISTRATION/CIRCULATION

Dawn Dunaway • dawnr@rtc-media.com

ACCOUNT MANAGER

SALES MANAGER

Vaughn Orchard • Vaughno@rtc-media.com

CUSTOM AND CONTRACT SERVICES

John Reardon • Johnr@rtc-media.com

COTS Journal

CORPORATE OFFICE

RTC Media

3180 Sitio Sendero, Carlsbad, CA. 92009

Phone: (949) 226-2023

Fax: (949) 226-2050 www.rtc-media.com

PUBLISHED BY RTC MEDIA

Copyright 2024, RTC Media. Printed in the United States. All rights reserved. All related graphics are trademarks of The RTC Group. All other brand and product names are the property of their holders.

is re-published each month on

Last month, more than 18,000 readers downloaded COTS Journal. This pushes our monthly readers to over 50,000 each month.

Issuu allows you to look back at all the great issues of COTS Journal and is the perfect resource to find articles on the most interesting topics for you.

Thanks to our partnership with Issuu, more people can enjoy COTS Journal each month.

https://issuu.com/search?q=cots%20 journal%20#google_vignette Or Contact us;

3180 Sitio Sendero, Carlsbad, CA. 92009

Phone: (949) 697-4032 www.rtc-media.com

A new technology ecosystem has also been launched as Microchip collaborates with over a dozen system and software partners to accelerate PIC64-HPSC adoption.

industry, integrate widely adopted RISC-V® CPUs augmented with vector-processing instruction extensions to support Artificial Intelligence/Machine Learning (AI/ML) applications. The MPUs also fea-

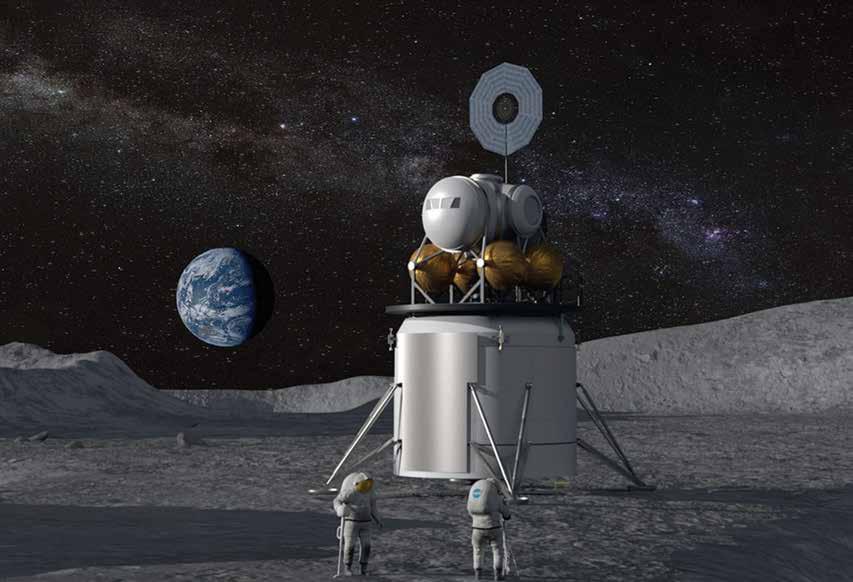

The world has changed dramatically in the two decades since the debut of what was then considered a trail-blazing space-grade processor used in NASA missions such as the comet-chasing Deep Impact spacecraft and Mars Curiosity rover vehicle. A report released by the World Economic Forum estimated that the space hardware and space service industry is set to grow at a CAGR of 7% from 2023’s 330 billion dollars to 755 billion dollars by 2035. To support a diverse and growing global space market with a rapidly expanding variety of computational needs, including more autonomous applications, Microchip Technology (Nasdaq: MCHP) has launched the first devices in its planned family of PIC64 High-Performance Spaceflight Computing (PIC64-HPSC) microprocessors (MPUs).

Unlike previous spaceflight computing solutions, the radiation- and fault-tolerant PIC64-HPSC MPUs, which Microchip is delivering to NASA and the broader defense and commercial aerospace

ture a suite of features, industry-standard interfaces, and protocols not previously available for space applications. A growing ecosystem of partners is being assembled to expedite the development of integrated system-level solutions. This ecosystem features Single-Board Computers (SBCs), spacegrade companion components, and a network of open-source and commercial software partners.

“This is a giant leap forward in the advancement and modernization of the space avionics and payload technology ecosystem,” said Maher Fahmi, corporate vice president of Microchip Technology’s communications business unit. “The PIC64-HPSC family is a testament to Microchip’s longstanding spaceflight heritage and our commitment to providing solutions built on industry-leading technologies and a total systems approach to accelerate our customers’ development process.”

The Radiation-Hardened (R.H.) PIC64-HPSC RH is designed to give autonomous missions the

local processing power to execute real-time tasks such as rover hazard avoidance on the Moon’s surface, while also enabling long-duration, deep-space missions like Mars expeditions requiring extremely low power consumption while withstanding harsh space conditions. For the commercial space sector, the Radiation-Tolerant (R.T.) PIC64-HPSC RT is designed to meet the needs of Low Earth Orbit (LEO) constellations where system providers must prioritize low cost over longevity while also providing the high fault tolerance vital for round-the-clock service reliability and the cybersecurity of space assets.

In 2022, NASA selected Microchip to develop a High-Performance Spaceflight Computing processor that could provide at least 100 times the computational capacity of current spaceflight computers. This key capability would advance future space missions, from planetary exploration to lunar and Mars surface missions. The PIC64-HPSC is the result of that partnership. Representatives from NASA, Microchip, and industry leaders like Northrop Grumman will share insights about the HPSC technology and ecosystem at the IEEE Space Compute Conference 2024, July 15–19, in Mountain View, California:

Microchip’s new PIC64-HPSC MPUs will be supported by a comprehensive space-grade ecosystem and innovation engine that encompasses flight-capable, industry-standard SBCs, a community of open-source and commercial software partners, and the implementation of common commercial standards to help streamline and accelerate the development of system-level integrated solutions. Early members in the ecosystem include SiFive, Moog®, IDEAS-TEK, Ibeos, 3D PLUS, Micropac, Wind River®, Linux Foundation, RTEMS, Xen, Lauterbach®, Entrust®, and many more. For information, visit Microchip’s PIC64-HPSC MPU ecosystem partners webpage.

The Microchip will also offer a comprehensive PIC64-HPSC evaluation platform that incorporates the MPU, an expansion card, and a variety of peripheral daughter cards.

EIF and NATO Innovation Fund join forces to unlock private capital for Europe’s defense and security future

The European Investment Fund (EIF) and the NATO Innovation Fund (NIF) signed a Memorandum of Understanding (MoU) to cooperate in supporting the long-term growth of the defense, security, and resilience sectors across Europe. The EIF is part of the European Investment Bank (EIB) Group, and the NIF is a standalone venture capital fund backed by 24 NATO countries.

The MoU aims to encourage more private capital funds to become active investors in technology sectors associated with defense and security, enabling E.U. companies to raise equity funding from a broader range of sources. The partnership reflects the shared interest of the NIF and EIF in establishing a framework to support start-ups, small and medium-sized enterprises (SMEs),

SMEs, midcaps, and the broader European innovation landscape.”

The MoU also outlines plans for EIF-NIF cooperation on ad-hoc activities to share knowledge and raise awareness about the potential of investments in defense and security. This will help foster a comprehensive investment ecosystem, ensure effective outreach to private capital funds, support companies in their investment plans, and raise awareness of the investment opportunities in the defense, security, and resilience sectors among limited partners.

The collaboration with the NIF is also in line with the EIB Group’s Security and Defence Action Plan, which is expected to support the effort primarily through the EIB’s venture-debt product designed to address the funding needs of innovative companies and which may complement EIF and NIF venture capital and private equity funding in some cases. The signatories will also exchange information with the European Commission in areas where its potential involvement may prove beneficial for the purposes of the MoU.

and midcaps and in enhancing the whole ecosystem by involving all the main stakeholders.

“By facilitating regular dialogue and knowledge sharing, the EIF and NIF will ensure a cohesive approach to strengthening the investment ecosystem for defense, security, and resilience,” said Marjut Falkstedt, chief executive of the EIF. “This will benefit

“There is great momentum in deep tech that is propelling innovations to help strengthen European defense, security, and resilience,” said Andrea Traversone, Managing Partner of NATO Innovation Fund. “We are excited to collaborate with the EIF, the EIB Group, and the Commission to unlock investment opportunities for European businesses, advance capacity building for dual-use innovation, and share best practices across investors, innovators, and government.”

The collaboration between EIF and NIF will also focus on designing new financial products to meet companies’ needs. The strategic alliance between the EIF and NIF represents a significant step forward in strengthening Europe’s defense and security capabilities, unlocking new avenues for private investment, and driving innovation in these vital sectors.

KULR Lands Initial $400K NASA Contract for Automated Battery Cell Testing, $2M in Total Orders Anticipated Over Several Quarters

KULR Technology Group, Inc., a global leader in sustainable energy management, today announced it has been awarded a purchase order exceeding $400,000 from the National Aeronautics and Space Administration (“NASA”), an independent agency of the U.S. federal government, as part of a $2M multiphase agreement for its advanced automated battery cell screening system. The battery safety contract with NASA is to test lithium-ion cells going into future battery packs designed for the Artemis Program, a series of United States-led international human spaceflight programs. KULR will perform the tests on cells in reserve for upcoming Artemis missions and other pivotal manned space voyages. The cells used on the missions are required

to meet certification to NASA’s strict specifications for manned flights, EP-WI-037.

With a leading position in safe battery design and testing and as a significant player in the global electrification movement, KULR is among the few companies to meet the stringent requirements and rigorous testing standards of NASA’s JSC 20793 Revision D for crewed space missions. This qualification enables KULR’s products and solutions to be used in the Artemis missions and other upcoming critical space voyages.

According to Straits Research, the global battery cell testing market is anticipated to grow at a CAGR of 4% between 2022 and 2030 and reach USD 7 billion by 2030.

KULR specializes in evaluating battery cells essential for manned space missions. To meet growing demand, the Company plans to expand its technology to support 21700 cells

by year’s end, enhancing safety and reliability for various mission-critical applications. The design and development work for this project will be a collaborative effort between KULR’s state-of-the-art facilities located in Webster, Texas, and San Diego, California, and is a vital cornerstone of expanding the KULR ONE Space (K1S) portfolio into CubeSat and SmallSat markets, customized battery design activities, and preparedness for low volume but high technical niche battery production.

KULR’s modular screening technology offers scalability to meet market demands, reinforcing its strategic partnership with NASA and its role in aerospace energy management and battery safety. As the drive for electrification and sustainable energy grows, KULR is well-positioned to leverage new opportunities and advance battery design and safety measures in collaboration with industry partners.

iDirect Government To Build 5G CoChannel Interference Mitigation Prototype for Defense Innovation Unit

Interference Mitigation Solution Provides Communications Resiliency for U.S. DOD

iDirect Government has won a contract with

the Defense Innovation Unit (DIU) to build an operational 5G co-channel interference mitigation solution prototype, leveraging iDirectGov’s leading Communication Signal Interference Removal (CSIR™) technology.

The award builds momentum for the recently established iDirectGov Engineering Center of Excellence, where iDirectGov specialized engineers work on the most advanced, secure, resilient satellite ground systems and functionality.

RTX’s Raytheon awarded a $1.2 billion contract to provide additional Patriot air and missile defense systems to Germany

Raytheon was awarded a $1.2 billion contract to supply Germany with additional Patriot ® air and missile defense systems.

These systems will augment Germany’s air defense infrastructure with additional Patriot

iDirectGov’s 5G co-channel solution will mitigate interference for DIU mission partners and provide a critical capability to Department of Defense (DOD) users who experience 5G co-channel

major end items. The contract scope includes the most current Patriot Configuration 3+ radars, launchers, command and control stations, associated spares, and support.

“Patriot remains the tried-and-true stalwart of air and missile defense, relied upon by our global customers to deter aggression and defend their interests,” said Tom Laliberty, president of Land and Air Defense Systems at Raytheon. “With each additional Patriot system, Germany is enhancing its air defenses and

interference. This solution is an extension of iDirectGov’s CSIR technology, which delivers uninterrupted, secure communications on any radio frequency to government users, allowing them to thwart electronic warfare challenges.

“Any signal interference is harmful to defense communications, and our 5G co-channel capability will ensure our customers have the crucial interference mitigation tool that helps them with communications resiliency,” said Tim Winter, iDirect Government president. “Our high-performance, scalable, and resilient product portfolio and enhancements bring flexibility, agility, transmission security, and efficiency to warfighters.”

Since its beginnings in 2007, iDirectGov has supported the DOD and other agencies, solving their communications challenges with practical and exceptional delivery.

strengthening NATO’s defense posture.”

Patriot is the only combat-proven groundbased air and missile defense capability available worldwide to defeat advanced long-range cruise missiles, tactical ballistic missiles, and the full spectrum of air-breathing threats. It is the foundation of air defense for 19 countries, including Germany, the U.S., and Ukraine, and it continues to demonstrate its effectiveness against the most advanced and complex threats.

VTOL UAV Market Surges to USD 21.70 Billion by 2031, Propelled by 19.17% CAGR - Verified Market Research®

The VTOL UAV market is driven by advancements in drone technology, increased demand for surveillance and reconnaissance, and applications in agriculture, logistics, and disaster management. However, market growth is restrained by high development and maintenance costs, regulatory hurdles, and concerns over privacy and safety. Additionally, limited battery life and payload capacity pose significant technical challenges. Ongoing research and investments aim to address these issues, potentially boosting market expansion.

The Global VTOL UAV Market is projected to grow at a CAGR of 19.17% from 2024 to 2031, according to a new report published by Verified

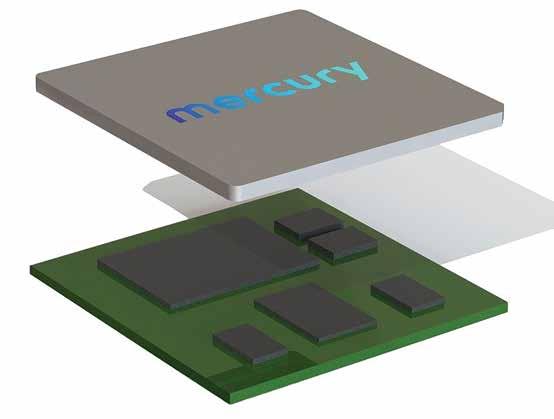

Mercury Systems, Inc. announced an agreement with the U.S. Navy to advance sensor processing technologies that will allow radar and electronic warfare (E.W.) capabilities to be designed on much shorter timelines.

Increasing system and software complexity has extended the timelines for developing and fielding military platforms for decades. The Office of Naval Research’s Open Rapid Chipletized Approach (ORCA) program aims to reduce the time needed to design edge processing solutions by increasing the modularity of components at the chip level. Under a $13.2 million contract, Mercury will develop a next-generation RF System-in-Package (SiP) that integrates the latest commercial chips from major semiconductor providers within a smaller and lighter footprint.

This work will build on Mercury’s RFS1140 SiP, which integrates an AMD Versal FPGA, Jariet Electra-MA high-speed data converters, and Micron memory for a truly advanced solution to support sensor processing.

“ORCA represents a significant evolution of the Mercury Processing Platform that will drive down radar and E.W. system development timelines, allowing next-generation capabilities to be

Market Research®.

fielded much faster,” said Tony Trinh, Mercury’s Senior Director of Advanced Packaging. “The ORCA approach opens up incredible opportunities to integrate mission-specific pre-processing chiplets to rapidly upgrade systems on a wide variety of existing platforms and stay ahead of evolving threats.”

pected to reach USD 21.70 billion by the end of the forecast period.

“Mercury is pioneering the way for on-shore advanced secure microelectronics integration and packaging capability with DMEA-certified full product lifecycle support, including concept, design, assembly, and test, to deliver application-tailored system solutions to the warfighter rapidly,” said Adam Miller, Office of Naval Research Program Officer.

General Dynamics Mission Systems Prog-

eny Systems announced that it was awarded an $11,996,038 cost-plus, fixed-fee modification to a previously awarded contract to exercise options to provide engineering and technical support for modernizing Virginia Class Block I/II submarines with the Common Weapon Launcher (CWL) sys-

tem, along with the continuance of other ongoing projects. Work will be performed in Manassas, Va., and is expected to be completed by July 2026.

“Progeny Systems has many years of experience supporting the U.S. Navy’s submarine programs, especially in combat systems. We are pleased that the Navy has contracted with us to modernize older Virginia Class submarines with the capable and flexible CWL system. The Progeny Systems team also offers software and hardware platforms for payload control, tactical control, torpedoes, acoustics, cybersecurity, electronic warfare, and mission readiness. We look forward to delivering this modern weapon launch capability to our Navy customers,” said Laura Hooks, vice president and general manager of Maritime and Strategic Systems at General Dynamics Mission Systems.

Progeny Systems was acquired by General Dynamics Mission Systems in 2022. Headquartered in Manassas, Va., Progeny Systems provides various capabilities and lifecycle support services for U.S. submarines and surface ships.

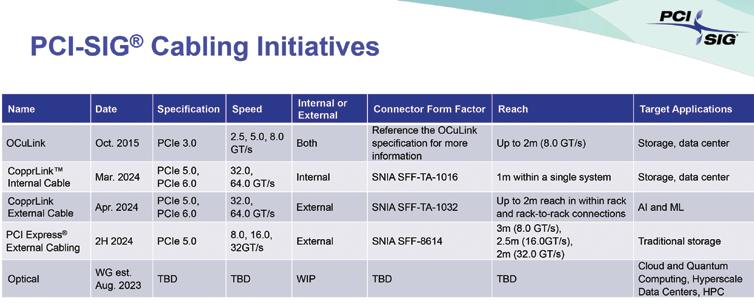

PCI-SIG® Announces CopprLink™ Cable Specifications for PCIe® 5.0 and 6.0 Technology

The specifications extend the PCIe channel’s reach for applications such as storage, data centers, artificial intelligence, machine learning, and disaggregated memory.

PCI-SIG®, the organization responsible for the widely adopted PCI Express® (PCIe®) standard, announced the release of the CopprLink™ Internal and External Cable specifications today. The CopprLink Cable specifications provide signaling at 32.0 and 64.0 GT/s and leverage well-established industry standard connector form fac-

tors maintained by SNIA.

“The CopprLink Cable specifications integrate PCIe cabling seamlessly with the PCIe electrical base specification, providing longer channel reach and topological flexibility.”

“The CopprLink Cable specifications integrate PCIe cabling seamlessly with the PCIe electrical base specification, providing longer channel reach and topological flexibility,” said Al Yanes, PCI-SIG President and Chairperson. “The CopprLink Cables are intended to evolve with the same connector form factors, scale for future PCIe technology generations, and meet the demands of emerging applications. The Electrical Work Group has already begun pathfinding work

on CopprLink Cables for PCIe 7.0 technology at 128.0 GT/s, showcasing PCI-SIG’s commitment to the CopprLink Cable specifications.”

• Supports PCIe 5.0 and 6.0 technology signaling at 32.0 and 64.0 GT/s

• Includes the SNIA SFF-TA-1016 connector form factor

• Maximum of 1m reach within a single system

• Example implementations include motherboard-to-add-in-card, motherboard-to-backplane, chip-to-chip and add-in-card-to-backplane in a self-contained server platform node

• Target applications include storage and data center compute nodes

• CopprLink External Cable Specification

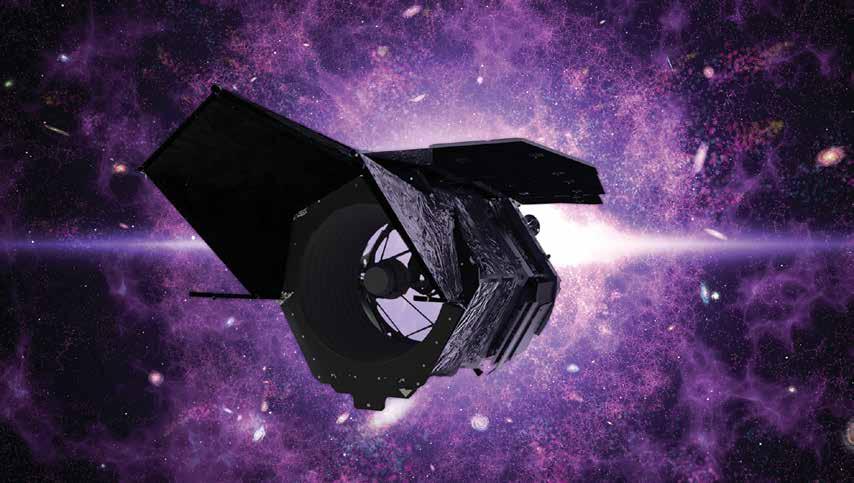

HWO is NASA’s next flagship astrophysics mission after the Nancy Grace Roman Space Telescope, which is scheduled to launch by 2027

BAE Systems and strategic partners L3Harris Technologies and the Space Telescope Science Institute (STScI) have been selected as one of three teams to mature technologies supporting NASA’s Habitable Worlds Observatory (HWO) mission concept. A first-of-its-kind telescope, HWO will be designed to seek out signs of life beyond our solar system and conduct transformational observations of the universe. Its driving goal is to identify and examine a promising sample of Earth-like planets orbiting other stars to determine if they could show signs of hosting life. The observatory would also provide a powerful lens to explore the stars, the planets of our solar system, galaxies, and the universe’s evolution with unprecedented sensitivity and resolution.

The team will conduct a two-year research effort called the Ultra-stable Large Telescope Research and Analysis Program – Critical Technologies (ULTRACT). The program is meant to close gaps in the performance of large space telescopes by advancing ultra-stable optical systems. BAE Systems’ Laura Coyle, principal optical engineer and astrophysics technology lead for the Space & Mission Systems sector, will be the principal investigator. ULTRACT continues the team’s work from two previous NASA awards, ULTRA, a one-year study identifying technology gaps for large, segmented systems, and ULTRA-TM, a fouryear technology maturation effort for key component-level technologies.

Detailed observations of exoplanets can be highly challenging, largely because the light they reflect is much fainter than the stars they orbit. This brightness ratio, or “contrast,” is about 10 billion to 1 for an Earthlike planet around a Sun-like star. While this unprecedented level of starlight suppression

would be achieved with a coronagraph, an extremely stable, large telescope is necessary to collect enough well-controlled light to feed this instrument and provide high-resolution imaging. In this case, the telescope stability required to support 10 billion to 1 contrast is on the order of picometers – or one trillionth of a meter — far beyond the capabilities of current state-of-the-art systems. To put this into perspective, the HWO telescope must be a thousand times more stable than the James Webb Space Telescope.

“Even slight thermal changes and minor vibrations will impact the telescope’s ability to maintain the contrast necessary to make these observations, so we need a system with both passive and active elements to minimize and compensate for disturbances,” said Coyle. “Bolstered by a legacy of supporting NASA’s most ambitious missions, our ULTRA team of engineers is excited to develop technologies that will address stability at the picometer level and continue to advance this groundbreaking project.”

By Aaron Paseur, a retired U.S. Navy SEAL and Jared Febbroriello, an Industry expert in security and government contracting.

This article discusses various aspects of COTS from a different perspective – through the eyes of the Military End-User and real-world, combat environment. It also provides an Industry viewpoint of where this must evolve to foster National Security, the protection of the War Fighter and perpetuate our Military superiority.

The decision to integrate Commercial Off-The-Shelf (COTS) technology into military applications marked a significant shift from traditional bespoke solutions designed exclusively for defense purposes. This paradigm shift was driven by the rapidly accelerating pace of technological change in the commercial sector. This article is not designed to discuss the inherent advantages/ disadvantages of COTS – rather it is to provide a perspective from a Military end-user and combat/battlefield viewpoint.

Improvements in additive manufacturing and rapid prototyping technologies offer advanced capabilities that even small commercial teams can now leverage to maintain a strategic edge in their product development. These capabilities (if available historically) would have been cost-prohibitive.

If time is the most valuable commodity, then speed is the great equalizer. Inexpensive generative AI, machine learning and other emerging technologies will continue to

The World’s Most Powerful Full-featured Wearable Computer for real-time tip-ofspear image and sensor processing.

accelerate development, driven more by the vision and work ethic of the development team than by resource availability.

Yet, with all these advancements, the knowledge gap between commercial design teams and military end-users continues to widen. A good example of the blending of COTS product solution and real-world, combat requirements is General Micro Systems (GMS) fully-featured, wearable Spider Man Pack for real-time “tip of the spear” image and signalprocessing (see sidebar for details).

Celebrating 50 Years of American Excellence:

Celebrating 50 Years of American Excellence:

By Buck Biblehouse, Senior Editor

OTEK Corporation proudly stands as an emblem of American ingenuity and perseverance in the dynamic realm of instrumentation and measurement technology. As the company marks its illustrious 50th anniversary alongside the esteemed Otto Fest, the narrative of relentless innovation, unwavering dedication, and staunch commitment to excellence takes center stage.

At the nucleus of OTEK’s triumph lies its formidable intellectual property (IP) arsenal, comprising a remarkable array of 18 leading patents and two pending. These patents, spanning groundbreaking analog meter direct replacement innovations to cutting-edge digital instrumentation solutions, epitomize OTEK’s relentless pursuit of advancement and steadfast dedication to redefining industry benchmarks. They showcase the company’s technological prowess and underscore its visionary outlook and commitment to pushing the boundaries of possibility.

A cornerstone of OTEK’s ascent to prominence has been the unwavering support it has garnered from industry peers and collaborators. Through steadfast partnerships and alliances forged over the years, OTEK has earned the trust and admiration of its customers, solidifying its position as a preeminent provider of innovative solutions that consistently surpass expectations. Established on the principle that the most challenging problems necessitate the most straightforward solutions, OTEK is a leader in the field of innovative solutions.

Central to OTEK’s ethos is the indelible imprint of its visionary leader, Dr. Otto Fest. Infused with a relentless pursuit of excellence, Dr. Fest has cultivated a corporate culture steeped in integrity, dedication, and customercentricity principles. This culture permeates every facet of OTEK’s operations, ensuring that the company remains unwaveringly committed to delivering unparalleled value and reliability to its clientele. Dr. Fest proudly conveys, “OTEK guarantees all its products for life—not just the product itself, but the company! When used according to specifications, there is no reason for our products ever to fail.”

Dr. Fest’s unyielding dedication to OTEK’s clientele and the various industries it serves is ingrained deeply within the fabric of OTEK’s identity. Dr. Fest, alongside his proficient and innovative team, has become renowned for their willingness to embrace challenges head-

on, customizing their industry-leading digital measurement solutions despite seemingly insurmountable challenges. Their commitment to innovation and problem-solving has led one impressed customer to coin OTEK the moniker affectionately “the digitizers,” lending further credibility to Dr. Fest’s commitment to his esteemed technology.

Dr. Fest’s profound love for family, heritage, and his adopted homeland of the United States resonates throughout OTEK’s operations. Since 1974, OTEK has stood unwavering by the side of the military, demonstrating steadfast support. In the beginning, the US military entrusted OTEK with the development of its pioneering “flatpack” digital meter, a revolutionary creation that remains unparalleled to this day. Remarkably, these meters continue to serve our nation’s defense forces flawlessly, a testament to OTEK’s enduring commitment to excellence and reliability in military technology.

At the heart of Dr. Fest’s leadership philosophy lies a steadfast commitment to prioritizing people above all else. Whether it’s his unwavering dedication to his family, friends, or employees, Dr. Fest’s emphasis on fostering meaningful relationships underscores OTEK’s human-centric approach to business. In an era characterized by rapid technological advancement, OTEK’s enduring success is a testament to the transformative power of people-first leadership and an unwavering commitment to excellence. His journey began in 1976, shaping DIN Standards and lecturing across Germany. Transitioning to NASA, he was pivotal in multiple Apollo missions, contributing to landing a man on the moon.

As OTEK celebrates its 50th anniversary alongside the remarkable legacy of Dr. Otto Fest, the journey of innovation, integrity, and impact continues unabated. Guided by a vision of excellence that remains as resolute as ever, OTEK stands poised to embark on the next chapter of its storied history, propelled by the spirit of American ingenuity and the enduring legacy of Otto Fest, a true patriot in every sense of the word.

4016 E. Tennessee St. Tucson, AZ 85714 USA

Sales@otekcorp.com

520-748-7900 • Fax: 520-790-2808

877-227-6835

The adoption of COTS products comes with a complex set of challenges for the military end-user. Most COTS products, while cuttingedge and cost-effective are not designed to survive demanding military environments and may cause casualties when signals are detected and intercepted by an adversary.

Operational realities necessitate a comprehensive pre-evaluation and modifications to COTS products prior to fielding, which can negate their utility value or frustrate the purpose of adopting these technologies to a real-world combat environment. This process requires experienced military end-users with broad knowledge of sensitive military initiatives, programs and target applications that have considerable combat experience.

In the era of 5th generation warfare, the lines between commercial and military combatants continue to blur. The rapid evolution of radio direction finding technology, drone warfare, loitering munitions, smart artillery, and the increasingly autonomous kill chain have changed warfare forever. The difference between life and death on the battlefield is now determined by an anomalous radio signature, a suspicious data pattern or even simply the wrong SIM card in the wrong phone. These modern tactics first began in 2014 when the Gerasimov Doctrine was applied in Ukraine. However, an overemphasis on technology instead of tactics may be a miscalculation.

While technology and tactics are

inextricably linked, history is replete with examples of technologically superior forces being defeated by an underdog. From the British Red Coats and their “Brown Bess” Musket to Eugene Stoner’s development of the M-16 in Vietnam, the lesson seems to be that great technology rarely defeats great tactics.

The first shots of 5th generation warfare were not fired from a gun; they began with advanced cyber tactics used to disrupt Ukrainian communications and infrastructure in February 2014. The world woke up to a new pervasive Universal Threat Environment bolstered by misinformation propagated through hacked information systems. These emerging information warfare tactics sowed confusion and economic pressure without provoking a full-scale, conventional war. Networked sensors, integrated surveillance, and precise targeting systems were used to effect rapid tactical strikes and establish overmatch on the battlefield. OSINT bolstered by poor operational security was leveraged to target the family members of commanding officers, who were then socially engineered to elicit electronic communications that were rapidly traced to GPS coordinates for a precision airstrike on the officer in the field.

Eight years and five trillion dollars of NDAA appropriations later, we continue to believe that all we need to win the day is more money and better technology.

Our armed forces are not exempt from the universal laws of time, speed, and intelligent

resource management. Just like every other organism in the known universe, our military will either adapt to these natural laws of technological evolution or perish. Thus, the rapid integration of COTS technologies into military systems is not an eventuality but a tactical certainty.

Intelligent and effective leveraging of COTS is the only way for our modern armed forces to maintain a technological edge with respect to military-grade equipment. As the pace of innovation continues to accelerate, forces that do not capitalize on the latest technological innovations will become extinct. This is a harsh reality that the operations side of the defense community, where the cost of failure is paid for in blood, has already begun to witness first-hand.

A Patriot PAC-3 Missile Segment Enhancement (MSE) sent to theater costs approximately $6,000,000, while a Shahed-136 loitering drone costs approximately $30,000. This economic disparity exemplifies a 5th generation warfare tactic of economic death by 1,000 cuts. The real challenge lies in redefining the long-term strategic vision of military command objectives and a false worldview that the economics of warfare are irrelevant to the mission. This is where the long-term strategic vision of commercial leadership objectives and the development of COTS can play a key role.

All technology begins with a concept, and it is the risk-taker who gets to choose which technology concepts they want to support. Someone has to pick winners and losers in

this technology race. A winning concept gets funded and potentially developed into viable technology, while everything else remains a concept or disappears into obscurity.

By definition, military commands cannot control the long-term strategic development plan for COTS because this is driven by supply and demand within the commercial market. Why not embrace this rather than fight it? Imagine what the commercial market could do with a trillion dollars of NDAA money. Moreover, if we took only $500 Billion and invested it into promising technology companies, critical industries, and talented development teams, we would probably dominate the commercial and military markets of the world and receive a shareholder dividend.

The idea that war ends at borders is antiquated. Everywhere, from our world to the quantum world, the cyber world, and beyond our atmosphere, it is all fair game. Whether we recognize it or not, our security, our institutions and our Western values are being tried by fire.

The argument can therefore be made that design teams should include a military or security liaison. The distinction between

military and commercial interests is one that our adversaries never had. In communist countries, the party comes first, and everyone, including companies, military commands, and organizations work towards a uniform goal. While we don’t advocate for a similar system, we cannot ignore its existence. Recognizing this mindset requires us to reassess the role of military consulting and military spending in support of COTS development.

https://www.instagram.com/reel/CxqO0zOheDg/

The best way to bridge this gap is to realign the structure for financial incentives among the military and commercial markets. The current military procurement environment for COTS has led to poor market performance. Procurement is replete with gaps in communication, funding, problems involving information security and weak supply chains. We are constantly taking a reactive approach to these issues and our national security suffers. It makes little financial sense for any company intent on remaining solvent to jump through the military procurement hoops before developing products for the commercial market. By providing financial and other incentives in the form of investment capital, access to controlled and sensitive information systems, access to machinery and equipment, and free access to SMEs and consulting teams that can assist with integration and product

development, we can create a more conducive environment for COTS development. In the words of Charlie Munger, “Show me the incentives, and I will show you the outcome.” Rather than incentivizing new entrants to these markets, we are currently punishing them by mandating increasingly complex systems of compliance and more hoops to jump through just to bid on contracts. Why would we think these incentives would produce anything other than a mediocre outcome?

If the military wants to pick winners and losers, it needs to share risk and have skin in the game or don’t be surprised when industry deems military interests and security concerns to be irrelevant. All systems and potential vectors of attack must be hardened to ensure success in a Universal Threat Environment. Securing our supply chain, critical industries, and developing talent for the future is a national security concern. By offering investment capital for growing companies and tying that investment capital to militarytrained security professionals, the military can have a seat at the table and secure its own defense industrial base, while providing valuable experience to the next generation of military leaders. Embedded personnel would also foster sensitive information sharing among commercial and military entities, while ensuring that shared information is kept safe.

COTS solutions that are responsive to real-world operational problems will also benefit significantly from SME input during the design, engineering, and fulfillment phases of the product lifecycle. While these gaps exist, we advocate for three functional roles within blended design teams: engineers, military operators (SMEs), and expeditor translators. To facilitate collaboration and support difficult design choices, the expeditor translator can act as a liaison between engineers and SMEs or act as a final arbitrator when tough decisions between competing interests must be made. As technology advances, the opportunity to weaponize or abuse emerging tech will continue to grow. Since these increasingly complex systems will rely on dual-use technologies, the distinction between commercial and military interests will become irrelevant. The way forward is to collectively embrace these new tactics and rapidly adapt to this changing threat landscape.

Active Crisis Consulting (www.activecrisis. com) delivers security and technology solutions that cater to the diverse needs of government agencies, military, and corporate clients. Our team is comprised of globally recognized experts who have spent their lives in government and military service. We pride ourselves on delivering unparalleled results. Our security and protective service teams ensure client safety in any situation; and our world-class training programs are bespoke, employing emerging technologies, cutting-edge special tactics, and electronic warfare techniques. Our mission is to prepare clients for the Universal Threat Environment by providing solutions that redefine the pinnacle of professional, military, and agency requirements. Please contact us at info@ activecrisis.com for more information.

Article has been co-authored by Aaron Paseur, a retired U.S. Navy SEAL and Jared Febbroriello, an Industry expert in security and government contracting. Mr. Paseur has tested numerous systems ranging from underwater propulsion, navigation and other sensitive projects, which utilize COTS or modified COTS systems adapted to military use. Mr. Febbroriello’s focus is on compliance, export control and strategic acquisitions – including red team penetration testing, information security, electronic security testing, and the export of firearms, explosives and USML weapons systems. His expertise spans SIGINT, OSINT, HUMINT, GEOINT, digital foot printing, and probing of financial and logistics systems.

The X9 Spider Manpack is a “tip of the spear” rugged battery-powered mobile computer that offers office-style computer workstation performance in a small, portable package designed to be worn on the battlefield. The Manpack is mounted into a rugged enclosure that provides intelligent cooling appropriate for manpack-wearable systems. Intended to provide embedded computing at the individual, squad and platoon level, it provides sensor, video and artificial intelligence (AI) processing while on the move in “dis-mounted” formation.

The Manpack ensemble provides hours of battlefield operation for applications such as Blue Force Tracking, tactical/moving maps, JADC2, IVAS, Nett Warrior interoperability, command and control, joint sensor review and display, and any application such as Minotaur that would run on a server or high-performance workstation computer. Plug-in GPGPU technology from NVIDIA adds battlefield AI into the system for target tracking, image enhancement/recognition, gDVE to see through smoke/dust, and audio processing such as live translation.

Built with a MOSA-inspired Distributed Computing Architecture, the Manpack uses Intel/Apple’s open standard Thunderbolt 4 technology that enables it to share common COTS/civilian interfaces with all X9 Spider products as well as any Thunderbolt or Ethernet product or system. This provides easy additional capabilities, technology refresh/preplanned product improvement, modifications to meet different mission profiles, and future obsolescence mitigation.

By John Reardon, Editor-in-Chief, COTS Journal

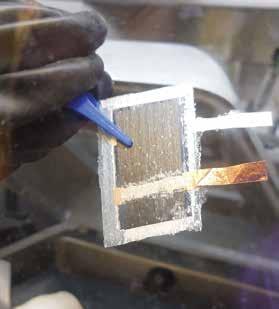

Carbon fiber has a history dating back to 1870 when it was initially used as a filament for light bulbs. It wasn’t until over a century later that its potential as a lightweight structural material was explored. Recent research

from Sweden and England has advanced the concept of multifunctional structural materials using carbon fiber, sometimes referred to as Massless Energy Storage. This concept involves using structural components to store energy, eliminating the parasitic weight of a conventional battery.

The goal is to create a single structural material that stores energy with less weight and improved efficiency compared to current solutions. This innovation has significant advantages over traditional carbon fiber structures combined with conventional lithium batteries. For instance, in electric vehicles (EVs), a 1200-pound battery pack accounts for approximately 25 to 30 percent of the vehicle’s total weight. By integrating the structural composition of the vehicle with energy storage, the vehicle becomes more energy-efficient with an extended range.

The potential impact on military systems, such as VTOLs, aircraft, and drones, is substantial. Reducing the weight of aircraft by minimizing the required batteries has far-reaching implications. Similarly, reducing the weight of battery packs used in communication and wearable solutions offers vast possibilities for various applications.

One area of interest is reducing the cost

and weight of wiring harnesses that transport energy between points. Using the vehicle’s entire structure for energy storage could eliminate the need for lengthy wire runs. Another promising area under investigation involves capturing energy from vibrations affecting the structure during normal use, similar to how regenerative braking contributes to energy storage.

The approach is not to embed a battery within a structural component but to create a unified solution that combines the attributes of carbon fiber and batteries without the weight concerns of traditional batteries. This is achieved by injecting carbon aerogel into the voids of a typical sheet of carbon fiber. Initial tests have shown some negative impacts on the carbon fiber’s strength, but overall results are promising.

While the benchmark of 4.1 kW/kg for conventional battery solutions hasn’t been reached, achieving 1.1 kW/kg with a dualpurpose material is an exciting development.

Using the vehicle’s entire structure for energy storage could eliminate the need for lengthy wire runs.

For example, a hybrid solution could store sufficient energy in a commercial aircraft’s wings to power the cabin, or a car’s body panels could store additional energy for increased power needs.

Although storing power in carbon fiber parts has been proven, scaling from limited lab tests to production-level solutions presents challenges. Companies like Volvo and Sinonus are working on bringing such solutions to market, with vehicle body panels showing promise. Questions about environmental impact, heat dissipation, and service cycles are still being addressed.

Structural power is still in its early stages, and replacing the average EV battery packs is a long-term goal. However, combining energy storage with the structural needs of a vehicle could provide an auxiliary power source, reducing weight and increasing efficiency.

For instance, a military radio’s enclosure could potentially reduce the battery size, contributing to greater SWAP-C efficiency.

The number of charge/discharge cycles a battery can undergo before failure is crucial for EVs and other applications. Although testing is ongoing, the longevity of structural energy storage solutions remains to be fully understood. Currently, replacing batteries in EVs or golf carts can sometimes exceed the vehicle’s value. This concern is still under discussion for structural energy storage applications.

The future battlefield presents numerous energy challenges, and massless energy storage within structures holds great promise. Whether it’s reducing the weight of drones to extend their range or storing energy within bulletproof vests for wearable solutions, this technology is an area to watch closely.

Sinonus has developed a carbon fiber based composite that can provide structural strength and store energy, all in one.

The current norm is to build mechanical structures of single purpose materials such as carbon fiber, aluminum, steel etc. In the same manner a battery is considered a separately unit with “no other” function than energy storage. From a silo perspective, the battery and the structural material performs well at their jobs, but from an efficacy standpoint, the single usage comes at a cost of system volume, weight and overall performance.

The approach is not to embed a battery within a structural component but to create a unified solution that combines the attributes of carbon fiber and batteries without the weight concerns of traditional batteries.

congatec modules set new benchmarks for secure edge A.I. applications

A close-up of a computer chip

congatec presents new high-performance computer-on-modules (COMs) with i.MX 95 processors from NXP expand its extensive module portfolio with low-power NXP i.MX Arm processors. In doing so, congatec underlines its strong partnership with NXP. Customers benefit from straightforward scalability and reliable upgrade paths for existing and new energy-efficient edge A.I. applications with high-security requirements.

In these applications, the new modules offer the advantages of up to three times the GFLOPS computing performance compared to the previous generation with i.MX8 M Plus processors. The new neural processing unit from NXP called ‘eIQ Neutron’ doubles the inference performance for AI-accelerated machine vision. In addition, the hardware-integrated EdgeLock® secure enclave simplifies the implementation of in-house cyber security measures.

The new conga-SMX95 SMARC modules are designed for an industrial temperature range of -40°C to +85°C, are robust in mechanical terms, and are optimized for cost- and energy-efficient applications. The integrated high-performance eIQ Neutron NPU allows AI-accelerated workloads to be performed closer to the local device level. Specific applications for the new SMARC modules can be found in AI-accelerated low-power applications in sectors such as industrial production, machine vision and visual inspection, rugged HMIs, 3D printers, robotics controllers in AMR and AGV, as well as medical imaging and patient monitoring systems. Other target applications include passenger seat back entertainment in buses and aircraft, fleet management in transportation, and construction and farming applications.

The feature set in detail

The new conga-SMX95 SMARC 2.1 modules are based on the next generation of the NXP i.MX 95 application processors with 4-6 Arm Cortex-A55 cores. NXP is now using the new Arm Mali 3D graphics unit for the first time, which delivers up to three times the GPU performance compared to predecessors based on i. MX8 M Plus. Also new is the image signal processor (ISP) for hardware-accelerated image processing. The NXP eIQ Neutron NPU is particularly noteworthy for hardware-accelerated A.I. inference and ma-

chine learning (ML) on the edge in the new SMARC modules. The corresponding eIQ® software development environment from NXP offers OEMs a high-performance development environment that simplifies the implementation of in-house ML applications.

In addition, the new SMARC modules also integrate a real-time domain for controllers. The conga-SMX95 SMARC modules offer 2x Gbit Ethernet with TSN for synchronized and deterministic network data transmission and LPDDR5 (with inline ECC) for data security. The new modules provide DisplayPort as the standard interface and the still widely used LVDS display interface for display connectivity. For direct camera connectivity, the modules have 2x MIPI-CSI.

congatec also offers an extensive hardware and software ecosystem and comprehensive design-in-services for simplified and accelerated application development. These include, among other things, evaluation- and production-ready application carrier boards and custom-tailored cooling solutions. In terms of services,

congatec offers comprehensive documentation, training, and signal integrity measurements for application development.

congatec congatec.com

Four new PXI/PXIe families deliver more density and high voltage & current capability

Pickering Interfaces, the leading provider of modular signal switching and simulation products for electronic test and verification, has announced four new industrial digital I/O families for PXIand LXI-based systems. Expanding the company’s range of industrial digital input and output modules, these four families deliver higher density, expanded voltage and current ranges, and programmable logic levels – all in both PXI and PXIe form factors. With these additions, Pickering has the industry’s largest and most comprehensive portfolio of PXI and PXIe digital I/O modules.

Digital input and output modules are used extensively in automated test systems for operating external devices or interfacing with external logic. Digital inputs test whether a signal voltage is above or below a threshold, and digital outputs provide a current source, sink, or, in some cases, a combination of both. Industrial digital I/O modules are suitable for acquiring signals from digital sensors and communicating with industrial devices, such as PLCs and driving relays, solenoids, and lamps.

“At Pickering Interfaces, we’re committed to providing the largest and most capable catalog of industrial digital I/O products in the industry,” noted Pickering’s Technical Engineering Manager, Paul Bovingdon. “These new modules reflect our commitment to meeting the evolving needs of our customers.”

High-Density Digital Output Modules (model 40/42-412A)

These high-channel-count output modules expand the 40-412 PXI range of digital input/ output modules, adding a PXIe option (model 42412A). The family offers up to 64 output channels (16, 32, 48, or 64 output channel variants), with an external maximum output voltage range of 50V and 0.5A low-side or high-side driving capability.

(model 40/42-414)

New family models, 40-414 (PXI) and 42-414 (PXIe), are digital input modules with high channel count, high input voltage capability, and dual programmable threshold settings per bank. Independent banks of eight channels allow the detection of multiple voltage levels across the module. At the same time, the dual thresholds provide a

convenient way of determining the status of digital signals by comparing each input voltage to two programmable threshold levels – quickly establishing if the input is low, high, or in an intermediate logic state. This feature is handy for functional test applications, as it can often replace the need for a DMM to determine if a device is working correctly. Variants are available with 32, 64, 96, or 128 input channels, and each may be specified with maximum threshold voltages of 50V, 100V, 200V, or 300V. The module provides an effective solution for determining the state of industrial digital signals, such as those used in automotive, aerospace, and rail, avoiding external signal conditioning circuits and reducing test system complexity and footprint.

40/42-419)

Another new family, models 40-419 (PXI) and 42-419 (PXIe), are digital I/O modules providing 16 to 64 I/O channels with up to 60V range via external supply or four built-in voltage rail selections (+3.3V, +5V, +12V or +24V), and up to 300mA current output capability. They also provide I/O direction selection for each port/channel. Each port of 8 channels can be set together as inputs or outputs. Alternatively, individual channels can be set as input or output within a single port. The module also provides semi-dynamic 8-bit pattern acquisition and generation using on-board memory.

(model 40/42-411A)

This ‘form-and-fit’ update to the existing model 40-411 provides PXIe options. It offers four channel-count variants from 16 to 64 low-side outputs, with external 60V, 1A relay driving capability, and three options for on-board relay voltage supply (plus a mixed voltage option) for low-power applications. Models 40-411A (PXI) and 42-411A (PXIe) are ideal for driving external relays from a PXI or PXIe system or Pickering Interfaces’ LXI modular chassis.

Models 40/42-411A, 412A, and 419 have builtin protection systems, including over-current detection and over-voltage clamp or thermal overload. So, the modules can drive relay coils without using flyback diodes or prevent relay coil current from flowing back into the chassis backplane using an isolation barrier. Collectively, the modules offer flexibility to provide external or internal supply, as well as high-side or low-side driving capability to suit different requirements on the load capacity.

Pickering pickeringtest.com

solutions for fast steering mirror control

The Measuring Division of Kaman Precision Products, Inc., the world leader in designing and manufacturing high-performance position measurement systems, highlights its family of precision differential non-contact eddy current measuring systems for free space optical communication. Widely used in commercial and military imaging and communication satellites, interplanetary exploration vehicles, laser targeting, night vision, and optics stabilization systems, the differential inductance transducer systems have a proven track record of outstanding performance. Kaman’s measuring systems provide reliable high-resolution position feedback, ensuring that a reflected laser beam finds its target hundreds or thousands of kilometers away. The differential measurement family includes the KD-5100+ high-reliability displacement system, the commercial grade DIT5200L dif ferential impedance transducer, and the KD5600 digital differential measuring system.

The KD-5100+ features a stable design, extremely small size, and low power consumption. It is ideal for laser communications satellites, ground stations, image stabilization sys tems, and directed energy systems for ground, shipboard, and air borne applications. With its small package size – only 2 x 2.12 x 0.75 inches thick – the KD-5100+ is ideal for meeting SWaP-C require ments. It is manufactured to MilPRF-38534 Class H, with MIL-SPEC components used throughout the electronics.

The KD-5600 digital differ ential measuring system features improved communication and convenience and highly accurate and easy-to-use precision. Kaman has combined its custom sensors, signal processing, analog-to-digital converter, and custom calibration system to deliver the precision KD-5690 system. This system provides digital, high bandwidth, and high linearity, with a high-end communica

Also on offer is the DIT-5200L, which offers a true differential for common mode rejection at an economical price. Capable of subnanometer resolution with high sensitivity (up to 10v/mil, 39 mV/μm) and outstanding linearity (up to 0.1 percent full range), this product provides a powerful solution for a diverse set of applications that demand exacting precision. The commercial-based, fully analog product is built to IPC A-160 Class 3 standards. Depending on the program requirements, it also offers commercial off-the-shelf screening opportunities. The I/O is on a 9-pin mini-D connector, and the input power connections are reverse voltage protected.

Kaman kaman.com

Labs Launches New EMI Filtered

ARINC 404 and ARINC 600 connectors are designed to optimize cost, quality, and performance

Mobix Labs Inc. launched its latest EMI-filtered ARINC 404 and ARINC 600 connectors for defense and aerospace applications. These versatile connectors can be customized with planar arrays, ceramic Pi Tubes, or chip capacitors to meet demanding military specifications, ensuring optimal cost, quality, and performance.

“Our new filtered ARINC connectors set a new standard in price, performance, and customization,” said Bob Ydens, General Manager of E.M. Filters at Mobix Labs. “These products highlight our commitment to delivering cutting-edge solu-

Per Vices addresses the demand for Wide Range SDR

Per Vices Corporation is pleased to announce the release of Calamine, the company’s latest and most comprehensive tuning range SDR. This release builds on the impressive product line already established and integrated into mission-critical systems for the defense, GPS/ GNSS, communications, and test and measurement markets. Calamine builds on the Per Vices existing I.P. to offer an impressive tuning range from near DC to 40 GHz with four (4) independent receive radio chains, each offering 300 MSPS sampling bandwidth.

The latest release will offer capabilities extending other SDR systems for use by government, defense/intelligence communities, and civil customers with direct applications for ra-

tions that meet the stringent requirements of our aerospace and defense customers. Our engineers are ready to assist with any custom design needs to ensure the highest level of performance and reliability.”

The new connectors are designed to deliver exceptional performance and reliability, featuring advanced EMI filtering options to ensure optimal signal integrity and minimal resonance. They offer insertion loss of 70-80 dB for Pi filters and 50-60 dB for C filters, making them ideal for demanding environments.

Filtered ARINC 404 and ARINC 600 Connector Features

• Advanced Filtering Options: Planar arrays, ceramic Pi Tubes, or chip capacitors for optimal signal integrity

• High Insertion Loss: 70-80 dB for Pi filters and 50-60 dB for C filters in demanding environ-

dar systems, signals intelligence, spectrum monitoring, and satellite communications systems. Per Vices, products aim to provide hardware and software solutions to address the growing need for high channel count, wide tuning range, and high bandwidth SDRs. Calamine sets a new standard for the tuning range demanded by the market.

“There has been a growing need in R.F. to operate at higher frequency ranges without sacrificing the ability to tune to lower frequencies. Our latest release of Calamine offers a perfect solution to address this need with multiple channels and high sampling bandwidths all within a compact 19” 2U form factor.” said Victor Wollesen, CEO of Per Vices. “We’re very excited to offer this product to our customers as we know it is critical for many applications.”

Per Vices Corporation is a Canadian compa

ments

• Customizable Designs: Tailored solutions for aerospace and defense applications.

• Robust Construction: Designed to withstand high shock, vibration, and extreme temperatures

• Quick Lead Times: Competitive pricing and industry-leading lead times to meet urgent deadlines

Mobix Labs mobixlabs.com

ny based in Toronto, Ontario, designing and producing high-performance commercial-off-theshelf (COTS), modified-off-the-shelf (MOTS), and fully customized SDRs that can be tailored to fit the most challenging and mission-critical customer applications. Per Vices has direct experience working with and supplying SDRs to support a wide variety of applications within the defense, civil, aerospace, medical, telecommunications, low latency networks, global positioning (GNSS/GPS), radar, test & measurement, spectrum monitoring, and broadcasting & wireless management industries. Per Vices leads the market for commercially available software-defined radios by offering mission-critical products to leading-edge intelligence community groups, advanced research agencies, and global defense prime contractors.

Per Vices Corporation pervices.co

NanoGraf Begins Production at Scale to Provide Military with More Powerful, Resilient Batteries

The production run will equip U.S. soldiers with better batteries for missions and in-field combat.

“NanoGraf, the battery material company enabling more robust, lighter, longer-lasting lithium-ion batteries, announced it has suc cessfully completed the first large volume pro duction run of its M38 18650 cell for the U.S. military.

NanoGraf has produced approximate ly 50,000 cells for customers with a high yield throughput, which will be used primarily for tactical radios and other military applications in support of the Family of Advanced Standard Bat teries (FASTBat) program. Thanks to NanoGraf’s proprietary silicon anode material, these batteries will last up to 15% longer than what U.S. soldiers currently use and are cross-compatible with more of their devices.

million. In March, NanoGraf also announced a new 67,850-square-foot facility for advanced manufacturing and expanded R&D capabilities,

“We’ve been working toward this production milestone for several years, and it’s incredibly exciting to see it come to fruition,” said Francis Wang, CEO of NanoGraf. “We’re very proud to reach our goal of producing this many finished cell products and continue our work with the Department of Defense to ensure soldiers have the power they need to complete their missions.”

NanoGraf’s production run was done on a standard high-volume manufacturing line with its third-party cell manufacturer. Its silicon anode material was successfully used as a drop-in to its traditional manufacturing process and has proven to be manufacturable in a high energy cell density.

“This production run is an exciting achievement for NanoGraf, validating that our commercial scale manufacturing successfully meets the performance requirements of the cell,” said Connor Hund, Chief Operating Officer of NanoGraf. “We look forward to our continued growth as we aim to expand commercial material production to 50 tons per year in our Chicago facility.”

The production run is just one of several recent announcements around NanoGraf’s growth. In January, the company announced a new contract worth up to $15 million from the U.S. Army to develop cross-compatible batteries for soldiers in the field, which brings NanoGraf’s

NanoGraf Corporation nanograf.com

VIAVI Introduces Industry’s Most Comprehensive Solution for Resilient Positioning, Navigation, and Timing for Critical Infrastructure

Viavi Solutions Inc. announced the availability of SecurePNT™ 6200 with SecureTimeSM services. This resilient timing clock solution delivers the most comprehensive assurance of positioning, navigation, and timing (PNT) services used in critical infrastructure operations worldwide. SecurePNT and SecureTime build on VIAVI’s proven assured PNT solutions with the addition of the Fugro AtomiChron® timing service, enabling intelligent zero-trust multisource assurance combining signals from Geosynchronous Orbit (GEO), Low Earth Orbit (LEO) and Medium Earth Orbit (MEO) GPS and GNSS constellations.

Essential networks worldwide – including 5G communications, transportation, energy, public safety, finance, defense, and data centers – rely on publicly available GPS and GNSS signals for synchronization based on timing and location. These signals are occasionally unavailable or at risk of being jammed or spoofed, or satellites can be attacked, with potentially catastrophic consequences. Governments have begun mandating that critical infrastructure providers improve the resilience of their networks through more re-

VIAVI’s portfolio of assured PNT products has been proven to provide redundant timing and location security in civilian and military applications based on connectivity to the market’s broadest range of timing sources. The Fugro AtomiChron® timing source enables the VIAVI SecureTime eGNSSSM GEO service to deliver true authenticated and encrypted resilience and higher accuracy, not previously supported by traditional GNSS, through:

• Anti-spoofing detection and mitigation

• Authentication on all GNSS satellite constellations beyond Galileo OSNMA

• Encryption

• <5ns accuracy and <1ns optional timing accuracy, traceable to UTC/NIST

• The most comprehensive and cost-effective global coverage in the market

This solution comes with the hallmarks of the VIAVI assured PNT portfolio:

• TrustedPNT™ sensor fusion technology –fusing, weighing, comparing, authenticating, and verifying as many timing space and terrestrial sources as possible, based on an intelligent zero-trust multisource model

• Patented μTranscoder™ – enabling users to rapidly retrofit their legacy GPS/GNSS clocks with a resilient and multisource PNT clock by

simply placing the 6200 between the legacy GPS/ GNSS antenna and its receiver

• Compliance with evolving government guidance, requirements, and standards, including the DHS Resilient PNT Conformance Framework, the NIST 8323.1 Cybersecurity Framework for PNT Profile, the CISA Federal PNT Services Acquisition Guidance, and the IEEE Resilient PNT P1952 Standard in progress.

“We’re delighted to partner with VIAVI to strengthen their PNT solutions. Time synchronization is one of the greatest challenges for critical infrastructure,” said Roel de Vries, Business Developer AtomiChron® at Fugro. “The Fugro AtomiChron® service improves the accuracy of timekeeping to the nanosecond and protects GNSS signals being spoofed, using our navigation message authentication.”

“The public and private sectors are on high alert against threats to critical infrastructure, with positioning, navigation, and timing being especially vulnerable,” said Doug Russell, Senior Vice President, AvComm, VIAVI. “We’re excited to be working with a fellow market leader in Fugro, augmenting our proven resilient PNT solutions with AtomiChron®’s precision, reliability, and global availability.”

VIAVI viavisolutions.com

Behlman

PICO

COTS

Periodicals

POSTMASTER: