BEHLMAN LEADS THE PACK AGAIN!

Behlman introduces the first test-proven VPX power supplies developed in alignment with the SOSA Technical Standard. Like all Behlman VPXtra® power supplies, these 3U and 6U COTS DC-to-DC high-power dual output units feature Xtra-reliable design and Xtra-rugged construction to stand up to the rigors of all mission-critical airborne, shipboard, ground and mobile applications.

VPXtra® 1000CD5-IQI

> 6U power module developed in alignment with the SOSA Technical Standard

> Delivers 1050W DC power via two outputs

> VITA 46.11 IPMC for integration with system management

VPXtra® 800D-IQI

> 3U power module developed in alignment with the SOSA Technical Standard

> Delivers 800W DC power via two outputs

> VITA 46.11 IPMC for integration with system management

COTS (kots), n. 1. Commercial off-the-shelf. Terminology popularized in 1994 within U.S. DoD by SECDEF Wm. Perry’s “Perry Memo” that changed military industry purchasing and design guidelines, making Mil-Specs acceptable only by waiver. COTS is generally defined for technology, goods and services as: a) using commercial business practices and specifications, b) not developed under government funding, c) offered for sale to the general market, d) still must meet the program ORD. 2. Commercial business practices include the accepted practice of customer-paid minor modification to standard COTS products to meet the customer’s unique requirements

—Ant. When applied to the procurement of electronics for the U.S. Military, COTS is a procurement philosophy and does not imply commercial. Office environment or any other durability grade. E.g., rad-hard components designed and offered for sale to the general market are COTS if they were developed by the company and not under government funding.

EDITORIAL

EDITORIAL SUBMISSION AND RELEASES

johnr@rtc-media.com

PUBLISHER/CEO

John Reardon • johnr@rtc-media.com

CONTRIBUTING EDITORS

John Reardon, Odile Ronat

ART AND PRODUCTION

CREATIVE DIRECTOR

Shae Reardon • shae.reardon@gmail.com

DIGITAL MARKETING MANAGER

Scott Blair • scott@blair-media.com

AD TRAFFIC

Vaughn Orchard • vaughno@rtc-media. com

FINANCE AND ACCOUNTING

Paige Reardon • paiger@rtc-media.com ADMINISTRATION/CIRCULATION

Dawn Dunaway • dawnr@rtc-media.com

ACCOUNT MANAGER

SALES MANAGER

Vaughn Orchard • vaughno@rtc-media. com

CUSTOM AND CONTRACT SERVICES

John Reardon • johnr@rtc-media.com

COTS Journal

CORPORATE OFFICE

RTC Media

110 S Rancho Santa Fe, Virgin UT 84779 PO 790039

Phone: (949) 226-2023

Fax: (949) 226-2050

www.rtc-media.com

PUBLISHED BY RTC MEDIA

Copyright 2025, RTC Media. Printed in the United States. All rights reserved. All related graphics are trademarks of The RTC Group. All other brand and product names are the

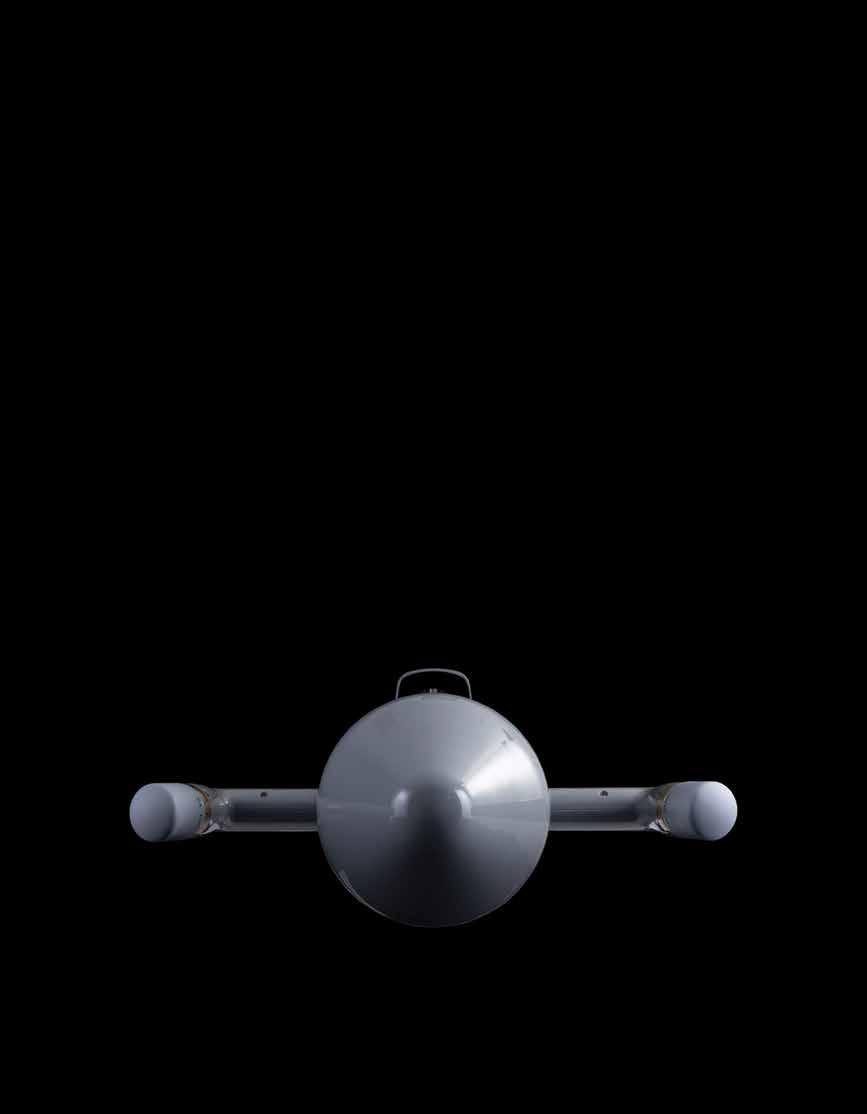

mPOD uses DRFM technology to emulate realistic combat scenarios, replicating near-peer jamming for fast, accurate electronic warefare training.

mrcy.com/mpod

PUBLISHER’S NOTE

By John Reardon Editor-in-Chief, COTS Journal

What’s Next in Advancing US Acquisition Policies

In a groundbreaking move that promises to reshape the defense industrial landscape, Secretary of War Pete Hegseth has dropped a trio of policy memorandums that fundamentally alter the acquisition process, prioritizing speed, modularity, and, crucially for the COTS (Commercial Off-The-Shelf) industry, a “commercial-first” approach. This isn’t just bureaucratic shuffling; it’s a paradigm shift designed to inject genuine competition into a market long dominated

by a handful of established prime contractors comfortable with the status quo. The message from the newly branded Department of War is clear: adapt to the urgent demand for speed and innovation, or find your future endeavors outside the Pentagon’s gates.

The Dawn of the Warfighting Acquisition System (WAS)

The most significant change is the renam-

ing and transformation of the antiquated Defense Acquisition System into the Warfighting Acquisition System (WAS). This semantic shift is intentional, signaling that acquisition is now a core component of the warfighting function, with “speed to capability delivery” as its organizing principle. Hegseth, in his address at the National War College, emphasized the urgency, telling industry executives that the Department is prepared to take on more acquisition risk

to decrease operational risk. This philosophy directly tackles the Achilles’ heel of traditional procurement: the years-long, requirements-heavy process that often delivers a 100% solution for yesterday’s threats. The new approach is open to buying the “85% solution” now and iterating with the industry over time.

For the COTS sector, this translates into unprecedented opportunities. The memorandums enshrine a “commercial-first” policy, making commercially available solutions the default purchase path over custom-built, government-funded developments. This moves the COTS philosophy, first popularized by the 1994 “Perry Memo,” from a mere suggestion to a core directive. This is a massive win for innovative, smaller companies that lack the infrastructure to navigate the complex, bespoke Mil-Spec (Military Specification) environment, and often operate on different capital cycles than the primes.

Leveling the Playing Field for Non-Traditionals

The new policies are a direct challenge to the large prime contractors, many of whom have become too comfortable with “vendor lock” and the slow, predictable pace of the old system. Hegseth is intent on making defense contracting competitive again. The directives explicitly require maintaining at least two qualified sources for critical program content to ensure meaningful choice and drive down prices.

Furthermore, the emphasis on a Modular Open Systems Approach (MOSA) is a game-changer. By mandating open standards and interfaces, the Department is ensuring that different companies can compete to provide upgraded components, thereby preventing a single prime contractor from owning

the entire lifecycle of a system. This enables smaller, agile COTS providers to plug their advanced solutions—whether in AI, high-performance computing (HPEC), or IoT technologies—directly into existing and future military platforms, something that was nearly impossible under the old, closed system.

The Department is also streamlining the use of alternative contracting approaches like Other Transaction Agreements (OTAs) and Commercial Solutions Openings (CSOs), which will be the default for all software development. These mechanisms are faster and less bureaucratic than traditional contracts, perfectly suited for the rapid development cycles typical in the commercial tech world.

A New Era of Investment and Innovation

Secretary Hegseth has signaled a willingness to use long-term contracts and other incentives to reward companies that invest their own R&D dollars and expand their capacity to meet the Department’s needs. This provides the clear, investable demand signals that the COTS industry has long craved, encouraging venture capital and private equity to back defense-focused tech firms.

The message to the COTS industry is clear: the door is open. The Department of War is actively seeking partners willing to move at the “speed of relevance” and provide the capabilities needed to maintain an advantage over our adversaries. This release and the underlying memos are not just procedural updates; they are a call to arms for the innovative, non-traditional defense industrial base to step up and deliver the future of warfighting technology, today.

The

Inside Track

Virtualitics Selected by U.S. Marine Corps 2nd Marine Aircraft Wing to Advance AI-Driven Aviation Readiness.

Virtualitics announced a new strategic contract with the 2nd Marine Aircraft Wing (2D MAW) to deploy its Integrated Readiness Optimization (IRO-MX) solution in support of aviation sustainment and mission readiness for MV-22 Osprey squadrons.

The award expands Virtualitics’ footprint across the Department of War (DoW), reflecting growing adoption of readiness AI solutions across each service branch. IROMX provides United States Marine Corps (USMC) leaders with predictive asset insights, enabling them to forecast demand, allocate resources, and sustain aircraft availability in high-tempo environments.

“At Virtualitics, our mission is to empower commanders with AI insights they can trust,” said Michael Amori, CEO and co-founder. “This partnership with 2D MAW shows how explainable AI solutions are transforming aviation sustainment, helping the Marine Corps maintain fleet readiness, reduce downtime, and strengthen mission success at speed and scale.”

The IRO-MX platform delivers mission-critical insights at speed, using AI-driven analytics to uncover hidden performance trends and accelerate mainte-

Elbit Systems Awarded Contracts in an Aggregate Amount of $210 Million from the Israel Ministry of Defense for

Tank Upgrades

Elbit Systems Ltd. announced that it has been awarded contracts from the Israel Ministry of Defense totaling approximately $210 million for the upgrade of Merkava Main Battle Tanks (MBTs). The contracts will be performed over a period of six years.

Under these contracts, Elbit Systems will carry out an extensive renewal of the elec-

nance decisions. Built with explainable AI, it fosters collaboration between maintainers and AI systems, builds trust in recommendations, and enables faster, more confident decisions. This human-centered approach ensures trust, transparency, and faster adoption across mission-critical environments.

Designed for interoperability, IRO-MX integrates seamlessly with existing USMC systems and across the DoW ecosystem, enhancing joint operations and aligning data strategies for unified mission outcomes.

“Supporting the Osprey community is an incredible honor,” said Rob Bocek, Chief Revenue Officer, Virtualitics. “The MV-22 is one of the most versatile and critical utility assets in modern warfare, and helping its crews sustain operational readiness with trusted AI is exactly what our mis-

sion is about. By delivering AI to the warfighter , at the edge, where decisions matter most, we’re advancing how the Department of War prepares, responds, and maintains superiority in every domain.”

This announcement follows Virtualitics’ recent milestone with the US Air Force Global Strike Command, which has accelerated adoption of its Mission AI solutions across multiple branches of the DoW. Together, these initiatives demonstrate how Virtualitics is unifying complex data, generating critical insights, and enabling decision advantage across various domains. This contract supports Virtualtics’ growing AI readiness portfolio and momentum ahead of the company’s next phase of expansion.

tronic assemblies of the tanks to extend their operational service life, as well as the upgrade and enhancement of multiple onboard systems. Among these are high-performance, lightweight, AI-enhanced electro-optical sights that provide panoramic day and night observation, along with advanced target detection, acquisition, and tracking. The contracts also include the supply of spare parts and the provision of comprehensive maintenance and support services.

Bezhalel (Butzi) Machlis, President and CEO of Elbit Systems: “Elbit Systems is proud to continue serving as a key partner of the Israel Ministry of Defense and the Israel Defense Forces

in advancing their technological capabilities. These new contracts reflect our ongoing commitment to providing cutting-edge solutions that enhance the operational effectiveness and survivability of Israel’s armored platforms.”

The

Inside Track

Lockheed Martin Uses 5th Gen Fighter to Command Drone in Flight

Lockheed Martin Skunk Works, with industry partners and the US Air Force, controlled an uncrewed aerial system (UAS) from the cockpit of a 5th Gen fighter while in flight.

During the flight out of Nellis Air Force Base, Nevada, an F-22 Raptor pilot successfully used an open interface in the cockpit to send control directions to another airborne UAS.

“This effort represents Skunk Works driving a breakthrough in air combat capability, where single-seat aircraft command and control drones with simple and intuitive interfaces in the cockpit,” said OJ Sanchez, vice president and general manager, Lockheed Martin Skunk Works.

The 22 pilot used a pilot vehicle interface (PVI) to command the drone to execute a specific mission profile. The PVI provides a flexible system for integrating with both current and future platforms.

This event demonstrates human-machine teaming capabilities and the future of air combat today. Lockheed Martin has been focused on the transformative power

GDIT Awarded $1.5 Billion Enterprise IT Modernization Contract to Strengthen US Strategic Command’s Operational Readiness

The company will leverage digital engineering, AI, and cyber capabilities to enhance strategic deterrence, including critical nuclear command-and-control systems.

General Dynamics Information Technology (GDIT), a business unit of General Dynamics,

of autonomous and AI-enabled operations in crewed and uncrewed systems for years, with particular focus on integrating autonomous drones with the F-22 and F-35.

This flight event and other ongoing evaluations are crucial steps in realizing the Air Force’s family of systems vision. Human-machine teaming enhances situational awareness, interoperability, survivability, and flexibility, unlocking a significant ad-

vantage for the US Air Force. By integrating the F-22 with other advanced systems, we’re bolstering our warfighters’ capabilities and ensuring American airpower dominance.

Lockheed Martin’s proactive approach to building, testing, and improving 5th Gen teaming capabilities is at the forefront of innovation, demonstrating the future of air combat today.

announced that it was awarded an enterprise IT modernization contract to strengthen the US Strategic Command’s (STRATCOM) operational readiness. The new $1.5 billion contract, awarded in May, covers a one-year base period and six option years.

STRATCOM oversees the nation’s strategic deterrence, global strike, nuclear command and control, and electromagnetic spectrum operations worldwide. To support its global missions, STRATCOM requires a cutting-edge enterprise IT network environment that connects data and systems to national decision makers and mobile warfighters.

Under this contract, GDIT will leverage its digital engineering capabilities to cut costs, increase efficiency, and enhance collaboration among mission partners. The company will also integrate artificial intelligence/machine learning technologies into STRATCOM’s enterprise data to empower decision makers to

act quickly. Additionally, GDIT will transition STRATCOM to a new hybrid cloud environment to enable greater flexibility and scalability. To protect the combatant command’s networks and data from evolving cyber threats, the company will also implement advanced cybersecurity and zero-trust solutions.

“Modernizing STRATCOM’s IT capabilities is critical to protecting our national security and maintaining our strategic deterrence edge,” said Brian Sheridan, GDIT’s senior vice president for Defense. “We look forward to delivering a secure, agile, and resilient network that enables our warfighters to be better connected, informed, and ready.”

The award further expands the company’s mission-critical IT services for combatant commands. GDIT also provides digital modernization services to the US Central Command and technical and mission support services to the US Special Operations Command.

Inside Track

Palantir and FTAI Aviation Enter Strategic Partnership to Accelerate the Transformation of Aircraft Engine Maintenance, Repair, and Exchange

Palantir, a leading provider of AI software, and FTAI Aviation Ltd., a global leader in aircraft engine maintenance, today announced a multi-year strategic partnership that will allow FTAI to leverage Palantir’s Artificial Intelligence Platform (“AIP”) across its global maintenance footprint.

Through this partnership, Palantir’s AIP is helping FTAI improve productivity and reduce manufacturing costs by optimizing maintenance scheduling and inventory across FTAI’s worldwide operations. This includes transforming its internal supply chain and driving further efficiencies through automated workflows, rapid asset

allocation, and dynamic component procurement strategies.

With AI-assisted decision-making, FTAI is targeting faster production turnaround times and improved unit economics, aiming to deliver further cost savings to its customers globally. This will allow FTAI to disrupt further the traditional maintenance, repair, and overhaul (“MRO”) shop visit model and accelerate its production rampup to meet growing demand.

“At FTAI, we have long prioritized technology as a key driver of productivity since the launch of our Maintenance, Repair and Exchange (MRE) offering,” said David Moreno, Chief Operating Officer of FTAI Aviation. “As our customer base continues to multiply, accelerating the integration of advanced technology into our operations is essential. We are excited to partner with Palantir to harness AI and transform engine maintenance for the world’s most widely used commercial aircraft. The initial

results in our facilities have been impressive, and AIP will play a critical role in achieving our longterm goal of 25% industry market share and enhanced value for our shareholders.”

“We are excited to partner with FTAI and showcase how our AI platform drives faster decisions, enhanced productivity, and optimized performance,” said Ted Mabrey, Global Head of Commercial at Palantir Technologies. “FTAI is at the cutting edge of process and operational efficiency, making them an ideal partner to take to the next level with our AI solutions. By integrating Palantir’s advanced AI capabilities with FTAI’s innovative approach to maintenance, repair, and exchange, we will help FTAI further transform how it serves the global engine aftermarket.”

This strategic partnership between Palantir and FTAI reflects the growing role of artificial intelligence and highlights the impact of collaborative innovation between technology leaders and industry pioneers.

Mercury Awarded Contract To Develop Multi-Mission Subsystem for US Military Programs

Mercury Systems, Inc. announced in September that it was awarded a multi-year, cost-plus-fixed-fee development contract to develop a multi-mission, multi-domain subsystem for a US defense prime contractor.

“This program will leverage open standards and a broad set of capabilities from the Mercury Processing Platform, including advanced microelectronics packaging, mixed signal conversion and distribution, thermal management, and chassis-level integration,” said Joe Plunkett, Vice President of Mercury’s Advanced Concepts Group, which will lead the program. “This award demonstrates the customer’s confidence in

our ability to rapidly develop trusted, integrated solutions and subsequently transition to the highrate manufacturing that is required to support multiple national security platforms.”

Mercury Systems –Innovation that matters®

Mercury Systems is a global technology company that delivers mission-critical processing to the edge, making advanced technologies profoundly more accessible for today’s most challenging aerospace and defense missions. The Mercury Processing Platform allows customers to tap into innovative capabilities from silicon to system scale, turning data into decisions on timelines that matter. Mercury’s products and solutions are deployed across more than 300 programs in 35 countries, enabling a broad range of applications in mission computing, sensor processing, command and control, and communications.

Inside Track The

How NGC2 Is Expanding the Battlefield Network at Ivy Sting 2

This month, Team Anduril joined the US Army’s 4th Infantry Division for Ivy Sting 2, the second in a progressive series of exercises designed to advance the Army’s Next Generation Command and Control (NGC2) ecosystem.

Just six weeks earlier, during Ivy Sting 1, the team demonstrated digital fires in live training, using NGC2 to connect sensors and shooters so artillery units could respond faster and hit with greater precision.

Ivy Sting 2 connected more data nodes, sensors, and Soldiers through a unified mesh network that linked every level of the fight, all the way to the division command post, delivering a more complete, real-time picture of the battlespace.

At the center of this event were two new integrations: Ghost-X, Anduril’s autonomous aircraft system, and the AN/TPQ-53 radar, which detects and tracks incoming enemy artillery, rockets, and mortars to pinpoint their launch points—both now feeding directly into the NGC2 ecosystem. These integrations brought real-time sensing, target recognition, and radar tracking into a single digital loop that enables faster decisions on the battlefield.

AI-Aided Target Recognition and Battle Damage Assessment

At Ivy Sting 2, Striveworks’ AI operations platform powered AI-enabled sensing and decision-making within the Next Generation Command and Control (NGC2) environment. Using Anduril’s Lattice Mesh network, a Ghost-X aircraft served as a forward observer—streaming live, full-motion video for automated object detection and real-time battle damage assessment.

Soldiers from the 4th Infantry Division, working alongside industry partners, trained and deployed AI models through Striveworks’ Chariot platform, the AI layer of NGC2. As Ghost-X captured video from the field, these models analyzed the feed in real time to detect and classify enemy T-72 tanks using automatic target recognition al-

gorithms.

Once a tank was identified, Striveworks’ Sky Saber application used that output to designate the target as hostile. The resulting data flowed through NGC2’s Lattice Mesh network to Soldiers coordinating fires, who reviewed the information and made the call to strike.

When artillery rounds landed, the same AI models compared pre- and post-strike imagery to verify the hit. The AI significantly reduced the cognitive burden on operators and shortened the time between detection and decision while keeping humans in control at every stage to review, validate, and authorize actions before execution.

Together, Striveworks’ Chariot and Sky Saber, Anduril’s Ghost-X, and NGC2’s open architecture demonstrated how AI, sensing, and networked command systems can work together—delivering real-time intelligence and faster decisions at the edge of the battlefield.

Data at the Speed of the Sensor

Ivy Sting 2 also introduced direct integration of the Army’s Q-53 radar into the NGC2 Mesh. Previously, radar data passed through multiple legacy systems before reaching the units that needed it—each step adding delay and risk. Now, a Voyager ruggedized edge computer running the Lattice software stack is co-located with the Q-53 radar, translating raw radar data into NGC2 format and sharing it instantly across the network.

This change eliminated data bottlenecks, letting Soldiers across fires, intelligence, and air-defense teams act on radar information in near-real time, whether connected to the cloud or operating in the field with limited connectivity.

From Edge to Cloud

Building on lessons from Ivy Sting 1, where NGC2 operated exclusively at the edge, Ivy Sting 2 expanded to run simultaneously at the edge and in the cloud. Data from Ghost-X and the Q-53 radar flowed seamlessly to command-post nodes and cloud-based applications, giving leaders a single, coherent operational picture across every echelon.

What’s Next

With Ivy Sting 2 complete, the Army and Anduril team are scaling toward greater complexity. Upcoming exercises will add new command-and-control nodes, mission threads, and airspace-deconfliction capabilities. Each iteration advances NGC2 toward division-wide deployment and the culminating Ivy Mass event in 2026, where the entire 4th Infantry Division will operate as one digitally connected force.

The

Inside Track

MDA Space Makes $10 Million Investment In Maritime Launch, Becoming An Equity Owner And A Strategic Partner

MDA Space Ltd. announced a $10 million equity investment by MDA Space in Maritime Launch Services Inc. for $0.223 per share.

The MDA Space investment in Maritime Launch Services marks a key milestone in advancing Canada’s sovereign launch capability, strengthening the country’s domestic space value chain, with complete capability from ground to orbit.

The equity investment will accelerate Spaceport Nova Scotia’s readiness for orbital launch

operations, providing reliable domestic launch capability for commercial, civil, government, and defence clients in Canada. MDA Space expects to become an operational partner at Spaceport Nova Scotia, supporting the development and future operations of the Spaceport.

“MDA Space’s investment and partnership come at a pivotal moment for Maritime Launch and for Canada’s space future,” said Stephen Matier, President and CEO of Maritime Launch Services. “By combining MDA Space’s world-class technical heritage with our operational focus at Spaceport Nova Scotia, we are creating the conditions our launch vehicle clients need: reliability, responsiveness, and integration across the full mission campaign. Together, we are building a complete sovereign launch solution that strengthens Canadian innovation, drives economic growth, and enhances security in space.”

Lanteris Space Systems - A New Space Era Defense and Infrastructure Solutions Provider

Maxar Space Systems has unveiled its new identity: Lanteris Space Systems. The rebrand reflects the company’s evolution into a next-generation defense and space technology company operating at the intersection of national security, missile tracking, space infrastructure, deep space exploration, and commercial connectivity.

The new identity emanates from Latin and Greek, embodying two powerful ideas: lanter-

Maritime Launch is a Canadian-owned commercial space company that is developing Spaceport Nova Scotia, Canada’s first commercial orbital launch complex. Located near Canso, Nova Scotia, on the Atlantic coast, Spaceport Nova Scotia is designed to provide responsive, cost-effective, and sustainable access to space for

ra (Latin, “to bring light”) and lempein (Greek, “to shine or stand out”), and signals the company’s positioning among the new space companies, building on decades of heritage while embracing the agility and innovation today’s missions demand.

“Our mission is to deliver mission-critical capabilities in space—faster, smarter, and more resilient than ever before, made possible by the dedication and expertise of our people,” said Chris Johnson, CEO of Lanteris Space Systems. “From tracking emerging threats to enabling humanity’s push into deep space, we’re building the systems that will define the future of security, communications, and exploration.”

launch vehicle developers and satellite delivery services to low-Earth orbit, over a wide range of launch inclinations, from a single site.

“Maritime Launch has been methodically advancing the development of Spaceport Nova Scotia, focused on doing it right, with safety, community, and operational excellence, to address the needs of the domestic and global space ecosystem,” said Mike Greenley, CEO of MDA Space. “In a rapidly changing space industry, establishing sovereign launch capacity in Canada that will respond to the global demand for alternative launch capabilities on Canada’s Atlantic coast is important. This is an example of strategically located critical infrastructure that is needed. MDA Space is pleased to partner with Maritime Launch on this exciting new chapter for the Canadian space industry.”

Spaceport Nova Scotia is expected to create significant economic benefits in the Atlantic and across Canada through high-quality jobs, local supply chain development, and global investment attraction.

The transaction includes an Investor Rights Agreement, entered into between MDA Space and Maritime Launch, granting MDA Space certain rights, including the right to nominate one individual to serve on the board of Maritime Launch and pro rata participatory rights in future financings of the Spaceport. The investment will be used for applicable research and development initiatives relating to the ongoing development of Spaceport Nova Scotia and will trigger the retirement of convertible debentures.

The

Inside Track

Cubic to Deliver Additional F-35 Air Combat Training Subsystems

The U.S. Army down-selected Lockheed Cubic has received a contract award from Lockheed Martin to provide 130 P5 Internal Subsystems (IS) units for the F-35 Lot 20 production aircraft, and to establish a Lot 21-22 long-term pricing agreement in advance of future awards.

“Cubic’s P5 IS provides secure, high-fidelity instrumented live training for the F-35 program,” said Russ Marsh, President, Cubic Defense. “The capability allows 4th and 5th generation aircraft to train together seamlessly in live flight events while safeguarding critical tactics, techniques, and procedures (TTP).”

The P5 Combat Training System (P5CTS) unlocks powerful mission insight through seamless integration with truth

Aitech Expands with New Business Unit and Leadership to Drive Growth in Classified US Government Programs and National Defense Initiatives

Aitech announced the launch of Aitech Defense Solutions, LLC (ADSL), a new division created to support classified US government programs. ADSL will partner directly with primes and the US government to design and deliver advanced embedded computing solutions for some of the nation’s most critical defense initiatives. The establishment of ADSL marks a significant step forward for Aitech in its ability to address the unique demands of classified defense initiatives and enhance its capacity to provide specialized support and solutions for government agencies.

data. Cubic’s solution drives precise live and post-mission assessments. It fuels the evolution of TTPs, enhancing combat effectiveness across 30+ test and training ranges in 17 countries, all within the trusted P5 training network. The P5 IS is a critical element of the P5CTS.

Cubic, along with its principal subcontractor, Leonardo DRS, will support all contractor activities related to the statement of work. The P5 IS improves the training systems used by the US Air Force, the U.S. Marine Corps, the US Navy, and coalition partners. The capability empowers Warfighters to relay precise time, space, and position information (TSPI) data throughout training missions—enabling joint, interoperable exercises with coalition partners on a unified platform.

formed ADSL after six years leading Aitech Defense Systems, Inc. (ADSI). He will work directly with the US government on programs that require classified access. Industry veteran D. Davis joins ADSI as general manager, leading initiatives in AI-powered rugged embedded computing systems across the sea, land, air, and space domains. The new leadership team, with deep defense industry expertise, coupled with Aitech’s legacy in innovation and engineering, positions Aitech to exceed the strategic objectives of its government clients, ensuring mission success and fostering trusted partnerships.

Pratish Shah will serve as general manager of the newly

“Aitech is meeting heightened demand with a dedicated team focused on government programs,” said Yaron Mund, CEO of Aitech. “We’ve built a strong foundation in the defense industry, and this expansion allows us to meet growing requirements and carry forward the momentum of providing best-inclass rugged embedded computing and networking solutions with unparalleled customization, program management, and engineering for some of the nation’s most critical missions.”

In his new role at ADSL, Shah will focus on strengthening engagement with classified US government programs and aligning customer-specific requirements with Aitech’s engineering and program management

expertise. He will ensure ADSL delivers best-in-class solutions that address the rapidly evolving needs of national Defense, reflecting the urgency to stay ahead of adversaries by modernizing military technology, accelerating the adoption of AI-enabled systems, and strengthening the US defense industrial base (DIB). ADSL is currently pursuing Facility Clearance (FCL) sponsorship and expects to obtain clearance by Q3 2026.

Davis brings extensive experience in business development, P&L leadership, and customer execution across leading defense and aerospace companies, including Leidos, BAE, Cobham, and General Dynamics. In his new role as general manager for ADSI, Davis will lead the company’s growth initiatives and oversee its portfolio of rugged embedded computing solutions used across sea, land, air, and space domains.

“I am looking forward to building on Aitech’s 40-year track record as an innovator in high-performance embedded computing solutions for military, aerospace, and space missions, while advancing the next generation of AI-driven capabilities,” said Davis. “The company’s mission-proven success, coupled with expanded clearance experience, underscores its unique position to support the future initiatives of key primes.”

The

Inside Track

American Rheinmetall Awarded $31M Contract to Support Bradley Damage Assessment and Repair Efforts.

American Rheinmetall has been awarded a $31M contract to support a Rapid Damage Assessment and Repair Demonstration for the US Army and the Ukrainian Armed Forces (UAF). Under this 18-month contract, awarded by the National Center for Manufacturing Sciences, Inc. (NCMS), American Rheinmetall will develop and demonstrate advanced damage assessment and repair processes by establishing a forward-deployed maintenance capability for assessing and repairing damaged or broken Bradley Infantry Fighting Vehicles (IFV) closer to operational areas.

Program Overview

The demonstration will use the Bradley IFV as a surrogate platform to validate a Rapid Damage Assessment and Repair (DAR) Team trained and equipped with advanced processes, tools, and a responsive supply chain ecosystem. The initiative

Thales Alenia Space signs multiple contracts to shape the consortium that will carry out the Lunar Descent Element for ESA’s Argonaut.

aims to bridge the gap between battlefield damage and complete depot-level repair by enabling rapid, efficient restoration of combat effectiveness until new parts or dedicated repair teams arrive.

Once developed, this program will validate a scalable approach to establishing remote damage assessment and repair sites capable of operating in hazardous or harsh environments. The outcome will reduce downtime, improve readiness, and strengthen resilience across heavy equipment and infrastructure.

Strengthening Allied Readiness

The Rapid Damage Assessment and Repair Demonstration supports US foreign assistance

efforts by helping the Armed Forces of Ukraine return Bradley IFVs to operational status amid the ongoing conflict with Russia.

“This contract underscores American Rheinmetall’s commitment to delivering innovative, mission-critical products and services that support the highest priority operational capabilities for the U.S. military and its allies,” said Matt Warnick, Chief Executive Officer, American Rheinmetall. “By bringing advanced repair capabilities closer to the point of need, we are helping ensure that vital equipment like the Bradley Fighting Vehicle can return to service quickly and safely at a time of crucial need for Ukrainian armed forces.”

The Argonaut lander will fly to the Moon and land on its surface, ensuring the European autonomous access to the Moon.

Thales Alenia Space, a joint venture between Thales (67%) and Leonardo (33%), has signed multiple contracts shaping the core industrial team that will build the European Space Agen-

cy (ESA) Argonaut Lunar Descent Element. ESA’s Argonaut Mission, planned for launch from the 2030s, will deliver cargo, infrastructure, and scientific instruments to the Moon’s surface.

These contracts follow the one already signed between ESA and Thales Alenia Space in January 2025. It referred to the design, development, and delivery of the Lunar Descent Element (LDE), including responsibility for mission design and integration.

As the prime contractor and system integrator for the LDE, Thales Alenia Space in Italy leads the industrial consortium responsible for the system, the entry, descent, and landing aspects, as well as the general and specific architectures of the thermomechanical, avionics, and software chains.

The core industrial team is made up of Thales Alenia Space in Italy, Thales Alenia Space in France, Thales Alenia Space in the UK, as well as OHB System AG and Nammo, both part of the consortium as strategic subcontractors for propulsion.

Inside Track

The BAE Systems and Air Force Research Laboratory collaborate on quantum sensing and networking research

BAE Systems’ FAST Labs™ research, development, and production organization and the Air Force Research Laboratory (AFRL) have signed a three-year Cooperative Research and Development Agreement (CRADA) to advance quantum sensing and networking capabilities.

“This agreement will enable us to push the boundaries of quantum sensing and networking,” said Jane Heyes, principal scientist at BAE Systems’ FAST Labs. “Working with the Air Force Research Laboratory advances new possibilities for enhanced soldier communications, spectrum awareness, and electronic warfare.”

This collaboration aims to refine and integrate cutting-edge technologies into

Echodyne and Poland’s Military Institute of Armored and Automotive Technology Collaborate on Integrating Counter-Drone Radar into Unmanned Ground Vehicles

quantum sensors, networks, and distributed sensing research in an effort to revolutionize capabilities and enhance future security for defense and civilian applications.

“We look forward to industry collaboration, which leverages AFRL expertise in quantum networking in concert with industry side expertise in quantum sensing,” said Dr. Erin C. Sheridan, research physicist in quantum information science at AFRL. “Combining multiples of these quantum RF sensors into an array is an exciting area of research in quantum sensing that will deliver new capabilities for the warfighter.”

Under the CRADA, BAE Systems’ FAST Labs will leverage its expertise in developing quantum RF sensors based on Rydberg atoms, highly excited atoms suitable for studying quantum mechanics and enabling new technologies. This approach allows for frequency-independent sensing, ideal for integration on smaller platforms.

Multiple RF antennas working together are necessary for different types of mea-

Echodyne, the radar platform company, announces a collaboration with Poland’s Military Institute of Armored and Automotive Technology (WITPiS), a leading research and development center in land vehicle technology. Through this collaboration, the teams will assess, integrate, and identify potential uses for Echodyne’s counter-unmanned aerial system (C-UAS) radars in Unmanned Ground Vehicles (UGVs) developed by WITPiS and its industrial partners.

Echodyne will work closely with its long-time partner and distributor in Poland, Linc Polska, to test, demonstrate, and showcase the capabilities of C-UAS radar technology with WITPiS’ UGVs. The three entities will work hand in hand to identify both civilian and military applications for radar-enabled UGVs in the region.

“The Military Institute of Armored and Automotive Technology brings critical expertise to our collaboration

surements important to a broad spectrum of defense interests.

Work on this program will take place at BAE Systems’ facilities in Merrimack, New Hampshire, and AFRL’s Information Directorate in Rome, New York, and at an AFRL field test site located in Stockbridge, New York.

to deliver best-in-class ground-based systems for detection and situational awareness,” said Eben Frankenberg, CEO of Echodyne. “As Allied militaries increasingly put the spotlight on modernizing their land force capabilities, Echodyne looks forward to continuing to demonstrate how our MESA radars provide the highest performance for on-the-move threat detection and integration into larger counter-UAS and defense systems.”

Echodyne’s 4D metamaterials electronically scanned array (MESA) radars are perfectly suited to provide the reliable precision tracking capabilities required for fixed, portable, and on-the-move C-UAS missions. Rooted in the belief that data fidelity makes all the difference to C-UAS mission success, Echodyne radars consistently generate a high-fidelity view of the airspace, detecting and tracking UAS intruders with pinpoint accuracy.

“Echodyne’s been a long-time partner of ours, and we know exactly what their consistent, reliable radar technology is capable of,” said Harald Dingemans, CEO at Linc Polska. “We look forward to showcasing different ways the radar technology can support the modernization of land capabilities with WITPiS UGVs.”

AI-ENABLED CONTINUOUS MONITORING: KEY TO NDAA COMPLIANCE

By Jason English, Senior Vice President of Supply Chain Risk and Vendor Vetting Solutions at Babel Street

The 2026 National Defense Authorization Act (NDAA) imposes some of the most sweeping vendor-vetting rules in recent memory. At its core is the Ernst Amendment, which requires stronger safeguards to block vendors with undisclosed ties to the Chinese Communist Party (CCP) or other foreign adversaries from entering the federal supply chain. The deadline for implementing the requirements outlined by the NDAA is September 30, 2026. Before this time, federal agencies and contractors must implement validated, end-to-end screening processes or risk compliance failures and mission disruption.

The 2026 NDAA doesn’t just add new requirements. It fundamentally redefines vendor vetting as a counterintelligence mission requiring continuous vigilance, advanced analytics, and cross-agency collaboration. What we’re seeing is a transition from “trust but verify” to “verify continuously.”

Federal acquisition professionals, defense contractors, supply chain risk managers, and policy leaders should start taking action now as the NDAA Ernst Amendment represents a fundamental paradigm shift in federal procurement. Its param-

eters require agencies and contractors to move beyond checkbox compliance and adopt active, intelligence-driven safeguards against hidden adversarial vendors.

Three Primary Shifts

Three core shifts illustrate this new direction, including moving from self-attestation to third-party validation, from focusing solely on ownership to accounting for broader influence, and from point-in-time checks to continuous monitoring. Together, these changes call for a more proactive, intelligence-driven approach to protecting the federal supply chain.

1. From Self-Attestation to Third-Party Validation – With this new policy, federal procurement is shifting away from its long-standing reliance on contractor self-reporting. Under the Ernst amendment, the Defense Counterintelligence and Security Agency (DCSA) will serve as the validation authority, requiring validated, end-to-end screening that moves vetting from trust-based attestations to independently verified oversight.

2. From Ownership to Influence – Traditionally, supply chain reviews have focused on foreign ownership, control, or influence (FOCI). However, adversaries increasingly leverage unofficial affiliations, political influence networks, and entities such as China’s United Front Work Department to gain access. As a result, legal ownership alone no longer captures the full spectrum of risks.

3. From Point-in-Time to Continuous Monitoring – One-time vetting at the start of a contract is no longer sufficient. The new framework requires continuous monitoring, with contractors required to maintain ongoing alerts, conduct periodic reassessments, and proactively report any material changes in their circumstances.

Risk-Based Tiering

A tiered approach can allow checks to be applied more strategically. For example, using a basic, lightweight review for low-risk suppliers with counterintelligence-grade vetting for high-risk cases. This can help agencies and contractors focus resources

effectively while meeting the law’s requirements.

• High-risk Suppliers – These include suppliers that support critical infrastructure or produce critical technologies, such as semiconductors and biotechnologies. This would also include suppliers with overseas ownership structures and those operating in geopolitically sensitive or contested regions.

• Medium-risk Suppliers – These are suppliers supporting non-mission-critical capabilities, or that may have limited foreign ties but lack transparent governance structures.

• Low-risk Suppliers – These include commodity-based suppliers, such as those providing facility maintenance equipment, office supplies, and general administrative goods.

Even with tiered risk assessments prioritizing the most critical vendors, continuous end-to-end supply chain monitoring can generate an enormous volume of data that must be tracked, analyzed, acted upon, and documented.

The information that must be sourced and tracked can encompass government procurement records, financial flows, business structures, multilingual open-source intelligence, watch lists, sanctions, foreign registries, and other relevant data. The sheer scale and complexity of integrating all this data make manual oversight difficult, if not impossible. For larger vendor supply chains, this requires AI-driven tools capable of compiling and processing vast datasets, identifying subtle risk patterns, and providing actionable intelligence.

Where Commercial Tools Fit

In an environment where adversaries continuously adapt their concealment methods, government systems alone cannot maintain the decision advantage necessary to protect the supply chain. Commercial platforms serve as force multipliers, providing deep analytics and adversary-focused intelligence that enable agencies to meet both the letter and the spirit of the Ernst Amendment’s requirements.

Commercial AI-enabled platforms scour open-source intelligence from pub-

licly available data, along with proprietary data, to deliver mission-speed analytics that resolve aliases, match entities across thousands of data sources, and identify obscured connections in real time.

The most advanced of these platforms integrate seamlessly with existing government systems through Application Programming Interfaces (APIs) and secure data feeds, augmenting rather than replacing internal capabilities.

The critical advantage is speed. While legacy systems may take days or weeks to process and correlate information, AI-driven tools operate much faster, performing link analysis and risk scoring quickly enough to support acquisition decisions without creating bottlenecks.

The goal is to translate technical intelligence findings into actionable insights that procurement officials and program managers can use to make informed, risk-based decisions.

Next Steps

On a recent webinar on this topic, John Tenaglia, principal director, defense pric-

ing and contracting at the U.S. Department of War (DoW), indicated that he will soon publish proposed policy rules. He added that they will then be published for public comment. Nevertheless, he underscored that the final rules will closely follow what the statutory language requires.

In the meantime, contractors should now begin building their risk frameworks by identifying and prioritizing (tiering) suppliers, starting with those critical to their operations. Conducting preliminary self-assessments of the supply chain will allow you to get ahead of government inquiries and eliminate surprises before contract awards. The regulatory details will continue to evolve, but the fundamental requirements are clear enough to begin meaningful preparation.

Other steps to take could include developing vendor intelligence tradecraft, that is, treating supply chain vetting as a distinct intelligence discipline rather than simply a compliance exercise. Teams need training to read and interpret beneficial own-

ership structures and to understand how shell companies, nested subsidiaries, and complex corporate arrangements can obscure accurate control. Equally important is learning how to interpret risk flags when they emerge and communicate those risks effectively to decision-makers. Building this competency takes time, so starting now is paramount.

U.S. adversaries are actively exploiting supply chain vulnerability. There’s a reason these policies are being put in place, underscoring the urgency of action needed.

As the federal community defines this challenge and formulates comprehensive policies, I would caution against waiting for final policy and implementation guidelines. Start identifying your risk framework. Begin mapping your critical suppliers and triage them to help you prioritize vendor vetting. In this way, when the policy, regulation, and collaboration guidelines are finalized, you will be ahead of the power curve and can be entirely focused on your mission.

About the Author

Jason English serves as Senior Vice President of Supply Chain Risk and Vendor Vetting Solutions at Babel Street, where he leads the development and execution of go-to-market strategies for global defense, intelligence, commercial, and international markets. A retired Naval Intelligence Officer with 26 years of distinguished service, Jason has directed intelligence operations across multiple DoD and Intelligence Community organizations, specializing in global risk management, military operations, and cybersecurity. At Babel Street, he leverages his operational expertise and strategic vision to deliver innovative vendor-vetting and supply-chain risk solutions in support of mission-critical DoD and IC requirements. His background includes proven success in business development, strategic planning, and governmental affairs. Jason is a graduate of the U.S. Naval Academy, the U.S. Air Force Command & Staff College, and the College of William & Mary.

TIME-SERIES, REAL-TIME, SECURE: COTS

DEVICE DATA MANAGEMENT FOR IOT & AI

By Sasan Montaseri, Founder - ITTIA

In the defense industry, pairing Commercial Off-the-Shelf (COTS) hardware with embedded software speeds fielding and reduces costs while aligning with open, modular standards and goals. Success hinges on rigor: ruggedization, deterministic real-time behavior, long-life support amid silicon churn, and built-in cybersecurity and safety. New technologies for artificial intelligence and the Internet of Things (IoT) must be thoroughly vetted and isolated in defense applications. With disciplined systems engineering and DevSecOps, COTS solutions deliver faster, easier tech refreshes and ensure compliance across decades of upgrades.

In the embedded world, data management often defines success or failure. As manufacturers integrate sensors, microcontrollers (MCUs), microprocessors (MPUs), neural processing units (NPUs), and electronic control units (ECUs) into connected products, they face one consistent challenge: managing and understanding the growing flow of device data. Choosing the right database technology to manage data has become just as critical as selecting the right hardware. Too often, developers adopt open-source database products because they’re “free,” only to discover later that such solutions lack determinism, reliability, and long-term maintainability, leading to

missed deadlines and expensive redesigns.

In embedded systems, adopting a COTS embedded database means selecting a commercially supported, drop-in data engine rather than building custom storage from scratch. When targeting MCU and MPU-based devices, this database must deliver deterministic latency for ingestion and queries, operate within tight RAM and flash budgets, and ensure power-fail safety through atomic commits, journaling, or copy-on-write mechanisms. Database storage should be flash-aware, minimizing write amplification and extending the life of storage media. Built-in security features like data encryption and authentication are essential for protecting operational data, while native time-series and indexing support enable real-time insights directly on the device. Equally important, selective synchronization ensures that only meaningful summaries or events traverse limited links to gateways or the cloud. Over time, schema evolution, OTA-friendly upgrades, and long-term vendor support keep products stable and adaptable throughout their lifecycle.

A COTS embedded database provides a complete, ready-to-integrate data management foundation that spans the full embedded ecosystem, from MCUs to MPUs and ECUs. On microcontrollers, it enables

deterministic data ingestion, time-series capture, and real-time decision-making within constrained resources. On microprocessors, it supports high-performance analytics, AI inference integration, and multi-threaded processing for edge and gateway applications. In electronic control units (ECUs), it ensures power-fail-safe, secure storage of operational and diagnostic data, vital for automotive, industrial, and transportation systems. When paired with an observability platform, engineers can visualize trends, drift, and anomalies in real time. At the same time, an integrated data distribution layer manages selective synchronization between nodes, gateways, and cloud environments. This unified approach empowers manufacturers to deploy scalable, secure, and maintainable embedded systems that seamlessly collect, process, observe, and distribute data across the entire device network.

Seven Critical Requirements for Embedded Database Success

1. Deterministic Performance

Embedded systems must operate within strict timing constraints. A robust database must guarantee bounded latency for ingestion and queries, avoiding unpredictable garbage collection or cache spikes, to ensure reliable real-time behavior under

multitasking or real-time operating system (RTOS) conditions.

2. Data Durability & Power-Fail Safety

Industrial and mission-critical systems must retain data through resets, brownouts, and software crashes. The database must employ atomic commits, journaling, or copy-on-write to ensure data integrity, even on flash or SSD-based storage.

3. Resource Efficiency & Scalability

Although COTS platforms often have more resources than MCUs, they still run multiple workloads, control logic, AI inference, networking, and analytics. The database must remain lightweight, efficient, and modular, scaling from kilobytes to gigabytes without consuming excessive CPU or memory.

4. Security & Access Control

With increasing connectivity, data security is non-negotiable. Embedded databases must include encryption and authentication, aligning with industrial cybersecurity standards such as IEC 62443 to ensure end-

to-end protection of sensitive operational data.

5. Data Distribution & Synchronization

Modern edge systems are inherently distributed. The database should support selective synchronization, replication, and data filtering, so only relevant, compressed, or aggregated data flows between devices and gateways, reducing bandwidth usage and improving responsiveness.

6. Observability & Analytics Integration

Visibility is key to performance optimization and AI enablement. The database must provide time-series management, real-time dashboards, and hooks for analytics and ML frameworks, enabling local monitoring, predictive maintenance, and continuous improvement at the device level.

7. Maintainability & Long-Term Evolvability

Embedded systems often remain in the field for a decade or more. The database should support schema evolution, version upgrades, and remote lifecycle manage-

ment without downtime or complex data migrations, ensuring the system evolves alongside firmware and AI updates.

Why ITTIA DB Platform Is the Ideal COTS Candidate

The ITTIA DB Platform brings these seven essentials together into one cohesive solution. It provides deterministic performance, power-fail safety, and security-by-design for MCU (ITTIA DB Lite), MPU (ITTIA DB), and ECU (ITTIA DB Lite or ITTIA DB) class systems. Developers gain a complete data management stack, from local time-series ingestion and AI-ready storage to selective synchronization, observability dashboards (ITTIA Analitica), and long-term maintainability. With unified components for real-time operation, analytics, data distribution (ITTIA Data Connect), and visualization, it enables manufacturers to build edge devices that are flash-safe, real-time, and secure, ready to support IoT and AI applications for years to come.

HOW ACT ENGINEERS RELIABILITY INTO EVERY WATT

By Jackson Toone, On Behalf of Advanced Conversion Technology

Finding the best power supply for harsh aerospace environments starts with understanding how much rides on reliable electrical power. You depend on stable alternating current-to-direct current (AC-DC) and direct current-to-direct current (DC-DC) conversion every time a system takes flight, transmits data, or guides a mission.

Without consistent voltage, even the most advanced technology can lose precision or shut down when it matters most. Whether managing avionics or defense systems, every circuit needs clean, uninterrupted power to maintain steady performance and keep operations safe.

Innovation in power conversion technology turns unstable, raw electrical input into the dependable current that fuels aircraft, satellites, naval equipment, and heavy machinery. Across air, land, and sea, engineers redefine what reliability means, designing more efficient systems to withstand temperature extremes and high-stress conditions.

When power stays consistent, every mission — from orbit to factory floor — runs smoother and safer.

The Critical Role of AC-DC and DCDC Power Supplies

AC-DC and DC-DC converters are the heart of every dependable power system you use. They transform raw, unstable energy into clean, consistent power that sensitive electronics can trust. In defense and aerospace operations, these converters ensure your systems operate at peak precision, even in unpredictable environments.

Today’s military and aerospace programs are shifting toward “more-electric” aircraft, ships, and vehicles. This shift focuses on efficiency, lighter builds, and more innovative energy use. As systems become increasingly digital, converters power radar, sensors, avionics, and onboard communication systems. Without them, mission-critical electronics would not function reliably or safely.

Designing for these environments can be challenging. You deal with constant challenges, such as variable input voltages, high vibration, extreme heat, and electromagnetic interference that can disrupt signal quality. Every component in your system must perform flawlessly, which means your power converters must be tough and adaptable.

Compliance with strict military standards, such as MIL-STD-704 for aircraft, MIL-STD-1275 for ground vehicles, and MIL-STD-1399 for naval systems, ensures that every platform remains safe and mission-ready. When your converters meet these standards, you provide reliable power and build the foundation for consistent performance across the most demanding missions on the planet.

What Is the Best Power Supply for Harsh Aerospace Environments?

Designing a power supply that performs flawlessly in extreme conditions takes more than standard

engineering. It requires creativity, precision, and resilience. Operating environments can be unpredictable. Your systems face blistering heat on a flight deck, then become exposed to freezing temperatures at high altitudes or radiation in space.

Ruggedization can become pivotal in these situations. Engineers strengthen components, protect housings from corrosion and moisture, and design circuits that shrug off vibration and shock. Meanwhile, redundancy gives your mission-critical systems a built-in safety net. If one circuit falters, another instantly takes over. It is the kind of thoughtful engineering that keeps your operations stable, your data accurate, and your missions on track, even when the environment is doing its worst.

Filtering plays an equally vital role in this process. You have probably dealt with electromagnetic interference or noisy signals that can throw sensitive electronics off balance. Advanced filtering techniques help block that noise and maintain steady, reliable power output across all subsystems. The result is smoother communication, safer operation, and longer equipment life.

Leading manufacturers like Advanced Conversion Technology specialize in building MIL-STD-certified power supplies designed specifically for these conditions. Its rugged, field-tested solutions prove that reliability survives and masters the environment. When your equipment has to perform where others fail, a well-engineered power supply becomes your mission’s most dependable ally.

From Design Lab to Deployment

Design is only the beginning when building the best power supply for

harsh aerospace environments. You must ensure that reliability takes center stage through rigorous testing and simulation. Once your system leaves the ground, there is no room for failure. Engineers push every component to its limits long before deployment, testing for vibration, thermal stress, altitude, and radiation exposure.

These simulations help uncover weak points, verify stability, and ensure consistent power delivery throughout a product’s life cycle. Life cycle validation goes further by tracking how materials and circuits age under real-world stress, which provides confidence that your military power supply will perform the same way years from now as it does on day one. This kind of endurance testing is essential in an industry where reliability defines success.

Customization is another key to making power systems mission-ready. Manufacturers often collaborate closely with OEMs to design power supplies that perfectly match the needs of specific aircraft, vehicles, or naval platforms. Each system has its power profile, and customization ensures every watt is used efficiently and safely.

However, even as technology advances, manufacturing automation in aerospace has evolved more slowly than in other industries. Low production volumes and the high cost of specialized equipment made automation a long-term investment rather than an immediate priority. Now, that is changing with more innovative tools and greater demand for precision. Digital manufacturing processes bring higher consistency and faster delivery. They help you achieve the rugged, high-performance power systems your missions demand, no matter how harsh the

Innovation and the Future of Power Conversion

Modern power systems operate differently now that they are intelligent. With digital monitoring, you can track performance metrics such as voltage, temperature, and load balance in real time, enabling you to respond before minor issues escalate. Predictive maintenance goes a step further by analyzing data trends to forecast potential failures, helping you prevent downtime and extend equipment life.

With artificial intelligence (AI)-driven fault detection, your systems can automatically identify irregular patterns, isolate faults, and recommend solutions without human intervention. These innovations turn traditional power conversion into a living, data-driven ecosystem where precision and reliability work hand in hand.

Engineers are designing smarter, more efficient systems that deliver more power in smaller packages to keep up with this transformation. SWaP-C optimization — reducing size, weight, power consumption, and cost — has become a guiding principle in aerospace and defense design. Modular architectures let you reconfigure systems faster and scale performance to fit different missions. Meanwhile, intelligent telemetry keeps you connected to the health of every component in real time.

Companies like Advanced Conversion Technology lead this shift, integrating digital intelligence into flexible, custom power supplies that think and adapt alongside your mission. By combining rugged durability with innovative data capabilities, you get a power system that

withstands harsh conditions. It also learns from them, which makes every flight, mission, or operation brighter than the last.

Sustaining Mission Readiness

Secure, domestic manufacturing plays a much larger role in defense reliability than most people realize. You need more than technical excellence. You need guaranteed access to the parts and materials that keep critical systems running. In global supply chains, that is not always easy. Parts shortages, export restrictions, and competing priorities from overseas suppliers can cause significant disruptions for defense programs.

Sometimes, shipments get delayed or withheld altogether, putting acquisition timelines and operational readiness at risk. Engineering power supplies for the most extreme environments goes beyond advanced

design. You must ensure every component — from circuit boards to enclosures — comes from a reliable, controlled, and traceable source.

Companies with complete inhouse engineering and manufacturing capabilities strengthen resilience across the supply chain. When your production happens domestically, you gain tighter quality control, faster turnaround, and protection from geopolitical or market instability. For defense and aerospace applications, that security directly translates into mission assurance. You can confidently deploy knowing every part was designed, tested, and built under consistent standards.

U.S.-based manufacturers such as Advanced Conversion Technology exemplify this commitment to engineering independence and longterm program support. Maintaining its entire process — from design to

testing — within its facilities ensures that reliability is not outsourced. In a world where every delay can compromise readiness, controlling your supply chain is essential for national security.

Engineering the Power of Trust

Reliable power conversion is the backbone of national defense and industrial safety, ensuring every mission runs precisely and confidently. As systems become smarter and more electrified, the demand for military power supplies that can withstand harsh environments will only grow, which drives innovation in efficiency, durability, and intelligent control. Companies like Advanced Conversion Technology demonstrate how powerful innovation continues to protect and enable every mission, shaping the future of defense through precision engineering.

November 2025

COT’S PICKS

ROLEC Announces Its Latest Diecast Enclosures For Defense Electronics

Growing demand for defense electronics has increased the need for ROLEC’s latest aluminum enclosures.

ROLEC’s IP-rated diecast enclosures are suitable for electronics in tracked and wheeled vehicles, warships, and fleet auxiliaries; training/simulation technology; military cranes; and railways used for troop transport, logistics, and supply.

Extreme Engineering Solutions expands its offering with the 13th-generation Intel i7

13th Gen Intel® Core™ i7 Processor-Based Rugged Small Form Factor (SFF) COTS System with 12-Port Gigabit Ethernet Switch & Router with Cisco IOS-XE®

The XPand6241 is a true CommercialOff-The-Shelf (COTS) rugged system based on the 13th Gen Intel® Core™ i7 series (formerly Raptor Lake-P) of processors and a Gigabit Ethernet switch hosting an XChange6300 Cisco IOS-XE® Gigabit Ethernet Embedded Services Router.

With a compact design, the XPand6241 maximizes processing and networking performance while providing a SWaP-optimized alternative to traditionally larger slot-based systems; it is an actual Small Form Factor (SFF) system based on COTS 3U VPX modules.

The premium hinged-lid aluDOOR (IP 66, IP 67, IP 68, IP 69K) features a recessed (or smooth) top section for fitting hi-tech controls and display systems. Features include ‘lid closed’ installation to protect the seal and electronics.

Versatile aluKOM (IP 66) offers a wide range of terminal enclosures in standard sizes, making them easy to replace existing units.

XPand6241 | Rugged Embedded System Front ShotXPand6241 | Rugged Embedded System Back ShotXPand6241 | Rugged Embedded System with Storage

The XPand6241 is a true CommercialOff-The-Shelf (COTS) rugged system based on the 13th Gen Intel® Core™ i7 series (formerly Raptor Lake-P) of processors and a Gigabit Ethernet switch hosting an XChange6300 Cisco IOS-XE® Gigabit Ethernet Embedded Services Router. With a compact design, the XPand6241 maximizes processing and networking performance while providing a SWaP-optimized alternative to traditionally larger slot-based systems; it is an actual Small Form Factor (SFF) system based on COTS 3U VPX modules.

The XPand6241’s first slot supports the XPedite8270 13th Gen Intel® Core™ i7 processor-based 3U VPX SBC, which can host an optional XPort6107 XMC NVM Express® Solid-State Drive (SSD).

The XPand6241’s second slot supports the XChange3031 3U VPX Gigabit Ethernet switch. The XChange3031 can be configured as a fully managed Layer 2 switch. The XChange3031 delivers full wire-speed across all of its ports and supports jumbo frames up to 10 kB. It supports IPv6 and a comprehensive set of IETF RFCs and IEEE protocols. The XChange6300 Cisco IOS-XE® router XMC installed on the XChange3031 provides highly secure data, voice, and video communications to stationary and mobile network nodes. The system supports a memory module bay to host a removable PCI Express Solid-State Drive (SSD) flash memory module.

The XPand6241 supports the rear I/O from the installed VPX modules with two circular connectors: a 130-pin connector for the SBC in the first slot, and a 93-pin connector with four integrated high-speed interface inserts for the switch in the second slot. This fully ruggedized system is designed to meet the rigorous standards of MIL-STD-810 and DO-160, while incorporating the latest power-saving and performance-enhancing technology. The heat from the internal conduction-cooled modules is conducted to the sidewall heat exchangers, where it is dissipated to an externally attached cold plate. The system includes an integrated MIL-STD-704 28 VDC power supply and MIL-STD-461 EMI filtering.

November 2025

COT’S PICKS

KRYTAR Announces New Compact 3 dB, 180-Degree Hybrid Coupler Covering 7.125 to 15.35 GHz

KRYTAR, Inc. announces a new 180-Degree Hybrid Coupler that delivers 3 dB of coupling over the frequency range of 7.125 to 15.35 GHz in a compact package. KRYTAR’s family of 3 dB, 180-degree Hybrid Couplers performs many functions, including splitting and combining signals in amplifiers, switching circuits, and antenna beamforming networks used in a wide range of commercial and military applications.

KRYTAR’s new 180-Degree Hybrid Coupler, Model 407125-1535, delivers exceptional versatility from 7.125 to 15.35 GHz

with excellent phase and amplitude matching. Specifications include 3 dB Coupling; Amplitude Imbalance: ±0.6 dB; Phase Imbalance is ±8 degrees; Isolation is >16 dB; Maximum VSWR: 1.6; and Insertion Loss of <1.1 dB. The 180-degree hybrids (also referred to as the “rat race” couplers) are fourpart devices used to either equally divide an input signal or add two fused signals. An additional benefit of this hybrid coupler is that it alternately provides an equally divided 180-degree phase-shifted output signal. In addition, Model 407125-1535 offers an average Input Power Rating of 20 W and a peak Input Power Rating of 3 kW. The hybrid coupler comes with industry-standard SMA Female Connectors. The compact package measures just 1.5 inches (L) x 1.50 inches (W) x 0.40 inches (H), and weighs only 1.5 ounces. Operating temperature is -54° to 85° C. This coupler is typically avail-

able from stock to 30 days, ARO. KRYTAR 180 Degree Hybrid Couplers are four-port components with dual input and output ports. KRYTAR hybrid couplers offer broad frequency coverage in single, compact packages, providing low insertion loss, high directivity, and tight coupling. These hybrid couplers offer excellent solutions for many ultra-broadband applications, including electronic warfare (EW), mmWave, 6G, 5G NR (New Radio), Wi-Fi 6 and Wi-Fi 6E, SATCOM, radar, MIMO (Multiple-Input and Multiple-Output) radio links, signal monitoring and measurement, antenna beamforming, and EMC (electromagnetic compatibility) testing environments. The couplers can also be manufactured to meet military specifications.

November 2025

COT’S PICKS

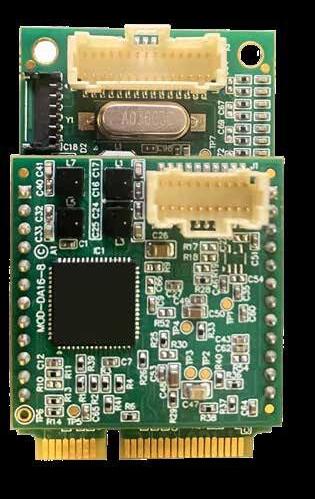

High-Speed Multifunction Analog I/O Line with 4-20mA current outputs/inputs for Embedded Systems in PCI Express Mini Card (mPCIe) Form Factor

ACCES I/O Products, Inc. announces the release of the mPCIe-DAAI16-8F, a high-performance PCI Express Mini Card (mPCIe) multifunction analog I/O module that delivers 16-bit precision, simultaneous analog I/O, and flexible digital I/O — all in a small, rugged design ideal for embedded and OEM applications.

The mPCIe-DAAI16-8F integrates eight 16-bit analog outputs supporting both voltage and current outputs, ideal for

applications that need 4-20mA control. In addition to the flexible DAC outputs, eight 16-bit analog input channels, software-selectable as eight single-ended or four differential inputs, are included. An aggregate analog-input sampling rate of up to 1 MSPS supports dynamic measurements, while each DAC channel can simultaneously perform hardware-paced waveform playback up to 125 kSPS. A compact, double-stack mPCIe Type F1 form factor with latching I/O connectors enables reliable operation in shock- and vibration-prone environments.

Factory options include extended temperature of -40°C to +85°C, current inputs (4-20mA, 10-50mA), voltage dividers for higher voltage inputs, and HART modem capability. Additional customization options include conformal coating, custom software/ product labeling, and more — even entirely new features tailored to your specific needs, enabled by our advanced FPGA-based design.

Key features of the mPCIe-DAAI16-8F Family include:

• PCI Express Mini Card (mPCIe) Type F1 (full length) with high-retention latching connectors vs shock/vibration

• Eight 16-bit analog outputs with software selectable current (4–20 mA, 0–20 mA, 0–24 mA) and voltage ranges

• Hardware-paced DAC waveform streaming up to 125 kSPS per channel using onboard FIFO + DMA architecture

• Eight 16-bit analog inputs — software-selectable as eight single-ended or four differential; up to 1 MSPS aggregate ADC rate

• Seven per-channel programmable differential, bipolar input ranges

• Eight digital I/O pins (4 inputs, four

outputs) can be used for triggering, status, or control, and optional digital integration features (pulse/PWM generation and measurement, edge-specific IRQs, and counting)

• Flexible A/D triggering — start sources include software, internal timer, external start, and externally triggered timer start for precise synchronization.

• Onboard watchdog with status output

• Factory options: HART modem (on DAC #0), 4–20 mA / 10–50 mA ADC inputs, per-channel input voltage dividers, conformal coating, and more.

• Made in the USA; RoHS compliant.

All ACCES mPCIe (and M.2) cards feature high-retention latching connectors for shock and vibration mitigation, as well as an optional extended operating temperature range of -40°C to +85°C. The small size (mPCIe Type F1: 30mm x 50.95mm) allows for maximum performance in embedded applications where space is a valuable resource. These cards are supported on most operating systems and include a free, Linux- and Windows-compatible software package. This package contains sample programs and source code in C# and Delphi for Windows. Linux support includes installation files and programming-level samples via our open-source kernel driver. Third-party support consists of a Windows-standard DLL API library usable with the most popular application programs. Embedded OS support includes the Windows family of Operating Systems, including IoT. ACCES also now offers a VxWorks driver/library for the ultimate real-time process monitoring and control solution.

COT’S PICKS November 2025

US Digital’s New ED4 Digital Encoder Display

US Digital announced the release of our new ED4 Encoder Display. Encoder displays provide immediate feedback on encoder status, including speed, position, angle, and count. The ED4 encoder display features a programmable alarm output on each channel.

• Easy, intuitive setup

• Dual encoder inputs

• User-defined display units

• Supports A/B, Analog, & PWM encoder outputs

Building on the proven performance of the ED3, the ED4 introduces a modern user interface, expanded input capabilities, and flexible configuration options for a wide range of motion control applications. Its color LCD with capacitive touchscreen and adjustable backlight offers improved visibility and an improved user experience. The ED4 supports

quadrature, analog, and PWM encoder inputs, ensuring compatibility with most encoders.

Users can easily customize units of measure, scale factors, trigger set points, and even the encoder name. Four I/O pins are included for alarm outputs and capture inputs. The Datasheet and Quick Start Guide provide full specifications and setup information to help integrate the ED4 into your next project.

As with all US Digital products, the ED4 was designed and produced in Vancouver, Washington, USA, and comes with prompt access to our technical and customer service teams, with same-day shipping on most orders. includes an integrated MIL-STD-704 28 VDC power supply and MIL-STD-461 EMI filtering.

COT’S PICKS November 2025

Curtiss-Wright Introduces New Universal Smart Chassis with Expanded Modular Interoperability for Tactical Network Flexibility