Hi!, I’m Roos Hulshof

Your Designer

An Industrial Product Designer with much interest in applying Sustainable choices & Programming to product design.

Who is Roos?

Hey there! I’m Roos, from the Netherlands and every day, I am excited to learn more about Product Design, Programming and Circulair Developments.

At the moment I am finishing a Professional Bachelor in Industrial Product Design. Over the past 4 years I concluded I would like to push my career towards sustainable design for electronical devices. One of the biggest accomplished learning moments in my studies yet has been my internship at Mystic Boarding. After taking the CS50 course, I was sure I wanted to combine design with programming for my career too. Which is why I am looking to move forward to a Software Design Master.

In my free time, I do a lot of sports like Kitesurfing. I would say my personality is passionate, open, and hard-working. My friends and family would describe me as sporty, enthusiastic, enterprising with great ambition.

This is why you should take a good look at this portfolio!

Education

Industrial Product Designing

University Rotterdam

2019- to date

Sport & Entertainment Marketing

Minor - University Utrecht

Intern - Product Developer

MYSTIC BOARDING

Feb 2022 – July 2022

High school Diploma

Mencia Mendoza Lyceum

Physics&Technic & Physics&Health

2014-2019

Employments

Trainer/Bartender

Revolt Bouldering

Nov 2022 – To Date

Junior Design Engineer

Secure One International BV

dec 2019 - To Date

Kitesurf Instructor

Kitesurfschool.nl & BLOW

Aug 2022– To Date

Sales Employee

SHAKA Kitesurfing

July 2020 – Feb 2022

Skills

Solidworks 2021-2022

Adobe Illustrator/ Photoshop/

Premier Pro

HTML/CSS/Python Basics

Cura - 3d prints

Figma

Languages English

Dutch

German

Idea generator

Prototyping

3d printing

Laser cutting & welding

Professional sketching

Hobby’s

Kite/Skate/Snow/Surf/Boulder/Run

Playing guitar

Sketching

Enjoying time with friends and family

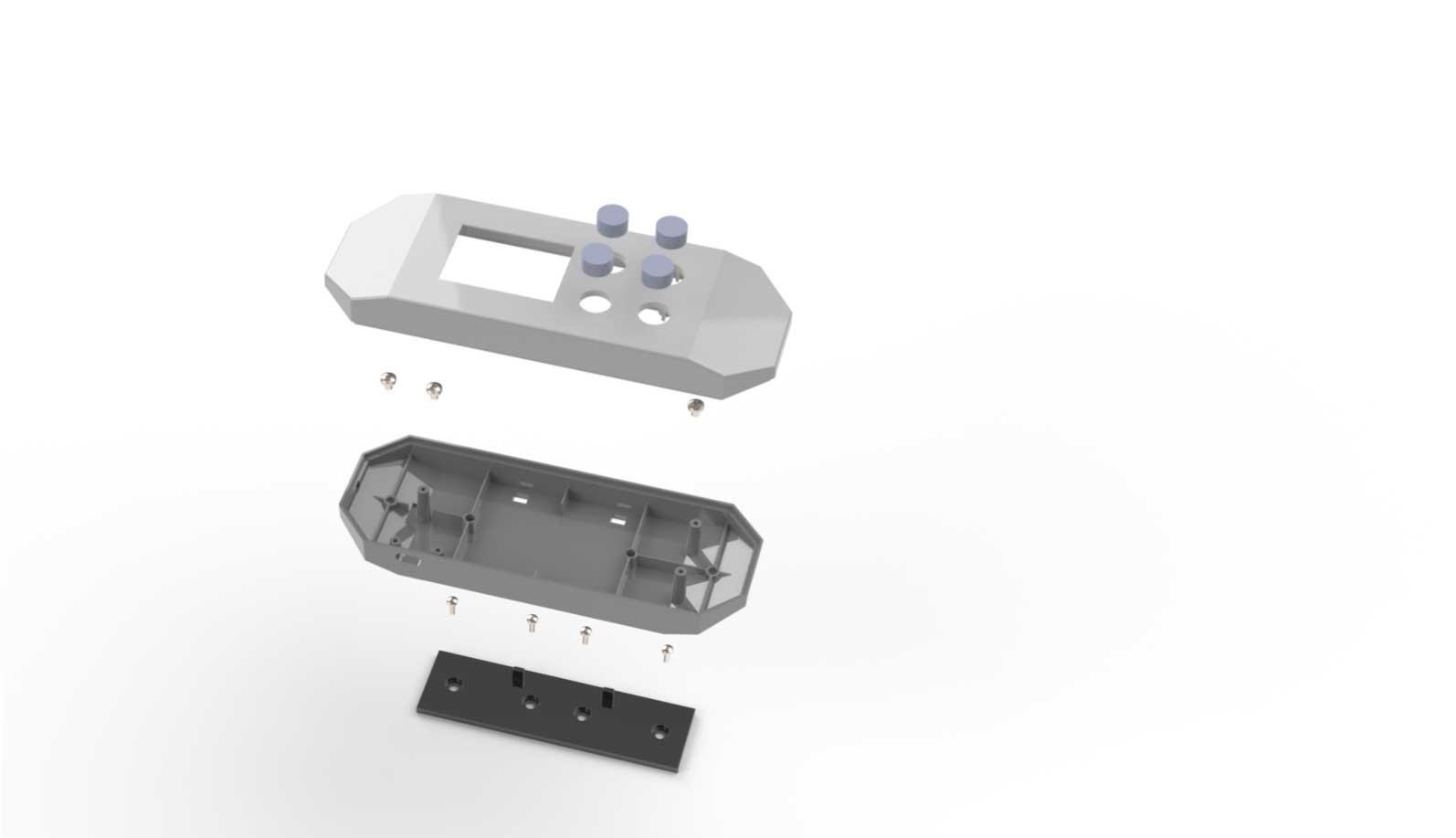

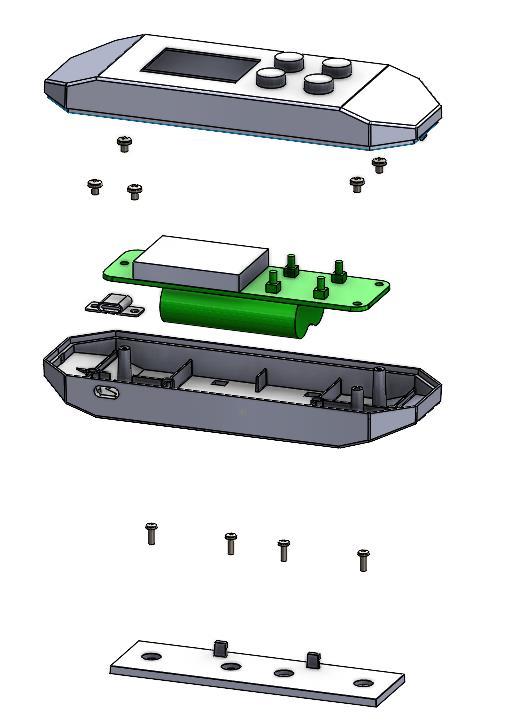

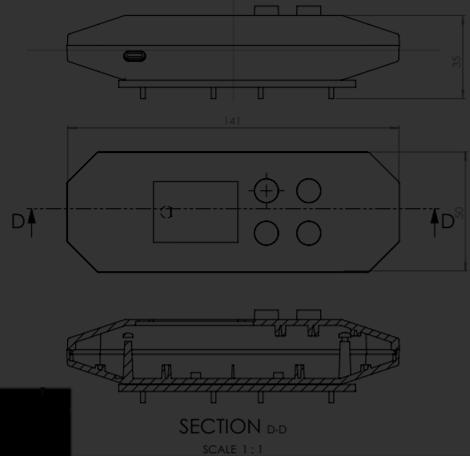

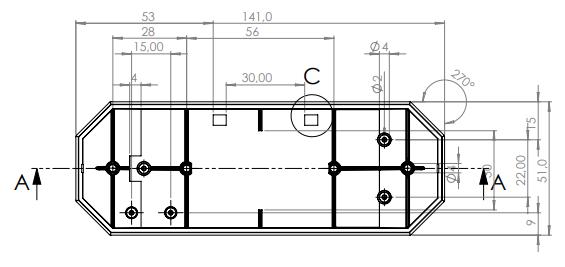

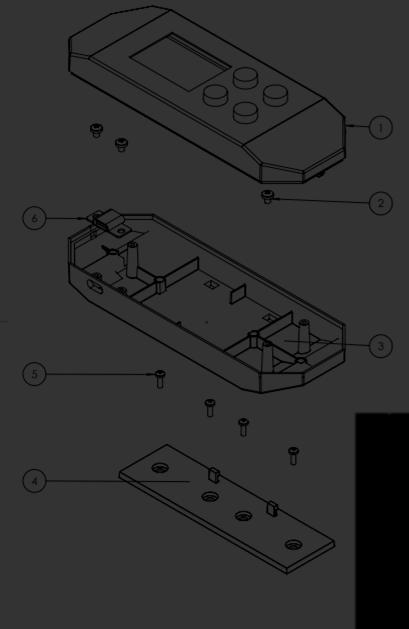

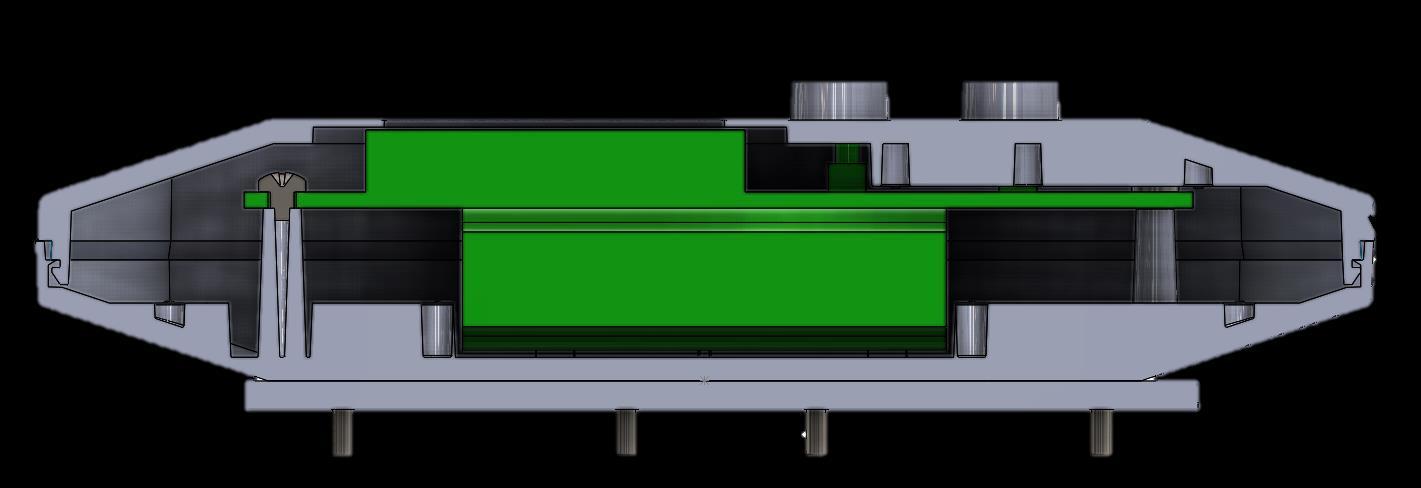

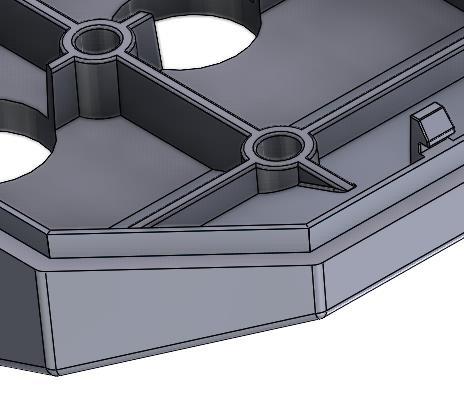

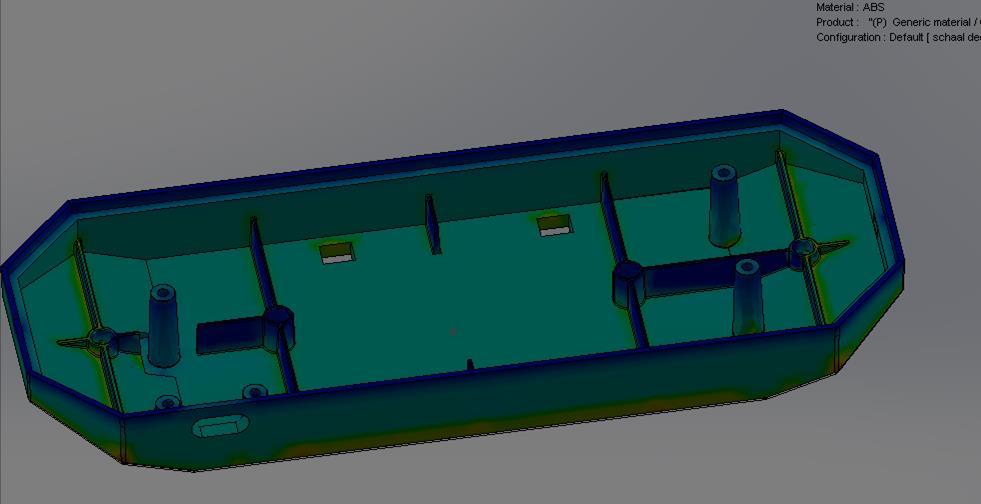

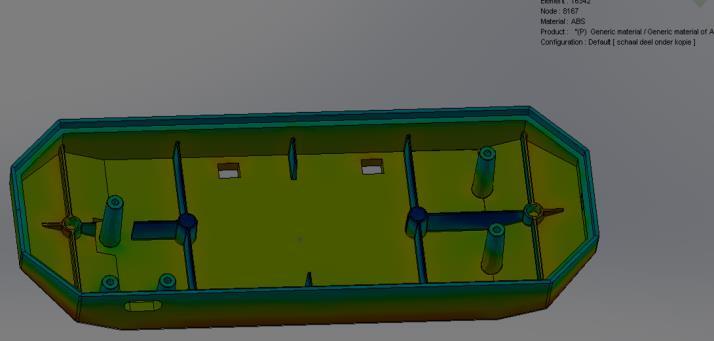

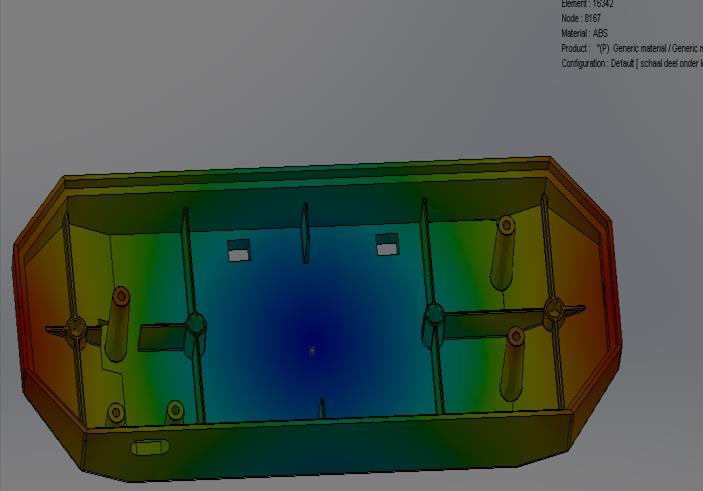

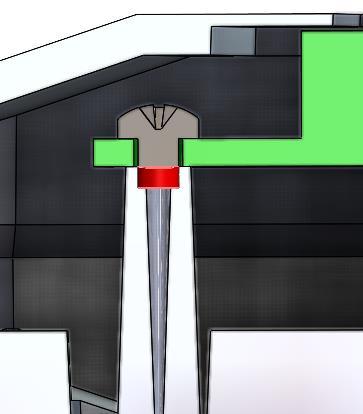

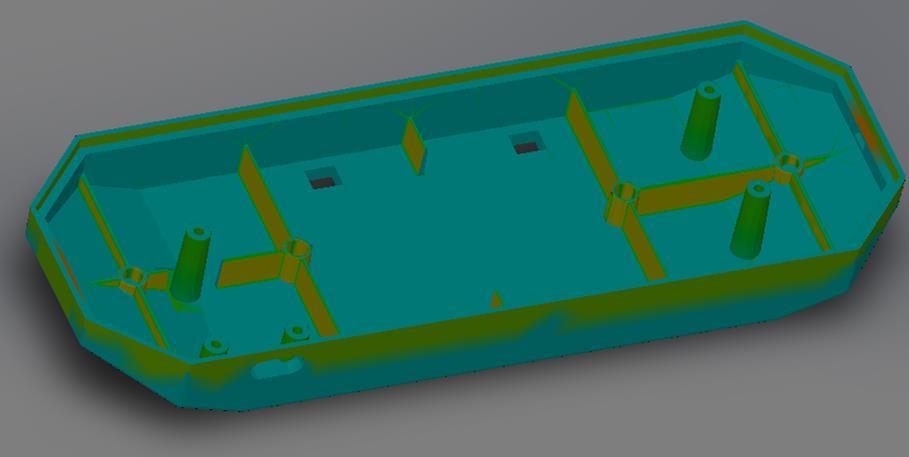

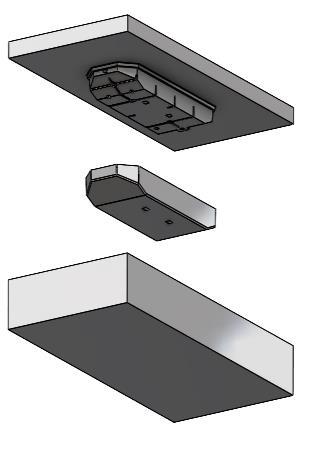

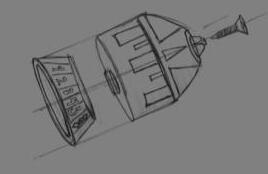

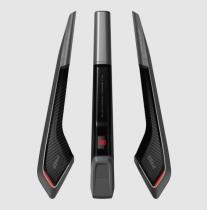

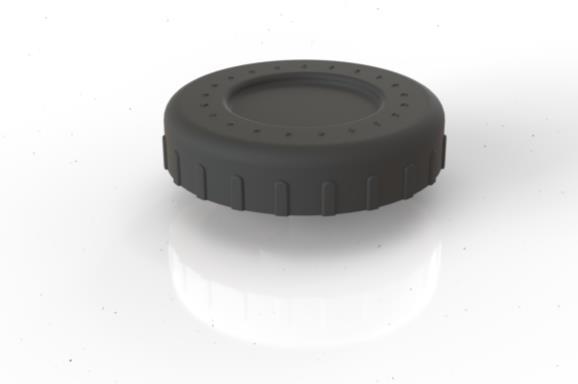

The goal of this project was to design a thermostat casing that would hold a PCB & battery in place in CAD with reference sketching.

Injection moulding simulations were used to improve the design.

Here you see the technical drawings like a mono drawing. And more Solidworks details like a snap-fit connection, exploded view & rib/screw pot dimensions.

Many injection moulding rules have to be considered to prevent the design from failing.

In this project

-Draft analysis

-Thickness analysis

-Fill & Cool time simulations

-Sink mark simulations

-interference detections were runned.

CAD moulds were made to check if the model is qualified to be injection moulded. Verifications show that the product will not fail.

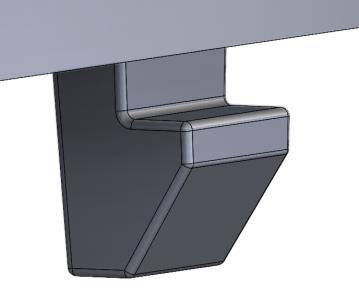

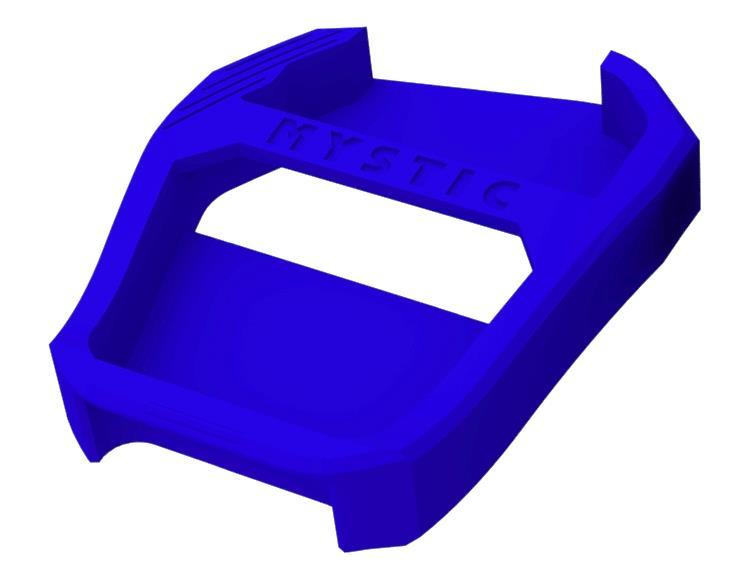

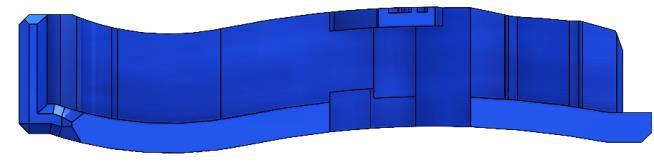

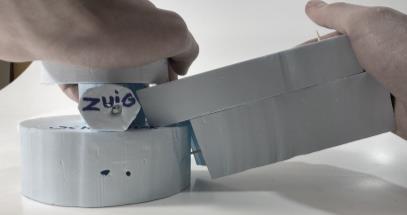

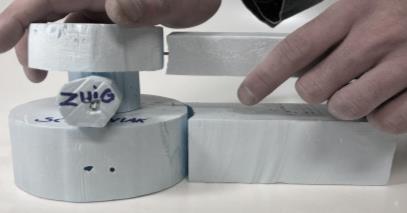

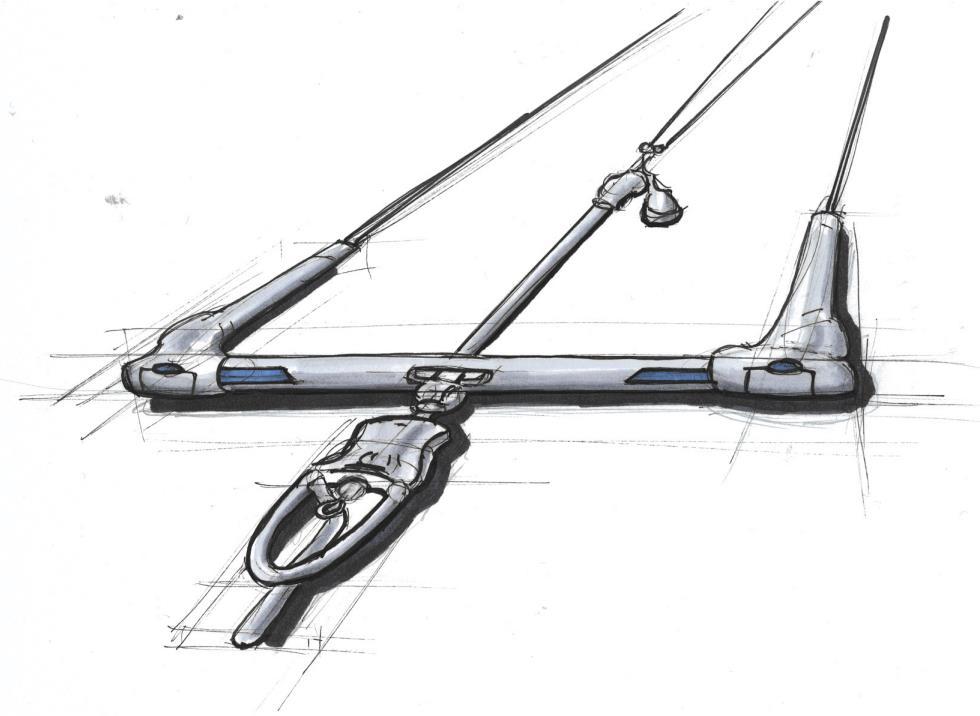

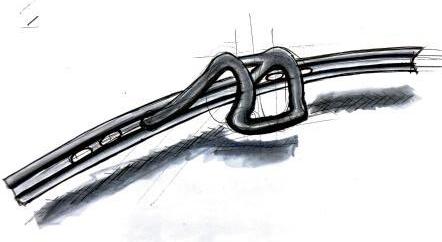

For the new Mystic Boarding surfline2023 I designed a rubber case for a metal roof rack buckle system that prevents scratching to your car roof. After testing with the buckle from the competitor I designed a system for the buckle to leave the rubber casing when needed. And keep the straps in their place when used.

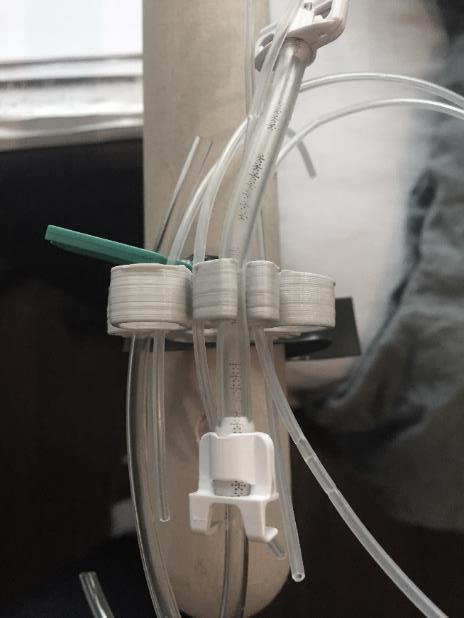

In childcare at the Erasmus MC intravenous drips were held together and hung as 1 big drip next to the care bed.

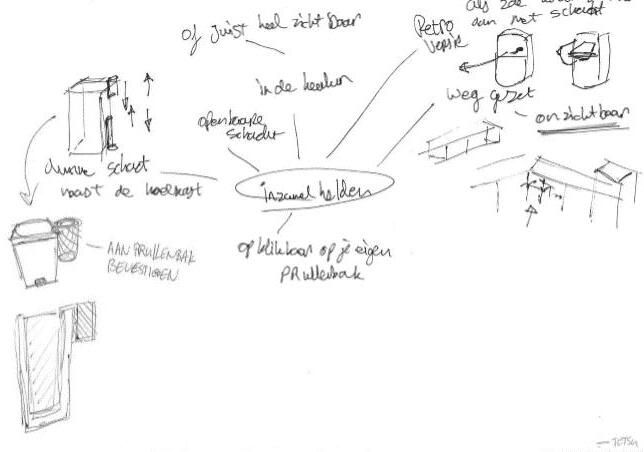

After analyzing the current situation and identifying the main and subproblems. I began putting as many ideas on paper as possible by learning design thinking. From crazy ideas to average, the combination brings product innovation.

You can see my project process by optimizing the design direction using mockup tests. Testing until the design met all requirements.

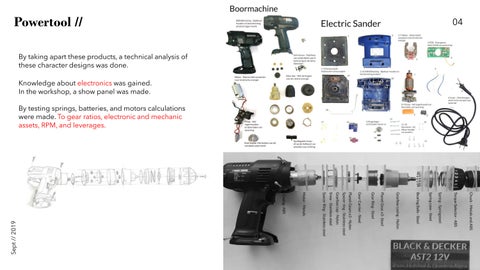

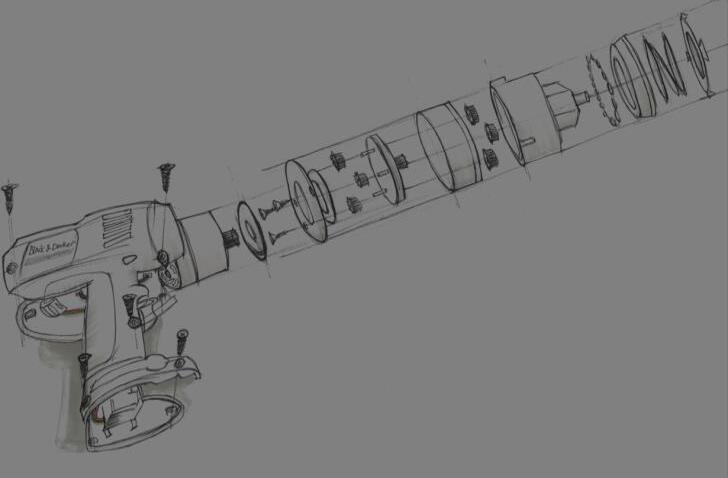

Powertool

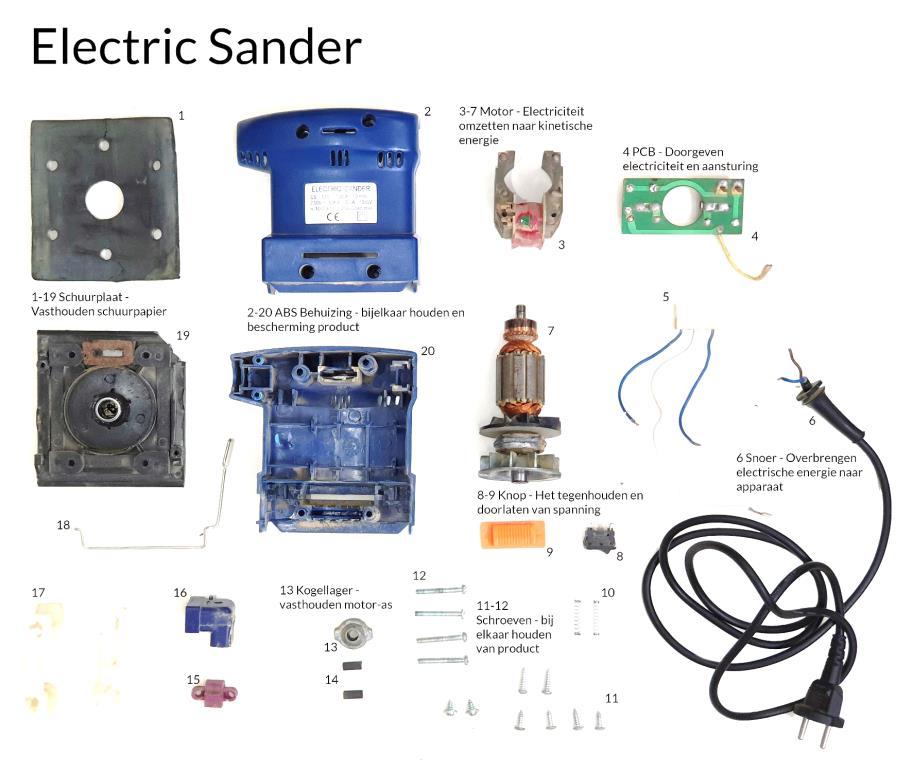

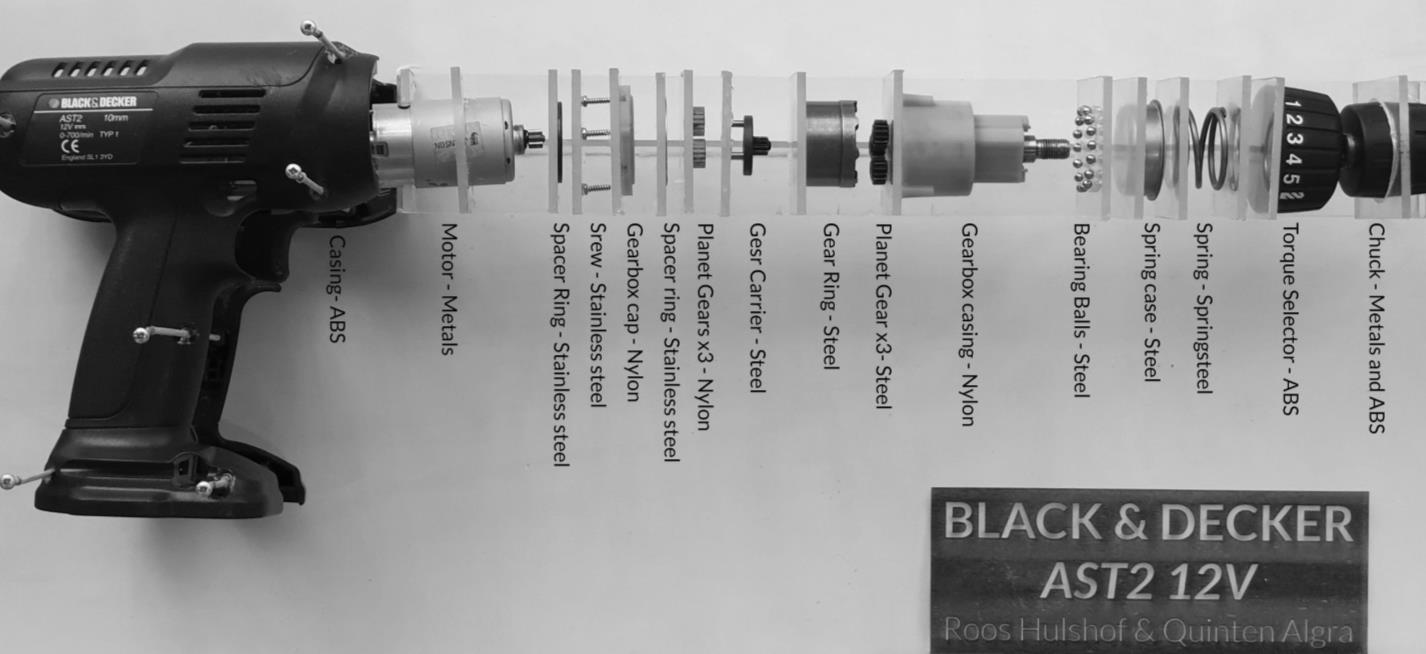

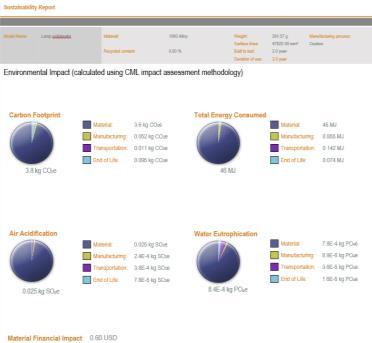

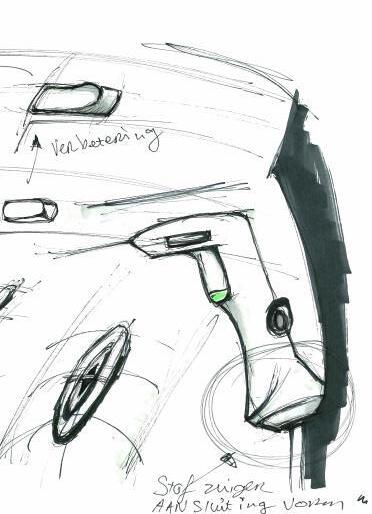

By taking apart these products, a technical analysis of these character designs was done.

Knowledge about electronics was gained. In the workshop, a show panel was made. By testing springs, batteries, and motors calculations were made. To gear ratios, electronic and mechanic assets, RPM, and leverages.

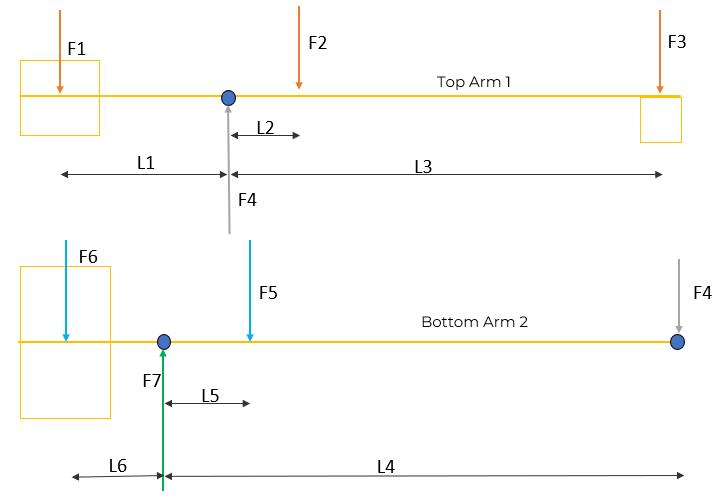

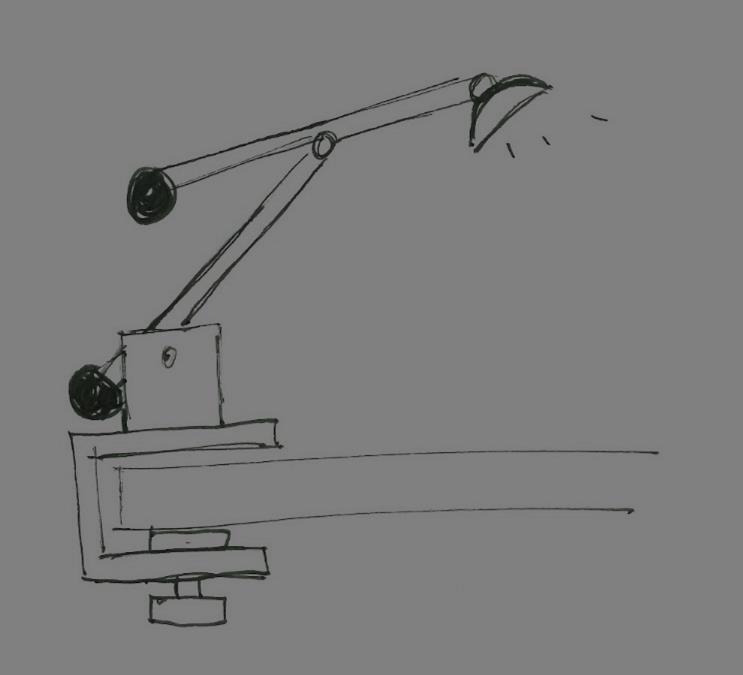

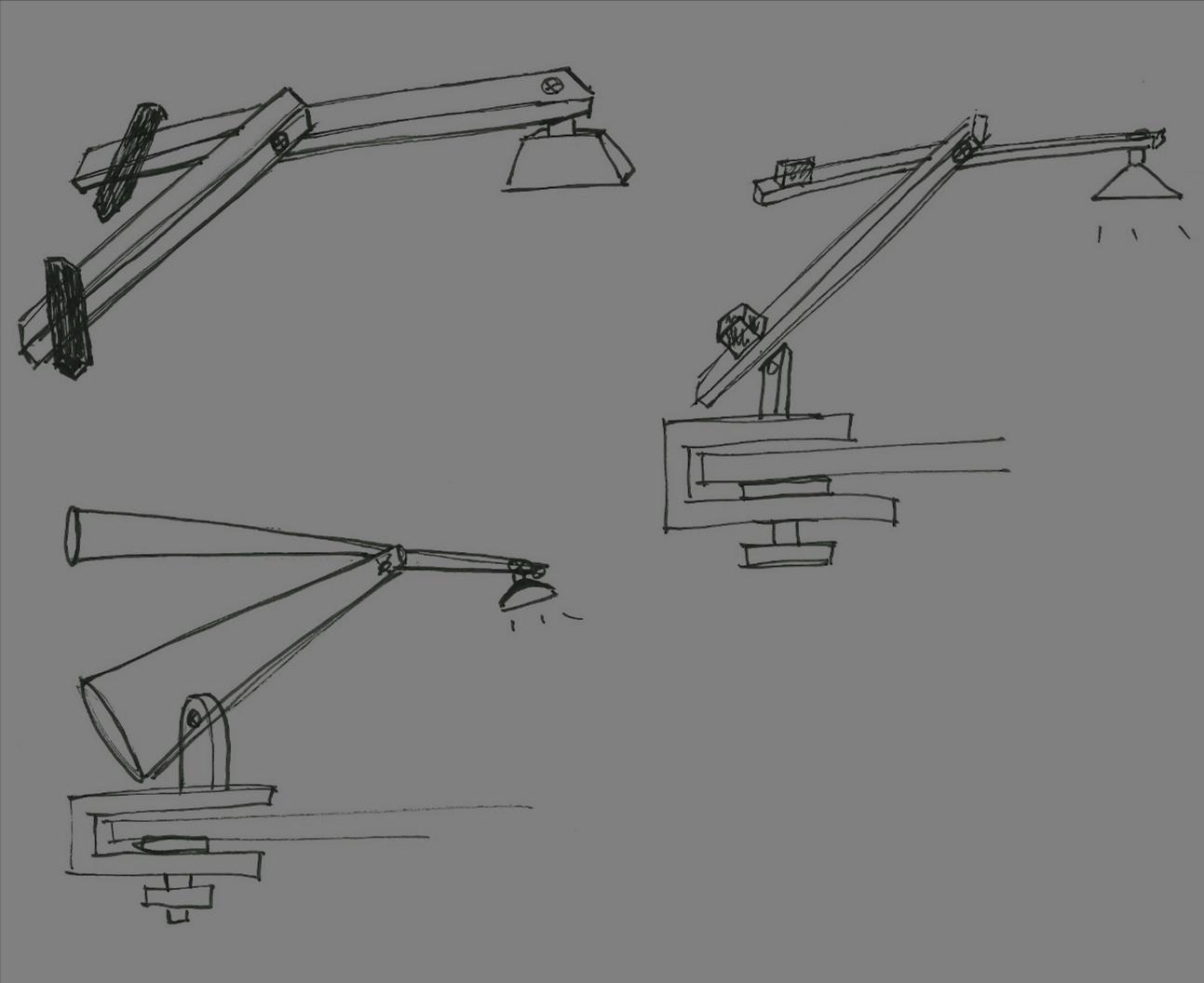

For this project knowledge about arm construction and calculations was gained. Length, weight, and density of materials were used to calculate what the volumes of the counterweights had to be. This way, in Solidworks, a lamp staying in balance was created.

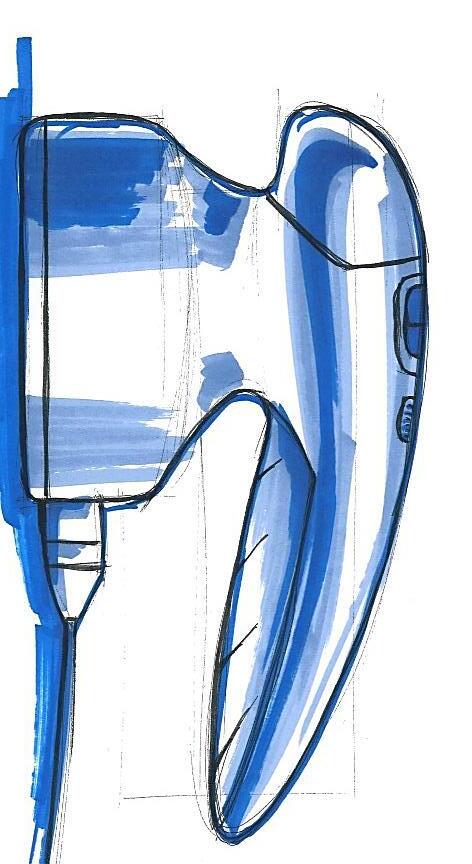

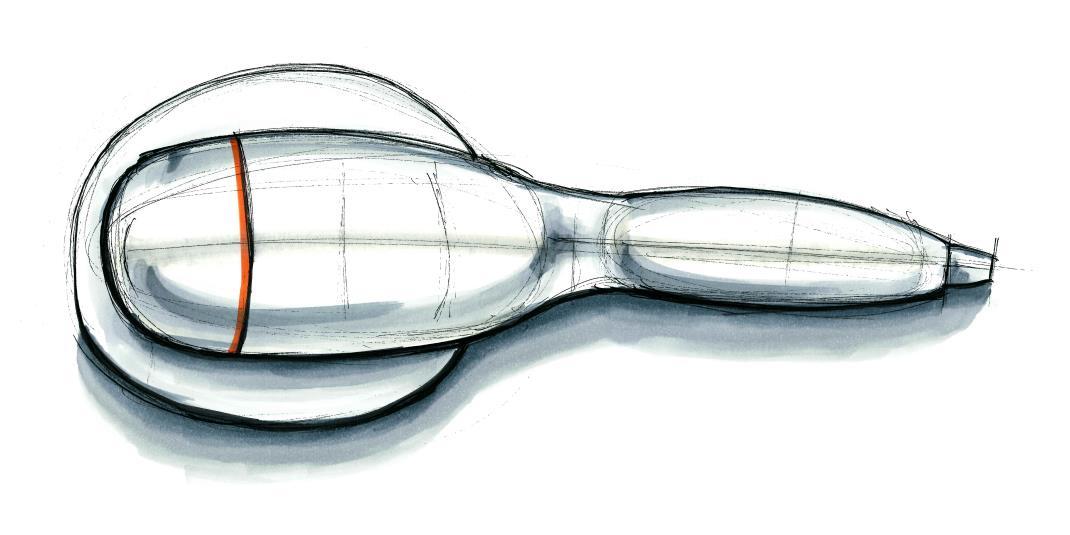

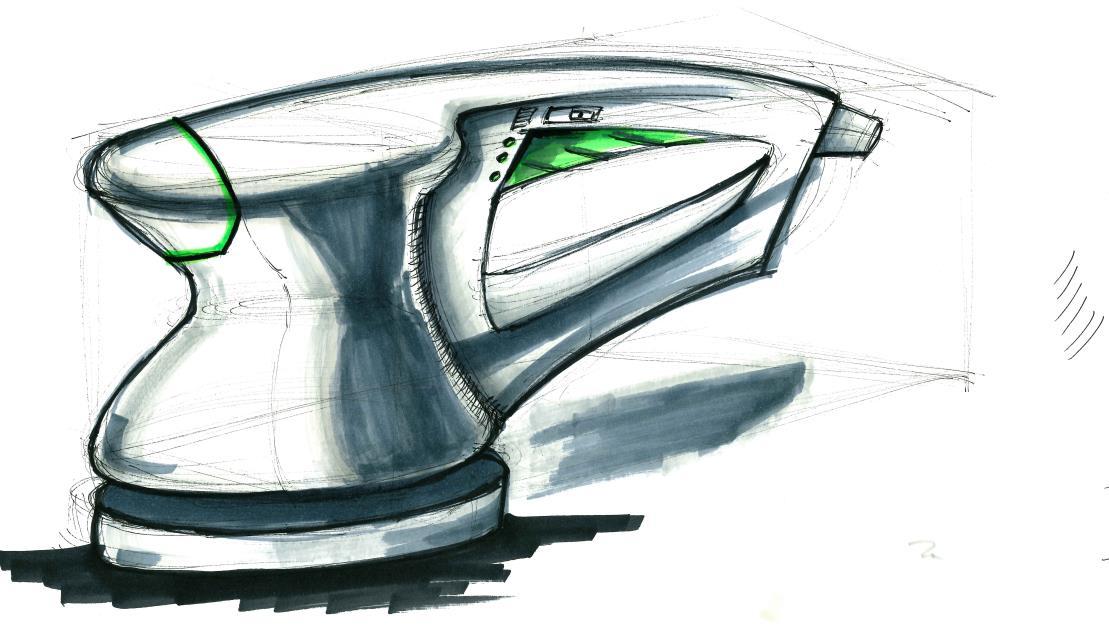

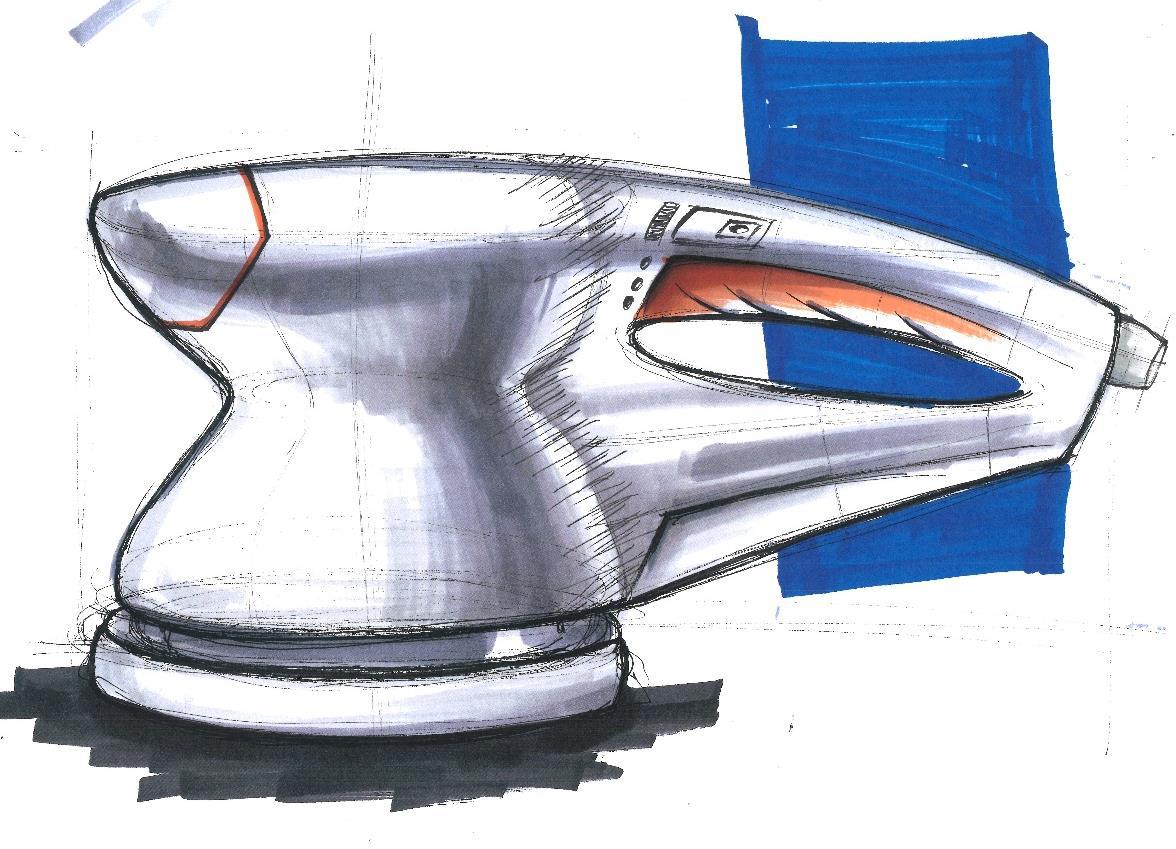

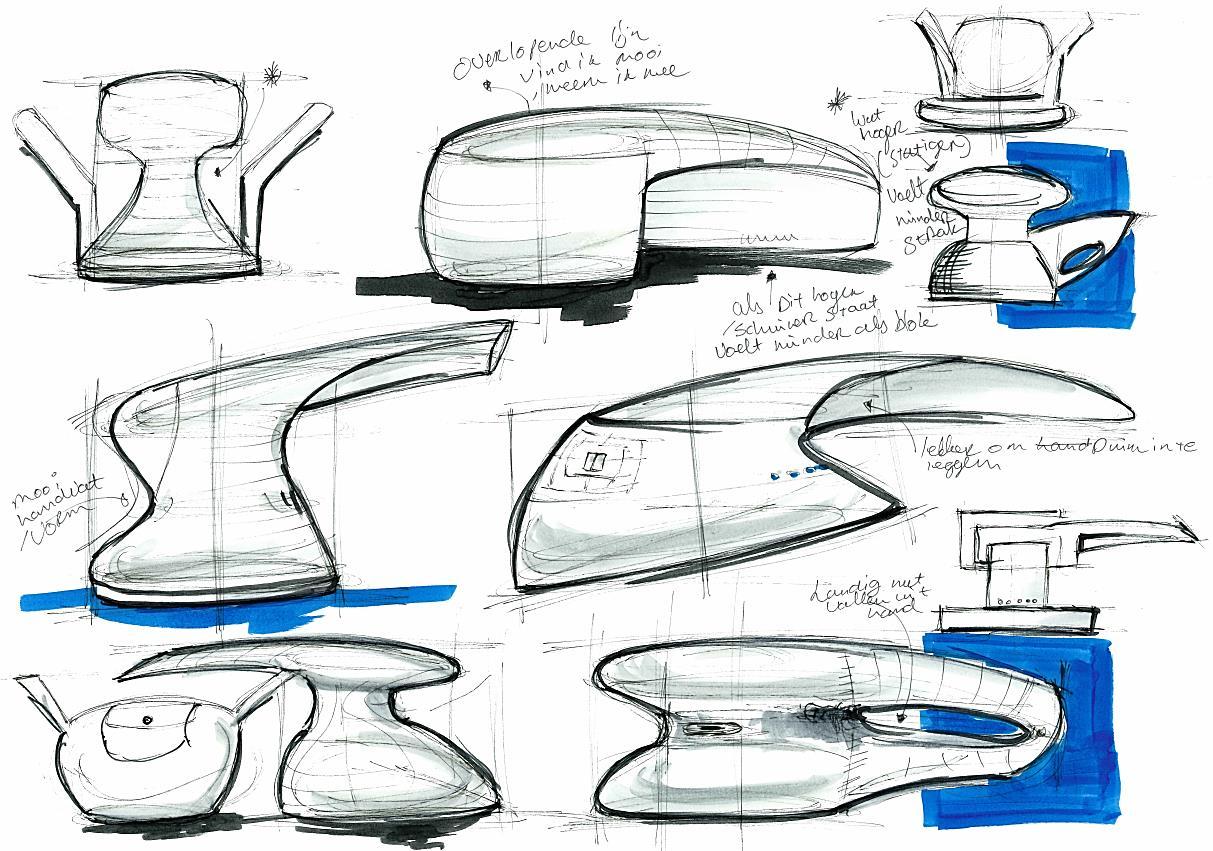

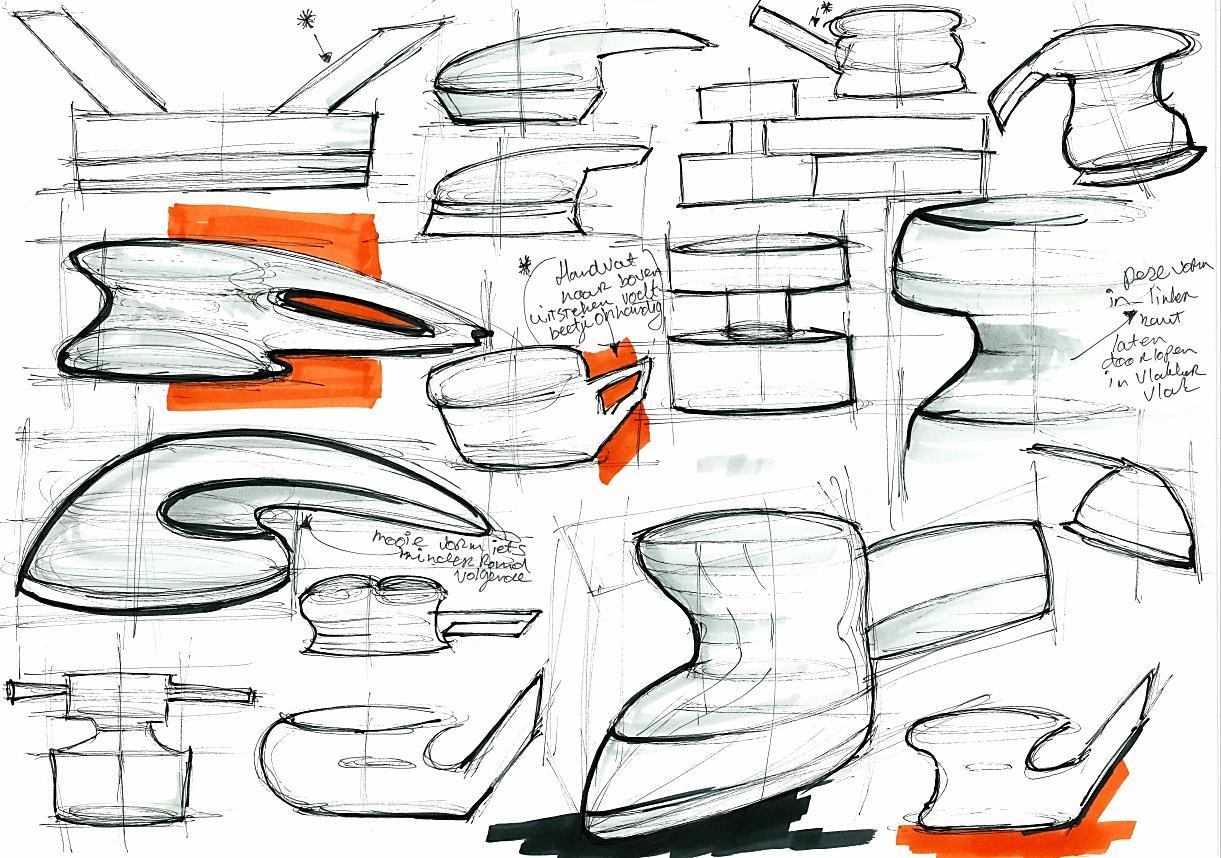

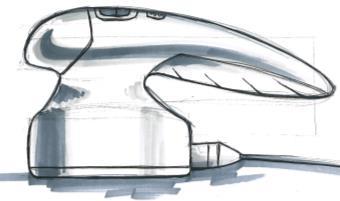

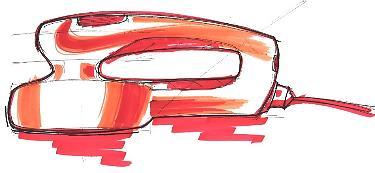

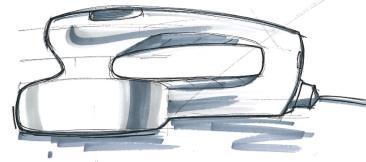

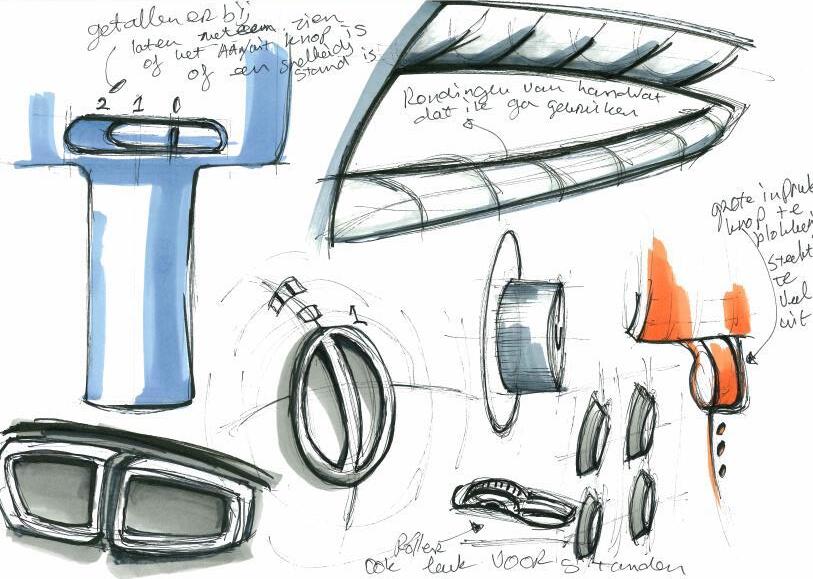

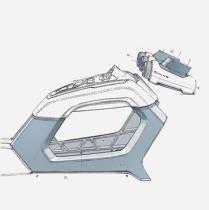

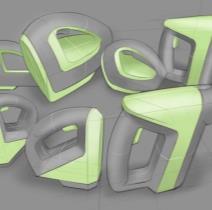

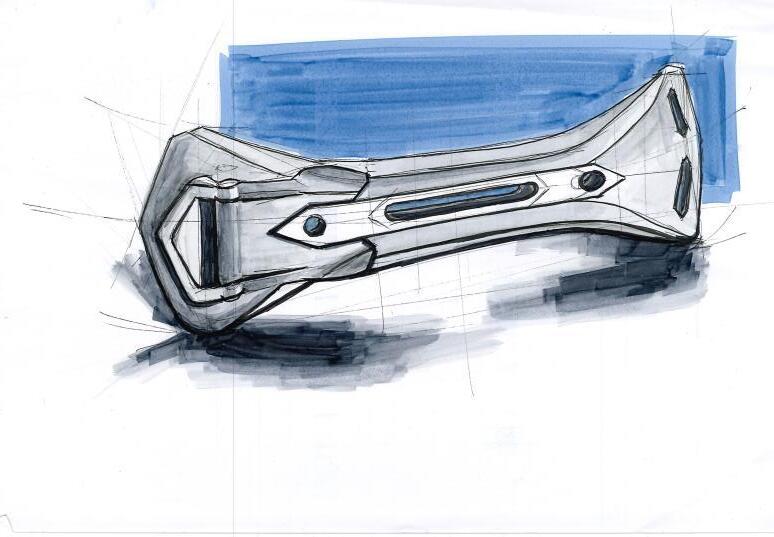

For this project, I designed an ergonomic sander for users who want to professionalize their sanding skills.

Gaining more knowledge about what type of shape affects the usage of a product was educational.

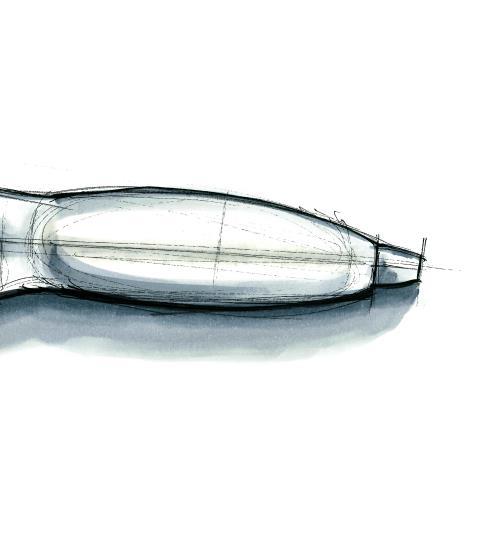

On the right, you see different variations of mockup sketches and some detail sketches.

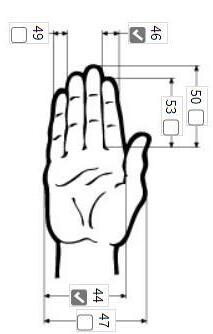

By using Dnet data banks from TU Delft I learned about anthropometrics and probability density functions.

A variety of 1:1 foam mockups was made. I tested 4 of them with my user. This resulted in 1st configuration getting the upper hand due to handling pressure points according to the tests.

By making a mood board for my target audience I could create the best design.

A self-produced helmet was created for Mystic Boarding during my internship. With 3D printing, I made some prototypes for a new earpad cover design. My input was to recreate the solid works parts for the renders.

Here are the final renders shown and some of the created Solidworks parts.

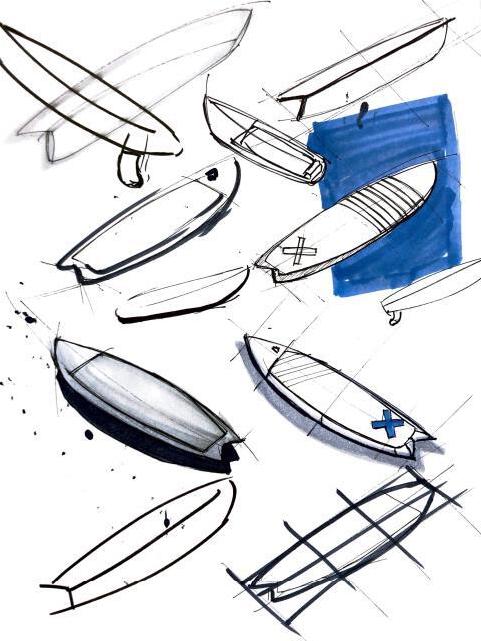

I made my own surfboard! I went through a lot of research and had some help from a friend. I learned from his knowledge and could apply that to my project. Here you see briefly how I went through the shaping process. Thereafter I went on to the glassing using fiberglass and epoxy.

I also printed my own logo on my board. Love using my board.

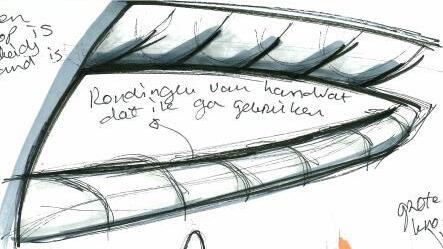

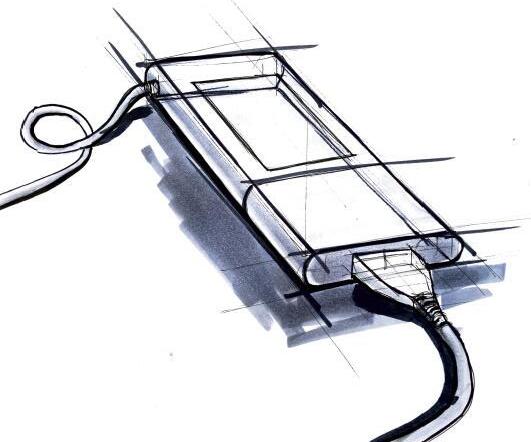

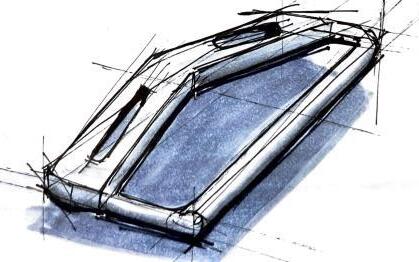

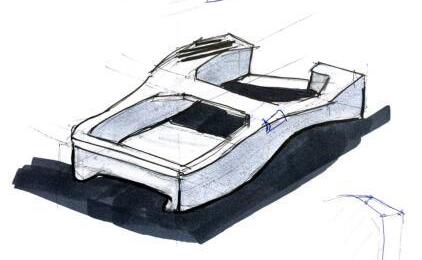

On the right, you see some of my personal sketching from surf-related gear.

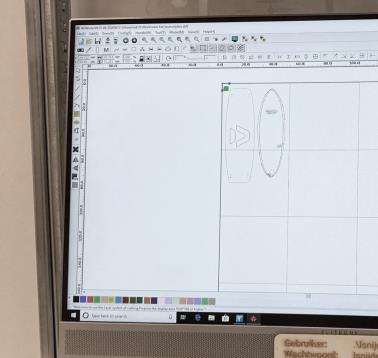

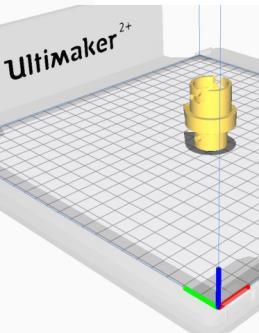

Learning how to laser cut 3dprint and weld gave me an understanding of these processes, I can apply when designing.

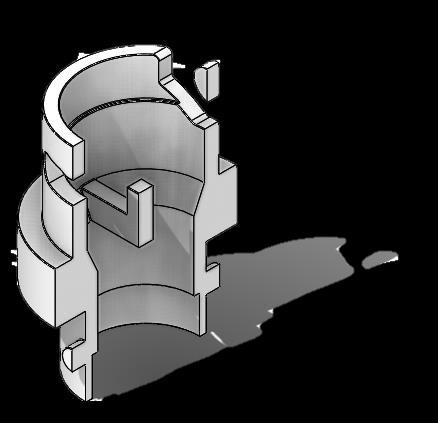

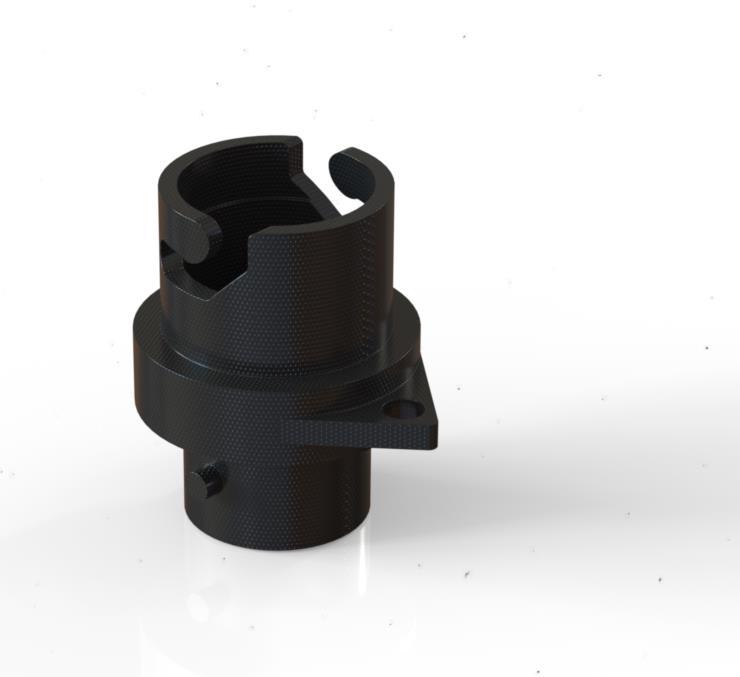

This kiteboard rack was made by using the laser cutter. A welded bookholder became necessary for my bookshelf. Ultimaker Cura, was used when iterating over the design in Solidworks for this replicated Duotone pump adapter I use to pump up my kite.