1 minute read

Powertool

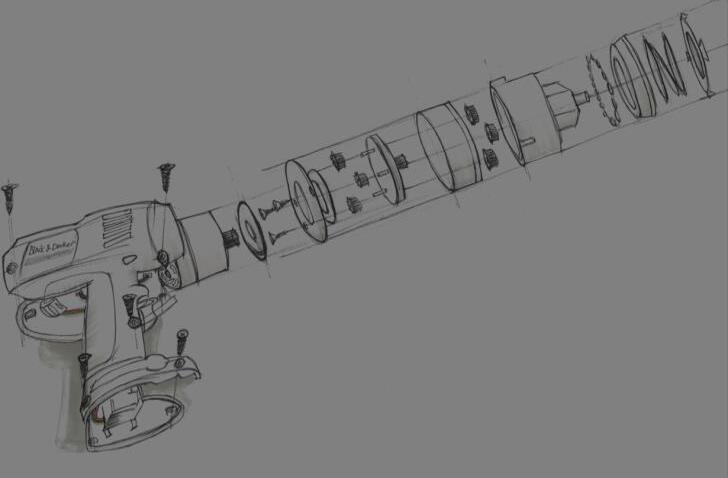

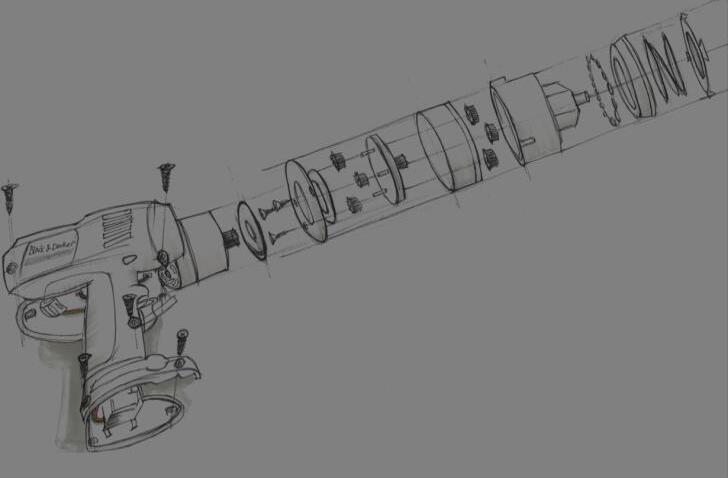

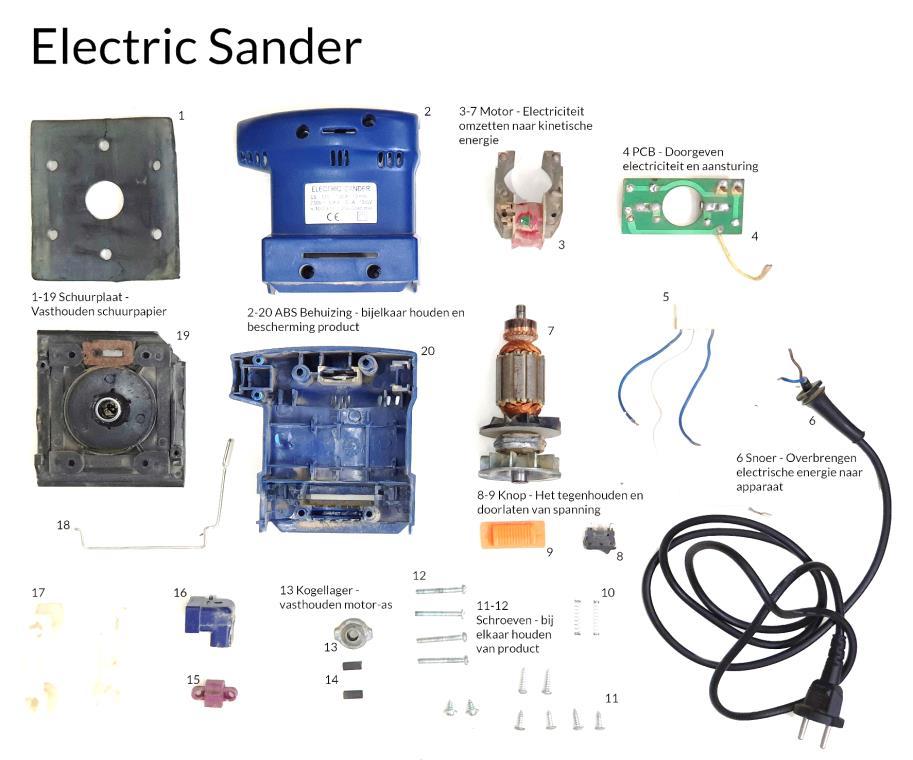

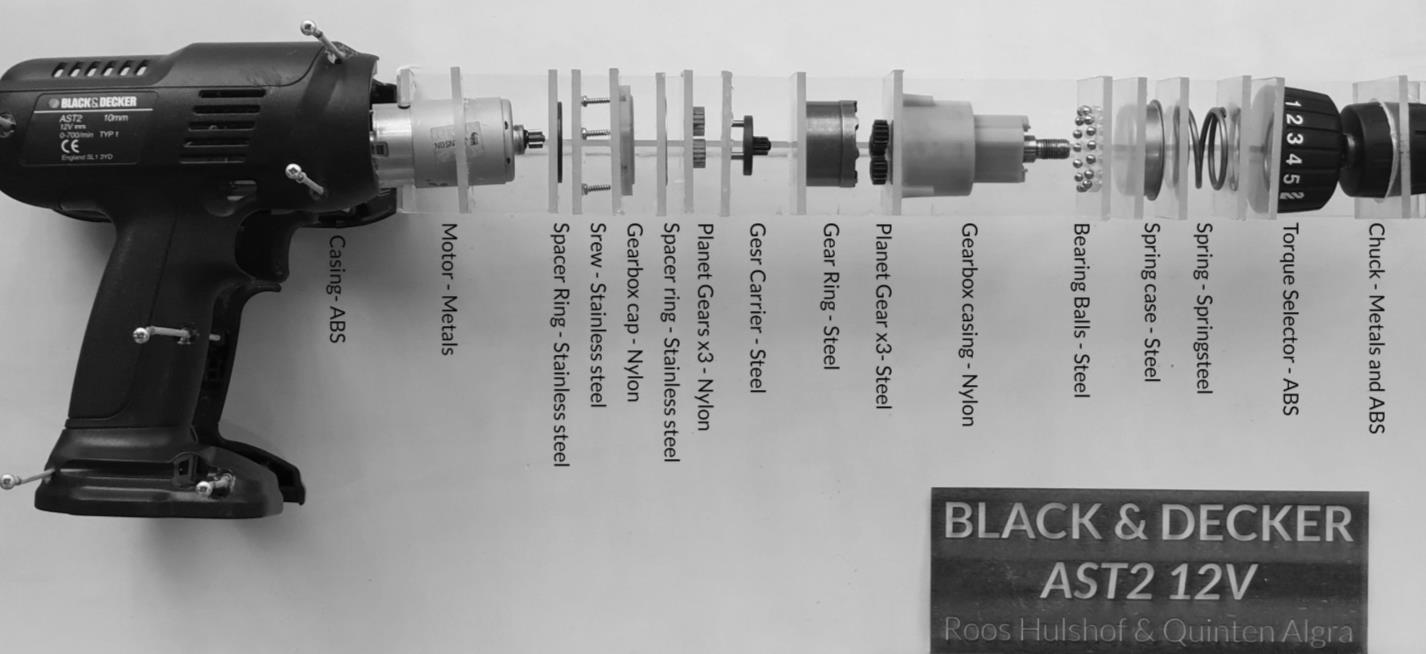

By taking apart these products, a technical analysis of these character designs was done.

Advertisement

Knowledge about electronics was gained. In the workshop, a show panel was made. By testing springs, batteries, and motors calculations were made. To gear ratios, electronic and mechanic assets, RPM, and leverages.

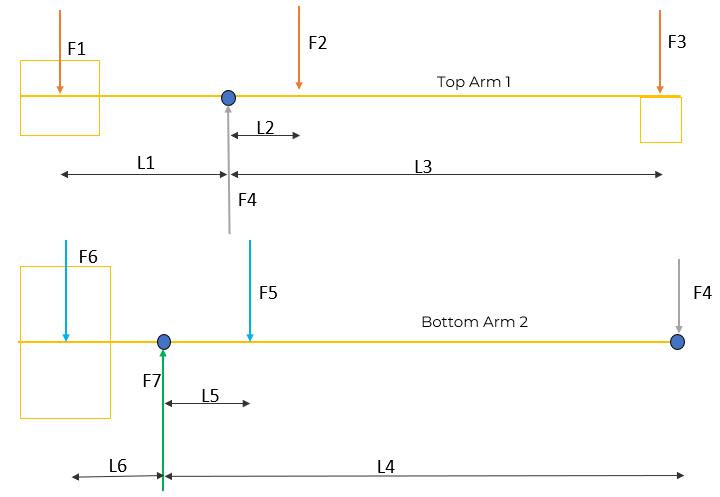

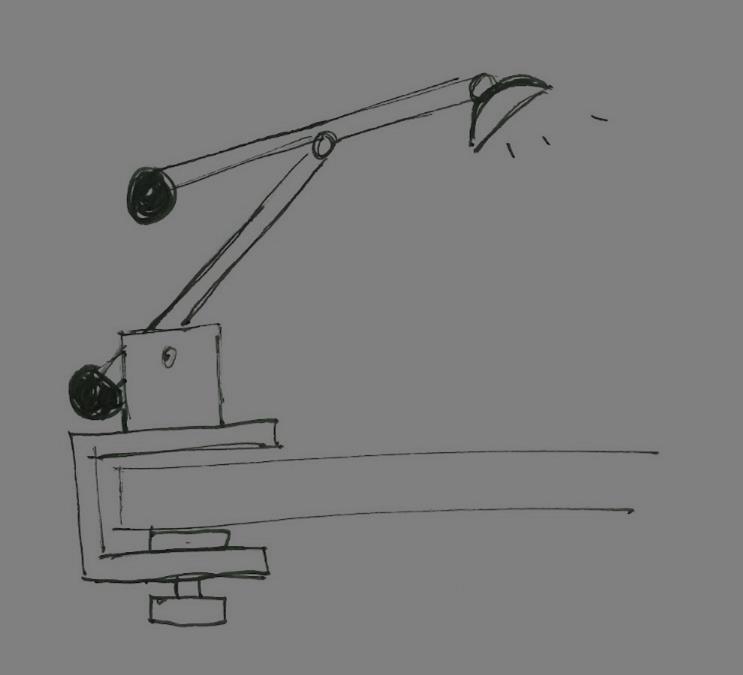

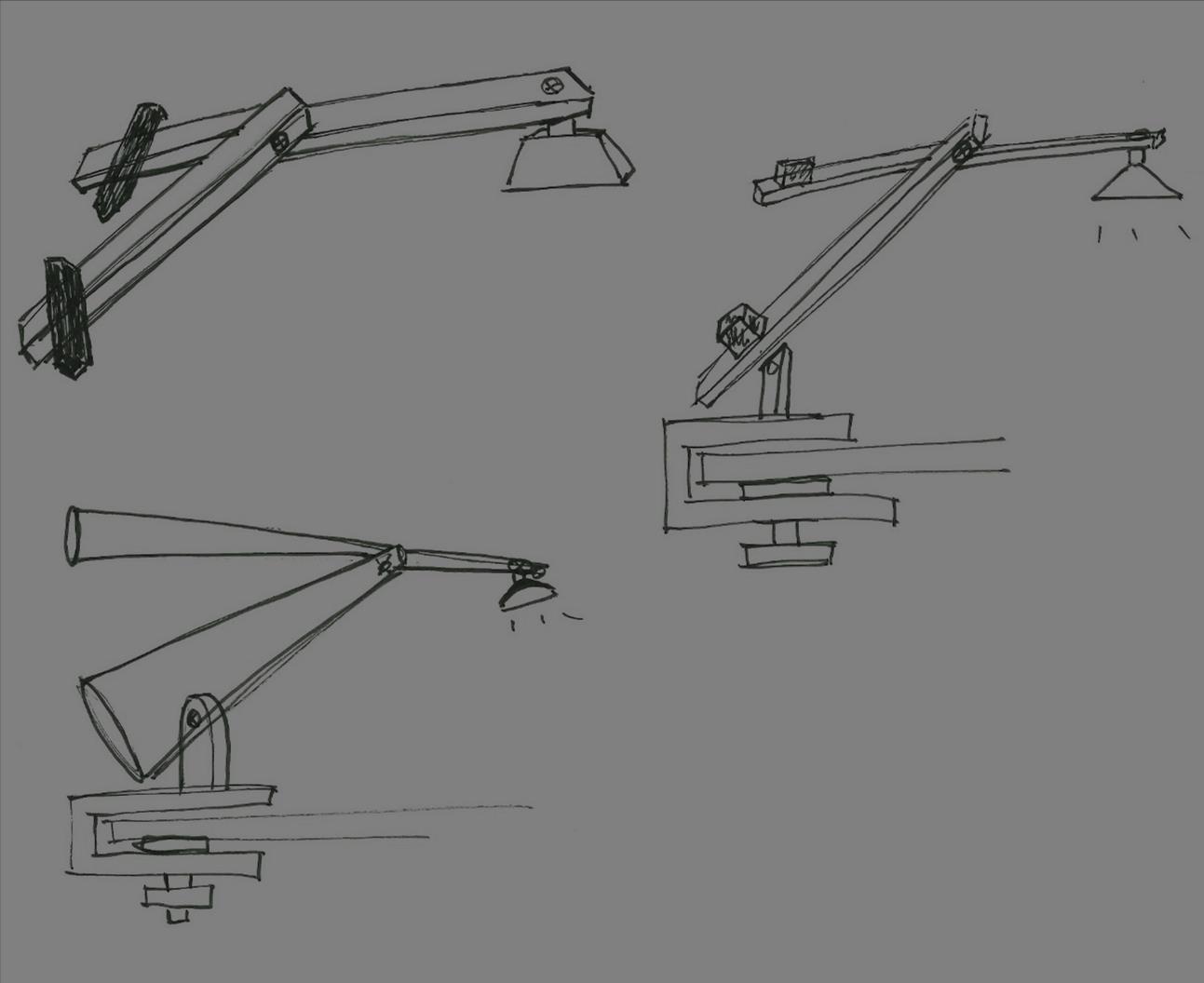

For this project knowledge about arm construction and calculations was gained. Length, weight, and density of materials were used to calculate what the volumes of the counterweights had to be.

This way, in Solidworks, a lamp staying in balance was created.

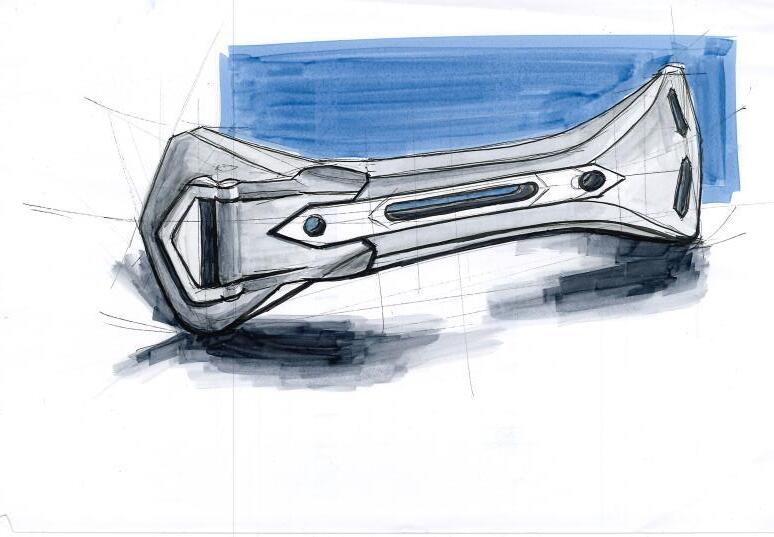

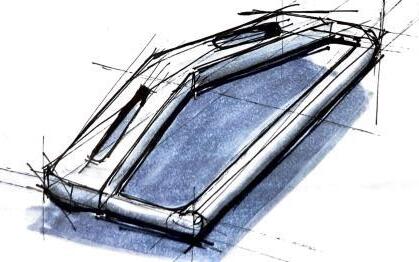

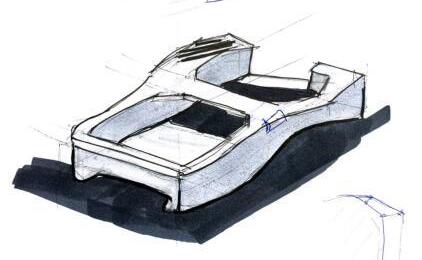

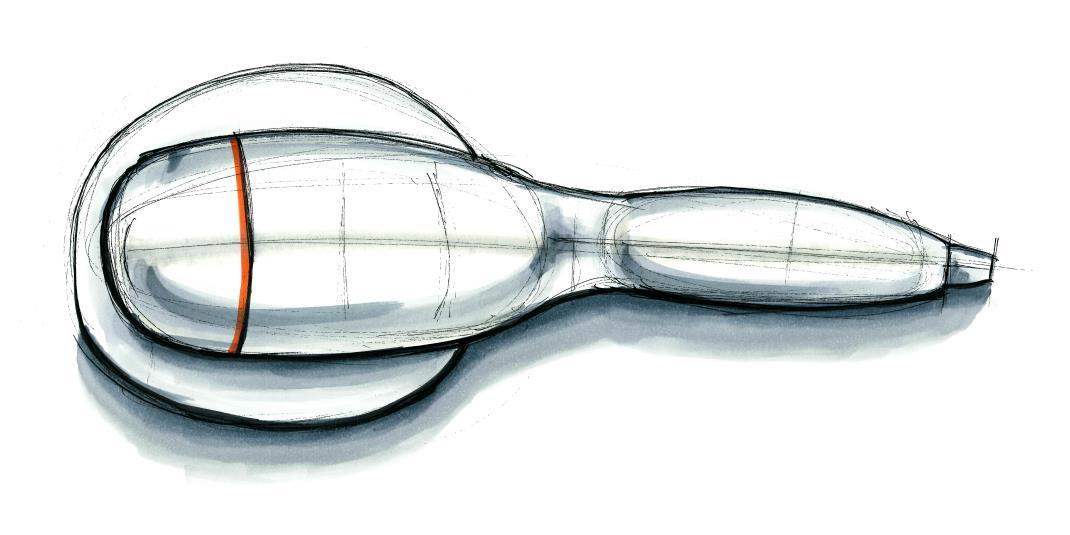

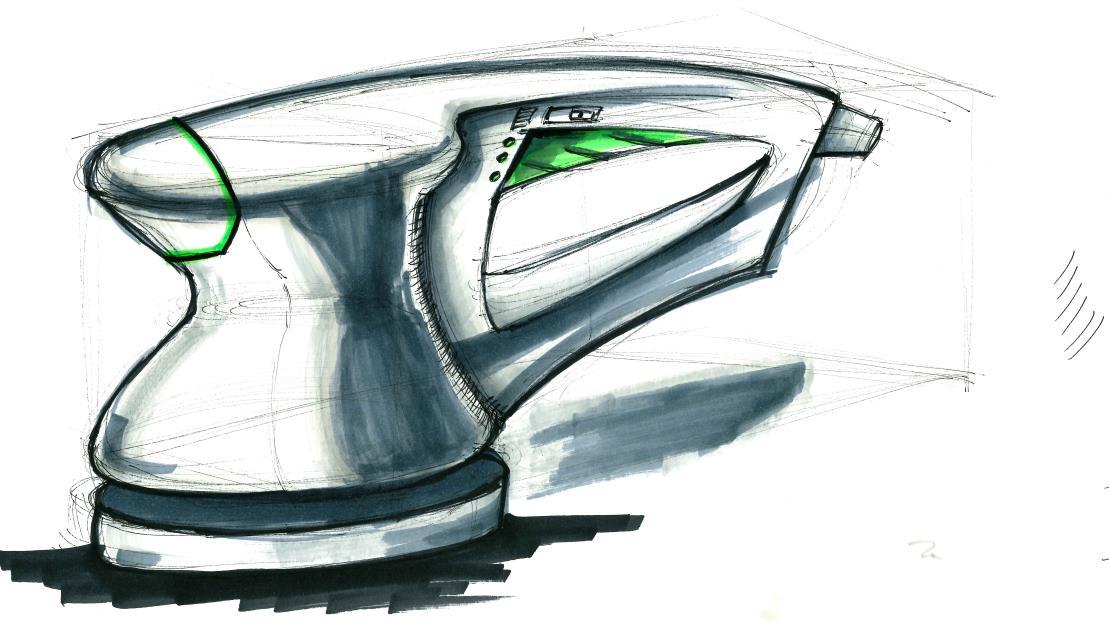

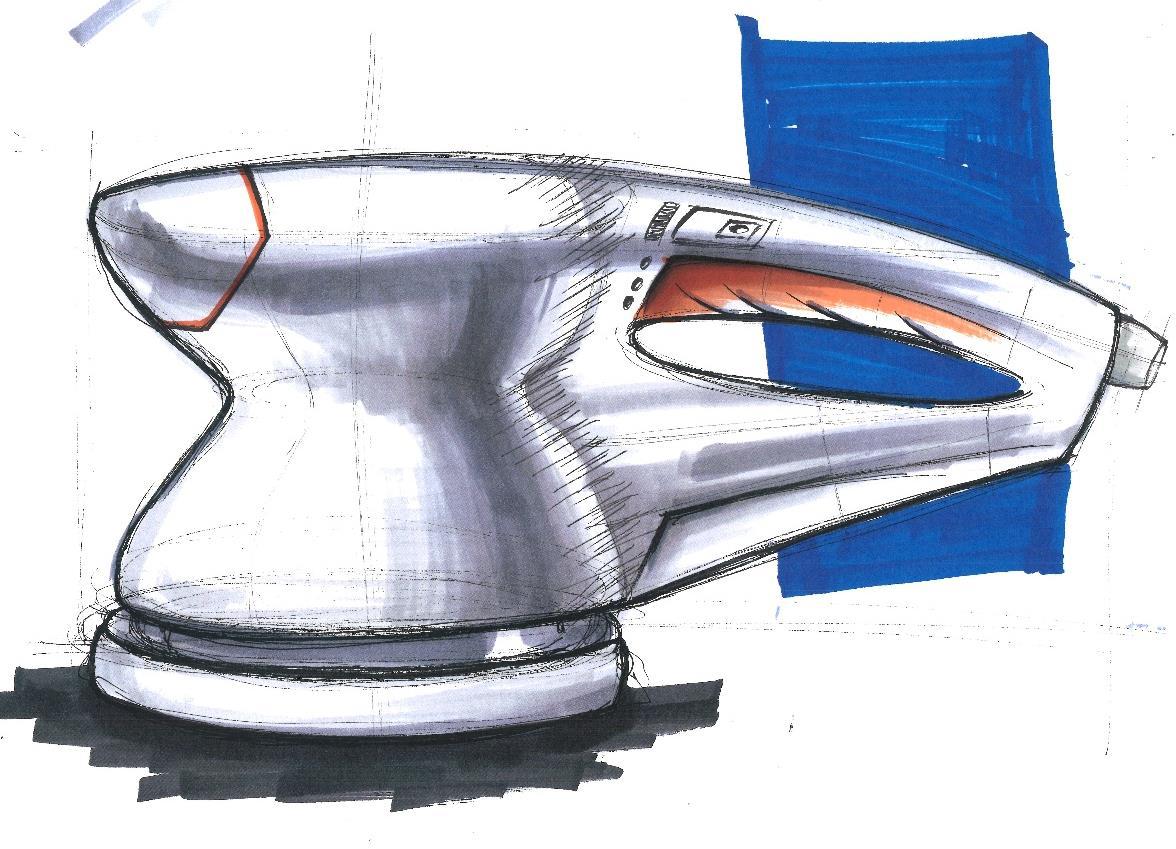

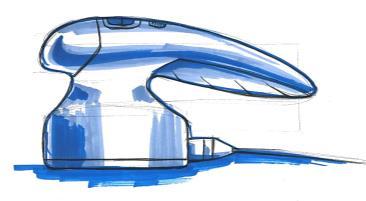

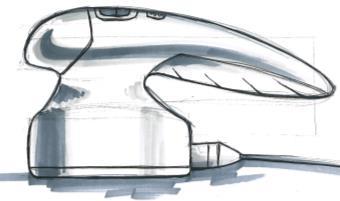

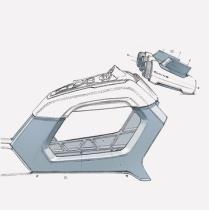

For this project, I designed an ergonomic sander for users who want to professionalize their sanding skills.

Gaining more knowledge about what type of shape affects the usage of a product was educational.

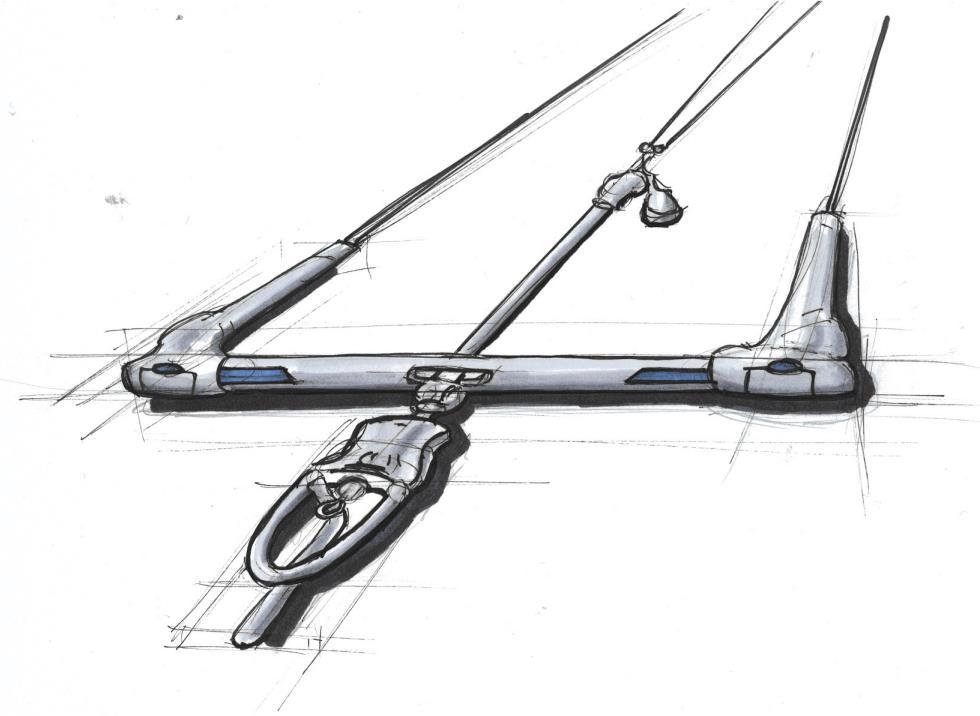

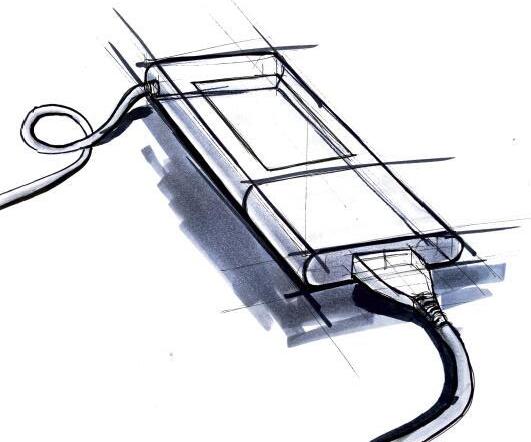

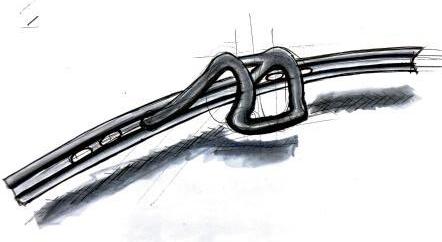

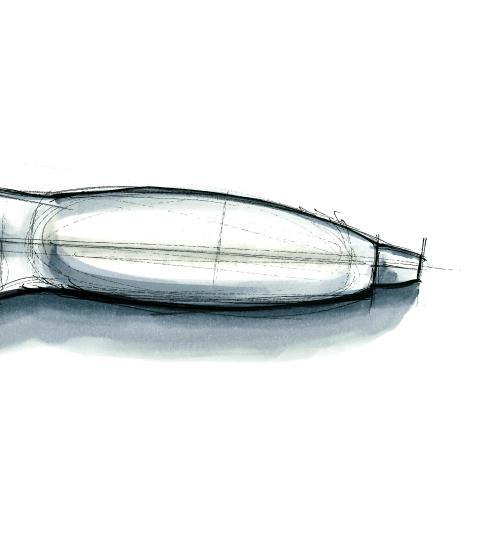

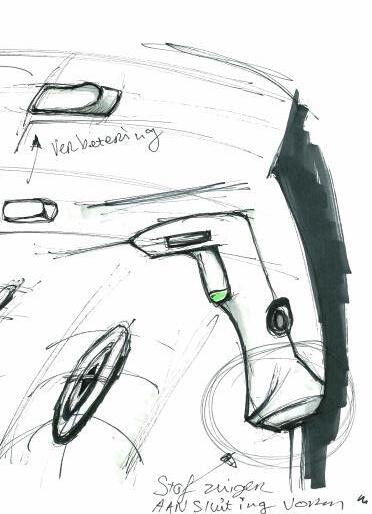

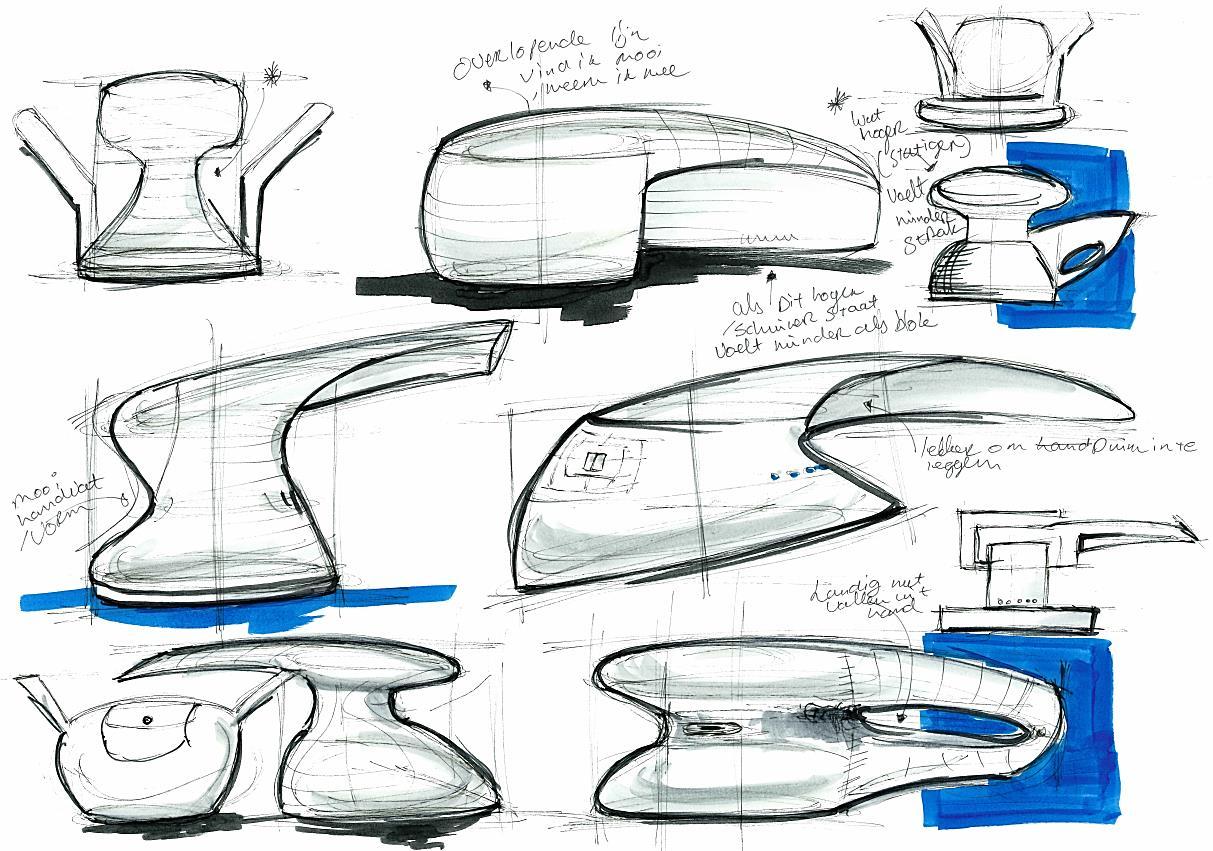

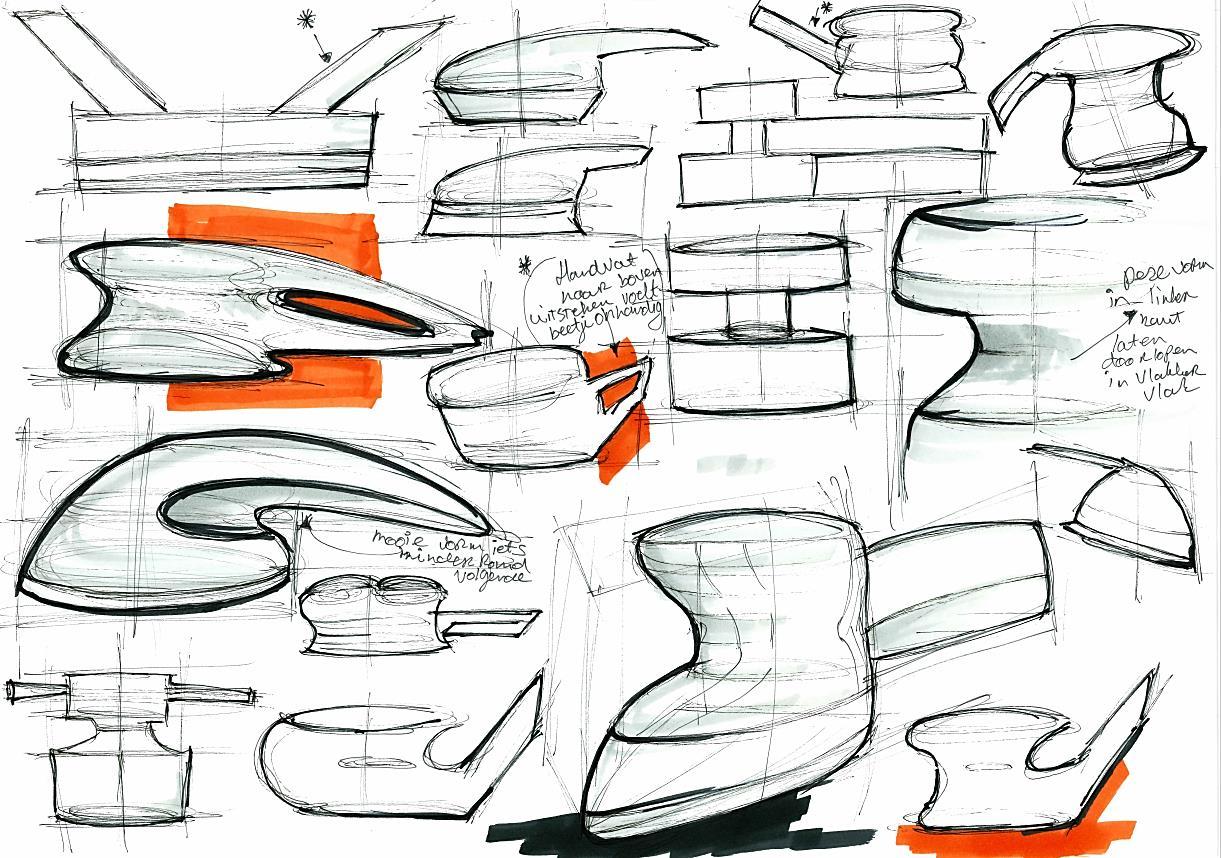

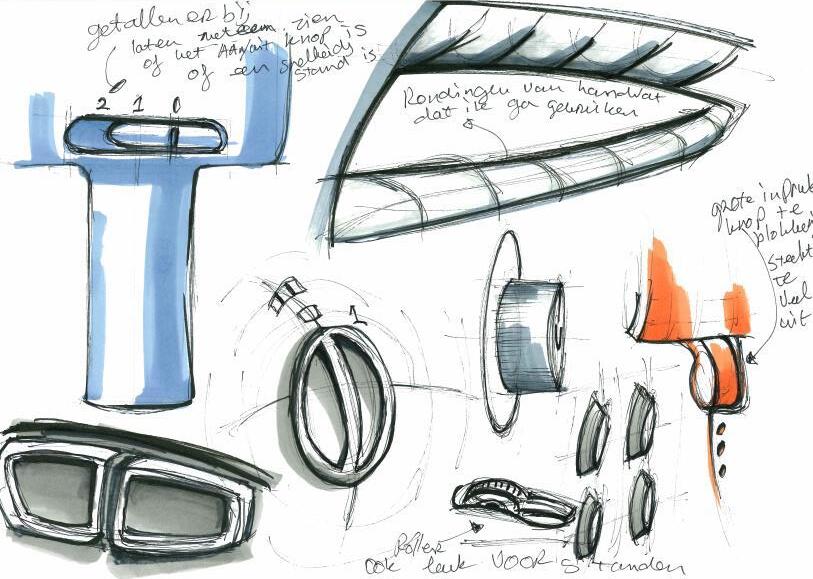

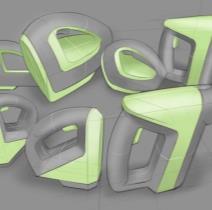

On the right, you see different variations of mockup sketches and some detail sketches.

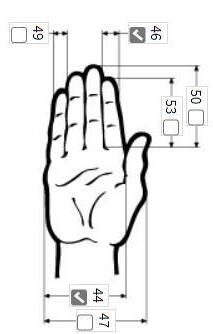

By using Dnet data banks from TU Delft I learned about anthropometrics and probability density functions.

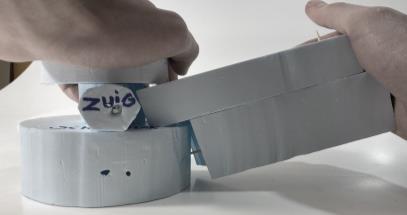

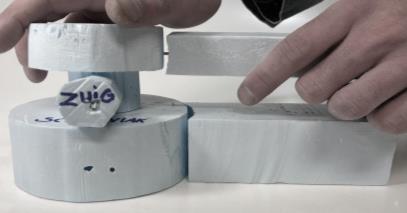

A variety of 1:1 foam mockups was made I tested 4 of them with my user. This resulted in 1st configuration getting the upper hand due to handling pressure points according to the tests.

By making a mood board for my target audience I could create the best design.

A self-produced helmet was created for Mystic Boarding during my internship.

With 3D printing, I made some prototypes for a new earpad cover design. My input was to recreate the solid works parts for the renders

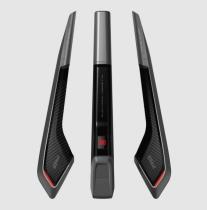

Here are the final renders shown and some of the created Solidworks parts.

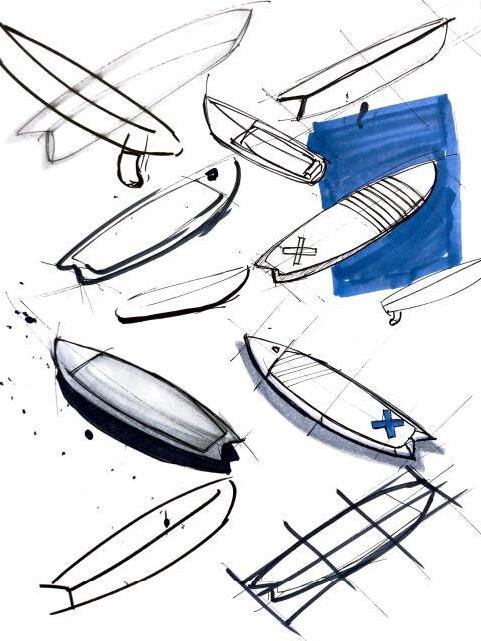

I made my own surfboard! I went through a lot of research and had some help from a friend. I learned from his knowledge and could apply that to my project. Here you see briefly how I went through the shaping process. Thereafter I went on to the glassing using fiberglass and epoxy

I also printed my own logo on my board.

Love using my board.

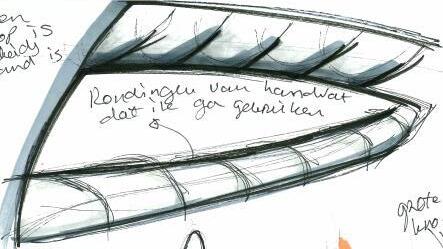

On the right, you see some of my personal sketching from surf-related gear.