NOVEMBER2024

DIGITAL PUBLISHING SOLUTIONS

DIGITAL PRINT, PACKAGING, AND PUBLISHING

NOVEMBER2024

DIGITAL PUBLISHING SOLUTIONS

DIGITAL PRINT, PACKAGING, AND PUBLISHING

TECHNOLOGIESANDTRENDSDRIVEPRINTTOTHEFUTURE

dpsmagazine.com

Volume 26, Number 7 • ISSN: 1529-2320

We close out 2024 with cautious optimism. Print and all of its core applications continue to evolve its relevance in an increasingly virtual world. While print is not going away, the industry is starkly different from ten to even five years ago. Here at DPS magazine we track the prevalence of digital print and supporting technologies. Our editorial has shifted in new directions as more segments look to digital print to reduce costs, turnaround time, and manual labor while improving sustainability and productivity.

Print and all of its core applications continue

Our annual Year in Review article, 2024 Year In Review: Technologies and Trends, highlights the top drivers of digital print, finishing, workflow, and even media advancements. For additional discussions on top trends, challenges, and changes, visit us online to read more articles and access two Year in Review webinars at dpsmagazine.com/webinars.

Inkjet is one of the key technologies driving print into the next generation. We discuss how continuous-feed inkjet presses take on longer runs in Hitting High Volumes. We also feature a target chart on ultra-high-volume production presses capable of reaching ten-million-plus pages per month.

Labels and packaging is a key growth area for digital. As more print providers expand offerings to include digitally printed labels and packaging we present an overview of label media in The Perfect Label.

Another key application for digital print is photobook printing. We spotlight a print provider that expertly provides this service in Finishing Books.

Looking back on 2024, a drupa year, we are impressed by the industry’s continued innovation with digital print and supporting technologies at the center.

Happy holidays,

Cassandra Balentine, editor cbalentine@rockportpubs.com

EDITOR IN CHIEF

Thomas Tetreault 978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

300 Newburyport Turnpike, Ste. 11 Rowley, Massachusetts 01969 Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 300 Newburyport Turnpike, Ste. 11 Rowley, Massachusetts 01969

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

By Melissa Donovan 0--

Printed photo applications are still in high demand, despite the constant influx of social media applications that heighten one's digital presence. Personalized photobooks provide an opportunity to curate a precise collection of printed images out of thousands of digital ones. To do this cost effectively print houses turn to digital.

Graphiscan celebrates over 30 years in business. With three locations-one in Alma, QC, Canada and two in Montreal, QC-the company offers a full range of offset, digital, and large format printing with a staffofnearly 100 employees.

Most ofthe company'scustomersare based in Canada, but with the nature of print on demand, the print houseis alsoable toservice clientsintheU.S., Europe,andthe Pacific regions with ease.

Packaging and books are its main products. The company has been producing case bound and perfect bound books, in-

One of Graphiscan's two Montreal locations specializes in digital print production. The digital technology and expertisehelpsthecompanyserveprint on demand markets as well as book making. "We're able to produce book ofone orders very efficiently with great quality," offers Alex Legue, director of operations, Graphiscan.

Withtheautomation we've tripled our capacities tobe ableto serve our clients even faster during the rush seasons of the year...

Adding digital to thebusiness was inevitable, according to League.When the company began producing photobooks and customers started to request smallerruns downtoone, itbecameapparent that investing indigital was a must.

"Our clients asked for better turnarounds, shorter runs, and all of that with great quality. So the digital transformation of one of our plants was inevitable. We've been serving them now for a long timeandit'sbeenfantastic," admits Legue.

In house, the print shop runs several HP Indigos, a few Canon VarioPrints, and Xecluding photobooks, for more than 20 years. Books represent about60percentofitsbusiness.

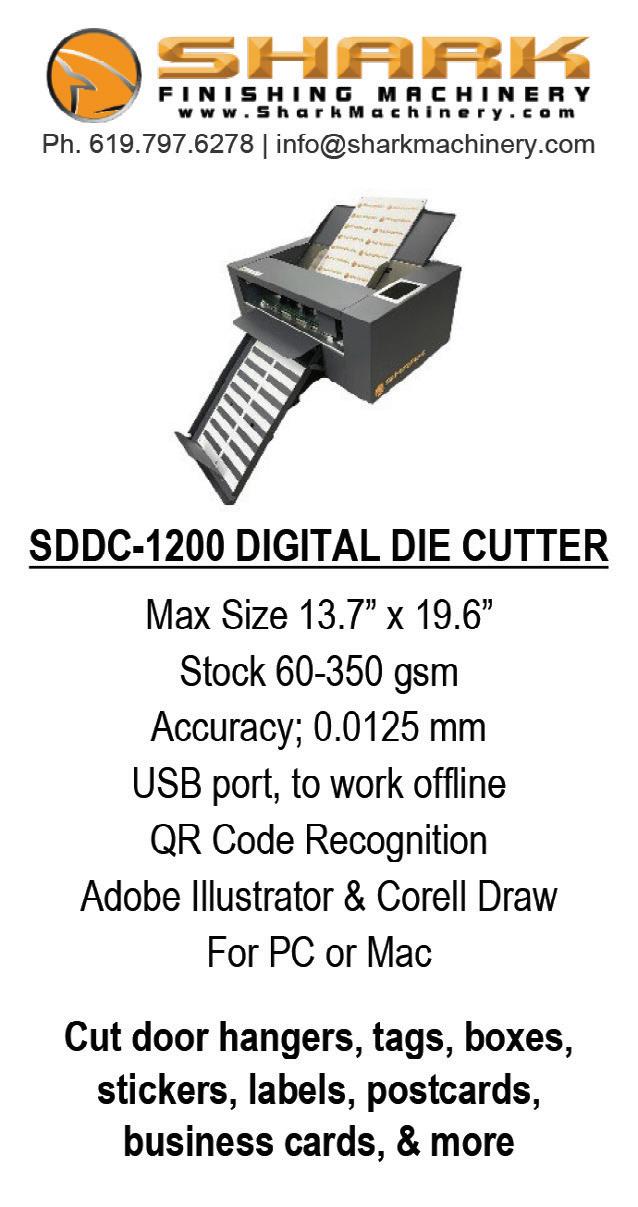

- Alex Legue, director of operations, Graphiscan 1. & 2. Graphiscan produces up to 1,1DO books per hour thanks to an automated digitalworkflow.

rox equipment. Legue refers to its HP Indigos as “workhorses” and admits these printers help Graphiscan stand apart from its competitors. “We’ve been partners with HP for years now, and its equipment is what’s required in terms of productivity and quality needed by our clients today. They run well, they run fast, and their quality is unbeatable for short-run printing.”

Always looking for smart investments to help the company stay ahead of the curve, Graphiscan recently acquired an HP Indigo 100K Digital Press. The B2 digital solution offers print capabilities at up to 6,000 sheets per hour.

3. Graphiscan recently acquired an HP Indigo 100K Digital Press. The B2 digital solution offers print capabilities at up to 6,000 sheets per hour.

“We’ve been upgrading our equipment as much as we can for years now. Digital printing is always becoming faster and better. The quality keeps improving as well as speed. We need to keep up as our clients also have increasing needs. They deserve the best service and quality, and digital equipment helps us with this,” explains Legue.

Part of the purchase included a Horizon fully automated book finishing line from Standard Finishing Systems, which was installed by its dealer, RM Machinery. The BQ-500 Perfect Binder runs inline with the LBF-500 Book Block Feeder, GF-500 Gauzer Feeder, and HT-1000V Three-Knife Trimmer.

The line allows Graphiscan to produce any type of book—no matter how small the order is—quickly. Even if it’s a small order, and another order is right behind with a different size, thickness, or even style—hardcover to soft cover— there is almost no downtime between the two.

“The flexibility of this line and the capability to improve and increase on what we were already doing well is what made it for us. With the automation we’ve tripled our capacities to be able to serve our clients even faster during the rush seasons of the year, like Christmas time for example,” shares Legue.

Prior to the inline system, Graphiscan ran a Standard Horizon BQ-470

page 27 for more information.

Perfect Trimmer with an offline HT-30 Trimmer in its book binding operation. Despite quality being top notch, the offline system was making it difficult to keep up with and meet customers’ shorter lead times.

“We are able to do about 350 books an hour, but as we began doing shorter runs and more book-of-one jobs, we knew we had to find a solution that gave us more automation and increased throughput without sacrificing quality,” explains Legue.

No doubt, part of the success of a fully automated finishing line is the software driving it. Graphiscan recognized this and pursued the purchase of iCE LiNK, which is Horizon’s cloud-based bindery control system.

Legue encourages the use of iCE LiNK for any business that wants to be data driven. The solution provides realtime insight into machine speeds, production capacities, and volumes running a day, week, or month, which allows Legue and his colleagues to make decisions at a business level.

Another benefit of iCE LiNK is the intuitive maintenance monitoring. “Basically, the system sends you an email when maintenance is needed, preventing unnecessary down time. It makes the life of the supervisor and operator easier, and if you do have an error, it tells you exactly what needs to be done to fix it,” says Legue.

To enjoy success in the photobook printing space, it takes the right combination of hardware, software, and skill—something Graphiscan has recognized and acted on. Today the company is able to produce up to 1,100 books per hour thanks to a much more automated workflow. “Faster equipment is one thing, but today we need to improve our automation, avoid down time, and make sure our orders move,” concludes Legue. dps

By Cassandra Balentine

Many years ago, digital print was a solution for limited applications. Namely, short-run work that only required “business quality” output. However, significant advancements to continuous-feed inkjet printing are disrupting the industry. At the same time, cultural shifts and demands favor shorter runs, personalization, faster turnarounds, and reduced waste are all primary benefits afforded by digital print technologies.

Today, continuous-feed production inkjet devices continue to advance in terms of speed, quality, precision, drying, and media handling and are more than capable of hitting millions of impressions every month.

Technologies

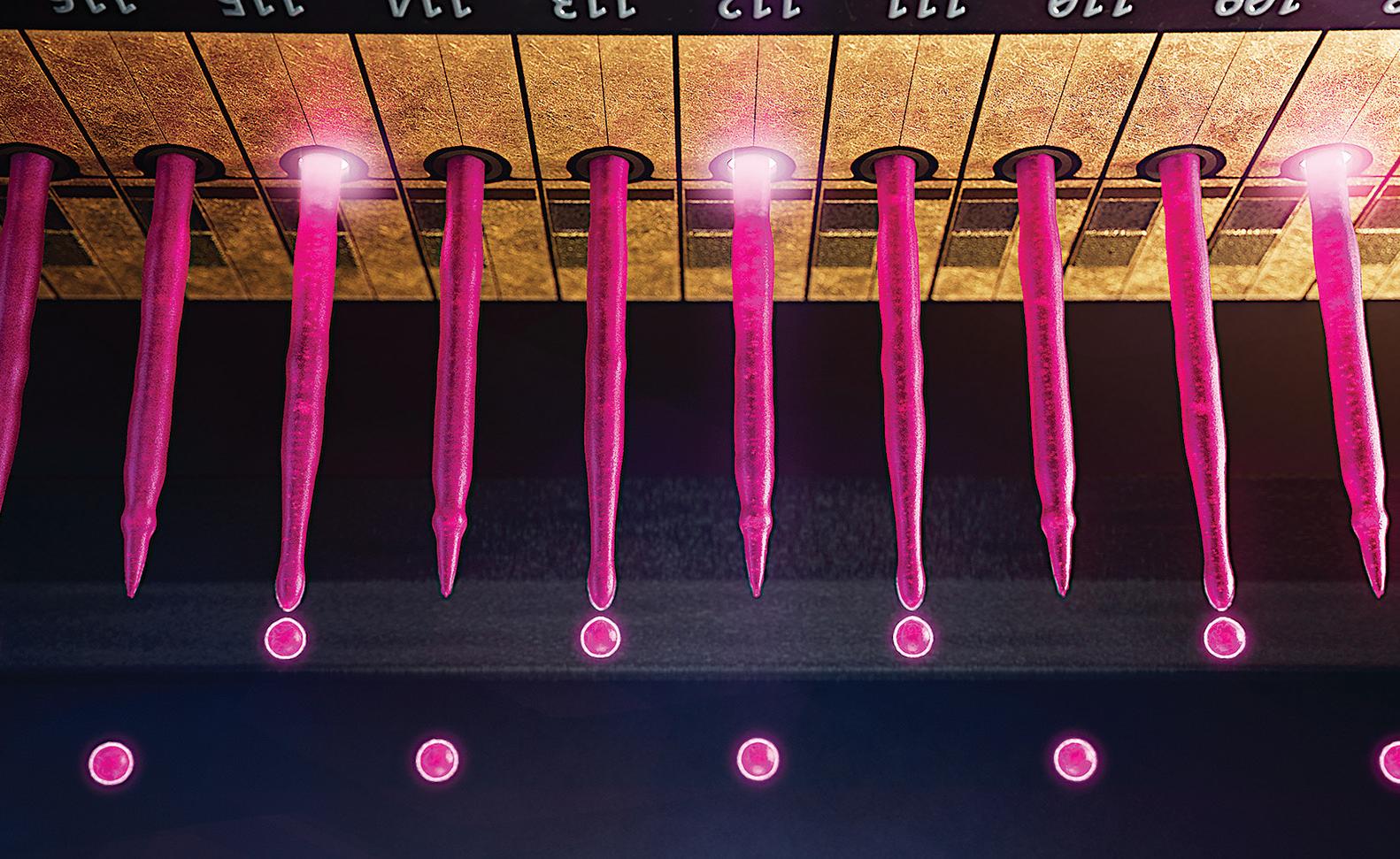

In the digital print space, continuous- or web-feed inkjet presses utilize drop on demand (DOD) or continuous inkjet (CIJ) technologies. Within DOD, both thermal and piezoelectric technologies are utilized in the commercial print space. “All DOD eject an ink droplet from the printhead nozzle when needed. The advantage is that it enables better control of

the ink drop placements with higher accuracy,” offers Rolando Martinez, head of HP PageWide Commercial Products and Solutions, HP Industrial Print.

Piezoelectric DOD technology handles a range of ink viscosities and compositions making it versatile for various

All inkjet printing processes involve ejecting ink droplets through specially designed firing chambers with small orifices or nozzles.

— Rolando Martinez, head of HP PageWide Commercial Products and Solutions, HP Industrial Print

printing applications. “Piezoelectric is typically more robust for high-volume printing environments. The initial investment may be higher, but it can be more cost effective in the long run due to lower maintenance and ink costs. The piezoelectric inkjet printheads also offer more flexibility in droplet size and can eject larger droplets at higher speeds, which is beneficial for faster printing without compromising

1.& 2 The KODAK PROSPER ULTRA 520 Press replicates offset quality and productivity on the most demanding high-ink coverage applications. Taking full advantage of KODAK ULTRASTREAM Inkjet Technology, PROSPER ULTRA 520 is aimed at the mid-volume market segment and printers that would have production volumes of around ten million A4 images per month.

quality,” explains Lisa Weese, senior director of marketing, Canon Solutions America, Production Print Solutions.

Both the Canon ProStream and ColorStream utilize Canon DigiDot piezoelectric DOD technologies.

Ricoh’s production inkjet portfolio also relies exclusively on piezoelectric, DOD-based technologies. “This approach provides end users with flexible, reliable solutions that are purpose built to solve their business challenges today and into the foreseeable future,” says Tim Bolton, manager, inkjet technology portfolio, Ricoh Graphic Communications.

Benefits of piezoelectric DOD include precise drop placement, dynamic variable drop size, high resolutions and frequencies, as well as industrial grade durability to support a range of applications in many different industries, such as commercial print, ceramics, textiles, wide/grand format, and additive manufacturing, according to Bolton.

HP utilizes its proprietary DOD thermal inkjet technology.

“All inkjet printing processes involve ejecting ink droplets through specially designed firing chambers with small orifices or nozzles. Over time, these nozzles can clog, which is a natural aspect of the inkjet printing process,” says Martinez.

HP’s thermal inkjet technology addresses this with cost-efficient, user-replaceable printheads. “Replacing these

printheads takes only a few minutes, providing users with greater control over print quality and productivity,” says Martinez, adding that HP thermal inkjet requires no purging, significantly reducing ink waste.

CIJ is also available either as a single jet or an array system. The systems can print at very high frequencies/speeds as part of a high-speed process.

Another positive of CIJ is the drop velocity is very high and can print at a significant distance from the substrate. “This can improve the reliability of the process, which is important when printing at high speeds,” says Paul Edwards, VP, digital division, INX International Ink Co.

When comparing CIJ and DOD technology, DOD is generally slower but has the benefit of greater print resolution. “It also has the ability to print a full-color process; although it is less common in CIJ, it is possible to print full color in some systems. The printheads are suitable for UV inks and different UV technologies, as well as for water and solvent. It is also easier to build a wide DOD system than a similar width for CIJ. The throw distance for DOD heads is lower, and more care and maintenance are often required compared with CIJ,” says Edwards.

Martinez points out that the CIJ method consists of ink droplets constantly being produced and ejected, but only when the drops are needed to land on the page is when they are diverted onto the paper, otherwise they are collected again.

“Strengths include more simple ink formulation and less procedures to service the printheads’ health since there

is less risk of ink drying or clogging the nozzles as they are constantly being fired, but they still degrade,” shares Martinez. “The main weaknesses is that there are higher risks of misdirection of ink drops reducing accuracy; limited redundancy when nozzles do go out; and since ink is recirculating after being in contact with air, there is a degree of contamination and evaporation that can alter the pigment-to-water ratio, which may have an impact on the color balance and print consistency.”

A full range of ink chemistries have potential in ultra-high-volume production. Each has their benefits and limitations, shares Edwards.

“Less common are oil/glycol-based inks, which tend to only be used where the substrate is absorbent. Hence, the ink dries by absorption. The very slow drying rate is a benefit for printhead reliability but it places a limit on substrates and leads to a slower production process. This technology is mostly used in DOD systems,” explains Edwards.

Solvent-based inks have benefits related to the speed of drying and range of polymers (adhesion), which can be used in the inks. “They can be printed at high speeds with minimal drying and are especially suitable for CIJ systems as the non-printed ink is continually recirculated and ‘made up’ to control viscosity by the automatic addition of solvent fluid. Inks can be used in DOD systems but tend to be slower drying and less

beneficial at higher speeds. Solvent inks canbean issue unlessthe emissionsare controlled," comments Edwards.

Water-based systems are somewhat in the middle of oil/glycol and solvent inks. "It is slower drying and more suitable to absorbent substrates, but also can be used on non-absorbent substrates if drying is sufficient. When used on non-absorbent substrates, the water drying time will be a factor due to speed potential and/or complexity ofthe equipment. Your choice of polymers in the ink is more limited with solvent, making adhesion more difficult to achieve on some substrates. Water-based inks can be used in both CIJ and DOD systems, and are viewed as more 'green' friendly and the safer choice," says Edwards.

UV inks are the final class, according to Edwards, who notes that these inks dry almost instantly on exposure to UV light and can be run at high speeds if curing is sufficient. These inks will also adhere to almost any substrate. "Since they are slow to evaporate, UV inks are usually very reliable in the printheads. But they are generally used in DOD technology since they can create high-quality images and their drop spread can be controlled via the cure process. UV can be used in CIJ printhead technologies, but it is not common

since viscosity constraints the formulation and ink properties."

Both pigments and dyes can be used in DOD and CIJ ink systems. The same can be said for all the different ink chemistries. "Dyes can be more difficult to use depending ontheirsolubilityinthedifferentchemicals, but they do provide a very bright and colorful image. Pigments can bedispersedintoallchemistriesandprovide good color, but they do have better fade properties and images last longer in brighter lighting conditions. Dyes can be more reliable than pigments as a pigmentneedstobedispersedtoensurestability, and they can become unstableover time," notes Edwards.

Canon's ColorStream uses waterbased pigment inks while ProStream uses ColorGrip conditioning fluid and a polymer CMYK pigment ink set with InkSafe technology.

Martinez says HP spent decades inventing, developing, and perfecting ink chemistries to meet the diverse needs of high-volume commercial customers. "HP ink chemists have formulated a high-performing pigment, water-based inkthatdeliversawidecolor gamutwith rich reds and deep blues, and boosts gloss by surpassing the sheet gloss level on a variety of coated papers. HP Brilliant Ink delivers stunning print quality on standard offset coated and uncoated

media, and is environmentally and workspace friendly with extremely low emissions. HP Pigment water-based inks provide high durability and permanence as well as a wide media range suitable for all commercial printing applications."

All PROSPER Presses utilize Kodak's CIJ technology, which provides high-quality, high-speed color printing with eco-friendly, water-based inks.

KODAKEKTACOLOR Inks are used in Stream Inkjet Technology, while KODACHROME Inks are designed for high-quality ULTRASTREAM Technologysystems.

''A common feature of KODACHROME and EKTACOLOR inks is a lower level of humectants compared to competitive inks. This results in very fast drying, even with high ink coverage on coated and glossy papers. The low humectant inks, together with interstation near-infrared drying-which is adjustable depending on volume and ink coverage-are enablers for printing heavy ink coverage on coated and glossy papers at top speeds," says Andrea Connor, worldwide marketing manager, Kodak.

Ricoh continuous-feed inkjet presses utilize aqueous inks with low water content in both dye and pigment formats. "These inks allow customers to effectively print and dry at increasing speeds and resolution. Dye inks are typically used in the RICOH Pro VC40000 based on the targeted applications of the press, but pigment and MICR options are also available. The RICOH Pro VC60000, VC70000, and VC80000 presses use pigment-basedinksexclusivelytoachieve wide color gamut and output resolutions for more challenging applications and print quality requirements. While waterbasedinksaretailoredalmostexclusively

4. The RICOH Pro VC40000 continuous-feed inkjet printer offers commercialandtransactionalprinters speed, flexibility, andimagequality.

to paper-based substrates, they also avoid many handling, environmental, or disposal concerns that often accompany other ink chemistries like UV," shares Bolton.

As traditionally offset printed applications shorten in run length, digital inkjet is an appealing solution for more commercial print work.

"We anticipate growth across commercial, publishing, book printing, and packaging sectors," notes Conner. "This growth is expected to increasingly capture market share from traditional printing methods, particularly offset printing. Factors such as cost pressures, shorter print runs, customer demands for quicker turnaround times, and a persistent shortage of skilled labor are driving this shift."

"Commercial and book printing continue to see runs shortened as print on demand and the need to reduce waste and improve efficiencies become increasingly important," shares Martinez.

Further, direct mail campaigns need to be more targeted and personalized to be relevant and continue to drive higher return on investment compared with pure digital campaigns. ''All of these trends continue to favor digital printing, which is forecasted to continue to grow in the next few years," says Martinez.

To capitalize on these trends, Martinez says HP is constantly innovating in the continuous-feed inkjet market with a proven track record of decades of innovations. HP plans to bring more intelligent automation to the print process with On Press profiling and Smart work cell controller technologies.

Continued advancements in versatility are expected as the market learns to leverage investments for more applications in order to diversify and capture greater share of the market and to expand into more applications. "They need their press to be versatile, flexible,

scalable, and sustainable in addition to highly productive," offers Martinez.

Bolton points out that Ricoh is investing in increased utilization and productivity of its current generation presses.

the presses installed since 2008 are still in use today," he offers.

Weese confirms that the future of digital continuous-feed printing aims at higher levels of throughput and produc-

Increased on-press automation, reduced tivity. "This is evident in the Canon 2024 reliance on operator skill set and judgement, as well as overall pressroom automation are big focus areas.

Conner feels that transitioning to continuous-feed digital printing can also help address sustainability concerns and reduce the carbon footprint of printing operations. "Our highlyautomated, high-speed inltjet presses and imprinting systems offer excellent solutions to these challenges, enabling consistent, high-quality production at full speeds, cost effectively."

Sustainability will continue to play an important role in the print industry and Martinez says HP presses' longevity provide customers with upgradable and scalable solutions. "We see that 95 percent of

announcements with the ColorStream 8200 and ProStream 3180. These advances help enable print service providers to produce more prints per hour so they can take on more jobs and/or meet tight service level agreements."

Thedigitalprintindustrycontinues to mature. While the adoption of continuous- or web-fed inkjet was once limited to transactional documents and books, today the technology attracts print buyers looking for the highest quality and customization in a variety of commercial applications.

Read more on available technologies in our web-exclusive round up. dps

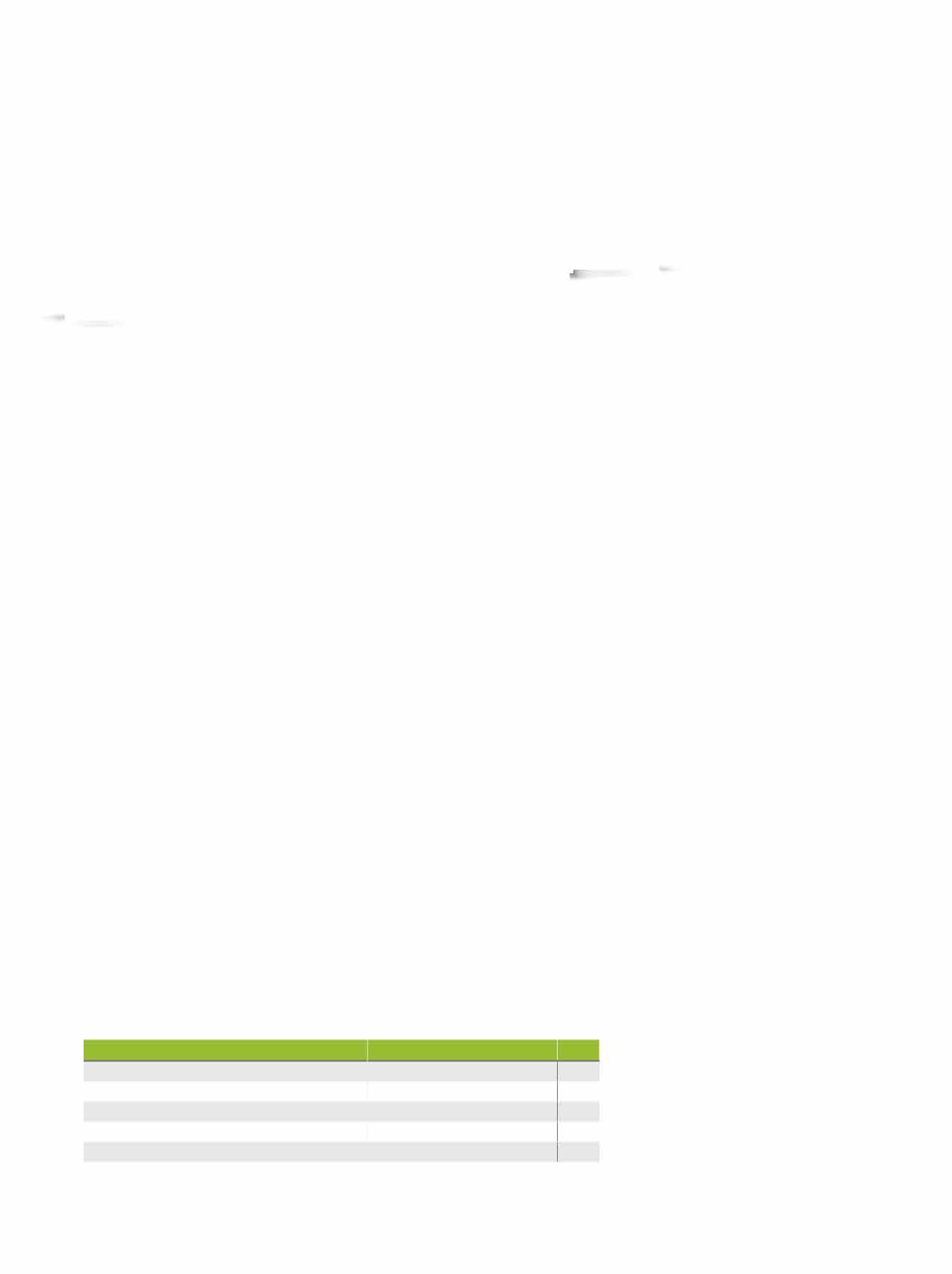

200Bluecrest EvoluJet

bluecrestinc.com

201 Canon Solutions AmericaVarioPrint i-series+

csa.canon.com

202 Fujifilm Inkjet J Press

fujifilminkjet.com

203 Komori Impremia IS29

on Demand komori-america.usImpremia NS40

204 Konica MinoltaAccurioJet

kmbs.konicaminolta.us

205 Kyocera TASKalfa Pro 15000c

kyocera.com

206Landa S11

sheets per hourNanography landanano.comS11P

per hourNanography 207 MCS MCS Merlin K146c

Drop on Demand mcspro.com

208Ricoh USA, Inc.Pro Z75

ricoh-usa.com

screenamericas.com

Xerox

csa.canon.com

ctc-j.com

per minutePiezoelectric Drop on Demand

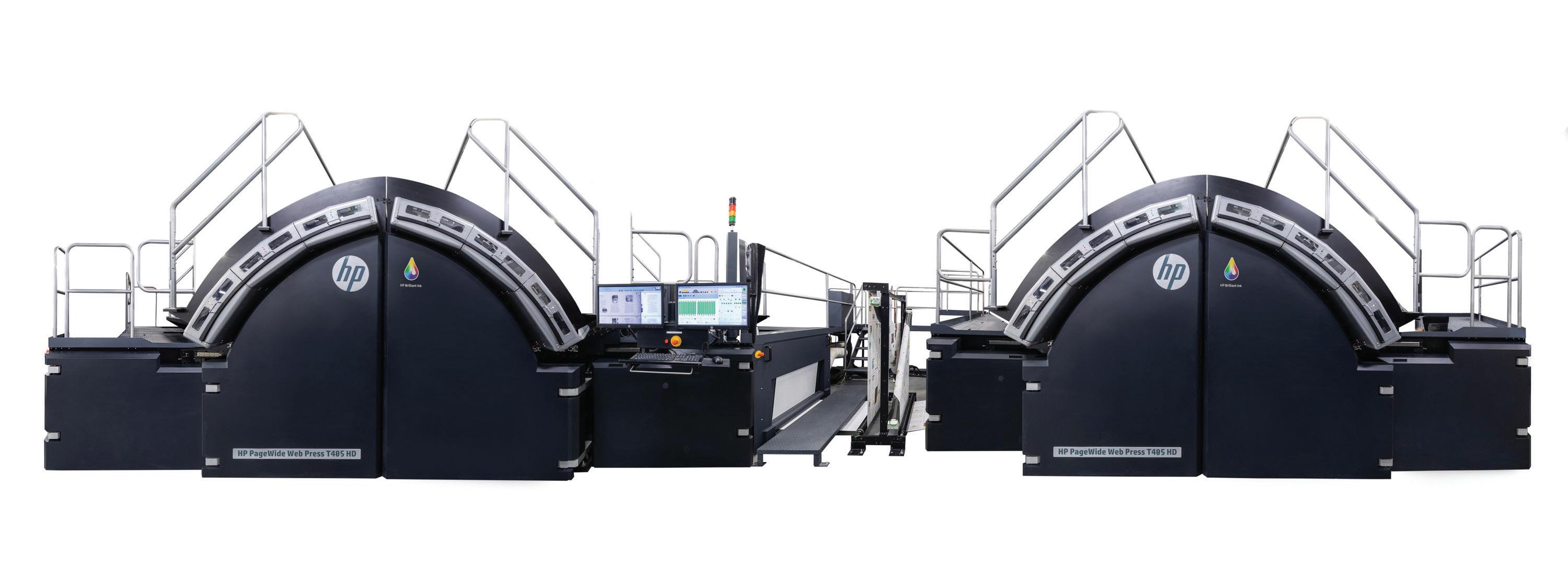

218HP IndustrialPageWide Web Press T250 HD500 Thermal Inkjet hp.com

PageWide Web Press T490 HD1,000 Thermal Inkjet

PageWide Web Press T485 HD800 Thermal Inkjet

PageWide Advantage 2200800 Thermal Inket

219Koenig & BauerRotaJET L 270 meters per minutePiezoelectric Drop on Demand us.koenig-bauer.com

220Kodak PROSPER 7000 Turbo 1,345 Continuous Inkjet kodak.com PROSPER ULTRA 520 Press 500 Continuous Inkjet PROSPER 6000 1,000 Continuous Inkjet

221Miyakoshi MJP20EXG 160 meters per minuteContact Manufacturer miyakoshi.co.jpMJPIXS/IXW 80 meters per minuteContact Manufacturer MJP20EX 80 meters per minuteContact Manufacturer MJP20E

By Melissa Donovan 0--

Label media used in digital printing includes paper and film for face stock options, with sub-categories underneath. Determining which to choose can be daunting for a print provider whether they are novice or experienced in the art of label printing. Agoodruleofthumbistoaskquestions. Specificallytothecustomerpurchasingthelabels. Wherewillitbeused? Whatlevelofdurabilityisrequired? Howlongwillthelabelbefunctioning? Generatingthemostinformationpossiblecanbe a huge help in determiningthe right material.

Plenty of options are available in terms of media for digital label printing. The trick is finding the perfect fit.

Manufacturers are constantly expanding their label media portfolios in response to customer demand. "We are always exploring and expanding the media choices for our digital printing customers. The customer drives everything we do and they are always ask-

director, North American roll sales, Wausau Coated Products.

"With today's advancements in printing technology, the possibilities are nearly limitless. From basic paper labels, such as shipping labels printed on a desktop laser printer; to sophisticated RFID or high-security labels printed on a roll HP Indigo Press, the variety of label media is as diverse as the methods used to print

them," explains Greg Kestler, product manager - narrow format digital/offset, General Formulations.

"In digital label printing, a variety of substrate options are available to suit different needs and applications. These include paper-based materials, synthetic films, and specialty substrates. Paper is a common choice for cost-effective, shortterm labels, while synthetic films like polypropylene (PP) and polyester ing us 'what if' we could print on 'fill in the blank.' The options are endless and range from basic semi-gloss papers and films to extravagant wood veneers, leather, cotton, and even textile

-

The substrateyou chooseneedstoalign withthe intended use ofthelabel.

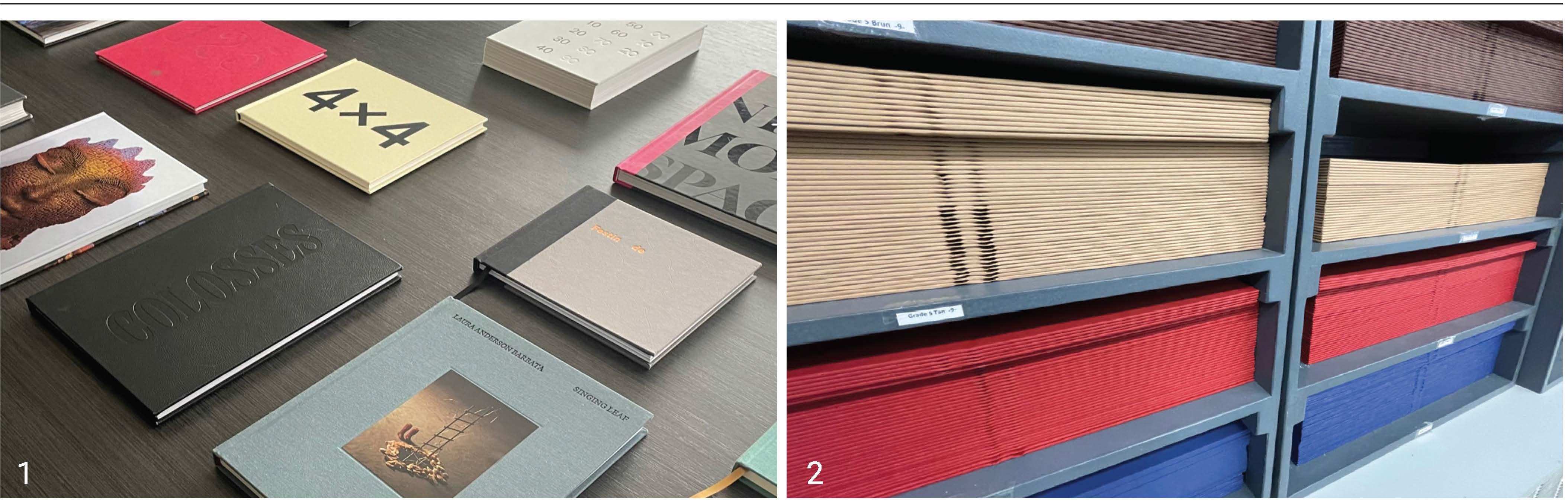

1.AlabelprintedonWausauCoated Products(W032316)Twill NaturalCloth. 2.The GeneralFormulations'NarrowFormatDigitallineofdigitalsheetsworkswellfordigitallabel printing and theseriesincludesa rangeoffilmtypesanddifferentadhesives to accommodate those different surface types,conditions,anddeliverableneeds. cloths," explains Adam Frey,

Amy Donato, globalstrategic marketing director, Teslin products, PPG

offer durability and resistance to moisture, chemicals, and the environment,” notes Amy Donato, global strategic marketing director, Teslin products, PPG.

Dividing into categories, first there are paper face stocks. These include standard white papers like uncoated offset, matte litho, semi-gloss, and gloss, says Kestler. Also available, specialty paper face stocks such as fluorescents, Astrobrights, brown kraft, bright and dull silver and gold laminated foils, 8 pt. tag, latex-impregnated paper, and Ryan-satin cloth, he lists.

Film face stocks are another option. Popular choices are vinyl, polyester, and PP. “These films are available in white or

3. Wausau Coated Products recently introduced its Hydro Opaque Product Series, which expands its wet performance label offerings. 4. General Formulations’ Narrow Format Digital line of digital sheets feature a specially formulated coating developed by an experienced technical research and development team to bring improved printability and enhanced clarity to customers’ digital print runs.

clear, and gloss or matte finishes. Polyester is also available in metalized versions, offering silver and gold in bright, matte, or brushed finishes. Unique materials like Teslin, Tyvek, and Tedlar can be adhesive-coated and printed digitally,” suggests Kestler.

“Specialty substrates like PPG Teslin label material combine the best of both worlds—offering the printability of paper with the durability of a film. Teslin substrate, for example, is particularly known for its broad print compatibility and excellent adhesion properties, making it ideal for demanding applications such as security labels and durable goods labeling,” shares Donato.

Beyond the face stock adhesive, options for adhesives are varied—and necessary. This is because, according to Kestler, there is such a wide array of surfaces labels are applied to, with different purposes served for each application.

“There are tinted adhesives to prevent show-through and specialized adhesives for easy removal, each tailored to different applications, whether it’s a name badge, a store window, or a painted wall. Even the type of paint on the wall can require a different adhesive. Low-energy surfaces, like powder-coated metal or Rubbermaid containers, present unique challenges for label adhesion. There are also adhesives designed for freezer temperatures, high humidity, or even submersion in water. Tamper-evident labels have their own specific adhesive requirements,” shares Kestler.

What do those new to label production need to know?

Understand the basics of substrate selection, printing technology, and surface application requirements. “The substrate you choose needs to align with the intended use of the label—whether it is for consumer goods, industrial products, or security applications. Also consider factors like durability, environmental resistance, and printability,” shares Donato.

Label needs are specific to the client. “When a client requests a permanent label, they should be prepared to answer several important questions. For example, what types of labels will you be producing? Will you need a range of label materials? Will this device be used exclusively for printing labels, or will it handle other materials as well?,” advises Kestler.

“When selecting media for digital label printing, it’s essential to consider factors like the label’s intended use, environmental exposure, and the surface it will adhere to. Understanding your goto-market strategy or your client’s needs is the first step in choosing the right label media and adhesive,” says Kestler.

To learn about the right substrate and print technology for the job, Frey encourages novice label producers to “leverage industry resources, including vendors and colleagues, to gain a solid understanding of printing technologies, adhesives, applicators, paper or film types, and essential questions to ask your customers.”

“Don’t be afraid to ask for product selection assistance. If provided with the right print method and field application information, we can often help you select the right label product quickly and easily. And if one isn’t available that is the right mix and match of adhesive, face stock, and print receptivity, we can often work to mix and match products and customize a product that is specific to your needs,” shares a representative from Tekra.

Considerations need to be made in terms of print technology when choosing media for digital label printing.

Identifying a print technology’s limitations and strengths is an opportunity to discover new solutions. “The options are only growing for digital printing engines that are available and learning where those technologies excel versus others is a big part of realizing success,” says Frey.

“Many lower to mid-range digital print platforms, which often use toner or inkjet systems, may have limitations on the types of label materials they can handle,” shares Kestler.

Donato agrees. “When choosing media for digital label printing, it’s crucial to consider the compatibility of the substrate with your printing technology.”

The representative from Tekra provides this example. A print provider is looking to purchase a narrow web UV inkjet printer, but it mostly runs polycarbonate labels. “Polycarbonate rolls don’t always come in 5,000-foot lengths, which is often desired to maximize the printer’s output abilities. Therefore, splices will appear in the roll. Splices are an option, but not typically recommended, as they can cause jamming or printhead strikes. If you primarily run papers or polyesters, which commonly come in longer rolls, splices are less likely to be needed, and a narrow web UV label printer may be the best option for your efficiencies and output.”

Again, it’s important to keep the customer’s wants and needs in mind. Asking questions like how they want to receive their labels—roll, multiple labels per sheet, or as individual labels? Also, inquiring about durability requirements and if the labels will need to be protected from scratching or scuffing is a good discussion to have, according to Kestler.

Many times the answers to these questions will lead to deciding between a printer’s feed type—roll or sheet fed—and the best type for the job at hand.

“The choice between these often depends on the volume and format of the

labels being printed. Roll-fed systems are typically used for high-volume, continuous printing, while sheet-fed systems are more common in lower volume printing, and typically digital printers. Consider a label stock that is available in both sheet and roll formats, providing flexibility for different production needs and ensuring smooth feeding in various printing environments,” advises Donato.

With the variety of substrates available, it can be tough to identify the right combination of media, adhesive, and ink for the job. To that end, print providers often look for a substrate that is compatible with the highest number of print technologies.

Kestler says one of the biggest challenges is that most printers want to print on the widest range of label materials. If this is the case, it’s important to partner with a distributor that provides in-stock, ready-to-print media with quick turnaround times for small quantities.

Pairing the chosen label substrate with the correct printer is another challenge print providers face. “Incompatible media can lead to poor adhesion, issues with ink adhering to the surface, or inadequate durability, which compromises the label’s performance,” explains Donato.

To combat this, Donato suggests using a label stock designed to be versatile across various printing platforms. “As an example, Teslin label stock’s microporous structure absorbs ink and toner effectively, ensuring vibrant colors and sharp

details, regardless of the print technology. Additionally, Teslin substrate’s static resistance and conformability help reduce print defects, making it a preferred choice for high-quality, durable labels.”

Meeting customer requirements can be difficult. “Make sure that your choice of a digital print engine and its capabilities align with your customers’ needs and wants for those labels you are producing for them. Understanding what matters most for your customer will help you align with the combination of the right media and digital print process to meet their expectations,” admits Frey.

Another challenge is identifying a label that offers superior durability and environmental resistance—when the application dictates it. “It’s important to select an option with the ability to withstand harsh conditions without compromising print quality in challenging labeling applications. This ensures that labels remain functional and legible throughout their lifecycle,” advises Donato.

Variety isn’t always the best, as it can lead to overwhelming decisions about which media is well suited for a label project. And when the incorrect substrate is chosen—the results aren’t ideal.

That’s why to ensure success, it is worth having an open conversation with your customer about where and how the label will be used. Ask as many questions as possible to help determine the best label media for the job. dps

By Cassandra Balentine

Environmental, generational, and cultural circumstances push the print industry towards shorter, more personal, and targeted print. With the help of automated and integrated workflows, print providers embracing digital technologies are well positioned for success in a shifting market.

The technology advancements fueling growth and adoption of digital print include the advancement ofproduction inkjet, artificial intelligence (AI), automated workflows, and growing sustainability practices, according to Tonya Powers, senior director ofmarketing, Canon SolutionsAmerica, Production Print Solutions.

CraigPowell, GM, NorthAmerica,printIQ, agrees, adding that the future of the print industry is shaped

by advancements in automation, personalization, and sustainability. ''Automation technologies like AI, machine learning, and smart workflows are optimizing print operations, reducing errors, and increasing efficiency. The growth of digital printing, including inkjet and on demand printing, is allowing for more customized and personalized print solutions while eco-friendly materials and sustainable practices are becoming priorities. Additionally, cloud-based print management systems enable remote access, streamline operations, and enhance collaboration."

As we close out 2024 and move into 2025, Marc Raad, president, Significans Automation, predicts

Above: Canon Solutions America, Inc. provides enterprise, production, and large format printing solutions supported by professional service offerings.

in colors, finishes, and designs too, unlocking unique branding and marketing opportunities,” offers Martinez.

Of course, offset technologies are still standard for many print providers.

Andrea Connor, worldwide solutions marketing manager, Kodak, points out that while this year provided clear evidence that we are living in the “and” era of print, “digital has arrived but offset still dominates.”

Going forward, Connor says the printing industry can expect a more fluid combination of technologies, enabling

printers to maintain efficiency and profitability. “The flexibility to select the most appropriate solution for any given situation—be it analog or digital printing— will be key to navigating shifts in market conditions and consumer expectations. This strategy ensures that print service providers can utilize the advantages of both technologies to enhance their operations and outputs, paving the way for a more adaptable, proactive, and sustainable industry,” adds Connor.

Lance Martin, VP product marketing, Komori America, believes that inkjet

technology—along with the proliferation of the B2-plus sheet size—will continue to develop, complementing traditional methods. “Furthermore, connected automation will develop to the point that companies will realize the concept of the smart factory.”

Dustin Graupman, senior director, inkjet division, Kyocera Document Solutions America, Inc., feels that the print industry is at a crossroads. “While legacy companies made difficult decisions regarding manufacturing and staffing, other production toner companies took significant cost-cutting measures to restore financial stability. This has led to one of the major trends we’ve seen—the growing adaption of inkjet technology as a primary printing method. The advancements in inkjet technology have resulted in greater adoption and companies beginning to purchase multiple devices. This leaves those who have been hesitant to adopt inkjet in a makeor-break situation.”

While Jesse Heindl, marketing manager, RISO, believes there will always be a need for more sophisticated, seven-figure cut-sheet or roll-fed production units, he expects it is light production toner as well as inkjet devices that drive

1. Muller Martini's Antaro Digital enables fully automated, single book production with manual feed or inline connection to the SigmaLine Compact digital book production system. 2. The Domino K300 fits inline at a label converter or a production line to meet the needs of a range of applications.

the industry for the near future. “Higher costs have led to less printing and those that are printing are doing so in smaller batches. It’s all about spending money tentatively and carefully. Smaller and more affordable units will drive the industry. The benefit of inkjet lies in the fact that it uses no heat, which means parts have a much longer life span. All lowering the overall print cost.”

Sevostyanov also sees a trend towards convergence, where printers become more universal by expanding their offerings to include business printing and packaging solutions. “This shift enables companies to tap into new markets and provide a broader range of services to their clients, helping them stay competitive in an evolving industry. They’re also exploring new, more profitable

niches to diversify revenue streams and adapt to changing market demands.”

This has commercial print providers expanding into labels and packaging.

In the label space, Steve Lynn, director of labels and packaging, Durst North America, sees 1,200 dpi high-speed inkjet as a technology changing the market. “Digital was historically perceived as only for short-run and variable jobs. Inkjet was historically perceived as not good enough to replace flexographic and toner in the prime label market. Those days are gone, 1,200 dpi inkjet delivers the quality, speed, cost of consumable, and efficiency that can allow a converter to run shortrun and multi SKU jobs efficiently with low waste at high speed, and also run medium/long-run jobs with minimal waste at high speeds, very cost efficiently.”

Rodney Pennings, sales director, print and packaging, BW Converting, foresees continued, digital advancements fitting a broader section of the flexible packaging market, both in widths, speeds, and application fit for use.

Digital print embellishments that offer effects like foil and embossing as well as specialty colors and gamut extensions are popular.

“Shelf space is at an all-time premium at retail stores so anything to make a product stand out will captivate the shopper and influence the buying decision,” comments Jeff Leto, VP, NBi FlexPack. For example, NBi recently installed a Cast & Cure system on its eBeam. “Cast & Cure creates holographic effects on

the packages that really make them pop. It also adds an additional layer of brand protection since it is more difficult to reproduce, especially when imaged with custom holographic logos and not just effects. This technology is impactful in giving customers’ brands star power to beat the competition and protects their products from counterfeiters making knock-off brands.”

Mark Geeves, director of sales and marketing, Color-Logic Inc., agrees, adding that personalization and print embellishment will continue to grow because brands need to stand out from their competition. “This has been shown in the world of labels and packaging for years, but is now also becoming a requirement for other print media like direct mail, signage, point of purchase, and the emerging market of name, image, likeness in sports.”

The hottest technology trend is without a doubt AI. Its evolution brings both opportunities and challenges.

Nir Zarmi, SVP, Landa, believes that the rise of generative AI opens up exciting possibilities for dynamic graphic design

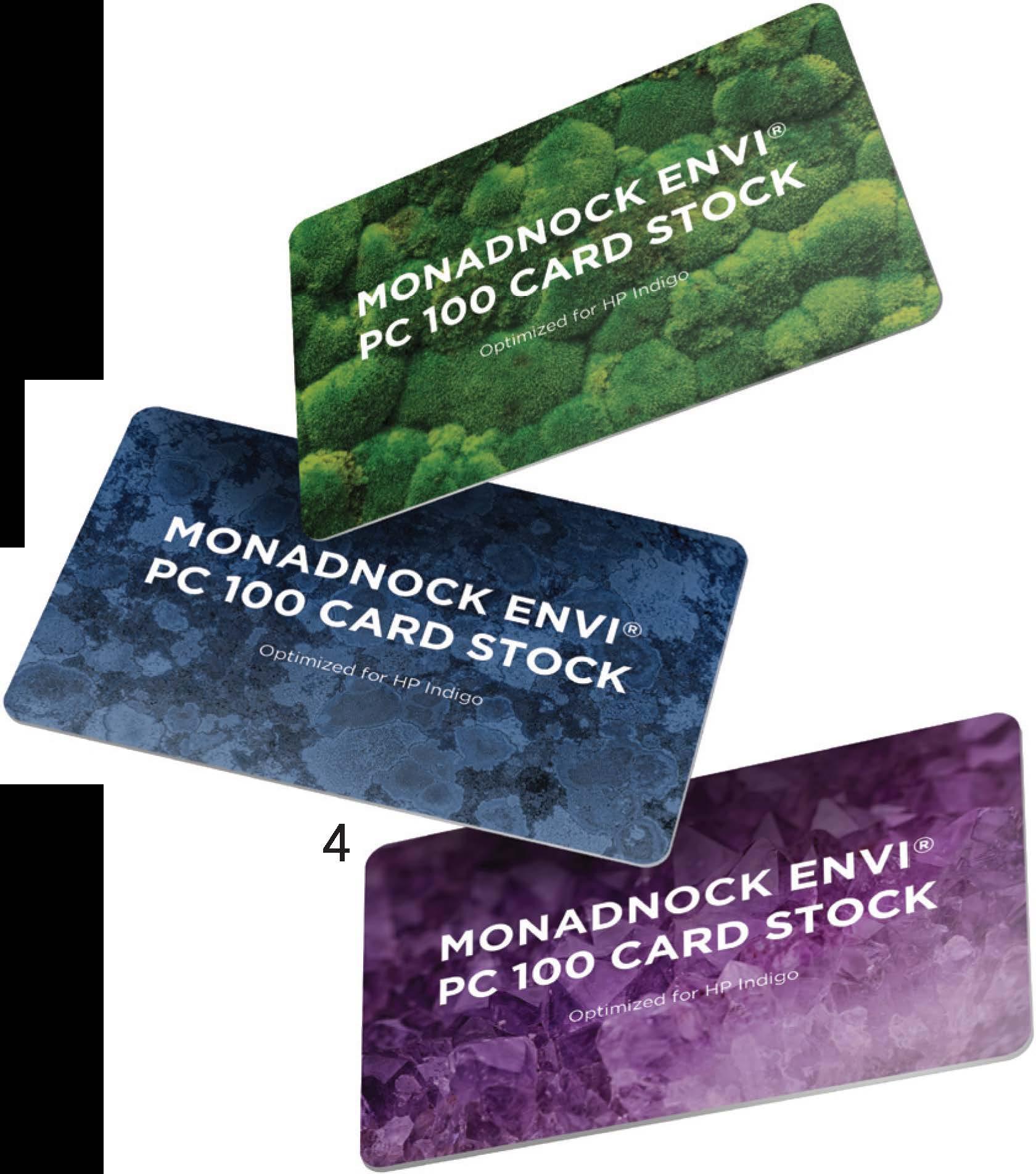

3. The HP PageWide Advantage 2200 is well suited for publishing and transactional applications—including MICR—on inkjet treated media. 4. The Monadnock Envi PC 100 card is optimized for HP Indigo presses.

and communication. "This technology enables brands to produce a broader variety of visuals and adapt messaging quickly to different audiences or regions, fueling the trend toward shorter print runs. The ability to create unique, AI-driven artwork on demand means brands can tailor campaigns more precisely, making digital presses with high-speed and high-resolution capabilities ideal for these agile, creative applications."

Terry Antinora, SVP, head of product and engineering, Xerox Corporation, sees the industry continuing to shift from traditional offset printing to digital printing, with AI and generative AI integrated more to improve efficiency, simplify design, and enhance specialty printing.

“AI is rapidly making inroads in many industries, and print is no different,” agrees Don Dubuque, director of marketing, Standard Finishing Systems. “While still in the early stages, we see many areas in which AI-powered systems could dramatically transform print including improved quality and efficiency, production scheduling, preventative maintenance, personalization, sustainability, and advancing automation even further. Just as when automation was introduced to the industry many years ago, I believe the companies that successfully incorporate AI early on will have a distinct advantage over those that don’t.”

While many companies are adopting AI for various applications, Raad points to studies revealing that a significant percentage of printers still have not integrated AI into their workflows. “According to an August 2024 report by Keypoint Intelligence, a huge 94 percent of 450 U.S. business leaders surveyed across various industries were already using AI in some way. Despite this, about 90 percent of U.S. printers have not even begun to use the technology. AI may still be in its infancy, but it’s destined to grow by leaps and bounds and is arguably one of the most important technologies created to date. Embracing these technologies is essential for ongoing growth and relevance in an evolving marketplace,” continues Raad.

While AI brings new possibilities, it can be challenging to figure out how to use it to one’s advantage and how it will affect the industry in the long term. “Digitalization, cross-media, and highly personalized content will continue to grow and become standard instead of an option,” says Randy Hardy, representative, North America, locr GEOservices and MAPS.

Pat Harnett, director of portfolio and development, HP Specialty Printing and Technology Solutions, says AI is bound to play a more prominent role in coding and marking systems. “The integration of AI will enable real-time adjustments, error detection, and predictive analytics that will optimize print quality automatically based on product type, environmental conditions, and production line speed.”

When it comes to efficiency and effectiveness, AI is a critical piece of the puzzle. “It is important to do things correctly

the first time versus trial and error, or being able to be more efficient in your operation whenit comes to workflow. AI can make you more efficient and make operations more streamlined," offers Dino Pagliarello, VP, product managementand Production Print, Sharp.

John Henze, VP, marketing and sales, Fiery, adds that AI has the potential to solve some of the most challenging problems in printing by automating routine tasks and making everything run more smoothly, from scheduling to resource management. As more AI features are introduced into the market, printers can drive additional efficiencies, reduce waste, and improve sustainability and profits.

AI also enables print providers to price out jobs more effectively and better understand what the consumer is willing topayfor certain output. "For example, it can be difficult to understand what your uplift could be on a particular sample that has metallics, varnish, or another type of special effect. There are software programs that now leverage AI and allow the commercial printer to charge the appropriate amount of money for that type of output. AI is going to beabigpartofthetechnologythathelps drive the growth of production print in termsofbothprofitabilityandefficiency," adds Pagliarello.

Automation is expected to play a critical role in gaining efficiencies, improving flexibility, and turnaround time,all while driving down costs, shares Antinora.

Michael Matthews, product manager, DP Color, Domino Printing Sciences, points out that companies turn to technology that will help them be more efficient to stay profitable, with automation of both software and hardware emergingaspopularoptionstohelpconverters streamline production processes.

AI will have an impact on certain sectors, but the bigger focus will be on

automation and combining tasks to drive efficiency. "Where AI can improve that, it will help and gain acceptance, even developing creative and iterations for marketing purposes. I also believe that the future of robotics is starting to filter out into more and more industries, and over the coming years, we will see more of that in place where it makes sense. Some companies offer that in the mailing and printing space today and I think it will only grow from here," says William Longua, senior director, Digital Print Group, Quadient.

Print inspection is an area where automation is increasingly important. "Conventional print inspection uses an array of cameras, optics, and lighting to provide inspection coverage acrossadefined field of view," explainsJohn Butler, senior director, North America Sales, Teledyne DALSA.

Advancementsinimagingtechnology provide manufacturers with the ability to utilize a single imaging module with integrated optics and lighting in place of multi-camera configurations. "These systems can be easily scaled in 100 millimeter increments with minimal engineering investment and offer high resolution and high-speed imaging capability along with the potential to cover wide conveyors or printing webs. The net result is a more cost-effective solution than many conventional systems without compromising image quality or inspection accuracy," notes Butler.

Andy Fetherman, president/CEO, Muller Martini Corp., points to fully integrated smart factory solutions that reduce labor,minimizewaste,and allow for the production of more products per square foot and labor hour as the technologies that will drive the printing industry going forward.

Automation also offers a solution to one of the biggest challenges currently facing the future of the industry, access to skilled labor.

Automation directs hardware to do things in line so labor is required to finish an output, commentsPagliarello.

Dubuque points out that while some ofthechallengesfacingtheindustrymay be temporary, like high interest rates, the skilled labor shortage has persisted. "While equipment providers have highlighted automation for a decade now, drupa and Printing United showed that manufacturers are going all-in on end-to-end automation coupled with user-friendlyinterfacestohelpalleviatethe challenges that their customers-both large and small-are facing."

Sevostyanov agrees, noting thatcompanies are focused on improving automationto enhanceefficiency andreduce reliance on manual labor.

Theabilitytoconductpreflightchecks on a customer's desktop before file submission is increasingly important in the print industry, aligning with several key trends and technologies. "Digital printing is growing due to itsspeed and quality, emphasizing the need for ready-toprint files. Automation and AI enhance operational efficiency, allowing integratedpreflightchecksthatcatchissuesearly. Sustainable practices emphasize efficient file preparation to reduce waste, while web to print solutions streamline online submissions with automated quality checks. Additionally, verifying

personalized designs before printing becomes crucial as demand for customization rises. By leveraging these trends, printers can improve service offerings and efficiency while meeting evolving customer needs,” shares Mary Gay Pettit, public relations, Markzware, Inc.

“I expect automation to continue to improve in all phases of production and spread across every corner of the industry,” offers Dubuque.

Martinez points out that with increased automation and digital production there will be elevated concerns over cybersecurity. “Companies need to ensure they have strong technology partners that provide secure and proven solutions.”

Integration is another buzzword arming print providers for success.

“We’ve mentioned automation as a key technology that will eventually become the standard for all print businesses. But automation is just one part of a broader digitalization of the industry.

What will really separate businesses in the future is how efficiently their digital workflows are integrated into the rest of their processes, from their online portals, distribution channels, and sophisticated design tools,” says Piet De Pauw, head of marketing, Enfocus. “The line between the physical print product and the digital world will continue to blur with the use of augmented reality, smart packaging, and digital distribution that relies on the internet of things to provide greater transparency throughout the supply chain.”

Workflows optimizing different segments—packaging, labels, commercial, promotional, and book printing—under one roof is a trend, notices Santosh Mulay, VP, business development, InSoft Automation Pvt. Ltd.

Further, Powell indicates that data-driven decision making helps companies optimize production and better anticipate customer needs.

Manufacturers are starting to leverage data analytics and data-driven decision making. “The connected factory provides a means to collect data on manufacturing systems and provides powerful insights that can be used to better optimize print jobs, enhance

the quality of finished products, reduce waste, and minimize costs. These advancements will help to ensure that the industry remains competitive and healthy in the years ahead,” notes Butler. Raad says his team has utilized AI for the automation of prepress checks, layout optimization, faster processing of large volumes of data, and much more. “We’ve been deploying specific AI technologies into our workflows for some time now. This allows us to analyze large datasets, convert legacy data, and identify meaningful patterns for print shop owners to make better-informed decisions based on accurate data insights. AI reduces errors, enhances production efficiency, helps manage inventory, estimation, and much more.”

Aligning with connected workflows, cloud-based technologies enable real-time collaboration and the seamless sharing of digital assets among remote teams, suppliers, and customers. “They eliminate the limitations of physical locations and enable global teams to work together efficiently. Cloud-based solutions also reduce IT infrastructure and maintenance costs, as the burden of hosting, security, and system updates lies with the cloud service provider,” explains Gemma Wood, Smartflow product manager, software, Loftware. Furthermore, they often provide integrations with other cloud-based tools and services, enhancing the overall ecosystem and enabling businesses to leverage best-in-class solutions for different aspects of packaging production. “Cloud-based technologies are

predicted to become more popular in the print industry, specifically in packaging applications such as project management, digital proofing, and digital asset management,” adds Wood.

Print on demand, digital printing, and personalization are growing as consumers demand faster turnaround times and tailored solutions.

“This trend is a natural extension of the shift towards more sustainable practices, as it minimizes waste and offers an expeditious path to bring products to market,” says Julie Brannen, director of sales and sustainable solutions, Monadnock Paper Mills.

“Sustainability will be paramount as clients expect to work with businesses that have sustainability as a core tenet of their operations,” stresses Antinora.

Sustainability is expected to continue to be a central driver, with renewable, fiber-based alternatives taking precedence, particularly in products like gift cards, recycled packaging options, and styrene replacements. “Both consumers and legislation drive the demand for recyclable and non-toxic materials as businesses seek to minimize or avoid their use of non-recycled materials,” notes Brannen.

“Over the next 20 years we will continue to see a move to technologies that reduce the environmental footprint, albeit, not at any cost,” believes Philip Easton, managing director, Industrial Inkjet Ltd. He admits that the print industry is broad and diverse, in some sectors it will not survive e.g. newspapers, and others continue to evolve and grow e.g. labels and packaging. “The trend is towards more digital printing,

this technology is still innovating and improving. It offers creative opportunity as you are not tied to printing the same thing for each imprint, has less waste for setup—both saving cost— but also improving the environmental footprint. The ongoing trend for more choice through more SKUs and diversity of products, but with lower volumes per SKU, again make digital printing the preferred technology.”

Eli Grinberg, CEO, Scodix, also believes that sustainability is a key focus, with increasing emphasis on custom, data-driven insights to inform decision-making. “By leveraging these insights, print service providers can not only track their sustainability efforts but also demonstrate to clients the tangible benefits of digital embellishment—such as reduced overproduction and optimized material efficiency—making sustainability not just a goal, but a strategic advantage.”

The consensus is sustainability will always be a strong trend in the industry. Harnett says manufacturers are innovating and exploring ways to make inks more sustainable while not compromising on print quality.

“Environmental and sustainable practices have requirements and regulations

that are only going to get tougher, so businesses need to look at how to move more work from older analog offset production methods that are less environmentally friendly,” suggests Martinez.

It is important to accept that while print is not going away, its reach is limited compared with its virtual counterparts.

“While the industry is evolving, it’s clear that print itself will remain a vital part of the communication ecosystem. Print offers a tangible, tactile experience that many consumers still value, particularly in important communications like billing, compliance documents, and personalized marketing,” stresses Ernie Crawford, M-EDP, president/CEO, Crawford Technologies. “However, the future of the industry lies in its ability to integrate seamlessly with digital channels, creating a unified omni-channel experience for consumers.”

The convergence of marketing and traditional transactional communications is driving this shift. “Increasingly, CXOs and customer experience leaders recognize the importance of merging invoicing and customer engagement efforts into a cohesive strategy. This trend

aligns with the growing demand for preference management where customers can choose how and when they want to receive communications via print, email, SMS, or mobile applications.”

Print companies no longer strictly provide physical documents; they are becoming data analytics experts. “By dissecting customer data, analyzing response patterns, and combining digi-

tal and print strategies, these companies help brands deliver personalized, relevant content. As a result, print providers that embrace AI-driven personalization and omni-channel communication will be well-positioned to enhance customer engagement and drive better results,” shares Crawford.

AI is also expected to play a role in customer communications. “There

See page 27 for more information.

InSoft Automation Pvt. Ltd.

Komori America komori-america.us

Kyocera Document Solutions America, Inc. kyoceradocumentsolutions.us/en116

Landa landanano.com

locr GEOservices and MAPS

Markzware, Inc.

Significans Automation

Teledyne DALSA

Transformations, Inc.

are numerous areas that will likely be affected like automating repetitive tasks—i.e., document composition, workflow automation, building more effective language in document design, efficient analyzing of data for predictive analytics and insights, predictive maintenance and capacity planning, enhancing revenue cycle management, and many more,” says Ryan Semanchik, president, Transformations, Inc.

Outside of customer communications management workflow, Semanchik expects AI to change how organizations operate other parts of their business. “For example, we use it internally to more efficiently engage with customer support queries by analyzing our full library of documentation and knowledge-based articles in seconds to instantly generate valuable responses.”

Print continues to evolve. New technologies, specifically AI, help print providers meet the growing demands of the ever-evolving print buyer. The ability to capture and interpret data help to optimize workflows. The ability to automate redundant tasks relieves pressure on skilled laborers. And, the ability to personalize and embellish print helps it stand out in a market crowded with messaging.

Dario Urbinati, CEO, Gallus group concludes that while we should continue to listen to the market and understand these shifts, “the only way we can ever really guarantee our survival and our success is to equip ourselves to adapt and change regardless of which direction the industry takes. We truly need to empower print business with the flexibility and agility to work in new ways, pivot, and adapt inline with these external forces.”

The trends and technologies covered in this piece are just one part of our Year in Review series, be sure to visit dpsmagazine.com for more. dps