Compared to analog technologies, digital print inherently brings a variety of benefits when used to produce the same applications. f course the top advantage is the ability to uickly and cost effectively turnaround short runs featuring variable data allowing each piece to be uni ue. It also presents environmental advantages.

This issue focuses on security with two articles dedicated to

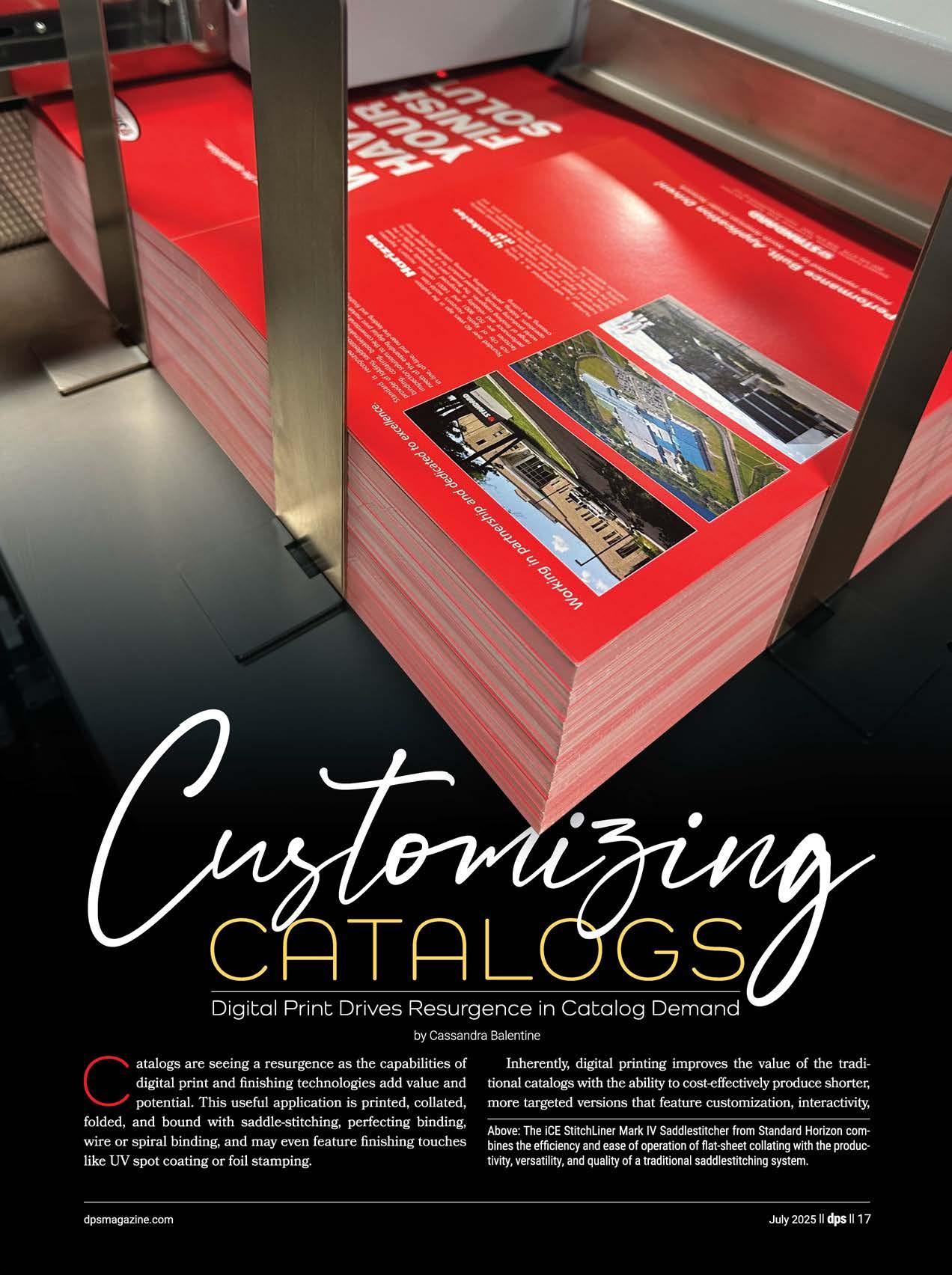

ur cover story Customizing Catalogs specifically looks at how digital print and supportive finishing technologies are revolutioni ing a traditional application that is now seeing a surge in demand due to new capabilities.

This issue focuses on security with two articles dedicated to different aspects. In Brand Protection we review strategies and effects that today s digital printers are able to incorporate to thwart counterfeiting and tampering.

e also discuss security from a networking standpoint. Securing Sensitive Data highlights ways that software and encryption tools protect sensitive data as it crosses between various mechanisms from hard drives to the cloud.

Finally we take a uick look at lamination in Expanding Markets. In addition to document protection this finishing tool is sometimes used to add value to digitally printed output.

lso in this issue find a recap of the recent Finishing 360 event held at Standard Finishing’s MA-based demonstration center.

dpsmagazine.com

Volume 27, Number 4 • ISSN: 1529-2320

EDITOR IN CHIEF

Thomas Tetreault 0

EDITOR

Cassandra Balentine cbalentine rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan rockportpubs.com

ART DIRECTOR

Sarah M. White swhite rockportpubs.com

WEB EDITOR elissa ueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, ina Ferrara ark anley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

300 ewburyport Turnpike Ste. owley assachusetts 0 6

Ph 0 0 F 0 edit rockportpubs.com

SALES

Amanda Doyon Ph 0 0 F 0 adoyon rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 300 ewburyport Turnpike Ste. owley assachusetts 0 6

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN Jeffrey Jensen

Cheers, Cassandra Balentine, editor cbalentine rockportpubs.com

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER Missy Tyler

By DPS Magazine Staff

The future of digital print technologies is propelled by innovations in finishing and workflow. This Spring, Standard Finishing Systems showcased its latest solutions at its annual VIP customer event. The annual Finishing 360 event was held at Standard’s National Demonstration Center in Andover, MA,

Taking place over two days—May 21 and May 22, 2025—visitors saw a lineup of automated Horizon and Hunkeler solutions, networked with peers, and gained finishing expertise from industry specialists.

The main draw of the event was the North American premiere of the Horizon BBS56 Book Block Solution, a plow fold book block-making system designed for shortto medium-run production. It can be fully integrated with a Horizon perfect binder and trimmer for a complete roll-to-perfect bound book solution operating at speeds of up to 800 books per hour.

Each selection of the system, from unwinding and plow folding to cutting, gluing, and stacking, with delivery to the BQ-500 Perfect Binder and HT1000V Trimmer was demonstrated live.

Also among its range of book binding solutions, Horizon’s newest perfect binder, the BQ-300 was showcased. The device features enhanced automation and built-in, user-friendly features to enable efficiently produced, professional quality books.

Also shown, the Horizon SPF-200 Bookletmaker, which folds, stitches, hole punches, and trims booklets in one system at up to 4,700 cycles per hour.

Highlighting the power of a Hunkeler/Horizon Integrated Solution, the Rollto-Booklet solution was demonstrated, featuring Hunkeler’s Gen8 unwinding and cutting modules integrated with the digital, high-speed Horizon StitchLiner Mark V Saddlestitcher to deliver finished books from a roll.

The Hunkeler Roll-Fed Finishing solution Roll-to-Cut/Stack configuration was

shown producing straight and fully separated offset stacks from one- to four-up, delivering full-bleed products as small as 5.5 by four inches.

Further demonstrating automation and efficient workflows, several Horizon systems were connected to iCE LiNK, Horizon’s cloud-based bindery control system.

Finishing 360 featured personalized group demonstrations as well as highlighted Standard’s pre-owned equipment and service programs, showing print professionals how to succeed with the latest technology breakthroughs in print finishing. dps

1.& 2. This Spring, Standard Finishing Systems held its annual VIP customer event, Finishing 360, at its national demonstration center in Andover, MA.

ByOPSMagazine Staff

Laminating is a popular finishing technique with big potential in both web- and sheet-fed digitally printed applications. Lamination offers both practical and aesthetic uses, including extended UV protection, adding chemical and abrasion protection, and enhancing or modifying the look of digitally printed output.

For some print providers, lamination is an occasional need. To many others, it may be a daily requirement. "By adding the capability in house a printer is able to include long-lasting/durable print as a key additional sales benefit," states Ray Hillhouse, VP sales and marketing, Plockmatic Group Offline Business Unit.

Printprovidersare discoveringways to offer more applications and types oflaminatingthatcanbedonewithasingleasset, suggests Jeff Truan, strategic account solutions specialist, Nobelus. Many pretreat laminates are used to increase bond strength while choosing newer adhesives that reduce the previous high costs ofdigital lamination.

In terms of value enhancement, more laminate finishes are available than ever before,

including tactile finishes and holographic patterns. "We've also seenwider adoption of laminating equipment that can give prints texture through embossing and shining effects using on demand digital cold foils," suggests Truan.

More laminators target shorter run lengths and smaller sheet sizes for the digital print space.

Toners and digital inks used for digital prints don't play nicely with traditional laminate films.

-Neil Drever, product consultant, Skandacor

"Toners and digital inks used for digital prints don't play nicely with traditional laminate films," explains Neil Drever, product consultant, Skandacor. "Traditional laminate films are made for offset prints, which are easier to adhere to. However, because ofthe high oil content in toners and digital inks, digital prints are notorious for peeling and other adhesion issues."

As smaller digital print shops start offeringlamination,factorslikecompactness, user friendliness, etc. become make or break. "These shops typically have limited floor realestate andyounger,tech-savvy

1. Nobelus offers a range of laminate finishes and thermal laminating systems. 2. Morgana provides a more traditional laminating solution with the Laminator Pro 450.

staff members. So big, clunky, machinery doesn’t suit the fast-paced environment of these shops,” notes Drever.

“Quicker machine setup times and practices that create less waste through reprints and waste sheets help increase productivity and decrease lead times. Advancements in laminating systems also mean operators have to be less technical to get high-quality results,” adds Truan.

Another important development in recent years is the emergence of lowcost digital laminating solutions. “These have been developed particularly with the needs of the short-run digital sector in mind. At the vanguard of this type of machine have been our partners at Intec. The ColorFlare range of digital laminator products require no dies to be manufactured. As that typically happens with an external supplier it means significant time and cost savings, which in turn can lead to the potential for better margins for the printer,” says Hillhouse.

The shorter run length of digital means that fully automatic feeders aren’t always practical. “There’s very little sense in setting up an automatic feeder to run 50 sheets. So we’re seeing more demand for semi-automatic feeders, which offer the perfect middle ground for shops with run lengths too long for a manual feeder, but too short for a fully automatic machine,” suggests Drever.

If you look specifically at laminating flexible digitally printed output, Sam Crosby, dealer manager, Graphic Finishing Partners (GFP), says the technology has remained relatively unchanged over the past 25-plus years. “It’s primarily due to the straightforward process of two rollers putting a flexible film over a flexible or rigid print. While always looking for ways to make laminating more consistent while adding efficiencies like temperature, speed, and pressure presets.”

Gfp has developed a way to better manage costly inventory and reduce waste while making better use of partial

rolls. Specifically, the Gfp 663TH 63-inch top heat-assist roll laminator features swing-out supply shafts, rear-rewind with inline trimmers, electronic nip control, counter and onboard label printer, and preset production lengths so operators won’t have to physically stand in front of longer runs helps frustrated shop owners while better managing inventory loss and/or reducing waste.

Digital print providers witness huge gains in a range of areas due to advancements in lamination, according to Truan. “In the past, value-add lamination was seen mostly as a niche offering with the majority of printers outsourcing post-print lamination. But Truan says this has changed significantly as differentiation becomes more important. “In fact, lamination has become almost a requirement in many spaces due to the need to enhance digital print in hypercompetitive markets.”

Drever believes that in order to stay competitive and increase profits, PSPs need to have a better solution for customers. “The progressive printers offering embellishment and in-house print finishing are the ones who are gaining traction and bringing embellishment more mainstream.”

Truan agrees, noting that marketing pieces are more crucial for brands, which leads to higher value packaging, special attention to tactile finishes like soft-touch and rough-touch options, and visual enhancements that draw the attention of consumers to increase the chances of interaction. “In an increasingly virtual age, we are actually seeing increased response rates at the mailbox for laminated direct mail, and we expect this trend to continue growing. Lamination is also becoming more important for protection purposes, such as keeping book covers from scuffing during shipping and ensuring collectible

items with attractive, unique finishes that remain in pristine condition long term.”

Drever notices a lot more print providers going beyond the typical traditional gloss, matte, and soft-touch lamination. “A lot of people offer creative options such as foil under a 10-mil laminate, incorporating metallized boards or films, etc. Another application that’s becoming more common is laminated Teslin. When done with a 10-mil laminate film, even though the final result often isn’t edge sealed, it makes a nice, thick, completely waterproof card.”

Films like Skandacor’s UltraGrip laminate line are specially formulated with an aggressive adhesive for digital prints.

Insourcing this type of lamination enables printers to increase margins in competitive spaces, offering brands more rapid turnaround times, and increase

their top line revenue. “More brands are asking for ways to differentiate their products in increasingly competitive markets, and the value-add features modern lamination offers provide a perfect way to create unique designs that appeal to multiple senses,” adds Truan.

The value lamination adds can vary between job size and market, but there tends to be a higher margin with digital lamination. “This is typically because of the short-run length and quick turnaround times that digital print customers usually require. On average, you can expect a 50 to 80 percent profit increase,” shares Drever.

“From what we have seen with our own customers, we estimate that the physical value of print and packaging can

increase revenue by more than 40 percent in many spaces, while margins are growing as much as ten to 15 points. This growth is most likely due to the greater importance brands place on differentiation,” offers Truan.

The value lamination can bring varies greatly. “For example, from 500 soft-touch business cards, which might add a small profit increase—let’s say $25—to a rush job of 500 backstage passes with 10-mil laminate that could bring a large profit increase—up to 80 percent,” says Drever.

Laminators support the digital print space by targeting shorter run lengths and smaller sheet sizes with features like semi-automatic feeders. In addition to protection, these devices also add value to prints. dps

By Cassandra Balentine 0--

Brand protection and security cover a wide array of topics, extending well beyond printing. "Safeguarding sensitive data involves advanced technologies and strategies to prevent, detect, and respond to threats that could compromise a brand's integrity and customer trust," admits Suzi Hagay, director of workflow solutions, Landa Digital Printing.

Ravi Koul, senior director, product marketing office technology and Mark DeSarno, directorsecurityandcompliance engineering, Kyocera Document Solutions, observe a significant rise in the demand for enhanced security printing solutionsoverthepastfiveyears. "Many of our clients have transitioned to systems that require authentication to accessprinting devices. This meansusers mustverifytheiridentitybeforetheycan utilizetheprinter, addingan extralayerofsecurity."

Issues such as phishing attacks, unauthorized data access, and data leaks must be addressed.Inhighlysecuresce-

narios, codes are generated on the fly just before printing and are automatically deleted from the database to ensure no code

isprinted more than once. Additionally, practice of integrated encryption/deaccess to the data is strictly limited-if cryptionofdataintotheentireworkflow allowedatall, explainsHagay. of design and production, and production access control and monitoring as

Security Features itrelatesto safeguarding information.

The latesttrendsin safeguarding sensi- "Solutions like Xerox Secure Print tiveinformationincludedataencryption, ensure that documents are encrypted invisible security features, access con- before they are sent to the printer, protrol, andsecureprintrelease. tectingconfidentialinformationthrough-

Tamir Hativa, headof security print- out the entireprinting process. This ening, HP Indigo, notes the increased cryption prevents unauthorized access,

Organizations areincreasingly interested in monitoring whois printing what, when, and fromwhich location. ensuring that sensitive data remainssecureatalltimes,"comments Matthew Raab, director of global portfolio marketing, XeroxCorporation.

- Ravi KouI, senior director, product marketing office technology and Mark DeSarno, director security and compliance engineering, Kyocera

1. The Xerox Versant 280 incorporates security features like story networking and data protection 2. Kyocera's products offer an extensive range of configurations that ensure both securityand productivity.

The basis for protecting customer’s sensitive information is through using encryption and security protocols. “The industry is moving to TLS v1.3 and FIPS 140-3 certified encryption methods to help to protect customer data at rest and in transit along with the latest in storage drive security products to protect encryption keys using Trusted Platform Module so that data is erased after job succession. We also see demands for more security printing features within Zero-Trust networks, Cyber Resilience within the HCD platform, and network connections and preparations for future Quantum computing,” says Mark Sinanian, VP of marketing, Canon U.S.A., Inc.

Koul and Desarno explain the architecture of remote, on-demand print job release. “This functionality allows users to send print jobs to a network and then

release them from any device connected to that network when they are ready to collect the printed documents. This ensures that sensitive documents are not left unattended at the printers and can only be picked up by authorized users.”

Moreover, Koul and Desarno see a growing need to track user activity within these systems. “Organizations are increasingly interested in monitoring who is printing what, when, and from which location. This tracking capability not only helps in maintaining security but also aids in auditing and compliance processes.”

Functions like engine-level file control allow users to control where and how jobs are printed. For example, Jeroen Van Bauwel, director solution design, Xeikon, says Xeikon’s digital workflow allows for granular control. Print jobs are restricted to specific engines, ensuring that sensitive

files are not inadvertently or maliciously routed elsewhere, and engine-specific locking ensures that even if data were accessed, it couldn’t be executed on unauthorized systems.

Using a host of flexible authentication methods, administrators control who has access to a printer, and to which features. Sinanian says this can be done using a PIN, username and password, or card log in with the addition of an optional card reader. Restrictions—such as access to color copying and scanning functions— can be applied by individual, group, or through customized roles. You can also define whether to allow unregistered users, such as visitors, to log in as guests and then specify their level of access.

“Administrators can set requirements for passwords, such as expiration period, lockout time, and complexity. They can

even access the device remotely with extensive control, from changing permissions to monitoring activity—even turning on or off devices or locking down specific equipment or functions,” adds Sinanian.

Some systems also provide protection with data erase features used to overwrite previous data on a solid-state drive. Sinanian says this is designed to help limit stored data from being read/written on PCs or a different printer. “These models feature the ability to turn on a function to help verify that the device boot process, firmware, and applications initialize at startup without any alterations or tampering by malicious third parties. Select models support automatic recovery of boot

process for self-resiliency. During operation, Trellix Embedded Control can be turned on to utilize a whitelist to help protect against malware and tampering of firmware and applications.”

Multi-factor authentication is also integrated into print workflows to further safeguard access to sensitive data. Raab explains that by requiring multiple forms of identification, it ensures that only authorized personnel can access confidential documents.

“These advancements are part of a broader trend toward implementing more comprehensive, multi-layered security systems that protect sensitive information across its entire lifecycle,” adds Raab. For data storage, Koul and Desarno say the implementation of AES256 certified encryption coupled with a secondary level TMP chipset cypher enhances security and ensures that sensitive information remains protected against unauthorized access and data breaches. “Furthermore, secure communication is facilitated using cloud-based SHA-2 384, TLS 1.3, and HTTPS protocols, providing robust encryption during data transmission. These advancements collectively offer comprehensive security measures to safeguard sensitive information in modern environments.”

With most of the U.S. corporate infrastructure migrating to cloud-based solutions,

Koul and Desarno say Kyocera products are adeptly designed to integrate seamlessly with clients’ new and existing platforms. They offer an extensive range of configurations that ensure both security and productivity. These configurations are meticulously crafted to support the diverse requirements of modern enterprises, enabling them to maintain high-security standards while optimizing their operational efficiency. “Kyocera’s technology not only facilitates secure data transmission and storage but also accommodates the growing need for versatile and scalable solutions in today’s dynamic digital environment,” they note.

Many cloud-based printing technologies offer access controls to provide users agility and flexibility for both in-office printing and remote workplace hybrid printing and scanning while providing security features. To that end, Canon offers uniFLOW Online.

Koul and Desarno point out that the integration of cloud-based OAuth2 protocols for Microsoft Azure Active Directory (Entra) and Google authentication services are trending in security. “This technology enables secure, token-based authentication that allows users to access applications without repeatedly entering their credentials.”

Security should be a top consideration in any print environment—whether it is in a print shop or a copy room.

“You need a sophisticated and professional IT department that is constantly implementing new methods in order to safeguard sensitive information for both the clients and company,” states Dan Lieberman, CEO, Nanografix Corporation.

Koul and Desarno note that the overall shift towards these advanced security printing measures reflects the increasing concern for safeguarding sensitive information and preventing unauthorized access in corporate environments. dps

Hillhouse cautions that producing targeted catalog mailings do require one additional item to create the perfect solution—data. “And not any data. Good data needs to be current—sieved for dead, divorced, and change-of-address issues. The level of detail may also vary. Does the data provided need to include product purchase information, or more family and lifestyle information? If so, there may be legal issues to consult and abide by in any given territory. These need thorough investigation before deciding which binding style to invest in.”

With the help of automation, catalog production is modernized with streamlined workflows, error reduction, scalability, and integration.

Automation is essential for the future of short-run catalog production, especially in markets where run lengths are low but job variety is high. “Automation ensures speed, accuracy, and minimal reliance on skilled operators,” states Sajith.

The latest digital print and finishing equipment solutions are equipped with automation. “From prepress to finishing, automated solutions reduce manual intervention, minimize errors, and enhance production speed. For example, Muller Martini’s Connex Workflow System ensures seamless integration across all stages of production, enabling real-time monitoring and adjustments for consistent quality and output,” offers Caruso.

Hillhouse points out that automation is likely to play a critical role in all print production, and inline finishing might be a major part of that for catalog production. “Downstream of post-press, automation will already have played a big part in the sifting of data, the preparation of that data, and the presentation of the information within the printing of the page. In finishing, the use of quick response (QR) codes, or similar technologies, can help to direct the specific job into one particular production channel.”

Dubuque believes shorter catalog runs mean more job turnover. “On legacy finishing machines, more job turnover means more downtime and less throughput as operators manually switch from one job to the next. Automation nearly

eliminates that downtime, allowing print service providers (PSPs) to process more catalog applications more efficiently and in a shorter amount of time than ever before. Automation optimized by artificial intelligence (AI) will also continue to play a

and in somecases, eco-friendlymaterials. The latest in digital production presses, supporting finishing, and workflow tools make this type of application easier and more cost effective than ever to produce.

Digitalprint technologies are transformative for catalog production, enabling shorterruns, fasterturnaroundtimes, and unparalleled customization. "Businesses can produce niche, personalized catalogs that resonate with their target audiences. Additionally, digital printing makes it cost effective to produce smaller quantities, opening up opportunities for businesses of all sizes to leverage catalogs as a marketing tool,'' suggestsRaquel Caruso, marketing manager, Muller Martini.

Catalog applications benefit from advancementin digitalandinkjetprinttechnology, agrees Don Dubuque, director of marketing, Standard Finishing Systems. "Recently, we've seen leading print manufacturers introduce a new generation of inkjet printers that further close the gap with offset printing in terms of quality and support for a wider range of formats and substrates. Finishing manufacturers have also stepped up their game with equipment that pairs up well with these new printers. This is great news for catalog customers looking to reduce costs

1. Morgana's PowerSquarestylebindersareableto deliverfinishedbooksofupto224pages.

without sacrificing quality, environmental responsibility, or the flexibility to test more layouts, designs, and customization options to capture the attention of distracted consumers. Expect to see more catalog applications produceddigitally as this new generation of print and finishing equipment continues to be installed on production floors."

The shiftto digital printing offers catalog producers agility, improved turnaround times, personalization, reduced waste, and an enhanced customer experience.

The demand for personalized, data-driven marketing materials is on the rise, and catalogs are no exception. The flexibility and efficiency of digital print make it ideal for producing customized catalogs that cater to specific customer segments. A representative from Xeikon feels that this trendis particularly evident in ecommerce, where businesses leverage personalized catalogs to enhance customer engagement and drive sales.

"The resurgence of catalogs asa marketing medium is evident, particularly in digital print environments. In today's digital-first world, catalogs offer a tangible, personalized experience that connects with customers on a deeper level. As ecommerce continues to expand,

catalogs serve as a complementary tool, driving engagement and conversions,'' adds Caruso.

"If you can mail a potential customer the latest information on products that you know they are interested in it makes all kindsofsense. Thebiggestdesireis, of course, a sale, but you are also appealing to the 'green' lobby with reduced paper, less physical product to mail, and more purposeful, targeted print,'' comments RayHillhouse, VP sales & marketing, the Plockmatic Group Offline Business Unit.

Pallippuram Sajith, managing director, Bindwel Technologies, India, agrees, noting that with digital printing, brands create area-specific messaging, adapt content frequently, and produce limited batches without waste. "This shift demands finishing systems that match digital print in agility."

As brands move toward targeted, data-driven marketing, Jean-Baptiste Bardinet, commercial market director, Landa Digital Printing, says personalized and localized catalogs are becoming more relevant than ever. "Digital print, with its flexibility and responsiveness, is perfectly suited for this evolution."

Improvedturnaroundtimesareanother benefit of digital print and finishing in the catalog space. Sajith points out that in India, where catalogs are more commonly distributed as handouts, newspaper inserts, or in-store leaflets-rather than mailed-there's a growing need for cost-effective and quick-turnaround solutions that still offer the premium feel of a high-end product and new machines support that balance. "Digital print has opened up new possibilities in the Indian market-especially for regional brands, local retailers, and niche product sellers. While traditional direct mail catalogs are not common here, there is high demand for hyper-localized catalogs and promotional booklets that accompany newspapers or are distributed in stores."

There is some work to be done to ensure the success of these solutions.

largerrole in catalogproduction, asPSPs will use AI to analyze large amounts of data for more dynamic and effective targetingforcustomizedcatalogswiththeultimategoal ofdrivingcustomerbehavior."

Bardinet believes automation is a cornerstone of next-generation catalog production. ':-\.t Landa, we collaborate with a range of global and regional workflow providersto offerend-to-endautomationfrom job onboarding to print execution and finishing. Beyond MultiPress, we integrate with systems such as Kodak and Esko in Europe, as well as EFI and Avanti in NorthAmerica. This broad connectivity minimizes manual intervention, reduces errors, and allows PSPs to scale efficiently while maintaining consistent quality. In a segment like catalogs-where high volume meets high variability-automation delivers both speed and profitability:'

Over the past several years, Dubuque points out that some consumer-facing companies have phased out their print

2. The Muller Martini Prinovasaddlestitcheris capable of 9,000 cycles per hour and can be changed overincrediblyquicklythankstoitsindividualfeeder.

BindwelTechnologies

Landa Digital Printing

MullerMartini

PlockmaticGroup Offline Business Unit

Standard FinishingSystems

Xeikon

catalogs in favor of digital campaigns to save money. However, some marquee brands are reintroducing their print catalogs in combination with digital campaigns. "This suggests that there is a resurgent demand for print from consumers, much like we're seeing in the book manufacturing space, and these combination print/digital campaigns enhance customer engagement and drive sales. And, because the catalog runs are more limited, brands can experiment with different formats and different substrates that make the catalog more memorable. With cost savings from automation in both printing and finishing as well as the cost savings from digital printing, even non-luxury brands are starting to experiment in this way."

Trends in this space include hyper personalization, interactive elements, sustainable materials, integration with ecommerce, and enhanced finishing.

Caruso agrees, pointing out that catalogs are designed to complement digital campaigns, often featuring QR codes or augmented reality elements to bridge the gap between print and digital.

Bardinet sees a shift toward shorter, more targetedrunswithpremiumfinishes and personalized content. "Brands are rediscovering the power of print as a tactile, emotionally engaging medium-particularly in luxury, travel, and high-end retail sectors. At the same time, sustainability is becoming a key differentiator. With water-based inks, recyclable substrates, and less waste, Nanography is helping our customers meet these new expectations. We also expect continued growth in digitalembellishmentand data-driven catalog campaignsthatblurthe linebetweenprint and digital experience:'

When it comes to finishing, Hillhouse sees a lot of catalog production switching to inline finishing, especially personalized products. "There are a lot of targeted shorter runs of catalogs being printed and finished inline. Longer runs are still "being produced, but these tend to be printed lithographically, and therefore offline," he shares.

':-\.s catalogs evolve from being just sales toolstobrand-buildingpieces, finishing technologymust evolve to deliver flexibility, speed, and apremiumtactileexperience-eveninsmallbatches," notesSajith.

Catalog production is suited for many industries. From fashion to home goods and travel, businesses are able to leverage the latest in print and finishing technologies to produce custom catalogs that enhance customerengagement and drive sales. "These personalized catalogs have proven to be effective tools for building brand loyalty and achieving marketing objectives," states Caruso.

Sajith adds that digital print technologies allow for localized printing closer to distribution points. "When you combine this with fast, automated finishing, you get catalogs that are short run, high quality, and immediately deployable-a powerful tool for modern marketers in both developed and developing markets." dps

anti-counterfeit marks with variable codes. Brand protection companies are developing the ability to generate these variable codes for both track-andtrace and authentication purposes," adds Hagay.

Holograms are also used in packagingas adeterrentagainstcounterfeiting.

"Traditionally, they've appeared on rigid, boxed products. However, the trend to include holograms on flexible packaging continues to grow. Holograms are typically standalone decals-either embedded into a substrate or affixed with permanentadhesive. Theireffectiveness lies in how difficult they are to replicate. However, one major drawback is that decals can be removed and reused on counterfeit items," shares Jeff Leto, VP of sales, NBi FlexPack.

Dan Lieberman, CEO, Nanografix Corporation,pointsoutthateachsecurity featurehastobe uniqueandsmartphone applicationsmust be ableto decipher encryptedopticalinformationthatishidden ineitherhologramsorotheropticalstructureswhere the informationisunique for each security feature.

1. HP Indigo presses support security printing for brands with UV inks, accurate printing, Taggant inks, microtext, and a variety of integrated security partners. 2. NanoCast instant Holography is a disruptive technology by Nanograf1x that can be used on any printingpress.

The demand for advanced anti-counterfeiting and authentication solutions has driven significant innovation in security printing, with key trends emerging in multi-layered security features like digital watermarks, invisible inks, and quick response (QR) codes, which Matthew Raab, director of global portfolio marketing, Xerox Corporation, says make counterfeiting more difficult.

"Xerox combines these technologies with specialty imaging solutions, such as MicroText Mark, GlossMark, and Infrared Mark, which provide both covert and overt security elements that are challenging to replicate. These innovations enable businesses to integrate customized security features-such as holographic printing and invisible textinto both static and variable data jobs, ensuringthateachdocumentisuniquely protected and reducing the risk of duplication," says Raab.

Features like UV fluorescing inks offer a powerful layer of invisible security-revealing their presence only under ultravioletlight.Thismakesthemanideal solution for combating counterfeiting and fraud, while also enhancing the authenticity andtrustworthinessofprinted materials. Beyond security, these inks enable precise tracking, tracing, and

verification across logistics and supply chain documents, adding both protection and intelligence to every print.

"Incorporating advanced security features digitally, especially those that integrate into existing workflows without added complexity, reflects Canon's commitment to innovation in secure document printing," comments Katsuhiro ''.Jerry" Matsufuji, VP, digital printing products & solutions, Canon U.S.A., Inc. "Our partnership with Arcis Solutions exemplifies this by embedding hidden security patterns directly into full-color images, visible only upon photocopy, providing an effective countermeasure againstcounterfeiting."

Komori's primary area of security printing is with presses that it makes for the banknote and passport printing markets. These are large scale, non-digital presses thatare used to print highly secure government-issued products. In this market, the use of secure substrates, inks, and features such as foils and threads is mature, with innovation being evolutionary rather than revolutionary. "We see this as a prime area where digital technology can offer something new to this market-not only for banknotes and passports, but other securely printed documents-driving licenses,visas,certificates,vouchers,tickets, tax stamps, etc.," says Steve Craig, group general manager and operating officer, Security Press Business Group, Komori Corporation.

In fact, Komori issued an in-house banknote,which forthefirsttimeincluded features printed on its digital presses-a digitally printed serial number; a series of unique origami birds, in which every note had a different variation; and these unique variations were linked to the serial number, giving two unique features on every document; and a digital invisible screenthatcan only be read using a smartphone application (app), and which verifies the unique serial number and phoenix design combination.

For applications like tax stamp printing, Jeroen Van Bauwel, director solution design, Xeikon, estimates that some companies have spent considerable resources on the development of new features that can be enabled via digital printing in recent years, like the generation of unique designs and hidden variable codes.

In the past, holograms used in applications like flexible packaging were primarily for visual appeal, achieved through repeating patterns manufactured into the film itself. These designs could be easily duplicated by sourcing the same film. Plus, because the hologram extended throughout the entire package it often creates a loud psychedelic effect that isn’t always desirable. “NBi FlexPack’s eBeam cast and cure changes that. It allows brands to place holograms only where they want them—adding visual impact and security without overwhelming the design,” notes Leto.

The rise of mobile authentication, QR codes, and serialization also transform how users and authorities verify products. “Track and trace and supply chain visibility systems become standard in tax stamps and pharmaceuticals. Variable data printing enables unique IDs and digital twins, linking physical items to blockchain or secure databases,” offers Van Bauwel.

Some of the latest trends and advancements that Tamir Hativa, head of security printing, HP Indigo, sees in relation to security printing for anti-counterfeiting/tampering engage consumers using different methods such as gaming interactions to authenticate products as well using their mobile phone to provide them with additional product information such as the digital product passport.

Van Bauwel says multi-layered security combines overt and covert elements. “The traditional ‘one-feature’ approach is no longer sufficient. Brands and governments adopt multi-layered security strategies to stay ahead of counterfeiters.”

When considering an enterprise setting, Ravi Koul, senior director, product marketing office technology and Mark DeSarno, director security and compliance engineering, Kyocera, point out that Kyocera multifunction printers have implemented sophisticated anti-counterfeiting measures that are activated when legal currency, checks, or sensitive documents are scanned or copied. “These security features ensure that attempts to duplicate such documents will result in an error or limit the reproduction to B&W prints only. This functionality serves to deter unauthorized duplication and helps maintain the integrity of critical documents.”

usage tracking, and consumer engagement analytics.

Digitally embedded watermarks can be verified using specialized readers or apps but are nearly impossible to detect or reproduce by counterfeiters.

By leveraging cutting-edge digital printing technology such as those discussed above, it is easier for businesses to authenticate documents and create highly secure, counterfeit-resistant materials.

Hativa feels that digital authentication is the most important trend, which takes away the need for training inspectors and border police and letting a well-defined algorithm verify a product or a document. “This can be in addition to physical or conventional authentication.”

“One of the fastest growing trends is the use of unique, item-level identifiers— serialized QR codes, barcodes, or alphanumeric strings enable secure verification at every stage of the supply chain,” says Van Bauwel.

Smartphone-based authentication and digitally embedded watermarks are also utilized.

“With global smartphone penetration, end users are now part of the authentication chain,” shares Van Bauwel.

He points out that integration with mobile apps also enable geolocation,

“Authentication in security printing is no longer about proving something is real—it’s about making it uniquely identifiable, verifiable, and traceable in real time. Technologies like digital serialization, smartphone scanning, and invisible codes, are transforming authentication into a dynamic, data-rich ecosystem,” shares Van Bauwel.

Leiberman stresses that when it comes to authentication, each security feature has to be unique and smartphone apps need to be able to decipher encrypted optical information hidden in either holograms or other optical structures.

Many industries rely on security printing solutions to protect their products and brands against counterfeiting, tampering, and also for authentication.

The demand for security printing functions is increasing, Van Bauwel says this is not only in terms of volume, but in complexity, sophistication, and strategic importance. “This trend is driven by a mix of global risks, regulatory changes, brand protection needs, and technological opportunities.”

Craig points out that according to reports from the World Trademark Review (WTR), global counterfeiting activity is on the rise, with European Union authorities detaining 31 percent more fake goods in 2021 than the previous year and counterfeiting claims before U.S. courts now accounting for 40 percent of all trademark disputes, tripling over the past five years.

''An OECD/EUIPO report from 2021 with the most recently available data on the global trade in counterfeit and pirated products estimates that international trade in fake goods amounted to as much as $464billionin 2019, or 2.5 percent of world trade. The report is based oncustomsseizure data, which included almost 6,000 customs seizures of counterfeit labels. This trade in counterfeit goods includes the assembly of counterfeit and pirated products from imported materials. Brand protection security features are aimed at deterring, detecting, and providing evidence of tampering, ensuring the security and integrity of the supply chain; providing assurance to consumers that theyare buying genuine, safe, and quality products; and preventing losses caused by theft, breakage, or waste," shares Craig. "We therefore see 3. Xeikonprovidestailoredsolutionsfor thecomplex andevolvingworldofsecurityprinting.

that the demand for security printing in brand protection and in personal identity will remain high."

Van Bauwel warns that global counterfeiting is now a multi-trillion dollar problem affecting industries from pharmaceuticals and luxury goods to tax authorities. "Security printing is increasingly seen as a first line of defense in supply chain integrity and product validation. But also governments and regulatory bodies are tightening controls around excise goods-alcohol, tobacco, and cannabis; pharmaceuticals; secure documents; and child toys. This has significantly increased demand for high-integrity printed assets, often with digital traceability and audit capabilities-a space where digital print technologies shine."

Hativa says brand protection has shown significant growth, the highest in security segments aswellas governmental security printing.

Theneedtoprotect sensitive information, reduce counterfeiting, and ensure authentication has driven this growth and adoption. ''As fraud concerns rise, businesses increasingly use specialty imaging to add an extra layer of protection to documents such as statements, event tickets, certificates, and coupons," confirms Raab.

Hagay sees significant interest in security and brand protection solutions among print houses, converters, and print buyers. However, she points out that implementation and deployment are ultimately determined by the brand owner who selects the most appropriate anti-counterfeit solutions for their specific requirements. This selection and deployment process is extensive, involving thorough evaluation by a brand's quality assurance and quality control departments.

"Once the solution is selected and implemented, replacing it becomes extremely difficult. Despite growing interest and increasing numbers of companies developing security and brand protection solutions, adoption of these technologies is-in my own opinion-relatively slow," admits Hagay.

Digital print technologies, with their ability to contain large levels of information, data, and to assign unique values to each item or product, offer a next-generation deterrent in the fight against counterfeit goods, suggests Craig. ''Analog processes can be counterfeited but traceable and readable information is embedded in digital print. These systems offer next-gen protection for secure documents."

When used correctly and by an authorized source, Hativa points out that digital technology is able to create highly secured packaging for products or governmental documents, as it provides a unique ID and ever-changing background and security elements which can be interconnected. "The benefits of digital printing in general make it easier to produce."

Unlike conventional print methods, Van Bauwel says digital workflows eliminate many of the vulnerabilities that can be exploited intraditional production environments, including the elimination of intermediate steps and physical plates.

“Conventional printing methods require physical plates, which can be copied, mishandled, or reused for fraudulent printing. In conventional printing the security is often created by combining multiple processes—every step in the process generates intermediate waste, semi-finished products, and stocks of secure products— all of this can lead to potential fraudulent leaks. In digital printing there are no intermediate reproduction steps, reducing the number of potential access points for sensitive data.”

Further, digital print allows every printed item to be individually tracked. “Digital workflows enable precise job-level and item-level tracking. Every printed piece can be uniquely identified, logged, and traced back to its source data. Integration with serialization and audit systems ensures full traceability from file creation

to final output. This creates a closed-loop, verifiable chain of custody for secure print jobs,” adds Van Bauwel.

One of the most powerful safeguards in Xeikon’s architecture is that the printable file never actually exists in a transferable form. “With Xeikon’s secure workflow, the print-ready bitmap is generated on-the-fly during the print process. There are no static output files— e.g., PDFs or imposed layouts—that could be intercepted, copied, or modified prior to printing. This means the actual printable content only lives ephemerally inside the engine, effectively making data interception or duplication virtually impossible,” says Van Bauwel.

Hagay feels that digital presses such as those from Landa are well suited to meet the demands of security and brand protection. “In specialized markets like

pharmaceuticals and luxury packaging the demand for fine details, micro-text, invisible watermarks, and variable codes is increasing. Landa’s ability to print at high resolution with precise color control makes it an ideal solution.”

Moreover, digital printing greatly improves the efficiency of printing variable codes. “Landa’s technology supports custom, unique code printing of each printed piece, or impression. Instead of using an offset machine followed by an offline inkjet to print variable codes, everything can be accomplished in a single pass, making the process faster and more cost effective,” says Hagay.

Hagay adds that some brand protection solutions (e.g., Alpvision) enhance security by applying coatings that change appearance under different conditions. Landa’s inline coater, which can

be UV or water-based, can significantly streamlinethis workflow.

Solutions like NBi FlexPack's technology for holograms offers a cost advantage over traditional holographic decals and films that are expensive. "With eBeamcastandcure,standardfilmscan beusedsincethehologramispartofthe finishedcoating.Whilethereisacostfor theembellishingfilm used to create the impression in the coating, it can be reused to produce over a million pouches beforeneedingreplacement.Depending on pouch size and quantity made, the cost per unitcanbe as lowas justa few cents," saysLeto.

5.Xeroxoffersseveralsolutionsspecificallydesigned forsecurityprintingonitsproductionpressesthrough XeroxSpecialty Imagingtechnology.

In the markets NBi FlexPack services, which include nutraceuticals, pet, snack, and particularly cannabis, brand security hasbecomemoreofaconcern. "While determined counterfeiters may stillattemptbrand identity theft, eBeam holographic images make it significantly more difficult and cost prohibitive for these thieves. At the same time, eBeam holographic images help authenticate brands and aid them in standing out in today'sincreasinglycrowded retail environments,"saysLeto.

Leiberman says digital printing is well poised to introduce new technologies such as NanoCast. "The new developments are to be able to print holograms, optical structures, lenticulars, moires, and lithographic effects

that are variable-each is different from the next-on anyprinting press.Nomoreoutsourcingforthe securityprinter."

Further, solutions like Canon's ColorStream series ofinkjet printersareabletoutilizespecialtyinks beyond standard CMYK, including MICR, fugitive inks, and UV-fluorescent inks. These inks help in creating security features on printeddocuments,suchaschecks withMICRencodingordocuments withtamper-evidentfunctions.

Invisible security available with Xerox Specialty Imaging technologies, such as MicroText Mark and GlossMark, embed covert security elements in documents, making them difficult to tamper with or replicate. "These features are especially valuable for protecting high-security documents like certificates, tickets, and coupons," notesRaab.

Digital print technologies inherently bring advantages in terms of security print-first and foremost being variable printing. However, advanced technologies are integrated into hardware and software and also found in effects capable in the inks and finishing processes foundindigitalproductionworkflows.

"Securityprintingisevolving-becoming more data-driven and layered with complex requirements. Digital printing technologies, combined with intelligent software, inline modules, and secure workflows, are now at the forefront of thistransformation;' attestsVanBauwel. "The flexibilitythatdigitalprintingoffers is essential in a world where counterfeiting adapts quickly, and print security muststayahead."

Findmoreonthetopicofprinteffects and technologies that center around securityandbrandprotectiononlineatdpsmagazine.com in the form of a webinar as wellas web-exclusiveeditorial. dps

2 Canon U.S.A., Inc. 2canonproductionprint.com/pursue

3 Duplo USA 7duplousa.com 10 Graphic Whizard 27graphicwhizard.com

4 InSoft Automation 9 insoftautomation.com 5 Komori America 25 komori-america.us 11 Kyocera Doc. Sols. 15 kyoceradocumentsolutions.com

5mullermartini.com

13nobelus.com

19presswise.com

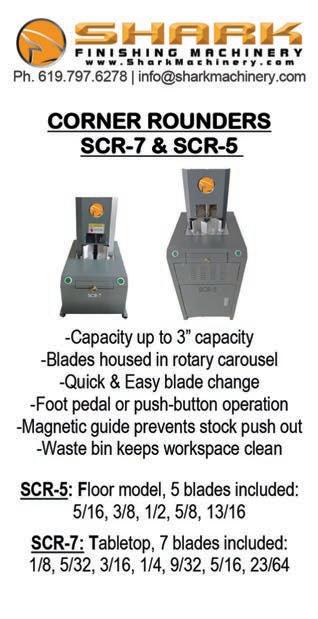

sharkmachinery.com

28signs365.com