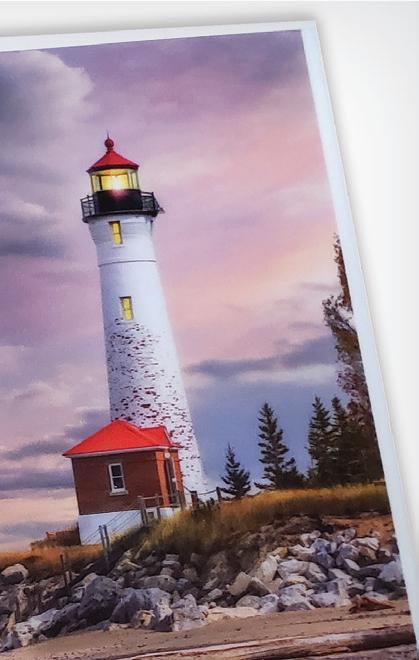

With the trade show season upon us, our cover story, Splish,SplashonFloorGraphics, has us longing for hotter temperatures into September and perhaps a quick return to Summer. With a focus on specialty floor graphic media and the various environments it is found in; one example is areas expected to get wet, including pools—both under the water and around the pool deck.

VOLUME XXIX, NO.9 DIGITALOUTPUT.NET ISSN: 1083-5121

EDITOR IN CHIEF

Thomas Tetreault ttetreault@rockportpubs.com

EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ASSOCIATE EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

WEB EDITOR

Melissa Mueller

ART DIRECTOR Sarah M. White swhite@rockportpubs.com

CONTRIBUTORS

Olivia Cahoon, Tim Greene, Mark Hanley, Melinda Tetreault, Amber Watson

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

NATIONAL ACCOUNT EXECUTIVES

Nicole Pizzi-Cerundolo npcerundolo@rockportpubs.com

Elsewhere in this issue, a spotlight on wraps, information on the rise in demand for smaller format flatbed printers and their use for ADA and braille signage, and a media chart.

DrawingaLineexamines an underrated application, vinyl striping, used to decorate not only vehicles but other surfaces as well—from dumpsters or floors and even walls. The end user appreciates the sleek simplicity of a strip—or two—of vinyl. For a print provider or even wrap installer it’s a great add-on service to offer customers.

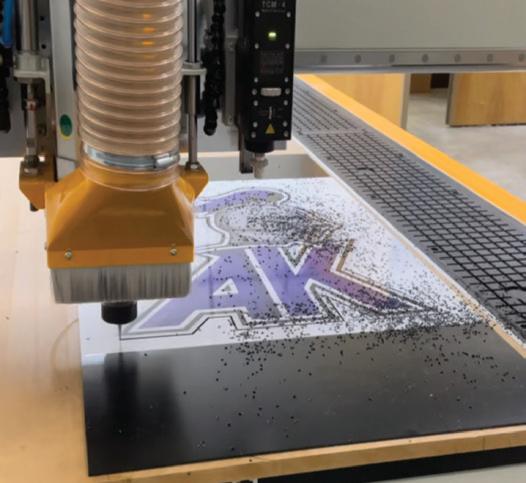

With product introductions rampant as we enter the last half of 2023, we turn our focus to finishing—especially flatbed router/cutters. Manufacturers advance their product lines with increases in speed, expanded tooling options, and even linear drive systems. Read more in ElevatingFinishing

978-921-7850, Ext. 160

Amanda Doyon adoyon@rockportpubs.com

978-921-7850, Ext. 170

Subscribe online at digitaloutput.net

CORPORATE & PUBLISHING OFFICE

100 Cummings Center, STE 321E Beverly, Massachusetts 01915

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

Digital Output is published monthly by Rockport Custom Publishing LLC. ©Rockport Custom Publishing, LLC 2023. Reproduction by any means of the whole or part of Digital Output without written permission from the publisher is prohibited. Views expressed in the editorial pages do not imply our endorsement.

Vendors: We welcome your product news. Include prices, slides, photos, and digital files with your press release. Please forward product samples and media kits to Reviews Editor, Digital Output, 100 Cummings Center, STE 321E Beverly, MA 01915. We cannot be responsible for unsolicited product samples.

SUBSCRIPTION RATES

U.S.: $82.95 per year; $165 for 2 years; single copies: $6.95; Canada and Mexico: $99.50 per year (U.S.D.); Other international subscriptions: $275 per year (U.S.D.)

POSTMASTER

Please send address changes and form No. 3579 to: Digital Output, 100 Cummings Center, STE 321E, Beverly, MA 01915. Periodical Class postage rates paid at Beverly, Massachusetts and additional mailing offices.

CHANGE OF ADDRESS NOTICE

Six to eight weeks prior to moving, please clip the mailing label from the most recent issue and send it along with your new address (including zip code) to: Digital Output magazine, change of address notice, 100 Cummings Center, STE 321E, Beverly, MA 01915. Attention: Circulation Department.

…longing for hotter temperatures into September and perhaps a quick return to Summer.

Best regards, Melissa Donovan, editor mdonovan@rockportpubs.com

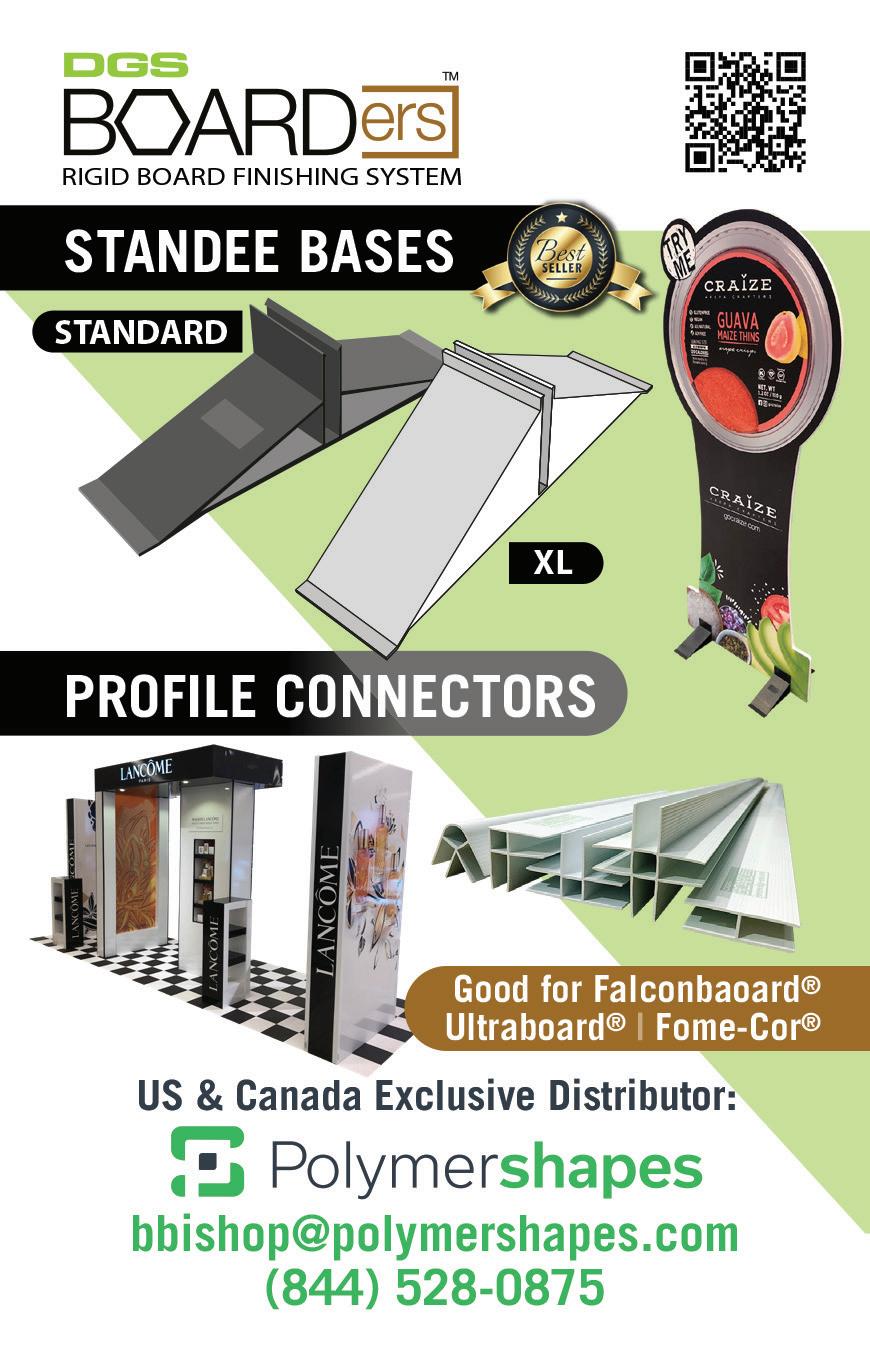

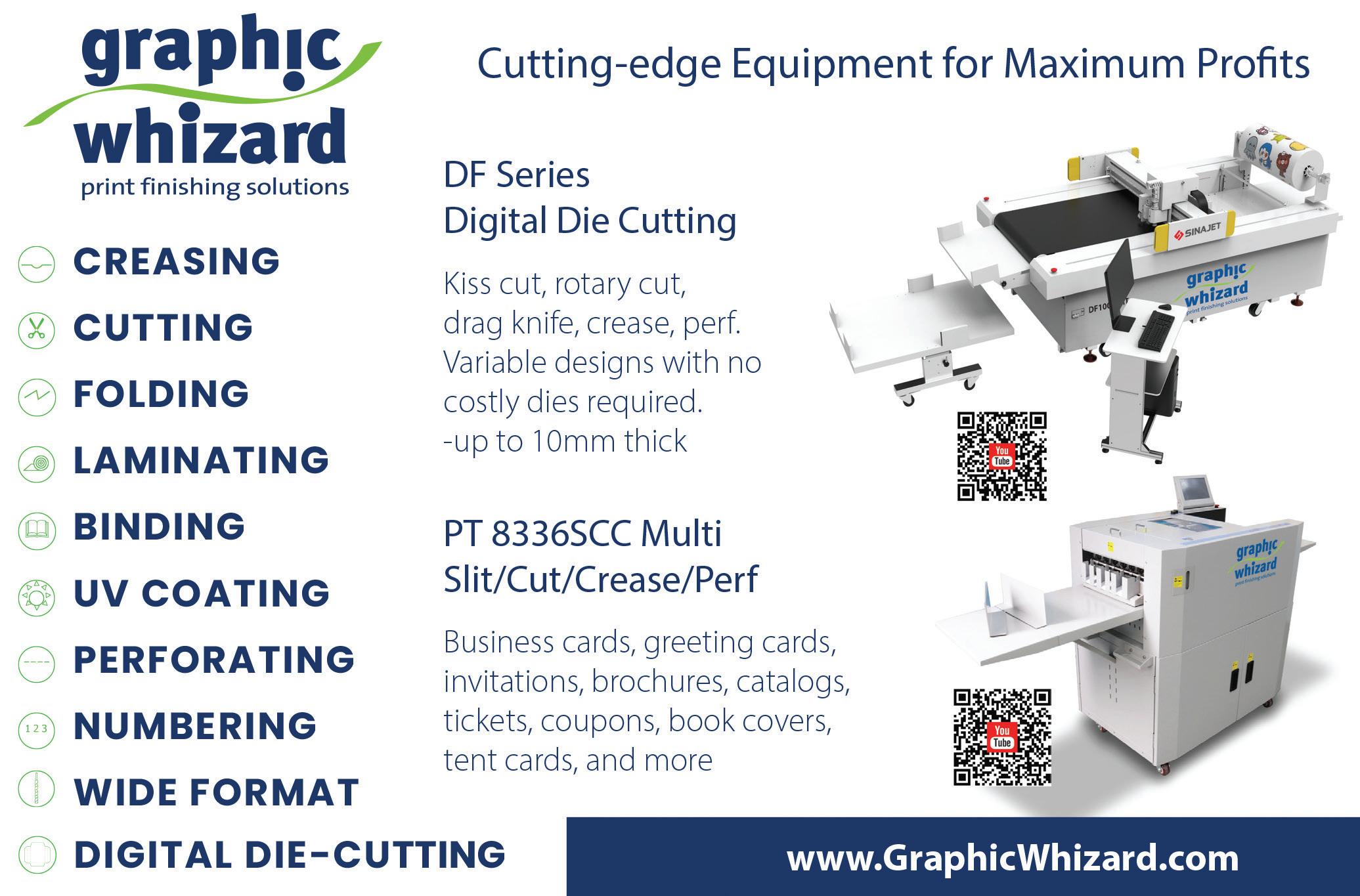

The PRINTING United Expo takes place this October 18 to 20, 2023 in Atlanta, GA at the Georgia World Congress Center. Over 600 exhibitors from all facets of the printing industry are scheduled to exhibit at the event. Here we include a sampling of those relevant to the wide format print space.

Aleyant, booth B17012, empowers print businesses with software and unmatched support to eliminate costly manual processes and foster profitable growth. Its automation print software reduces manual touches, errors, and production time for your print shop. With it, connect online design to business-to-consumer and business-to-business online web-to-print storefronts. Connect your print store to estimating, production management, and to customer service and prepress automation. Use Aleyant software products separately, together, or with 1,000s of third-party applications via direct API or Zapier. INFO# 290

DigiTech, booth C2247, demonstrates a dual printer inline solution connected directly to the cutter. This

print-and-cut system runs live jobs during the show while printing and cutting over 100 4x8-foot boards per hour. The company also introduces the TruFire LTX2 and the Canon Solutions America Texas LTX2 with orange or varnish. Using just the right amount of automation to make printing shops more productive while reducing labor. Texture printing also available upon appointment. INFO# 291

DreamScape, booth B15121, invites attendees to explore the complete range of its wall and floor media products. Tangible samples of the complete collection are on hand. The company also unveils its latest innovation—Duralon, the newest addition to the DreamScape family. Duralon sets a new standard as a commercialgrade Type II printable wallcovering, and what makes it even more remarkable is its PVC-free composition. Be among the first to witness the future of wallcoverings with Duralon. INFO# 292

Drytac, booth B13119, displays a range of its adhesive science solutions including print media, laminates, and mounting adhesives, with a focus on demonstrating how

these products support visitors with window, wall, and floor graphics work. Among the highlights are products from the new Drytac Zero collection of nonPVC options for use in graphics, signage, and display. Samples are available for visitors to touch and feel. INFO# 293

Epilog Laser, booth C2161, showcases its CO2 and fiber laser engraving, cutting, and marking systems. See a variety of laser machines in action, cutting and engraving several different substrates. See firsthand the speed, precision, and other features of the U.S.-made laser engraving and cutting equipment. Dozens of samples are on hand to illustrate what types of unique and colorful projects users can create. INFO# 294

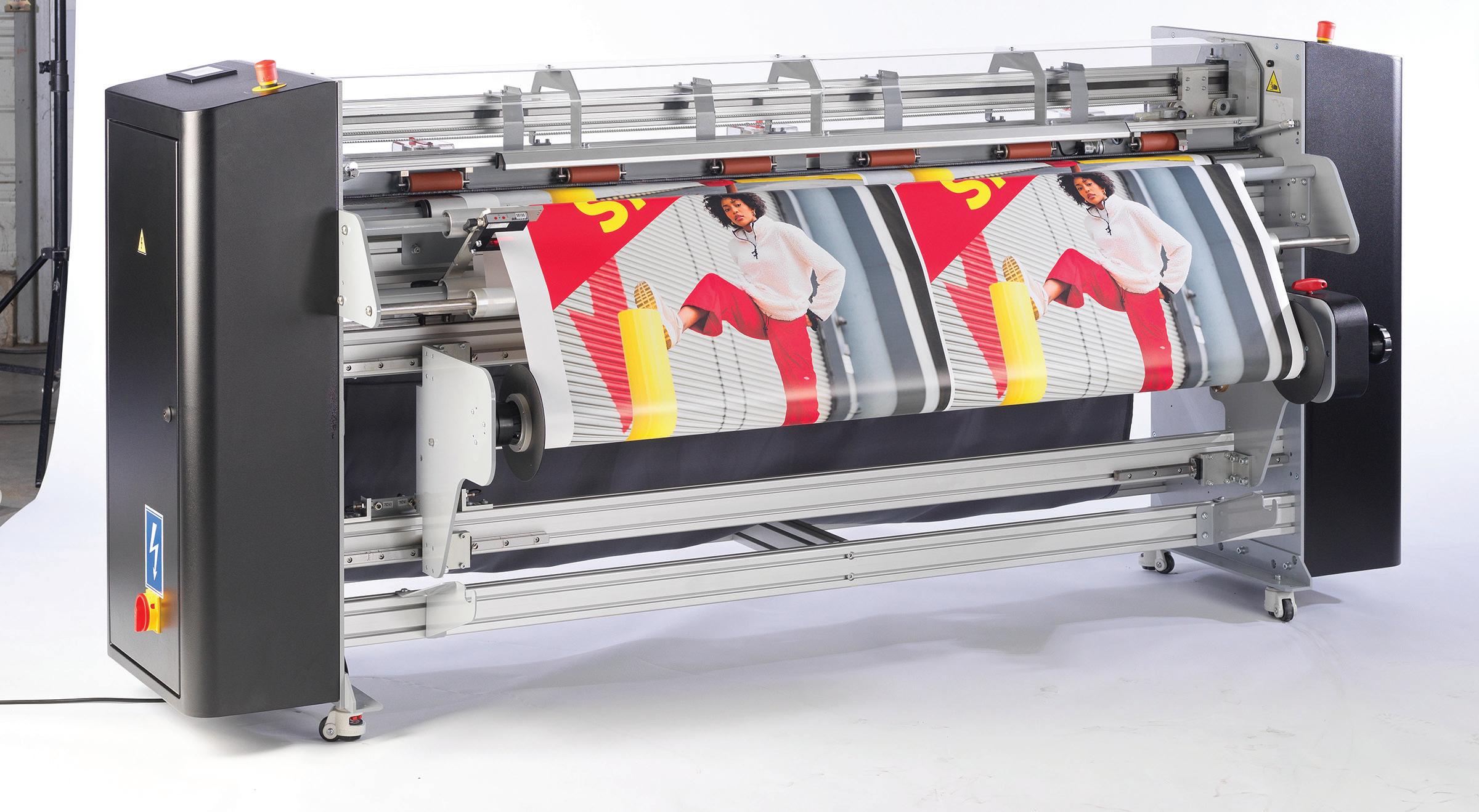

GBC, booth B10011, displays SEAL wide format laminators, specifically the 65 Pro MD—a highproduction, versatile laminator that can run both hot and cold applications. The 65 Pro MD has the unmatched capability of running speeds of more than 15 feet per minute without sacrificing quality. Also in the booth is the GBC Foton 30 automated desktop laminator, flatbed applicator, and products from ACCO Brands. INFO# 295

Global Garage, booth B13097, invites attendees to learn about the premier marketplace for used wide and grand format printing equipment from Agfa to Zünd and every manufacturer in between. Buyers benefit from both equipment inspection and financing options offered for their purchases. Sellers will find

easy-to-use technology and the biggest pool of motivated buyers on the planet. INFO# 296

Global Imaging, booth B18033, presents its latest booth design fabricated entirely with its newest

product line, T3 Systems from Tecna Display. Stop by to learn about this versatile, modular display

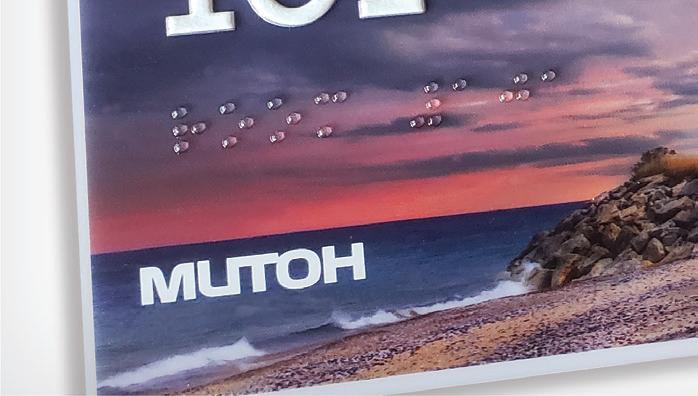

Printing ADA compliant braille signage with a Mutoh UV LED printer is a great way to increase profits. Mutoh is the only printer manufacturer legally authorized to offer UV LED printed ADA compliant braille signage using DCS’ patented intellectual property. Don’t be caught violating those patents by using an unauthorized printer.

Don’t let other printer manufacturers blindside you into thousands of dollars in legal fees by violating those patents. Request a print sample from the XpertJet 461UF and XpertJet 661UF printers today at mutoh.com. INFO# 315

Newlife introduces the only printable magnet sheet that is currently HP Certified for Indigo presses (RM-ART20). Our new HP Indigo certified sheets are designed especially for the HP Indigo Presses. Newlife premium Press Mag (IM-IP16M) magnet sheets can be printed Indigo, UV offset, and on most dry toner machines. Press Mag has a photoquality PP print surface, is PVC free, and will stack and cut easily. We offer both pre-magnetized and non-magnetized solutions as well as magnetizing equipment to magnetize post-print if needed. Visit newlifemagnetics.com for more information. INFO# 316

Engineered and manufactured in Europe, the KalaXY Cutter/Trimmer reduces labor and increases profits by eliminating the time consuming task of manually cutting printed digital images. The line of automatic XY cutters are the ideal solution for processing a wide range of media including wallpaper, paper, direct to film, canvas, laminated/encapsulated films, banner material, polycarbonate, and other non-woven roll goods. Increase your output while reducing operation costs with KalaXY Cutters. For more information visit supply55.com, call 734-668-0755, or email sales@supply55.com. INFO# 317

AquaFlex is a digitally printable waterproof substrate designed to brand and advertise in pools, ponds, water features, and aquascapes. It's perfect for anyone looking to make a big impact with their marketing in new and innovative ways! AquaFlex is easy to install and position by hand or with a pool brush without draining water and is engineered to lay flat and remain in place without tape or adhesive. Plus, the material's blue backside is made from recycled industrial pool liner and made in the U.S. To request a printed sample of this unique substrate, visit ultraflexx.com. INFO# 318

ULTRAFLEX SYSTEMS, INC.

SUPPLY55, INC.

ULTRAFLEX SYSTEMS, INC.

SUPPLY55, INC.

system and connect with business development experts to learn about the newest products on the market from DigiTech, Durst, Kongsberg, Rexframe, Summa, and T3 Systems. INFO# 297

Graphic Finishing Partners (Gfp), booth C3166, features the 663TH Production Top Heat Laminator with smart finishing technology. The laminator includes a digital microcontroller system, touch screen user interface, swingout supply film shafts, inline rotary slitters, rear take-up for roll-to-roll operation, and a roll label printer to help manage supply inventory. Gfp also features the 363-TH Top Heat Laminator with integrated rear rewind, 255-C Cold Laminator, and FT48 Finishing Table with transfer and cutting table sides. In addition, the second generation of self-wound overlaminate from the Gfp Film Products portfolio will be processed through each machine. INFO# 298

GTI Graphic Technology, Inc., booth B12104, showcases its LED color viewing systems. Featured products include the CVX-3052/LED/FS and VPI-52/LED. The CVX-3052/LED features a 29x52-inch viewing area, D50 LED lamps,

LiteGuard lamp monitoring, side walls, a print bar, and a height adjustable floor stand. CVXs are offered in four model sizes. The VPI-52/LED is designed for the visual inspection of large format prints. It features a 52x45-inch vertical viewing area, D50 LED lamps, LiteGuard lamp monitoring, and casters for easy positioning of the viewer. INFO# 299

HP, booth B13013, focuses on sustainability and the benefits derived from its water-based HP Latex inks. As part of this, it exhibits the HP Latex R2000 Plus, one of the most popular selling hybrid printers in the market, the HP Latex 2700 W Printer, the HP Latex 3600 Printer with excellent productivity, the HP Latex 800 W Printer, and several new products. INFO# 300

Innova Art, booth B16053, features its new Supernova dyesublimation (dye-sub) receptive media. Opaque, translucent, and clear flexible films with unique dye-sub coatings achieve brilliant colorful images that are scratch and chemical proof. Great for use in areas that need regular cleaning. Whether you are looking to expand your offering with wall art made using your existing dye-sub equipment or want to replace aging C-Print equipment, the Supernova range has what you need. Fine Art and photo media from Innova Art is also on display. INFO# 301

InSoft Automation, booth 9098, demonstrates Imp and Imp+. Imp offers precision imposition. Explore how dynamically software computes optimal printing layouts,

maximizing efficiency and minimizing wastage. Imp+ is a unique print estimation software powered by Imp. Generate order winning accurate quotes, job card, and print

ready layouts along with optimal job routing data. A print estimating software that gives you a competitive edge and keeps profits rather than leaks profits. INFO# 302

INX International, booth B1944, offers an array of innovative products ranging from advanced digital solutions—including premium inkjet inks and digital

printing systems—to sustainable packaging inks and color management expertise. Learn more about the benefits and value eco-friendly inks and functional coatings provide—INXhrc natural-based inks for flexographic, offset, and gravure applications; Genesis washable inks for labels; and Ecostage GB-XA high-performance Oxygen Barrier coatings for food preservation and mono-material packaging. Check out the RUCOINX 937LED and 945UV/MA inks for glass and plastic bottle screen printing needs. INFO# 303

Leister Technologies, booth C3307, showcases the HEMTEK ST banner welder and UNIPLAN 500 automatic welder. The HEMTEK ST stationary welder is an efficient and affordable banner finisher. The UNIPLAN 500 is not just capable of welding hems and pockets, but also overlaps. Switching between hem and overlap welding takes just a few seconds. The UNIPLAN 500 also has a brushless blower motor, making the tool nearly maintenance free. Additionally, users can save their welding settings on the machine to be recalled at any time. INFO# 304

Marabu, booth C2367, exhibits the PeriOne single-spindle, cylindrical printer based on the technology of the PeriQ360. This printer provides ease of entry into the direct-to-object market, while also providing fast and efficient performance

for light production, prototyping, and personalized media. Stand out features include the ability to print directly to clear glass without the use of a barrier, automated wiping and capping of the inkjet heads, and faster print speeds than its nearest competitors. INFO# 305

Nekoosa, booth B8073, features hands-on samples of innovative print media. This includes the new PVC-free line, Nekoosa Promise—a broad portfolio of sustainable print media, featuring new and existing PVC-free alternatives for promotional signage and graphic displays. Additionally, Nekoosa features a brand-new offering—Nekoosa Glass Finishes, which includes a range of printable window films designed to transform the appearance of interior and exterior commercial buildings for privacy and finishing purposes.

INFO# 306

Panel Processing, Inc., booth B11094, is a composite wood panel manufacturer who provides panels for digital printing and fixture needs. Panel showcases how it can punch, cut, paint, laminate, and machine a multitude of wood substrates to create digital print media, chalkboard, markerboard, slatwall, laminated panels, and pegboard that can be found in store fixtures, schools, and RTA furniture. It also showcases Pegboard Skinz pegboard paper punching service for quick, easy, and cost-effective display versatility.

INFO# 307

Photo Tex, booth B9054, is a peel and stick, multi-U.S. patented, adhesive material made of

100 percent polyester fabric. Its dependable adhesive can be removed and reused multiple times

without any alteration or damage to the surface. Offering several versions to meet all inkjet and

surface needs, including an updated opaque block-out media with enhanced tack, updated coating on non-opaque making it water resistant for outdoor glass, and a high-tack version that is approved for floor graphics. Photo Tex comes in rolls sized 24 to 60 inches by 100 feet, is LEED certified, safe, non-toxic, and fire rated. INFO# 308

PrestoTex, booth C2330, features its premium product line of self-adhesive, printable, wallcovering media. The digitally printable fabric textile features a removable and repositionable self-adhesive backing that provides a temporary or permanent wallcovering solution. The media can transform a space and add visual interest by printing

any design, artwork, branding, or image onto the substrate and then installing it on the wall. Both 10- and 17-mil options are displayed along with a full booth wrap featuring the media printed with custom artwork. Sample sheets featuring the wall media in all color variations, including white, deep gold, gold iridescent, and silver, are displayed and available for attendees to mix and match to build their own swatch book. INFO# 309

Safety Speed Manufacturing, booth B1449, introduces a new Triton Work Station available in various sizes. Additionally, the DFC-H5 Panel Saw and Substrate Cutter Combination machine is on display. INFO# 310

Serge Ferrari Group, booth B18025, showcases its range of products for the visual communications market. Serge Ferrari Group’s Seemee and Decolit lines offer unrivaled print rendering for indoor and outdoor advertising such as retail/point of purchase displays, wallcovering, and exhibit displays. Seemee Loop Mesh and Seemee Loop Frontlit printable fabrics are made from 100 percent recycled materials from post-consumer waste. They provide sustainable printable solutions for a variety of indoor and outdoor print media applications such as banners and billboards. Both products are made of 100 percent recycled polyester yarn and coating composed of 100 percent recycled polymers from post-consumer waste. They are GREENGUARD Gold certified, PVC-free, and phthalate-free. INFO# 311

Splash of Color, booth C3039, shows converting equipment from NEPATA GmbH, XY trimmers/cutters from KALA Finishing Systems, and direct to film cutters from Supply55, Inc., a leading manufacturer and distributor of workflow products for the signage industry. INFO# 312

Trotec Laser, booth C1932, invites attendees to learn how its world class laser engraving and cutting machines can help take their business to the next level. See live laser demonstrations on the SP2000 large format laser cutter and highperformance Speedy Series laser engravers and cutters. Discover the benefits of a Trotec laser system, get free samples of signage and engraving materials, and take advantage of special trade show pricing and promotions. INFO# 313

Xanita, booth C2113, showcases Xanita Board, its flagship product. This versatile, lightweight, and durable fiberboard is a game-changer for the printing industry. Explore the various applications of Xanita Board, from captivating retail displays to functional exhibition stands. Be inspired by the possibilities and see how Xanita board can transform print projects. It also plans to unveil its newest product offering, Xanita Aspect, designed for signage and other 2D applications, catering to the growing sustainability needs of the printing industry. INFO# 314

Our October issue will include more vendors’ plans for the PRINTING United Expo—be sure to check back! D

Vehicle wraps remain an exciting area of digital wide format print. From race cars to fleets of big rigs, a wrap can transform a piece of machinery into a work of art and/or marketing tool.

Based in Claremont, NC, Custom Graphics serves the Hickory Unifour area. In business since 1997, the company has three employees and operates out of a 4,000 square foot facility.

Mark Johnson, owner, Custom Graphics, shares that all of the shop’s work is wide format and digitally printed, with an estimated 60 percent of its business vehicle wraps. It offers both primary and partial wraps, mostly in a business-to-business capacity.

Vehicle wraps are individual to each job and client. Custom Graphics strives to understand what the customer is looking

for and works closely with the help to bring the idea into fruition. The shop has a team of designers on hand to ensure this process is as smooth and efficient as possible.

Johnson estimates that about 75 percent of its wraps are designed in house with input from the customer. The most challenging part of the design process is determining what the customer wants. To get there, his team asks the right questions and works from a rough sketch to a final proof. The creative process may be different for each customer, but it’s always about achieving an eye-catching design with different elements, colors, and images.

Much of the company’s graphics are applied on flat surfaces and the objects are wrapped with calendared film. For this, it relies on media from Substance, due to the “superior quality and user-friendly features of the product,” shares Johnson.

Our team worked to create a wrap that exceeded our customer’s expectations.

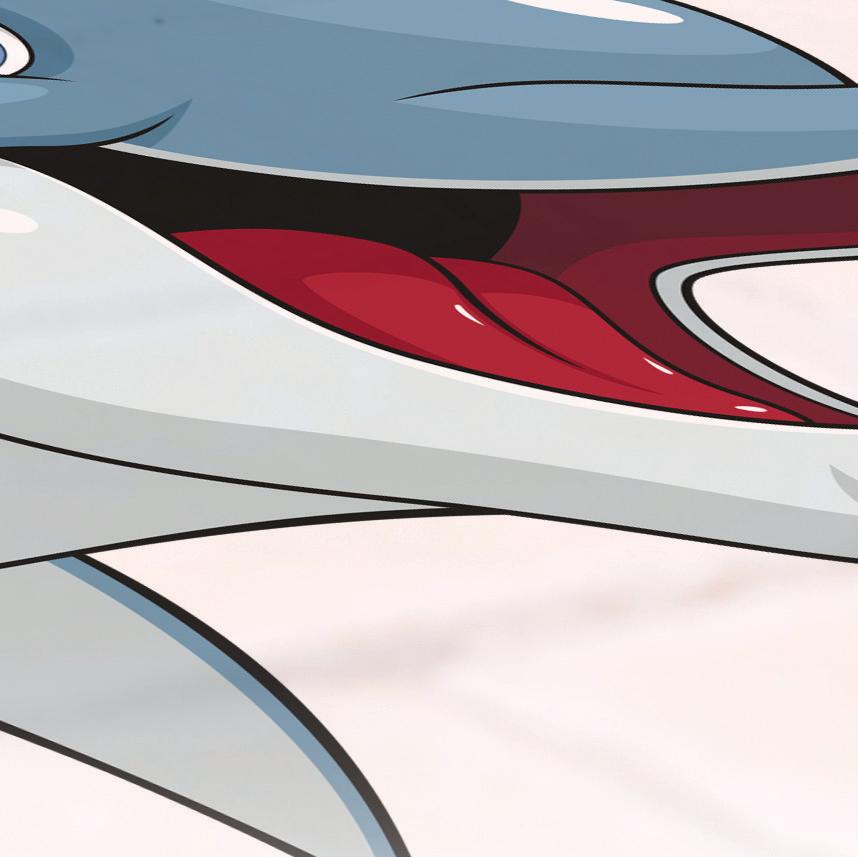

GraphicsRace cars wrapped by Custom Graphics, printed on media from Substance.

The path to Substance was interesting. When dealing with supply chain issues around COVID-19, Johnson searched online for a vinyl provider and came across the company. After placing an order for a sample, he got a call the next day asking to pick it up, as the vinyl provider was headquartered less than two miles away.

Today 90 percent of its vinyl work incorporates media from Substance. “I haven’t had any problems with defects, adhesive, or muddling,” he claims.

Finding Substance has been a “blessing” for Custom Graphics.

Not only in terms of supply issues, but in terms of the relationship.

For instance, Substance came out with its ICON RS-275 line of calendared film, specifically designed for race cars. It so happens that racing is a passion for Johnson, and therefore he wraps a lot of race cars—including his own—and has a growing network of other racers.

After using the media, Substance followed up with a list of questions about how it worked out for him. “It’s great to find a business led by people so passionate about what they do,” adds Johnson.

Custom Graphics primarily wraps vehicles like boxcars and vans for businesses, as well as storefront graphics. However, due to Johnson’s affinity for racing, he ends up doing a fair amount of race car wraps as well.

For the most part, the completed race car wraps are partial. However, once in a while they are full wraps. Recently, Custom Graphics was tasked with wrapping a late model race car for a customer looking for an aesthetically pleasing design that highlighted its sponsors while standing apart from the other cars on the track.

“Our team worked to create a wrap that exceeded our customer’s expectations. We used Substance ICON RS-275 with ICON PL-3150 overlaminate for the job,” shares Johnson.

The turnaround from design to installation was five days. The wrap is expected to last the full racing season, from February to October.

From storefronts to vehicle wraps, Custom Graphics is passionate about its work, its customers, and its peers. D

See page 18 for more info.

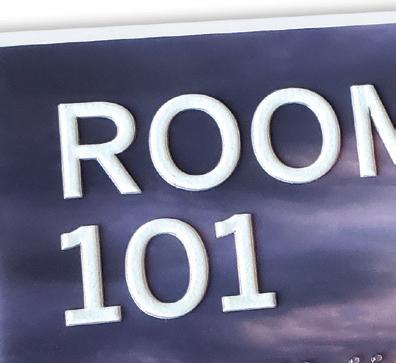

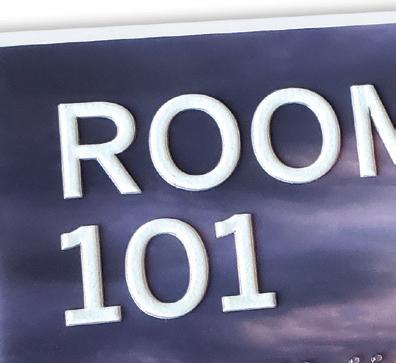

1) Mutoh UV desktop/tabletop flatbed printers include the software necessary to produce durable, high quality, and legally compliant ADA and braille signage. 2) The DCS series of flatbeds are available in small, medium, and large formats to accommodate customer needs.

by Melissa Donovan

by Melissa Donovan

Boosting business can be as simple as investing in a desktop or tabletop device. These multi-faceted, smaller format printers present endless application opportunities.

Recently, there’s been buzz surrounding digital printers used in the production of ADA and braille signage. Like most applications that are traditionally manufactured via more manual methods, ADA and braille signage benefits from digital printing’s speed, productivity, and efficiency.

Digital desktop/tabletop flatbed printers influence the modern production of ADA and braille signage.

“Digital printers introduced a paradigm shift in the manufacture of ADA signage. The reduction in

steps affects labor and costs and allows additional creative approaches,” attests Kevin Currier, director of marketing, Direct Color Systems (DCS).

Hugo Gonzalez, senior segment specialist, IP, Mimaki USA, Inc., agrees. “The small format flatbed printer industry greatly influenced the production of ADA braille signage. It significantly reduces the amount of operator input required to make a single sign. Printing braille and ADA signage can all be done on one machine while handling the material once and printing multiple copies per setup. This also frees up the operator during printing.”

A digital printer’s ability to jet layers for texture is another advantage. “ADA-compliant signs can be recognized by texture as well as color, so

Digital desktop/tabletop flatbed printers are revolutionizing the production of ADA and braille signage, o ering improved e ciency, design flexibility, cost e ectiveness, and versatility.

— Hugo Gonzalez, senior segment specialist, IP, Mimaki

color blind people can read and visual blind people also can touch braille. One of the easiest ways is to use layered UV inkjet printing to make these signs,” shares Juan Kim, CEO, Valloy Incorporated.

Emilio Rangel, UV desktop product manager, Mutoh America, Inc., says methods of producing ADA-compliant braille signs include braille raster beads, etching, thermoforming, or photopolymer. These involve additional steps to create the braille dots, tactile elements, and text required for compliancy.

Another traditional braille production method is routing, which

also requires multiple steps and longer production times, says Currier. “Digital provides an additive process that is fast to setup and easily reproduced later without any inconsistencies.”

Without digital printing, the production of ADA signage is manually intensive. An operator needs to handle each piece and be present at every step of the process. “In traditional methods, many steps require an operator to handle the material one piece at a time to perform tasks like adhering materials, routing, drilling, and placing beads all on different pieces of equipment,” explains Gonzalez.

Enhanced/new features on recent desktop/tabletop printer introductions focus on increased quality and layered printing.

“Increased printing quality and layered printing techniques play a vital role in creating ADA braille signage that is legible, durable, compliant, and accessible to individuals with visual impairments. Without layered printing, ADAcompliant braille is not possible to produce on a digital printer,” explains Rangel.

Layered printing is specifically of interest in architectural signage,

according to Currier. DCS’ series of flatbeds offer the ability to create functional ADA complaint signage combined with imagery and decoration due to layering.

Kim cautions on the challenges involved with layered printing. “If you use the same speed, resolution, and jetting amount for textures and colors, you print too many layers with too many passes. To reduce the production time, there needs to be a control for fewer passes and resolution with a larger amount of drops during texture printing before high-resolution color printing. In this way production time can be reduced.”

Other features are important to note. Kim brings up software and how it is integral in the process of slicing layers for fast production to create a semi three-dimensional effect accurately.

For a wide format graphics shop unfamiliar with ADA and braille signage, leveraging existing, familiar technology makes sense.

Taking on printing of ADA and braille signage expands the portfolio variety of a business. “It allows a shop to offer customization and include embossed and textured effects to logos and images that can be printed simultaneously with little or no additional required time. Additionally, the range of high contrast colors is no longer limited by available materials,” explains Gonzalez.

This type of work is complementary to many of the projects already offered. “A graphics provider should consider the advantages of being able to take on a construction or wayfinding project in its entirety. ADA signage can be offered as an additional job, keeping it in house and ensuring consistency across the project,” says Currier.

“When those unfamiliar with ADA see the capabilities of the printer, the profits to be made, and the ease of use, it will be quite clear how expanding offerings to existing clients can lead to increased profits,” attests Rangel.

With enhanced software features, layered printing, productivity, and high quality, utilizing digital printing for ADA and braille signage makes sense.

“Digital desktop/tabletop flatbed printers are revolutionizing the production of ADA and braille signage, offering improved efficiency, design flexibility, cost effectiveness, and versatility. These advancements empower sign makers to efficiently create high-quality, compliant signage,” states Gonzalez.

As awareness of digital print in this space spreads, it won’t be surprising to see traditional methods of production dissipate in favor of digital print. D

#24

#23

#26

#27

#22

#24

#23

#26

#27

#22

eyond the typical grocery or retail store, floor graphics are cropping up everywhere. However, when going beyond smooth areas into more unpredictable territory, it is essential to consider surface factors that affect adhesion, durability, and safety.

Micah Causey, VP, FloorSignage, LLC, sees floor graphics used in a range of environments,

by Cassandra Balentine

by Cassandra Balentine

including unusual applications such as garages, open parking lots, crosswalks, mile markers on walking paths, hopscotch and other games on school playgrounds and parks, on top of dugouts at baseball stadiums, stair facing and landings, you-are-here maps, safety compliance in manufacturing facilities, portable helicopter landing pads, as well as residential and business curb address markers, just to name a few.

Each area must consider floor certifications, slip resistance, longevity indoors or outdoors,

and surface detail—from smooth cement to tight weave carpet—to determine the adhesive level and necessary certifications that best suit the conditions, stresses Walter Gierlach, president, Photo Tex Group, Inc.

“The most important step in any graphic application, after making sure that your material is the right product for the job, is to properly prepare the surface, creating the best possible

opportunity for success with your installation,” adds Jay Kroll, product manager, cut, transit, and wall solutions, General Formulations.

Floor graphic media is increasingly used in areas that are expected or bound to get wet, including pools— under the water and around it.

Mike Richardson, business development manager, Jessup Manufacturing Co., recommends utilizing floor graphic media specifically designed for wet environments that can withstand exposure to water, as well as chlorine and other pool chemicals.

“We recommend using a graphic that will stay in place and is easy to install—even positioned easily by hand or with a pool brush with no need to drain the water. An ideal product is one engineered to lay flat and remain in position without the use of tape or adhesive,” explains Kylie Schleicher, director of product development and product management, Ultraflex Systems, Inc.

Upon installation, Richardson suggets a clean, dry surface free from any contaminants or residues that may interfere with adhesion. “Apply the graphics when the pool or splash pad is not in use to allow sufficient drying time and prevent any disturbance to the installation process.”

“It is important that these surfaces are thoroughly clean of chemical residue—like chlorine—and dirt and be completely dry before applying a product with a pressuresensitive adhesive,” adds Causey.

When looking at adhesive properties, Richardson says to verify that the adhesive used is compatible with the specific pool or splash pad surface material to ensure proper bonding and prevent any damage or discoloration.

For graphics applied around pools and outdoor concrete, Causey suggests a permanent adhesive as well as a product that can be compressed perfectly to conform to the exact texture of the surface to prevent moisture released underneath that can weaken the adhesive.

Richardson also suggests using anti-slip laminates or textures to

enhance safety and prevent slippage when the surface is wet.

“Select an option that tests high for coefficient of friction/ slip resistant standards for wet environments,” states Causey. For durability, he suggests a floor graphic media that does not shrink when exposed to water and/or direct sunlight.

“Ensure the media has high resistance to fading, discoloration, or degradation caused by UV rays or water exposure,” seconds Richardson. “Consider the longevity of the adhesive in a wet environment, ensuring that it maintains its strength and adhesion even when submerged or subjected to splashing water.”

Causey recommends replacing floor graphics in these environments with each season for best slip resistance and safety.

For pools and splash pads, Richardson says a two-step product may be ideal. By using a two-step system that includes an overlaminate with slip resistance, you can ensure the longevity of the graphics while also providing a non-slip surface in areas prone to getting wet. This combination enhances the durability of the graphics and helps maintain safety in wet conditions.

Carpet is another tricky surface, but there are options to ensure successful installation.

Specialized floor graphic media designed for carpeted surfaces typically have a strong adhesive and a textured surface to ensure proper adhesion and prevent slipping, states Richardson.

“Carpet graphics require a specially designed adhesive with enough tack to grip and hold onto the carpet fibers, but is ‘hard’ enough to not flow into the fabric and risk damage or residue upon removal,” adds Kroll. “The adhesives in these applications require a unique balance of tack and bond specific to their intended surfaces and, as such, are not generally interchangeable with other applications.”

Prior to installation it’s a good idea to test a small section of the carpet with the graphic media to ensure it adheres properly and does not damage or leave residue

on the carpet fibers. It is also important to thoroughly clean the carpet before applying the graphics to remove any dust, dirt, or debris that may hinder adhesion.

Causey’s first recommendation is to only apply carpet graphics to low pile/industrial carpeting. He also suggests considering a material that can resist being punctured by high heels.

It is also important to consider the removal process and choose a graphic media with adhesive that can be cleanly removed from the carpet without leaving behind residue or damaging the fibers.

Causey suggests a removable adhesive for carpet graphics. “Be cautious of thick adhesive coat weights. When removed these can separate and leave residue on the carpet.”

In terms of durability, a good rule of thumb to avoid the adhesive from damaging the carpet is remove after three months. “Also consider the environment such as harsh sunlight, which can accelerate the adhesive migration onto the carpet surface,” shares Causey.

In terms of safety, be mindful of any raised edges or uneven surfaces created by the graphic that could pose a tripping hazard. “Regularly inspect the graphic for any signs of lifting or peeling that may increase the risk of slips or falls,” says Richardson.

“Consider the thickness and wear resistance of the graphic media to ensure it can withstand the rigors of being placed on

carpet,” adds Richardson. “Opt for materials resistant to fraying or tearing, ensuring the graphic remains intact even with repeated use.”

Richardson suggests that a onestep product, which combines the graphic and the adhesive in a single layer, is generally more suitable for carpet surfaces. “These products are specifically designed with carpet adhesion in mind and offer ease of installation without the need for additional steps.”

An uneven surface like cement can be unpredictable when it comes to installing floor graphics.

“Cement graphics require an awareness of the amount of moisture in and around the application area as staining can occur, and special attention should be given to the condition of the surface to make sure there is no loose or broken concrete, which could cause injury or graphic failure,” explains Kroll.

When applying to cement, Richardson suggests cleaning the surface thoroughly to remove any dirt, grease, or loose particles that may hinder adhesion. Also, ensure the surface is dry before applying the graphic media to promote proper bonding.

Causey seconds the rule of only applying graphics to concrete that is thoroughly clean of dirt, debris, fuel, or chemical residue and that is completely dry. “If necessary, clean by power washing and a degreaser. Avoid placing on areas that are broken, chipped,

cracked, or spanning over expansion joints. Also avoid areas that are susceptible to frequent drain or run off from irrigation.”

René Bourgeois, VP, sales, North America, ASLAN - a Poli-Tape Group Company, says the best practice for all floor graphics is using the correct product tailored to the application and surface. “Also take into account if it’s indoors or outdoors to specify the best anti-slip lamination.”

A graphic media suitable for outdoor use and can withstand environmental factors like UV exposure, moisture, and temperature fluctuations is ideal for cement, offers Richardson.

Keep in mind important durability factors, like the length of time the customer wants the graphics in place, the type of traffic the graphics will be exposed to i.e., heavy pedestrian traffic, bicycles/ skateboards, utility carts, shopping carts, forklifts, automobiles; exposure to the elements; and the coefficient of friction/slip resistant test scores when the product is exposed to moisture such as ANSI A137.1, ANSI B101.3, and HB198. “It is also a good practice to apply test pieces to the exact area prior to producing the project to make sure the material meets the customer’s expectations,” offers Causey.

When it comes it adhesive, for cement surfaces, find a floor graphic media with adhesive that is specifically designed for cement surfaces, as they may have different porosity levels and require stronger adhesive

properties. “Consider any surface coatings, sealants, or finishes on the cement. In addition, choose an adhesive that adheres effectively to those particular materials,” advises Richardson.

He also suggests evaluating the durability of the adhesive on cement, considering factors such as foot traffic, cleaning methods, and exposure to outdoor elements. “Choose floor graphic media that is designed for outdoor use and can withstand the harsh conditions associated with cement surfaces, such as exposure to sunlight, temperature fluctuations, and foot traffic.”

For safety, consider the potential for the cement surface to become slippery when wet or in highmoisture conditions and choose floor graphic media that provides slip resistance even in these situations. “Ensure proper cleaning

and maintenance of the graphic to prevent the accumulation of dirt, debris, or liquids that could compromise its slip resistance.

Address any cracks, uneven surfaces, or other hazards on the cement that may affect the adhesion or safety of the floor graphic,” says Richardson.

To avoid slip/trip hazards, Causey says graphics on concrete should be replaced either when the slip resistant texture is worn down, the graphic is damaged, or an edge is lifting.

Richardson points out that both one- and two-step products can be suitable for cement surfaces, depending on the specific requirements and conditions. One-step products are often preferred for cement as they provide ease of installation, combining the graphic and adhesive in a single layer.

Ultimately, the choice between a one- or two-step product depends on factors such as surface characteristics, adhesion requirements, environmental conditions, and the availability of specialized products designed for the specific surface, recommends Richardson. “It is important to consult with the manufacturer of the floor graphic products for their recommendations based on their products’ compatibility and performance on different surfaces.”

“The level of durability you desire will determine the approach,” agrees Bourgeois. “For shorter lived campaigns or areas with low foot traffic, one-step solutions are ideal. However, if you aim to maximize durability or operate in high foot traffic areas, I suggest employing two-step solutions to safeguard the print from mechanical wear and tear.”

Causey says one-step products are much faster to produce, saving time and money plus some onestep products have better slipresistance properties than most two-step products. To add protection to images exposed to harsh sunlight and frequent cleaning, an optional clear coat liquid laminate can be applied following production or even after it is installed.

As opposed to smooth surfaces, there are opportunities for floor graphics on uneven and unpredictable flooring. So, specialty floor graphic material versus a

more universal product makes sense in these situations.

“This comes down to making sure you have the right material for the job—it reduces the amount of rework you’ll need to do, makes the installation easier, and ultimately leads to a better business for you in the long run,” says Kroll.

Bourgeois points out that there is no universal product for these surfaces/situations. “Go for targeted, specialty floor graphic material with the correct adhesive for the desired surface to avoid issues with adhesion, removability, and slip resistance.”

There is no “one-size-fits-all” product in the floor graphics category, agrees Causey. “The best quality floor films are designed with specifications for the type of surface, the environment, type of traffic, safety precautions, preferred methods for installation, removal, and length of posting.”

Richardson points out many characteristics for specialty floor graphics, including enhanced durability, improved safety, compatibility with surface characteristics, customization and visual impact, as well as compliance and safety standards.

In terms of durability, specialty floor graphic materials are designed with specific surfaces or environments in mind. “They may offer superior durability, resistance to wear and tear, and protection against external factors such as water, chemicals, or UV rays. This can result in longer lasting graphics that maintain their visual

appeal even under challenging conditions,” shares Richardson.

Specialty floor graphic materials may prioritize safety features such as slip resistance or antiskid properties. “For surfaces like pools, splash pads, or areas prone to moisture, using a targeted material with enhanced grip can reduce the risk of slips, falls, and accidents. This is particularly important for high-traffic areas or locations where safety is a primary concern,” says Richardson.

Compatibility with surface characteristics is a top benefit of speciality floor graphics. “Specialty floor graphic materials are often developed to adhere effectively to specific surfaces such as carpet, cement, or textured flooring. They take into account the unique characteristics of these surfaces, ensuring proper adhesion, conformability, and longevity. Using a targeted material increases the likelihood of achieving optimal results in terms of adhesion and graphic performance,” shares Richardson.

He points out that customization and visual impact are also improved with the right floor graphic media. “Specialty floor graphic materials may offer unique features that allow for customization and visual impact. They may include options like textured surfaces, photoluminescent, or vibrant colors that enhance the overall appearance and branding of the graphics. This can be particularly valuable in retail environments, events, or promotional campaigns where attention-grabbing visuals are crucial.”

“Specialty product provides the customer with more options in marketing their message and allows them to be more creative in their customizing,” notes Schleicher.

And of course, safety and performance comes to mind when it comes to choosing the right floor graphic media. “Specialty floor graphic materials may be specifically tested and certified to meet safety standards and regulations, such as slip-resistance certifications. Using these materials provides assurance that the graphics meet required safety guidelines and mitigate potential liability concerns,” says Richardson. “By opting for targeted, specialty floor graphic materials, print providers and end customers can ensure a higher level of performance, safety, and customization compared to more

universal products. These materials are specifically engineered to address the unique challenges posed by different surfaces and environments, ultimately enhancing the overall quality and effectiveness of the floor graphics.”

These products may cost a little more, but manufacturers and distributors can educate print providers and end users on these details to help them make the decision on which product they want to use. “This starts with asking important questions and gathering as much information as possible, then contacting your favorite sales representative or the manufacturer to determine which product is best for the project,” says Causey.

“It’s crucial to consult with the manufacturer of the floor graphic

media for specific safety guidelines and recommendations, as different materials may have unique considerations or requirements. Additionally, complying with relevant safety standards and regulations is essential to ensure the well being of individuals interacting with the floor graphics,” concludes Richardson.

While many floor graphic media options serve smooth, dry environments, speciality options exist to enable successful placements on carpet, cement, and even pools and splash pads. Special consideration to the exposures unique to the end environment, durability requirements, and adhesive are best practices for choosing the right floor graphic media for the job. D

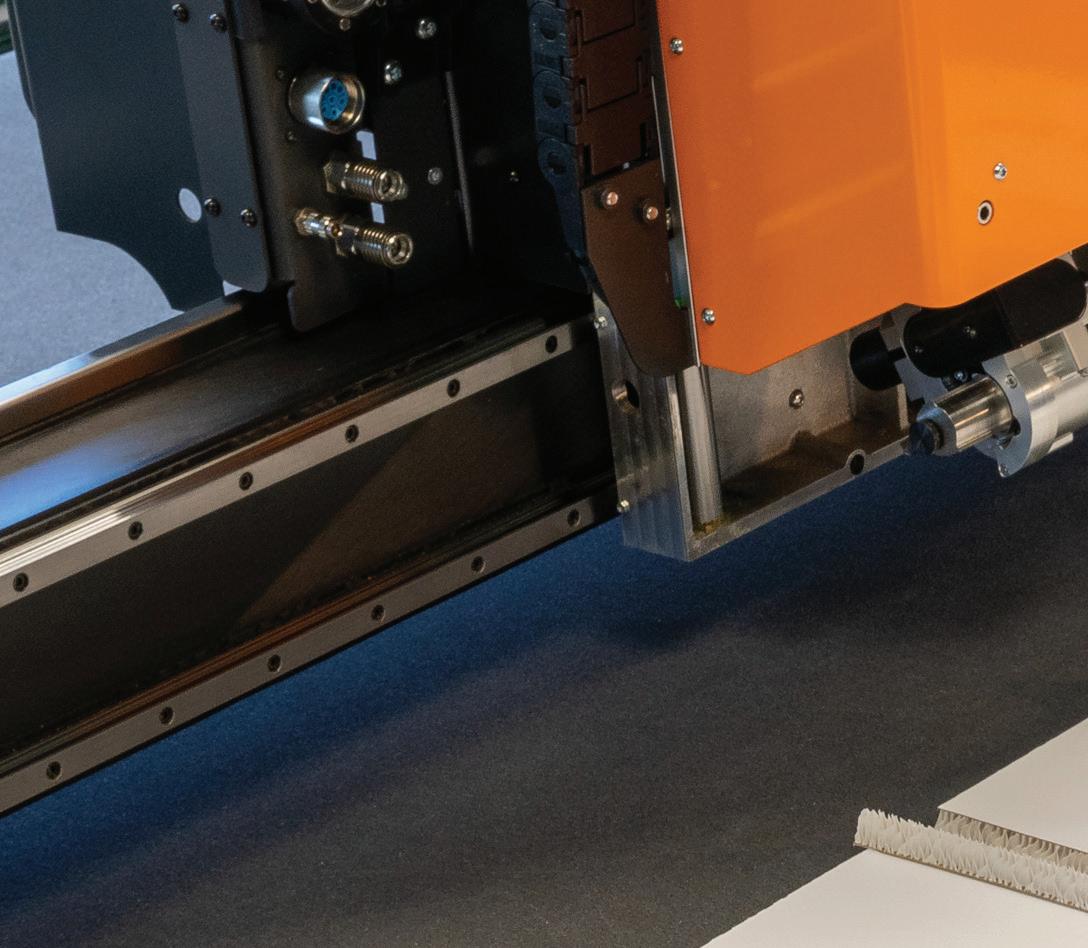

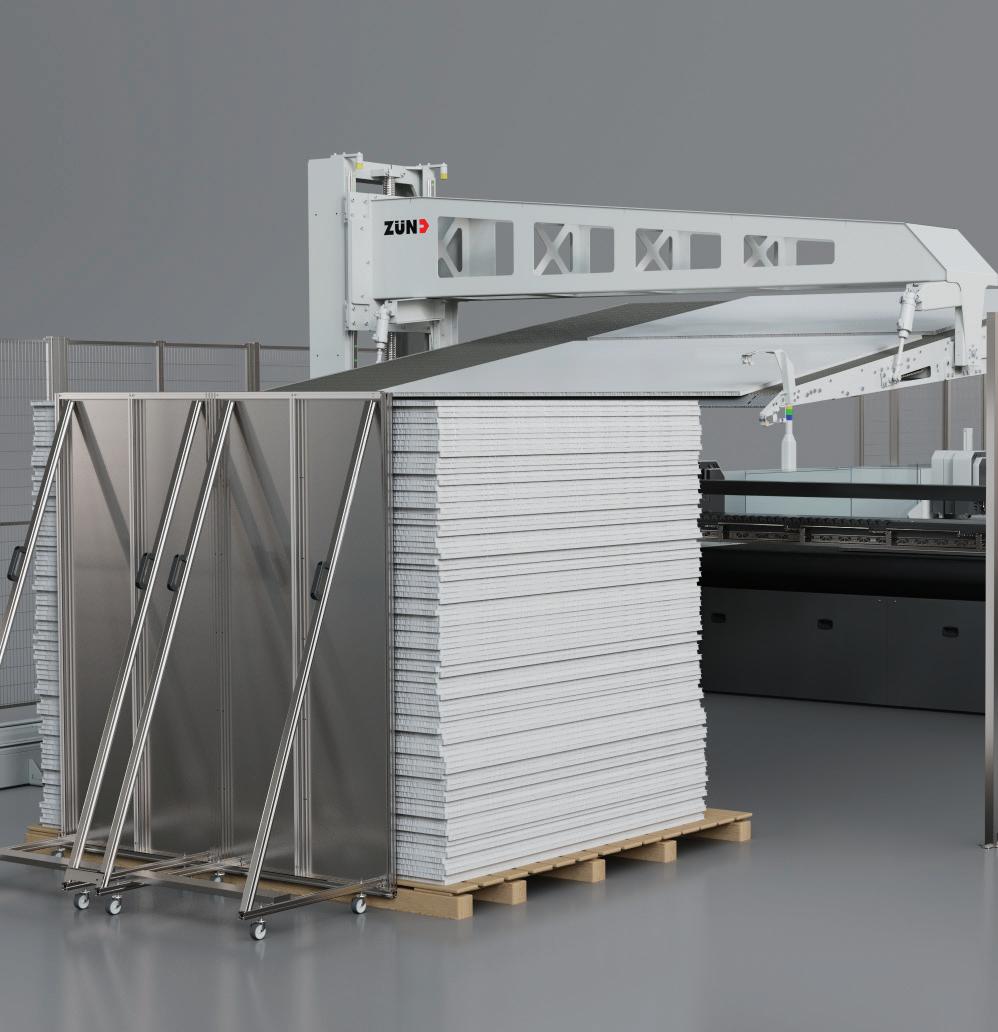

s we enter into the Fall months, product introductions are rampant. In the finishing space particularly, flatbed routers/ cutters advance with increased speed, multiple tooling options, and

a transition to linear drive systems. To meet quick turnarounds and smaller runs, as well as address the lack of operators/help, features like speed, multiple tools, and linear drive systems combine to enhance productivity. Print service providers

(PSPs) look for these features and more when considering new routers/cutters to their businesses.

Enhancements to existing products or new features on recent

introductions focus on increasing speed. With this common

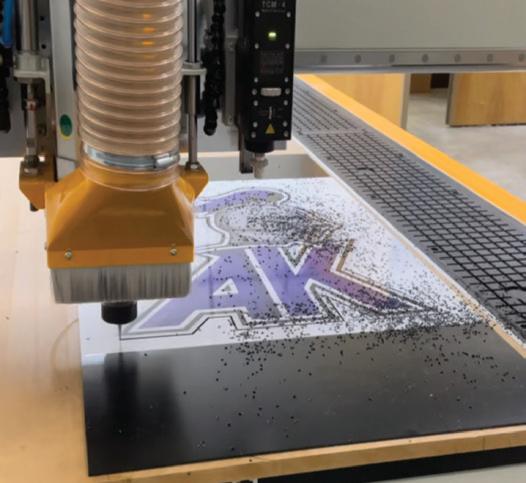

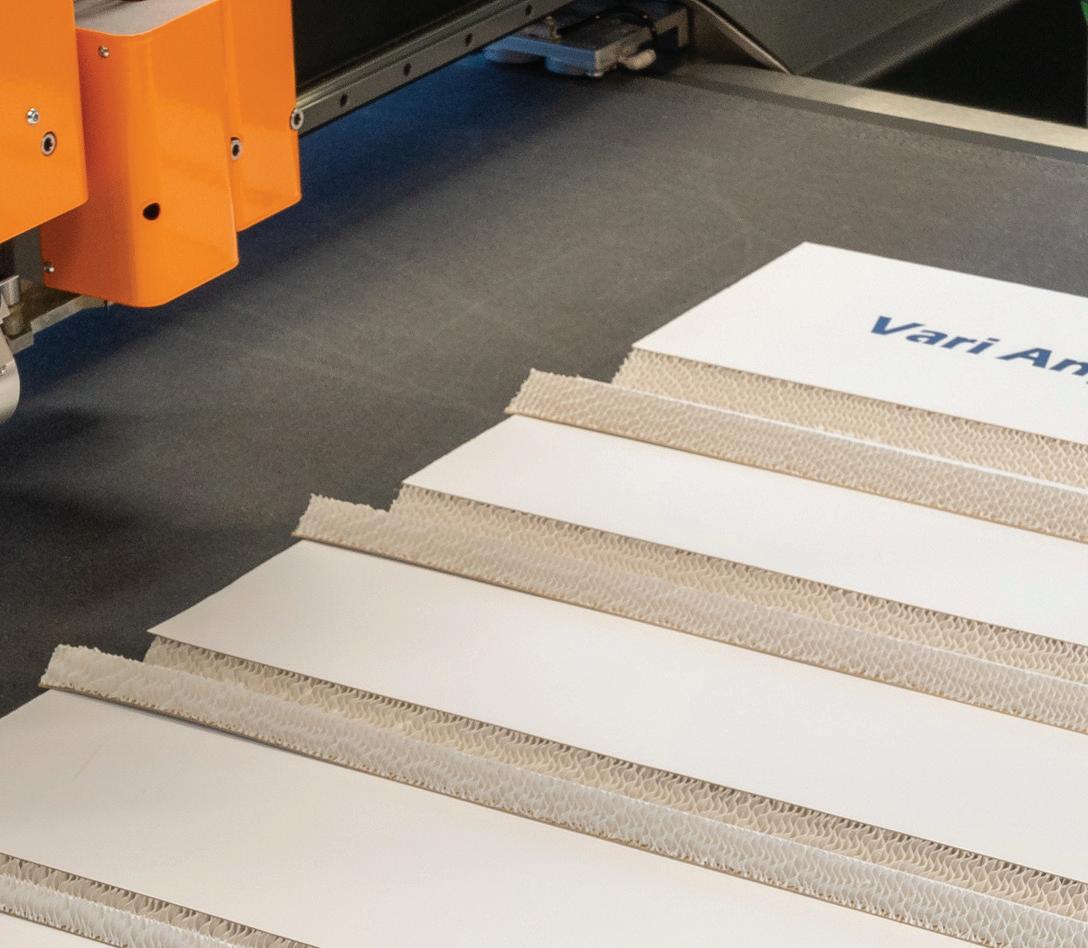

Above) The VariAngle offered by Kongsberg automatically changes the cutting angle of the knife, allowing you to run the cutting table without the need for intervention during the production. Conventional V-notch solutions stop production to change tools or blade angle.

denominator it seems safe to say speed is one of the most important offerings PSPs consider when it comes to new flatbed router/cutter systems.

The need for quick finishing “mainly comes from the ever-increasing speed of digital printers, along with the continued digitalization of packaging manufacturing,” shares Beatrice Drury, marketing communications manager, Zund America, Inc.

Nikolai Mikkelsen, president, VTX Tools, points out that speed increases on the print side means following on the finishing end. “With wide format digital print making leaps in performance over the last decade, narrowing in on

traditional lithography/offset, while allowing for one-off and justin-time production, the need for digital flatbed finishing is growing lock step. This is especially true in the packaging and point of purchase (POP) market segments.”

“Cycle time is one of the most important factors in productivity. Every company strives to satisfy customer needs. In an everyday scenario, an order is received and is then pushed through the production process. This job is quoted, designed, printed, finished, assembled, and packed up. Each step along the way has varying metrics to determine how long something should take and how much will be charged for each department. Getting the job done right and on time are always high on the priority list. But was the job completed efficiently within the projected/ budgeted allotment?” asks Raum DiVarco, GM, Cutworx USA.

Price is no longer the main factor when it comes to customers choosing which PSP to work with. “Not only does increased speed allow for increased output, but the faster your turnaround, the happier your customers will be, which often means they will send you more work, even if your price is a bit higher than your competition,” admits Josh Martinez, account manager, X-Edge Products.

Also a large part of increasing speed is where the finishing device is placed in the production line. “Inline ability speeds up production and minimizes labor and handling of each job,” notes Keith Verkem, senior product manager, Colex Finishing, Inc.

Speed isn’t relative. DiVarco warns of the importance of distinguishing between rapid traverse and actual cutting speed. “Linear magnetic drive systems offer increased acceleration and cutting capabilities, which benefits materials like diecut decals; graphics on coroplast, cardstock, and foamboard; as well as corrugated displays and boxes.”

Faster speeds also mean machines are used for more than signage, agrees Max Allen, director of wide format, GW wide format, Graphic Whizard Inc. This includes packaging, die cutting, and roll labels without tying up the cutter for extended periods. “Productivity equals profit. The increased speed of cutting tables can mean more throughput and more jobs completed during times of heavy workflow.”

Speed is important throughout the entire workflow. This is essential

to understand. “From a production perspective, being fast in only one area can lead to production bottlenecks, so overall productivity is key to best results, with the introduction of greater automation to keep productivity to optimum levels,” suggests Caroline Anne Bell, marketing coordinator, Elitron.

“In reality, users aren’t looking for greater speed in finishing; what they really need is increases in productivity—especially, productivity they can count on. Without reliable workflow automation encompassing all aspects of the digital cutting/finishing process, from prepress to logistics, any advantages gained from high machine speeds quickly evaporate. This is why comprehensive and fully integrated workflow automation is so important and valuable,” concurs Drury.

Automation comes in the form of feeding, stacking, loading/unloading, and even sheet turning systems that complement a flatbed router/cutter, adds Bell.

Drury also believes an “intelligently automated system needs to include automated material handling. It would not make sense without the benefit of automated, unattended, pallet-to-pallet production capabilities.”

Multiple tools and/or automatic tool changing (ATC) systems is another topic surrounding new product announcements.

“Productivity is the driving factor behind the demand for ATC

and multiple tools. Maximizing machine runtime during an eight hour workday is essential for meeting deadlines. ATC features are beneficial for both productivity and ease of use, especially for less experienced operators,” says Nick Walters, technical sales director, Amcad & Graphics.

According to Mikkelsen, tool changing has been around a long time in the router world and is currently becoming prevalent in flatbed digital cutting. “The ability to change tools efficiently without operator intervention allows for productivity gains as the machine sets the changeover time versus the person. Especially if running ‘lights out’ or having one operator handling multiple cutters or machines. In addition, by allowing the machine to handle this process, the human error factor is also reduced.”

“The demand for ATC is driven by making the cutting process faster and more efficient. Having tools on hand or the ability to automatically change the tool allows for less manual intervention while running jobs,” agrees Verkem.

Allen points out that “reducing touch points through automation will minimize errors and costly mistakes, as well as lead to more uptime on the equipment.”

Equipping a flatbed router/cutter with multiple tools—whether automated or not—is also good in terms of versatility. “The addition of the ATC provides the customer with greater capabilities beyond just digital printing and cutting. It allows customers especially in the

POP, theater, or exhibit manufacturing sector to use the machine in their production workshop to cut wood, plastic, foam, and metals,” says Roy Valentine, sales manager, Techno CNC Systems.

“The demand for increased versatility is on the rise, hence sophisticated tooling systems are developed. Cutting, creasing, multi-milling, v cut, kiss cut, all in one system. This provides the opportunity to offer a multitude of possibilities to clients and increase creativity, while using many different materials,” explains Bell.

Multiple tools as well as ATC meet the versatility of substrates seen in today’s print shop. “With an

ever widening selection of materials comes a need for even more diverse tooling selection. With that, the need to quickly change between those tools to handle the various materials while still increasing throughput, an ATC and/or multiple tooling becomes a must rather than a luxury,” states Martinez.

“This is another important aspect of workflow automation aiming to maximize productivity and keep the need for manual/operator intervention to a minimum,” adds Drury.

The sophisticated technology involved in linear drive systems continues to advance.

Linear drive systems are the next step in the evolution of cutting and routing. “As the performance requirements for cutting productivity continue to scale, the speed of rack and pinion and belt drive systems are beginning to plateau. This is why linear motors are becoming the latest buzz word. Just as linear drives did for wide format digital printers, these types of drive mechanisms allow for previously unheard of accelerations and speeds, equating to performance gains,” explains Mikkelsen.

“Linear drives offer tremendous advantages in terms of speed, acceleration, and positioning accuracy. They are also highly reliable, wear free, and energy efficient. These capabilities all play a tremendous role in generating the kind of productivity Zünd was looking for in developing its latest, fourth generation of digital cutting systems,” shares Drury.

According to DiVarco, evolved linear drive systems reduce mechanical wear and tear. “In the past, achieving higher speeds with rack and pinion drives required larger motors, heavier gantry systems, increased costs, and potentially compromised performance. However, innovations in encoder designs, linear motion, and driver technology have enabled machines to operate at faster speeds without sacrificing performance, versatility, and precision.”

“There are certainly technological advancements for linear

drive systems, and these result in greater speed, acceleration, and accuracy. This leads to jobs being completed in less time and greater precision, resulting in an overall increase in the quality of the end product,” adds Bell.

Additional trending topics surrounding flatbed routing and cutting include sustainability and high-performance materials used in the construction of the actual hardware.

Sustainability is more than a buzzword. Elitron is combating it head on with its Elitron Power Management System (EPMS). Installed on the company’s full range of cutting systems starting in 2023, EPMS reduces the energy consumption of the vacuum found on the finishing devices by up to 50 percent.

“It’s engineered using an electronic control board, designed entirely by Elitron, interfaced with the inverter, to manage a series of dedicated sensors, to optimize the operation of the vacuum motors. The electronic board ensures optimum vacuum power is used on the working area. Simultaneously, it monitors the maximum current absorbed by the motor, to guarantee continuous optimal working conditions. A compensation valve is used to constantly guarantee the required vacuum power, while maintaining the optimal working temperature of the vacuum motor even during intense workloads,” shares Bell.

The construction of the newest routers/cutters should be addressed. Mikkelsen points out that

with linear drive systems increasing speed, thus setting new acceleration benchmarks, this leads manufacturers to introducing new inertia loads, which require fresh approaches to design.

“The forces resulting from such unprecedented speed and acceleration require changes to the machine substructure, whose build needs to be exceptionally stable to guarantee smooth operation and maximum cutting accuracy,” agrees Drury.

Materials such as carbon fiber to lighten or strengthen the gantry or concrete that creates both mass

and rigidity to the machine’s base are used to dampen inertia, lighten loads, and create more rigidity, explains Mikkelsen. “The more rigidity incorporated into a design, the greater the increased performance available from linear drives can actually be utilized,” he continues.

Mineral casting, a type of concrete that combines minerals with a binding agent, provides stability for the Zünd Q-line substructure and is capable of handling any load level while maintaining superior precision, according to Drury.

More devices are being constructed from stable materials. Techno’s

Titan is an all tubular steel construction that is welded, precision machined, and stress relieved. “This allows the machine to route any wood, plastic, or metal with precision and ultra smooth cutting results. Top-of-the-line components result in long operational life,” attests Valentine.

Kongsberg Precision Cutting Systems’ (PCS’) MultiCam Apex 3R CNC router “features a heavy, all-steel tube frame that ensures durability and makes it more rigid, which reduces vibration and improves routing quality,” shares Matt Thackray, VP/GM, Kongsberg PCS operations in America.

Mikkelsen says the next hurdle is tool model design. “For example, the current frequency of oscillating tools for cutting corrugated cardboard precludes most new linear drive machines from running at peak performance. Overcoming this performance achilles heel is the next test of a manufacturer’s ingenuity in design.”

It’s a new age for digital finishing with breakthrough advancements. Manufacturers introduce innovative technology, from the substructure of a device to swiftly changing from one tool to the next or automating material handling. D

inyl striping is an underrated tool in a print service provider (PSP’s) or wrap installer’s arsenal. There is cost effectiveness in a single strip of vinyl—or two— decorating a vehicle or some other surface. Installation is similar to

other graphic applications, so the ability to complete a quality install is inherently learned. Finally, a stripe is a timeless design. Whether it is a car or a boat, even a retail storefront, a solid color strip of vinyl communicates a clean, sleek message. Conversely,

a metallic finish conveys a flashy, yet subtle tone. Simple striping, yet endless possibilities.

There is a recent jump in interest in vinyl striping, also known as pin striping or cut vinyl embellishment.

Molly Waters, senior technical specialist, Avery Dennison Graphics Solutions, believes striping is in Above) Vinyl striping is a great complement for shops offering digitally printed graphics because it allows the shops to complete two-tone striping as well as get into the market of recreating OEM decals. This two-tone graphic was completed by Eagle Enterprises using Avery Dennison media.

demand now because of trends in the automotive industry. “There is a shift to electric vehicles and automotive dealers are keeping fewer stocked vehicles on the lots. End users are also increasing the demand because they are trying to replicate the factory striping kits for personalizing their vehicles. It’s becoming a challenge for installers.” Albeit, a good challenge.

Vinyl striping is also prevalent due to funding from the federal government and various infrastructure bills, according to Michael Aldrich, product manager, FDC Graphic Films, Inc. “Orange cones and barrels are everywhere with reflective striping. New construction vehicles and equipment are being purchased for these infrastructure jobs that need a stripe to match the other vehicles and equipment in the company. Summer is a popular time for stripes in general as many RVs and campers are striped also.”

“Pin striping, embellishments, and other cut vinyl decals are sometimes overlooked for the flashier, large-scale vehicle wraps that we see on the street, but these legacy graphics represent a constant in an ever-growing market,” adds Jay Kroll, product manager of cut, transit, and wall solutions, General Formulations.

Demand for vinyl striping remains steady due to durability, ease of application, variety of colors and designs, affordability, and the opportunity for customization, lists Nate Goodman, technical product manager, Mactac.

“We do large format stripes; a lot of which are used for fleet, service station canopies, gas station pumps, and really anywhere someone needs a long field of color that is consistent in size and color. The use of striping promotes continuity and sameness within a design,” shares Chris Bowen, CEO, Trim USA.

Vinyl striping isn’t limited to vehicles, other applications benefit.

“Vinyl striping is popular for businesses and individuals who want to add personality, style, or branding to their space,” explains Goodman. This means virtually any surface is poised to benefit.

Boats, RVs, horse trailers, and even railroads are adopting striping, notes Waters.

“Striping is used in multiple applications. Vehicle stripes are most recognized, but striping is used on dumpsters for different companies, school buses, garbage trucks, tankers, semi-trucks, trailers, snowmobiles, and jet skis. There are many applications beyond that as well,” notes Aldrich.

Beyond vehicles—other objects also benefit from vinyl striping. “It’s something you might also see used in shop windows, on bikes and boats, or even as floor marking tape in a workshop or warehouse setting. These often mimic a painted line, but do so with significantly less setup and skill required as compared to paint. The versatility of vinyl also allows to expand beyond a typical pin stripe or broad line to

include fine filagree details and embellishments with the use of a plotter cutter,” explains Kroll.

Vinyl striping is commonly associated with solid colors, but specialty films with effects are used too.

Kroll admits that “there is always going to be a contingent of specialty color or decorative finishes, but as with sign vinyl you will see a predominance

of black and white with maybe some silver or red thrown in for good measure.”

“Two-tone graphics using two different colors of film are most common, for example, a matte black hood stripe outlined with carmine red pinstripe,” explains Waters.

Solid color stripes are most popular, admits Aldrich, because otherwise fading is a challenge. For example, some colors fade from red to white. Special media

like holographic “are not typically seen because the outdoor life expectancy is very short causing the exposed holographic to turn black or brown.”

For specialty films, Waters points to carbon fiber as a textured film used for striping. Also, printed carbon fiber is often utilized.

“Reasons why specialty films might be used in striping include adding a touch of style or personality and adding a unique and eyecatching look to a vehicle, image, or project,” suggests Goodman. He says specialty films with effects like metallic and gemstones are sometimes seen here.

Stripes are made, according to Bowen, based on the dynamics of the film in question. “We make stripes from cast and reflective films due to limitations on how dyes can be made. Other materials

are suspect as to whether or not they can be converted.”

Application tip/tricks for those unfamiliar with vinyl striping go along the same lines as any other adhesive-backed application.

Kroll preaches practice and patience. “The surface needs to be clean and dry, preferably wiped down with an isopropyl alcohol to remove any dirt or wax. Peel back the release liner on one end and apply the striping to the application surface, then gently remove the rest of the liner while keeping the tape away from the surface. Without putting too much tension on the vinyl, eyeball the alignment as you adhere the striping to the surface, matching the desired contour.”

Mask strips are helpful when installing cast vinyl, especially

when the application is as long as the length of the car or even longer. “This keeps it from stretching the vinyl too much during application and helps keep the stripe as straight as possible. The mask also makes the strip a little more rigid for ease of handling,” suggests Aldrich.

“The thicker the film, the easier the application process. A pre-masked striping for cast and high-gloss products where scratching and stretching may be an issue is recommended. Work slowly and be patient, and with a little practice, you can apply vinyl striping like a professional,” advises Goodman.

For a twist on design, knifeless tape is sometimes used “to hold down the sides of cars or hoods of vehicles by lying the knifeless tape out in a shape, stripe, or design. They then apply their wrap or vinyl over the top of this and pull the knifeless tape creating a cool stripe or graphic on the fly,” says Aldrich.

Vinyl striping is a great complement to digitally printed graphics, whether it is a full vehicle wrap or a decal.

“Vinyl striping can be used on a wrap for stripe accents, and a unique look can be achieved with a print on the stripe or fading from one color to another,” shares Aldrich.

Waters agrees. “Vinyl striping allows shops to do two-tone stripe

graphics as well as get into the market of recreating OEM decals. The boating market is another area they could get into easily using the same printing methods and films.”

“Vinyl striping is especially effective in supplementing a printed design that includes bands of consistent color and size. Using the striping in this situation offers benefits over printing as the pigmented cast material will hold its color for longer,” adds Bowen.

Part of the allure, the cost of vinyl striping materials is significantly lower when compared to digital print material. “Vinyl striping can essentially turn a printed partial wrap graphic into something that incorporates the whole vehicle, creating more of a full wrap aesthetic. The use of lines or shapes in that cut vinyl material can still be impactful in the overall design when done well,” says Kroll.

“By offering vinyl striping to complement current services, businesses offer enhanced services for signage, motorsports, and architecture installations. If the customer wants to avoid a full wrap or graphics, sometimes putting a large decal with a stripe pattern can make for an effective layout at a lower cost,” advises Goodman.

Vinyl striping is a great way to enhance PSPs’ and wrap installers’ current service offerings. For more information on this topic, visit digitaloutput.net/webinars to watch a replay of a recent webinar. D