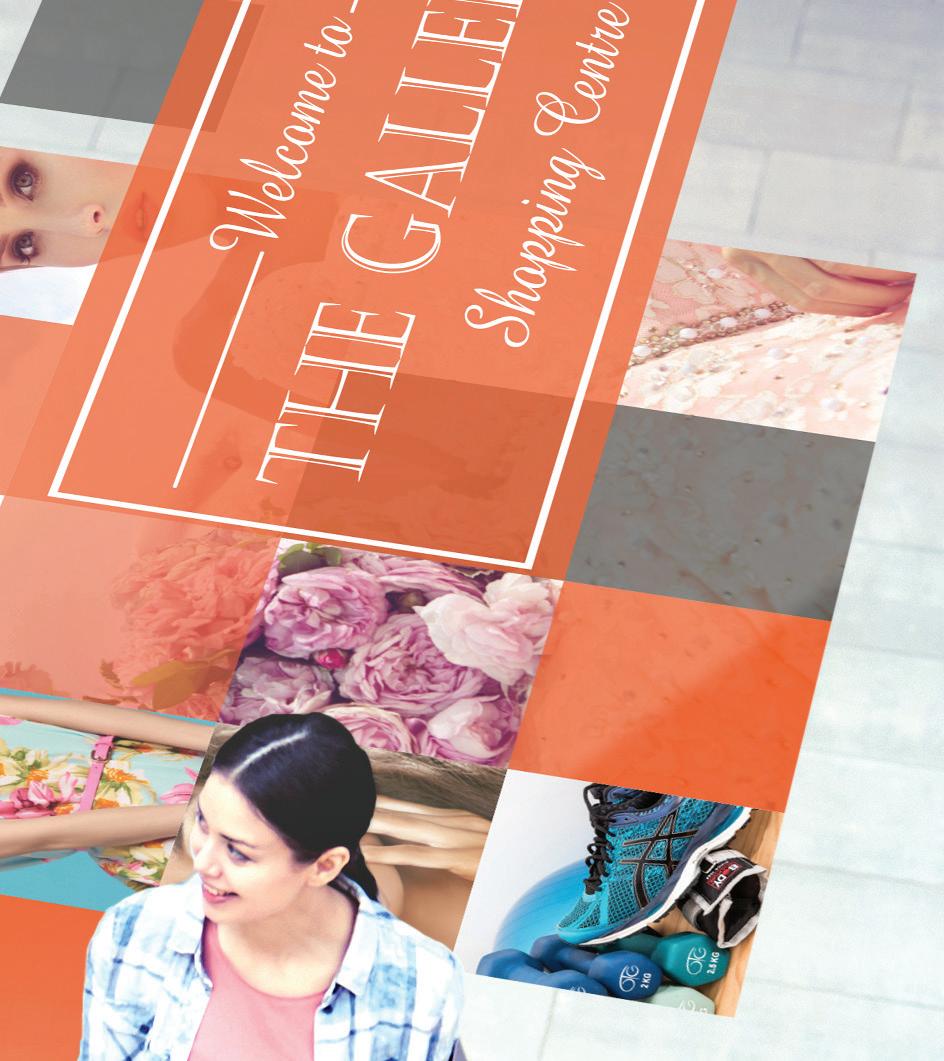

It’s a busy time of year. We embark on a flurry of activity in and surrounding the industry with our October issue. The cover story, Play Well Together, mimics this buzz of activity with a focus on multiple materials and how they complement each other in the display and point of purchase (POP) space. Rigid board, film, fabric, magnets, and more—materials collaborate to create the ideal POP display for any environment.

VOLUME XXIX, NO.10 DIGITALOUTPUT.NET ISSN: 1083-5121

EDITOR IN CHIEF

Thomas Tetreault

ttetreault@rockportpubs.com

EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ASSOCIATE EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

WEB EDITOR

Melissa Mueller

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

CONTRIBUTORS

Olivia Cahoon, Tim Greene, Mark Hanley, Melinda Tetreault, Amber Watson

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

NATIONAL ACCOUNT EXECUTIVES

Nicole Pizzi-Cerundolo npcerundolo@rockportpubs.com

978-921-7850, Ext. 160

Checking in with SEG looks into where we are in regards to fabrics and silicone edge graphic (SEG) frames. Manufacturers continue to advance the products, focusing on key features like stretch, opacity, and even sustainability. Backlit displays, trade show, retail—all environments benefit from this application.

Gathering information on printing processes helps print businesses make informed decisions. Collecting Data on Ink shares the various data points that can be tracked through ink management tools, either found on third-party software products or those embedded into the hard drive of a printer.

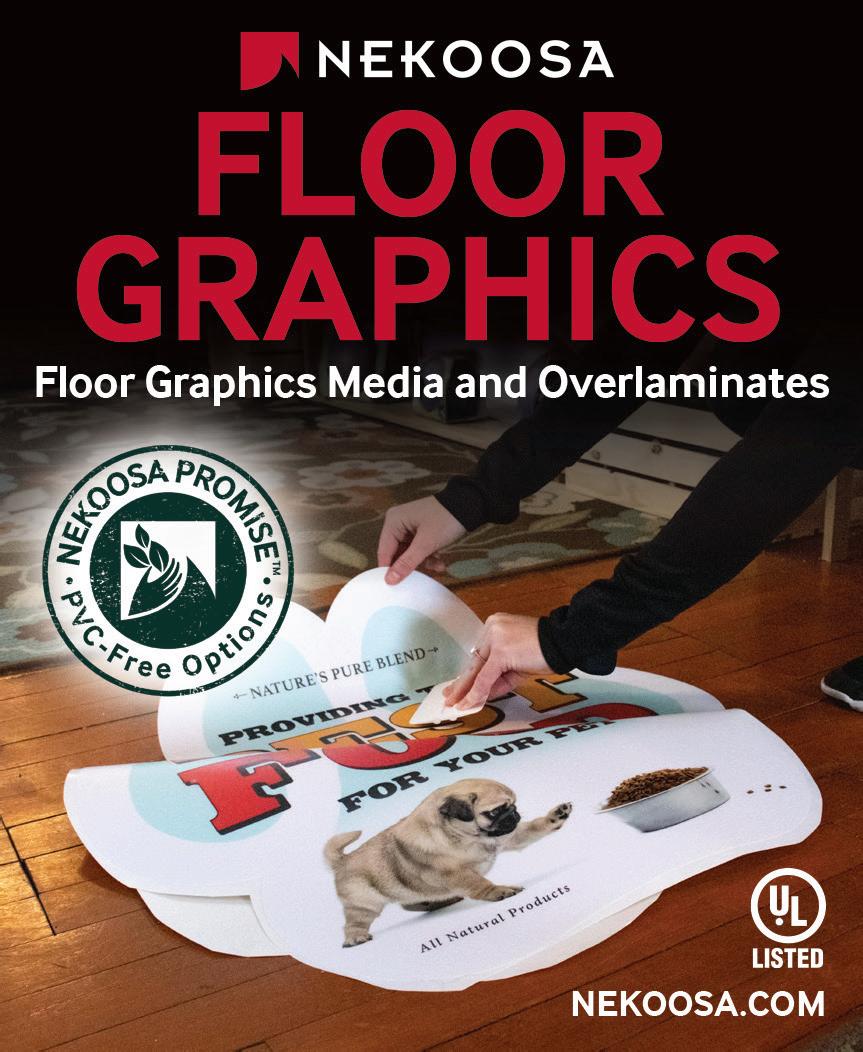

The edition rounds out with a chart detailing various floor graphic media options and a second look at the PRINTING United Expo in October.

Amanda Doyon adoyon@rockportpubs.com

978-921-7850, Ext. 170

Subscribe online at digitaloutput.net

CORPORATE & PUBLISHING OFFICE

100 Cummings Center, STE 321E Beverly, Massachusetts 01915

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

Digital Output is published monthly by Rockport Custom Publishing LLC. ©Rockport Custom Publishing, LLC 2023. Reproduction by any means of the whole or part of Digital Output without written permission from the publisher is prohibited. Views expressed in the editorial pages do not imply our endorsement.

Vendors: We welcome your product news. Include prices, slides, photos, and digital files with your press release. Please forward product samples and media kits to Reviews Editor, Digital Output, 100 Cummings Center, STE 321E Beverly, MA 01915. We cannot be responsible for unsolicited product samples.

SUBSCRIPTION RATES

U.S.: $82.95 per year; $165 for 2 years; single copies: $6.95; Canada and Mexico: $99.50 per year (U.S.D.); Other international subscriptions: $275 per year (U.S.D.)

POSTMASTER

Please send address changes and form No. 3579 to: Digital Output, 100 Cummings Center, STE 321E, Beverly, MA 01915. Periodical Class postage rates paid at Beverly, Massachusetts and additional mailing offices.

CHANGE OF ADDRESS NOTICE

Six to eight weeks prior to moving, please clip the mailing label from the most recent issue and send it along with your new address (including zip code) to: Digital Output magazine, change of address notice, 100 Cummings Center, STE 321E, Beverly, MA 01915. Attention: Circulation Department.

Rigid board, film, fabric, magnets, and more— materials collaborate to create the ideal POP display for any environment.

Best regards, Melissa Donovan, editor mdonovan@rockportpubs.com

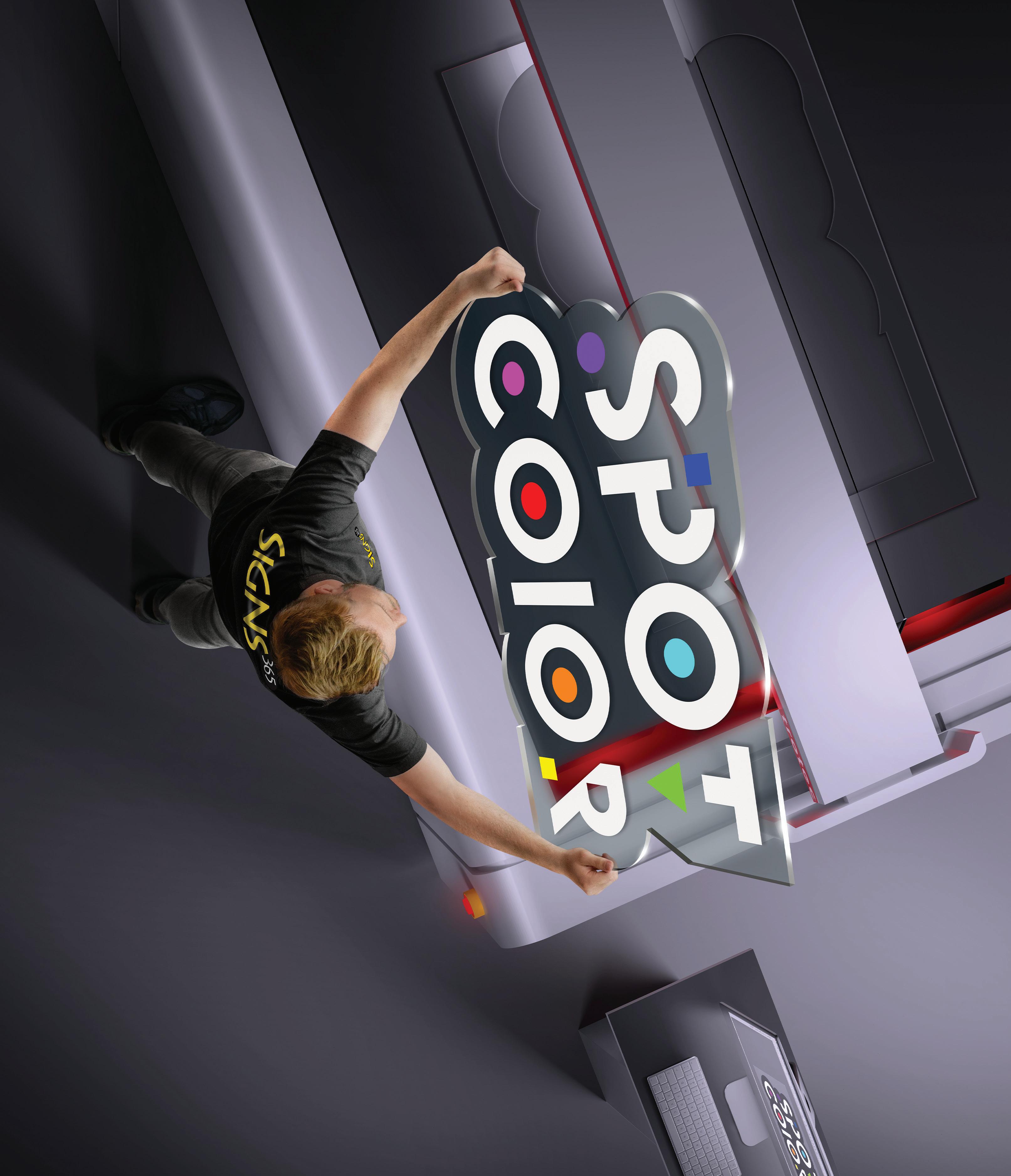

1) DGS, booth B15111, exhibits its BOARDers Rigid Board Finishing System, designed to build trade show booths, backdrops, and POP displays using half-inch substrates such as Falconboard, Fomeboard, and Ultraboard. 2) EngView, booth B11097, presents its EngView Packaging Suite, which is professional software for structural design and preproduction of boxes and displays.

With PRINTING United right around the corner, we asked vendors in the wide format digital print space to share their plans for the show. Be sure to check out our September edition for information from additional exhibitors not featured here.

Advanced Greig Laminators Inc. (AGL), booth B10033, displays the Patriot laminator. Productive tools found on the machine include cantilevered air shafts facilitating faster roll change outs of both supply shafts as well as the product wind up location. An unwind slitter to match up the width of laminate to the width of media for more efficient use of laminates is featured. AGL also displays its latest addition to the Print Smart media line of products. This media incorporates a bright white matte finish with an air egress liner and provides a high white point blockout feature. A heat and humidity resistant backer prevents media curling. INFO# 180

AFFORD, booth B12106, exhibits its range of digital printing inks. With a focus on its play-and-plug solutions

for direct to film, eco-solvent, and UV-curable printers, AFFORD shows its portfolio including chipped cartridges, bags, and bottles. A range of screen printing inks, pad printing inks, UV flexographic inks, and UV varnishes and coatings are also displayed. INFO# 181

ASLAN, booth C2461, highlights the glittering film SparkleColour ASLAN SC 123, the flocked decorative film CaressColour ASLAN CC 124, and the protective laminate MagicProtect Matt ASLAN SL 99 with its unique spray paint-repellent and anti-sticker surface. INFO# 182

Caldera, booth B17119, presents PrimeCenter, a powerful prepress solution designed to optimize job preparation for digital printing and cutting. Job preparation and prepress play a critical role in ensuring the quality and consistency of the final output. Automating repetitive tasks such as preflight, nesting, and adding cut marks and annotations guarantees less bottlenecks, and significant time and media savings, and increased productivity. Optimize job preparation to save time, reduce production costs, and focus on added-value tasks with Caldera PrimeCenter. INFO# 183

Canon U.S.A., Inc., booth B4033, showcases the Colorado M-series with UVgel white ink as well as the versatility and efficiency of the imagePROGRAF printers. Explore the Arizona 2300 XTF flatbed printer equipped with FLOW technology and wrap up with a dive into the latest advancements of PRISMA workflow solutions, designed to help users optimize digital printing and large format processes and help elevate your print services. Engage with Canon’s industry experts, who are eager to share their insights and help you learn how to use Canon solutions to help elevate your business. INFO# 184

Colex, booth B11113, demonstrates the Colex Sharpcut SXC1732 with Colex Cut Center 8 Production Automation offering versatility and increased productivity. The full line of Fotoba X/Y Cutters capable of cutting a 150foot roll in under ten minutes, the Bubble Free Application Table, and Roll Laminators are also demonstrated. INFO# 185

DGS, booth B15111, exhibits its BOARDers Rigid Board Finishing System, a proprietary product designed to build trade show booths, backdrops, and point of purchase (POP) displays using half-inch substrates such as Falconboard,

Fomeboard, and Ultraboard. The system includes different shape connectors and trims to cover exposed edges for a professional finish as well as two types of Standee Bases that hold halfinch boards up to 96 inches high. DGS also presents BEEngo! Rigid Board Design Library, a comprehensive portfolio of structural designs such as trade show booths, backdrops, POP displays, and furniture. Each design provides material count, artwork instructions, pre-mapped Sketchup render, cut files, and assembly instructions. INFO#186

DuPont, booth C553, demonstrates Artistri digital inks, which combine DuPont proprietary dispersions, polymers, and ink formulations for the most innovative digital inks in advanced printing. From the brightest and richest colors to custom formulations, Artistri provides color consistency across production runs and over time. And with an over 30 year

history in technology and innovation, DuPont Artistri delivers an innovative portfolio of ink products to bring your colors to life for direct to film, direct to garment, and roll to roll.

INFO# 187

Durst, booth B11033, showcases its comprehensive Production Excellence solutions. Offerings provide end-to-end coverage of the entire printing production process. It has a selection of innovative printing systems, with the most productive roll-to-roll printer on the market making its North American debut, and advanced software solutions, demonstrating full coverage “From Pixel To Output.” INFO# 188

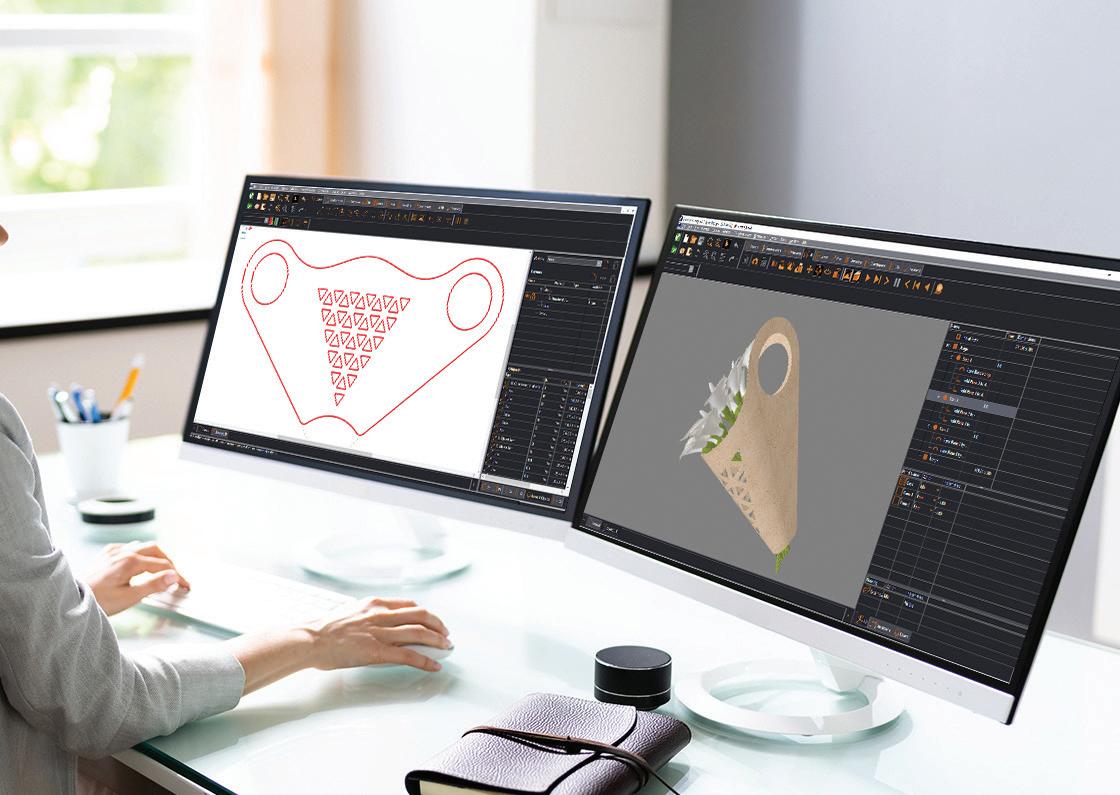

EngView, booth B11097, presents its EngView Packaging Suite, which is professional software for structural design and preproduction of boxes and displays. Its range of tools speed up and automate the day-to-day jobs of structural and graphic designers, diemakers, and salespeople. The software functionalities facilitate the entire process of two-dimensional drafting, three-dimensional modeling, real-time graphics visualization, and preparation for optimal production. INFO# 189

Epson, booth C2847, shows solutions ideal for a variety of applications—indoor and outdoor signage, photography, graphics, and textile. With the theme of “Seventy 5 Video Arcade,” the booth offers visitors the opportunity to play classic arcade games, drink free coffee, see live demonstrations, and get a preview of new technology. Attendees can score first-hand experience with wide

format solutions, view print samples, and speak with product experts. As part of its product demonstrations, Epson shows the new SureColor F2270 hybrid printer purpose-built for both direct to garment and direct to film. INFO# 190

Fisher Textiles, booth C2615, debuts GF5600 Raw Canvas, GF5020 Gumbee, ET9118 WhiteOut, and GF8819 DS Nirvana. GF5600 Raw Canvas is a 100 percent cotton canvas with a natural beige finish and is ideal for banners, retail displays, and home furnishings that require a natural look and feel. GF5020 Gumbee is a stretch fabric with near equal stretch and an excellent white point. ET9118 WhiteOut is a printable blockout with a face made from 100 percent post-consumer recycled polyester and a coated back for opacity. GF8819 DS Nirvana has a unique construction with two layers of GF4019 Nirvana black-back laminated together for extreme opacity. INFO# 191

Flatbed Tools, booth B8105, provides a compelling alternative to current service providers. Experience substantial savings on essential consumables such as blades, bits, and belts. The company’s cutting-edge products are engineered for efficiency, durability, and cost effectiveness. Flatbed Tools can elevate production capabilities while reducing your operational costs. INFO# 192

General Formulations (GF), booth C2567, invites attendees to come kick around ideas and have the GF team field questions

about solutions designed to meet your graphic needs. Learn wrap techniques from a special guest

installer, stroll along its floor graphics options, and engage with active demonstrations designed

to help pick the right material for your applications. Also learn why semi-rigid films are

Printing ADA compliant Braille signage with a Mutoh UV LED printer is a great way to increase profits. Mutoh is the only printer manufacturer legally authorized to offer UV LED printed ADA compliant Braille signage using DCS’ patented intellectual property. Don’t be caught violating those patents by using an unauthorized printer.

Don’t let other printer manufacturers blindside you into thousands of dollars in legal fees by violating those patents. Request a print sample from the XpertJet 461UF and XpertJet 661UF printers today. INFO# 215

Newlife introduces the only printable magnet sheet that is currently HP Certified for Indigo presses (RM-ART20). Our new HP Indigo certified sheets are designed especially for the HP Indigo Presses. Newlife premium Press Mag (IM-IP16M) magnet sheets can be printed Indigo, UV offset, and on most dry toner machines. Press Mag has a photoquality PP print surface, is PVC free, and will stack and cut easily. We offer both pre-magnetized and non-magnetized solutions as well as magnetizing equipment to magnetize post-print if needed. INFO# 216

NEPATA converting centers are the most successful and widely used converting centers worldwide. Engineered and manufactured in Germany to the highest quality standards, NEPATA converting equipment utilizes the latest in computer numerical control technology resulting in unprecedented control and accuracy over the converting process. NEPATA converting centers deliver precise material cuts, highly accurate rewinds, and advanced inventory control, allowing for quick delivery times across a range of media. For more information visit supply55.com, call 734-668-0755, or email sales@supply55.com. INFO# 217

AquaFlex is a digitally-printable waterproof substrate designed to brand and advertise in pools, ponds, water features, and aquascapes. It’s perfect for anyone looking to make a big impact with their marketing in new and innovative ways! AquaFlex is easy to install and position by hand or with a pool brush without draining water and is engineered to lay flat and remain in place without tape or adhesive. Plus, the material’s blue backside is made from recycled industrial pool liner and made in the U.S. To request a printed sample of this unique substrate, visit ultraflexx.com. INFO# 218

a money saver for your shop, why textured surfaces require special handling, and explore a broad pallet of products for walls, windows, floors, and beyond. INFO# 193

Hasler Cutting Systems, booth C3105, announces a five-meter wide digital flatbed XY cutter, equipped with the latest Optiscout software, delivering unparalleled quality, versatility, and affordability. Optiscout software empowers users with advanced capabilities for precision cutting, ensuring optimal results for a diverse range of materials and applications. INFO# 194

Jessup Manufacturing, booth B10034, features a range of graphics media products, with ARMORLam 15 taking center stage.

ARMORLam 15 is a crystal-clear overlaminate that enhances the durability and vibrancy of prints, leaving a lasting impression. But that’s not all—explore non-slip materials, designed for safety and performance in various applications. Plus, discover its selection of safety signs, crafted to meet industry standards, and ensure workplace safety. Additionally, be sure to inquire about Jessup’s unique Solve+Make process, allowing you to customize materials to meet your specific needs. INFO# 195

Kornit Digital, booth C1322, demonstrates how its solutions continue to validate market readiness for mainstream, digital on demand production. Driven by requirements for accelerated timeto-market, agile inventory management, and sustainability—more

fashion and apparel brands and retailers are digitally transforming their analog supply chains with on demand solutions. At the event, Kornit highlights its Apollo high-throughput system for digital, on demand decoration at scale alongside the Atlas MAX POLY direct to garment system for polyester. INFO# 196

Lintec, booth C3322, debuts two new products. The first is a 2-mil optically clear, polyesterbased window graphics film compatible with latex printing. This material has been tested thoroughly and wet installs with no ink scratching or defects. The second product is a 2-mil scratch resistant, printable, optically clear window graphic film for UV printing made with 100 percent recycled content, water bottles.

Samples of both products are available at the show. INFO# 197

LogoJET , booth C2319, highlights its direct to object UV printers. Visitors can experience printing demonstrations, conversations with experienced technicians, and an up-close view of LogoJET’s newest technology. Watch digital customization come to life with UV printing on the LogoJET R-series and new Strata series. INFO# 198

Mactac, booth B9113, debuts its application-based brand platform, including refreshed product identities and logos, easy-to-use product guides, and selection tools. Mactac and Spinnaker experts are available to educate show attendees on new and updated products, such as Printvinyl Scored and Windowview, as well as share their secrets for the seamless installation of top-selling Mactac solutions. INFO# 199

Mimaki USA, Inc., booth C2831, showcases the new UCJV330 Series cut-and-print UV LED rollbased printers for signage and graphics applications. Key among its features is new technology that reduces color irregularities in high-density areas even in high-speed mode. It also features clear inks that can create textured surfaces and supports five-layer printing. Additionally, the new TxF300-75 direct to film printer for textile heat transfer applications adds a second printhead to increase print productivity by up to 300 percent. INFO# 200

Mutoh, booth C2047, exhibits its latest innovation, the XpertJet #9

1462UF. Building upon the success of the XpertJet 661UF, this UV LED flatbed printer is designed to take productivity and print quality to new heights. Joining it will be the XpertJet 461UF and 661UF printers. Keep a look out for the eco-solvent Pro Series line. The XpertJet-1641SR Pro, dubbed “The Wrapper’s Choice,” showcases its features and the value it can add to your shop. For dye-sublimation enthusiasts, Mutoh has you covered with the XpertJet 1642WR Pro. INFO# 201

PrintFactory, booth C2518, shows its comprehensive software ecosystem, tailored to revolutionize large format printing. With a rich history spanning over 30 years in the industry, PrintFactory is attuned to the challenges faced by printing professionals. Unlike conventional RIPs, PrintFactory offers more than just the basics. It represents a software ecosystem that envelops every facet of the printing workflow, from initial design to the final delivery, all within one seamless package. INFO# 202

Ricoh Graphic Communications, booth B1916, invites attendees to immerse themselves in Ricoh’s TMI is BEAUTIFUL art gallery, featuring museum-quality prints created by a diverse group of emerging and established artists and produced using Ricoh’s printing technology. Surrounded by the art installation, the new RICOH Pro C9500 and RICOH Pro C7500 are showcased alongside the EFI Pro 30H. INFO# 203

Roland DGA Corporation, booth B13071, highlights the LG and MG series UV printer/cutters and the

new AP-640 Resin printer, which join VG3 and SG3 eco-solvent inkjets in the TrueVIS family. Also on display, VersaOBJECT CO Series UV printers, VersaSTUDIO BN2 Series desktop printer/cutters, and the VersaSTUDIO BN-20D Direct-toFilm System for apparel customization. Innovative LEF2 benchtop UV printers and the high-productivity IU-1000F UV flatbed are on display as well. INFO# 204

SEI Laser/Matik, booth C2811, invites attendees to see innovative lasers in action. SEI Laser’s X-Wave Conveyor is the fastest professional laser system for precision cutting of organic and technical fabric rolls. It has a maximum width of 5.25 feet and is the ultimate solution for manufacturers of textile products for a range of applications. X-Wave offers cutting

speeds of up to 13.125 feet per second. Featuring user-friendly control software, X-Wave delivers precise and controlled fabric handling. INFO# 205

Showdown Displays, booth B9007, features top-selling products from many of its major product lines including table covers, banner displays, flags, floor displays, and signage. Don’t miss the expanding line of silicone edge graphics, framing out the back of the booth. As the global leader in lightweight, portable signs and displays it makes it easy for trusted partners by offering no minimums, fast delivery, and innovative solutions for any portable display opportunity. INFO# 206

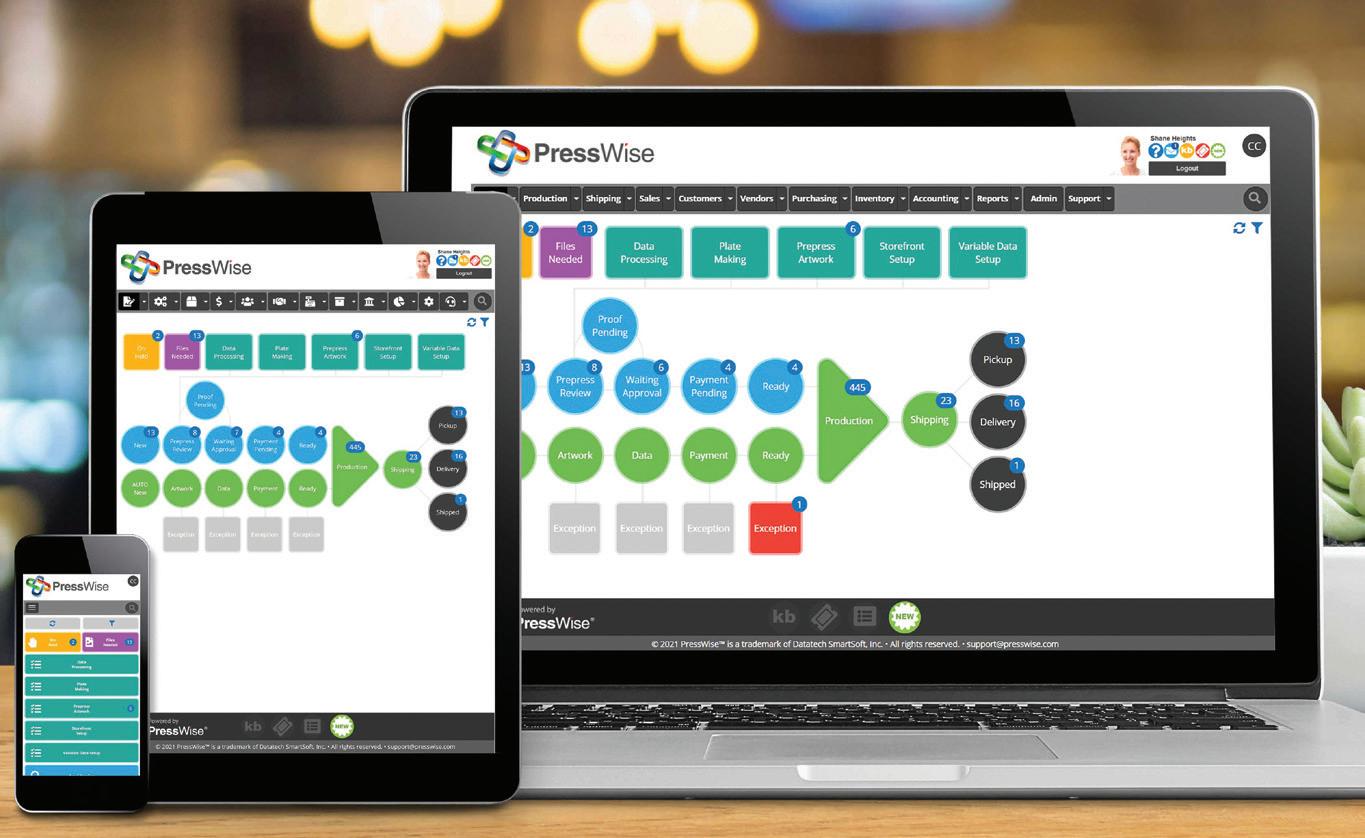

SmartSoft, booth B2951, shows the latest updates to PressWise,

its all-in-one print MIS, web storefront, and print automation platform. This includes an all-new integration with PlanProphet, the CRM platform tailored to the print industry that provides your shop with marketing and customer experience automation to grow and manage your sales funnel. The PressWise team also shows numerous other enhancements made to the user experience throughout the platform, including enhanced security features for credit card processing and email handling. INFO# 207

Tekra, a Mativ brand, booth B8053, is “cinema themed” this year to highlight solution-based medias, light management films, and a vast diversity of market genres. Whether solving a mystery in its R&D lab or highlighting performances with an A-list cast of top performing vendors, Tekra is sure to stop the show. See featured presentations at the expo, which include JetView Backlit films, LEXAN light diffusing options, adhesive bonding solutions, Loctite series inks, Dura-Go print receptive substrates, and see which new polyester film Tekra is rolling next. INFO# 208

Ultraflex Systems, booth B10019, exhibits frontlit banners, backlit signage, flooring solutions, and wallcoverings. Sustainable solutions, including the EcoVantage Line, a range of PVC- and phthalate-free as well as eco-conscious materials, are featured. VorTex Transfer Paper is a dye-sublimation transfer paper designed to create superb graphics by providing exceptional transfer yields, high ink release

efficiency, and remarkable color retention. VorTex Soft Signage are application-driven fabrics and textiles designed for optimal print performance, including the new VorTex Stretch Eclipse D250, a black-backed blockout with stretch. Decor Solutions include Floorscapes floor media, Wallscapes wallcoverings, and upholstery material. INFO# 209

Vanguard Digital, booth B11049, showcases the diversity of its portfolio, bringing a solution for every print service provider, and also unveils its latest, most stateof-the-art flatbed printer. Stop by the booth to see how Vanguard can help by Growing Your Business Together. INFO# 210

Vision Engraving, booth C2336, displays its 2x4-foot 25 Series CNC Router/Engraver and Express Small Engraver. The 25 Series Router has multiple options making it a highly versatile machine. Options include an automatic braille inserter, oscillating knife, and DACS print-to-cut. The Express Small Engraver fits on most countertops and is ideal for sign shops with limited space. Make a variety of signs with Vision’s machines including dimensional letters, print-to-cut, braille, and other signs. Work with Dibond, Coroplast, metal, wood, and plastic. INFO# 211

VTX Tools, booth B9041, shows its line of premium performance carbide router bit and blade tooling as well as its cutting table vacuum underlayment, VTXtra Grip. One of its most popular products is the 500 series of rainbow diamond-like carbide-coated

router bits, which provide longer running life in many denser and/ or harder materials. The product line consists of knife cutting blades, router bits with optional stop rings, coated router bits with optional stop rings, cutting table underlayment, cutting table conveyor belts, and cutting table accessories. INFO# 212

Vycom, booth B9073, works with select exhibitors to recapture materials before they end up in a landfill. The Vycom Recycling Program is designed to take back and recycle printed and unprinted rigid PVC and acrylic sheets, as well as scraps and drops from finishing and fabricating. Sign shops and print providers using these materials in their projects are invited to stop by the Vycom booth to learn how to take advantage of this program. INFO# 213

Zund America, booth C2627, introduces Q-Line, the new and advanced, 4th generation of Zünd Digital Cutting Systems. The Zünd Q-Line with BHS180, UNDERCAM scanning, and fully automated tooling system is geared towards packaging and display manufacturers. It offers the latest in advanced, highspeed digital cutting technology for completely automated, non-stop, pallet-to-pallet industrial production. Also featured are Zünd Gen3 cutting/routing systems, configured for different applications. INFO# 214

This October PRINTING United takes place October 18 to 20, 2023 in Atlanta, GA at the Georgia World Convention Center. D

ilicone edge graphics (SEG) are a trendy and efficient display option, well suited for retail, trade show, and event marketing.

Fabric manufacturers and distributors continue to create materials that support SEG, incorporating features like stretch and recyclability.

For fabrics utilized in SEG, the most predominate requirement is stretch, followed by opacity, and sometimes sustainability.

“The best SEG fabrics will feature stretch, opacity, good white point, and for retailers—recyclable fabrics,” states Ken Bach, business development director, CleanRTex, by Aberdeen Fabrics.

“Stretch is an important feature of SEG fabric because it must have just enough, and not too much, to give a tight fit in the framing system, while also maintaining a clearly visible printed image,” comments Sharon Roland, director of marketing, Fisher Textiles.

She adds that a tight fit is key in keeping the desired aesthetic of the frame, with crisp, clean lines. “Loose or ill-fitting fabric does not have the same effect.”

Steve Weiss, NA sales manager - sign, Serge Ferrari, agrees, noting that when it comes to SEG, features like stretch for ease of installation are essential. “Uniform shrink and stretch allows the printer to create the graphic to the correct end-use size. Furthermore, most professional printers now fit a graphic to the frame prior to sending the graphic out, which is important for an easy installation.”

Opacity is another feature to consider. “The fabric needs to have just enough opacity to not be able to see the frame through it. For backlit SEG especially there must be no pinholes or hot spots, where the light shows through,” shares Roland.

Wrinkle-resistance is important to ensure graphics can fold and ship in a box, versus on a roll to save on shipping costs, she adds.

Additionally, environmental demands play a role in customer requests. SEGs are known to be easy to change out, which Nova Abbot, head of marketing, Kavalan, says is even more impetus for switching to a sustainable textile solution. “Such high turnover of materials means more strain on the environment.”

SEG displays are known for versatility in terms of easy installation and low shipping costs. This makes them a popular option with retailers, from big box stores to restaurants, but the opportunities don’t end there.

Bach says SEG is used by anyone using backlit displays, as well as some trade show displays.

Following the pandemic, the return of events and conferences mean SEG continues to see a resurgence, adds Abbot.

“SEG continues to be very popular in the retail space. With competition always increasing, SEG provides a quick, easy, and impactful way to change out promotions and campaigns, which can be carried out by store employees rather than professional installers thanks to their user-friendly nature,” offers Abbot.

However, the potential does not end with retail and events. Abbot sees a growing opportunity in the hospitality space, including hotels and restaurants, where SEG are a great way to foster a connection between the visitor and the brand and

offer an easy way to add a “wow” factor. “As choosing a sustainable and environmentally responsible product or service becomes increasingly important to consumers, using a ‘greener’ textile solution for SEG hospitality displays can be a strong differentiator,” he offers.

While retail and exhibitions are primarily where SEG displays are used, Michael Crook, business development director, UFabrik says “stretch frames are starting to be utilized in commercial

interiors for elements such as single-piece wall graphics.”

Weiss says retail/point of sale (POS), trade shows, décor, and just about anywhere graphic advertising and branding are needed, SEG displays provide an excellent option. “The versatility, functionality, and customization make SEG the single most widely used textile system in the marketplace.”

Roland points out that trade show booths continue to be the

number one source for SEG, although retail stores, sporting events, concerts, banks, hospitals, car dealerships, as well as airports all are catching on to this trend.

SEG fabrics continue to evolve with advancements in textile manufacturing and the need to meet demands related to things like sustainability.

CleanRTex by Aberdeen Fabrics offers Aberdeen 6653+R100, which is made from 100 percent recycled yarn and according to the company the only graphic fabric manufactured without producing waste water thus not adding microplastics into the environment. Aberdeen manufactures its fabrics under the CleanRTex process, which according to Bach, is the most environmentally friendly process in the industry. “This fabric has the stretch needed for easy installations of SEG and is high opacity to block out the frame.”

Bach says the product was developed by the request of its customer’s customer, especially for retail displays. “Retailers

request green products that look good in their stores while being easy to install.”

Fisher Textiles’ newest SEG fabric is ET8050 Super Sonic Backlit, made with 100 percent post-consumer recycled polyester. It contains 48.7 recycled PET bottles (500ml) per linear yard and is a soft, sueded knit fabric that produces excellent vibrancy of print, amplified when backlit. The fabric weighs 7.7 ounce/ square yard, is stocked 126 inches wide, and is flame retardant (NFPA 701).

“This product was developed last Fall in response to the increased demand for sustainable print media,” offers Roland.

Abbot believes that Kavalan Moonlight River is a “revolutionary replacement textile signage banner that eliminates the dyeing and washing process, thereby reducing its overall freshwater usage by 67 percent.”

The high-quality, flexible material is well suited to both backlit and non-backlit SEG displays.

Abbot points out that textile manufacturing is a highly water-intensive process. “The motivation to develop Kavalan Moonlight River in 2018 was the need to address textile production’s impact amid an impending global water crisis—more than one billion people are currently without access to freshwater and known reserves of freshwater sources such as underground aquifers, rivers, and lakes will start to disappear by 2040.”

As with Kavalan’s full range of PVC-free banner solutions, Moonlight River matches traditional banners’ quality, durability, and performance, while being better for the future of the environment.

Serge Ferrari recently re-engineered its Seemee Select Blackback Premium to achieve an eight percent stretch. This change is designed to make it an easy to install blackback. Weiss says it is now the third highest-run fabric in the industry. “This fabric provides several improvements

to traditional blackback print fabrics, including a whiter print surface and better scratch resistance on the black backside.

It also provides excellent color rendering for dye-sublimation (dye-sub), UV, and latex prints,” shares Weiss.

New in 2023 is a re-engineered Greyback, a sister product to Serge Ferrari’s blackback as a blockout without a back coating.

Weiss says these products were developed as the company understands that to maintain a leadership role as a manufacturer of fabrics, remaining strong in

SEG fabrics for both frontlit and backlit is necessary.

“We started with soft and heavy knits as well as stretch and then developed our backlit for direct UV, direct dye-sub B4400, and transfer dye-sub B4420, which gives the customer added stretch for ease

of installation. We then developed our 3.2- and five-meter Seemee Select Zumba, a widely used fivemeter backlit seen in airports, retail malls, and major global events such as the Superbowl.”

The company listened to the market and feedback from its customers to guide its research and development efforts. “Stretch in Seemee Select Zumba and Seemee Select Blackback Premium were added as they’re critical to North America’s largest printers and installers,” says Weiss.

UFabrik Backlit ECO Textile is produced from 100 percent

recycled PET plastic bottle waste. Combined with traditional flame protection certifications, it is also REACH, Global Recycled Standard certified, and complies with California Proposition 65.

SEG remains a popular and effective display option. Its primary benefits include its propensity for easy install and change out. Due to the fabrics utilized in the process, they are also lightweight and cost effective to ship and travel with. Stretch, opacity, and increasingly, sustainability are core features end users are looking for out of SEG textiles. D

ingularly, any material able to be printed on a digital printer meets a print service provider (PSP’s) goals, and by extension their client’s goals as well. Thinking outside of the box by combining multiple substrates to create complementary applications can really make a brand standout.

This is especially the case for marketing campaigns in the display and point of purchase (POP) space.

Between rigid board, magnetics, and fabrics as well as vinyl and film, each substrate complements the other in

display and POP environments. Utilizing different materials in one marketing campaign creates multiple dimensions of texture and depth.

“Different substrates offer distinct attributes that complement each other and provide functional performance and aesthetics when used together as components in display and POP environments,” shares Jodi Sawyer, strategic business unit manager, FLEXcon Company, Inc.

Sawyer explains that many films can be dyed, brushed, laminated, printed, and applied to foamboard

or rigid styrene to help create displays that match the brand colors on the package container or label. A holographic/prismatic pressure-sensitive product or a reflective film can be laminated to a rigid substrate or banner to provide a look and feel that could not be achieved with direct print. Alternatively, they can be embossed, which offers different types of texture and a tactile feel for displays.

Note, multiple substrates also means multiple applications. In retail especially, shoppers are inundated with all types of messaging. “One effective way

to achieve top-of-mind awareness is to utilize multiple forms of signage with overhead, shelf level, display cases, and floor graphics. This approach delivers high awareness per shopper with quick repetition of impressions for each graphic in a space that literally grabs their attention,” explains Micah Causey, VP, FloorSignage, LLC.

An example of multiple applications in action, “window films that get the customer’s attention at the door or from the parking lot. This is often unconsciously noticed, but the message is still carried as the customer walks

through the store. This is then reinforced with in-store POP graphics,” shares Aaron Vananda, supply chain executive North America, Newlife Magnetics LLC.

“Different substrates such as printed wall graphics paired with channel letters or LED TV screens really complement one other to create an eye-catching experience for the customer. The wall graphics set the overall tone or feeling of a space, while channel letters or TV screens convey additional information and messaging,” says Amanda Lowe, global marketing director, Drytac.

Another illustration is a translucent fabric hanging in front of a rigid or flexible opaque printed

image—textiles work well with styrenes, PETG, Gatorfoam products, and others, suggests Hoddy

Peck, Southwest sales manager, Fisher Textiles. “In most cases, the complementary nature of the wide

format substrates takes advantage of the differences between them, while drawing on the strengths of each. Some feature contrasts might include rigid versus flexible, translucent versus opaque, backlighted versus reflective, shapeable versus geometric, and stretched versus flowing.”

“Combining substrates in display and POP environments offers a compelling advantage by providing visual contrast, customization options, and flexibility,” adds Roy Ritchie, president, DreamScape.

Merging multiple substrates together creates dimension. “Each company’s offerings are unique, so by incorporating different thicknesses, materials, and offerings, you can make a

display with multi-level colors and dimensions. The display then doesn’t become one dimensional but more defined and eye appealing,” shares Tim Witucki, senior account manager, Panel Processing, Inc.

“A flat display or a standalone sticker might be enough to get your message across, but mixed media and depth can truly make your promotion stand out. Add to those layers with different print films, mixing matte and gloss, plain and a rainbow holographic material for accents, chalkboard vinyl or dry erase sections for handwritten daily specials,” suggests Jay Kroll, product manager for cut, transit, and wall solutions, General Formulations.

A successful marketing campaign pops in a crowd. “Carefully selecting and combining substrates creates a diverse range of visual effects, textures, and functionalities that produce more engaging and effective displays that leave a lasting impression on customers,” says Aarona Tesch, product marketing manager, GBC, an ACCO Brands Company.

“Combining various substrates and applications within a display or POP can really grab the consumer’s attention, which is the best way for a campaign to provide the desired results. In a crowded retail space, displays that stand out are the key to success,” advises Becky McConnell, marketing manager, Durst Image Technology.

Multi-faceted marketing campaigns with multiple digitally

printed substrates are common in certain environments over others. Today, we see them used more often due to advancements in print technology.

Kroll seees these types of campaigns in movie theaters, specialty retail, and high-end brand displays. “There are pockets of popularity with these types of displays, but their complexity for both print and assembly, and the subsequent cost to produce, make them less common for commodity applications. The quantity is likely lower, the cost threshold a little higher, and there is a built-in expectation that the final presentation will create a sense of space with the display of brand messaging.”

Transit advertising also benefits. Also referred to as station domination, “this is when a brand secures all of the advertising inventory at a rail or bus station, which may include display boards, column wraps, and floor graphics,” notes Causey.

Tesch believes more people turn to campaigns in display and POP with multiple substrates because of advancements in digital print technology. “It allows for more cost-effective and efficient production of a variety of substrates. This includes not only paper but fabrics, plastics, and vinyl.”

“Multi-faceted campaigns with multiple digitally printed substrates are growing due to advancements in printing technology, enhanced personalization, flexibility, brand differentiation, and the need for omni-channel marketing. The utilization of

multiple substrates allows for brands to be more creative when designing custom environments that align with their unique identity and cater precisely to their target audience,” explains Ritchie.

Sawyer credits growth to the pandemic as well. “The demand for social distancing graphic kits gave PSPs the opportunity to work with multiple substrates and materials they may never have worked with in the past. Narrow format label printers who were accustomed to printing on paper were printing floor and counter graphics on pressure-sensitive film products. PSPs specializing in vehicle wraps and commercial printers, for example, were partnering with metal and plastic fabricators to provide digitally printed hand sanitizer stations or with dyesublimation (dyesub) printers for textile banners and soft signage.”

“Most wide format printers that have

been routinely printing UV curing rigid or flexible substrates are being asked by clients about textile opportunities. This led to incorporating dye-sub textile printing

into their production capability in recent years. This is a reflection of the need for complementary substrates, in addition to the economy of one-stop shopping for the ultimate retailer,” says Peck.

After a brand owner executes a campaign of this nature, it’s

hard to go back. “Once a brand or retailer sees results from multi-faceted campaigns, I think it’s fair to say that they take advantage of similar campaigns in the future,” admits McConnell.

“Each brand has an advertising allotment and is unique in how they advertise. Some go out with a splash using extra-large building wraps or lit displays that make a Michael Jordan come alive. There will always be tremendous business for branding using fabrics, PVC, and mesh. Retailers may change, but someone wants the top billing,” attests Steve Weiss, NA sales manager/sign digital, Serge Ferrari.

Big box brands are prime contenders for multi-faceted marketing campaigns that leverage different substrates. However, small- and mediumsized businesses can also benefit from a multisubstrate campaign if it is executed appropriately.

In general, digital print media is advantageous for “a business looking to add flare and eye-catching graphics,” recommends Witucki.

Kevin Duffy, VP, sales and marketing, Vycom, believes “any size business can benefit from multifaceted campaigns. The beauty

of digital print is that there are no makeready minimums, and so many substrates are available now that short runs are within reach for small- and mediumsized stores.”

“Every retailer can take part in their own way. You don’t have to advertise in/like Grand Central Station to get noticed. Smaller can be big if it’s done right and in the customer’s vision/sight,” suggests Weiss.

A multi-faceted approach is used by small- and medium-sized businesses for the same reasons a big box brand would choose to use it—to effectively reach a target audience, differentiate from competitors, and create a memorable experience for the prospective buyer. To be successful, “the key is to understand their audience, tailor the campaign to their specific needs, and utilize the available resources and technologies to create visually appealing and impactful materials,” says Tesch.

“For small- and mid-sized companies without national brand recognition, customer acquisition and the cost to acquire each new customer is very important. This can be done with POP, large and grand format advertisements, along with digital marketing, and we are seeing a resurgence of mail out advertising,” notes Vananda.

According Ritchie, anyone benefits. “Big brands leverage larger budgets to create visually stunning displays and environments, while smaller businesses can also

stand out, connect with their audience, and adapt quickly due to accessible wide format digital printing technologies.”

While Causey says that big box brands utilize multi-faceted marketing campaigns with multiple substrates more often, “emerging new brands can strategically implement the approach for big bang impressions that will make consumers aware of their brand and products.”

Examples include “boutique local and regional retailers that offer private label brands for personal care, food, and beverage using multi-faceted campaigns—window graphics, banners, street side menu boards, vehicle graphics, and a host of other visual communications—to engage with consumers on the streets and in their neighborhoods,” cites Sawyer.

Peck doesn’t see business size as a driver. Instead, he notes that it’s all about how the project is implemented. “Effectively using multiple substrates and images in a retail environment requires some design expertise to make it work. Sometimes the merchandizer owns the design inspiration, but sometimes it’s embedded with the print producer who uses it as a selling tool for their team. In the best lasting relationships, the printer and retailer have a design partnership that works. In short, some of the most effective and creative uses of multiple digitally printed substrates have been in chains of less than ten stores.”

“Big box stores and smaller businesses benefit from multi-faceted

campaigns as many of the different substrates are obtainable from your traditional PSP. PSPs should educate customers on these applications as a way to upsell their services and offerings,” recommends Lowe.

At the end of the day, Kroll says it’s all about engagement.

“There’s an argument to be made that any increase in visibility or mindshare is going to ultimately benefit a business, providing that the message and delivery are done in such a way as to best engage with the audience. This would apply to businesses large and small.”

With the many materials available to PSPs, it can be overwhelming thinking of how to use them best. We asked vendors in this article to share a bit about their products.

DreamScape’s repositionable Wall+Floor Wrap products offer synergy with other materials, delivering efficiency due to ease

of installation and removal capabilities on walls, floors, counters, windows, ceilings, and fixtures. Additionally, a three-ply construction ensures durability and effectively conceals imperfections on the applied surface, providing a smooth finish.

Several Drytac media offerings work well with various multi-faceted campaigns. ReTac Textures adds depth and visual appeal to static, flat images with its embossed textured finish. With ReTac ultra-removable adhesive on the back, eye-catching graphics printed on ReTac Textures can easily be removed and repositioned multiple times without the worry of adhesive residue. The film is easily applied, removed,

and repositioned without surface damage or loss of adhesion.

Fisher Textiles offers numerous fabric types optimized for digital print. “Softer with better touch and feel; they complement retail apparel products. For example, a photo of women’s apparel in a store looks better and more realistic printed on textiles, then on plastic,” notes Peck.

FLExcon’s pressure-sensitive film products provide several benefits that enhance the look and performance of the finished graphic. Pressure-sensitive film laminations such as metalized polyester/vinyl can be laminated to a rigid plastic or foamboard to create a design component that

mimics the look of metal without the cost of using real metal and shipping a heavier display. Products like FLEXcon PRISMcal holographic films and FLEXcon SHIMMERcal glitter films, when laminated to rigid substrates, give displays and POP graphics functionality, light and movement, and aesthetics that stand out.

For large format print media like FloorSignage’s floor graphics materials, Causey suggests using the floor graphic substrate to lead the shopper from the parking lot, down the sidewalk, through the entrance, and directly to the display.

GBC’s media offering provides enhanced durability, protection from the elements, and a professional appearance, according to Tesch. The print media and lamination solutions work well with various types of digital print devices and enable businesses to create a range of laminated products tailored to their specific needs.

General Formulations’ array of adhesive-backed digital print media gives a flexible solution that can bridge multiple surfaces and substrates to bring cohesiveness to a display, tying in floor and wall graphics, or decorative film elements, into the final presentation.

Newlife Magnetics’ magnet is often applied to polystyrene and expanded PVC boards. This is then used to mount the magnetreceptive products as graphics.

Panel Processing’s rigid boards are environmentally friendly.

With a wood substrate and water-based coatings the consumer can dispose of the product.

It breaks down in the elements and/or landfill, as well as will not leave a footprint. The wood

With many display and point of purchase (POP) roll outs, packaging is part of the equation. It is important that the packaging is cohesive in the color/shade/hue with the rest of the brand messaging.

“Cohesiveness is very important,” attests Miguel Gonzalez, director of sales, Mutoh America, Inc. “When it comes to packaging. It’s not just about the name. The color/shade/hue is even more important. It’s not just red. It’s Coca-Cola red.”

One example, “microbreweries utilize multi-faceted campaigns with signage and product merchandising that matches their container labeling and promotes their unique brand style,” explains Jodi Sawyer, strategic business unit manager, FLEXcon Company, Inc.

Although, Becky McConnell, marketing manager, Durst Image Technology, points out that many times the packaging does not match the display in terms of color, graphics, etc. “Many retailers and brands don’t design new, cohesive packaging to meet brand messaging on the display, relying on the display to be the exciting part of the interaction with a consumer, whether that be stand alone or a shelf display. There’s no doubt that packaging specifically designed for a short-term campaign can be very attractive in a retail environment and drive interactions with shoppers, but there’s more risk in short-term packaging choices.”

substrate version is available in varying thicknesses and size offerings. “This gives the end user more choice when designing their display,” notes Witucki.

Serge Ferrari produces products for trade show, retail, and events as well as for solar protection, furniture, awnings, and tensile

architecture. Trade shows want cost-effective, crease-free fabric. Retail requests brilliant light boxes. Other markets look to technical aspects with warranties. “The application and the expectancy of each are critical to suggest the correct fabric. Further, knowing the theme can be critical when using a fabric with a rigid. Achieving the

special effect the customer and audience want is often what we try achieve,” adds Weiss.

Vycom’s Celtec rigid PVC material offers an extensive range of thicknesses, finishes, and colors. Signage specifications for a single retailer may include a lightweight substrate such as Celtec DigiLite PC for sectional signage, Celtec Thick Gauge PVC for display shelving, and Celtec Woodgrain PVC for a rustic appeal in a gardening area. “Rigid PVC is a primary signage material choice for PSPs that outfit large retail chains and big box stores due to its versatility and durability, along with its ability to be printed on two sides,” shares Duffy.

If print providers plan to offer multi-faceted marketing campaigns, they need to confidently output graphics to all media types, ensuring color matching across the different substrates.

It comes down to working with the right combination of hardware, software, media, and ink. “PSPs that have a handle on color matching across substrates and devices have perfected this for years, and as a result, many printer, ink, and software developments certainly changed how and how easily this can be achieved. Relying on recommended and approved inks is a critical component to

4)

achieving color matching, and many software tools allow PSPs to take the guessing out of color results,” explains McConnell.

Intelligent printing technologies are helpful here as well. Features like optimizing printheads by arranging the dots in a way to take into account how they look to reduce banding for smoother print images is one example, shares Miguel Gonzalez, director of sales, Mutoh America, Inc. Other tools specific to Mutoh are Local Dimming Control, which allows the user to control the density of the UV LED lights on printers and DropMaster 2, which automates work once completed by visual confirmation and manual print inputs.

With multiple materials at a PSP’s disposal, there are endless possibilities for display and POP campaigns. That being said, it’s important that the PSP’s team is capable of executing this approach.

“It takes savvy design skills combined with a solid knowledge of available materials and substrates to put together a cohesive package that enhances the visual appeal of a POP display,” cautions Kroll.

According to Peck, “the best print salespeople listen to their clients and prospects and use material variability and complementary nature to provide unique and interesting visual solutions for retailers.”

Learn more about multi-faceted marketing campaigns in a recent webinar on digitaloutput.net. D

RIPs and other workflow tools capture data on ink usage and consumption for today’s wide format print providers (PSPs).

Ink data from workflow tools can confirm a print job’s profitability and determine pricing on new orders.

“Once they have enough historical data on ink usage, they can use that data to estimate costs on new jobs.

by Cassandra BalentineThis can help them be more competitive by not overcharging for ink use,” says Patrick Donigain, senior manager, marketing, Canon U.S.A., Inc.

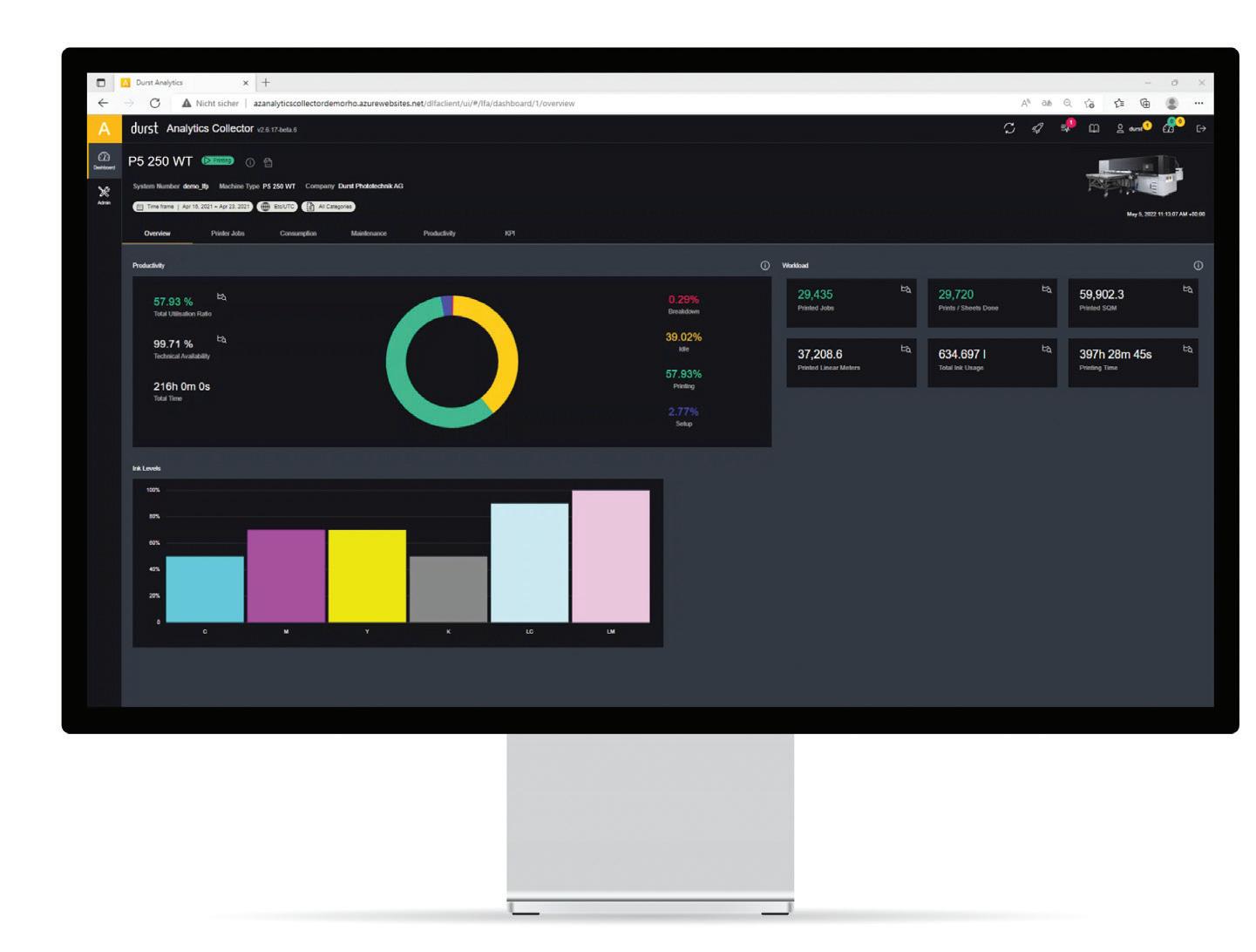

Dr. Jonathan Rogers, marketing, Onyx Graphics, Inc., agrees, adding that shop owners who can visualize and Above) ONYX Hub provides visibility into print production and cost data, including ink usage and media waste.

understand the story their print production data is telling them are able to answer questions such as “how much ink did I use?” or “what’s my media waste?” or more importantly, “did I make money on that job?” as well as identify areas for improved efficiencies internally or training needs of print operators.

Various data points are collected through ink tracking tools.

Donigain suggests one data point is the amount of ink used to print the job. He admits that waste ink is difficult to capture for many systems, especially waste ink that is used between jobs. “As a double check, many companies separately track the square feet printed on a printer and the volume of ink purchased for that printer. This method captures all of the ink used by a machine but doesn’t give you the granular per job data they are looking for. Data from either method usually gets boiled down to a milliliter per square foot number, which can then be easily converted into a cost per square foot.”

Canon’s PrintSight software collects and collates ink usage data from multiple devices. Configurable, it allows users to customize the interface and reports to meet their needs.

Mutoh America, Inc. offers software that collects ink cost and consumption as well as monitors ink levels and the system as a whole including smart cards and ink cartridge sensors, shares Emilio Rangel, product manager, Mutoh.

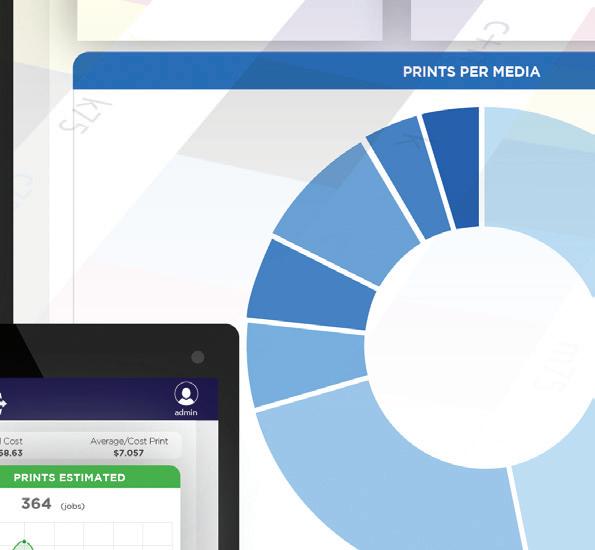

Durst Analytics is a web-based software tool that visualizes Durst printers’ data on a single screen, providing easy, interpretable data for data-driven decision making, reports Leland Morgan, North American product manager, Durst Software. The software starts with analyzing the print file and suggests proper settings to reduce the ink consumption, it then measures totals used, including waste.

Epson’s Cloud Solution PORT captures hundreds of data points on printers and their activity. “Each printer connected to the Epson Cloud Solution PORT will report the remaining ink levels, operation history, and current status, among many other items. For each completed print job, a user can see how much of each ink color was used, as well as the area of media and assign costs to that based on their purchase price to result in a bottom line cost estimate for a print job,” shares Eric Holm, associate product manager, Professional Imaging, Epson America, Inc.

If privacy is a concern, there are systems in place. Holm points out that Epson Cloud Solution PORT allows users to share job names, and includes a privacy option in case those names contain sensitive information. “No print job data is sent to the cloud in any way. In addition to using bank level encryption, putting these privacy controls in the hands of Epson users allows customers to see very rich and useful data while maintaining their privacy.”

There are a few ways to track and analyze ink usage in today’s wide format print environments.

In Rogers’ experience, software tools for print production such as RIP and print workflow solutions gather ink use information using a push and pull mechanism between the chosen print mode and data received back from the printer. “This combination provides ink usage data by printer, station, job, nest, or order. In addition, software solutions meant for business intelligence that connects—either natively or via API—and aggregates this data are presenting it in easy-to-consume and understand dashboards to help print businesses better understand ink use, ink waste, and media coverage.”

Donigain breaks down two ways to calculate data. The first uses an estimate created by a RIP. “This method can get you in the ballpark for ink usage but sometimes has some accuracy issues,” he explains.

The other method, according to Donigain, uses direct communication with the printer to report back exact milliliters of ink used, which is much more accurate. “Shop owners typically receive ink data summarized by month or year, which may show ink usage trends over time or just give them a total for the entire time period. Sometimes they find ink data summarized by machine useful to better understand machine usage.”

In the case of Epson Professional Imaging printer products, Holm

explains that the company once had a local PC software utility that would report ink and media usage after a print was completed, however this functionality has moved to its cloud service, which changes the game. “Having the data shared to your organization’s PORT account lets the entire team pool their data, enabling the big picture to be seen from one place—regardless of where the printers are located—as long as they are connected to the internet. It all happens automatically when printers are connected to the Epson Cloud Solution PORT. This allows printer operators to focus on production while managers can evaluate the entire organization’s cost, efficiency, and consumable needs. Operators get great features like a mobile application that provides virtually real time notifications of errors or job status.”

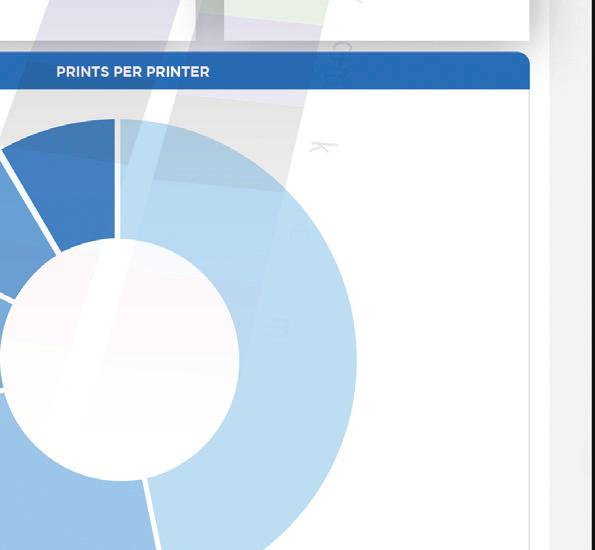

When a printer is connected to Epson Cloud Solution PORT, status data and print job meta data are sent up to the cloud. PORT then presents the historical usage data in a clean, easy-to-read operations dashboard. “Printers can be organized into custom groups and locations so that an organization can quickly focus on different sections and slices of their business. Users see what percentage and during what part of the day a printer, or group of printers, was printing or in a stand-by state,” says Holm.

Mutoh’s RIP software Vertelith along with its printer monitoring software Mutoh Status Monitor (MSM) has several tools included

that track and analyze ink usage, ink consumption, as well as ink cost per job.

With this solution, data is presented in the form of detailed print information analysis and associated charts and graphs through MSM, as well as per job ink usage and cost information in the RIP.

With Durst Analytics, data is collected on ink usage using the proprietary software, which is included in the hardware purchase. The information is then presented with an easy-to-read report that can be accessed at any time. Monthly reporting can also be automated directly from the software.

Measuring ink usage is one way to ensure it is managed correctly, saving time and money for both the PSP and its customers.

“The ability to collect accurate ink usage and cost data allows shop owners to optimize their operations, reduce costs, and improve efficiency,” shares Rangel.

Morgan says most PSPs review ink usage to determine how to reduce ink consumption on jobs, either by profiling or changing artwork for repeat jobs or in preparation for upcoming orders. It is also used for forecasting on orders or expected orders.

Shop owners use ink tracking data to indicate problems or as a tool to help with estimating. “Sometimes excessive ink use can indicate either the use of an ICC profile that has not been optimized or that a printer is not being maintained properly and is spitting excess ink during print jobs,” adds Donigain.

Ink data is also exportable to common formats (CSV, XML,

JSON) and imported into any other software or workflows that can make use of those formats. “For example, the savvy Microsoft Excel user could easily open the CSV and start manipulating the data they exported from Epson Cloud Solution PORT in ways that are more meaningful to them,” suggests Holm.

An enterprising manager with some scripting know-how could use JSON or XML in the same way. “This data is leveraged to gain insight into how an organization’s printers are used beyond guess work. If, for example, a shop with three printers can objectively see that printers are used every hour they are open, they can understand that they are at capacity and consider adding a fourth printer, or a second or third shift, to their operations,” continues Holm.

The ability to track ink usage is in demand.

Rangel says it was one of the most requested features when developing its software to give end users the details and data that can help them be the most efficient and cost effective on their end.

“In our opinion, modern print businesses understand the need for data to improve efficiency and increase profitability, and actively seek ways to access and understand their print production data to make better business decisions,” says Rogers.

“Job level ink and media accounting is often a requested feature, as well as customers having more data to optimize their business,” says Holm. “Users want to understand their cost to better understand their business overall and how they can optimize.”

Donigain agrees, noting that many print providers utilize this feature. “Understanding the cost stack of a job is key to staying in the black. Although for most graphics jobs ink makes up a small percentage of the job’s overall costs, with media costs being up to 20 times higher than ink costs, ink is still an important component and one that can be optimized.”

Relative to ONYX software solutions, Rogers says one tool that connects natively to its RIP and Print Workflow solution ONYX Thrive is its business intelligence tool ONYX Hub. ONYX Hub provides site-wide visibility into print production and cost data, including ink usage and media waste that is presented in dynamic, easyto-understand dashboards and reports. Print business owners and product managers can track and analyze data by printer, station, or job with live, historical, and trend reporting. Because ONYX Hub connects directly to the RIP, station data is easily imported, which reduces set up time and ensures no loss of print production data.

Access to production data points like ink usage are helpful for businesses looking to optimize production. A variety of tools— from the RIP to production workflow—make this a possibility. D