On the Front Lines Trade-Only Wholesale Printers

by Digital Output Sta

Trade-only wholesale printers are out on the front lines, working with fellow print service providers (PSPs) to craft a variety of applications. They are some of the most knowledgeable folks to discuss application trends.

Top Applications

According to Keoni Denison, CEO, Capital Wraps, top applications going in and out of its main facility in Raleigh, NC include banners for buildings, architectural graphics, commercial signage, and event signage—in addition to its main service, vehicle wraps.

Capital Wraps has grown over the years with talented designers, experienced installers, and top-of-the-line equipment. It offers knowledgeable customer service representatives dedicated

to the success of your vehicle graphic wrap. Vehicle graphics expertise includes NASCAR, ARCA, numerous local events, and thousands of satisfied customers that have purchased elevator wraps, car wraps, murals, event graphics, building banners, and numerous other large format projects.

With a multitude of offerings, managing client requests and prioritizing jobs is a challenge. Capital Wraps has a “team who manages the offerings to understand what the client wants, and prioritizes based on delivery dates and complexity and requirements of the jobs,” shares Denison.

Throughout the year, application demands may change due to upcoming holidays, school events, political season, and weather conditions.

— Grant Waters, operations manager, Supreme Color

Supreme Color Graphics, LLC, located out of Mandeville, LA, is another trade-only wholesale provider that offers a wide breadth of services—from yard signs to crafting

1) Capital Wraps of Raleigh, NC offers knowledgeable customer service representatives who are dedicated to the success of your print job. 2) Supreme Color, located out of Mandeville, LA, offers a breath of services—from yard signs to crafting custom and distinctive signage that requires cutting, routing, and specialized finishes.

custom and distinctive signage that requires cutting, routing, and specialized finishes. The company is known for working with customers to source the right substrate if it isn’t in stock. As such, clients rely on Supreme Color for speed, support, and a variety of product offerings at a great price.

Out of the many products it offers its growing client base, Grant Waters, operations manager, Supreme Color, notes yard signs and banners are top application requests. Yard signs are popular due to “the simplicity of production and temporary nature, often eliminating the need for sample proofs,” according to Waters.

Banners are also frequently ordered because of “the versatility of options and multiple applications, like yard signs, they offer an affordable way to inform and engage large audiences,” continues Waters.

As its name might imply, Yard Sign Ninjas’ most requested application is corrugated plastic yard signs. According to Jeff Hartman, CEO, Yard Sign Ninjas, the popularity stems from their superior quality, weather resistance, and competitive pricing, making yard signs a go-to solution for campaigns, promotions, and events.

With over 20 years in the signage market, Bettendorf, IA-based

Yard Sign Ninjas stands out from the competition for its top-quality materials, digitally printed signs, and fast turnaround times. The company combines expertise and efficiency to empower its partners to thrive in the competitive signage industry.

“We manage client requests on a first-come-first-serve basis for regular jobs, with three rush service options available to handle urgent orders without compromising quality or turnaround times,” says Hartman.

Ebbs and Flows

Trade-only wholesale printers handle a range of products on a daily basis. That being said,

top applications may change throughout the year.

Seasonal requests are common. At Yard Sign Ninjas, Hartman says “polybag signs, for instance, are particularly popular during political seasons due to their cost effectiveness for high-volume, short-term campaigns.”

“Throughout the year, application demands may change due to upcoming holidays, school events, political season, and weather conditions. The demand for yard signs and banners, our top application requests, stays fairly constant, but experiences a noticeable surge at certain times of the year,” shares Waters.

To keep up with fluxuations in demand, Supreme Color operates by assigning dedicated customer service team members to each project. This is also because most of the trade-only printer business involves custom projects—the procedure allows team members to manage unique requests effectively.

Focused on Science and Engineering

Newlife Magnetics is the world’s largest manufacturer of flexible magnetic materials. Our company’s focus on science and engineering has led to our success in leading the magnet industry through research and development of exciting new products that solve customer problems, increase efficiency, and improve our customers’ lives without harming our environment. We currently offer the thinnest, widest, lightest, and strongest magnetic materials on the market. Do you need a fresh way to display your graphics? Give our new Retail Pro a shot. Visit newlifemagnetics.com for more information. INFO#10

Finishing Simplified

Engineered and manufactured in Europe, the KalaXY Cutter/Trimmer reduces labor and increases profits by eliminating the time-consuming task of manually cutting printed digital images. Our line of automatic XY cutters is the ideal solution for processing a range of media including wallpaper, paper, direct to film, canvas, laminated/encapsulated films, banner material, polycarbonate, and other non-woven roll goods. Increase your output while reducing operation costs with KalaXY Cutters. For more information visit supply55.com, email sales@supply55.com, or call 734668-0755. INFO#11

“Our job prioritization is centered around meeting the customer’s specified in-hands date, and we strive to accommodate special requests as best as we can,” adds Waters.

More to Look For

Capital Wraps, Supreme Color Graphics, and Yard Sign Ninjas are part of a vast network of trade-only wholesale printers serving the large format graphics segment. Other notable players offer similar services and we include some of them here.

SUPPLY55, INC.

NEWLIFE MAGNETICS, LLC

4over operates as a businessto-business wholesale trade printer. The Glendale, CA-based company works out of six production facilities across the U.S. Signs and banners are a portion of 4over’s services, but whether rigid, fabric, vinyl, or mesh— customers choose from a variety of substrates and have them printed right at 4over.

FireSprint is a wholesale-to-thetrade sign and graphics printer out of Omaha, NE. Next day production and one to three day shipping is available on many of its most popular products. Think FireSprint for yard signs, stickers, banners, foamboard, posters, political signs, corrugated plastic, PVC, styrene, magnetic, and vinyl.

Good Guys Signs (GGS) is selfproclaimed as the Tampa Bay, FL area’s premiere custom banner and sign printer. As a customization specialist company, GGS can customize nearly any material— from aluminum to coroplast to t-shirts. Founded in 2009, it offers free shipping on orders over $89 and fast turn times are its standard.

ImagineThis is a premiere large format digital print shop. It specializes in going large—whether it’s banners, rigid materials, window media, magnets, backlit signage, or adhesive-based projects. Customers can request a sample kit after their account is approved with ImagineThis. The sample kit is a great tool for showcasing live samples and further understanding the printable materials it offers. The

company operates out of Massillon, OH.

Headquartered in Brooklyn Center, MN, Showdown Displays is a global manufacturer and supplier of cutting-edge visual communication, event, and display products. It partners with leading distributors across industries including promotional product distributors, marketing and experiential agencies, exhibit display providers, sign shops, commercial printers, and event planners to offer signage, tents, banners, and flags.

Signs365 is a grand format, trade-only wholesale printer. The Shelby Township, MI-based company offers a wide variety of full-color, high-quality printed products all produced in 24

hours. $10 Overnight Anywhere shipping is available on all products. It is known for its promotion of supporting artists of the trade from yesterday to today.

Wholesale trade printer SinaLite celebrates over 20 years in business. Today it operates out of a 100,000 square foot facility in Dublin, OH. Large format printing includes wholesale signs, banners, wall decals, and more. These services are just one part of its offerings, as it also provides clients with business cards, promotional materials, stationery, labels and packaging, and apparel.

YardSignsResellers.com based out of Orlando, FL offers both design and print services for yard signs, rigid substrates,

magnetics, banners, adhesive vinyl, and poster paper. In business for over 20 years, the family-owned company continually invests in new digital print equipment to offer its customers the best quality signs.

Trading Up

Trade-only wholesale printers deal with the ins and outs of the wide format business on a daily basis. They are in a position to identify trending applications and act quickly. Some of the most requested applications include yard signs, due to their simplicity in production as well as low cost. Working with a trade-only wholesale printer is a great option if you need to offload certain applications like yard signs. D

See page 16 for more info.

by Cassandra Balentine

ide format printed output often requires a form of cutting. For some popular applications—like stickers, decals, and vehicle wraps—it is an integral step. To improve productivity and profitability on these jobs, prepress tools provide many benefits.

Production software is evolving and expanding to handle increasingly complex print orders and skilled labor shortages.

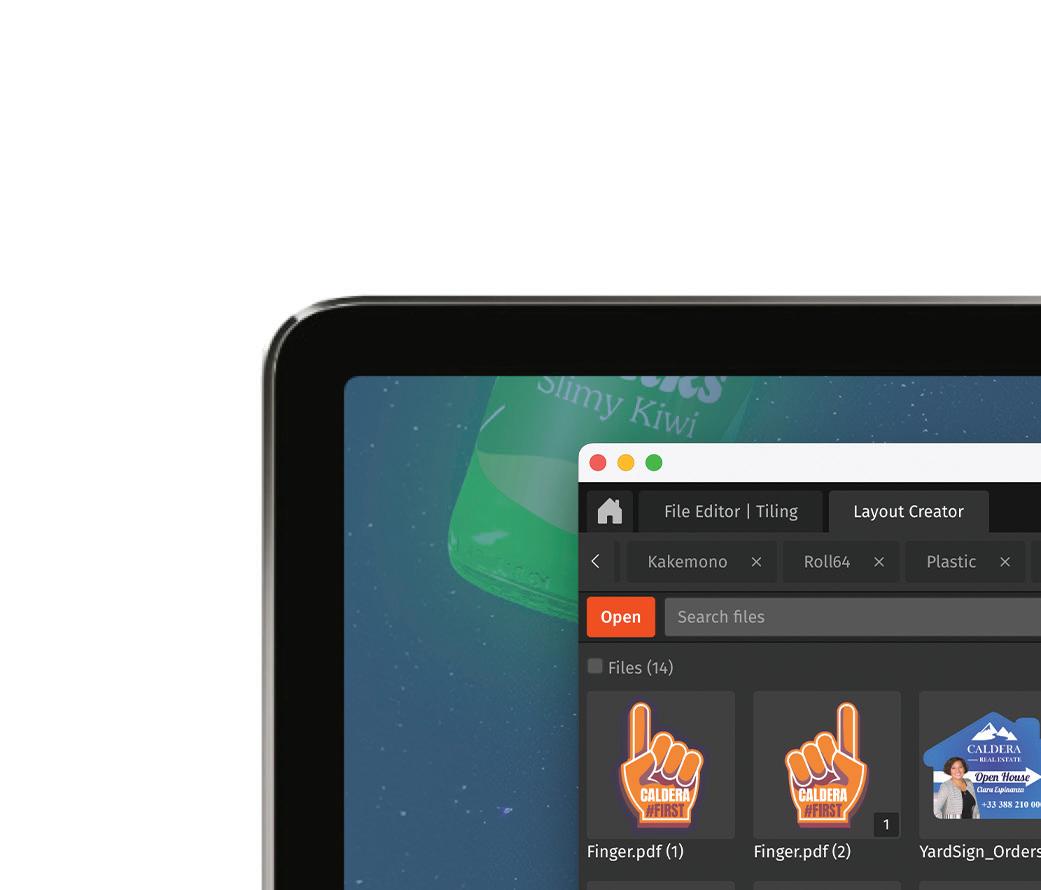

Above) Caldera PrimeCenter is a powerful print-and-cut prepress automation software designed specifically to streamline and optimize the preparation and workflow of print jobs.

Once a time-consuming task, preflighting files with software has given the industry a boost in productivity. “Tasks that took hours can now be completed within minutes due to the advancement of prepress software,” says Sebastien Hanssens, VP marketing and operations, Caldera.

Software has evolved with a strong focus on automation, integration, and efficiency, particularly in regards to printing and cutting. David Lunardi, VP of sales, OneVision, Inc., points out that software tools streamline workflows by automating file preparation, ensuring compatibility across devices, reducing manual intervention and errors, while increasing production speed and accuracy. “This evolution aligns with the industry’s demand for faster turnaround times and higher precision.”

Debra Hobden, global marketing director, PrintFactory, feels that the role of prepress software has evolved from being a static tool for basic file preparation to a dynamic solution that integrates and automates every stage of the print production process. Advanced prepress tools now focus on streamlining workflows, enhancing color accuracy, and reducing waste. “With the addition of automation features, prepress software transforms artwork into finished products effortlessly, ensuring a seamless production pipeline from design to delivery.”

While we often classify these advancements in print-and-cut workflows under the umbrella

of prepress software, Mary Gay Pettit, public relations director, Markzware Inc., points out that because cutting is a post-press process there are distinctions. “Prepress encompasses all activities that prepare a printed image for production, such as file formatting, color management, and proofing. In contrast, cutting occurs after the printing process, where printed materials are trimmed or shaped to their final specifications. This differentiation is crucial because it highlights that cutting does not involve preparing the artwork or managing print quality; rather, it focuses on finishing and refining the printed product.”

Initially focused on file preparation, Pettit says prepress software has evolved into integrated solutions that streamline both printing and cutting processes. “These innovations enhance efficiency, reduce waste, and include features like automated nesting algorithms to optimize material usage.”

Forging Ahead

Print service providers (PSPs) seek to improve their workflows for many reasons. “The primary drivers of new advancements in prepress software are automation, ease of use, and color consistency. These factors are crucial for improving efficiency and ensuring high-quality output,” shares Bobby Cagle, NA sales director, SA International (SAi).

Print providers face increased demand for faster turnaround times, greater customization, and improved efficiency. Hobden says

customers expect higher quality with less margin for error, pushing the industry towards automation and precision. Print workflow and prepress tools leverage automation to optimize artwork preparation, reducing manual input while ensuring accuracy.

“Everyone is doing their best to ‘do more with less,’” admits Joseph Lehn, director of product management, PressWise by Smartsoft. “This often means fewer staff handling larger quantities of orders with shorter runs. Without automation to help provide downstream instructions, the chance for error always increases. Staff turnover means taking time away from production to provide training for new people. Automation reduces the need for training on multiple steps of the process, getting the staff back to production and adding to the bottom line.”

Increased demand for short-run, personalized printing and just-in-time production drives

innovation in software development, including artificial intelligence (AI)-driven automation, seamless integration with digital and traditional workflows, and holistic digital production tracking that includes analog work steps and machines. “All of this helps PSPs to be efficient enough to maintain margins, have an alternative when skilled labor is scarce, and also address sustainability issues,” says Lunardi.

The growth of wide format printing also drives new advancements in this space. “It has created a need for solutions

that handle a diverse range of machines and processes. Wide format printing has experienced a surge in demand, opening new possibilities for printing across sectors. This growing diversity has resulted in a greater need for prepress software that can adapt to different machine specifications and output requirements,” adds Piet De Pauw, head of marketing, Enfocus, an Esko Company.

Expanded Integration

Wide format presents a broad spectrum of products printed on an array of substrates.

As production environments become more diverse, Lunardi says seamless integration between prepress software and various printers, cutters, and finishing equipment is essential for optimizing workflows.

“It’s not just ‘print on paper’ anymore. This creates the need for alternate ways to provide cutting instructions not only for the differences in the shapes of the products, but the various cutting methods needed for the alternative materials,” comments Lehn.

Expanding integration capabilities with a wider range of hardware solutions would be highly beneficial. However, the diversity of equipment available makes it challenging for software companies to keep up with all the different features and models. To address this, Cagle says hardware providers must collaborate closer with software

developers, providing access to drivers and workflow options to ensure seamless integration.

The growing diversity of printers, cutters, and substrates in the wide format space necessitates broader integration capabilities, agrees Hobden.

“Software developers need to focus on creating more flexible and adaptable solutions that work with a range of different hardware solutions,” says De Pauw.

Marc Raad, president, Significans Automation, points out that one way print equipment suppliers continue to offer improved workflow automation is in the form of digital front ends (DFEs) that optimize their flagship presses. “Prepress departments must understand the intricacies of how they work in order to constantly feed flawless, printready files into these presses and finishing devices for errorfree production.”

Most print shops also use multiple combinations of workflow systems and related business software. “These could include web to print, CRM, ERP, ECM, shipping, AI, robotics, and so on. Prepress must interact on a daily basis with all of these software

1) While many solutions provide RIP functionality for print and cut, SAi says few can import, edit, and modify files in formats such as .EPS, .PDF, and .JPG, then seamlessly create contour cuts and send the file to a printer and cutter—all within a single software—like Flexi. 2) Significans includes ongoing support and guidance, from implementation to optimization, from a team of integration specialists. This dedicated team has a combined 100-plus years of hands-on, print shop floor experience.

systems. Only an experienced integration partner or consultant can guarantee that these disparate systems will communicate effectively and seamlessly,” explains Raad. “The question we as software integrators invariably ask is, ‘how can we get all our customers’ systems to talk with each other to reduce touch points, errors, and significantly increase efficiency?’”

As a general rule, Raad says the more printing and finishing devices you use, the greater the need to expand—and simplify— prepress workflow processes.

“Remember that each of these complex devices has its own DFE, which must be integrated with your current workflow systems as part of your end-to-end, in-shop production goals. Expanding integration capabilities enables prepress software to serve as an easy-to-use ‘central hub’ for coordinating all processes seamlessly across various devices, including printers and digital cutters, to ensure smooth and efficient production.”

Broadening integration also yields workflows that remain scalable and adaptable as a business grows and new, more sophisticated hardware technologies emerge. “This is even more critical in the wide format sector where, because of the higher costs of substrates, prepress tasks such as nesting and imposition are essential to reduce costly waste,” shares Raad.

Defining Optimal

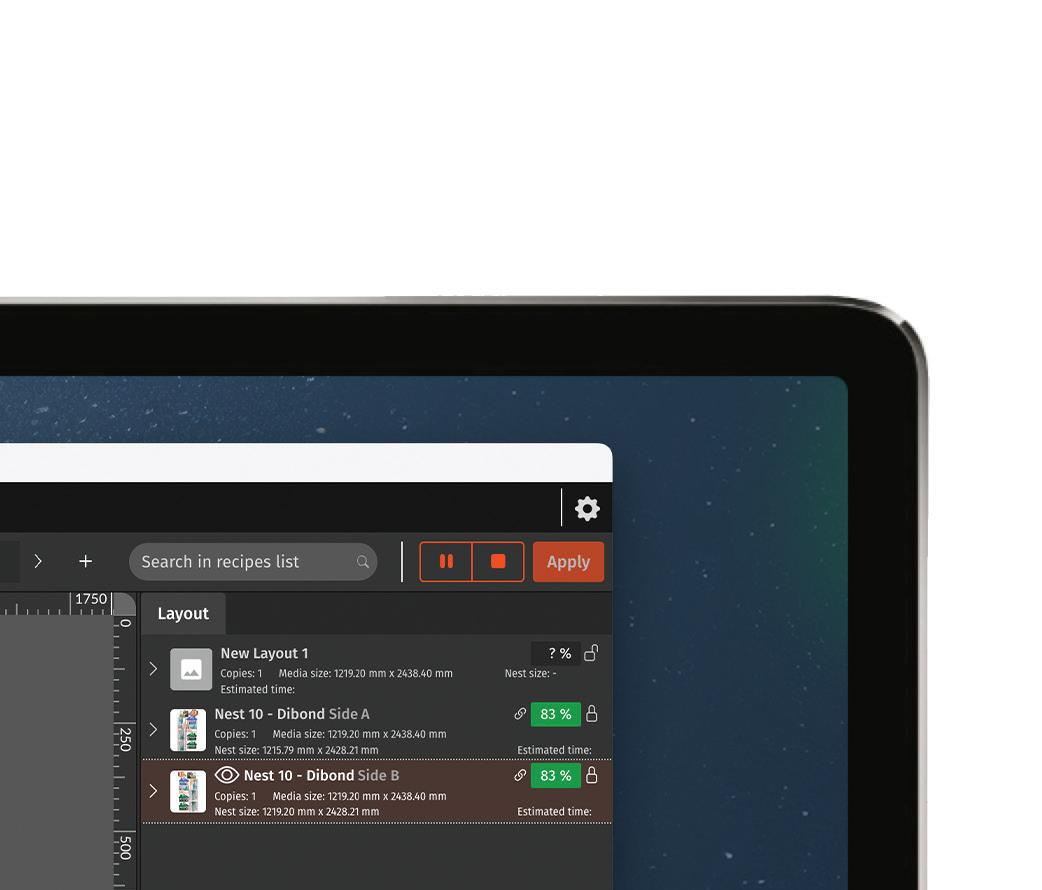

Optimal print-and-cut workflows allow users to take printed

materials directly from the printer to cutting equipment to determine—via barcoded programs—what needs to happen in order to cut out the final product successfully based on provided registration marks, explains Lehn.

Key elements of an ideal print-tocut workflow include automated nesting and cutting path optimization for maximum material utilization, integrated color management to ensure consistency across multiple devices, centralized control with real-time monitoring and updates, and scalability to adapt to changing business needs and volumes, offers Hobden.

Hanssens walks us through the steps of an optimal print-and-cut workflow. First, the customer places an order via the front end or website; next the uploaded art goes through MIS software where the order is created, then prepress software receives information—art files—and processes them; next the nested file moves to the RIP where it is processed for printing.

“The ideal print-and-cut workflow environment would be highly automated, efficient, and would minimize error occurrence. An optimal setup is a one-touch or even no-touch model, where a design file would enter the system, undergo automated processing, and require only a brief operator review before processing to production,” explains De Pauw.

From a design perspective, an optimal print-and-cut workflow enables employees to create

print-and-cut designs without needing assistance from a graphic designer. “The ability to add contour cuts to files submitted by end users and seamlessly convert them into print-and-cut jobs through an automated process is ideal. This streamlines operations and enhances productivity,” suggests Cagle.

From a prepress perspective, Lunardi describes an optimal workflow as highly automated, integrated, and error free. Realtime data exchange between prepress, press, and cutter ensures accurate job execution, while a user-friendly interface allows for easy monitoring and adjustments. “Such a system minimizes manual intervention, reduces downtime, and delivers consistent, highquality results at scale.”

Pettit says an ideal workflow would integrate the automation of efficient file management and thorough quality checks to

streamline operations and minimize errors. “This begins with using a robust MIS or ERP system that facilitates transferring files along with preflight instructions to the prepress department. The automated system performs essential checks on incoming print files ensuring compliance with desired specifications such as resolution, color accuracy, and bleed requirements.”

By automatically generating cut paths and adding necessary registration marks the workflow reduces manual adjustments between design, printing, and cutting stages. “Prepress software plays a crucial role in this environment by enabling preflighting processes that identify potential issues before printing. This includes verifying image quality, checking for font consistency, and ensuring that all design elements are correctly formatted. By adhering to best practices—such as maintaining

high-resolution images, ensuring proper bleed margins, and selecting appropriate file formats—prepress teams can significantly enhance the quality of the final printed product while reducing the likelihood of costly reprints,” comments Pettit.

3)

The approval process is another key aspect where automation can improve efficiency. Once a job is approved by the customer, automated systems can modify it according to specific printer instructions to nest jobs for optimal media usage and prepare files for cutting without further human intervention. “This automation speeds up production

and ensures that jobs are processed consistently and accurately,” adds Pettit.

Sam Mulay, VP – business development, InSoft Automation, admits that while current prepress workflows provide automation, one missing part is the optimization that makes a difference in the bottomline.

Achieving Automation

Automation is trending in prepress operations, which extends to finishing. The key to a successful print-and-cut workflow is communication and integration, driven by automation.

“As new, more sophisticated technology enters the market, prepress software is adapting to handle every possible production scenario, while ensuring that all systems communicate clearly with each other. Therefore, some existing prepress software systems may have to be ‘upgraded’ to handle new challenges. Finally, as a print shop’s ‘frontline’ worker, many of today’s prepress specialists are now adept at image editing, color management, layout and imposition, and much more, in addition to creating flawless print-ready files,” offers Raad.

Optimal print-and-cut workflow environments are characterized by a high degree of automation in file handling, rigorous preflighting protocols, and standardized practices for quality assurance, says Pettit.

Additionally, seamless communication among all stakeholders involved is critical in the printing process. “By focusing on these elements, organizations can achieve greater efficiency, reduce operational costs, and deliver high-quality printed materials consistently,” concludes Pettit.

Visit digitaloutput.net for more information on print-and-cut workflows. D

by Melissa Donovan

ehicle wrap installers—professional, amateur, hobbyist, and everything in between—turn to the newest films and media to create efficiencies in the application process, as well as enhance the overall look of the final product.

A combination of the proper adhesive, liner, and material helps achieve a successful vehicle wrap application. Today’s newest options boast updates to release liners, repositionability, bubble-free installation, and bonding strength.

“These innovations not only enhance the installation process but also deliver a smoother, more professional finish, allowing installers to focus on precision and efficiency,” attests Ryan Allen, regional technical specialist, Avery Dennison Graphics Solutions.

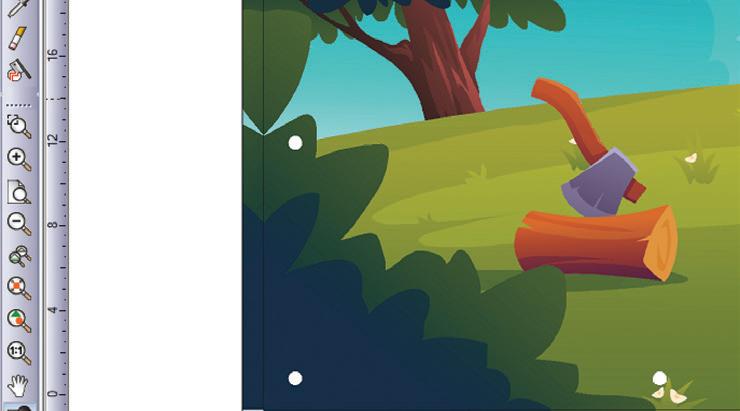

Above) Shop Vinyl Vixen Wraps of AZ printed this latest design on a Mutoh America, Inc. printer. The shop sets the printed graphic panels of this Japanese-motif full car wrap in sections where it will be applied on a Honda Civic. This is a recommended first step before installing a full wrap, especially one with a complicated design. The wrap features Avery Dennison Supreme Wrapping Film in Matte Metallic Silver, Avery Dennison Chrome in Gloss Silver, and DOL 1360Z protective overlaminate.

Here, we take a look at each component—release liners, repositionability, bubble-free installation, and bonding strength—and recent improvements.

Catch and Release

Advancements in release liner technology continue to propel vehicle wraps forward.

Marco Boyer, co-founder, Omega-Skinz, which is produced in conjunction with Grafityp and SOTT International, explains that the first release liners were mostly made up of siliconized paper and were much thinner than today’s iterations. This led to curling and disintegration when they came in contact with moisture. “Today’s better liners are sealed with a layer so this

can no longer happen. Also, the air channels are shallower and have a different structure.”

Improvements to release liners influence both the installation process and the final appearance of vehicle wraps, says Trip Harris, business development manager, General Formulations. “Advanced release liners now allow for adjustable degrees of release, reducing static and speeding up liner removal during installation. Additionally, air egress patterns are less visible on the surface, which sharpens the depth of color and enhances the overall visual appeal of the wrap.”

“Release liner advancements include the pattern of the structure as well as the release characteristics of the liner from the adhesive. The liner structure creates air channels in the adhesive. The pattern in the adhesive

allows the liner’s slideability on the vehicle’s surface and the release of the air behind the film. This helps with the positioning of the graphic and the ease of application. The release of the liner has to be good enough not to tunnel when printing but easy enough to expose the adhesive when ready to install. Both of these advancements allow for easier and faster installation, which is key to profitability,” admits Nate Goodman, product manager, Mactac.

Allen agrees that significant enhancements have occurred in recent years, like liners being carefully formulated to ensure a smooth release and excellent lay flat properties.

“Recent advancements in structured release liners have significantly simplified the car wrapping process. These innovations

ensure smooth application and enhance product performance. Enhancement improves the overall aesthetic of the installed wrap, elevating the finished product’s appearance,” explains Daniele Perotti, PM and BPM graphics and industrial, Fedrigoni Self-Adhesives.

Repeated Moves

Another critical component to vehicle wrap media is its ability to be repositioned repeatedly during the installation process.

“Historically, excessive repositioning could lead to air channel collapse, causing imperfections in the final application. However, newer liner and film combinations are designed to withstand multiple adjustments without sacrificing performance,” shares Harris.

Repositionability and adhesive technology go hand in hand. Developments in pressuresensitive adhesives allow for low initial tack, this enables the film to be repositioned without affecting adhesion capability, notes Allen. This is “critical in providing installers with the flexibility to align graphics accurately and make adjustments without stretching or distorting the material, leading to a flawless final wrap.”

Low tack is only one part of the repositionability equation. Making the process more straightforward is the combination of a low-tack adhesive with a micro-structured liner, according to Perotti. “This reduces the adhesive contact area on the

1) Mactac IMAGin B-free Slide-able GRUV is the company’s newest wrap product. It incorporates a vertically integrated liner from Lintec and a specialty adhesive system.

vehicle’s surface, allowing easy repositioning. Over time, the adhesive flows through the micro channels, ensuring 100 percent surface contact for secure, longterm adhesion.”

Goodman argues that repositionability can be referred to as slideability. “Slideability allows the material to be placed and moved to the correct position without the adhesive tacking to the surface of the vehicle. This provides a more accurate placement of the graphics. Once they are in place, pressure can be applied and the adhesive will bond to the surface.”

Boyer notes that while repositionability is a nice-to-have feature, a good vehicle wrap installer can successfully apply any film without it. He admits that a repositionable film does allow faster—and easier—installation.

No Bubbles, Please

The technology behind bubblefree installation continues to change for the better.

Part of the reason for this is improvements in the construction of air egress channels. “While structured liners with bubblefree technology have existed for a decade, earlier versions often resulted in a grid effect as the face film collapsed into the adhesive channels,” explains Perotti.

“Advancements in air egress patterns have revolutionized bubble-free installation, not only making it easier to achieve a flawless finish but also significantly speeding up the

application process. The ability to quickly eliminate air bubbles is the result of improvements in both film and liner technology. Additionally, enhanced cleaning and installation techniques have contributed to egressing the air out of the film more efficiently,” notes Harris.

Quick transfer of airflow is key. “The amount of airflow to remove the bubbles from behind the film has increased due to the designed structure in the liner that transfers the pattern into the adhesive. The repositioning of the adhesive also allows the adhesive to be pulled up so the air can be removed as it is reinstalled,” suggests Goodman.

“Air egress channels allow air to escape during application,

drastically reducing installation time and eliminating the need to puncture or work out air pockets manually. Bubblefree technology ensures that the final product looks professional and lasts longer, as trapped air can compromise the bond between the film layer, adhesive, and applied surface over time,” says Allen.

Hold Strong

A vehicle wrap needs to remain in place for its intended lifespan. This is made possible thanks to the bonding strength found in the same adhesive chemistry that allows for repositionability.

Recent improvements in adhesive chemistry enhance bonding strength, according to Allen, which helps wraps maintain their

integrity over time even on complex curves, rivets, and contours.

It’s a dance between repositionability and long-term bond, as the adhesive developed for the application must perform a certain way during and after the installation.

“The adhesive needs a light initial tack to work with the pattern imparted by the liner and slide over the vehicle’s surface without sticking until pressure is applied to lock it down. It will also need to be released from the surface when pulled up to be reinstalled where needed. The adhesion must also lock down with heat and build over 24 hours to prevent lifting around complex curves or rivets,” says Goodman.

Materials need to achieve the correct balance of initial repositionability and ultimate adhesion for a strong bond when the film is set in its final position. “This is critical for long-term vehicle wraps, especially in extreme weather conditions where consistent adhesion prevents lifting or peeling,” comments Allen.

“In the past, vehicle wrapping was a labor-intensive process due to adhesives with high initial adhesion, requiring expertise and significant time to apply. Modern advancements have struck the perfect balance between low initial adhesion for easy installation and high final adhesion for long-term durability. This improvement ensures a secure bond

between the film and the vehicle surface while simplifying the installation process for professionals,” states Perotti.

The same adhesive that offers repositionability and a strong bond, also must remove cleanly.

“Bonding strength technology has advanced significantly, improving the ability to remove films cleanly without leaving behind adhesive

residue. This has long been a challenge as improper practices often result in excessive adhesive being left on surfaces. To address this, modern adhesive systems are designed to balance a strong bond with clean removability,” shares Harris.

“Additives in adhesives often improve adhesion. But bond strength isn’t that different. Now film can be removed more easily without leaving adhesive behind,” adds Boyer.

Solving the Complexities

Release liners, repositionability, bubble-free installation, and bonding strength collaborate to achieve the ideal vehicle wrap material.

And what is the ideal material?

One that lays flat over complex curves and rivets, allows for repositionability multiple times if necessary, bonds well to the surface once install is completed, and finally, removes cleanly.

companies mentioned

115 Avery Dennison Graphics Solutions graphics.averydennison.com

116 Fedrigoni Self-Adhesives selfadhesives.fedrigoni.com

117 General Formulations generalformulations.com

118 Grafityp/Omegz-Skinz omega-skinz.com

119 Mactac mactac.com See page 16 for more info.

2) General Formulations AutoMark cast films are highly conformable with maximized flexibility, enhanced slideability, and superior repositionability. The AutoMark cast laminates provide graphic protection from UV exposure, moisture, and abrasion. The car depicted here was designed using AutoMark cast films and laminates by Redline Designs.

It’s a complex combination of elements that scientists behind the scenes work to achieve while keeping up with other advancements in tandem, whether it is ink related or environmental.

Visit digitaloutput.net in March when an exclusive webinar on this same topic is available to view. D

#13

#15

#12

#14

printer purchase, whether narrow format, wide format, roll-based, dedicated flatbed, or a hybrid, is a big commitment. Protecting your investment right away with a manufacturer warranty is a safeguard for all the “just in case” scenarios that might pop up along the way.

Traditional warranty agreements are one year or 12 months. There are also

by Melissa Donovan

options to extend those warranties to two or even three years.

Warranties are available for most printers, but for the purposes of this article we focus on wide format—over 24 inches—roll-to-roll printers.

Common Period

It’s largely agreed upon that a typical roll-to-roll printer warranty is one year.

“This duration is standard because it aligns with the expected lifespan of critical printer components under normal usage. Manufacturers choose this time frame to provide users with sufficient coverage during the initial learning curve and heavy usage period.

Left to right) Epson offers a one year factory “in box” limited warranty for most of its wide format roll-to-roll printers. swissQprint’s standard 36 month warranty, like on the Karibu, includes full coverage.

Standard warranties usually include parts and labor for repairs due to manufacturing defects, as well as technical support for troubleshooting and operation guidance,” states Sohil Singh, VP of business development, StratoJet USA.

This reason is partly because during the first year of service “any manufacturing issues will become apparent,” explains Josh Hope, director, marketing, Mimaki USA, Inc.

Adam Tourville, channel manager, Fluid Color, believes a 12 month “timeframe is common because it balances manufacturers’ limited liability with the expectation that printers—even with minimal maintenance—will perform reliably for at least a year.”

“12 to even 24 months offers the customer an incentive to make the investment on a new piece of hardware. The original warranty usually covers parts and labor,” says Miguel Gonzalez, director of sales, Mutoh America Inc.

Alan Chen, senior service product manager, Service Product Management, Epson America, Inc., notes that every major printer manufacturer handles warranties and extended service plans differently, so it’s critical to understand what is covered. “For example, while many manufacturers consider the printhead a non-maintenance part, and

therefore exclude it from the limited warranty or extended service plan coverage, Epson has a ‘bumper-to-bumper’ mentality for limited warranties, so our non-maintenance parts, including the printhead, are covered.”

While 12 months is standard and during that period any manufacturing defects may be covered, it would presumably include “certain exclusions for operator error or other print service provider (PSP)-based fault,” shares Erik Norman, president, swissQprint America.

Beyond the Traditional

Extended warranties or service plans that go beyond one year are increasingly offered to PSPs.

Financially speaking, Tourville says extended warranties improve budget predictability. “This helps businesses avoid costly downtime and unplanned expenses. For equipment requiring high performance and reliability, these warranties often serve as a safeguard to maximize the printer’s value and operational lifespan.”

“Extended warranties, often referred to as service maintenance agreements (SMA) provide additional coverage that extends beyond the one year warranty period. Warranties and SMAs provide the highest level of after sales support to maximize the customer’s return on investment,” notes Deborah Hutcheson, director of strategic business development and distribution, digital print, Agfa.

An extended warranty provides comfort. “Customers want to get the most out of their printers, so keeping the printer running smoothly is not only critical to a business’ success, but it also helps ensure the printer will stand the test of time,” explains Chen.

Epson offers the Epson Preferred Plus extended service plan, which provides up to a total of five years of continuous coverage. The plan offers the same level of service as Epson’s standard limited warranty—just for longer.

“Extended service agreements provide peace of mind for PSPs that—if something goes sideways—the necessary support is available in a timely manner,” notes Hope.

He points out that not all extended service agreements cover all components of a printer— coverage varies by manufacturer and model. “The most widely covered item

under an extended service agreement is the printhead—arguably the most critical component of the printing system.”

“Piece of mind is the biggest motivator for extending the warranty past the original warranty,” agrees Gonzalez. Mutoh offers two to four year options for additional warranties.

“Customers can maximize the protection of their long-term technology investments by purchasing an extended time contract,” explains Daniel Valade, product manager of digital print, Roland DGA Corporation.

For example, at Roland a customer currently under a two year limited warranty could opt to purchase an extended warranty contract that provides up to five years of coverage—three years over and beyond the company’s standard two year manufacturer’s warranty.

Another advantage to an extended warranty is the added periodic maintenance and software updates, helping to maximize the printer’s efficiency and lifespan, adds Singh.

1) Mimaki warranties its products, accessories, and supplies against defects in manufacturing and workmanship during the Mimaki Total Care warranty period. 2) If something fails due to a manufacturing defect, there is no cost to the printer when swissQprint customers are covered under its 36 month standard warranty. 3) Mutoh’s warranty coverage, mostly 12 months, applies to defects in materials and workmanship. 4) Due to the size of Epson large format printers, the limited warranties offered generally provide onsite, next-business-day service, pending the location of the printer.

“Extended warranties sometimes include benefits that aren’t part of the standard warranty. They may offer enhanced technical support, faster response times, or coverage for specific components not included in the base warranty. Some manufacturers also bundle extended warranties with periodic maintenance services, ensuring optimal performance over time,” continues Singh.

Questions to Ask

Prior to committing to a wide format roll-to-roll printer purchase, it is worth asking the right questions not only about the printer itself, but the standard warranty and subsequent options to extend that warranty.

“Printers should ask to see the warranty details to understand what’s included and what’s not, how the warranty process is managed, and whether the warranty includes travel and labor time. The latter can be a big ticket in some instances. Additionally, they should understand the track record of the OEM in terms of mean time between failure and operating uptime,” recommends Norman.

When it comes to who will be providing the service, it’s important to find out whether it will be an authorized service personnel, whether they will provide the parts, where their location is in relation to the PSP’s, and generally how long it takes for them to get on site, suggests Hope.

Also, determine inclusions and exclusions prior to purchase. “For example, if a PSP chooses

to use third-party ink and requires service, will the service be covered? If not, another reason to always use OEM inks,” adds Hope.

informed purchasing deci-

on-going operator training.

“Explore if additional train-

A better operator ensures a

These questions help ensure informed purchasing decisions. Tourville recommends asking if the warranty covers on-going operator training. “Explore if additional training and classes are available. A better operator ensures a better printer experience.”

Chen encourages PSPs to ask what is covered in the limited warranty or extended service plan, what the expected response time is if a repair is needed, what maintenance needs to be performed to maintain the printer on a regular basis, what is the maximum amount of time a customer can cover the printer under a service plan, and if there are discounts for purchasing an extended service plan at the time of purchase.

“When purchasing an extended contract, the end user should always ask if parts are covered, and if labor is an additional charge. Some manufacturers also limit the number of printheads that can be replaced during the coverage period, so that should also be clarified up front,” suggests Valade.

Another important question to ask is “can the warranty be transferred if the printer is sold to another user,” suggests Singh.

Hutcheson says “it is important for a PSP to understand exactly what is included in the warranty or SMA, like if flexible payment plans—monthly, quarterly, or annually—are available.”

In the long run, “asking these questions helps providers avoid unexpected costs and ensures they have the support needed to keep their equipment running smoothly,” recommends Singh.

Notes on Warranties

The vendors interviewed for this article shared insight on some of the warranty options associated with their wide format roll-to-roll printers. For additional information on each of these programs visit digitaloutput.net.

All Agfa engines come with a standard one year warranty, covering non-consumable parts, telephone and remote support,

and onsite services including preventive maintenance.

Epson offers a one year factory “in box” limited warranty for most wide format roll-toroll printers. Due to the size of Epson large format printers, the limited warranties offered generally provide onsite, nextbusiness-day service, pending the location of the printer—at times, it may take a few additional days for a technician to reach remote locations. Epson also provides customer support via phone, providing customers access to the service team who can troubleshoot the printer remotely and, if necessary, ship required parts and schedule an

onsite technician within days to complete the repair.

Fluid Color’s three year warranty for roll-to-roll printers offers comprehensive coverage. During the first year, the warranty includes non-consumable parts, labor, manufacturer defects, and CMYK printheads, ensuring full operational support. In years two and three, the warranty transitions to cover non-consumable parts only, providing extended protection for key components. This structure ensures reliability and support throughout the printer’s early life while minimizing operational costs for the user.

Mimaki warrants its products, accessories, and supplies against defects in manufacturing and

workmanship during the Mimaki Total Care warranty period. The Total Care warranty period begins on the installation date noted on the signed installation report. If the installation report is not completed within 60 days after shipment from Mimaki, the Total Care warranty period begins on the day the product is shipped, according to the company website.

Mutoh’s warranty coverage applies to defects in materials and workmanship. All Mutoh printers come with a 12 month onsite parts and labor limited manufacturer’s warranty except the XPJ-1341SR-P and XPJ-1641SRP, which come with a two year parts and labor warranty.

Roland’s eco-solvent, UV, and latex roll-to-roll printers come with a one year warranty, plus an additional year of warranty coverage when the owner registers the printer within 60 days of delivery, connects to the Roland DG connect app, and uses Roland DG inks exclusively during the warranty.

StratoJet offers a standard 12 month warranty on its roll-toroll printers, which covers parts, labor, and technical support. For customers seeking longer protection, it provides extended options of up to 36 months.

swissQprint’s standard 36 month warranty includes full coverage. “If something fails due to a manufacturing defect, there is no cost to the printer. Normal consumable items are excluded, and printheads are not a consumable,” says Norman.

At swissQprint, the decision to offer a 36 month warranty was driven by “doing what’s right for the customer given our reliability track record. The benefit for our customers is peace of mind, knowing that all they need to focus on is generating business from the printer,” continues Norman.

Full Protection

Warranties on any printer—roll, hybrid, or flatbed—are a good economical decision.

“We remind customers that printing issues and errors can happen, and it is recommended to safeguard their investment with an extended service plan. This is especially critical for customers that rely on these products to support their business, when extended downtime can lead to an inability to produce products and meet customer demand,” shares Chen.

When the printer is the heart of the company, downtime is not afforded. Investing in a warranty and perhaps an extended option is certainly worth considering. D

5) Printers from Mimaki like its CJV200-160 are included in the Mimaki Total Care warranty.