Gas Safe news

Gas Safety Week is nearly here: are you ready?

Technical Landlords’ gas safety record checks

Technical Ventilation of gas fires

Win: 10 personal CO alarms to keep you safe at work or at home

Gas Safe news

Gas Safety Week is nearly here: are you ready?

Technical Landlords’ gas safety record checks

Technical Ventilation of gas fires

Win: 10 personal CO alarms to keep you safe at work or at home

17 Letters

18 The good, the bad and the ugly

20 Technical

Do you know your landlords’ gas safety record checks? We set out what should you check and record and what you shouldn’t

28 Your business

Are you charging your customers enough?

31 Plumbing

Specifying valves for large buildings

37 Training

38 Products

The latest launches from Alpha, Intergas, Navien UK, Navigator, Nexus, Stiebel Eltron, Testo and Worcester Bosch

32 Controls

Buyers would pay more for a smart home, a new survey has found; Keep a rein on rising energy costs; Our changing relationship with thermostats; The benefits of Bluetooth over Wi-Fi controls

This month brings the 13th Gas Safety Week, the biggest pan-industry gas safety campaign. We know it can be tempting to think “what’s in it for me” and to watch from the sidelines. But it isn’t only big companies that get involved: there are real benefits to sole traders and small businesses too.

It’s an ideal opportunity to refresh your website or social media with easy-to-use images and animations that you can download free from the toolkit on the Gas Safety Week website.

If you’re stuck for something to say, you can take advantage of pre-written updates that tie in with the daily themes.

Supporting the industry-wide campaign can help to distinguish you from your competitors; it can reassure your customers that you’re serious about the job you do and that you’re registered, competent and will keep them safe in their homes.

This year will focus on the diversity and different experiences of gas engineers. We can’t wait to see your amazing stories and we’ll showcase some of the highlights of Gas Safety Week in next month’s issue. Will you be in it?

Nicki Shearer, editorGas Safe Register, PO Box 631, DARLINGTON, DL1 9GD

Email: enquiries@gassaferegister.co.uk, register@gassaferegister.co.uk or technical@gassaferegister.co.uk

Managing editor: Sue Harker sue.harker@gassaferegister.co.uk

Editor: Nicki Shearer editorial@registeredgasengineer.co.uk

Publisher: Peter McCreary publisher@registeredgasengineer.co.uk

Technical consultants: Carl Banister, Stephen Gallagher, Jonathan Palmer, Rob Walkerdine

Production: Mark Turpin

Advertising enquiries only: Ian Carter ian@rgemagazine.co.uk

Additional print subscriptions £25 per year email: wgardiner@circdata.com, Tel 01635 869 868

The views expressed in this magazine are not necessarily those of Gas Safe Register. The publishers will accept an advertisement or other inserted material only on the condition that the advertiser warrants that such advertisement does not in any way infringe copyright or contravene the provisions of the Trade Descriptions Act. All copy is subject to the approval of the publisher, who reserves the right to refuse, amend, withdraw or otherwise deal with advertisements submitted to it at its absolute discretion and without explanation. All advertisements must comply with the British Code of Advertising Practice. ABC membership approved 19 March, 2009.

Registered Gas Engineer is written, designed and published by The Team on behalf of Gas Safe Register. 30 Park Street, London, SE1 9EQ

The UK’s biggest national gas safety event takes place this month. On 11-17 September, the industry will join together to share messages and tips that help to keep the nation safe from the dangers of gas.

How will you be joining in? You can download a digital toolkit from Gas Safe Register to support you in whatever you do: whether it’s as straightforward as adding a banner to your website to show your support, or sharing gas safety tips on social media throughout the week.

You might choose to give a talk on gas safety in your community, or how about sending an article to your local

11-17 September 2023

news outlet about the importance of gas safety? You can use the press release template in the Gas Safety Week toolkit, and add your own quotes, showcasing your

Resideo is urging you to consider installing CO alarms in your customers’ homes – and it’s giving you the chance to win one in a special competition in support of Gas Safety Week.

The Honeywell Home R200C-1 (stand-alone) or the R200C-N1 (interconnected) alarms are part of the expanded Honeywell Home R200 CO, smoke, heat, and combo alarm range, backed by a

10-year warranty.

For your chance to win one of 10 alarms up for grabs, just answer this multiple-choice question correctly: How long is the warranty on Honeywell Home R200 CO alarms?

a) 2 years

b) 5 years

c) 10 years

Send your answer, plus your name, address and registration number to: editorial@registeredgasengineer.co.uk and please include Resideo Gas Safety Week Competition in the subject line. Ten winners will be chosen at random from all correct entries received by the closing date of Friday 29 September 2023.

*Our standard competition T&Cs apply, see page 43.

business in your local area at the same time.

Or how about giving a special offer on boiler servicing during the week? It can be a great way to find new customers and add to your order book.

There are many reasons to show your support: you’ll be joining thousands of others to share and amplify essential gas safety messages to your own customers and communities.

Joining in can help to improve awareness of your business and your work: just tell Gas Safe Register what you’re doing to support the campaign and it will share as many of your activities as possible on social media during the week, in the campaign round-up afterwards, and in this magazine. Don’t forget: Your competitors may well be supporting too, so don’t get left behind.

Every day of the week has a different theme, and it’s easy to get involved and use and share these themes when you download the free Gas Safety Week toolkit.

The toolkit provides everything you need to create a fresh and eye-catching social media post every day, including bright images and animations. And there are posters, logos, leaflets, articles, factsheets and banners for your website too.

You can download the toolkit at: www.GasSafetyWeek.co.uk

Gas Safe Register is gearing up for an impactful awareness campaign on multiple fronts.

It will be running targeted Google ads, captivating YouTube ads and engaging social media campaigns, highlighting the

important contributions of gas engineers, as well as reminding people to book their annual gas safety check with a qualified Gas Safe registered engineer. And look out for a special Facebook competition too.

If you’re stumped for what to say on social media, the Gas Safety Week toolkit makes it easy for you. Just copy and paste the suggested messages into your social media accounts ready to go out before, during and after Gas Safety Week. You’ll also find videos and images for Facebook, Instagram and Twitter to help you get started.

All about trust Gas Safe Register is celebrating gas engineers from across the UK by bringing their voices together for an amazing one-of-a-kind project.

We’re keeping this under wraps until the week itself, but we’ve had a sneak peek and it highlights the diversity of the nation’s Gas Safe registered engineers, recognising them for the essential role they play in keeping people safe in their homes and the trust that they instil in householders up and down the country.

The Register has carried out research that highlights the importance of trust between gas engineers and their customers. Nearly 9 in 10 gas engineers say their customers confide in them, often about money worries or mental health and wellbeing concerns.

Nearly 8 in 10 gas engineers say their role gives them the opportunity to make a positive impact on the wider community as well as their customers’ lives.

“We’ll be sharing gas safety tips and advice throughout the week on our socials @iheatonline.”

Ben Mars, relationship manager, iHeat

“We’re proud to support and promote Gas Safety Week 2023 to raise awareness of the importance of keeping appliances well maintained and serviced. We’ve been providing safety guidance and LPG standards for over 45 years and it’s at the heart of what we do at Liquid Gas UK.”

Noelene Maguire, membership development manager, Liquid Gas UK

“Safety is one of our core values at SGN and our top priority both for our customers and our colleagues. Gas Safety Week is an excellent opportunity to share important gas safety messaging and raise awareness of the dangers of carbon monoxide as part of this national safety campaign, which is why we’ve supported this campaign since it launched in 2011.”

Dan Edwards, social impact programme lead, SGN

What are the changes?

We are changing and adding to the ways that Gas Safe Register provides you with important information through additional touchpoints and increasing how often you hear from the Register.

Starting in the autumn, you'll receive a new email newsletter from this magazine that contains the latest information from Gas Safe Register, as well as important industry and technical updates.

Gas Safe Register is also launching Tech Talk (see right), a regular online discussion from its Technical Team. This will focus on a different topic each time and respond to recent engineer questions to the helpline.

Starting in November 2023, this magazine will be published in print every two months. It will remain at the heart of communicating the technical information that you need and

will have a deeper focus on this. We're also going to refresh the design to ensure that this information is as accessible as possible to all readers.

You'll be able to find all the industry's latest news and updates faster at www. registeredgasengineer.co.uk

Why are we making these changes?

We carried out a major reader survey earlier this year: you told us that the content you value most in the magazine is technical information. More than four in five readers expressly stated that they would like to receive an email newsletter.

Will the magazine be online only?

No. The printed magazine will continue to be posted to your registered address, as it always has been, but its frequency will change to six times per year from November 2023.

Current and previous full

Gas Safe Register will be introducing two-factor authentication (2FA) later this year. It’s designed to protect you and the information that the Register holds about you – and many will already be familiar with it when you log into your banking, email or other apps.

2FA protects sensitive data, such as your personal details and information: it’s for your security and protection. When it’s implemented, you’ll need to use it every time you log into your Gas Safe Register online account. 2FA will be brought in

incrementally but there are steps you should take now to get ready:

• Every person who logs into your online account on your behalf must set up their own account with their own unique user ID and password. This includes anyone who handles your registration renewal, notifies, adds engineers or orders a licence card on your behalf. You will no longer be able to share your user ID and password with anyone else.

• You can add new users and set them up in your online account by choosing Account

2AF verifies your online identity by asking for a second authentication in addition to your password. Most governmental websites already use it. It provides an additional layer of protection to your sensitive information, so that even if someone else knows or guesses your password, they can’t access your data. When you log in to your account, you’ll be sent a code, which you need to enter to prove that it’s really you. You can also use an authenticator app.

about what's changing and the reasons why.

editions will also continue to be available online at www. registeredgasengineer.co.uk and by signing into your Gas Safe Register online account.

It looks as though I’m getting less for my registration fee The Register will be providing essential information more

information is online too means you'll be able to find it it faster. And including it in the magazine means that you can continue to keep print editions to read and refer back to at your leisure.

The new monthly newsletter from us will also include any important updates that you need to know.

number of editions you receive over two years will depend on when your subscription started.

What do I need to do?

You don’t need to do anything: these changes will happen automatically. You'll receive the new email newsletter at the email address at which you already receive information from Gas Safe Register. And the magazine will continue to be posted to your nominated address. You can check that your details are up to date by signing into your Gas Safe Register online account.

Tech Talk is a new regular way to stay up to date with technical topics from Gas Safe Register. It’s hosted on YouTube, and the Register’s Technical Team share their expertise on some of the latest industry issues and answer some of the questions they receive on the engineer helpline.

frequently and in more ways. As well as this magazine, you'll receive a monthly email newsletter and be able stay up to date with the latest news at www.registeredgasengineer. co.uk. You'll also be able to see and listen to the new Tech Talk from Gas Safe Register’s Technical Team.

I’m worried that I’ll miss out on important information All essential gas safety information will always be included in print as well as online at www.registeredgasengineer. co.uk

Making sure that this

I prefer reading RGE in print You'll continue to receive this magazine in print. We know that many of you like to take your time to absorb technical information in print rather than online.

My company pays for additional copies of Registered Gas Engineer on a subscription basis. What will happen to this?

Additional subscriptions have been managed previously on a yearly basis that covers 12 editions. Therefore, from November, you will receive up to 12 editions of the magazine within a two-year period: the exact

What if I don’t want to receive a newsletter from this magazine?

We know that 97 per cent of you already manage your Gas Safe Register account online. But if you don’t want to receive a newsletter from us, you will be able to opt out. Note: You cannot opt out of receiving emails about your registration if you have agreed to manage your registration online.

Can I opt out of receiving the print magazine?

Gas Safe Register is reviewing this option and will communicate any changes directly.

The first Tech Talk took place last month (August). Members of the Technical Team introduced themselves and how they work, highlighting that the team have access to all relevant standards and industry documents to provide the right information and to support engineers to make the right decision for their situation.

They shared some of the questions that the team have been asked recently, including queries on back boilers, lead pipework and pipework sizing.

Moving on to open-flued appliances, the team highlighted that some newly qualified gas engineers don’t feel confident working with these because they are not as common as they used to be – experienced engineers tend to be more familiar with them, having worked with them more in the past.

Decorative gas fires and their ventilation needs also came under the spotlight – and you can read more about this on pages 25-27 of this magazine.

Tech Talk is on YouTube at www.youtube.com/@ GasSafeRegister, please choose Playlists. You can also find an audio version and text transcipt on our website, as well as the details of the next Tech Talk, when confirmed.

If there’s a topic you’d like the Technical Team to cover in next month's Tech Talk please email: Technical@ GasSafeRegister.co.uk

And look out for more details at: www.registeredgasengineer. co.uk

“As well as this magazine, you'll receive a monthly email newsletter from us and be able to stay up to date with the latest news online.”

If you change any of your business details, you must tell Gas Safe Register within specific timescales, as set out in the Rules of Registration.

You can change your contact details yourself on the phone or by logging into your online account. But if you need to change your trading title, Gas Safe Register has to make additional checks to confirm any changes to the ownership of the business – for example, changing from a non-limited company to a limited company.

Your trading title, under which gas work is carried out, must be and remain the trading title registered with Gas Safe. Registered businesses that use the Gas Safe brand with a trading title that is different to that entered on the Register may face action, as set out in the Brand Enforcement Policy.

How do I request a change of trading title?

Simply log into your online account and choose Change Trading Title Request under My Business > Business Details, and then complete the indicated information.

If you prefer to make changes in writing, you must do so within five business days of any change. You will need to provide the following information:

• The current and new trading title of your business

• The company name, if different

• The type of business entity

• The Companies House registration number for the business

• Business address and contact details of the responsible person for the business.

Note: Not all changes are possible under the Rules of Registration. Some changes may require that you complete a new application. More information about the different types of change request is in the tables on the right.

How much will it cost?

It doesn’t cost anything to request a change to your trading title. But if you need a new ID card to show your updated details, this costs £11 plus VAT.

Renewing soon?

If you’ll be renewing your registration soon, Gas Safe Register recommends that you should change the trading title first, if required, so that your ID card(s) and registration certificate will be sent out with the new company name. Please allow plenty of time before your renewal date.

Non-limited business name change

No change in the controlling interest of the business

Information

Where the registered business is a partnership that splits, and both parties wish to continue to be registered in their own right, each party will need new separate registrations unless a signed agreement from both parties is provided, allowing one of the parties to retain the existing registration. They will need to sign an indemnity accepting responsibility for any gas work previously undertaken by the partnership

Limited business sold or transferred

Non-limited business to limited business (incorporation with Companies House). This changes the legal entity status of the business

Name change of limited business

No change to the legal entity status

Limited business reverts to non-limited business

A change to the legal entity status

Refer to Section 8.1 of the Registration Policy regarding keeping appropriate records

A signed indemnity accepting responsibility for all gas work undertaken by the previous non-limited business is required. The Gas Safe registration number passes to the newly incorporated business

A copy of the Certificate of Incorporation or Change of Name must be provided with the Change of Trading Title document

Where the controlling interest in the business remains the same, ie, sole director becomes sole trader

Important: You must notify Gas Safe Register if your limited company is dissolved or goes into liquidation, administration or receivership. This must be done in writing by email, or online, and within five business days.

Where a business ceases to trade, goes into administration or is liquidated, and Gas Safe Register has documented evidence of this, it will arrange for the registration to be cancelled.

If you have any questions about completing the online form, you can call 0800 408 5577 or email enquiries@GasSafeRegister.co.uk. The Register may need you to provide more information, and failure to provide this within five business days will result in the registration being archived, as per the Registration Policy.

The Register’s policies on Registration and Brand Enforcement are at: GasSafeRegister.co.uk/who-we-are/our-policies/

Non-limited business sold or transferred

A change in the controlling interest of the business

Limited business to limited business

A change to the legal entity status

Name change of limited business

No change to the legal entity status

Limited business reverting to non-limited business

A change to the legal entity status

For acquisitions, refer to Section 8.1 in the Registration Policy regarding keeping appropriate records

The new business will be operating under a different Companies House incorporation number. A change in legal entity status occurs

If the limited business has gone into liquidation, receivership or administration

Where there is a change in the controlling interest, ie, more than one director of the business has gone into liquidation, receivership or administration

A revolution in design, efficiency, connectivity and sustainability.

Year-round comfort

Aquarea heat pumps provide heating, cooling and hot water for the whole house.

Green future Aquarea L Generation air to water heat pump is engineered with natural refrigerant R290 with GWP 3.

High performance Innovative hydraulic split heat pump, with 75 °C water outlet down to -10 °C outside, and operation down to -25 °C.

Harmony at home Compact design blends into indoor and outdoor spaces. The heat pump’s quiet operation brings harmony between technology and the home.

Smart control Wi-Fi included for smart control, advanced monitoring and servicing.

A self-employed plumber has received a suspended prison sentence for pretending to be registered and carrying out dangerous gas work.

Ben Craig Siddle, 24, trading as BCS Gas and Plumbing, worked in numerous homes in Hampshire in 2021 and 2022, Portsmouth Magistrates’ Court heard. He left two of the properties he worked on in an unsafe condition.

At one property on East Cosham Road, Portsmouth, Mr Siddle had installed a boiler and flue that were subsequently found to be Immediately Dangerous. He installed a boiler at another property in Portsmouth that was classified At Risk.

He was prohibited from carrying out gas work by HSE in July 2021 but ignored this. Between March 2022 and August 2022, he removed and capped two gas fires at a property in Waterlooville.

He falsely told his customers that he was registered.

Registered and qualified gas engineers had to correct and repair the installations on which Mr Siddle had worked.

Ben Craig Siddle, from, Waterlooville, Hampshire, pleaded guilty to five breaches of Regulations 3(7) and 3(3) and 5(3) of the Gas Safety (Installation and Use) Regulations 1998 as Amended, and two breaches of Section 33(1)(g) of the Health and Safety

at Work etc Act 1974.

He was given a six-month custodial sentence, suspended for 12 months, told to carry out 150 hours of unpaid work and ordered to pay £5,000 in costs.

HSE enforcement lawyer Jon Mack said: “Mr Siddle was a convicted fraudster and rogue gas fitter who had dishonestly and intentionally breached the law, with no regard for the safety of his customers or their families.

“When challenged by one of his customers, a childminder, Mr Siddle had shown her a Photoshopped Gas Safe Register entry, which he had stolen from an unconnected company... He repeatedly lied in WhatsApp messages to another customer.”

One-third of all heat pump installations carried out as part of the Boiler Upgrade Scheme (BUS) were fitted by just 30 installers, according to Ofgem’s Boiler Upgrade Scheme Annual Report – Scheme Year One.

The MP for Fareham toured the trade counter and southern distribution centre in her constituency town, welcomed by the merchant’s chair Ray Stafford, who founded Van Watch, a crossindustry, not-for-profit organisation campaigning against tool crime.

Ray asked her for support, further to the Equipment Theft (Prevention) Act 2023, to add more police resources, change sentencing guidelines, pressure manufacturers to improve security and require online selling platforms to do more to prevent re-selling.

Suella Braverman said: “All victims of theft deserve more from the police and justice system than simply a crime number, and they should expect all reasonable lines of enquiry should be followed up.”

The BUS launched on 23 May 2022 and provides upfront capital grants towards the cost of installing approved heat pumps and biomass boilers in homes and small non-domestic buildings in England and Wales.

During the first year of the scheme, 15,768 applications were received, 95.9 per cent of which were for air source heat pumps. The rest were for ground-source heat pumps (GSHPs), biomass boilers and shared ground loop GSHPs.

By the end of March 2023, 9,983 BUS grants had been paid, worth more than £50 million. Almost all the grants issued (99.6 per cent) were for installations in domestic properties.

The grants are issued to installers in the form of vouchers, which can be redeemed once the installation is complete.

According to Ofgem, which administers the scheme, 1,511 of the vouchers issued expired before being redeemed – some 15.5 per cent of all the vouchers due to expire before the end of the first scheme year.

Almost half (46 per cent) of the systems being replaced were gas boilers, with 23 per cent replacing oil boilers.

In 16 per cent of BUS installations no heating system was being replaced: the installation was carried out in an eligible self-build property.

Figures show that the South-west of England had the highest number of BUS installations, accounting for 19.6 per cent of the total, closely followed by the South-east of England with 18.4 per cent. Just 2.7 per cent of installations were in the North-east.

Steven Ladd is walking 150 miles across the Lake District, from Barrow-in-Furness to Carlisle, then follow Hadrian’s Wall to Whitley Bay to raise money for two charities close to his heart.

Gas engineer Steven, 43, of SL Plumbing in Bristol, will start the walk on 30 September with his friend Pete Britton. Every penny the duo raise will be split between Mesothelioma UK and St Peter’s Hospice in Bristol.

Steven’s father-in-law has been diagnosed with mesothelioma, an asbestosrelated cancer that he may have contracted from his work as a carpenter.

Mesothelioma affects many people in the plumbing and heating industry, and Steven hopes the charity walk will highlight the dangers that tradespeople face at work.

More than 2,700 cases of mesothelioma are diagnosed

Viessmann has teamed up with Hiber to add a new financing package that you can use to access and offer finance to your customers.

Hiber provides instant quotations, a platform to manage applications, and financing experts. The scheme is for boiler installations initially, and heat pumps will follow later. The services add to the existing Tradehelp financing option.

The partnerships enable heating engineers to become FCA-accredited, so they can provide flexible finance payment options on installations.

Muti-channel manager James Carter says: “We are levelling the playing field and making it easier for smaller businesses to compete with the large corporates.”

every year, and exposure to asbestos is thought to be responsible for up to 90 per cent of cases. Occupations with a high risk of asbestos exposure include plumbers, heating engineers, electricians, carpenters and joiners.

An increasing number of veterans are also being diagnosed following their military service, making it a cause very close to Steven’s heart: he was a soldier before he became a plumber 15 years ago, and then a gas engineer five years later. He is also an Army reservist.

He works mainly in local homes, working on boiler servicing, installations, breakdowns and landlords' gas safety record checks.

The second charity being supported is St Peter’s Hospice, which provides care and support to adults living with a progressive life-limiting illness in the Bristol,

South Gloucestershire and North Somerset areas.

In 2021, Pete’s stepmother Carolyn was diagnosed with motor neurone disease and spent her final weeks being cared for at the hospice. Sadly, Pete’s father is also living with terminal cancer.

Steven and Pete completed a 125-mile walk last year for St Peter’s Hospice, raising more

You must register for self-assessment and file a tax return if, in the tax year 2022 to 2023, you were:

• self-employed as a sole trader and earned more than £1,000

• a partner in a business partnership

• a director of a limited company.

If you haven’t registered yet, you need to do this by 5 October 2023.

The deadline to submit an online self-assessment return is 31 January 2024. But you don’t need to wait until the deadline. If you file your tax return earlier, you’ll find out sooner whether you’re owed a refund. If you are owed a refund, you’ll get it quicker.

If you don’t register for self-assessment and file a tax return on time, HMRC may charge you penalties and interest.

Go to GOV.UK and search:

• ‘Register for Self Assessment’ – to find out how to register

• ‘File your tax return early’ – for the benefits of filing early

• ‘Queries about Self Assessment’ – for other queries.

than £4,000, and they are hoping to smash that target this time. They've been steadily building up their training in readiness for the 150-mile hike, in the gym three or four times a week and walking twice a week, increasing their distance every time.

If you would like to show your support, you can donate at: www.justgiving.com/ crowdfunding/men-on-a-walk

The government is reviewing the effectiveness of energy labelling requirements for space heaters and it’s asking for your help by completing a short survey.

The Department for Energy, Security and Net Zero is proposing to revise the UK Energy related Products Regulations, and how they affect space heating. It wants to gather first-hand experience of how energy labelling is applied currently, and suggestions for how it could be improved. This evidence will be used to consider how best the regulations should be revised.

The survey should take no longer than 15 minutes to complete, and it closes on 16 September 2023. ec.europa.eu/eusurvey/ runner/UKSpaceHeater2023

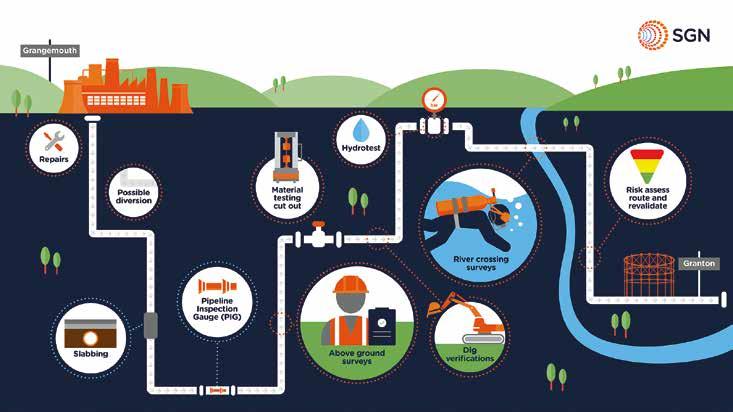

SGN has been given approval to proceed to the next stage of its project to trial 100 per cent hydrogen gas through a 30km pipeline.

The £30 million LTS Futures project is verifying the compatibility of local transmission system (LTS) with hydrogen. The company has been carrying out tests on the suitability of a decommissioned pipeline for a live hydrogen repurposing trial. The 30km pipeline runs from Grangemouth refinery to Granton on the outskirts of Edinburgh.

Over the past year, SGN engineers and researchers have carried out surveys and assessments to determine the integrity of the pipeline. The tests included an operation that involves pushing a pipeline inspection gauge (PIG) through the pipeline, using compressed air to clean it and identify any critical defects. A hydrotest was also carried out, during which engineers filled the entire

pipeline with water exceeding the pressure to which the pipeline will be exposed during the trial. The team also inspected the condition of the pipeline above ground, below ground and at river crossings.

SGN submitted the evidence gathered from this testing to Ofgem, which confirmed the suitability of the pipeline for hydrogen testing and has given the go-ahead for the project to progress to the next stage.

Gemma Simpson, SGN director of LTS Futures, says: “We’re delighted Ofgem has allowed us to continue to the second stage for this critical project, which will be to connect the existing pipeline to a hydrogen supply from our project partners, INEOS. Offsite trials will allow us to test procedures for making new connections to the pipeline. This includes the first ever live welding procedure on a hydrogen pipeline.

“If we’re successful, we’ll be

A decision on whether to proceed with the hydrogen village trial in Redcar, Teeside, will be made later this year after the government said Whitby in Ellesmere Port is no longer being considered as a location.

The village trial will convert around 1,000-2,000 properties to hydrogen or an alternative heating solution instead of natural gas. It will trial the conversion of existing gas network infrastructure in the local area, repurposing it for 100 per cent hydrogen.

This will involve replacing people’s natural gas appliances with hydrogen-compatible equivalents and making any other property adjustments needed. Hydrogen will be piped to premises through the existing natural gas network for the trial period.

The hydrogen village is expected to be operational by 2025, with the trial lasting for at least two years. Before any community trial can go ahead, HSE will need to be satisfied that it will be run safely.

able to proceed to a live trial in 2024, which will deliver a blueprint for repurposing Great Britain’s LTS network, driving decarbonisation and supporting our net-zero goals.

“We believe hydrogen has the potential to provide customers with a choice on how they heat

their homes as part of a whole-systems approach for decarbonising heat.”

The UK’s gas infrastructure firms are helping to build an evidence base for hydrogen, which will inform the government’s heat policy decisions, expected in 2026.

INTEGRATED DEFROST BUFFER

Sized to provide energy needed to defrost the outdoor unit when required.

HYDRO AUTOCONTROL

4/3 way valve integrally installed and dynamically adjusts to maintain minimum flow rate to the outdoor unit.

ONE BASE CONTROL

7” colour touchscreen display, with WiFi inside offering remote monitoring and fault diagnostics.

+ Rated heating output 2.1 to 14.9 kW

+ MCS SCOP up to 65°C

+ 70°C flow temperature for high hot water comfort

+ Environmentally responsible, natural refrigerant R290 (propane) with a particularly low GWP100 (global warming potential) of 0.02

Become a Heat Pump Partner and access the following benefits:

+ Qualified heat pump sales opportunities

+ VPlus loyalty scheme rewards

+ Access to extended guarantees

+ Pre-sales design service

Sign Up Now!

In reply to Richard Weir’s letter in the July issue of Registered Gas Engineer, I would agree that heating system control training is a MUST – but that has nothing to do with ACS.

The things you find in people’s sheds. Here’s an unused bottle of Fernox – as old as the boiler, I presume. I’m sure it will come in handy in the new install.

Gerhard Geldenhuys

We asked Fernox’s technical team if they knew how old this bottle could be. Fernox suggested that it dates from around 1990 – Floc was still being made then but was replaced soon afterwards by Superfloc. “Floc was essentially just an alkaline flocculant solution. It was a clear, colourless, highly viscous liquid.” It would have retailed for around £5-6, says the company.

What’s the oldest thing you’ve found when you’re working?

Let us know at: editorial@ registeredgasengineer.co.uk Editor

ACS is concerned with Matters of Gas Safety, which does not and never will stretch to heating system controls. ACS centres are charged with making sure that the engineers we assess are safe and are not going to cause death or major injuries – not to make sure that someone isn’t going to be cold or get wet.

The fact that Richard would

suggest we need to enforce system controls, etc, during ACS reassessment shows the state of education within our industry, in my opinion.

How has the industry allowed this lack of knowledge to fester from apprenticeship level? There has always been a requirement for system design within the Level 3 frameworks, so why is this not being taught?

We are now seeing the result of this failure, with an industry and workforce who are predominantly concerned with the heat source and not paying too much attention to the

systems and how they are controlled. Surely, as an industry, we should be concentrating on making new and existing systems and buildings more efficient, as the heat source is kind of irrelevant.

I am also not sure about the comment “self-certifying gas engineers, not complying with Part L of the Building Regulations”. Not having weather compensation fitted to a boiler does not make it a non-compliant installation, as far as I’m aware.

Julian Hearn, Sterling Assessment ServicesI was delighted to read the letters from R Ward and DT Peters in your July issue. Why don’t our MPs ‘think customer’ and then consider the ways of resolving the problem(s)? That’s what we have to do. It’s not difficult. Makes me wonder if there’s a reason why they think the way they do in Westminster. There

have been several reports in national papers that the Germans are reviewing heat pumps.

But the need to remove carbon from fuels is urgent and just installing heat pumps is not the answer. Twenty-seven million boilers and 600,000 changes a year = 46 years.

Surely [we must have] a

change of gas and removing the carbon from existing gas equals hydrogen. What else can quickly resolve our problem?

We have used gas for nearly 200 years: first town gas and now ‘fossil’ gas. Hydrogen is a major part of both.

Neil HusbandsRegistered Gas Engineer wants to see your pictures – whether you’ve come across some horrors or instances of really good work. Please email your stories and pictures to editorial@registeredgasengineer.co.uk or via Twitter to @RGEMag

We may share some of your pictures on social media, so remember to include your contact details so we can tag you (or let us know if you’d rather we didn’t).

Timothy Raine saw that the joint on this chimney/flue installation had been patched up, so he made the boiler safe and arranged to replace the chimney/flue.

Paul Holland was called to a fault with a fire and back boiler unit and found debris completely blocking the chimney/flue outlet. Fortunately, the boiler had an FSD that shut off the pilot light.

Darren Coles discovered that the intake of this chimney/ flue terminal had recently been covered by a roofing company, which had cladded and insulated the wall. Darren made the installation safe.

Gary Squires found this meter installation where a builder had boxed in the pipes to make the inside of the cupboard look neat. Unfortunately, the ECV was left inaccessible behind the new boxing. Gary created access to the ECV.

Terry Ralph saw this room-sealed boiler chimney/flue well hidden between the window and security door. The customer was advised to cut away the foliage and keep it maintained to prevent it affecting the appliance.

Stuart Gibby recently installed a new boiler and was called back after three months to remind the customer how to use the controls. He discovered that a kitchen fitter had cut a hole in the boiler casing when fitting the new kitchen because he couldn’t get the cabinet door to fit. The appliance was made safe.

Mohamed Sharif found that builders had altered the chimney/flue at a property because they thought the products of combustion were damaging the insulation. A new boiler has now been installed in a different location.

Duncan Maclean was carrying out a landlord’s gas safety record check when he discovered this removable chimney cover, which had been installed to stop debris falling on to the fire basket. The DFE fire had no purpose-provided ventilation and no data badge. It was made safe.

There’s a prize for the best photo sent in (in our opinion). Please remember to take your pictures at high resolution and email them to: editorial@registeredgasengineer.co.uk

This month iHeat is giving away a 25-piece Wera Kompact tool set with tools and bits from Wera’s top 20 for plumbing and heating systems.

iHeat is one of the fastest-growing and most trusted boiler installation companies in the UK, seeing major success due to its forward-thinking approaches, as well as the convenience it provides for its engineers.

iHeat operates with a network of more than 300 self-employed installers all over the country, each having the freedom to manage their own workload at the touch of a button via the straightforward iHeat app.

The simplicity of iHeat’s strategy means engineers never have to worry about working out of their local area or working into the evening. iHeat takes care of all the logistics, invoicing, materials and customer communication for any job, freeing up installers to work as much or as little as they’d like.

Some installation companies carry out disruptive and delaying location assessments, whereas iHeat provides time-saving online quotes in as little as 60 seconds.

iHeat covers all types of boiler installation, including upgrades, conversions, servicing and back-boiler removals. Installing highly efficient and eco-conscious boilers from the most well-known and celebrated manufacturers in Europe, iHeat fuses simplicity with innovation, representing the future of the domestic heating industry. www.iheat.co.uk

This month’s winner is Stuart Gibby from Neath. Congratulations!

Gas Safe Register’s Technical Team sets out the details of what gas engineers must carry out during a landlord’s gas safety check, what’s best practice, and how to fill in the record correctly.

The Gas Safety (Installation and Use) Regulations 1998 (GSIUR) give guidance on the minimum information that should be recorded and what tests should be undertaken.

What checks do I need to do?

Regulation 36 of the GSIUR clearly states the minimum work that must be carried out during a landlord’s gas safety check and the information that must be captured so that the check complies with the regulations. Within the regulations, 26(9) sets out the checks that shall be carried out:

• Visual inspection of the gas installation, appliance(s) location, terminal, chimney/ flue route/position and signs of incomplete combustion

• Appliance operating pressure or heat input, or both where necessary. If it is not

You must take all reasonable steps to notify any defects to the landlord or responsible person. If the appliance is supplied with LPG, you should notify the gas supplier, and in any other cases you should notify the transporter.

What other checks should be carried out?

It is recommended that you carry out a tightness test, although this is not a legal requirement.

You should also check the gas meter/emergency control valve for accessibility in an emergency, for maintenance and for correct labelling. Where specified in the appliance manufacturer’s servicing and maintenance instructions, combustion gas analysis should also be carried out.

What about gas appliances that are not provided by the landlord?

What information must be recorded on the gas safety record?

• The date on which the appliance or chimney/flue was checked

• The address of the premises

• The name and address of the landlord or agent at which the appliance or chimney/flue are installed

• A description of the location of each appliance or chimney/flue that has been checked

• Any gas safety issues identified, and any remedial action taken. This record must be retained until two further checks of the appliance or chimney/flue have been made or, if an appliance or flue has been removed from the premises, the record must be kept for a period of two years from the date of the last check

• Confirmation that the safety check complies with (but is not limited to) Regulation 26(9) of GSIUR

reasonably practicable to carry out either of these checks, then you can rely on the combustion analysis

• Ventilation is clear and sufficiently sized, etc

• Flue flow and spillage testing where appropriate for correct operation of flue

• All flame supervision devices and/or other safety controls for correct operation

• Investigate any evidence of unsafe operation of appliances.

If gas appliance(s) belong to the tenant not the landlord, you should give them a visual inspection only. The most common example is a cooker because not all landlords supply a cooking appliance. An appliance that is owned by the tenant is not the landlord’s responsibility.

What if an appliance fails the safety check?

The safety check record will contain details of any gas safety defect identified and the remedial action taken. Landlords must ensure that any gas safety defect is rectified (by a Gas Safe registered engineer) before the

• Your name, signature and registration number.

equipment is used again. It is recommended that they keep copies of work done to rectify defects identified by the safety check.

How do I record defects?

You should only record defects that are gas safety issues on the gas safety record. These are situations that are classified as At Risk or Immediately Dangerous, in accordance with the Gas Industry Unsafe Situations Procedure (IGEM/G/11).

Defects that are not related to gas safety should be communicated either verbally or via a job report or invoice but NOT added to the defects on the gas safety record. This is because doing so could potentially confuse the responsible person over what is safe and what is unsafe.

Can I still complete the record if an appliance is AR or ID?

A LGSR is NOT a certificate: it is a record of your findings when you attended that property and should always be issued once all

“You should only record defects that are gas safety issues on the gas safety record.”

relevant checks have taken place. You must complete the record to state whether the appliance/s are safe to use or not, and any gas safety defects that the landlord must address.

Do I need to complete a new record if I fit a new appliance?

No. If a gas safety record is currently in place covering the existing landlord’s appliances, the record is still valid.

As an example, let’s say the landlord has a boiler, cooker and a fire in a rented property. All appliances are owned by the landlord, so they are covered under Regulation 36.

The gas safety record check was completed in January but the landlord asks you to fit a new boiler in March. When you install the new appliance, you have a duty of care to carry out a visual inspection on the other gas appliances in that property, as per the table above, to ensure their safe operation.

After installing the boiler, the property’s cooker and fire are due to be tested and checked the following January, and the boiler in March. However, GSIUR does provide one-off flexibility to re-align the safety check the

following January, with all three appliances on the same record. Note: This can only apply to one appliance and the maximum period that the safety check can be extended is two months.

How often should installation pipework be maintained?

Landlords have a duty to maintain the gas pipework in their properties. This is a separate and distinct duty from the annual safety check but can and should be undertaken at the same time.

There is no formal or legal requirement to keep pipework maintenance records. However, landlords would need to prove, if asked, that they have regularly maintained installation pipework from the meter – or emergency control valve in the case of an LPG installation – to the appliance, and have completed any required repairs.

What if I suspect there has been tempering or theft of gas?

If you believe a gas meter has been tampered with or there has been theft of gas, you must follow the guidance in IGEM/G/11 if you consider it to be a safety defect, and report it to the responsible person or landlord. n

Checks required

An appliance is encountered while working on another appliance

An appliance forming part of a tightness test

An appliance, when purging the system of air and relighting, following work elsewhere on the installation

✔ = Required

✱ = Considered best practice

Source: IGEM/G/11, Table 3

Landlords can arrange for gas safety checks to be carried out any time 10-12 calendar months after the previous gas safety check, but still retain the original date as if the check had been carried out exactly 12 months after the previous check – much in the same way as car MOTs.

Note: The expiry date on a landlord’s gas safety record must be preserved for 12 months, even when the check has been carried out earlier than this. The Register is aware that, in some instances, gas engineers carrying out a check a month before 12 months have elapsed are then incorrectly filling in the expiry date on ‘next gas safety check due before’ as just a month later, rather than 13 months ahead.

Gas Safe Register says: “Where the gas safety check is carried out less than 10 months or more than 12 months after the previous gas safety check, this will have the effect of ‘resetting the clock’ and the new deadline date will now be 12 months from the date of this latest gas safety check.”

Some record pads include a facility to capture “next due date”. There is no legal requirement for this date to be added to the record but if a landlord wishes it to be filled in with the following year’s date, you should inspect the previous record to confirm the date on which last year’s record was completed.

Regulation 36 of the Gas Safety (Installation & Use) Regulations 1998 (GSIUR) covers the duties of a landlord regarding the gas safety of appliances. It’s important to note that the onus is on the landlord to ensure that any landlord’s gas safety record contains all the relevant information and that it is completed on time. This is NOT the gas engineer’s responsibility.

You can find more information about landlords’ responsibilities in Technical Bulletin 055: Duties of Landlords, by signing into your Gas Safe Register online account at: www.GasSafeRegister.co.uk/sign-in

The ventilation requirement for a gas appliance is usually determined by the appliance flue type. Appliances that need purpose-provided ventilation other than that needed for cooling purposes are generally conventional/open-flue or flueless appliances. Fan-assisted open flue and vertex flue gas fires may require ventilation. The requirements are usually specified by the appliance manufacturer but you should reference the relevant British Standard if none have been provided1

Why is ventilation required?

Natural gas needs oxygen to support the combustion process: for every one unit of natural gas burned, two equivalent units of oxygen are required.

Fresh air is made up of several different elements and contains

21 per cent oxygen, which means that one unit of natural gas needs 10 units of fresh air to achieve satisfactory complete combustion. If the combustion process is incomplete, increased levels of carbon monoxide (CO) will be present in the products of combustion (POCs).

CO is commonly found in POCs: however, anything that interferes with the correct combustion process will cause it to be produced at a greater rate.

How is ventilation calculated if you do not have access to the appliance manufacturer’s instructions?

When calculating the combustion ventilation requirements for an appliance in a room, you should take adventitious ventilation into account. This is ventilation supplied naturally via gaps in

floorboards, around windows and doors, etc. The usual allowance for adventitious ventilation is 7kW.

If the building containing the appliance has been built more recently and contains considerable draught-proofing, double-glazing, UPVC doors and has a solid floor construction, it will have undergone air tightness testing. In this case, please refer to Approved Document F of the Building Regulations for further guidance.

Note: The ventilation supply must be sleeved when it passes through a cavity wall; grills must be non-closable and unrestricted, ie, with no fly screens or insect mesh.

Ventilation should be taken directly to outside atmosphere

wherever possible. If this is not possible, it can be routed through other rooms: however, it is not permitted to route through a bathroom, and bedrooms should be avoided unless the appliance requiring the ventilation does not exceed 12.7kW net (14kW gross), and it must incorporate an oxygen depletion device.

If no other option is available, the ventilation can be ducted through the room to outside, keeping the duct as short as possible. This must not exceed 3m in length and it should have no more than two 90° bends. The duct should be accessible for internal inspection.

In areas where radon gas is confirmed as an issue, ventilation shall not be taken from any area below the floor. Where underfloor has been chosen as the route for ventilation and radon gas is

First, take the maximum combined appliance net heat input in kW. You can convert to net from gross (if required) by dividing the gross heat input by 1.11. Deduct the 7kW allowance for adventitious ventilation, then multiply the remaining kW by 5cm².

Using this formula, the calculation for a 21kW net heat input back boiler with a 6kW gas fire front located in a room is:

Combined appliance total heat input gross 27kW−7kW allowance for adventitious ventilation = 20kW requiring ventilation, Therefore, 20kW x 5cm² = 100cm²

For an existing conventionally flued or flueless appliance, 90 per cent of the actual ventilation requirement is acceptable if the appliance is otherwise working satisfactorily.

This type of appliance is fixed on the front face of the chimney and can generally be hearthmounted or wall-mounted above floor level.

In the first instance, if required, the ventilation requirement should be specified in the manufacturer’s installation instructions. Otherwise, it would be calculated in the same way as the example above when the appliance has a heat input rating in excess of 7kW.

This type of appliance is installed inset to the fireplace opening and offers a less obtrusive installation option than an outset fire.

Ventilation requirements, if required, should be specified in the manufacturer’s installation instructions. Otherwise, it would be calculated in the same way as above, when the appliance has a heat input rating in excess of 7kW.

This type of appliance is used purely for decorative purposes and usually resembles a solid fuel basket-type fire with artificial coals or logs as a fuel bed.

As previously, ventilation requirements for these types of fire should be specified by the manufacturer’s installation/servicing instructions. In the absence of these, refer to BS 5871-3:2005 due to the fact DFE ventilation is not covered by BS 5440 Part 2. BS 5871-3 states that unless the appliance manufacturer

provides a definite ventilation requirement, size, or that purpose-provided ventilation is not required, a ventilation system shall be supplied with a free cross-sectional area of at least 100cm².

Remember: when carrying out spillage testing on conventionally flued appliances, if the spillage test fails it could be due to the negative effect of an extraction fan operating in the room containing the appliance or in an adjacent room.

Increasing the ventilation into the room containing the appliance can sometimes help: however, before you install a permanent source of ventilation, it’s good practice to create additional ventilation by opening a window first to confirm whether additional ventilation rectifies the spillage problem.

The ventilation requirements will be specified by the manufacturer’s installation instructions. If these are not available, you should contact the manufacturer for further guidance.

This type of appliance is designed to operate without the need for a chimney and uses a catalytic converter-type device to clean the POCs before releasing them the room. As with all gas appliances, the installation must be completed in accordance with the installation instructions. These instructions should specify both the site and ventilation requirements.

In the absence of such instructions, refer to BS 5871-4:2007. This standard gives the following guidance regarding ventilation: the air vent should be adequately sized, not adjustable or closable, have no fly screen or restrictions, be sleeved through any cavity wall, and should be located at least 1000mm from the appliance.

The appliance must only be fitted in a room that contains an opening window or other form of opening that communicates directly with outside air and that has a primary heat source, such as a radiator.

These take air for combustion from outside through the outer duct of the flue assembly. For this reason, they do not usually require any combustion air provision into the room. Any ventilation requirements will be specified in the appliance installation instructions.

confirmed, ventilation may be supplied via a sealed duct running from outside the property to the ventilation location inside the property. This duct may run through the underfloor void.

Air vents supplying fresh air into the roof space or underfloor space must have a free area the same as or greater than the total effective free area of any ventilation requirement taking its air from that space.

Note: Avoid flexible ducting so as to prevent debris build-up in the duct.

Where multiple air vents are to be installed in series and pass through more than two walls, increase the ventilation requirements by 50 per cent for the internal ventilation grilles. The ventilation grilles must be located no more than 450mm from floor level. This is to help

prevent the spread of smoke in the event of a fire.

Air vents must not communicate with a roof space or underfloor space when that space communicates with another property.

Where air is being taken from a roof space, it must be verified that the roof space is ventilated in accordance with the minimum unrestricted ventilation requirements in BS 5250.

The combustion ventilation taken from such an area must be taken from at least 150mm above the loft insulation and 300mm above the roof joists, whichever is the greater, and be measured from the bottom louvres in the ventilation grille.

“One unit of natural gas needs 10 units of fresh air to achieve satisfactory complete combustion.”

Determining that existing ventilation provisions are satisfactory

First, establish that the ventilation route is satisfactory, sleeved where required, free from restrictions such as debris, fly screens or gauze, and does not communicate with any rooms that are not permitted. The ventilation grille must not be closable.

Confirm that the free area is correct: if the ventilation grilles display the free area provided by the vent manufacturer, the dimensions displayed should be taken as correct and no further measuring is needed.

If the vent needs to be measured manually, the preferred

method is to use a ventilation probe. Use another suitable measure device if you do not have a ventilation probe.

Louvres should be measured at right angles to the blades or vanes, and the most restrictive area of the component to be used should be used to calculate the free area.

The openings in the air vent must be large enough to permit the entry of a 5mm diameter ball but prevent the entry of a 10mm ball.

Remember: Always check that the appliance ventilation requirements are correct at the time of appliance installation, commissioning and maintenance. ■

1 The standards that apply to gas fires and ventilation

BS 5440-2 2009: Flueing and ventilation for gas appliances of rated input not exceeding 70kW net. Part 2: Specification for the installation and maintenance of ventilation provision for gas appliances.

BS 5871-1 2005: Specification for the installation and maintenance of gas fires, convector heaters, fire/back boilers, and decorative fuel effect gas appliances. Part 1: Gas fires, convector heaters, fire/back boilers, and heating stoves (2nd and 3rd family gases).

BS 5871-3 2005: Specification for the installation and maintenance of gas fires, convector heaters, fire/back boilers, and decorative fuel effect gas appliances. Part 3: Decorative fuel effect gas appliances of heat input not exceeding 20kW (2nd and 3rd family gases).

BS 5871-4 2007: Specification for the installation and maintenance of gas fires, convector heaters, fire/back boilers, and decorative fuel effect gas appliances. Part 4: Independent gas-fired flueless fires, convector heaters and heating stoves of nominal heat input not exceeding 6kW (2nd and 3rd family gases).

BS 5250:2021: Management of moisture in buildings. Code of practice

shares its insights to help you shape your pricing strategy.

Pricing isn’t perhaps the most thrilling of subjects but its importance is undeniable. Customers are more discerning than ever as they analyse prices and make highly considered purchases.

It’s important to get your pricing strategy right because it affects the amount of profit you make, the number of customers, and the overall success of your business.

We’ve broken down the average price of common gas engineering jobs. For comparison, we’ve broken it down to the average pricing figures from June 2023 and five years ago.

The June 2023 figures show the average of where your competitors price themselves in your region. If you charge less than the average but are constantly filling up your calendar, you may wish to consider increasing your prices.

By striking a balance, your revenue will either maintain its level with fewer hours or increase with the same number of hours – a win-win scenario.

Setting low prices can look appealing and you’ll probably attract more customers because of it. But beware: lower prices mean less profit per job, and raising prices while keeping your customers can be incredibly tough.

You also need to remember that slim margins mean that it only takes one or two jobs that go off track to wipe out your entire month’s profit.

This is all without stopping to consider that the customers attracted by low prices are often not those who remain loyal and return for repeat business.

Ultimately, every business needs to think about what their short and long-term goals are. Do you want to:

• Maintain a small-scale operation?

• Drive growth and hire more employees?

• Position yourself as a highquality service provider?

• Run a highly competitive and economical business?

Pricing strategies play an integral role in achieving any of these. And it’s up to you where you want to position your company in the market. ■

We’ve noticed two distinct characteristics that separate successful businesses from the rest:

1) The majority of those earning an above-average revenue per head are charging more than the median for individual tasks. Those charging well below the median earn far less. Because those companies that charge slightly more can still fill their calendars, this suggests that a significant portion of gas engineers under-price their services.

2) Running an organised company that does the basics well helps to provide real value to customers and sets you up to charge a premium.

Gas Engineer Software is an all-in-one software platform for heating and plumbing companies. Its easy-to-use job management software helps more than 5,000 heating and plumbing companies schedule jobs, build quotes, send invoices, issue certificates and get paid faster. www.gasengineersoftware.co.uk

Discover JG LowFit, the low-profile underfloor heating system that’s purrfect for all kinds of installations from retrofits to new builds. It’s also fit for the most demanding customers. Explore our full range at johnguest.com/lowfit

16 MM

BESPOKE HEATING DESIGN

QUICK, HASSLE FREE INSTALLATION

PERFECT FOR RETROFIT & NEW BUILD

LIFETIME TECHNICAL SUPPORT

Creating a plumbing system specification for a large commercial building is a complex task, and one where valves are often overlooked. Eric Winter, RWC’s EMEA director of product development (valves), sets out what you need to know.

W hen planning the plumbing system for a large commercial building, there’s a lot to consider, including the demands for each building, and complying with all the necessary regulations and any maintenance requirements. Then there is the need to make buildings more efficient and economical in the long term. All these factors play an important role when specifying the right plumbing fixtures and fittings.

Many of the valves you’ll come across in a commercial building are also used in a domestic setting. These include pressurereducing valves (PRVs) and thermostatic mixing valves (TMVs), but there are also valves designed specifically for large, multi-occupancy buildings, like the tenant valve (TV).

Pressure-reducing valves

PRVs work by reducing a high inlet pressure to a safer, lower pressure at the outlet. Water pressure in the UK can vary from 1 bar to 20 bar, so PRVs minimise the risk to plumbing systems. In large buildings, high pressure is often needed to enable the water to travel around the systems, but this same pressure would damage the outlets, so PRVs reduce the pressure at the point of use.

Thermostatic

TMVs keep the water at a safe temperature to prevent scalding and also allow the system to be kept at a high enough temperature to help prevent the build-up of harmful Legionella bacteria. In most commercial buildings, TMV2-approved valves need to be specified, but for hospitals and buildings in the healthcare sector, a TMV3approved valve is required. The requirements for the TMV3 scheme are higher than

TMV2, as it is designed to regulate valves for use in healthcare. These valves go through extra testing to ensure performance, based on the NHS’s HTM64 -D08 specification, which includes a requirement for valves to maintain constant water temperature, irrespective of varying hot and cold water supply conditions, and to fail safe in the event of an interruption in either the hot or cold water supply.

TVs are designed specifically for large commercial buildings, such as apartment complexes. TVs combine an isolating valve, approved as a stop valve, a PRV with an integral strainer, a patented dual reading pressure gauge, water meter carrier and a double check valve in one small, compact unit.

Thermal balancing valves (TBVs) regulate the flow rates in hot water systems depending on the temperature, so that a balanced water temperature is available when and where it is needed throughout the building. It’s important to maintain a consistent

temperature in a circuit, as this prevents Legionella growth and helps avoid heat spikes that could cause scalding or damage other plumbing components.

Preventing backflow keeps the water supply sanitary and safe. These valves protect plumbing systems from contamination via either back pressure or back siphonage.

There will be situations where the water supply to fixtures must be isolated to allow for repair and maintenance. Ball valves enable this to be done quickly and easily.

When specifying valves in large commercial buildings, the products need to comply with water regulations. This means they need to be WRAS, KIWA or REG4 approved. PRVs and backflow prevention valves should comply with European and British Standards.

When specifying any building, you need to consider whether the valves will need to be serviced, as well as any ongoing maintenance

requirements on the surrounding pipework.

Where valves need to be serviceable, it is best practice to include an isolation valve so that this can be done easily. Valves that include an integral strainer will need periodic maintenance.

You also need to consider the related pipework. In the case of a PRV, it is recommended that you have five times the pipe diameter both upstream and downstream of the valve, so if you have a 2-inch valve you should have a 10-inch straight line before any elbows to stop noise. You also need to size your valves correctly to reduce noise. For example, it is best not to put a 2-inch valve where a flow rate of a 1-inch valve can do.

For PRVs, specifying the right valve is key, as you need to consider the pressure reduction ratio. It is generally 10:1, so a 16 bar inlet pressure can reduce to 1.6 bar. You also need to correctly size the PRV to suit the flow rate of the water pressure passing through it, not the inlet pipe size, as this can lead to over-sizing and have adverse effects on the system. ■

www.reliancevalves.com

Most home buyers would be prepared to pay a premium for a smart home when choosing a property, according to Samsung UK’s new report.

Consumers want smart technology in their daily lives and are prepared to pay a premium for a smart home, according to Samsung UK’s Smart Home Buyers Index – a survey of 1,000 adults looking to buy or rent a new home within the next five years.

The survey, combined with analysis of Google search trends between March 2022 and 2023, showed that people would pay 6.5 per cent more than the average house price in the UK – which would add more than £18,000 to the UK average house price of £285,000.

It also showed that people are increasingly prioritising energy efficiency, with almost threequarters (71 per cent) describing it as a key factor when considering a smart home.

One-third of those questioned were drawn towards new-build properties, as they believe they are more likely to be pre-fitted with smart technology. Almost 40 per cent of Generation Z buyers (18-24 years old) want their next property to be a smart home, while 55 per cent said the main reason for wanting a new-build is that they are ‘designed for modern life’.

The vast majority (81 per cent) of those questioned said it was important for smart technology to be compatible and work seamlessly with current devices.

More than one-third (35 per cent) of respondents said they would be much more likely to go for a home if it was fully equipped with smart tech, while just over

Smart meters lead the way When asked specifically which devices are most attractive to consumers in the home, the majority chose a smart meter or smart TV as the most popular device.

In a breakdown of UK Google searches during April 2023 for smart devices across four

a smart home and more than half (56 per cent) said it will save them money.

Mark Seaman, head of new business development at Samsung UK, says: “These results have shown there is a real opportunity for the construction industry to answer the technology requirements of the modern consumer, to build homes that are future-fit, to give buyers smarter, more efficient and better-connected properties that stand the test of time.”

one-third said they would move into a home without smart tech but would retrofit it later. One in 10 said they would only move into a house with smart technology.

Almost nine in ten (88 per cent) of those planning to buy or rent in the next five years would consider a new-build property, with nearly half of those doing so because the homes are likely to be energy efficient.

Searches for ‘energy efficient new build homes UK’ doubled between March 2022 and April 2023.

categories – energy, lifestyle home appliances and security –smart energy devices stand out the most, with half searching this category.

It’s clear that concern around the cost of living and our impact on the environment is growing in importance. Some 29 per cent said they would like an air source heat pump in their home, which again was in the top three searches for smart home products, after a smart meter.

Almost three-quarters (71 per cent) said energy efficiency is a key factor when considering

The survey shows that smart tech in the home has evolved considerably, with consumers now more tech-savvy and more serious about the impact of devices on their lifestyles.

Those in the construction industry have a real opportunity to get involved in the smart technology movement, answering the clearly signalled requests from consumers for devices that will improve the energy efficiency of their property, save money and enhance their daily life. ■

www.samsung.com/uk/ business/appliance-solutions/ construction

“Almost three-quarters of respondents say energy efficiency is a key factor when considering a smart home and more than half said it will save them money.”

Chris Ingram, founder of Continal Underfloor Heating, looks to the future of heating controls in light of the government’s proposals to phase out gas boilers in favour of heat pumps.

T his year is proving to be a turbulent one for the heating industry. The government plans to phase out the installation of gas boilers in new-builds and is encouraging homeowners to get heat pumps installed wherever possible to improve energy efficiency.

But gas and electricity prices have been rising, and although we seem to have passed the peak for utility bills, millions of households have been forced into fuel poverty.

Take-up of the Boiler Upgrade Scheme, which provides £5,000 grants towards the cost of installing heat pumps and biomass boilers in England and Wales, has been disappointing to date. This suggests that homeowners are reluctant to pay the upfront cost of installing this technology, as people tighten their belts.

Then you have to consider that recent Building Regulations changes require all heating systems in new properties –as well as those undergoing substantial refurbishment – to be designed with a 55°C maximum flow temperature, which will have a significant impact on how the system has to be designed to ensure high efficiencies.

So where does that leave

heating engineers? What systems should you be installing now to future-proof your customers’ homes? And how do you make sure that your customers’ heating controls enable these systems to work the way they should?

While the government seems to be pinning its hopes on heat pumps, there are other possible heat source systems that can replace gas boilers, including hydrogen boilers and biomass. The only thing we can really be sure of is that any heat emitters and controls fitted today will need to be suitable for use with as many fuel sources as possible, to future-proof your customers against whatever changes lie ahead.

Underfloor heating (UFH) works with all types of heat generator from gas boilers to heat pumps and biomass boilers. Water-based UFH is the most efficient type of heat emitter available and, when designed and installed correctly, will work perfectly with whatever the cheapest, most energysecure fuel source is at the time that the property’s heating system is being upgraded.

When correctly sized and installed with a properly designed heat emitter, such as UFH, heat pumps deliver savings in two key areas compared with a

conventional heating system. First, in the quantity of carbon used per kW of heat output to the building, and, second, by achieving lower running costs compared with conventional boiler-driven heating systems.

For these two factors to be realised, however, the installation needs to be considered and designed carefully to ensure the proper sizing of the heat pump to suit the property’s demands, the correct sizing of the heat emitter to maximise the efficiency of the heat pump, and the integration of

which is why it is preferable to choose a bespoke system tailored for the project, that takes into account the customer and heat pump requirements.

Different systems require different control solutions. The issue revolves around the type of compressor within the heat pump: most use scroll compressors, which are either on or off, and there is virtually no modulation with them.

Although most do have some form of soft start, which provides a reduced starting current, it is

appropriate controls to satisfy the demands of the user and provide successful integration with the heat pump.

The sizing of the heat pump is usually as specified by the appliance supplier and tends to be smaller than that of the equivalent boiler, especially considering that many boilers are thought to be oversized by about 20 per cent. Heat pumps are usually designed for steadystate conditions and are therefore sized more tightly.

The choice of heat emitter has a major impact on the efficiency of the system. European studies have shown that UFH, when used in conjunction with air source heat pumps, is 20 per cent more efficient than when used with radiators. When used with ground source heat pumps, they can be an impressive 30 per cent more efficient.

The UFH system design should ensure that the required flow temperature is as close as possible to that for the heat pump.

Integrating the UFH and heat pump controls can be complex,

not good practice for these heat pumps to be ‘hunting on and off’ because:

• It can send power spikes up and down the power lines

• It can reduce the life expectancy of the heat pump

• It reduces its efficiency.

Therefore, the system controls must be designed to reduce these effects, by ensuring that a heat pump always ‘sees’ a minimal water quantity.