AUSTRALIAN FORESTERS in PAPUA NEW GUINEA 1922-1975

PNGAF MAG ISSUE # 9J W4 of 22nd June 2023 Part 1

PNG WOODS SERIES

PNG FOREST PRODUCTS RESEARCH CENTRE HOHOLA

PART 1

Why PNG Wood Science ?

1 District Forester TPNG 1963-1975

TABLE OF CONTENTS

“FORWOOD”

Properties of Timber Species and Notes on Uses

Timber Usage Classifications

Merchantable and Non-Merchantable Species

The Use of Timber as a Structural Material

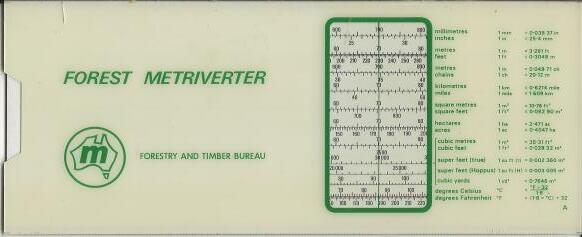

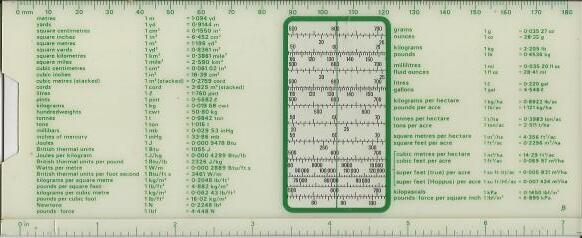

Systems of Measurement

Minor Forest Products

References

Acronyms

page 3

page 8

page 13

page 15

page 19

page 20

page 21

page 22

page 23

In 1911, James Mann4 (1857-1921) of Melbourne University, presented a paper of his work on six Papuan timber species titled 5 Papuan timbers - some of the properties of six specimens, by James Mann, 1911 from timber samples collected by Gilbert Burnett (Queensland Forest Service) during his timber resource assessment of Papua in 1908. Prior to 1940, little other than that of an empirical nature was known of the characteristics of the many timber species growing in Papua and New Guinea. The timber industry was concerned mainly with speculative exploitation of cedar, sandalwood from around Port Moresby, and New Guinea walnut from New Britain and New Ireland. The utilisation of the forests was mostly incidental to other activities like gold mining.

Lane Poole 6 1922/24 for the Australian Federal Government, collected wood samples that he examined himself using a set of hand lenses. He recorded a general description of each, the width of the sapwood, the colours of sap and heartwood, and measurements of the frequency of the rays and pores. He remarked on how the wood cuts in general categories of ‘cuts hard,’ ‘cuts firm,’ ‘soft to cut,’ ‘splits easily’, etc. Lane Poole collected and described samples of the bark. His report included measurements of the basic density of the wood samples and of the colour and presence of precipitates in solutions extracted from many but not all the wood and bark samples. He does not report whether he made the density measurements and extractions himself. (Presumably, this work was done by James Mann of Melbourne University).

During WW 2 (1939-1945), the need for development of detailed wood science commenced in TPNG The great demand for sawn timber during the war years was the Allied Forces deciding to produce as much as possible of these requirements themselves within PNG. (The high cost of shipping and lack of timber supply from Australia contributed to this decision). By the end of the war, approximately 190 thousand cubic metres of sawn timber had been produced. In addition, the forests had yielded a considerable quantity of round timber for encampments, corduroy, bridge timbers, telephone posts, piles, firewood, and many other needs of a vast army.

Evan Shield advised7 that he holds one of the few remaining rapidly yellowing copies of Technical Memorandum No. 12 NEW GUINEA TIMBERS8 a 133-page publication issued by the General Headquarters, Southwest Pacific Area, Office of the Chief Engineer (MajorGeneral Hugh J. Casey) dated 1 April 1944. The preface acknowledges CSIRO, C.E. LanePoole, Jim McAdam, Alec Crane (later Tas. For Comm) and C.J.J. Watson (the latter of the Queensland Timber Control Office) ... Only a single Class 1. species - Metrosideros spp.from the Labu swamps near the mouth of the Markham River.

4 Entry in Encyclopedia of Australian Science

5 https://www.biodiversitylibrary.org/itemdetails/33805 Vol 24 of 1912 pages 20-45

6 From exploitation to science: Lane Poole’s forest surveys of Papua and New Guinea, 1922–1924. Historical Records of Australian Science 17: 71–90. by John Dargavel. School of Resources, Environment and Society, Australian National University, Canberra, ACT 2000, Australia.

7 Personal communication Evan Shield of 4th Nov 2022.

8 Allied Forces South West Pacific Area Office of Chief Engineer 1944. New Guinea Timbers. Vic Govt Library Services.

At Yalu Lae in 1944, C.T White, the Queensland Government Botanist, ran a botanical school for the Australian Army Forest Survey Unit under J B McAdam with Eric Dadswell9 lecturing on wood technology. Under Dadswell directives, mechanical and other tests were conducted at the Division of Forest Products, CSlRO, on several New Guinea species. Major Max Jacobs headed the technical unit in Australia responsible for organising wood testing.

Since 1945, this cooperative CSIR (in 1949 it became CSIRO) work has been continued for the Department of Forests, Territory of Papua and New Guinea.

The cessation of hostilities in 1945 found that all the towns, with exception of Port Moresby, in ruins. Salamaua, Lae, Rabaul, and Madang were destroyed. Given the demand for timber in Australia and the scarcity of shipping space, it was necessary that the bulk of timber required for reconstruction be produced locally. The provisional administration through the TPNG Department of Forests established and operated sawmills using war surplus equipment and staffed largely by personnel recruited from the wartime Army Forestry Units.10

Rodgers11 (1947) advised that the Division of Forest Products CSIR wood structure section had made a comprehensive study of the macroscopic and microscopic characteristics of Australian timbers. During World War 2, card sorting keys were developed for the timbers of the Pacific Islands which were of considerable benefit to the Allied Forces fighting in that zone.

Rodgers (1947) advised that future work of the Forest Products Division of CSIR would be acting in close co-operation with the New Guinea Forests Department, where the Division proposed to continue and extend the work on the examination of physical and mechanical properties of New Guinea timbers.

Dadswell and Ingle12 (1948), reported on a survey dealing with the timbers of the south-west Pacific area and covering 22 genera of the family Anacardiaceae. Based on the examination of available species, the anatomical features of each genus were summarized and the relationship between botanical classification and the wood anatomy of the genera discussed. From the information presented it was suggested that a simple card sorting key can be readily developed.

Material for this survey was taken from the standard collection of the Division of Forest Products CSIR. This included various authenticated specimens received on an exchange basis from forestry authorities in India, Burma, the Dutch East Indies, and the Philippines. Special reference must be made to the specimens of Malayan timbers received in 1941 through the courtesy of Dr. H. E. Desch; to specimens of New Guinea timbers, kindly made available by Mr. C. E. Lane-Poole, collected during his survey in that region in 1924; to specimens from the Waterhouse collection in New Guinea and the Solomon Islands supplied by the late Dean S. J. Record of Yale School of Forestry; to specimens of timbers from New Guinea and surrounding islands and from North Borneo collected by the Australian Army Forestry Units

9 Dadswell H. E. & Eckersley A.M. 1943 Some timber species of Papua and New Guinea with descriptive notes of properties and uses and means of identification. Vic Govt Library services.

10 J B McAdam 1952:” Forestry in New Guinea” Paper to Papua & New Guinea Scientific Society’s Annual Report

11 Rodgers 1947. History of Research work in Forestry and forest Products in Australia and PNG. Unasylva Vol 1 #3 Nov-Dec 1947. FAO.

12 Dadswell H. E. & Ingle H. D. 1948 THE ANATOMY OF THE TIMBERS OF THE SOUTH-WEST PACIFIC AREA I. ANACARDIACEAE.

during the Pacific war period; to specimens from New Guinea supplied by Mr. J. B. McAdam, of the PNG Forests Department; and to specimens from the British Solomon Islands collected by Mr. F. S. Walker in 1945 and 1946. The botanical identifications of the material from New Guinea, collected by Mr. Lane-Poole and by the Australian Army, and of that from the British Solomon Islands collected by Mr. F. S. Walker were conducted by Mr. C. T. White, Government Botanist, Brisbane.

In 1949, there was commenced a tannin extracting industry based on the mangrove forests of the Gulf of Papua where the bark extract (called cutch), was used to dye materials khaki and to preserve fishing nets. It threatened to leave to waste vast quantities of timber following commercial stripping of the bark. The Dept of Forests TPNG13 engaged CSIRO’s Frank Phillips to look at whether this waste timber from the debarked trees, could be used for pulp and paper manufacture. Phillip’s work was of great significance in influencing the development of PNG’s wood science for the development of sustainable forest industry enterprises.

Photo Gulf of Papua Mangroves Dick McCarthy Thankfully, the cutch industry, did not last long because it was an ill-conceived industry being one of pure exploitation of an important ecological resource. i.e., the Gulf of Papua mangrove forest resources.

By 1952, the TPNG sawmilling industry had reached the stage where it was able to meet the local demand. Mill output had reached 24,000 cubic metres per annum.

In January 1954, the establishment of a plywood mill at Bulolo by CNGT (Partners Australian Government and Bulolo Gold Dredging Company) commenced production.

The mechanical properties of klinki pine (Araucaria hunsteinii syn. A. klinkii) have been reported (Ryan14 1959), and the properties of several timbers from the Territory were included in an earlier compilation (Stewart and Kloot15 1957).

Boltz and Kloot16 (1966) study re the mechanical properties of 81 New Guinea timbers, objective was to determine which species were likely to provide timber suitable for structural purposes

13 Personal communication Des harries 20th June 2022.

14 Ryan A 1959. The mechanical properties of klinki and Parana pines Technol. Pap. Div. Forest Prod. CSIRO Aust No. 5.

15 Stewart A.M. & Kloot N. H. The mechanical properties of Australian, New Guinea and other timbers. Bull. Comonw scient. Res. Org. No 279

16 Bolza E & Kloot N H 1966. (formerly in Division of Forest Products technological Paper # 41 1966) now 1976 The Mechanical Properties of 81 New Guinea Timbers CSIRO Building Research.

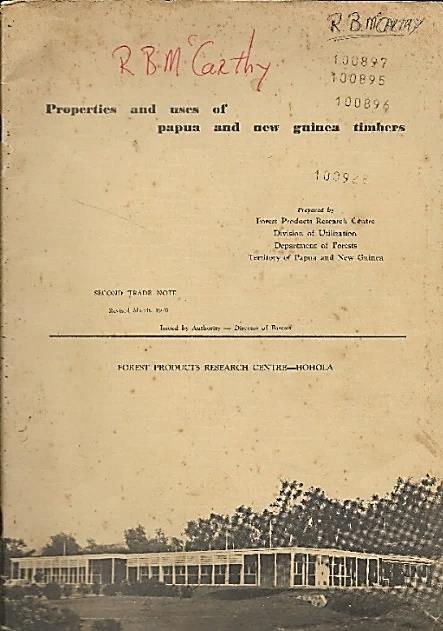

Properties and Uses of PNG Timbers

Following World War 2, PNG Wood scientists continued the work of ascertaining the properties and uses (actual and potential) of PNG Timbers. Many of the more common species continued to be tested by the then Division of Forest Products CSIRO Melbourne Australia even after the establishment of the FPRC at Hohola PNG in 1966.

This ongoing work22 was published in works as Properties and uses of PNG timbers (first published 1961) and Commercial Timber of Papua New Guinea. Each known timber species was delineated by:

Number. Hand sample numbering of FPRC Hohola and linkage to Lae Herbarium NG Botanical series.

Trade Name PNG timbers are recognised by several different local names. Adopting the procedure of Standards Australia, the standard trade name is the one officially recognised by the Dept of Forests PNG.

Botanical name and Locality. Following international botanical nomenclature, plants are named by the name of their genus followed by the species name and then the abbreviation of the name of the botanist who originally described the species. PNG wood scientists have given each timber plant its species name and specific epithet e.g., Octomeles sumatrana recognised by the PNG National Herbarium.

Density. The weight of wood in kilograms which would occupy a volume of one cubic metre at a moisture content of 12 %.

Basic Density. The weight of wood at 0% moisture content in kilograms, which would occupy a volume of one cubic metre when in the green condition.

22 Dept of Forests TPNG Properties and uses of Papua and New Guinea Timbers First edition 1961 and Eddowes PJ 1977 Commercial Timbers of Papua New Guinea FPRC Dept of Forests PNG

Strength groups. Adopted from the Australian system of seven strength groups.

Modulus of Rupture. This is the measure of the maximum compressive or tensile stress in the fibres at the point of fracture, i.e., a direct measurement of the strength of wood in bending.

Modulus of Elasticity. This is a measure of the stiffness or rigidity of wood. e.g., for a beam a measure of its resistance to deflection.

Maximum Crushing Strength. (or compression parallel to grain.) this is a measure of the maximum stress sustained by the timber under a load slowly applied parallel to the grain. It indicates the relative suitability of timber for columns.

Maximum Shear Strength. (shear). This is the measure of the ability of timber to resist slipping of one part upon another along the grain.

Boltz and Kloot23 (1966) study re the mechanical properties of 81 New Guinea timbers objective was to determine, as part of a more general survey, which species were likely to provide timber suitable for structural purposes, and, to this end, sampling of as wide a range of species as possible has been arranged.

In all, 81 species are listed, the mechanical properties for each being tabulated for ready reference for those working in the field of wood technology. To obtain the information, tests were conducted in general conformity with accepted timber testing specifications. The format of presentation follows that used in

Permeability. Timbers have been classified according to ease of penetrating the heartwood with preservative under pressure at 1380 kilopascals.

Class 1 Treatable through full section, ideal for treatment at 1380 kilopascals.

Class 2 Wide treatable sapwood and/or reasonably uniform treatment in heartwood, suitable for treatment at 1380 Kilopascals.

Class 3 Resistant, erratic non-dependable penetration of heartwood.

Class 4 Highly resistant, comparatively narrow sapwood or untreatable heartwood.

Sapwood. Lyctus Susceptibility. A timber’s propensity to infestation by lyctine insects, principally the powderpost beetle Lyctus brunneus

Rating Description

L.S. Sapwood – Lyctus susceptible

L.N. Sapwood Lyctus non susceptible (L.S.) Where susceptibility has been noted in undetermined species from within a particular genus.

Timber Movement. Timber is hygroscopic, meaning that it will gain or lose moisture from the air based upon conditions of the surrounding environment, as the wood gains or loses moisture, the cells expand or contract resulting in shrinking or swelling, which ultimately affects the overall dimensions of a piece of timber, often referred to as the wood’s movement.

Timber is anisotropic meaning that this movement is dependent on the direction or orientation of the grain and is it’s not the same in all directions, often referred to as dimensional shrinkage.

Moisture Content in timber has a profound effect on the material, causing swelling in high humidity, and shrinkage in low humidity environments.

EMC or Equilibrium Moisture Content is the percentage of moisture content a piece timber will stabilise at when it is kept in the same conditions throughout the year.

Fibre Saturation Point When all the free water is removed from the timber during the drying process it is said to be at the fibre saturation point and up to this point there will be very little to no shrinkage. As the drying process continues past the fibre saturation point the timber will experience shrinkage.

Shrinkage. A basic measurement of shrinkage expressed as a percentage is the amount that the wood shrinks when going from its green to oven dry/kiln dried state. In other words, since wood in its green state is at its largest dimension, and oven dry represents its driest (and therefore smallest) volume, green to oven dry is a measurement of the maximum possible percentage of shrinkage; this is referred to as the wood’s volumetric shrinkage.

Volumetric shrinkage tells how much a wood species will shrink, but it doesn’t indicate the direction of the shrinkage. The two primary planes or surfaces of wood where shrinkage takes place are across the radial plane, and across the tangential plane, corresponding to radial shrinkage, and tangential shrinkage; these two values, when combined, should roughly add up to the volumetric shrinkage.

Timber Usage Classifications.

Eddowes 199726 detailed a PNG Timber Trade classification of the multiplicity of PNG timber species into the following categories.

Group Category

Group1

Group 2

Group 3

Group 4

Group 5

Group 6

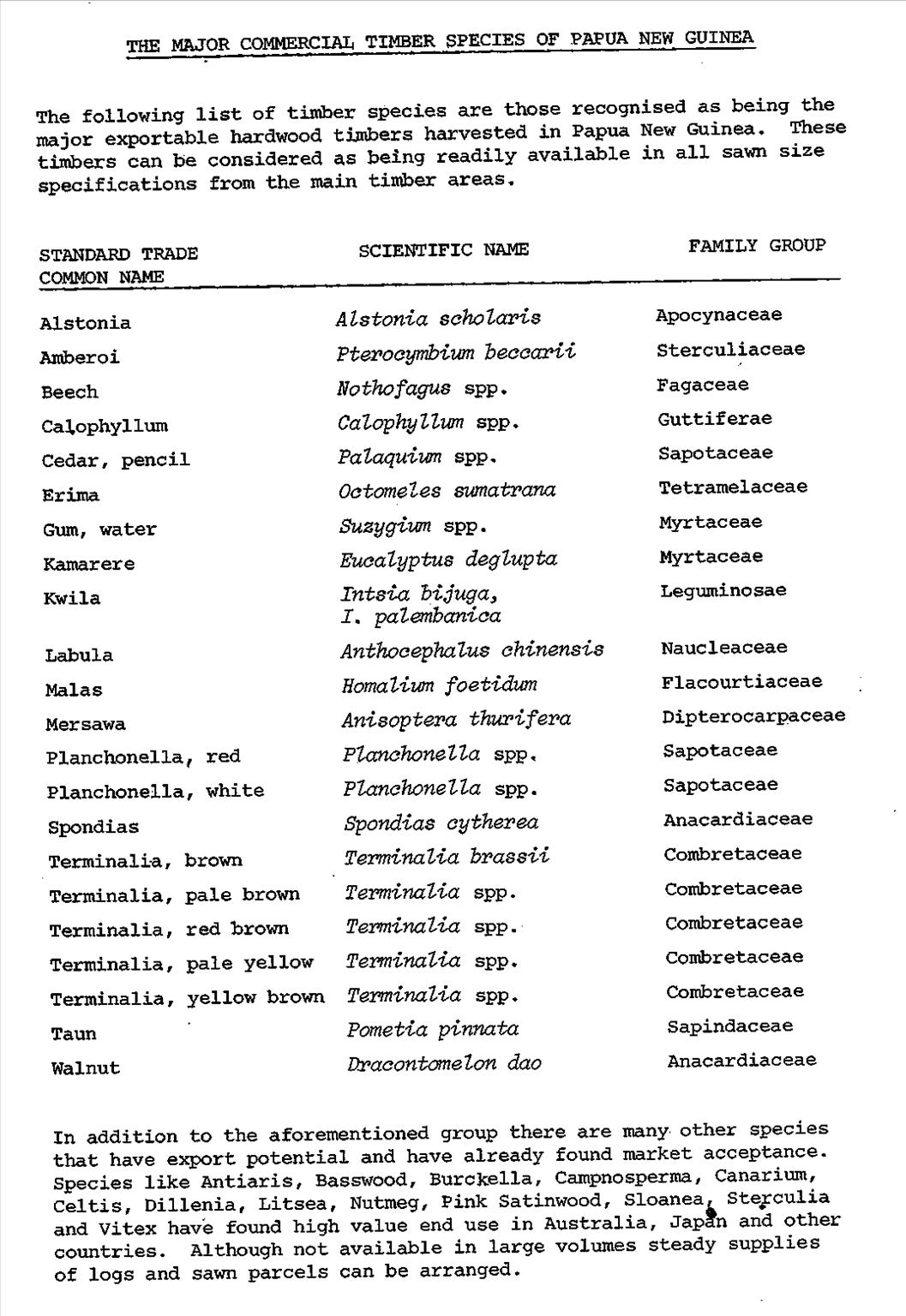

Major exportable hardwoods

Commercial hardwoods

Minor Hardwoods

Softwood group

Plantation Species

Other species

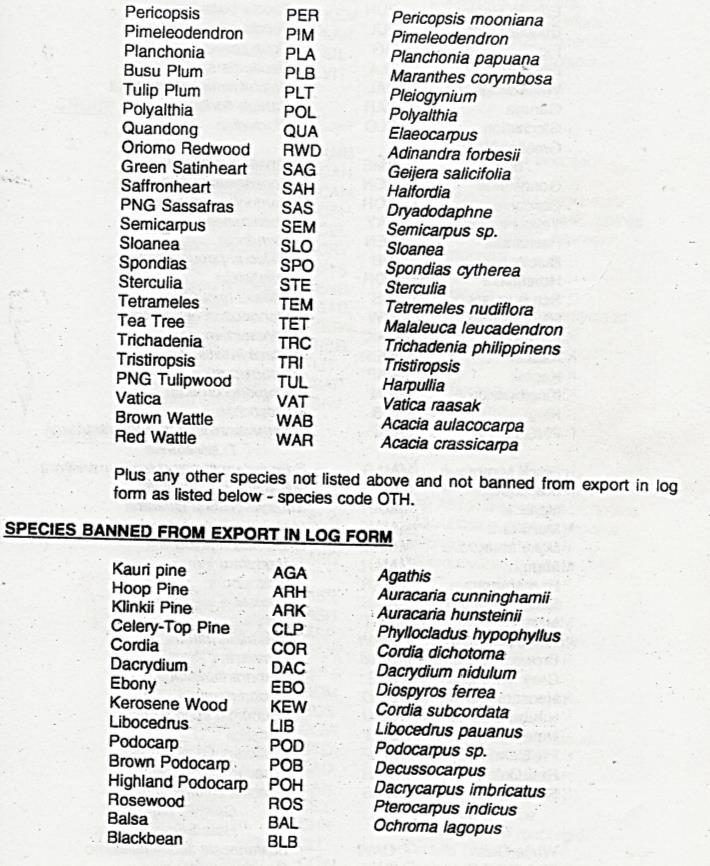

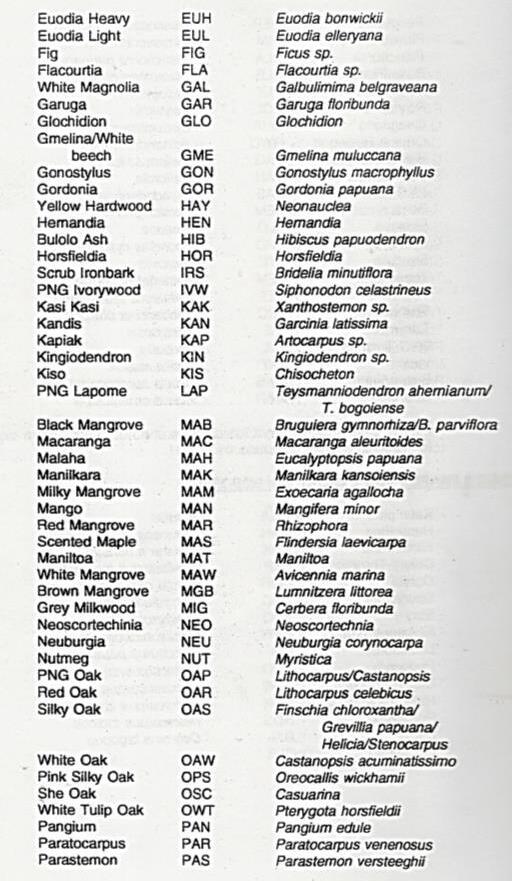

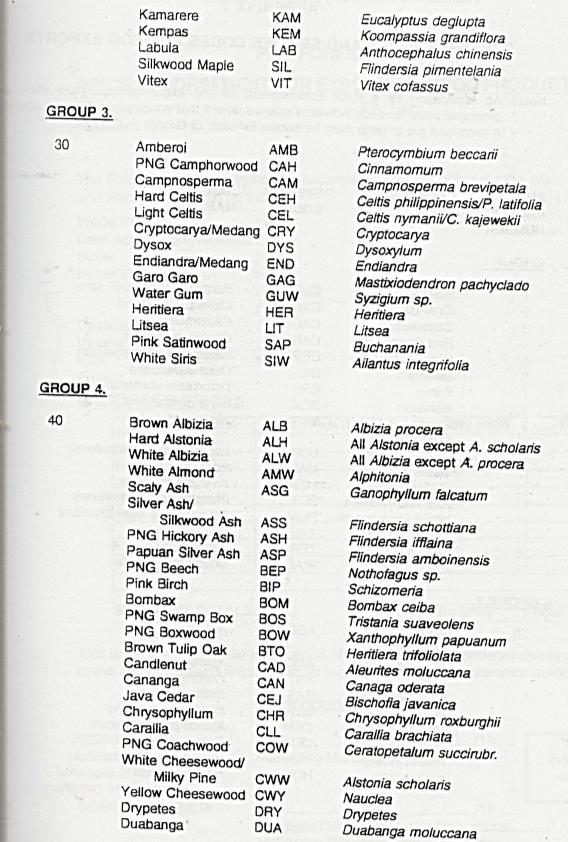

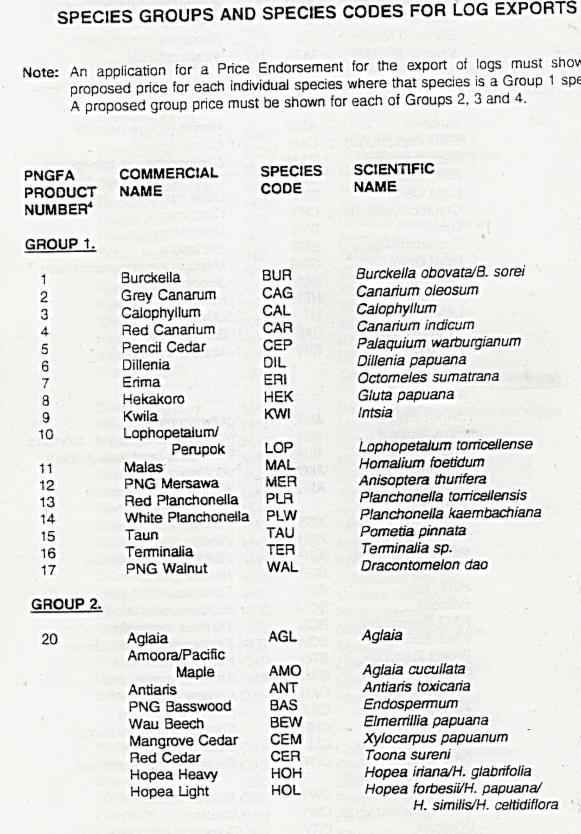

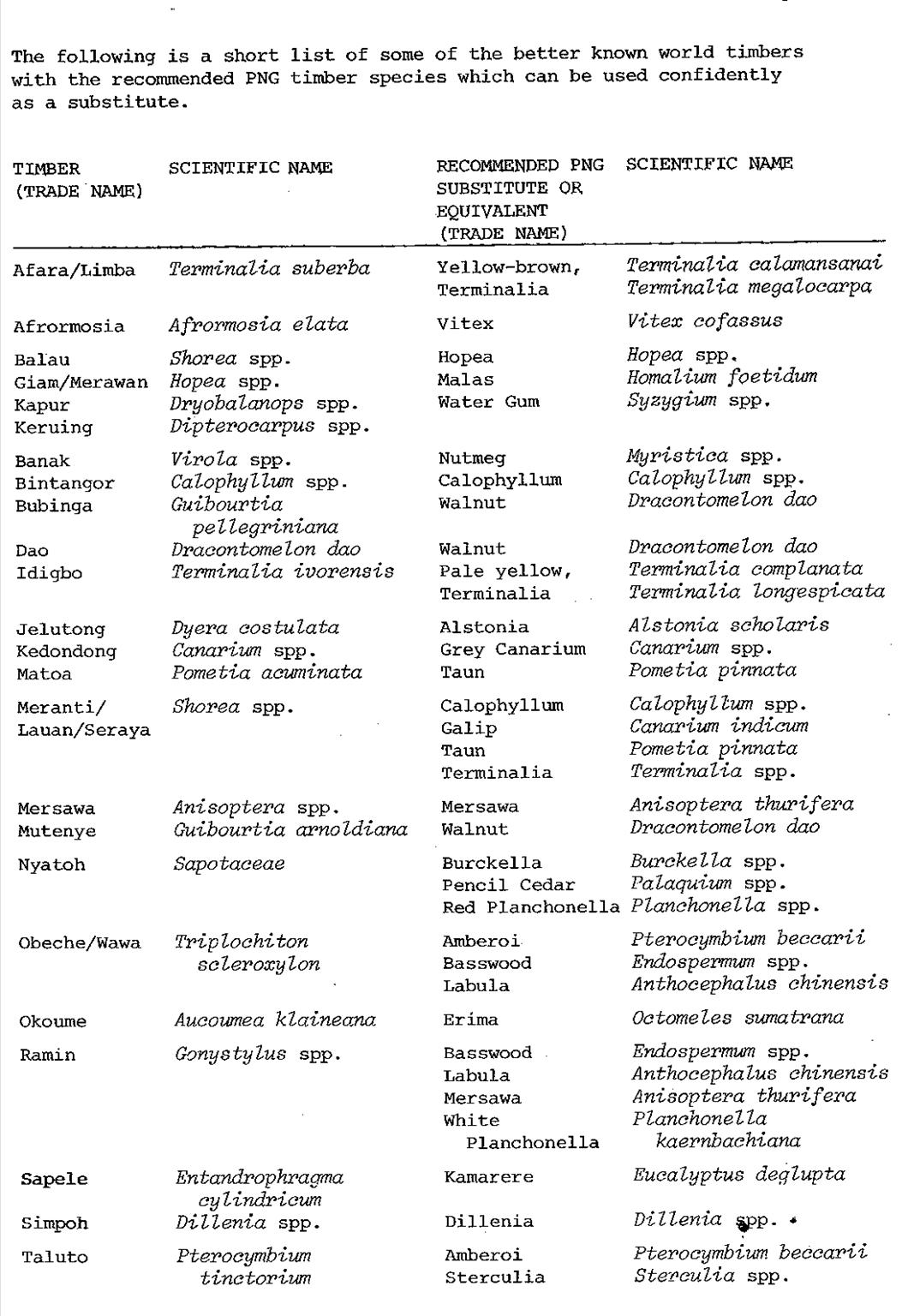

Forest Industries Council 198527 detailed a PNG Timber Trade Classification of species.

Forest Industries Council 1979 Timber Training Manual #1 Introduction to Grading.

Group Category

Heavy Hardwoods Heavy construction timbers over 750kg/m3 at 12 % m c.

Naturally durable but sapwood not durable.

Medium hardwoods Constructional timbers ranging in weight from 575 to 750 kg/m3 at 12 % mc.

Require preservative treatment before on ground contact.

Light Hardwoods Range in weight from 250 to 575 kg/me at 12 % mc.

General utility timbers requiring preservative treatment before on ground contact.

Softwood Group Require preservative treatment before on ground contact.