EPDM ROOFING MEMBRANES

Available cut to size in your local Roofbase branch from 30.5m rolls in 3.05m, 4.57m and 6.1m widths.

Available cut to size in your local Roofbase branch from 30.5m rolls in 3.05m, 4.57m and 6.1m widths.

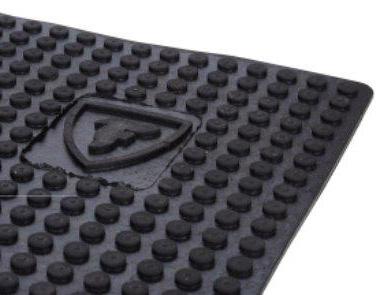

The Firestone RubberCover EPDM membrane is a 100% cured single roofing membrane made of a synthetic rubber Ethylene Terpolymer. It is lightweight, flexible, easy to work with and allows short installation time. It comes in large sheets which can cover most residential roofs in one piece without any field seaming.

Firestone RubberCover offers unmatched resistance to UV radiation, ozone, alkaline rains and high or low temperatures. Along with a 20 year guarantee.

APPLICATION Allow 0.4m for overhang. Lay the membrane out on the substrate for 30 minutes prior to adhering to the substrate. Install the RubberCover EPDM membrane in accordance with the installation instructions and details.

Substrates need to be clean, smooth, dry and free of sharp edges, loose or foreign materials, oil, grease and other materials that may damage the membrane. All surface voids greater than 5mm wide shall be properly filled with an acceptable fill material.

The dimensions ofthe membrane are calculated to coverthe substrate and possible upstands. Provide an additional length (150mm) at upstands for easy manipulation.

Elastomeric membrane with a good combination of high elasticity and tensile strength. Excellent resistance to UV and ozone. Retains its elasticity even at temperatures as low as -45°C. Resists to temperature shocks up to 130°C. Excellent resistance to alkali rains, less resistant to oil products. Contact with mineral and vegetable oils, petroleum-based products, hot bitumen and grease must be avoided.

Note: As European standards continue to develop, please contact Firestone’s Technical Department or visit www.firestonebpe.com for the latest updates on physical properties.

Storage: Store away from sources of punctures and physical damage. Store away from ignition sources and open flame. Shelf life: Unlimited.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

Water Based Adhesive is designed specifically for bonding Firestone RubberCover EPDM membranes to approved insulations in addition to wood, masonry and other acceptable substrates.

Apply the Water Based Adhesive with a solvent resistant roller, and roll the adhesive onto the mating surfaces. When applying Adhesive, ensure complete uniform coverage of both surfaces that will be adhered. Care must be taken not to apply Adhesive over seam areas. Adhesive can be dispensed by means of RoofTop SuperSpreader in order to achieve a more uniform coverage and obtain higher coverage rates.

Allow adhesive to flash off until tacky (time depending on ambient air conditions) prior to mating the surfaces. Test the adhesive for its dryness, using the touch-push test procedure. As an alternative to the contact adhesion application method, outlined above, Water Based Adhesive may also be mated while still wet directly over plywood or OSB substrates only. Apply Water Based Adhesive over plywood or OSB with a solvent resistant paint roller, taking care to completely cover the plywood or OSB substrate evenly to avoid globs and puddles of adhesive. The EPDM membrane shall be mated as soon as possible after the adhesive is applied by rolling the membrane in place over the plywood or OSB.

To ensure proper adhesion, compress the bonded portion of the sheet to the substrate with a stiff push broom or heavy roller. The optional Wet Mating Method is only applicable when membrane is bonded indoors, not exposed to any wind stresses for 48 hours and not exposed to freezing temperatures for minimum 48 hours.

Surfaces that will receive RubberCover Water Based Bonding Adhesive must be clean, smooth, dry, free of sharp edges, loose and foreign materials, oil, grease, and other contaminants. The mating surface shall be cleaned with a brush or clean rag. Restore the adhesive to room temperature (15°-25°C) before use if the product has been exposed to temperatures lower than 15°C for a prolonged period. Stir the adhesive thoroughly (to achieve a uniform mix with no sediment on the bottom and no marbling evident) before and during use.

Coverage rate needs to be between 2.5 and 3m2 per litre. Some surfaces are more uneven and porous and will result in lower coverage rates, while smoother substrates are less porous and will therefore result in higher rates.

Refer to Material Safety Data Sheet. Avoid prolonged contact with skin. Keep away from eyes. Thinning is not allowed.

Physical Contains no solvents (odor-free and non-hazardous)

Excellent resistance to aging

Good resistance to heat and cold

Outstanding adhesion to approved substrates for maximum performance

Technical Base Acrylic dispersion

Colour White

Solids (%)55% (minimum)

Viscosity36000-44000 cp

Specific gravity1.02

PACKAGING / STORAGE / SHELF LIFE Packaging

Part numbers W56RAC7200 / W56RAC7201 / W56RAC7202

Storage: Store in original unopened containers at moderate temperatures (15°C-25°C) in a dry, well-ventilated area. Protect from direct sunlight. Do not allow product to freeze. If necessary, use an insulated box to maintain the product at moderate temperatures during transport to the job site, before and during application. This will assure the appropriate viscosity, efficiency and performance of the adhesive.

Shelf life: 12 months can be expected if stored in above-mentioned conditions. Verify production date on each pail. Subzero temperatures will make product unusable. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling of the accessories. Once opened, use within 48 hours.

Disposal: Make sure that the pail is empty prior to disposal. Adhesive cannot be disposed in drains.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

A non-flammable, water based SBR adhesive specifically developed for adhering membrane to ply on flat or gently sloping roofs. Contact adhesive is recommended for up-stands and other substrates.

Should be applied using a notched trowel or serrated spreader to an approximate coverage rate of 3m2 / litre. A larger quantity of adhesive is necessary for open texture and rough surfaces. Smooth surfaces such as plywood may require less adhesive up to a maximum of 4m2 / litre dependent on experience and technique of application. Do not dilute the adhesive or use on a damp surface.

PREPARATION

Surfaces should be clean, dry and free from dust, grease, loose material and other contaminants.

The roof sheet should be laid into the adhesive during this period and pressed firmly into the adhesive with a roller or squeegee. Ensure recently laid roof area is adequately protected against the elements. Protect adhesive from frost. Alternatively a desiccator can be connected to the small bung hole of the drum, which will dry the incoming air, replacing the adhesive used. Asuitable desiccator with the relevant pipework can be supplied by Abrabond. This will last for approximately 3 months prior to regeneration. Further information is available upon request. If water enters the drum of adhesive, it will react giving off carbon dioxide which can cause over pressurisation of closed cans and drums.

CHARACTERISTICS

Technical Base SBR

Colour White Solids (%)50% Viscosity40,000

Tack life5-30 mins

Cleaner Waterwhen wet

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: The adhesive has a long effective open time, ranging from approx. 5 to 30 minutes after application assuming average UK weather conditions. 6 months - 12months between 5oC and 30oC.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone RubberCover Bonding Adhesive BA-2012 is a solvent-based contact adhesive designed specifically for bonding Firestone RubberCover EPDM membranes to approved insulations in addition to wood, metal, masonry and other acceptable substrates. Used for upstands and masonry. Allow adhesive to be touch dry before mating.

Apply RubberCover Bonding Adhesive BA2012 at about the same time onto both surfaces to be adhered, in order to allow approximately the same drying time. The adhesive can be manually applied using a solvent resistant roller, can be dispensed by means of a Rooftop SuperSpreader or can be applied using approved spray equipment. The latter methods may be used to achieve a more uniform coverage and obtain higher coverage rates. Contact Firestone for detailed information about RoofTop SuperSpreader and spray equipment.

Apply RubberCover Bonding Adhesive BA2012 evenly, avoiding areas of accumulation onto the mating surfaces. When applying RubberCover Bonding Adhesive BA-2012, ensure complete uniform coverage of both surfaces to be adhered. Care must be taken not to apply RubberCover Bonding Adhesive BA-2012 over seam areas.

Application temperatures may vary between 5°C and 35°C. At temperatures below 5°C the adhesive may become too thick for correct application. The condensation risk also increases at temperatures below 5°C. At temperatures above 35°C and when the membrane surface is exposed to direct sunlight drying time will be shortened significantly and may result in loss of tackiness. Work in smaller sections and check for tackiness before mating. Apply a second layer of adhesive if necessary.

Allow the adhesive to flash off until tacky (time depending on ambient air conditions) prior to mating the surfaces. Test the adhesive for its dryness using the touch-push test procedure. If the surface is porous, check thoroughly if there is sufficient adherence and apply an extra layer if necessary.

APPLICATION

The Firestone RubberCover Bonding Adhesive BA-2016 S is a sprayable solvent-based contact adhesive designed specifically for bonding Firestone RubberCover EPDM membranes to approved insulations in addition to wood, metal, masonry and other acceptable substrates.

Gently apply the RubberCover BA-2016 S onto both surfaces to be adhered, first on the substrate and afterwards onto the EPDM membrane. The ideal distance between the surface and the nozzle of the spray gun or spray can is 25 - 30 cm. Try to apply the correct amount of adhesive in a single layer and avoid areas of accumulation. Care must be taken not to apply RubberCover BA-2016 S over seam areas.

Application temperatures may vary between 5°C and 30°C. At temperatures below 5°C the adhesive may become too thick and consequently an insufficient quantity of adhesive may be sprayed on the surface. The condensation risk also increases at temperatures below 5°C. At temperatures above 30°C and when the membrane surface is exposed to direct sunlight, the adhesive may dry too quickly for proper adhesion. Work therefore in smaller sections and always check for tackiness before mating.

Apply a second layer of adhesive if necessary. At high temperatures, protect the canister and hose from direct sunlight and keep the canister inside the carton. If the canister or the hose heats up, this may negatively affect the spraying pattern.

Allow the adhesive to flash off until tacky prior to mating the surfaces. Test the adhesive for its dryness using the touch-push test procedure. If the surface is porous, check thoroughly if there is sufficient adhesion and apply an extra layer if necessary.

Refer to the instructions in the Technical Information Sheet of the Spray Gun Kit for additional information regarding use of the canister.

Packaging 750 ml spray can: 12 cans/carton - 76 cartons/pallet 17 L pressurized canister: 36 canisters/ pallet

Part numbers

W56RAC1084 - 17 L pressurized canister

W56RAC1085 - 750 ml spray can

Storage: Store at temperatures between 10°C and 25°C in a dry, well-ventilated area. Do not store at less than 5°C to avoid the product becoming unusable. Keep away from heat, sparks and open flame. Protect from direct sunlight and do not expose to temperatures exceeding 30°C. If necessary, use an insulated box to maintain the product at moderate temperatures during transport to the job site, before and during application. This will assure the appropriate viscosity, efficiency and quality of the adhesive. Do not pierce or burn the cans. Always carry the canister, even when in its carton, by its handle located at the top of the canister. Do not manipulate or carry the carton by its sides or corners because the canister may drop through the bottom of the carton.

Shelf life: 12 months can be expected if stored in the above-mentioned conditions. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the method of storage and handling. The product is still usable as long as it can be sprayed. The canister can be rolled or shaken prior to improve mixing of the components. It is not necessary to shake the aerosol can.

Transport: The maximum total quantity of 17 L canisters per transport (whether on their own or where products are combined in a transport) should not exceed 333 litres (19 canisters), otherwise special ADR transport must be organized. The carrier must have 2 fire extinguishers in all cases. Relevant placards must be affixed on the trailer when above mentioned quantity is exceeded. Being the 17 L canisters a UN 3501 class, there are specific additional requirements: canisters must be transported in a cardboard box and the truck must be ventilated. A standard curtain-sider is considered a ventilated truck. If a box trailer is used (hard sides), then it must be mechanically ventilated, otherwise a warning sign should be affixed on the trailer “warning –no ventilation, open with caution”. Unloading of closed vehicles shall not be done by people carrying equipment that can ignite any flammable vapours. The 17 L canisters cannot be transported when connected with spray application equipment, with the exception of canisters transported to and from a job site and that are already in use. Sprayable adhesives in canisters (UN3501) cannot be shipped overseas together with other bonding adhesives (UN1133).

Disposal: Empty canisters can be disposed with old metals, while aerosols have to be collected by a specialized company in accordance with regional regulations. Preparation to dispose the canister with the old metals:

Step 1 - remove the hose and connect it directly on another canister to avoid dry glue in the hose.

Step 2 - open the canister crane on top to release the remaining gases.

Step 3 - use a screwdriver and a hammer to perforate the canister at the weak round spot on top of the canister.

Step 4 - remove the flammable gas label.

EDGE TRIM GUTTER TRIM

INTERNAL EDGE TRIM CORNER

EXTERNAL CORNER

EXTERNAL GUTTER TRIM CORNER

CORNER ADHESIVE

EDGE TRIM GUTTER TRIM

INTERNAL EDGE TRIM CORNER

EXTERNAL CORNER

EXTERNAL GUTTER TRIM CORNER

CORNER ADHESIVE

All trims come complete with clips and fixings.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

PLASTISOL WALL TRIM

TERMINATION BAR

METAL EDGE TRIM

BATTEN BAR

WALL TRIM FIXINGS, HEX HEAD FIXINGS & TERMINATION BAR FIXINGS

PLASTISOL WALL TRIM

TERMINATION BAR

METAL EDGE TRIM

BATTEN BAR

WALL TRIM FIXINGS, HEX HEAD FIXINGS & TERMINATION BAR FIXINGS

All trims come complete with clips and fixings.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone QuickPrime Plus is designed to clean and prime the RubberCover EPDM membrane and/or substrate before the application of a QuickSeam product. QuickPrime Plus must be applied with a QuickScrubber™ pad and handle.

Apply QuickPrime Plus to the RubberCover EPDM surfaces and/or other substrates to receive QuickSeam products with the QuickScrubber™ pad and handle, using long back and forth strokes with moderate to heavy pressure along the length of the area until surfaces become dark grey, with no streaking or puddling. Allow the primed surfaces to dry completely (usually less than 10 minutes) before applying a QuickSeam product.

Surfaces to be primed must be clean, dry and free of foreign materials, talc and dirt. Pre-cleaning may be required. Stir QuickPrime Plus thoroughly before and during use. When exposed to lower temperatures for a prolonged period of time, restore to room temperature prior to use. Pour the required amount of QuickPrime Plus into a bucket for ease of application.

Thinning is not allowed. The following can be achieved with 1 can (0.95 l):

QuickSeam SA Flashing: 8 lm - 1 side.

QuickSeam Corner Flashing: 50 pieces - 1 side.

QuickSeam Cover Strip: 20 lm - 1 side.

PRECAUTIONS

Refer to Safety Data Sheet (SDS). Flammable. Keep away from fire and open flame and other possible ignition sources during storage and use. Do not smoke when using. Use only in well ventilated areas. Avoid contact with skin and eyes. For professional use only. Keep out of reach of children.

CHARACTERISTICS

Technical Base Synthetic rubber polymers

ColourTranslucent grey

SolventsHeptane, toluene

Solids (%)16%-18%

ViscosityVery thin, free-flowing

Specific gravity0.793 (Water = 1)

Flash point-17.8°C

PACKAGING / STORAGE / SHELF LIFE

Packaging 0.95 l (1⁄4 US gallon) pail – 12 pails per carton

Part number W56RAC1695

Storage: Store in original unopened containers at temperatures between 15°C and 25°C until ready for use. Keep the material out of direct sunlight until ready for application.

Shelf life: 12 months can be expected if stored in above-mentioned conditions. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling of the accessories. Quality and applicability should thus always be verified: when mixed, product should stir into a smooth and homogeneous blend with no evidence of major clumping or separation/phasing.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

The Firestone QuickSeam FormFlash 18” is a 450mm wide uncured EPDM strip factory-laminated to QuickSeam Tape. It has a polyester release liner for easy removal and excellent weather resistance. The QuickSeam FormFlash 18” can be used to carry out general roof repairs and flash in drain insert pieces. Used for detailing around pipes, skylights, external corners and other awkward areas. Firestone Quickprime plus is required for this product.

APPLICATION On cloudy days with ambient temperature below 15°C, the use of a heat gun is recommended to warm the QuickSeam FormFlash and to ensure good formability. On sunny days, pre-heating of the product is usually not necessary. QuickSeam FormFlash is to be applied as per the Firestone specifications and details.

The RubberCover EPDM surfaces and/or mating surfaces must be prepared with QuickPrime Plus, using a QuickScrubber or QuickScrubber Plus tool. Use of other products is not allowed. Restore the product to room temperature prior to use if exposed to temperatures below 15°C for prolonged periods.

COVERAGE

In accordance with length of detail.

PRECAUTIONS

Refer to Material Safety Data Sheets.

CHARACTERISTICS

Technical

EPDM FlashingQuickSeam Tape

BaseEPDM Rubber polymers

ColourBlackBlack

SolventsNoneNone

Solids (%)100%100%

StateSemi-cured Cured

Thickness1.6mm0.6mm Width 450mm456mm

PACKAGING / STORAGE / SHELF LIFE

Packaging

15.2m (50’) rolls - 1 roll per carton

Part number W56RAC162A

Note: QuickScrubber and/or QuickScrubber Plus pads and handles are included in each carton. Quantities vary depending on the QuickSeam product.

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months, when stored in above-mentioned conditions. Verify production date on each roll. Shelf life will be reduced if exposed to higher temperatures.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone QuickSeam Cover Strip is a 152mm (6”) wide semi-cured EPDM strip laminated to a QuickSeam tape. The strip is used to cover and seal butt-joined Firestone RubberCover EPDM membranes. Used for weathering batten bars, lead or metal edge trims. Firestone Quickprime plus is required for this product.

Place the roll of cover strip on the membrane, positioned so it unrolls from the top of the roll (release paper will be on top) and center the cover strip over the exposed membrane edge(s). Unroll the cover strip onto the clean and primed surface. Advance the roll keeping the strip centered over the membrane edge(s) and peel the release paper as you apply the strip.

PREPARATION

The RubberCover EPDM surfaces must be prepared with QuickPrime Plus, using a QuickScrubber tool. Use of other products is not allowed. Restore the product to room temperature prior to use if exposed to temperatures below 15°C for prolonged periods.

In accordance with length of seam to be covered. Adjoining QuickSeam Cover Strips require an overlap of 25mm and a cover patch.

PRECAUTIONS

Refer to Material Safety Data Sheets.

CHARACTERISTICS

Technical

EPDM FlashingQuickSeam Tape

BaseEPDM Rubber polymers

ColourBlackBlack

SolventsNoneNone

Solids (%)100%100% StateSemi-cured Cured

Thickness1.02mm0.88mm

Width 152mm156mm

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

7.62m (25’) rolls, 8 rolls per carton

W56RAC1693

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months can be expected if stored in above-mentioned conditions. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling ofthe accessories. Quality and applicability should thus always be verified: QuickSeam Cover Strip can be used only as long as the release paper can easily be removed from the tape without tearing the paper apart.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone QuickSeam Cover Strip is a 152mm (6”) wide semicured EPDM strip laminated to a QuickSeam tape. The strip is used to cover and seal butt-joined Firestone RubberCover EPDM membranes. Used for joining two pieces of EPDM together when placed side by side or sealing to lead. Firestone Quickprime plus is required for this product.

Place the roll of cover strip on the membrane, positioned so it unrolls from the top of the roll (release paper will be on top) and center the cover strip over the exposed membrane edge(s). Unroll the cover strip onto the clean and primed surface. Advance the roll keeping the strip centered over the membrane edge(s) and peel the release paper as you apply the strip.

The RubberCover EPDM surfaces must be prepared with QuickPrime Plus, using a QuickScrubber tool. Use of other products is not allowed. Restore the product to room temperature prior to use if exposed to temperatures below 15°C for prolonged periods.

In accordance with length of seam to be covered. Adjoining QuickSeam Cover Strips require an overlap of 25mm and a cover patch.

Refer to Material Safety Data Sheets.

CHARACTERISTICS

Technical

EPDM FlashingQuickSeam Tape

BaseEPDM Rubber polymers

ColourBlackBlack

SolventsNoneNone

Solids (%)100%100% StateSemi-cured Cured

Thickness1.02mm0.88mm

Width 152mm156mm

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

7.62m (25’) rolls, 8 rolls per carton

W56RAC1693

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months can be expected if stored in above-mentioned conditions. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling ofthe accessories. Quality and applicability should thus always be verified: QuickSeam Cover Strip can be used only as long as the release paper can easily be removed from the tape without tearing the paper apart.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

Firestone’s 76mm (3”) and 152mm (6”) QuickSeam Splice Tape is designed for field splicing of RubberGard EPDM membrane panels. Used for joining two pieces of EPDM together with an overlap. Firestone Quickprime plus is required for this product.

APPLICATION A 76mm (3”) wide tape is used for splicing standard seams without mechanical attachment in the seam. A 152mm (6”) wide tape is used for splicing seams with mechanical attachment centred within the seam. Refer to the Firestone installation guidelines for specific installation instructions.

PREPARATION

The RubberGard EPDM surfaces must be prepared with QuickPrime Plus, using a QuickScrubber or QuickScrubber Plus tool. Use of other products is not allowed. Restore the tape to room temperature prior to use if exposed to temperatures below 15oC for prolonged periods.

COVERAGE

In accordance with length of seam. At end of the roll, overlap a minimum of 25mm (1”).

PRECAUTIONS

Refer to Material Safety Data Sheets.

CHARACTERISTICS

Physical

Excellent moisture resistance

Excellent resistance to heat and cold

Excellent green tack

Technical Base Rubber polymers

ColourBlack

SolventsNone

Solids (%)100%

State Cured

Thickness0.76mm ± 0.127mm

Note: QuickScrubber and/or QuickScrubber Plus pads and handles are included in each carton. Quantities vary depending on the QuickSeam product.

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months can be expected if stored in above-mentioned conditions. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling ofthe accessories. Quality and applicability should thus always be verified: QuickSeam Tape can be used only as long as the release paper can easily be removed from the tape without tearing the paper apart.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

QuickSeam SA Flashing is a 457mm (18”) wide non-reinforced GeoGard EPDM fully laminated to Firestone QuickSeam Tape. SA Flashing is a labour saving and environmentally friendly alternative to conventional methods which uses contact adhesive for attachment. SA Flashing can be used for pipe base flashing where pipe diameter allows. It can also be used for repairing cuts and punctures in the GeoGard EPDM . Used for dressing the side of skylights. Firestone Quickprime plus is required for this product.

PREPARATION

The GeoGard EPDM surfaces and or compatible mating surfaces must be prepared with QuickPrime Plus, using a QuickScrubber tool. Use of other products is not allowed. Restore the SA Flashing to room temperature prior to use if exposed to temperatures below 15oC for prolonged periods.

In accordance with length of detail. Pieces must overlap a minimum of 75mm and extend a minimum of 75mm beyond critical points.

PRECAUTIONS

Take care when moving, transporting or handling to avoid sources of punctures and physical damage. Isolate waste products, such as petroleum products, greases, oils (mineral and vegetable) and animal fats from Firestone QuickSeam SA Flashing. As the product is fully cured, QuickSeam SA Flashing has good chemical and root resistance.

CHARACTERISTICS

EPDM FlashingQuickSeam Tape

Technical BaseEPDM Rubber polymers

ColourBlackBlack

SolventsNoneNone

Solids (%)100%100% State CuredCured

Thickness1.5mm0.5mm

STORAGE / SHELF LIFE

Storage: Store in original unopened carton at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: Shelf life is expected to be 12 months, when stored in above-mentioned conditions. Verify production date on each roll. Shelf life will be reduced if exposed to higher temperatures.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone QuickSeam™ Reinforced Perimeter Fastening Strip is a 152 mm (6”) wide strip of RubberGard™ MAX Reinforced EPDM membrane with a 76 mm (3”) wide QuickSeam™ tape factory laminated to it along one edge. The strip is used for non-penetrating base tie-ins as described as in the Firestone guidelines.

Unroll the QuickSeam Reinforced Perimeter Fastening Strip with the release paper up and the tape portion furthest away from the wall or penetration. Once the strip lies flat, fasten it to the substrate with Firestone Batten Strips or approved plates and fasteners (max. 300 mm o.c.). Apply QuickPrime Plus to the back of the RubberGard EPDM membrane. When the primer is dry, remove the release paper from the QSRPF Strip and roll the EPDM membrane onto the strip. Roll the strip using the QuickRoller or a silicon rubber roller to ensure proper adhesion. Refer to the Firestone guidelines for specific installation instructions.

The substrate needs to be clean, smooth, dry and free of sharp edges, lose or foreign materials, oil, grease and other materials that may damage the material. Restore to room temperature prior to use, if exposed to temperatures below 15°C for prolonged periods.

In accordance with length of tie-in detail.

CHARACTERISTICS

Note: QuickScrubber and/or QuickScrubber Plus pads and handles are included in each carton. Quantities vary depending on the QuickSeam product.

Storage: Store in original unopened containers at temperatures between 15°C and 25°C, in a well-ventilated place. Keep the material dry and out of direct sunlight until ready for application.

Shelf Life: 24 months can be expected if stored in above-mentioned conditions. Verify production date on each roll. Shelf life will be reduced if exposed to higher temperatures. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling ofthe accessories.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone QuickSeam™ R.M.A. Strip is a 254 mm (10”) wide strip of Firestone RubberGard™ EPDM MAX reinforced membrane with two Firestone QuickSeam™ Tape strips factory laminated to it along its length. The QuickSeam R.M.A strip is used for non-penetrating RubberGard™ EPDM membrane attachment, as specified in the Firestone guidelines.

Unroll the QuickSeam R.M.A. Strip with the release paper up in accordance with the layout plan specified. Once the strip lays flat, fasten it to the substrate with Firestone Batten Strips or approved plates and fasteners. Apply QuickPrime Plus to the back of the RubberGard EPDM membrane. When the primer is dry, remove the release papers from the QuickSeam R.M.A. Strip and roll the membrane onto the strip. Roll the strips using the QuickRoller or a silicon rubber roller to ensure proper adhesion. Refer to the Firestone guidelines for specific installation instructions.

The substrate needs to be clean, smooth, dry and free of sharp edges, loose or foreign materials, oil, grease and other materials that may damage the material. Restore to room temperature prior to use, if exposed to temperatures below 15°C for prolonged periods.

In accordance with length of mechanical attachment.

CHARACTERISTICS

Technical

RubberGard MAXQuickSeam Tape

BaseEPDM Rubber polymers

ColourBlackBlack

SolventsNoneNone

Solids (%)100%100%

Thickness1.2mm ± 20%0.6mm ± 0.1mm

Width 254mm76mm

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

30.5m (100’) rolls, 1 roll per carton

W56RAC1610 - 254mm (10”)

Note: QuickScrubber and/or QuickScrubber Plus pads and handles are included in each carton. Quantities vary depending on the QuickSeam product.

Storage: Store in original unopened containers at temperatures between 15°C and 25°C, in a well-ventilated place. Keep the material dry and out of direct sunlight until ready for application.

Shelf Life: 24 months can be expected if stored in above-mentioned conditions. Verify production date on each roll. Shelf life will be reduced if exposed to higher temperatures. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling ofthe accessories.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

The Firestone QuickSeam Corner Flashing is a 216mm in diameter round piece of uncured EPDM FormFlash laminated to QuickSeam Tape. It is designed to flash outside corners or to be used as a cover patch where appropriate. A circular cut of Firestone 9” Formflash used for detail work or patching. Firestone Quickprime plus is required for this product.

APPLICATION On cold days with ambient temperature below 5°C, the use of a heat gun is recommended to warm the QuickSeam Corner Flashing and to ensure good formability. On normal days, preheating of the product is not necessary.

PREPARATION

The RubberCover EPDM surfaces and/or mating surfaces must be prepared with QuickPrime Plus, using a QuickScrubber tool. Use of other products is not allowed. Restore the product to room temperature prior to use if exposed to temperatures below 15°C for prolonged periods.

COVERAGE

One piece per corner.

PRECAUTIONS

Refer to Safety Data Sheet.

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

20 pieces per carton

W56RAC1646

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months can be expected if stored in above-mentioned conditions. Shelf life will be reduced if exposed to higher temperatures.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

The Firestone QuickSeam Pipe Flashing is specifically designed to be used for flashing of rigid round penetrations of 25mm to 150mm. It is a prefabricated pipe boot with a QuickSeam Tape laminated to the bottom of the flange of the boot. Each QuickSeam Pipe Flashing will fit various penetrations and shall be cut at correct pipe diameter before installation. Used for flashing circular penetrations from 25mm to 175mm diameter. Firestone Quickprime plus is required for this product.

PREPARATION

The penetration must be clean of prior flashing and foreign materials. The RubberCover EPDM surface must be prepared with QuickPrime Plus, using a QuickScrubber tool. Use of other products is not allowed.

COVERAGE

One piece per penetration.

PRECAUTIONS

Refer to Safety Data Sheet.

CHARACTERISTICS

EPDM FlashingQuickSeam Tape

Technical Base Moulded EPDMRubber polymers

ColourBlackBlack State CuredCured

Thickness1.4mm – 1.9mm0.76mm

Flange diameter330mm216mm

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

10 pieces per carton. Stainless steel clamping rings are included.

W563581063

Storage: Store in original unopened containers at temperatures between 15°C and 25°C. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months can be expected if stored in above-mentioned conditions. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling. Quality and applicability should thus always be verified: the QuickSeam Pipe Flashing can be used only as long as the release paper can easily be removed from the tape without tearing the paper apart.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

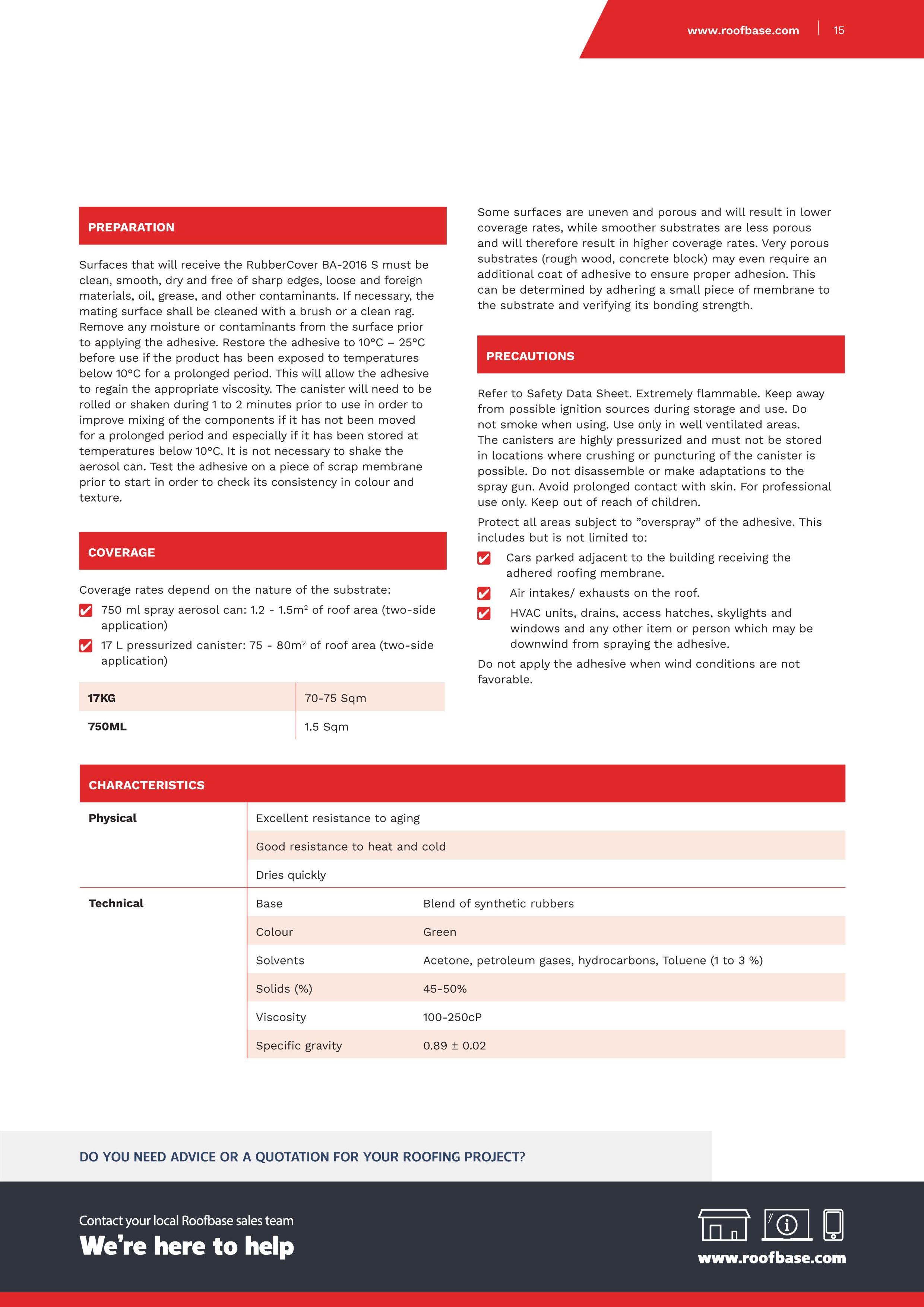

The Firestone QuickSeam Walkway Pads are high quality rubber pads with QuickSeam Tape factory laminated to the bottom. They are used for protection of the Firestone RubberGard EPDM membrane in areas of regular roof traffic (periodical maintenance around mechanical equipment, access doors, etc.).

APPLICATION Position the QuickSeam Walkway Pads so that the flat surface is over the completed RubberGard EPDM membrane, spacing each pad a minimum of 25mm and a maximum of 150mm from each other to allow for drainage.

If the installation of the Pads over field fabricated seams or within 75mm of a lap edge cannot be avoided, the seam must be stripped in using QuickSeam Batten Cover/Flashing.

The cover strip must extend beyond the walkway pad a minimum of 150mm each side of the pad. Refer to the Firestone guidelines for specific installation instructions.

When installing walkway pads on a ballasted system, additional ballast must be added around the pads to maintain the required ballast coverage per m2

Do not install walkway pads within 3 m of a roof edge when used in conjunction with ballasted systems. Concrete paving stones must be used in these areas.

The RubberGard EPDM surface must be prepared with QuickPrime Plus. Pre-cleaning with Splice Wash may be required. Use of other products is not allowed.

In accordance with length of detail.

Refer to Safety Data Sheet.

CHARACTERISTICS

Walkway PadQuickSeam Tape

Technical Base Rubber polymersRubber polymers

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

Each pad is 762 x762 mm - 50 pads/carton

W56RAC1860

Storage: Store in original unopened containers at temperatures between 15°C and 25°C, in a well-ventilated place. Keep the material dry and out of direct sunlight until ready for application.

Shelf Life: 12 months can be expected if stored in above-mentioned conditions. Verify production date on each roll. Shelf life will be reduced if exposed to higher temperatures. Shelf life information is only a recommendation and not a fact of life. The real expiration date highly depends on the history of storage and handling ofthe accessories.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

The Firestone Water-Block Seal is designed to provide a watertight seal when used in compression at drain and scupper details, wall terminations and other details as specified in the Firestone guidelines.

The sealant is applied with a mastic gun at the specified location and put under a continuous compression. Install a continuous bead to substrate surface and roll or press the flashing surfaces firmly. Water-Block Seal may not remain exposed after installation. Refer to the Firestone Specifications for complete installation instructions.

Surfaces on which the Water-Block Seal is to be applied must be clean, dry and free from loose parts of concrete, stone, mortar, foreign materials and other contaminants. Restore to room temperature prior to use, if exposed to lower temperatures (< 15°C) for a prolonged period.

About 3lm per tube or 2 drains per tube.

Flammable. Keep away from fire, open flame and other possible ignition sources during storage and use. Do not smoke when using. For professional use only. Use only in well ventilated areas. Avoid contact with skin and eyes. Do not contaminate with foreign materials. Keep out of the reach of children. Recommended cleaners are mineral spirits, naphtha or kerosene. Thinning is not allowed.

CHARACTERISTICS

Physical Grey liquid with mild odor

Technical Base Butyl rubber

Colour Grey

Solvents Heptane

Solids86%

Viscosity1,600,000 ± 300,000 cp (at 27°C)

Specific gravity1.31

Flash point-10°C

PACKAGING / STORAGE / SHELF LIFE

Packaging

Part number

25 tubes/carton

W563587071

Storage: Store in original unopened containers at temperatures between 15°C and 25°C in a dry, well-ventilated area. Keep away from heat, sparks and open flame. Keep the material out of direct sunlight until ready for application.

Shelf Life: 12 months, when stored in above-mentioned conditions. Shelf life will be reduced if exposed to higher temperatures.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

Firestone Lap Sealant HS is a low volatile organic compound (LVOC) sealant designed to be used with Firestone Splice Adhesive SA-1065 for seam edge treatment applications and as a sealant in other applications as indicated by current Firestone specifications and details. Designed to seal and protect the exposed edge of Quickseam products

1. Surfaces to which Lap Sealant HS is applied must be clean, dry, and free from loose or foreign materials, oil, and grease.

2. Wait to apply seam edge treatment a minimum of four (4) hours after the completion of a flashing seam, but no later than the end of the next day following the completion of the seam. If inclement weather is threatening, apply Splice Adhesive SA-1065 to the edge of the flashing splice before leaving project.

4. Apply a layer of Splice Adhesive SA-1065 along the entire seam edge, a minimum of 1” (25.4mm) on each side of the step-off, following current Firestone Splice Adhesive SA-1065 application procedures. Allow the Splice Adhesive SA-1065 to flash-off properly. (Refer to current Firestone Specifications for readiness check.)

5. Using the plastic nozzle applicator supplied by Firestone, apply a continuous bead of Lap Sealant HS approximately 3/8” x 1/4” (9.5mm x 6.3mm) centered over the flashing seam edge. Be sure to keep the nozzle applicator centered over the lap step-off. Refer to current Firestone seam details.

Prior to application of the Splice Adhesive SA-1065, if the seam edge has been contaminated, clean the seam edge a minimum of 1” (25.4mm) on each side of the step-off with Firestone QuickPrimeTM Plus Primer, and allow to dry.

COVERAGE

11 fl oz (0.33 L) Cartridge: 20’ to 22’ (6m to 6.7m) of 3/8” x 1/4” (9.5mm x 6.3mm) bead per cartridge

1 qt. (0.945 L) Cartridge: 60' to 64' (18.3m to 19.5m) of 3/8" x 1/4" (9.5mm x 6.3mm) bead per cartridge

20 fl oz (0.57 L) Chub: 35’ to 38’ (10.7m to 11.6m) of 3/8” x 1/4” (9.5mm x 6.3mm) bead per chub

5 Gallon (18.93 L) Pail: 1,250’ to 1,280’ (381.0m to 390.1m) of 3/8” x 1/4” (9.5mm x 6.3mm) bead per pail

Review Material Safety Data Sheet (MSDS) prior to use. Flammable. Keep away from fire and open flame during storage and use. Do not smoke during use. Use only in well ventilated areas. Do not contaminate with foreign materials.

CHARACTERISTICS

Technical

BaseEPDM Rubber

ColourBlack

SolventsLight Aliphatic Solvent Solids by Volume80% (minimum)

Press-Flow Viscosity30 to 50 seconds to extrude 20 g through 0.104” (2.64 mm) diameter orifice at 72 °F to 74 oF (22.2 °C to 23.3 oC)

Weight11.2 to 12.2 lb/gal (1.34 to 1.46 kg/L)

Specific Gravity1.34 to 1.46

V.O.C. ContentLess than 2.1 lb/gal (250 g/L)

PACKAGING

Shipping UnitQuantityContents

Pail:

Plastic Pail:28 Cartridges per Pail11

Cardboard Carton:25 Cartridges per Pail11

Carton:10 Cartridges per Carton1

Carton:20 Chubs per Carton20

Storage: Store in original unopened containers at temperatures between 60 and 80 °F (15.6 and 26.7 °C). When exposed to lower temperatures, restore to room temperature prior to use. For optimum results, rotate stock to ensure stored material has not exceeded the shelf life of one (1) year.

Shelf Life: Shelf life of one (1) year can be expected when stored in original, sealed containers at temperatures between 60 and 80 °F (15.6 and 26.7 °C). Shelf life will be shortened if exposed to elevated temperatures.

Clean up: Recommended cleaner is rubbing alcohol followed by soap and water.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

APPLICATION

A low modulus, neutral cure silicone sealant. Suitable for applications where joint movement does not exceed 30% and where the long term durability of silicone is required.

Apply using a standard sealant gun. Cut tip from cartridge, be careful not to damage the screw thread. Cut the nozzle at an angle of 45° and fix to cartridge. Using a caulking gun apply sealant to the joint. Tool within 5 minutes using a tooling rod or wet spatula, for reasons of health and safety do not tool with finger.

Ensure all surfaces are clean, dry and free from grease or any contaminants that may hinder adhesion. Movement joints must have a bond breaking backer tape or backing rod applied prior to the use of universal sealant.

Storage: Store in cool, dry conditions at a temperature between 5-30o C. Protect from frost.

Shelf Life: 12 months from date of manufacture when stored in unopened tubes.

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

RAIN WATER OUTLET LEAFGUARD FOR RAIN WATER OUTLET

HORIZONTAL THRU WALL OUTLET LEAFGUARD

HORIZONTAL THRU WALL OUTLET

HORIZONTAL THRU WALL OUTLET SPIGOT

ROOF VENT

RAIN WATER OUTLET LEAFGUARD FOR RAIN WATER OUTLET

HORIZONTAL THRU WALL OUTLET LEAFGUARD

HORIZONTAL THRU WALL OUTLET

HORIZONTAL THRU WALL OUTLET SPIGOT

ROOF VENT

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?

SILICONE DETAIL ROLLER

QUICK SCRUBBER PAD

PENNY ROLLER

PAVING RING SUPPORT

QUICK SCRUBBER KIT

9” ROLLER & SLEEVE

QUICK SCRUBBER HANDLE

INSULATION PLATE

EPDM SLITTER

DOUBLE HANDED ROLLER

V PLATE

4” ROLLER & SLEEVE

SILICONE DETAIL ROLLER

QUICK SCRUBBER PAD

PENNY ROLLER

PAVING RING SUPPORT

QUICK SCRUBBER KIT

9” ROLLER & SLEEVE

QUICK SCRUBBER HANDLE

INSULATION PLATE

EPDM SLITTER

DOUBLE HANDED ROLLER

V PLATE

4” ROLLER & SLEEVE

DO YOU NEED ADVICE OR A QUOTATION FOR YOUR ROOFING PROJECT?