TTC OPERATED BY ENSCO

The Importance of Rolling Stock Health to Track Health Managing wheel forces through proper maintenance of rolling stock Matthew Dick, P.E., VP - Strategy & Business Development, ENSCO, Inc., Pueblo, CO

T

rack infrastructure inspection and maintenance are fundamental to safe and eff icient rail transportation and a central focal of RT&S. This article highlights how the condition of rolling stock directly impacts track infrastructure. Most track deterioration is caused by the rolling stock traversing it, and poor rolling stock condition can accelerate that damage. The reverse is also true: degraded tracks can worsen the condition of the vehicles running on it. Both the rolling stock and track infrastructure are parts of an integrated system and maintain both in good health leads to better performance and reduced risk. Truck Steering Fundamentals The latera l wheel forces impar ted into t he track ca n cause ma ny track maintena nce cha l lenges including rai l wear, Rol ling Contact Fatig ue (RCF), rai l seat deterioration in concrete ties, plate cutting in wood ties, broken fasteners, a nd deteriorated ties. These conditions are of course a large por tion of track maintena nce a nd if unaddressed ca n lead to derai lment risk . The weight of the car is one of the largest factors to drive lateral wheel load in cur ves. Its intuitive that the weight of the railcar directly correlates to the vertical wheel load. But how

4 Railway Track & Structures // July 2025

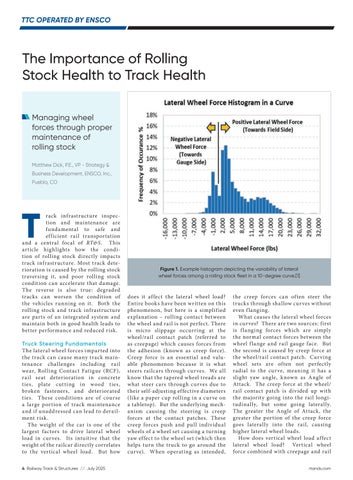

Figure 1. Example histogram depicting the variability of lateral wheel forces among a rolling stock fleet in a 10-degree curve.[1]

does it affect the lateral wheel load? Entire books have been written on this phenomenon, but here is a simplif ied explanation – rolling contact between the wheel and rail is not perfect. There is micro slippage occurring at the wheel/rail contact patch (referred to as creepage) which causes forces from the adhesion (k nown as creep force). Creep force is an essential and valuable phenomenon because it is what steers railcars through cur ves. We all k now that the tapered wheel treads are what steer cars through cur ves due to their self-adjusting effective diameters (like a paper cup rolling in a cur ve on a tabletop). But the underlying mechanism causing the steering is creep forces at the contact patches. These creep forces push and pull individual wheels of a wheel set causing a turning yaw effect to the wheel set (which then helps turn the truck to go around the cur ve). When operating as intended,

the creep forces can of ten steer the trucks through shallow cur ves without even f langing. What causes the lateral wheel forces in cur ves? There are two sources: f irst is f langing forces which are simply the normal contact forces between the wheel f lange and rail gauge face. But the second is caused by creep force at the wheel/rail contact patch. Cur ving wheel sets are of ten not perfectly radial to the cur ve, meaning it has a slight yaw angle, k nown as Angle of Attack. The creep force at the wheel/ rail contact patch is divided up with the majority going into the rail longitudinally, but some going laterally. The greater the Angle of Attack, the greater the portion of the creep force goes laterally into the rail, causing higher lateral wheel loads. How does vertical wheel load affect lateral wheel load? Vertical wheel force combined with creepage and rail rtands.com