Smarter MOW Starts Here

CENTER LIFT TECHNIQUE

• MINIMIZES HEAD COUNT

• REDUCES ON-SITE RISK

• KEEPS ADJACENT LINES OPEN

The CENTER LIFT TECHNIQUE is proven to be at least 50% more efficient than traditional approaches. Visit DavRail.com to find out more!

See our team in action using the innovative Center Lift Technique to complete a full mud spot remediation in just 1 shift with minimal headcount and machinery. Our team required 30 minutes total for panel removal and reinstallation.

Railways turned the American promise into American progress. It’s a legacy we’re proud to continue as today’s trusted leader in railway maintenance technology — cutting-edge innovations made in the USA, for the USA. Welcome to the next chapter of American progress.

Vol. 121, No. 9

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189

Telephone (470) 865-0933 Website www.rtands.com

DAVID C. LESTER Editor-in-Chief dlester@sbpub.com

JENNIFER M c LAWHORN Managing Editor jmclawhorn@sbpub.com

EDITORIAL BOARD

David Clarke, University of Tennessee

Brad Kerchof, formerly Norfolk Southern Jerry Specht, CPKC/AREMA

Scott Sandoval, Genesee & Wyoming

Robert Tuzik, Talus Associates

Gary Wolf, Wolf Railway Consulting

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102

Telephone (212) 620-7200 Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 847-559-7372

Reprints: PARS International Corp.

253 West 35th Street 7th Floor New York, NY 10001

212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

Computer Integration is Not an Issue to Dissuade Mergers

By David C. Lester, Editor-in-Chief

The discussion of transcontinental mergers has brought about the usual wailing and moaning about service meltdowns that can occur when trying to integrate the computer systems of two merging railroads. When the CPKC integration of the Canadian Pacific and Kansas City Southern systems resulted in some difficulties and customer dissatisfaction (which I’m not minimizing), lots of analysts and observers said that the railroad had “stumbled” casting doubt on the approval of any future mergers. I’m sorry, but this is simply a bucket of hogwash.

Before I explain further, let me acknowledge that when the supply chain is disrupted by a rail merger, incomplete communication, missed deliveries, lost shipments, increased dwell time, and other problems reverberate throughout the system. This is a huge headache for everyone, and it takes several weeks or months for recovery to occur. Many who read that last sentence will immediately say that “recovery from the merger meltdowns in the 1990s took years.” True, but those mergers were 30 years ago, and computer technology has improved greatly since then.

Integration of computer systems during a merger is not an easy task. Shippers may respond by saying “I don’t give a damn how hard it is, I shouldn’t have to put up with it!” Well, yes and no. If shippers are going to benefit from mergers in terms of fewer interchanges, and single-line service from coast to coast, some pain will be incurred when the merger is implemented. And, if shippers benefit from reciprocal switching as a result of a transcon merger and seek other favorable terms, I question if the traditional worries like higher rates and poorer service will materialize. Of course, there may be some exceptions to this, but the long run situation should improve for most shippers.

Part of the challenge of integrating computer systems, even today, is that the systems can be vastly different. For example, my understanding is that the integration

problems CPKC had were due in large part to KCS having an older, less sophisticated, system than Canadian Pacific. Computer systems, even if you’re using the same hardware and software, can be configured to accommodate different standards and workflow from road to road. So, even sophisticated and modern systems can have trouble integrating if these differences are not identified and planned for before the switch is flipped. The complexity of systems, though, makes this really challenging.

There’s no doubt that meticulous planning on the part of IT departments and operations teams is absolutely necessary. This kind of planning takes a minimum of two years. This is the case with large, complex organizations in any industry. Take large hospitals and hospital systems, for example. Planning for a new system to replace or integrate with parts of the old system takes, in most cases, a minimum of three years. Moreover, no matter how wellplanned a cutover is, something will always arise that wasn’t thought about during planning. It’s virtually impossible to have a newly live system perform exactly the way it did in a test environment.

Railroads and shippers must prepare carefully for the integration of computer systems and perform as much testing as possible. Also, if there is any possibility of cushioning the supply chain with extra goods (yes, I know that’s costly) or making other adjustments to allow it to weather problems more effectively, they should be taken. Railroads must also communicate several times a day with shippers around problems that are occurring.

Yet, as I said at the beginning, integrating computer systems should be the least concern around deciding to go forward with a merger. Careful planning and execution will minimize or even eliminate many issues.

DAVID C. LESTER Editor-in-Chief

Hands-On Experience Building at the TTC

TTC Derailment Investigation and Prevention Workshop

Matthew Dick, P.E., VPStrategy & Business Development, ENSCO, Inc., Pueblo, CO Gregory Holtman, Training Coordinator, ENSCO, Inc., Pueblo, CO

Return on Investment (ROI) is a critical metric for any organization considering improvements. In the case of training, one element of ROI is information retention: how well a student retains knowledge to be more effective in their job duties. This raises the question: what makes training impactful?

A 2025 study from the National Center for Construction Education and Research concluded that On-the-Job Training (OJT) in real-world situations under expert mentorship is the most impactful method of training. [1] The study also found that OJT is further enhanced when paired with logical classroom instruction. We all know OJT is an extremely valuable and effective method of training. But why is that the case? Certainly, its strength

lies in hands-on experiences in real-world conditions. However, a deeper look reveals more to it. A paper in the Journal of Technology Education found that hands-on training, engaging tactile and motor functions, triggers more brain activity compared to classroom training, which relies solely on visual and auditory experiences.[2] This broader brain stimulation helps set deeper, longer-lasting memories. The next question is how to obtain these invaluable hands-on experiences with an expert mentor when that resource does not already exist within your railway organization. The TTC has addressed this challenge and recently completed its first initiative built around these principles.

Derailment Workshop

On July 22-24, the TTC hosted the first Derailment Investigation and Prevention Workshop. The attendees were 51 students including representation from 18 different railways, as shown in Figure 1. The workshop leveraged the mantra “Tell me and I will forget, show me and I may remember, involve me and I will understand.” This was done with active round table discussions among the attendees discussing their own derailment experiences and challenges interwoven between the hands-on and classroom sessions.

Expert mentorship was provided by the workshop leaders, Matthew Dick and Greg Holtman. Matthew has over 25 years of experience investigating and preventing derailments, beginning with his time at the Union

Pacific R&D Lab operated by Rail Sciences, Inc. During his tenure there, he leveraged his background in metallurgy and computer simulation to investigate approximately 250 derailments across all Class 1 railroads and many short line and passenger transits, including serving as an onsite subject matter expert during the 2008 Chatsworth Collision NTSB investigation. In addition, Matthew has applied his derailment prevention expertise throughout his career, including the use of innovative technologies.

Greg has more than 15 years of experience in railway operations and training, starting with his work as a Conductor and Switchman for Union Pacific. He later served at RTDDenver as a Transportation Rules Trainer and Manager, where he revised critical operating rulebooks and oversaw control center operations, followed by leading all transportation training and certification programs. In his current role at the TTC, operated by ENSCO, he develops and delivers both field and classroom training, drawing on his extensive operational expertise.

The workshop’s success was also made possible through the invaluable support of numerous technical professionals at the TTC.

Hands-On Sessions

Attendees experienced multiple hands-on sessions throughout the event. This included conducting a site inspection of the mock derailment shown in Figure 1. Attendees utilized best practices to record car positions,

Figure 1. Overview of the attendees of the first TTC Derailment Investigation and Prevention Workshop.

orientations, and identifying information, along with the discussed methodology of how to identify the Point-of-Derailment (POD) and the first derailed car. Collecting this information is important to understand how the cars are situated in the pile up because that can provide insights into the investigation.

Another hands-on session was conducting real-world inspections of thirty-two different component failures that can lead to derailments, depicted in Figure 2. An important aspect of this activity was accurately identifying defective conditions that are the cause of a derailment, rather than broken components that were caused by the derailment event. This is key to ensure accurate derailment cause finding. It’s common that at a derailment site there are lots of broken components such as broken rail and wheels. But were any of them the cause of the derailment? There are specific characteristics on a broken rail or broken wheel that caused the derailment vs. being caused by the derailment. This includes rail end batter and batter on a broken wheel. Additionally, broken wheels have additional damage on their tread from continuing to roll on the track prior to the derailment.

Attendees also had the opportunity to have hands-on experience with failed component photography best practices. Many times, the field personnel are the only ones that can get critical photographs needed for the investigation. Capturing quality photographs, particularly at nighttime, can be a challenge as shown in Figure 3. Using photography best practices can make sure that important features of the fracture surface are captured so that an accurate investigation can be made. In the case of Figure 3, it is a broken weld caused by a fatigue crack initiated at the base. Often at a derailment, the broken rail is heavily damaged. But by using the method shown on the right side of Figure 3 where a flashlight was shining from the side, the features of the fracture surface stand out well, allowing a metallurgist investigator clearly to identify where the fracture surface initiated from, even if the broken rail is damaged.

A unique aspect of the workshop was that it had both track and rolling stock (mechanical) attendees and both got the opportunity to experience hands-on activities that they wouldn’t normally have in their typical job duties. Figure 4 is one of these hands-on sessions which was conducting a first derailed car inspection. Attendees performed inspections on both freight and passenger railcars using all the necessary gauges and measurements to fill out an inspection form. This included using finger

gauges that are needed for assessing wheel wear such as a thin flange which can play a role in a switch point derailment. This unique session allowed non-rolling stock staff to have memorable experiences to enable them to be better informed when conducting a derailment investigation. Depicted in Figure 4 are attendees performing a center bowl measurement. Issues with a center bowl are one of multiple railcar factors that can play a role in increasing lateral wheel force, which can be a contributor to wheel climb, rail rollover, and gauge widening derailments.

Similarly, attendees had the opportunity to identify a POD and take track geometry measurements at 15.5-foot stations both leading up to and following the POD. Figure 5 shows attendees making these station measurements themselves. Each participant measured gauge, crosslevel, profile, and alignment using a level board and stringline. Additionally, they applied best practices to adjust the unloaded track geometry measurements so they would be representative of loaded conditions. This was an excellent opportunity for new railway professionals to

Figure 2. Attendees reviewing one of thirty-two examples of component failures that can lead to derailments.

Figure 3. At the workshop, photography best practices were incorporated into failed component hands-on inspection. Shown is a broken weld example of how lighting affects photographing a broken rail at a nighttime derailment investigation.

gain hands-on experience in inspecting and measuring track.

Conclusion

The TTC recently completed its first Derailment Investigation and Prevention Workshop, which featured impactful hands-on experiences in a real-world environment with expert mentors. Below are examples of feedback from attendees:

“It was an honor to attend the workshop. I have attended over 11 classes in my career with BNSF, UPRR, Metrolink, AREMA, and other contractors. ENSCO was the most informative with understanding how all departments look at derailments from each angle, key notes and measuring tools that everyone uses. The big difference is in the field with the most valuable information. In every other workshop that I have attended, there was not field exercise with any of the stations that ENSCO had. Which was easier to explain to my co-workers how this all ties together.” –Rafael Gutierrez Jr., MOW Senior Instructor/

“It is obvious to me that tremendous preparation, coordination, and organization went into the event. I have attended numerous courses and instructional events in my railroad career. I can say unequivocally that Matthew Dick was top notch. A truly outstanding instructor! I feel extremely fortunate to have been a participant in this comprehensive workshop.” – Ernest Montgomery, State Investigator, New Mexico DOT

The next TTC Derailment Investigation and Prevention Workshop is scheduled for March 24–26, 2026. It is open to all organizations and is expected to sell out early again. More information can be found at ttc-ensco.com/derailment-workshop.

References:

1. h ttps://www.nccer.org/ media/2025/06/NCCER-ROIFrom-Training-to-PerformanceReport_2025.pdf

2. ht tps://jte-journal.org/articles/10.21061/jte.v1i2.a.3

The Symbol of Innovation in Maintenance of Way Equipment

Racine Railroad Products’ cutting edge operator control interface and computerized automation not only increases production, it also improves safety while making our machines easier to operate and maintain the equipment. We offer a wide-range of innovative powered portable hand tools.

Visit us at racinerailroad.com

Follow us on LinkedIn: linkedin.com/company/racine-railroad-products

See our machines and operator controlled screens at youtube.com/@racinerailroad1986

Contact us on how we can assist you with your MOW needs (262) 637-9681

Racine Railroad Products, Inc. 1955 Norwood Court, Racine, WI 53403

Figure 5. All attendees used level boards and stringlines to make track geometry measurements needed for a mock derailment investigation.

2026 NRC Conference Is Positioned to Be the Best Yet

The NRC anticipates more than 1,400 railway industry leaders will attend the 2026 NRC Conference and NRC-REMSA Exhibition at The Diplomat Beach Resort and Spa in Hollywood, Fla., from January 7-10, 2026.

The NRC is hard at work all year round, but we proudly acknowledge that the pinnacle of our year starts in January, when we host our annual conference. Registration is now open for the 2026 NRC Conference and NRC-REMSA Exhibition. We hope you will join us and more than 1,400 contractors, suppliers, railroad and rail-transit representatives, and other government and industry professionals at The Diplomat Beach Resort and Spa, in Hollywood, Florida, from January 7 through 10.

Next year’s conference is set to be bigger and better thanks to your support and input. At the conclusion of every conference, we invite attendees to share their opinions and suggestions for changes for the next conference. Our staff and board take this feedback seriously. We poured over ratings and comments to evaluate changes for the upcoming conference in January. Here’s some of what you can expect.

Conference attendees tell us the networking is one of the best values of the conference and is a tremendous way to start the year. Networking will continue to take center stage along with the presentations by railway leaders about capital plans and budgets for the year ahead. Your comments tell us this information is invaluable in developing and fine-tuning your action plans for the year. Again in 2026, our program will feature presentations by more than a dozen railway

engineering and operations leaders. Attendees also will have the opportunity to ask questions and interact during formal and informal settings. These presentations are not infomercials. They feature detailed plans along with concrete ways contractors and suppliers can influence and participate in this work.

WE AREN’T JUST IN THIS INDUSTRY. WE ARE THIS INDUSTRY!

Many attendees said the speed networking meetings – where members of their team meet with purchasing and operations personnel from Class I and short line railroads – are worth the price of attending alone. We’ve expanded our lineup to include four railroads. Always in high demand, these sessions fill up right away. Be sure to immediately sign up right after these sessions are announced later this fall.

The conference will also continue to feature highly rated breakout sessions and panel discussions. These segments allow you to hear from and interact with some of the sharpest, most impressive professionals

in our industry. Your ratings and suggestions have helped us to hone in on relevant business and professional development topics at the next conference.

Some attendees told us that while they appreciate the jam-packed schedule, the sessions start too early – even for railroaders – particularly for those coming from western states when the conference is in Eastern Standard Time. Because we know you are already balancing day-to-day work obligations with the conference schedule, the January conference will start a bit later each morning. This extra window will give you more time for rest and to manage your workload.

Our conference partner REMSA is putting together our largest exhibition yet. The expansive exhibition hall is open during prime time throughout the first two days of the conference to give attendees many opportunities to connect with decision-makers in the railway construction and maintenance market. Contact REMSA to lock in your exhibit space.

Registering for the conference early guarantees a discounted hotel rate in our room block at The Diplomat. It also ensures you, your co-workers, and customers have a spot for golf and trap shooting, which have sold out in recent years.

Don’t miss the best networking event of the year along with conference sessions that will fast-track your business plans. Register today and start your year off right.

JOE DALOISIO Chairman, National Railroad Construction and Maintenance Association (NRC)

AILWAY GE

W OMEN IN RAIL

Schaumburg, IL

October 15 & 16, 2025

Hyatt Regency Schaumburg

Connect. Inspire. Innovate.

Women in Rail 2025 is a must-attend event, highlighting diverse experiences and practical strategies for moving the industry forward. The third annual conference features dynamic panels, a celebratory awards luncheon, and the chance to network with a wide-reaching group of like-minded rail professionals.

Join Us For:

• Leadership Journeys in Freight Rail, Passenger Rail & Engineering

• Railroading’s Heroes

• Commanding the Track: Your Leadership Toolkit

• Executive Edge: Branding, Negotiation & Presence

• Trackside Impact: Environment & Community

• Allyship to Action: Maintaining a Culture of Belonging

Supporting Organizations

• Railway Age Women in Rail Awards

• RT&S Women in Railroad Engineering Awards

CSX

AND THE U.S. NAVY

Training Grounds for a Top-Flight Engineer

By David C. Lester, Editor-in-Chief

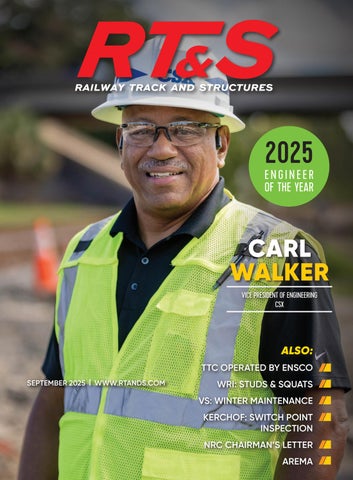

Carl Walker, Engineer of the Year, CSX

Railway Track and Structures is pleased to honor CSX’s Carl Walker, Vice President of Engineering responsible for Communications and Signals, PTC, and Dispatch Systems, as our 2025 Engineer of the Year. Like last year’s winner, Jeff Watson of Genesee & Wyoming, Carl has combined a military background with a successful railroad career.

Carl spent much of his U.S. Navy career as a communications officer aboard the USS George Washington , a Nimitz-class aircraft carrier, responsible for communications among the different ships, submarines, and aircraft that make up a carrier battle group. While he was fascinated with and effective in this work, Carl says his most gratifying portion of his Navy career was serving as a drill instructor. He spent two more tours in this role. “It helped me become a better leader,” Carl says, “because it’s a role in which I could motivate people to do what they didn’t think they could do.” He adds that “changing a person’s life in eight weeks is a big deal.”

Carl finished his Navy career as a combat systems officer at the Trident Training Facility in Kings Bay, Georgia. After spending so many years in the Navy, he developed an interest in customs operation and earned a degree in criminal justice in preparation for a position with U.S. Customs. He also earned a communications degree, and while he was at King’s Bay, a friend retired from the Navy to become a locomotive technician at CSX. This got him to thinking about a career with the railroad, and he reached out to another Navy alum who was a submariner whose sister worked at CSX. His friend’s sister put him in touch with a gentleman who was responsible for hiring engineering trainees at the railroad and Carl met with him. However, at the time, CSX was not hiring anyone from the outside, and the engineering lead asked Carl to call him every Thursday, and something might break loose. Well, Carl called him every Thursday for 18 months. He called one Thursday, and the gentleman said “let’s go to lunch.” While the engineering lead did not have a job for Carl, he told said that there may be some opportunities in CSX Technology and encouraged him to meet with that group. Carl was concurrently talking to U.S. Customs about a position and told RT&S that “Ironically, I got calls

on a Thursday from both CSX and U.S. Customs with job offers.” He accepted the job at CSX, a manager in the communications solutions group, and called U.S. Customs and told them that he had accepted the position with CSX but thanked them for the offer and the time they had spent recruiting him. Customs

AT THE TIME, CSX WAS NOT HIRING ANYONE FROM THE OUTSIDE, AND THE ENGINEERING LEAD ASKED CARL TO CALL HIM EVERY THURSDAY, AND SOMETHING MIGHT BREAK LOOSE. WELL, HE CALLED HIM EVERY THURSDAY FOR 18 MONTHS.

told Carl that “if you ever change your mind, you’ll have a place with us.”

Carl says that while he had a lot to learn about the railroad industry, the transition from the military to the railroad was fairly straightforward. That’s because the structure, demands, and requirements are very similar. For example, a system that operates 24 hours per day, one could be called any time at night and be told to be somewhere in hours. The way the operations group goes about its business is similar. Get done what needs to be done and eliminate roadblocks. “On my first day on the railroad, I was running conference meetings,” Carl says. “The first meeting I ran on the railroad wasn’t as difficult as some I had run in the military, so despite some railroad knowledge gaps, I was able to handle it successfully.”

Carl’s first project at CSX was managing a new communications system for the crew call center and the railroad’s customer service center. A few months later, in January 2000, his group was given a big project to replace 100 AEI readers out on the railroad. He had been with the railroad for eight months

at the time. “I was able to report to my manager that the work was complete in October 2000. In addition, there were ten tag readers that were supposed to have been installed in 1999, and we got those in, too. So, we put in 110 new AEI tag readers in 2000, and we only took ten months to do it.”

For his team’s successful installation of the AEI readers, they received a Technology All Star award that was given for key projects completed successfully on time and on budget with no one hurt. “I was in a project-driven group,” Carl said. Carl was then placed in a position called Director of Program Management and reported directly to the head of the communications group. He stayed in that position for two years, then took over as Director of Communications South until June 2006, then moved to Assistant Chief Engineer for communications and directors from both the south and north regions reported to him.

During the challenging years of PTC installation, Carl was named chief

engineer of signal construction. He had the responsibility of making sure that PTC was installed correctly from a communications and signals perspective. In March of 2017, Carl was appointed Chief Engineer of Communication and Signals, then in 2021, Assistant Vice President of Communications and Signals, PTC, and Dispatch Systems. In May 2023, he was named Vice President of Engineering Maintenance of Way, Communications and Signals, Dispatch, and PTC Systems. “My responsibility involves managing these areas from field and regulatory perspectives, and I’m also a board member of Meterocomm, which is a communications organization owned by the four U.S. Class I railroads.”

Carl also just finished a term on the AREMA Board of Governors and leads the African American Business Resource Group at CSX.

Like most railroad engineering groups, Carl speaks highly of the ability of data analytics to provide data-driven, factual analysis for capital planning and

equipment performance. “I’m particularly impressed with predictive analytics when it comes to evaluating our wayside

TECHNOLOGY IS MUCH BETTER TODAY THAN WHEN I STARTED, AND IN MANY WAYS, WE ARE A TECHNOLOGY-DRIVEN COMPANY.

approaching so we can replace it beforehand.” Carl’s group spends a lot of time during the year talking about wayside device performance, along with the many other types of equipment in its capital plan.

As other engineers have reported to RT&S , capital planning meetings are more effective today because requests for capital spending by various groups is driven by the data. “It used to be that the senior person in the meeting was often the most successful in obtaining capital for their projects, but now that the allocation is based on facts and data, each department receives the capital they need to keep the railroad running in good order.”

equipment. We’re able to accurately anticipate when equipment end-of-life is

Carl has also been impressed with the evolution of technology since he began his railroad career. “Technology is much better today than when I started, and in many ways, we are a technology-driven company. We’re able to know more about what’s going on on the railroad and anticipate problems before they become

-Nate Bachman, REMSA Chairman

problems.” He adds, though, that new technology is not added for its own sake. “While we are always on the lookout for new technology that will help us run the railroad more effectively, we don’t always believe we have to have the latest tech. We often do pilots with new technology that becomes available, but unless we see it significantly improving our operation, we don’t implement it.”

Asked what a typical day on the job is like for Carl, he provided RT&S with the following outline. “My day begins at 6:00 a.m. with a morning call, followed by a 7:00 a.m., 8:00 a.m., and a 3:45 p.m. call. These calls are opportunities to discuss safety and operations with various operational leaders and other departments to ensure our key focus of safety, customer service, and people are at the forefront of what we do.” Carl adds that much of his day is spent addressing questions and issues from the field and he also walks the floor to see what’s going on with his team and people in other departments, looking for ways to help out in any way possible.

“During the evening, I monitor my email and usually go to bed around midnight.”

Carl believes that one’s leadership style is an important part of job effectiveness. “I have had the opportunity to observe a lot of leaders in my careers in the military and on the railroad,” Carl says, “and I’ve seen some that are very good and some that are bad.” Carl’s first opportunity to lead people was in the military, which taught leaders to teach someone reporting to you to assume your responsibilities in case something happens to you. “Make sure your people are properly trained, respectfully hold them accountable, understand that their jobs are demanding, and they need some semblance of quality of life. A leader can be respectfully demanding without being demeaning,” Carl adds.

“My leadership style is to be a servant leader,” Carl says. “I am here to serve the people I work with and the company I work for. People I’m responsible for are more important than I am –– they always come before me.” Carl also points

out that nothing should be more important to a leader than the people they’re responsible for. Also, leading by example, building trust, and empowering those who work for you by giving them the opportunity to make decisions will build the confidence of the team.

Carl concluded our discussion by offering the following observations. “I’ve had two jobs in my life –– the military and CSX. Both organizations are ones that serve this country, and if I had it to do all over again, there is nothing I would do differently. Doing the best for my country, company, and leading the people I have on my team keeps me grounded and focused. I’ve had tremendous support from my family, and I’ve built some great relationships that I’ll have for the rest of my life.”

Carl is also bullish on the railroad industry. “There is a lot of opportunity ahead in the rail industry, and the vendors that support the industry are going to play a major role in realizing those opportunities. The importance of being a team in railroading, and one that people want to

be a part of, is paramount. Together, we can develop the best service products, safety metrics, and service reliability. I’m very optimistic that everyone in, and those who support, the rail industry will continue to develop as a team and forge a bright future for railroading.”

The Railway Educational Bureau Track Resources

Ballast Railroad Design

Ballast Railroad Design presents a valuable resource that dives into the design of ballasted track. The book presents a comprehensive procedure for the design of ballasted track based on a combination of extensive laboratory testing, computational modeling and field measurements.

Design and Construction of

Railway Bridges,

of Track

SWITCH POINT INSPECTION

by Brad Kerchof &

Wheel-Climb Derailment Prevention

Do you have experience arguing about derailment causes with another department? If so, chances are you have negotiated the cause of a switch-point wheel-climb derailment. The details of the conversation are predictable. The roadmaster to the mechanical supervisor: “Hundreds of cars have passed over this switch, and then that car derailed. It’s got to be a car problem!” The mechanical supervisor, if he’s on his game, responds, “What, are you nuts? That car has traversed hundreds of switches and then derails on that switch. It’s got to

be the switch!”

More often than not, the argument comes to an uncomfortable conclusion when the mechanical supervisor pulls out their wheel gage. They measure the normal wheel parameters — flange thickness, flange height and tread wear, and pronounce the wheel fit for service. (None of these parameters have any effect on a wheel climbing a switch point. The one wheel measurement that is important in this instance —- a vertical flange — is exceedingly rare. More about this later.) The roadmaster, unable to evaluate his switch point

in a similarly quantitative manner, is forced to take the cause on switch out of adjustment or switch point worn or broken (FRA cause codes T311 or T314 if you are keeping score).

What does the FRA have to say about switch points?

Not much. FRA’s Track Safety Standards provide remarkably little guidance on what makes a switch point condemnable: 213.135 Switches (h) Unusually chipped or worn switch points shall be repaired or replaced. Metal flow shall be removed

to insure proper closure.

The meaning of “unusually chipped or worn” is in the eye of the beholder and often depends on the inspector’s derailment experience. In fact, the best evaluators of switch point condition likely achieved that status following a very expensive education: years of switch-point wheel-climb derailments have refined their ability to identify high-risk points.

What three conditions are present in most switch point wheel climb derailments? The first two are intuitive — a worn

Figure 2: FRA Track Safety Standards say that a switch point is condemnable if it is “unusually chipped or worn.”

Figure 3: The first requirement for a wheel climb derailment is a worn, broken or gapped switch point. This point has worn to a ramp – note the flange mark up the point.

Figure 1: This switch point contributed to a wheel-climb derailment due to a) a slight gap and b) a top-worn stock rail that reduced the effectiveness of the undercut. A flange impact mark is visible at the tip.

Figure 4: The second requirement for a wheel-climb derailment is a worn flange. Note near-vertical flange and the sharp edge at flange tip.

Figure 5: A worn flange root (red arrow) allows the flange tip (blue arrow) to get much closer to the point.

switch point and a worn wheel. The third condition is less obvious, but still important — wheel tracking position, or how close is the wheel flange to the switch point?

1. A worn, broken or gaped point, such that the point provides a climbing surface for the wheel. A new (or like-new) switch point, properly adjusted, will not provide that climbing surface.

2. A worn wheel — one with a worn flange root and often a sharp edge on the tip of the flange. A worn flange has two attributes that increase the risk of derailment. First, a worn flange root (the base of the flange) allows the flange tip to ride much closer to the top of the point, where it is more likely to get on top of a worn or broken surface. And second, the overflow at the tip of the flange, created by flange-togage face contact, can provide the grip needed for wheel climb. Figure 4 shows a worn wheel that presents a high risk of wheel-climb if it encounters a compromised point. The drawing in Figure 5 shows the profile of a worn wheel compared to the profile of a new wheel.

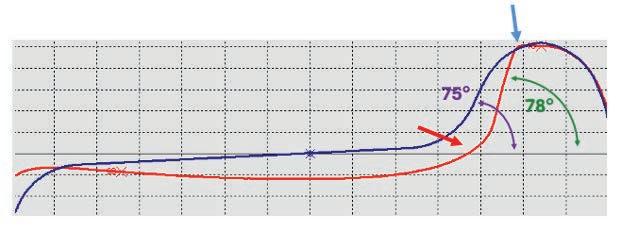

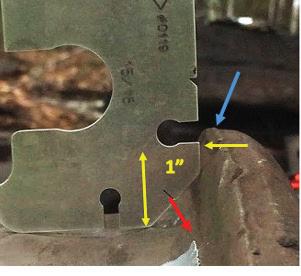

A word about vertical wheel flanges. While a flange may look vertical — see Figure 4 — the typical worn flange measures around 78o, matching the gage face angle of worn high rails. Figure 6 shows the challenge of condemning a wheel for a vertical flange. This wheel parameter absolutely has an impact on the risk of wheel climb. But encountering a wheel that fails the gauge is exceedingly rare — the gauge must contact the flange 1 inch above the tread.

3. T racking position — the worn wheel is shifted toward the worn switch point. You could have a ramped switch point and the ugliest wheel imaginable, but if that worn flange is not tracking against the switch point, wheel climb will not occur. Tracking position explains why some cars make it over a defective point and others do not (and why the first cars to traverse a run-through switch do not always derail).

Figure 6: For a wheel to be condemnable because of a vertical flange, the gauge must contact the flange 1 inch above the tread. The worn flange root is indicated by the red arrow, and the sharp edge on the flange tip by the blue arrow.

Figure 7: An illustration of tracking position: A wheel with a worn flange is tracking hard against the stock rail as it approaches a slightly gapped point.

Railway Equipment Co excels in manufacturing robust switch heaters, ensuring operational reliability and safety during harsh winter conditions. Our Sno-Net technology allows railroads to remotely monitor these heaters, providing maintenance teams with a crucial advantage during cold winter days and nights.

Figure 8: Stock rail top wear reduced the effectiveness of the undercut. That, combined with slight stock rail overflow and loose stock rail braces, allowed a slight point gap.

Did a wheel climb this switch point?

The switch point shown in Figure 8 had seen a lot of wheels pass successfully. And that fact is what caused the track inspector to say “good to go” on his last inspection. But a combination of stock rail wear and a slight gap exposed the tip of the point. And when the right wheel came along — one with a worn flange and overflow on the tip — that was tracking hard against the stock rail, the result was wheel climb.

Diverging points vs. straight points

It is no surprise that diverging points experience more wear than straight points (and why diverging points in yards get switch point protectors). The reason is related to tracking position: wheels rolling through the straight side of a switch are centered between the rails and normally don’t make flange contact. A diverging point, on the other hand, juts out

Figure 9: After derailing on this switch point, this wheel was re-railed and photographed as it was moved closer to the point. The wheel climbed the point during the controlled re-run, as well.

from its stock rail into the path of the approaching flange.

An indication that a problem is developing

Like so many other aspects of railroading, a switch point will usually tell you that a problem is developing. A point that shows flange contact is saying “pay attention to me as I wear.” A thin point is more likely to break out, especially if there is an overflow lip on the stock rail (Figure 12). Wheel contact can also cause a point to wear in the shape of a ramp (Figure 3). Both abnormal shapes can give a worn flange the purchase it needs to climb.

Any concerns with either of these switch points?

Figures 13 and 14 show the left and right points of the same switch. Both points have issues, but do those issues present an increased risk of derailment? Due to track geometry or in-train forces, wheels are tracking

Figure 10: The diverging point, except for the tip, which is protected by the stock rail undercut, is in front of the “gage line” of the stock rail, thereby inviting wheel flange contact.

Low Profile Portable Derail

Western-Cullen-Hayes portable derail. The LP-TS incorporates th same proven, overall design as the TS Derail, but with a Lower top of rail height to clear locomotive pilots.

The LP-TS comes in either a left hand or right-hand version.

Light weight - approximately 41 pounds w/o flag

Can be padlocked in the derailing position

Resists sliding - unique, patented, design holds derail securely to rail

Rugged - fabricated from high strength alloy steel

Easy to install - requires no special tools

Equipped with a highly visible warning flag

Fits rail 75 to 141 pounds

WESTERN-CULLEN-HAYES,INC.

2700 W. 36th Place • Chicago, IL 60632

(773) 254-9600 • Fax (773) 254-1110

WebSite:www.wch.com

E-mail:wch@wch.com

Figure 11: The straight point, protected by the stock rail bend and behind the “gage line,” rarely sees wheel flange contact.

to the left, wearing against the left point and staying away from the right point.

Five switch point inspection tips

1. O perate the switch both ways to observe how each point fits up against its stock rail.

2. L ook for wheel flange contact at the front of the point.

3. Ke ep “tension” on your switch stand to hold the point tight against its stock rail.

4. G rind stock rail overflow.

5. M aintain your switch points with worn wheel flanges in mind!

If you inspect your switches properly (tips 1 & 2), maintain them properly (tips 3 & 4), and adopt the philosophy that you need to do a better job maintaining your switches than the car department does maintaining its wheels (tip 5), you should be able to avoid wheel-climb derailments.

The Railway Educational Bureau Federal Regulations

Track Safety Standards Subparts A-F

Track Safety Standards, contains the Track Safety Standards, Subparts A-F, for Classes of track 1-5. The standards cover general information, Roadbed, Track Geometry, Track Structure, Track Appliances and Track-Related Devices, and Inspection. Includes Defect Codes. Updated July 1, 2025

BKTSSAF Track Safety Standards, Subparts A-F $13.95 Only $12.50 for orders of 50 or more!

Bridge Safety Standards

FRA Part 237 establishes Federal safety requirements for railroad bridges. This rule requires track owners to implement bridge management programs, which include annual inspections of railroad bridges, and to audit the programs. Part 237 also requires track owners to know the safe load capacity of bridges and to conduct special inspections if the weather or other conditions warrant such inspections. Updated July 1, 2025

BKBRIDGE Bridge Safety Standards $14.00 Only $12.60 for orders of 50 or more!

Workplace Safety

This reprint includes the FRA's Railroad Workplace Safety Standards addressing roadway workers and their work environments. These laws cover such things as: personal protective equipment, fall protection, and scaffolding for bridgeworkers; and training issues. Also includes safety standards for on-track roadway vehicles. Updated July 1, 2025

Track Calculator

The Track Safety Standards Calculator is a must for anyone who works on track. This slide rule type calculator contains many of the details for Classes of track 1- 5. Deviation from uniform profile and from zero cross level. Difference in cross level. Compliant with part 213.

Track Calculator $12.50 Only $11.25 for orders of 50 or more!

Figure 12: Switch point exhibiting flange contact. As wheel traffic accumulates, the point will continue to wear until it breaks out.

Figure 13: This point is wearing thin and could break out soon. But the risk of derailment is mitigated by the switch point protector, which holds flanges away from the point.

Figure 14: Even though this point is chipped and the stock rail has some ugly overflow, it does not represent a derailment risk — wheels are not tracking to this side.

LIGHT RAIL 2025

PRESENTED BY RAILWAY AGE AND RT&S

PLANNING, ENGINEERING AND OPERATIONS

OCTOBER

1 & 2

Fairmont Pittsburgh Pittsburgh, PA

Light Rail 2025 delivers a focused, in-depth look at the technical, environmental, and socio-economic challenges of planning and operating light rail transit (LRT) systems in today’s urban environments.

Who Should Attend Professionals in LRT planning, operations, civil and systems engineering, vehicle technology, and signaling.

Program Content Includes

• Major New-Builds and System Expansions

• Capital Program Management

• Extreme Weather Events: Planning and Mitigation

• Innovations in Rider Experience

• Alternative Propulsion Technologies

• Special Regional Tour

Connect with LRT professionals from around North America!

Speakers Include

Andy Lukaszewicz Deputy Chief Officer Rail Ops Pittsburgh Regional Transit

Casey Blaze Deputy Project Mgr.

Greater Cleveland Regional Transit Auth

Ida Posner COO Railroad Development Corp.

Justin Selepack Dir., Railcar Maintenance Pittsburgh Regional Transit

Nate Asplund President Pop-Up Metro, LLC

Rachel Burckardt, P.E. SVP/Sr. Project Mgr., Northeast Lead WSP USA

SPONSORS

Bryan K. Moore Project Mgr., Railcar Replacement Program

Greater Cleveland Regional Transit Auth.

John Mardente Civil Engineer, Passenger Rail Div. Federal Railroad Administration

Barbara M. Schroeder, P.E., P.M.P. Rail Transit Project Manager Benesch

Stuart Grassie, Principal of Rail Measurement Ltd / Stuart Grassie Engineering Ltd.

STUDS: Squat-Type Defects

that are Misunderstood and Mismanaged

by Jeff Tuzik

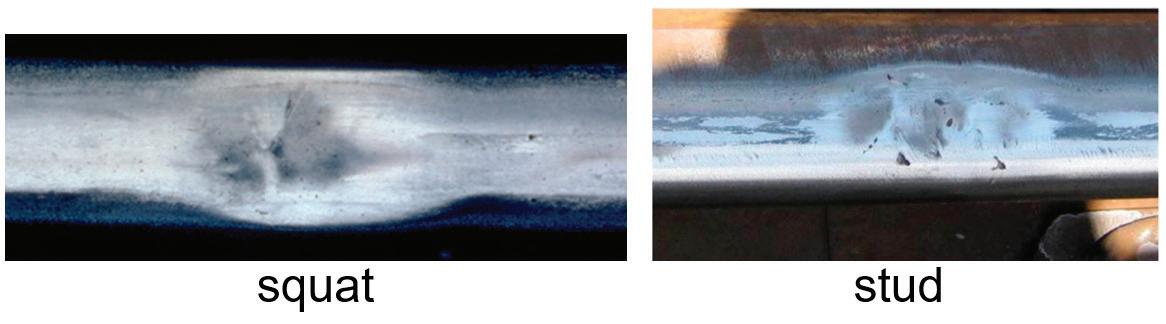

Squats and studs (squattype defects) are a topic of discussion and debate in the world of wheel/rail interaction. Their similarity in appearance leads many experienced track people to misidentify them and the urgency with which they need to be addressed.

As previously reported in “Squats & Studs: Emergent Damage Mechanisms on Rail Transit Systems” ( RT&S March 2024), squats and studs have a complicated and somewhat confusing history.

“Frankly, studs remain a quite

poorly understood defect to this day,” Stuart Grassie, Principal of Rail Measurement Ltd / Stuart Grassie Engineering Ltd, and primary investigator of the stud phenomenon, told attendees of the 2024 Wheel/Rail Interaction Transit conference.

Squats

Squats were first identified on relatively high-speed rail lines like British Rail’s West Coast Main Line in the 1970s. Much work was undertaken by British Rail Research, which gave rise to published papers such as

that shown in Figure 1. Squats tend to develop cracks that grow into the rail along grain boundaries in pearlite that is heavily sheared in the direction of (wheel) traction, Grassie said. “These cracks grow this way through the first few millimeters of the rail until they reach a depth where they grow under bending stress in the rail.” If left untreated, such a crack is likely to develop a transverse defect, i.e., a rail break.

Another characteristic of squats is that they develop quite slowly. “Squat crack growth is typical of general RCF

development,” Grassie said. It generally takes ≈40 MGT for “seed cracks” to develop in the sheared pearlitic structure of the rail surface, and ≈100 MGT for the crack to reach the edge of the heavily sheared layer—the so-called elastic/plastic interface of the top few millimeters of the rail. “This slow development means there is ample opportunity to treat the defect before it progresses.”

A combination of factors, including harder rail steels and more sophisticated rail maintenance efforts like corrective and preventive rail grinding, had, by the 1990s, curtailed the proliferation and imminent danger of squats, Grassie said. “Squatcaused broken rails simply don’t exist anymore.”

Studs

Just as the concern over the danger of squats subsided, a new defect began to be noticed. These were first documented towards the end of the

1990s on heavy haul systems, and subsequently also on transit systems. Superficially, the defects looked very similar to squats (see figure 2). But Squats had been documented only on relatively high-speed passenger railways. This new defect was appearing on various types of railways worldwide. Because of their superficially similar appearance, they initially were thought to be squats; The prospect that squats we reappearing was alarming because of the numbers involved and their appearance on all types of railway systems.

“Any rail defect requires attention. Defects that lead to rail breaks require immediate attention and remediation. The proliferation of these new squat-type defects found on all types of railroad systems—heavyhaul, metro systems, and high-speed passenger lines sent a wave of panic through segments of the industry.

Further investigation determined that what appeared to be squats were

in fact a new phenomenon—a class of defects that Grassie termed “studs.” Unfortunately, Grassie said, by the time that studs appeared, most of the experts who had performed critical, early research on squats were no longer active. “We lost a lot of institutional knowledge.” As a result, a widespread assumption has persisted in the industry that treatments that were relevant to squats, were also relevant to studs.

Gaining Understanding

While there are superficial similarities between studs and squats, Grassie said, there are significant differences. Significant progress has been made in cataloging these differences. They include:

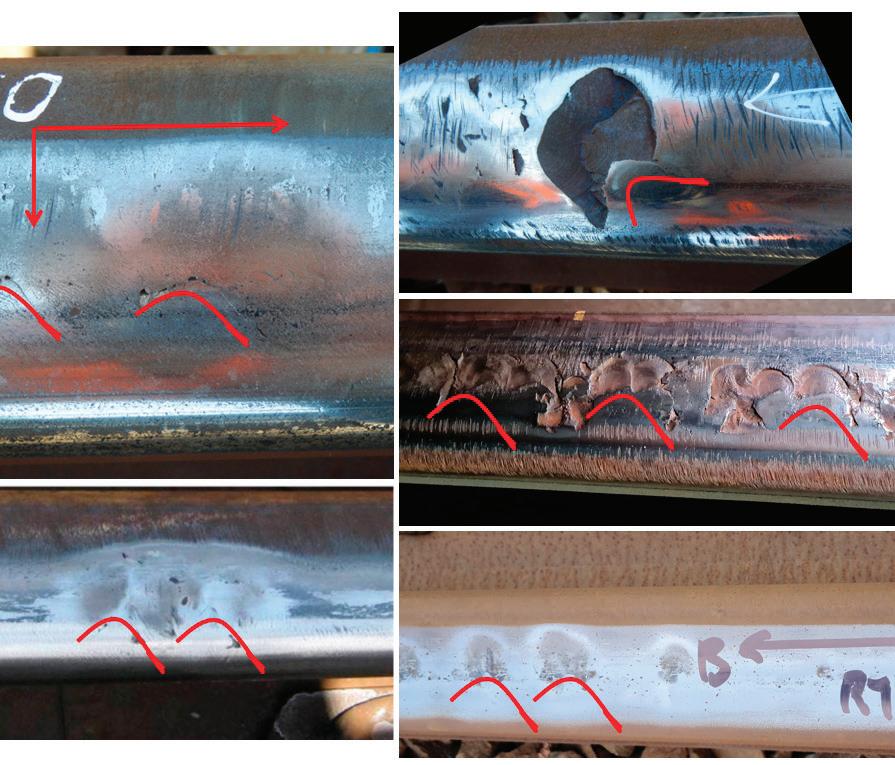

• U nlike squats, studs often appear in periodic patterns or clusters.

• U nlike squats, studs are frequently associated with spalling and shelling-out of the rail surface.

Figure 1: Excerpts from Clayton, P., & Allery, M. B. P. (1982). Metallurgical Aspects of Surface Damage Problems in Rails. Canadian Metallurgical Quarterly, 21(1), 31–46. https://doi.org/10.1179/cmq.1982.21.1.31

Figure 2: Note the visual similarity between squats and studs.

Figure 3: Multiple characteristics of studs on display, including periodic clustering, spalling,and their typical V-shaped crack structure.

• W hile squats are typically associated with high-speed passenger lines, studs are found on all types of railroad systems—particularly on heavy-haul lines and metro systems).

• O n the rail surface, cracks that develop into studs develop from a crack that appears like an inverted U or V shape (relative to the gage corner of the rail (figure 3). These grow across the rail, initially at an angle of about 20 degrees to the rail surface. After they reach a depth of about 3mm, they tend to grow across the rail. Eventually, they may rise to the rail surface and spall out. Most importantly, they do not grow down into the rail and develop under bending stresses.

• M ost significantly, perhaps, “studs develop very quickly, typically in 5 to 10 MGT, and they’re often associated with spalling,” Grassie said. “This is very unlike squat growth patterns.”

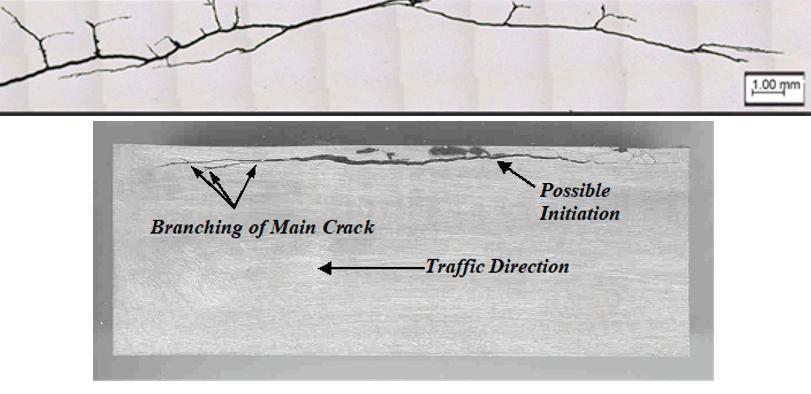

Cross sections of stud cracks examined by agencies like Transportation for New South Wales (TNSW), the National Research Council of Canada (NRC), and London Underground also showed that the cracks tend to “wander” (see figure 4) rather than

follow the grain structure of sheared pearlite, as is characteristic of classical squats, Grassie said; “In many cases, studs develop in the complete absence of sheared pearlite.”

There is a great deal of evidence that

Unfortunately, Grassie said, by the time that studs appeared, most of the experts who had performed critical, early research on squats were no longer active. ‘We lost a lot of institutional knowledge.’

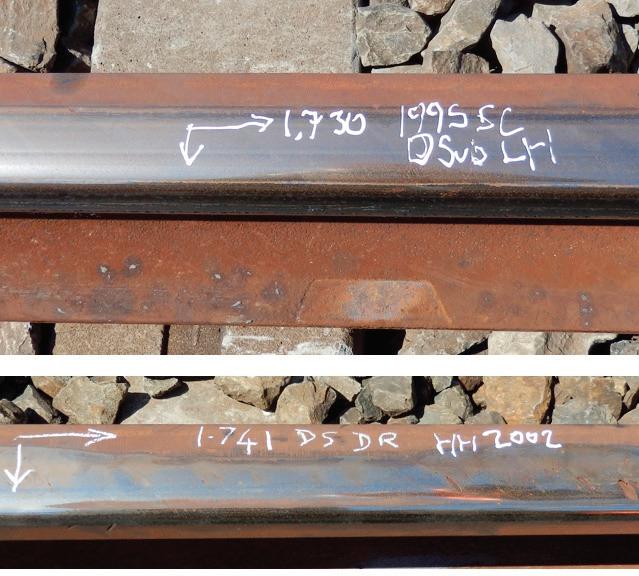

studs are more common in harder rail steels. This is contrary to the universally accepted behavior of conventional rolling contact fatigue (such

as head checking or indeed, squats), which develop more slowly in harder rail steels. Figure 5 shows such an example. The top rail is 1995 standard carbon rail with ≈20 years of traffic and no evidence of studs; the bottom rail is 2002 head-hardened rail in the same curve with only ≈10 years of traffic. Yet the head-hardened rail is in the process of being replaced due to the number and severity of studs.

There is some evidence that AC traction has a significant effect on the formation of studs. “[This research] indicates that studs tend to appear at the same location on opposite rails, often at a spacing matching that of axles on power cars,” Grassie said.

On London Underground, studs were commonly found on lines equipped with AC traction (the Piccadilly, Northern, and Central lines) but absent on lines operating under conventional DC traction. Similarly, Grassie noted that studs are not present on Vancouver SkyTrain, a system that uses a linear induction system to move trains rather than tractive effort.

“We’ve also seen that deliverable adhesion has increased with successive generations of AC traction in both transit vehicles and heavy-haul locomotives, just as studs have increased on these systems. It may be that we’re seeing the effects of

Figure 4: Cross sections highlighting the “wandering” crack growth structure typical of studs. Top image: NRC. Bottom image: TNSW.

controlled wheel slip.”

Building a Better Understanding

All of that said, the industry does not yet have a firm handle on the differences between squats and studs, due in part, no doubt, to their similar appearance. But it’s important to distinguish between them and understand the differences between them. In simple terms, the greatest difference is that squats break rails and studs don’t, Grassie said. “If we continue to apply the understanding we’ve built up about

squats to studs, we’re wasting a hell of a lot of time and money,” he said. “We should not be treating a defect that is relatively benign (studs) like something that is extremely dangerous (squats).”

There is a predicament in which classical squats are well understood but extremely rare, and studs are extremely common but poorly understood. Grassie’s prescription is more, much more, research into studs— primarily how (and how quickly) they develop, and their relationship to AC traction and rail hardness. “This is

an issue that should be tackled with the joint cooperation of both rail and vehicle suppliers,” he said. “Both stand to gain from the research.”

Jeff Tuzik is Managing Editor of Interface Journal.

This article is based on a presentation made at the 2024 Wheel/Rail Interaction Transit conference and includes updates and information current as of July 2025.

All images are courtesy of Stuart Grassie unless otherwise noted.

Figure 5: In two rails on the same curve, studs appear only in the head-hardened rail, not the standard carbon rail.

SIT AND LISTEN

C.

Railway Age

David C. Lester

Railway Track & Structures

Kevin Smith International Railway Journal

Railway Age, Railway Track & Structures and International Railway Journal have teamed to offer our Rail Group On Air podcast series. The podcasts, available on Apple Music, Google Play and SoundCloud, tackle the latest issues and important projects in the rail industry. Listen to the railway leaders who make the news.

William

Vantuono

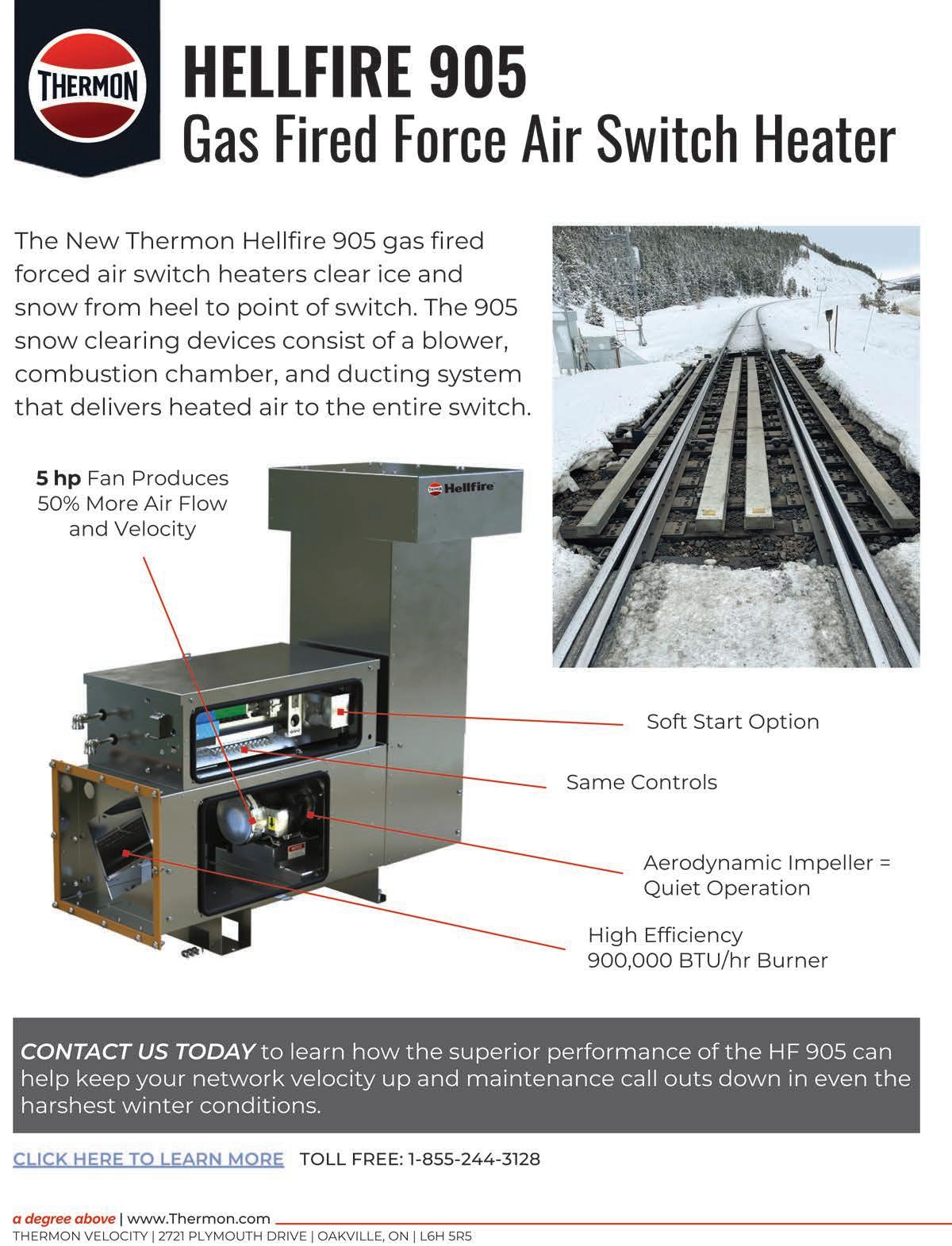

DE-ICE, DE-ICE, BABY

Just as railroads need to account for extreme heat in track maintenance, they must also contend with the bitter cold.

By Jennifer McLawhorn, Managing Editor

For most in North America, we are still in the middle of the summer heat and have only just begun eyeing fall.

In the northeast, passenger agencies have utilized AquaTrack machines and laserequipped trains to clean and remove fallen leaves from the rails. However, as we approach the upcoming colder months, railroads must assess their winter maintenance programs to account for freezing temperatures and snow. RT&S spoke to a couple of players in the winter maintenance market about the equipment and services they offer for the winter season.

From Pettibone, the “Speed Swing 445F2 offers dozens of rail maintenance attachments, including equipment specifically designed for clearing snow from railways and crossings. A standard Speed Swing machine can be equipped with adjustable V-plows or snow buckets for heavy-duty snow removal. A sweeper-broom attachment is often used to brush snow off switches. A track-cleaning bucket features builtin notches that can slide over each rail as the bucket advances and cleans snow off the tracks.

The 445F2 can travel up to 25 mph on hi-rail and 20 mph with all-terrain rubber tires. The tires allow maneuverability off the rails to simplify certain winter maintenance tasks.

“For colder climate operation, Pettibone offers diesel heating systems for the Speed Swing. The system can be programmed to start the engine at a set time before scheduled work. This ensures

the engine, hydraulics, and inside of the cab are all properly heated without having to idle the machine and burn costly fuel all night long. Users can also take advantage of cold-weather fluids. Gear oil and hydraulic fluids that are less viscous will perform better in cold temperatures. Customers can specify cold-weather packages when buying a new Speed Swing.”

Railway Equipment Company COO and EVP Matthew Bolte told RT&S that “RECo’s service extends beyond just the sale of our units. We offer detailed installation and technical support. Covering everything from gas and electrical connections to seasonal adjustments which ensure peak performance throughout the winter. Regular maintenance is crucial for these systems. We provide thorough guidelines on essential tasks like motor greasing, low-pressure regulator adjustments, and general troubleshooting. We also have a 24/7 technical support line ensuring that our customers can always operate their systems with confidence. Our commitment to safety and efficiency makes our products a reliable choice for maintaining clear and operational railway tracks during snowy conditions.”

Thermon says it’s “array of snow-clearing devices are designed to reliably withstand even the harshest winter storms. By offering a variety of options such as electric elements, hot air blowers and high velocity ambient air blowers, we ensure our customers have their selection of

high performing products that are appropriate for their applications. Our SCD’s are designed with safety, efficiency and quality in mind to carry our customers through the winter and result in less maintenance, decreased down time and increased dependability. Buyers are looking for cost savings, decreased lead times and reliable quality products. We have centralized our manufacturing to our San Marcos, TX facility to reduce costs, improve lead times and keep our quality superior to our competitors. We continue to work closely with the railroads to exceed their expectations and keep costs down while delivering dependable products consistently. We urge customers to plan early and order material ahead of winter to prepare for any unforeseen roadblocks that may arise. Take advantage of our many offerings and work with our knowledgeable team of experts to find what would work best for your specific application. With many years of demonstrated success, we are confident that our products will result in smoother maintenance for your lines. Thermon is currently working on our next generation of Hellfire gas fired blowers with trials expected to take place this winter. We are revolutionizing our current design to include updated components, expanded communication capabilities, OLED character display + organized status LEDs and a new forward-thinking design that allows the Hellfire to adapt its performance to changing winter conditions.”

Photo Credit: Pettibone

Message From The President

JJERRY SPECHT, AREMA President 2025-2026

erry Specht is the Assistant General Manager of South Signal & Communications (S&C) Operations at Canadian Pacific Kansas City (CPKC), where he leads strategic and operational initiatives across the southern region of North America’s only transnational railway. With over two decades of experience in railway signal engineering and operations, Jerry brings deep technical expertise and leadership to one of the most critical infrastructure networks on the continent.

Before joining CPKC, Jerry served as Director of Signal Engineering at BNSF Railway, where he played a pivotal role in modernizing and maintaining signal systems across the network. He also held senior leadership roles at Wabtec Corporation, where he led product management and engineering teams focused on

rail technology innovation around Wireless Crossings.

Jerry earned his Bachelor of Science in Electrical Engineering from North Dakota State University (NDSU) in 1999. A native of Center, North Dakota, he has remained closely connected to his alma mater and the broader engineering community. He is also a member of the North Dakota State University College of Engineering Advisory and Advancement Board.

He is an active member of the American Railway Engineering and Maintenanceof-Way Association (AREMA), currently serving as President for the 2025–2026 term. He is also on the AREMA Board of Governors and has previously held leadership roles as Senior Vice President, Director, and Functional Group Vice President for the Communications, Signals, & Information Technology

Functional Group.

In addition to his governance roles, he remains active on Committees 36-Highway-Rail Grade Crossing Warning Systems, 37-Signal Systems, and 39-Positive Train Control. His long-standing involvement with AREMA reflects his commitment to advancing industry recommendations and mentoring the next generation of railway professionals.

Jerry enjoys sports, hunting, fishing, camping, and anything outdoor-related. He enjoys working on vehicles, small engine repair, and fixing things that people want to just throw away. He is involved in high school sports athletics, volunteering as the cook for their team events, and helping out whenever needed.

He has a wonderful family of 5 with 3 children (Haley, Tyler, and Ryan) and a very supportive spouse (Ann) who keeps the ship on the right course.

I thought it was important to provide a biography, so you know who your new President is and to learn more about me both professionally and personally. I am thrilled to be AREMA’s President and look forward to connecting and learning more about each of you through this next year. As I look at my career and personal life presently, I gratefully (or fondly – another word) must remember how I got here.

From a young age, I was always fascinated by tearing apart and fixing things — understanding how things work, how systems work together to create something greater than the sum of their parts. That curiosity eventually led me to the railway industry, a field where engineering, logistics, and legacy intersect in powerful ways.

My journey began as a track laborer working during the summer months in Montana while attending NDSU as a student in Electrical Engineering. This led the way to an internship and eventually a full career in the railway industry. I was drawn to the idea of contributing to something that moves people and goods, that supports economies, and that evolves with technology — MAKING A DIFFERENCE!

What started as a technical interest quickly became a passion. I found myself immersed in the challenges of signal design, signal maintenance, and infrastructure resilience. Each challenge brought new opportunities to learn, collaborate, and innovate. I was especially inspired by the way the industry blends tradition with transformation— honoring its historic roots while embracing cutting-edge technologies like AI, automation, and digital transformation.

But beyond the engineering, what truly solidified my commitment was the community. The railway industry is filled with professionals who are not only skilled but also deeply dedicated. There’s a shared sense of purpose, a culture of mentorship, and a drive to build a safer, smarter, and more sustainable future. The lifelong connections and relationships in the railway industry have been extremely rewarding. With these relationships, it’s good to note that this many people can certainly

solve any problem there is when they put their minds together.

The connections established through AREMA certainly are the most powerful thing for the railway industry – bringing people together with common interests and ideas to make things better. For those who are interested in pursuing a career in the railway industry, the best advice I can give is to get involved right away. Meet others and establish relationships! There are so many experts in every facet of this industry; getting to know them and listening to their experiences and advice is truly important to have a successful career. You

I THOUGHT IT WAS IMPORTANT TO PROVIDE A BIOGRAPHY, SO YOU KNOW WHO YOUR NEW PRESIDENT IS AND TO LEARN MORE ABOUT ME BOTH PROFESSIONALLY AND PERSONALLY.

may not know everything, but you should know those who do. AREMA has been the catalyst for making this happen!

Today, I’m proud to be part of this journey. Whether I’m solving technical problems, mentoring new talent, or contributing to long-term planning, I know I’m helping shape the future of railroading—one piece at a time.

Enough about me, we’re about to hold the AREMA 2025 Conference & Expo in Indianapolis, IN, and I’ll be the newly minted President of AREMA. With this honor, I am humbled by the many people who have been supportive of this transition and their confidence in asking me to lead the organization. There are many people to name, and surely, I will accidentally leave some out of this message, but a big thank you to my wife Ann Specht, Beth Caruso, Bill Riehl, Vic Babin, Brian

Lindamood, Ray Verrelle, Stacy Spaulding, and many others who have supported me throughout this change. You all are truly inspiring and have been a tremendous help to me! My successor as the Senior Vice President of AREMA is David Clark, Director of Construction Engineering at CSX. He is a great person whose leadership skills and expertise in the industry will be great for AREMA, ultimately propelling this organization going forward!

Some of the Conference highlights this year are the AREMA Educational Foundation Golf Tournament, Welcome Reception at the Indianapolis Motor Speedway Museum, Young Professionals Event, Meet The Next Generation Career Fair, Educational Sessions, Technical Presentations, the Presidents Dinner, the Expo itself, Committee meetings, and many other activities. Throughout the Conference & Expo, there are many opportunities to see all the latest technologies, learn from the presentations provided, and meet others. Attendees gain valuable insights into the latest innovations, sharpened their technical skills, and get to connect with peers and mentors. Whether you’re a seasoned engineer or a rising professional, the Conference & Expo events offer tools and inspiration to help you stay competitive and drive success in the rail industry.

I look forward to the upcoming year in this role as President. My plans going forward are going to be looking at our footprint of AREMA and how we can make this organization bigger, reaching out to many others like me who want to meet others and develop their professional network. I plan to discuss how we can do more for our members in the areas of technical leadership and providing guidance on what the future holds for the railway industry. Next month’s article will be more detailed about the Conference & Expo and the detailed agenda of what to expect for my term in 2025-2026. Many thanks again to everyone. Looking forward to serving as President.

Jerry Specht

FYI

Skip the line and register online. Join us for the AREMA 2025 Annual Conference & Expo in Indianapolis, Ind., September 14–17 . Don’t miss your chance to experience top-tier education, inspiring speakers, dynamic networking events, a vibrant Expo, and more. Visit www. conference.arema.org today and register now to avoid delays onsite.

Discover the ultimate guide for railway engineering professionals in the 2025 Manual for Railway Engineering. With over 6,100 pages of essential practices and detailed specifications, this comprehensive resource offers everything needed to design and build efficient, safe, and cost-effective railway

systems. It is available in print or PDF formats for immediate use. Order online now at www.arema.org.

Download the AREMA 365 App for essential rail resources and networking opportunities. Easy access to news, events, and educational materials lets you stay informed and connected to the industry. Download it today by searching for AREMA in your phone’s app store.

Did you know we offer a wide variety of On Demand education for learning on your time? Browse our most popular webinars, seminars, and Annual Conferences to earn your PDH credits on the go. Visit www.arema.org to start your On Demand learning today.

If you’re looking for a podcast to binge, listen to AREMA’s Platform Chats. It features guests from every aspect of the railway industry. Catch up on all five seasons available on all your favorite listening services today.

Leverage the power of your trusted association’s Railway Careers Network to tap into a talent pool of job candidates with the training and education needed for long-term success. Visit www.arema. org/careers to post your job today.

NOT AN AREMA MEMBER? JOIN TODAY AT WWW.AREMA.ORG

CONNECT WITH AREMA ON SOCIAL MEDIA:

UPCOMING COMMITTEE MEETINGS

SEPT 9-10

Committee 15 - Steel Structures Virtual Meeting

SEPTEMBER 13-14

Committee 24 - Education & Professional Development

*Indianapolis, IN, in conjunction with AREMA 2025 Annual Conference & Expo

SEPTEMBER 14

*Indianapolis, IN, in conjunction with AREMA 2025 Annual Conference & Expo

Committee 14 - Yards & Terminals

Committee 10 - Structures

Maintenance & Construction

Committee 11 - Commuter & Intercity Rail Systems

Committee 12 - Rail Transit

Committee 16 - Economics of Railway Engineering Operations

Committee 17 - High Speed Rail Systems

Committee 18 - Light Density & Short Line Railways

Committee 33 - Electric Energy Utilization

Committee 5 - Track

Committee 40 - Engineering Safety & Training

SEPTEMBER 15

Committee 41 - Track Maintenance

Committee 13 - Environmental

Committee 35 - Information Technology

SEPTEMBER 17-18

Committee 38 - Information, Defect Detection & Energy Systems

Committee 39 - Positive Train Control Indianapolis, Ind.

Committee 4 - Rail

SEPTEMBER 18

Committee 27 - Maintenance of Way Work Equipment

Join a technical committee

OCTOBER 2-3

Committee 8 – Concrete Structures and Foundations

Newark, NJ

OCTOBER 6

Committee 2 - Track Measurement and Assessment Systems

Pueblo, CO

OCTOBER 9

Committee 9 - Seismic Design for Railway Structures Virtual Meeting

NOVEMBER 12

Committee 28 - Clearances Virtual Meeting

Joining a technical committee is the starting point for involvement in the Association and an opportunity for lifelong growth in the industry. AREMA has 30 technical committees covering a broad spectrum of railway engineering specialties. Build your network of contacts, sharpen your leadership skills, learn from other members, and maximize your membership investment. If you’re interested in joining a technical committee or sitting in on a meeting as a guest, please contact Alayne Bell at abell@arema.org.

For a complete list of all committee meetings, visit www.arema.org.

RT&S Incoming AREMA

President Interview Questions

AREMA: Why did you decide to choose a career in railway engineering?

SPECHT This is an interesting question for me. My first year attending college (1993), I was running low on money in the Spring of 1994 and needed to get a good job. I went down to the local Job Service and saw that there were positions open for railroad laborers. Figuring the pay was great and it was something I’ve never done before, thought it would be a great fit. Low and behold, BNSF offered me a position as a track laborer starting in Glendive, MT. From there, I developed an interest with the whole railroad thing and then eventually started an internship with BNSF in the summer of 1996 in the Signal department. The rest is history as I progressed from internships and eventually choosing a path in the Signal department.

AREMA: Outside of your job and the hard work you put into AREMA, what are your hobbies?

SPECHT I’m not sure where to start with this as there are many things that I am interested in and have many hobbies. I am an outdoor person who enjoys spending time with my family doing anything from hunting, camping, canoeing, mechanic, handyman, and sports activities. I am also one who is involved heavily in the community from being part of the homeowner’s association to involvement with North Dakota State University on an advisory board for the School of Engineering. Up until my youngest graduated high school this year, my wife and I were active in cooking for the football and baseball teams by smoking brisket and pulled pork for the team meals. I was also active in providing the music entertainment and sound effects for the football team during the games – Friday Night Lights. Spending time with my family outdoors is one of my favorite things to do. As of early August, we just finished up the annual father/ son camping and canoeing trip in Van

Buren, MO, fully reminding me of the real reason we are here on this earth is to enjoy the time and make memories with family and friends.

AREMA: If you could share one interesting fact about yourself with the readers of RT&S, what would it be?

SPECHT I would say that I am a person who is eager to learn and continues to self-educate. Not everything has to be taught to you by someone else. I am constantly looking to teach myself new things, from performing mechanical work on vehicles/machinery to fixing broken electronic items that others have thrown away. I like to tinker with things to challenge myself to fix it. Part of this comes from a background where money wasn’t always available and I had to make do with what I had. This has made me the most parsimonious person, which is known as a tightwad! There is a balance to this as I remember the saying: He who is always saving for the future may not be there when it arrives. For that reason, you have to make sure you enjoy yourself but be prepared for things to come.

AREMA: What advice would you give to someone who is trying to pursue a career in the railway industry?

SPECHT My biggest advice to someone who is pursuing a career in the railway industry is to get involved and be part of an organization like the American Railway Engineering and Maintenanceof-Way Association (AREMA). Be part of organizations that help you network and develop contacts. You will learn so much from others, inspiring you with new ideas that could potentially be the next big thing in the railroad industry. As most of us are engineers, push the boundaries of your introverted personality! Challenge yourself to meet other people and develop those long-lasting, professional relationships. There are so many people who have experienced problems that you may be encountering that make your job easier. It’s almost like ChatGPT, but with real people!

PROFESSIONAL DEVELOPMENT

Get PDHs at your Own Pace with AREMA’s On Demand Education

Access to important professional development content is just a few clicks away with AREMA Education. Our On Demand content spans many disciplines of PDH accredited courses that allow you to get your PDHs by learning from experts online without leaving your office.

BENEFITS OF LEARNING ONLINE

1. LEARN MORE

Studies show that participants learn more while taking On Demand courses as you can skim through the material you understand and take more time in the more challenging areas.

2. GET INSTANT ACCESS

With AREMA On Demand courses, you don’t have to wait to learn and get your PDHs as they’re available instantly after purchase.

3. CONVENIENT AND FLEXIBLE

Above all things, On Demand education is meant to take at your own pace and on your time. Study from anywhere in the world, whether from your office or the convenience of your sofa.

4. COURSE VARIETY

AREMA On Demand education offers a wide variety of topics for all studies of the railway engineering community.

Register and Start Learning today at www.arema.org.

BECOME A MEMBER AND SAVE

Not an AREMA member? Join today at www.arema.org and get discounts on all AREMA Educational Offerings, from Virtual Conferences to our Webinars.

Cordel’s PTC Asset Connect platform has reached a major milestone: its Positive Train Control Product, PTC Asset Connect, is now being demonstrated live to our Class 1 railroad partners. This first release allows our partners to collaborate with Cordel’s team to refine the solution ahead of its commercial launch, scheduled for January 2026.

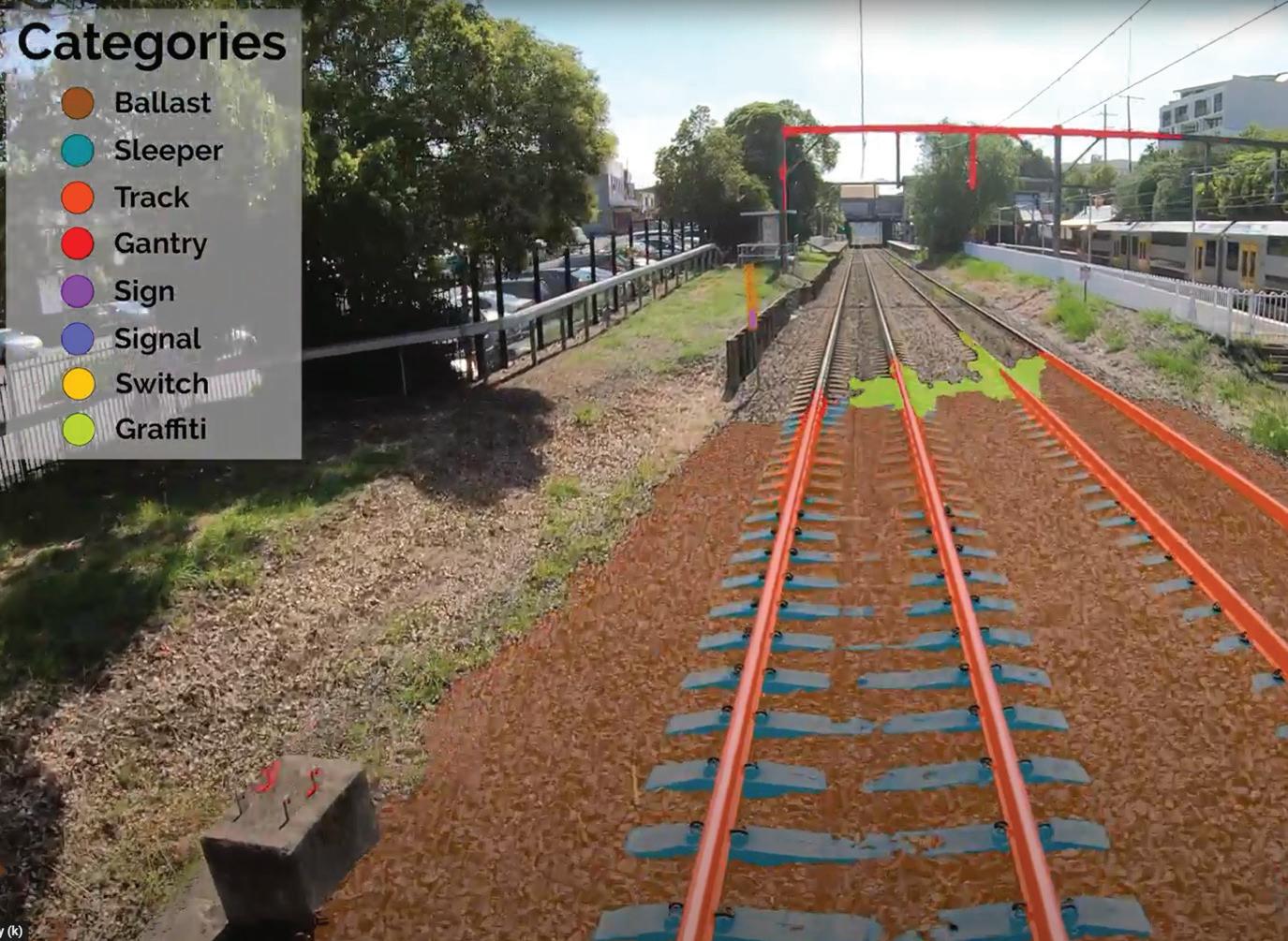

Railways face the complex challenge of managing thousands of miles of trackside infrastructure, traditionally relying on costly, time-consuming, and errorprone manual inspections with boots on ballast. Cordel’s platform transforms this process by leveraging advanced LiDAR and AI analytics to automate

the identification and management of Positive Train Control (PTC) assets like signals, switches, speed sign, track centerlines and more.

Trained on thousands of miles of track data, the system produces precise, up-to-date asset inventories that support regulatory compliance and improve safety. A standout feature is its continuous, automated change detection process, which analyzes collected data after capture to identify asset modifications or issues. This enables rail operators not only to respond proactively but also to distill thousands of individual asset checks into a manageable number of high-impact decisions.

Compliance reporting is streamlined