ballast Georgetown Rail Equipment Company

Herzog Railroad Services, Inc.

Georgetown Rail Equipment Company’s research and development department has made strategic advancements for the DumpTrain® aggregate delivery-via-belt system and Solaris®/GateSync® and BallastSaver® services. DumpTrain advancements have focused on perfecting the DumpTrain for Curves® (DTfC). The Solaris/GateSync program has seen software improvements as well as integration with BallastSaver. Solaris kits convert manual ballast gates to a wireless remote-controlled system, while GateSync automates car unloading at speeds of 10 mph with no ground personnel. GREX’s patented BallastSaver LiDAR ballast inspection system identifies a track’s ballast deficiency while moving at 30 mph. New enhancements enable railroads to detect clearance envelope encroachments, as well as pinpoint excess material volume and location, helping determine where ballast needs to be regulated and identify the exact location of track-fouling debris and vegetation. Assuming ballast dumped at a rate of two cars per mile, a ballast savings of more than 20% over several thousand miles is possible. BallastSaver has also been incorporated into GREX’s Aurora® Tie Inspection System, in which tie and ballast condition are presented in a 3-D digital environment where exact measurements are taken and exceptions are verified.

In 2015, Herzog Railroad Services, Inc. finished building the first half of its new, one-of-a-kind Automated Conveyor Train (A.C.T.), which is built with a single belt under each of the machine’s 30 100-ton-capacity cars. At the end of the car, material is transferred up an incline belt and discharged into a hopper at the end of the next car, allowing material unloading in a curve of up to 13 degrees with a superelevation of up to five inches. The cars can be unloaded in just under three minutes each at up to 2,000 tons per hour, and are capable of carrying multiple commodities simultaneously. The A.C.T. automation system allows the operator to select which car to unload and in what order. The A.C.T. can unload material as fine as sand or as large as five- inch +/– “B” stone. Knox Kershaw

Knox Kershaw Inc’s expanded service department includes extra service personnel for onsite training services and equipment maintenance/repair of, both domestically and internationally. A new manufacturing facility expansion accommodates service work for machines that customers do not have time to complete, from general maintenance to complete overhauls.

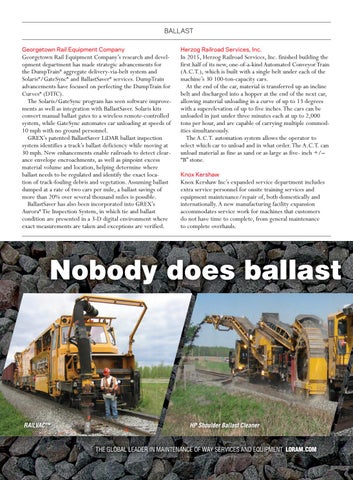

Nobody does ballast

RAILVAC™

HP Shoulder Ballast Cleaner

THE GLOBAL LEADER IN MAINTENANCE OF WAY SERVICES AND EQUIPMENT LORAM.COM