Asset Lifecycle Analytics (ALA)

At Radwell, we understand the critical importance of proactive obsolescence management. Our Asset Lifecycle Analytics (ALA) service offers unmatched insights into your industrial equipment ecosystem, ensuring uninterrupted production and optimised performance. By partnering with Radwell, you are choosing a path towards greater reliability, efficiency, and future-proofing your operation

The need for a streamlined, real-time solution has never been greater. In today’s dynamic industrial landscape, relying on manual processes and static reports limits your ability to make timely decisions. These outdated methods contribute to increased downtime and higher operational costs, often resulting from delayed responses to managing obsolescence.

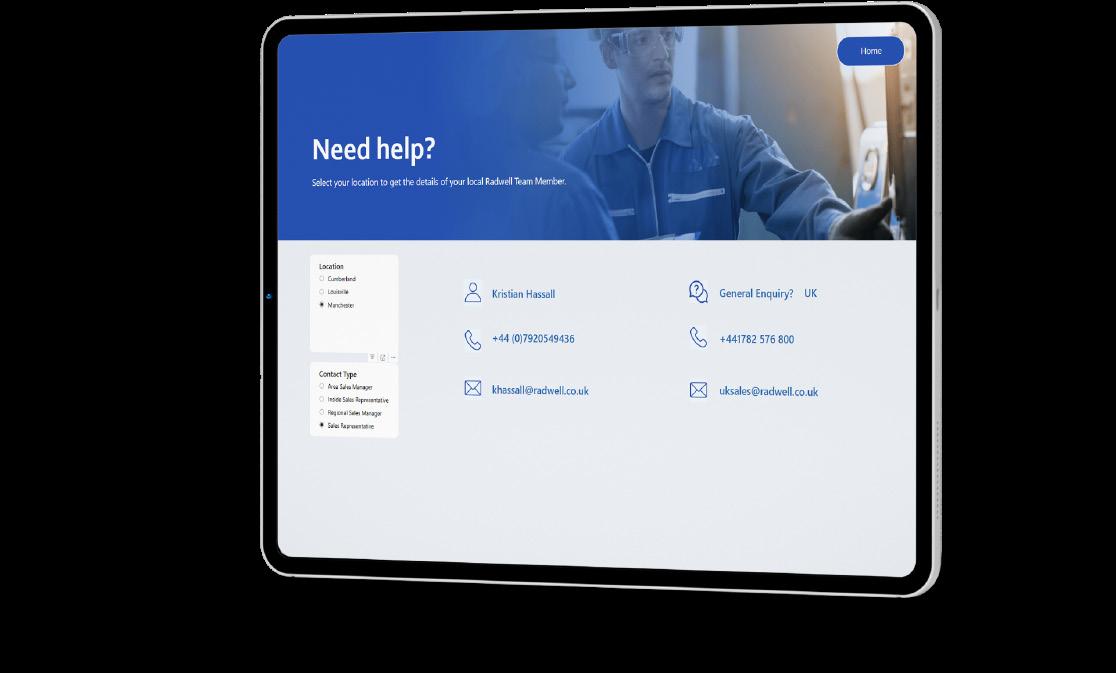

The ALA programme is an advanced, integrated tool that delivers live data on lifecycle status and inventory insights, empowering you to proactively manage obsolescence. With our cutting-edge digital portal, you get access to automated data updates, providing instant access to vital information and enabling more efficient decision-making. Here's a step-by-step overview of how it works:

Initial Consultation:

We begin by understanding your unique operational needs, challenges, and goals related to obsolescence management. This helps us tailor our approach to support your facility and objectives.

Comprehensive On-Site Audit:

Our expert team conducts a detailed inspection of your production lines, gathering data on naming for areas, processes, and Cabinet IDs, along with part numbers, manufacturers, and product quantities.

Data Analytics & Reporting:

Collected data is carefully analyzed to assess obsolescence risks. The ALA digital portal offers a clear overview, letting you filter by site, process, area, or cabinet.

Real-Time Monitoring:

A live data dashboard is created through your personalised account on Radwell’s website, giving you global lifecycle and availability insights to proactively manage risk.

Actionable Recommendations:

Based on our analysis, we provide options for replacements, repairs, or upgrades - backed by access to Radwell’s global inventory and cost-effective solutions.

Ongoing Support:

We deliver continuous updates on parts, lifecycle status, and ensure data protection and easy access.

Proactively manage obsolescence to prevent disruptions and ensure continuous operations

Gain a dynamic, holistic view of your entire site(s) or drill down by site, process, area, or cabinet for detailed insights

Access up-to-date lifecycle and inventory data instantly for quick, informed decision-making

Centralised platform for monitoring all parts and components across your operations

Reduce manual effort and improve resource allocation, enhancing overall efficiency

Contribute to sustainable practices by reducing waste and extending equipment lifecycles, supporting your company’s ESG goals

Continuous data refresh eliminates the need for manual updates, ensuring the most accurate information Benefit from robust security measures that protect sensitive data, ensuring compliance with industry standards

Full Visibility: Gain comprehensive oversight of part numbers by location, ensuring better planning and response.

Sustainability: Extend the lifecycle of existing equipment and reduce waste, contributing to environmental goals.

Proactive Management: Manage parts proactively in relation to replacements, repairs, and planned upgrades.

Complexity of Replacements: Understand the complexity of replacements where parts are obsolete, enabling maintenance and engineering teams to anticipate potential downtime for more complex or engineered parts.

Streamlined Sourcing: Centralised information on lead times, stock availability, and pricing simplifies procurement and reduces effort.

Interactive Features: Utilise buy-now buttons, QR code uploads, and RFQ capabilities to expedite purchasing.

Supplier Reliability: Ensure a reliable supply of parts while supporting sustainable procurement practices.

Accurate Financial Planning: Detailed insights into life cycle costs help forecast maintenance budgets accurately and avoid unexpected expenditures.

Cost Efficiency: Automating data updates reduces manual effort and associated costs, leading to more efficient resource allocation.

ESG Reporting: Improved tracking and reporting on sustainability initiatives.

Operational Security: Proactive obsolescence management reduces the risk of unexpected equipment failures that can disrupt operations.

Strategic Decision-Making: Real-time, comprehensive data supports long-term planning and operational optimisation.

Governance: Enhanced oversight and accountability support governance goals and compliance with industry standards.

A large dairy manufacturer faced unexpected operational disruptions due to phased-out components. These issues led to significant production delays, increased maintenance costs, and a decline in customer satisfaction.

Recognising the critical impact of obsolescence, the company partnered with Radwell to implement the Asset Lifecycle Analytics (ALA) portal. This comprehensive assessment evaluated the risk of obsolescence within their production line and identified critical components nearing the end of their life cycle.

Radwell’s detailed analysis identified a key drive module approaching obsolescence. The manufacturer had announced the end-of-life date for this module. The dairy company proactively purchased a stock of these modules to ensure continued availability.

88,800 SAVINGS PER YEAR In downtime expense savings Sustained Productivity Gains £

The Outcome

When a module failed unexpectedly, the company swiftly replaced it, minimising downtime. This proactive strategy prevented production delays and associated costs, saving the company approximately £88,800 per year in downtime expenses. Additionally, the company experienced increased operational efficiency and enhanced planning capabilities, leading to sustained productivity gains.

Radwell’s ALA portal has empowered numerous companies across various industries to achieve operational excellence and future-proof their operations. Don’t miss out on the opportunity to transform your business with our innovative solutions.

We minimise downtime with same-day shipping on a vast inventory of new, surplus, and refurbished parts, alongside emergency repair services – ensuring seamless operations and business continuity.

We source and supply hardto-find and discontinued components by leveraging a global sourcing network, providing businesses with reliable solutions to maintain legacy systems and avoid costly upgrades.

Innovative Cost Optimisation

We minimise operating expenses through automated procurement technology and a global vendor network – streamlining sourcing, reducing administrative burden, and ensuring the lowest total MRO cost.

We extend the lifespan of our customers’ equipment by providing cost-effective alternatives, including verified substitutes – reducing capital expenditures while promoting sustainability and circularity.

We drive sustainability and circularity by leveraging asset recovery, surplus sourcing, and refurbishment to reduce waste and build a more resilient and sustainable industrial supply chain.