Chapter 1 Safe operating procedure

Cautions:please read and understand the safety regulations before use. If you have and questions ,please do not use the equipment without authriation.Is the nearest dealer or manufacturer to solve it!

1、safe operation instructions

(1) Check and clean up the sundries on the machine before you start;

(2) Please remind the staff around to pay attention to safety check when start;

(3) See the hot melt adhesive allowance before heating the glue box;

(4) The yellow (red) colors in the machine are hot objects, charged objects or high-speed rotating knives, etc. Please pay special attention;

(5) Please press the emergency stop switch immediately if there is any abnormal condition in the process;

(6) Please maintain and repair the switch while the power is off;

(7) Non-professional personnel are prohibited to open the control box and electronic control cabinet;

(8) Please cut off the power outlet of the machine before replacing the electrical components;

(9) Regularly check the safety protection device, find fault should be immediately maintenance solution;

(10)When putting the sealing sideband, its head should pass through the delivery pulley, Do not exceed the cutter, otherwise in sealing the first plate may cause part of the damage.

2、matters needing attention

(1) It is strictly forbidden to change the structure of the machine without the written permission;

(2) Purchase and use of original components;

(3) Use Manual does not cover the content of repair and maintenance, please contact the nearest dealer or manufacturer to resolve;

(4) Thisuser's manual applies toRK-5ALL-PREMIUMModel;

(5) As the equipment is constantly being updated and improved, When the new product is not in accordance with the manual, please take the actual product as the standard

Chapter 2 Technical parameters and functional combinations

1、 Technicalparameter

Panel Thickness 10-60mm

Edge Thickness 0.4-3mm

Workingpressure 6bar

Motor power 16.5kw

Dimension 6750*970*1800mm

2、Functional combination

The main wording process of the edge sealing machine is as follows:

RK-5ALL-PREMIUM

Gluing→Pre-miling→ End cutting→Rough trim→Fine trim→Corner trim→

Scraping→Buffing

Chapter 3 Handling and installation

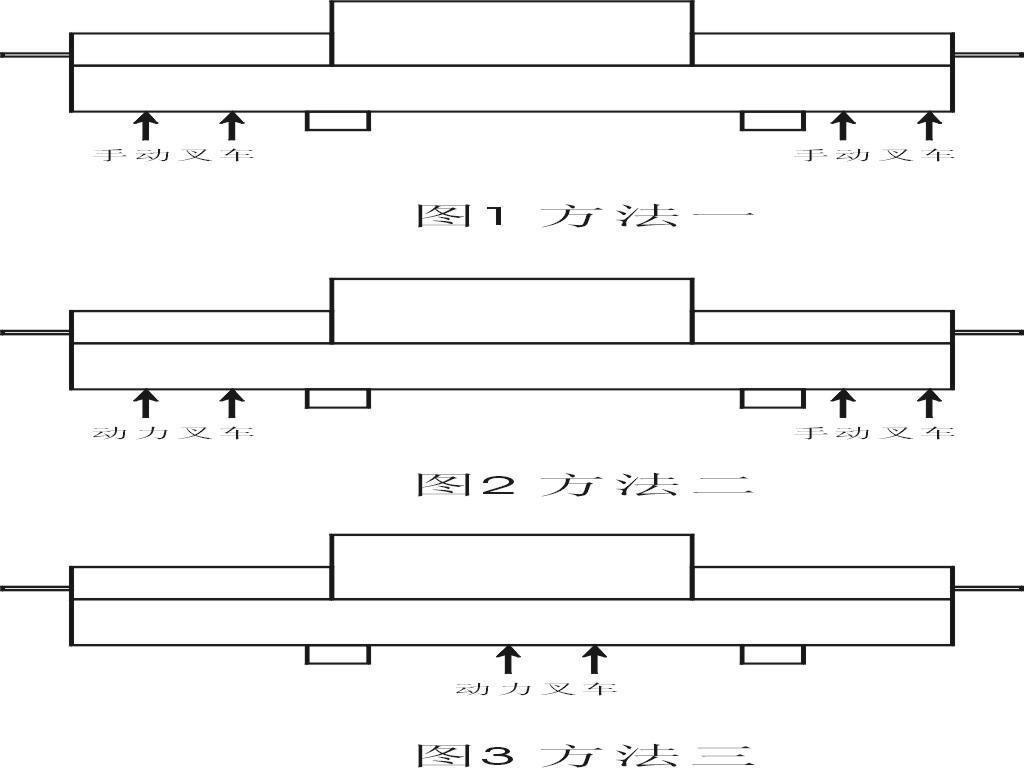

Can Be handled by hand forklift and power forklift,The forklift truck must bear 3 tons or less,There are three ways of forklift truck handling,As shown in the image below:

User Manual

Chapter 4 mechanism debugging

1、Adjust the guide plate

The function of the guide plate is to ensure that the side surface of the plank is parallel with the conveyor beltinordertoensurethatthesealingedgequalityproblemwill notappearinthesubsequentsealingedge process.

The plank to be placed on the edge of the board is to ensure that the sides of the board are snapped to the face of the guide plate (shown in figure II). If a part of the board into the conveyor belt after found that the front and back end of the board and not the same as the guide plate snapping (as shown in Figure III), it shows that the face of the guide plate and conveyor belt movement direction is not parallel, need to adjust the guide plate.

The adjustment method of the guide plate is as follows:as shown above1 As shown in the, first turn off the edge-banding machine and remove Shields on the guide plate, loosening the adjustment screws1and adjustcrews 2 On the four lock nuts and then adjust these two screws will guide the plate The working face of The is initially set to the sidevertical distance from the conveyor belt as35mm,Tightening Screws1thetwo locknuts on the (shown in Figure four)After locking, open theedge-banding machine and press the conveyor belt on he Operation Box panel.button to open the conveyor belt,andthe conveyor belt speed to slow, other Edge-banding machine function is not open, (note: At this time can not open the heating switch, to prevent the adjustment of the guide plate when touching the heating plate and electric shock or scald!) ). Properly placed a piece of the board on the feeding board, slightly push the plank, so that the edge of the board and the guide plate face before and after, and the plank to the conveyor belt.

User Manual

In the process of entering the roller and conveyor belt, the moving test switch is used to control the forward and stop of the conveyor belt, and to observe carefully whether the face of the plank and the back end and the guide plate are always snapping. If it is found that one end of the side panel to be sealed and the face of the guide plate is not snapped (as shown in Figure III), it can be adjusted according to the following methods:

(1) The front end of the plank and the face of the guide plate are not snapping the appears as shown in Figure three A, the rear end of the guide plate is less than the side vertical distance from the conveyor belt35mmyou can adjust the screws at this time2 Loosen the two nuts slightly and twist the adjustment screws2Fine-tune the guide plate to adjust the screws1The is not always moving. Adjust a quantity and then use a board to run the test.

(2) the back end of the edge side of the plank and the Guide board are not snapping the appears as shown in Figure three B The case indicates that the back end of the guide plate is more vertically away than the side of the conveyor belt35mm, you can release the adjustment screws at this time2unscrew the screws with two lock nuts on2Fine-tune the Guide board, and also adjust the screws1The is not always moving.

iterate through the paragraph(1) Step and subclause (2) step to fine-tune the guide plate to make the entire face of the guide plate parallel to the side of the conveyor belt, and the vertical distance between the two sides should be maintained in the % -36mmbetween. So the guide plate has been adjusted.

User Manual

2、Pre-milling function

This is milling cutter 1, which should Rotate counterclockwise during processing.

Millingamount adjusting shaft for milling cutter 2

This is milling cutter 2, which should rotate clockwise during processing.

Millingamount adjusting shaft for milling cutter 1

The pre-milling function is composed of milling cutter 1 and milling cutter 2,which can be on and off by independent switches on the control panel.

Due to the panel in the process of cutting or transporting, it may be inclined or incomplete, resultinginunsatisfactoryedge sealing effect. After millingbythe pre- milling function, the various defects on the panel surface can be removed, so that the edge sealing can be the optimal state.

The milling amount is adjusted according to the processing condition of the surface to be processed. Generally, the milling amount of the milling cutter cannot be over than 0.5mm.

Fig. 1: Fix the pre-milling function

User Manual

The milling cutter 2 rotates clockwise to mill the front part of the board to be covered. The milling cutter 1 rotates anticlockwise to mill the tail of the board to be covered

When the milling edge is problem, it can be adjusted through the adjustment parts shown in Fig. 1

Lifting adjustment shaft: adjust the height of two milling cutters and the board. It usual make the lower edge of the cutter protrude from the lower edge of the board by about 2mm

Rotating adjusting screw rod: after the board passes the pre-milling, Pls heck if the milling surface is perpendicular to the upper and lower surface of the board. If not, the rotation axis of the cutter can be adjusted to be vertical to the processing surface of the board by rotating the adjusting screw rod.

Two milling cutters adjustment: Pls adjust the milling amount of two milling cutters respectively. Before delivery, the milling amount of two milling cutters is the same, and the counter returns to zero.

3、heating glue coating mechanism

The function of the heating coating mechanism is to melt the hot melt adhesive and apply the melted glue to the side surface of the plank. The heating glue contains some regulating mechanism, which can make the coating onthe plank reach the effectof uniformthicknessand flatness, so as to ensure the bestsealing edge effect.

The adjustment of the coating layer includes four aspects:the adjustment of the contactpressure of the roller in the plank, the adjustment of the thickness of the coating layer, the adjustment of the amount of the glue and the vertical adjustment of the roller in the plank.

(1)adjusting the thickness of the coating layer:

as shown in figure I, to ensure that the coating on the board is evenly thick, you can pass the figure1inM6The screws to adjust the vertical distance between the face of the guide and the side surface of the plank. If the vertical distance between the working face of the guide and the side surface of the plank is too small, will result in the coating layer too thin, which will make the bonding strength of the plank on the board isnot enough; Conversely, if the distance is too large, the cots can not be completely coated with glue on the board.

the specific adjustment method is: release first M6 The nut on the screw, throughM6working faces and templates for screw regulator Guides the vertical distance to the edge of the envelope is adjusted to0.10.5mmbetween. Open the edge-banding machine conveying function and heating glue function, with the appropriate size of the board to test the edge. Look at the thickness of the coating on the plank after sealing and the strength of tearing off the edge band. If the coating layer is too thin, the sealing edge tape is not strong, then adjust the M6screws to increase the clearance between the guide and the board. Conversely, if you tear off the tape and found that the coating layer is uneven, adhesion is not strong, through the adjustment of the M6 screws to reduce the gap between the guide and the board. The thickness of the coating can be satisfied by the clearance between the small adjustment guide and the plank.

User Manual

(2) Adjust the amount of glue out

Through the control of the gap between the rubber door and the coating roller can be achieved to adjust the purpose of the glue volume is to make the glue applied on the board uniformly. control the gap between the glue door and the glue roller is mainly by adjusting the chart2in the M8 Screws and M8 tighten the screws toad,ustthe glue door so that the glue door and the .The smaller the gap between the cots, the less the amount of glue.

(3) Adjustment of the contact pressure of the glue roller tothe plank Adjusting the contact pressure between the roller and the plank can ensure the glue sticking and The planks are firmer so that the glue is easily penetrated into the plank.tuning methods: Figure3as shown by the screws 2 can adjust coating The pressure of the cots on the plank.The greater the compression of the spring, the pressure the greater the force, the smaller the opposite. Through the screws1You can adjust and restrict The stroke of the work movement of the glue Assembly, the general itinerary is1.5mmaround, that is, after the plank passes through the guide the Glueassembly back the journey is 1.5 mm Around.

The gap between the dge banding and the plank indicates that the amount of plastic is not enough and need to be increased Large M8 the gap between the front end of the screw and the rod.

(4)The relationship between the thickness of the coating layer and the amount of glue to be produced. when diagram1 The gap between the glue roller and the plank is small, and the figure2large amount of gum out, it appears in Figure four A there is glue overflow on the top and bottom of the board shown, when the diagram1 The gap between the coating rollers on the board is large, and the figure2outwhen the glue is too small, the figure appears 4 Medium B the phenomenon of incomplete glue is shown. Atthis time can be integrated to adjust the thickness of the coating and the amount of plastic, so as to achieve satisfactory results.

User Manual

(5)Adjustment of the verticality of cots and planks

When there is no glue on the top or bottom surface of the plank when the board is closed,is because the glue roller and plank to seal side surface is not caused by vertical.

Adjustment method: When the board is found on the edge of the surface without glue, then the Gelatinize roller on board occurs as shown 6MediumA The skew shown in the figure5as shown, you can Retract screws2, and then tighten the screws1 to make the glue roller perpendicular to the plank. when it is found that there is no glue on the bottom surface after the plank is closed, it is the roller on the board that occurs as pictured 6 MediumB The tilt shown, you can set the screws1Rollback and screws2 The screw in is the glue roller perpendicular to the plank. Repeated micro-adjustment screws1and screws2, until the edge of the board after the upper and lower surface evenly cloth glue.

User Manual

4、Send-with truncation mechanism

Thefunction ofthebelt-cutting mechanismis to automaticallypulloutand truncatetheedge banding required for the plank to be sealed from a roll-banding edge band. The belt cut-off mechanism can ensure the smooth and automatic conveying of the edge banding and adjust the distance between the bottom edge and the lower surface of the plank.

(1)adjusting the distance between the lower surface and the surface of the plank under the edge of seal. Adjust the edge of the lower surface and under the board surface distance can ensure that the subsequent trimming function to provide a certain amount of processing allowances.

Adjustment method:

1、the diagram1four screws in the are all loosened;

2、Tuning Chart1four fixed screws in2to take the edge off the surface and the distance of the lower surface of the plank A ( as shown infigure2) is set to 1-1.5mm,and then To move the Strap panel to ahorizontal position:

3、Tighten screws2The fixed the strap panel.

(2) Auto-Strap

Adjustment

In order to ensure that the cut-off mechanism of the belt is successfully sent to the edge of the plank, it is necessary to adjust the three links.

User Manual

Adjustment method:

First link

the diagram1MediumBpartial parts by Figure3 The sets the gap between the limit rod and the upper surface of the edgebanding to about0.5mm, so that the edgebanding canpass withoutoffsetting. (Note:You mustreplace the banding bands of different widths)

Second link

the diagram1MediumCpartial parts by Figure4 The sets the pressure block and the edge Band on the table shown the clearance for the face is approximately0.5mmto enable the banding band to pass without Happening Offset. (Note: The replacement of different width of the banding tape must be adjusted)

The third part in Figure one Dsection by Figure5the shows the first release of the cylinder block fixing screws to set the distance between the belt pulley and the block before opening the belt function1mm (initial setting). Then Unscrew the two screws in6A, and move the strap wheel seat so that the banding belt is just passing through. (Note: You must adjust when replacing the banding bands of different thicknesses)

Note: In the installation of banding, new boot, and so on, before the first plank edge to ensure that the front end of the belt through the belt pulley does not exceed the cut-off knife, or in the first plank edge will cause damage to some institutions!

User Manual

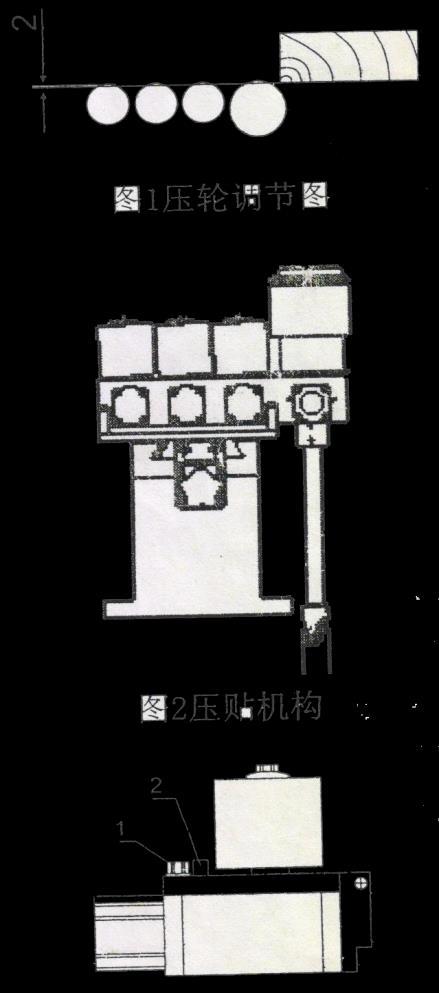

5、pressure sticking mechanism

The role of the pressure-sticking mechanism is to paste the sealing edge with the glue on the side surface, and can be adjusted to ensure that the different thickness of the sealing tape can be firmly and evenly bonded.

The vertical distance from the board should be set to when the pressure wheel is standby and working2mm , which is more appropriate (as shown in Figure one), and the working pressure of the large pressure wheel is set to1bar, the working pressure of each small pressure wheel is set to2barmore appropriate (as shown in figure II).

When the pressure sticking mechanismis in normal working state, replace the sealing edge of different Thickness Band, simply select the five-star hand wheelon The press body to transfer the counter readings to the hickness of the edge banding can be. If the edge band thickness is 2mm, simply Adjust counters to 0020.(Note:The second digit of the readoutfor the counter is last The unit is in millimeters)

If the edge is pressed on the plank,the upper surface or bottom of the board Surface observation found that the edge Of the tape and the board is not fully adhered to,in dicating the rotation of the press wheel he axis is not per pen dicularto the template's pending edge.At this point, you can use the Adjust chart3 to 2 tight Fix the screws to adjust them properly.

Tuning method: Loosen two screws first1,and then adjust the two fixed screws Test the edge of the board with the plank , passing through the big roller and the last picture1 Pressure wheel

Adjustment When drawing a small pressure wheel,carefully observe whet her there is a gap between the contact surface of the pressure wheel and the edge Banding The nobserve the closure of the plank on the edge of the tape is firmly adhered.

User Manual

before and after:

The main main use of the abreast mechanism is to be pasted on the board before and after the more than the edge banding cut off, so that the two sides of the edge of the plank and the board before and after the two ends, and the edge of the seal can be removed at both ends of a certain chamfer.

(1) The working process of the parallel mechanism the work process of the abreast organization is as shown 1 ,shown when the plank touches the stroke switch1after the abreast structure enters working status. With the movement of the conveyor belt, the front end of the template is contacted with the Guide 1face, the abreast part is pushed to the left and the board surface is contacted with the two bearings on the guide's 2. When the front end of the plank and the guide1face out of the matter, the abreast saw blade will be more than the end of the edge of the plank side of the cut off; when the two bearings on the guide's 2 are off the board surface, The tail end of the plank is removed with more than the edge band. At this time the abreast organization work, the organization reset. the pressure regulating valve in figure one1the function of the is to adjust the air pressure of the abreast part of the body so that it can rise and fall freely while working, generally maintained in the 3-4mpa/c M² around; pressure regulating valve2the role of the is to adjust the end of the part of the mechanism to make it work when the instantaneous descent of the action, air pressure is generally not more than2mpa/cm² .

User Manual

(2) Adjust the abreast effect

after the abreast operation is complete, if it appears as shown in the figure2 Medium A The edge bands shown are also remnants of the phenomenon, the figure2 Medium1 the number screws are selected clockwise, the motor is moved forward, or if the board appears as pictured2 Medium B The phenomenon shows that the banding band appears to be cut a lot, then rotate the diagram in a reversible clockwise2 Medium1 The number screws to adjust. Through repeated subtle adjustments until a satisfactory abreast effect is achieved. the also can adjust the angle of the motor and the guide rail, get figure3 Medium A and B the shows the abreast effect.

Note: After daily use, clean up the sawdust on the linear guide with the blower tube, then use wd-4oThe cleaning Agent cleans the linear guide rails and keeps the linear guide constantly clean. If due to the lack of timely cleaning or other man-made factors caused by linear guide way and slider damage to the company is not responsible.

User Manual

7、one trimming and two edge trimming structures

the function of a trimming and two trimming mechanism is to highlight the upper and lower edges of the edge banding strip and cut off the upper and lower surface of the plank, so that the upper and lower sides of the edge banding are aligned with the upper and lower surfaces ( LT-220no thick trimming structure).

(1)Trim Parts for trimming bodies

(2)adjustment of one trimming knife (with Cmodel configuration Coarse trimming knife)

Decrease for one trimming (that is, thick trimming) Rtrimming milling for rounded corners, resulting in a more flat Rrounded corners and not fixed Rrounded corners, while the need to repair the flat edge, add this set of trimming mechanism.

User Manual

One trimming knife is a flat blade, installation and commissioning method is the same as the installation method of two times trimming knife, just a trimming knife the angle between the blade line and the horizontal direction is Tendegree or so.

(3)two-time trimming knife adjustment when using a trimming mechanism to refurbish a work piece Rrounded corners, only the upper trimming mechanism and the lower edge trimming mechanism of the counter value set with the thickness of the edge banding should be corresponding. Methods: If you use the 2mmthick banding, then set the counter ⑩ value to (002.0) and use the figure 1 The Screw ② in the is finely tuned.

(4) replacement steps for Trimming Knives un screw diagram2in the ① number screws, the direction of the ② Axis arrow pointing to the replace ment of the profile disc is slightly pulled out, the wrench is jammed in the ③ position,and then the 17mmthe wrench of the twists open the nut before trimming knife, the trimming knife is removed, the new trimming knife is replaced, the installation process is opposite to the above.

(Note: In the installation of new trimming knives, should pay special attention to the motor rotation and trimming knife rotation of the relative relationship, if the trimming knife installation counter, the operation will make trimming knife damage. At the same time because the motor at high speed rotation, trimming slightly unbalanced, the motor will produce a strong vibration, resulting in many parts of the damage, so as long as the repair knife is only slightly damaged must be replaced immediately

1:Corner trimming standby state 8、Corner Trim function structure

Dust hood

Fig.

Fig. 2:Corner trimming working state

User Manual

(1)

Introduction ofworking processing

The corner trimming function is that the motor can mill the two ends of the edge banding belt sealed on the board into an arc by following the movement of the board, which makes the edge sealing of the board more beautiful and smooth

As shown in Figure 1, the corner trim is in standby state, and the light of sensor 2 is on. When the front end of the board reaches at the designated first position, the lower corner trimming motor is pushed forward, and the two cylinders act at the same time to make the corner trimming mechanism always closely fit with the board, so as to carry out profiling trimming on the board. When the front end of the board reaches at the designated second position,theuppercornertrimming will bein workingstate, and theupperleftcornerofthe boardwill be trimmed. When the rear end of the board reaches at the designated third position, the upper corner trimming mechanism trims the upper right corner of the board.

In the process of the down corner trimming moving to the working state, if the corner trimming moves too fast, it will cause a strong collision between the machine and the shock absorber. So the lower corner trimming mechanism will produce great vibration. In this vibration, the down corner trimming will break away from the sensing range of inductor 1 intermittently, and the lamp of inductor 1 will flicker constantly. Therefore, this machine will not work normally or end work ahead of time and return to standby working state.

The solution of this problem is as following::

1. Adjust the pressure gauge to change the working pressure

2. Adjust the flow control valve to change the gas flow of the cylinder

3. If this problem is not solved, first correct the installation position of sensor 1, and then use methods 1 and 2 to adjust it.

(2)Adjustment of workpiecemilling quantity

Figure 3 shows the movement direction of the workpiece to be processed, and a, B and C are used to indicate the position of the board. When the milling quantity of board A is large, but the milling of position C is small, Pls loosen the No. 5 screw, screw back the No. 2 machine meter, screw in the No. 1 machine meter, make the tracker offset to the direction of the No. 2 screw, tighten the No. 5 screw and place the board for testing.

When the milling quantity of the processed part A is small and the milling at C is large, Pls loosen screw No.5, screwback No.1 Machine meter and screwin No.2Machine meter to make the trackeroffset to screwNo.1. After tightening screwNo.5, put the board for testing. Adjust the milling quantityat position B andD of the board through the screw in Figure 3.Adjust the milling R angle with these three screws and screw rods.

Fine adjustment: when the milling quantity at position A of the board is large, screw in the No. 2 machine meter.Otherwise, screw back the No. 2 machine meter. When the milling quantityof the processed partC is large, screw in the No. 1 machine meter. Otherwise, screw back the machine meter No. 1

User Manual

When the machine processes in the normal working position, after changing the edge banding tape to different thickness, it only need to adjust the screw rod 4 to make the reading of the counter consistent with the thickness of the edge band tape that used. (Note: the general corner trimming function can only be used when the thickness of the edge band tape is more than or equal to 1.5mm) (

3

) Motor angle adjustment

As shown in Fig. 4, the sensor switch 1 is the end of work sensor. And the sensor switch 2 is the rotation angle adjustment sensor of the working motor. When the sensor switch 2 is far away from the sensor switch 1, the rotation angle of the motor increases. When the sensor switch 2 is close to the sensor switch 1, the rotation angle of the motor decreases.

Fig. 4 Motor angle adjustment diagram

User Manual

(4

) Tools change procedure

Screw out the two screws No.1 in Figure 5 to take down the structure of figure C as a whole. Then use a wrench to clamp two parts of the motor shaft in Figure B, and use a wrench to screw out the nut 3 at the front end of the tool to replace a new knife. Replace the tools and install it.

Notice: Pls well keep the bolt on the motor shaft)

9、Edge Scraping Structure

the installation and commissioning of the scraping-edge structure is similar to that of the trimmingstructure, and the function is to remove the knife marks left by the trimming cutter and to finish the repair. R The fillet, so its installation is directly related to the workpiece processing quality. Scraping the edge of thebody of the work of the edge of the tape cut off, should be thin to the air nozzle blown away the degree is normal. Trimming mechanism in the normal state, if the scraping out of the debris is too thick to reduce the amount of scraping, if the scraping knife can not scrape the workpiece, then increase the amount of scraping. The effect of the air nozzle is to blow away the scraped fragments, to prevent its clamping to the workpiece and the guide wheel, affecting the quality of processing, so the nozzle position should also be adjusted to facilitate the blow away the location of debris, but also should be based on processing, appropriate control of the process in all directions of the guide wheel relative to the workpiece pressure.

User Manual

10、polishing mechanism

The polishing mechanism is to removethe edge burrsof the edge banding and The residual glue between the edge band and the plank, which makes the plank seal Out The edges are smoother.

(1)Adjust the working position of the polishing mechanism

If the different thickness of the board to the edge, you need to adjust Up And down to polish the spacing of the Bren, just twist the top and bottom two adjustable nut tune.

The spacing between the knots.To Adjustthe Brenand the upper and lower surfaces of the plank Tilt, you can loosen the fixed motor screws, adjust the motoraxis and The vertical Angleof the upper and lower surfaces of the board, asshown in the figure 2the angle shown in A in 10~15 between degrees;releasing screws1to adjust the horizontal angle of the motor;Adjusting the upper and lower position of the motor by using the lifting and adjusting screw rod so that the processed R fillet embedded in Bren 3~5mm;tighten each fixed screw.

(2) Polishing theBren replacement

The polished cloth wheel is a wearing part,when the plank is polished after polishing EffectThe is significantly lower than before,and the Bren needs to be replaced immediateely.As shown in the figure 1, the Loosen the screw of the fixed motor, unscrew the lock nut in front of the LUN and unload Under the old cloth wheel, replace the new LUN, and then use the nut to fix it,and the electricity The machine is fixed to the slider by its original position.