VOLUMETRIC MODULAR Buildings M Tall

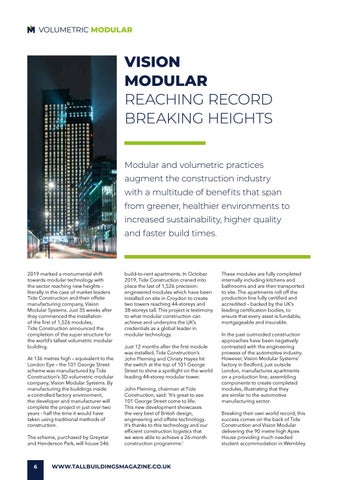

VISION MODULAR REACHING RECORD BREAKING HEIGHTS Modular and volumetric practices augment the construction industry with a multitude of benefits that span from greener, healthier environments to increased sustainability, higher quality and faster build times. 1 2019 marked a monumental shift towards modular technology with the sector reaching new heights – literally in the case of market leaders Tide Construction and their offsite manufacturing company, Vision Modular Systems. Just 35 weeks after they commenced the installation of the first of 1,526 modules, Tide Construction announced the completion of the super structure for the world’s tallest volumetric modular building. At 136 metres high – equivalent to the London Eye – the 101 George Street scheme was manufactured by Tide Construction’s 3D volumetric modular company, Vision Modular Systems. By manufacturing the buildings inside a controlled factory environment, the developer and manufacturer will complete the project in just over two years - half the time it would have taken using traditional methods of construction. The scheme, purchased by Greystar and Henderson Park, will house 546

6

build-to-rent apartments. In October 2019, Tide Construction craned into place the last of 1,526 precisionengineered modules which have been installed on site in Croydon to create two towers reaching 44-storeys and 38-storeys tall. This project is testimony to what modular construction can achieve and underpins the UK’s credentials as a global leader in modular technology. Just 12 months after the first module was installed, Tide Construction’s John Fleming and Christy Hayes hit the switch at the top of 101 George Street to shine a spotlight on the world leading 44-storey modular tower. John Fleming, chairman at Tide Construction, said: ‘It’s great to see 101 George Street come to life. This new development showcases the very best of British design, engineering and offsite technology. It’s thanks to this technology and our efficient construction logistics that we were able to achieve a 26-month construction programme.’

WWW.TALLBUILDINGSMAGAZINE.CO.UK

These modules are fully completed internally including kitchens and bathrooms and are then transported to site. The apartments roll off the production line fully certified and accredited – backed by the UK’s leading certification bodies, to ensure that every asset is fundable, mortgageable and insurable. In the past outmoded construction approaches have been negatively contrasted with the engineering prowess of the automotive industry. However, Vision Modular Systems’ factory in Bedford, just outside London, manufactures apartments on a production line, assembling components to create completed modules, illustrating that they are similar to the automotive manufacturing sector. Breaking their own world record, this success comes on the back of Tide Construction and Vision Modular delivering the 90 metre high Apex House providing much needed student accommodation in Wembley