P52

OFFSITE AWARDS 2025

The votes have been counted, and the judge’s decision is final but who has made this year’s shortlist?

P60

PARADISE

Pushing the boundaries of innovation and sustainable design with another landmark timber building

P52

OFFSITE AWARDS 2025

The votes have been counted, and the judge’s decision is final but who has made this year’s shortlist?

P60

PARADISE

Pushing the boundaries of innovation and sustainable design with another landmark timber building

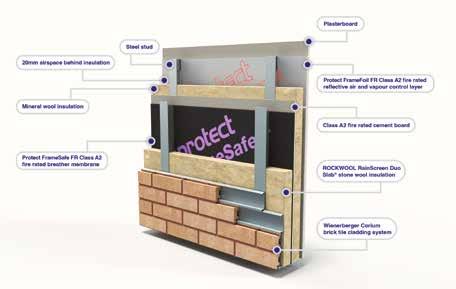

Essential for compartmentation in multi-storey residential buildings, Frameclad systems are rigorously tested and deliver up to 120 minutes of fire resistance.

FIRE-TESTED – in accordance with BS EN 1365, BS EN 1364 and BS 476

TECHNICAL EXPERTISE – 14-strong team of in-house designers and engineers

DIGITAL ENGINEERING – bespoke Tekla software offers complete traceability

MANUFACTURING – one of the largest ranges of steel sections available in the UK today

EXTENSIVE SUPPORT – regional teams assist with specification and compliance

INDEPENDENT VALIDATION – BOPAS Accreditation, CE Certified, and SCI / NHBC

BUILDING SAFETY – fully compliant steel framing systems to rigorous safety standards

–

FRONT COVER

Modular and Portable Building AssociationImage courtesy of Portakabin

PRINTED ON: FSC Mix paper by Buxton Press

PUBLISHER:

Offsite Magazine is produced and published by Offsite Media Ltd

Suites A & B Hermes House, Oxon Business Park, Shrewsbury, SY3 5HJ T: 01743 290001 www.offsitemagazine.co.uk ©Offsite Media Ltd.

SUBSCRIBE TO RECEIVE OFFSITE:

This magazine is a bimonthly publication and the annual subscription fee for UK postage is £29.70 plus VAT for all six issues (£4.95 per copy). Visit www.offsitemagazine.co.uk

ADVERTISING ENQUIRIES PLEASE CONTACT:

Julie Williams // T: 01743 290042 E: julie.williams@offsitemedia.co.uk

SEND US YOUR NEWS:

Gary Ramsay // T: 01743 290001 E: gary.ramsay@offsitemagazine.co.uk

BACK ISSUES VISIT: www.offsitemagazine.co.uk

FOR OFFSITE ENQUIRIES PLEASE CONTACT: E: info@offsitemagazine.co.uk

DISCLAIMER: The content of Offsite Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

KEEP IN TOUCH:

@ExploreOffsite

linkedin.com/groups/7456674 offsitehub

Welcome to the latest edition of Offsite Magazine. As we reach the halfway mark of the year, the offsite sector feels like it sits in a period of reflection and assessing how best it fits into an era of low carbon, sustainable and ‘industrialised’ construction.

The market is a tough one. At an event I attended recently, virtually everyone I spoke with attached to construction said the same thing – confidence is low, projects are difficult to cost and even more difficult to secure. The Government’s Spending Review will hopefully add some impetus to correct this. Amongst the umpteen headlines and takeaways from Chancellor Rachel Reeve’s announcement, was the £39billion cash injection to the social and affordable housing programme over the next 10 years. Offsite manufacture has a gigantic role to play here. It can meet delivery, quality and affordability demands, through pattern book designs and repeatable components giving affordable homes providers reliability when it comes to procurement, energy efficiency targets and routine on-going maintenance.

A large part of this issue is taken up with coverage of two key events – the Industrialised Construction Conference being held at the

Manufacturing Technology Centre (MTC) in Coventry is about to happen. As you’ll read inside, the world of automation, robotics, platform design, standardisation, lean manufacturing –and everything else that gets heaped into the huge tub called Industry 4.0 – will be discussed and put into an offsite and wider construction context over two days.

The other event doesn’t need much introduction. The entries are in, and the judging has taken place. Decisions have been made everyone! Inside you can see the shortlisted projects and people for the Offsite Awards 2025. Each year the sheer variety and quality that shines through is quite something and shows the everyday excellence that is being delivered across the UK and beyond.

A final note for all regular readers of Offsite Magazine. After nearly 50 issues, we are working behind the scenes on a redesign of the publication. Keep an eye out for the refreshed ‘new look’ magazine that will be sat on the shelves at Offsite Expo 2025 in September.

Thanks to all our contributors, advertisers, and supporters for their help this issue. I know I say it every time, but it is genuinely appreciated.

Gary Ramsay Consultant Editor

Email: gary.ramsay@offsitemagazine.co.uk

offsitehub.co.uk/blog MAXIMISE THE OFFSITE OPPORTUNITY

OFFSITE EXPO has a range of exhibition packages available to suit any marketing aims, resources and budget.

www.offsite-expo.co.uk/exhibit

P06 | SPEARHEADING A NEW ERA OF INDUSTRIALISED CONSTRUCTION

Volumetric modular construction has reached new levels of maturity in the UK across healthcare, education and commercial sectors, driven by the long-term commitment of Modular and Portable Building Association members to industrialise the way buildings are delivered.

P60 | PARADISE: PUSHING THE BOUNDARIES OF TIMBER INNOVATION

Alex Brock, Senior Pre-Construction Manager at B&K Structures, describes how Paradise sets new benchmarks in offsite manufacturing, fire safety and sustainable construction, while showcasing the immense potential of timber as a primary structural material.

The Offsite Awards continues to celebrate the many achievements across the offsite construction sector, covering every aspect of the industry to reward those outstanding projects, innovative people and technical wizardry. Who have the judges shortlisted as potential best in class this year?

A special section covering one of the offsite sector’s key delivery methods including a focus on the outstanding healthcare work being done at Milford Community Hospital by MTX, plus news and project snapshots from Boutique Modern, Merit, CPAC Modular, Wernick Buildings, Reds10 and others.

08 | Industry News News and developments from across the UK offsite industry and wider construction arena including: BSI publishes PAS 8700:2025, its new specification for MMC use in newbuild homes, Element Europe slips in Administration, 19 companies join LHC Procurement Group’s £265million Modular Buildings (MB3) framework and Reds10 unveils a raft of leadership changes.

26 | Offsite Opinion OFFSITE OPINION seeks out the views from key personalities within the offsite world – from those making things happen in the factory environment and on-site – to thought-leaders and board level decision makers.

28 | From Exception to Expectation

BUILDOFFSITE launched its Manifesto 2025–2030 recently. Fareita Udoh outlines this ‘bold, practical five-year vision’ to make offsite construction the standard, not the exception for construction plus how you can get involved and find out more at Offsite Expo 2025.

34 | Smarter, Faster, Greener

Tristin Willis, Managing Director of Ultrapanel Building Technologies, offers his perspective and a sense of urgency as he champions a shift to industrialised construction.

38 | Industry Viewpoint

Darren Richards, Managing Director of Cogent Consulting, considers the positive impact of recent government spending announcements, and the opportunities presented for new mainstream construction models and practices.

46 | Building Safety Act

By embracing regulation not as a burden but as a blueprint for excellence, Light Steel Frame Association members are not only compliant – they are transformative.

50 | Fire-Tested and Future-Proof

Martin Jamieson and Nik Teagle, Joint Managing Directors of Frameclad consider the importance of fire testing to meet the rigorous standards of the Building Safety Regulator.

62 | Reflections on Engineered Timber

As the built environment seeks more sustainability and innovation, Valentina Galmozzi, Design Director at AKT II explains how engineered timber is delivering exceptional structural and environmental performance.

68 | Industrialised Action Required

The construction industry suffers from some familiar and longstanding issues – not least the persistent skills shortage, a shrinking workforce and difficulties responding to the rising demand for housing. What can be done?

74 | Questions of Carbon

In the run up to the Structural Timber Conference being held in October, we spoke to Adam Graveley, Head of Technical and Innovation at the Future Homes Hub, about carbon and collaboration.

As the housing industry grapples with an escalating crisis, volumetric modular technology –hailed as the first true form of industrialised construction – is quietly redefining the education, healthcare and commercial sectors.

With the majority of members operating across these industries –Jackie Maginnis, Chief Executive of the Modular and Portable Building Association (MPBA), believes it is time to broaden our horizons and bring these sectors into the conversation.

The pandemic clearly demonstrated agility in our built environment is not a luxury, but a necessity. Hospitals required immediate expansion. Schools had to adapt quickly. Offices transformed to accommodate hybrid working. This moment marked a turning point and revealed the urgent need for a smarter, faster, more adaptable way to build – whether temporary or permanent.

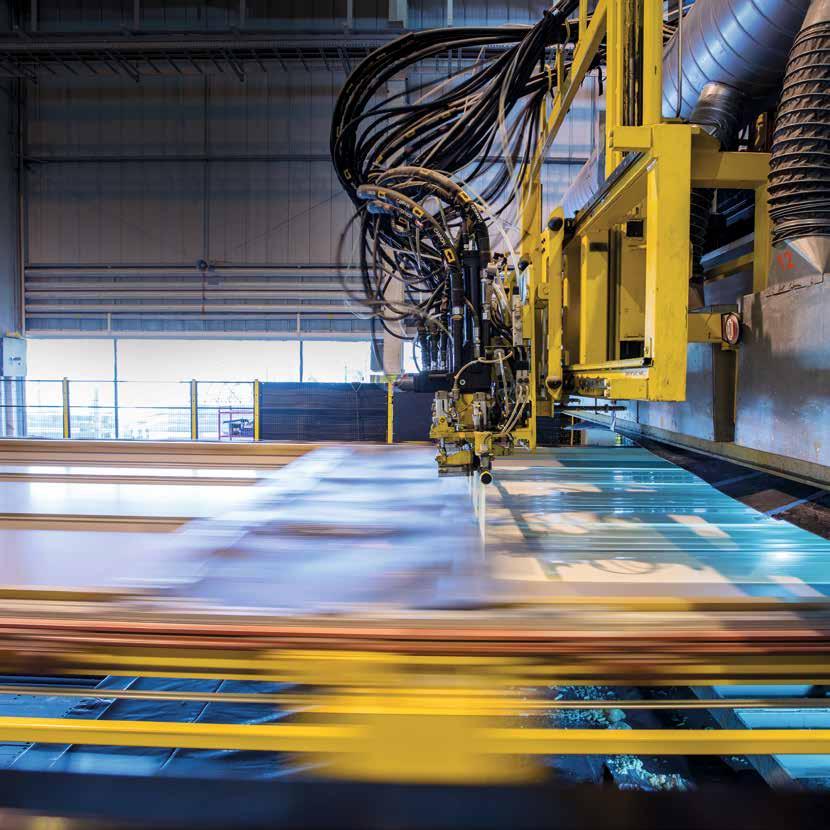

Volumetric modular construction has reached a new level of maturity in the UK, driven by the long-term commitment of MPBA members to industrialise the way buildings are delivered. Over the years, the manufacturers within our ranks have evolved from labour-intensive manual assembly to highly efficient, semi-automated production lines –

1introducing robotics, advanced CNC cutting and digital planning tools that streamline processes and drive quality.

A volumetric modular approach applies mass production principles, factory based manufacturing and precision engineering to building –something other forms of construction have never fully achieved.

Crucially, industrialised modular construction offers a scalable permanent or temporary solution, as we witnessed during the pandemic when factories run 24 hours a day seven days a week to keep up with demand. Our members can ramp up production quickly, without compromising quality or performance. Unlike traditional builds, which are often constrained by fragmented supply chains, skilled labour issues and bad weather – volumetric modular construction, according to the Royal Institution of Chartered Surveyors –can reduce build times by up to 50% and offer standardised quality at scale.

The MPBA has been instrumental in this journey – championing best practice, fostering innovation, and

shaping the frameworks that enable modular to deliver at pace. As demand grows, MPBA members are ready –with the maturity, capability and vision to deliver industrialised construction that’s smarter, greener, and built for the future. In a time where adaptability is linked to resilience – volumetric modular buildings offer scale and speed without sacrifice.

Beyond speed and scalability lies sustainability. With construction responsible for nearly 40% of global carbon emissions, change is not optional – it is essential.

Modular manufacturing, conducted in factory-controlled environments, significantly reduces waste, optimises material use and lowers transport emissions. Many MPBA members are already integrating carbon-conscious design, renewable energy systems and lean production techniques into both their buildings and operations.

Waste reduction can be vast – up to 90% less material waste compared to traditional methods. Transportation and onsite energy use are minimised. Increasingly, modular factories are powered by renewable energy and operate with remarkable efficiency.

Moreover, modular buildings are designed for disassembly and reuse. Components can be repurposed or reconfigured, extending the material lifecycle and reducing landfill – a critical advantage as we move toward a circular economy.

In sectors like education and healthcare, these benefits are especially valuable. Modular solutions help schools, NHS Trusts and local authorities meet sustainability targets while delivering high-performance buildings.

Modular buildings also offer superior energy performance – a growing concern as many homes and public buildings continue to fall short on energy efficiency. Thanks to precision engineering, factory-built modules achieve tighter tolerances and better thermal performance. The result is consistent insulation and superior airtightness across the entire structure.

Many modular buildings exceed the requirements of Part L of Building Regulations, achieving Passivhaus or BREEAM ‘Excellent’ standards. This level of performance is particularly important in healthcare settings, where indoor air quality, temperature stability and hygiene are critical. In schools, modular classrooms offer lower operating costs and healthier learning environments. In commercial projects, energy efficiency boosts both environmental, social and governance (ESG) and bottom-line performance.

Fire resistance remains a top priority for the MPBA and our members. The controlled nature of modular construction allows for consistent fire safety measures that not only comply

3 2 4

with UK Building Regulations but often exceed them.

As an industrialised construction method, modular technology is uniquely positioned to meet the requirements of the Building Safety Act (BSA) with greater control. Factory-based environments allow for more consistent quality assurance, rigorous documentation and traceable manufacturing processes – all of which align closely with the emphasis on accountability, safety and the golden thread of information.

Additionally, the centralised nature of modular production makes it easier to implement and monitor safety protocols. Fire-resistant materials and detailing are incorporated from the design stage. Factory conditions ensure the precise installation of non-combustible linings, fire-rated insulation and reliable fire-stopping systems – key elements in preserving compartmentation and system integrity.

Also driven by the Building Safety Act, it must be acknowledged how the temporary building industry reacted quickly and positively to the requirements of The Joint

Code of Practice for Fire Prevention on Construction Sites following changes made by the Fire Protection Association.

MPBA members routinely engage in full-scale fire testing and participate in third-party certification to validate performance. This rigorous approach ensures modular buildings are tailored for safety as well as function.

The UK can no longer afford to rely on outdated construction practices. Volumetric modular offers something unprecedented, the power of industrialised construction. Delivering speed without sacrificing quality, and scale without compromising sustainability.

To find out more about the positive impact of this key offsite method, turn to the Volumetric Supplement on page 79.

Images:

01. Portakabin Manufacturing Facility, York

02. McAvoy Group - Lister Community School

03. Premier Modular - Willowfield Building Kings College Hospital

04. Jackie Maginnis, Chief Executive, MPBA

Founded in 1938, the MPBA plays a key role in connecting all sectors of the modular and portable building industry. Members gain a strategic advantage, with access to a network of resources and platforms that amplify and influence. As part of a dynamic community, the MPBA provides an environment where like-minded professionals collaborate, share ideas and forge meaningful connections that drive innovation and growth.

We understand the importance of continuous learning, which is why the MPBA founded its own dedicated Learning & Development Centre, to support personal and professional growth within the sector. Above all, we are driven by collaboration, energy and a forwardthinking attitude – continually pushing the boundaries of what is possible in industrialised construction. We are the industry leaders, technical experts and champions of our sector.

For more information visit: www.mpba.biz

New specification to build confidence in MMC for residential developments, provide consistency on how projects can partially or wholly adopt MMC, as well as improve the efficiency, quality and sustainability of MMC solutions has been published by BSI.

‘Modern methods of construction for new build residential properties – Specification’ (PAS 8700:2025) is the first PAS to set out comprehensive requirements and processes for the deployment of MMC in residential building projects.

As the housing industry looks to adopt innovative building approaches to meet national demands, the first-of-its-kind standard, provides a unified framework for delivering safe, durable, and efficient new homes using MMC. It is intended to support all stakeholders – from designers and manufacturers to developers, lenders, insurers and regulators – in adopting consistent, best-practice approaches across the residential construction lifecycle.

PAS 8700:2025 is the first standard specifically designed to define the effective use of Design for Manufacture and Assembly (DfMA) and MMC in residential building projects, encompassing both entire building systems and individual elements. It provides provisions for the sector on the consistent application of MMC throughout all project phases – from design and manufacturing to assembly, maintenance, adaptation, and end-of-life considerations. The

standard aligns with existing technical regulations and accreditation schemes, avoiding duplication and unifying fragmented practices into a clear, accessible specification.

The successful integration of DfMA and MMC in project delivery relies on timely engagement with knowledgeable stakeholders, selecting the right construction methods and materials, understanding system limits, and managing interfaces between pre-manufactured and on-site elements. This PAS highlights the importance of early-stage design and planning to reduce risks, standardise solutions, and engage the supply chain.

By adopting manufacturing principles and effectively deploying MMC, the aim is that projects can achieve benefits such as cost and timescale certainty, improved productivity, material efficiency, reduced labour, and overcoming skills shortages. Other advantages could include better quality control, faster delivery, reduced waste, enhanced health and safety, lower carbon footprint, sustainable use of materials, reduced energy and maintenance costs, improved thermal and acoustic performance, better indoor air quality, access to previously inaccessible sites, and increased recyclability, all driving innovation and systemic improvement.

The PAS was developed through collaboration between a diverse network of sector stakeholders and government bodies, including the Ministry of Housing,

Communities & Local Government (MHCLG), Studio Partington, the Health and Safety Executive, BSR, the Association of British Insurers (ABI), and the Buildoffsite Property Assurance Scheme (BOPAS), among others. This broad coalition of experts from fields such as architecture, construction, fire safety, insurance, legal, and research organisations, such as RIBA, RICS, the National Fire Chiefs Council, and the University of Salford, aimed to create a comprehensive specification for the built environment, with a particular focus on offsite and modular construction.

Scott Steedman, Director - General, Standards at BSI, said: “The built environment sector has a pivotal role to play in our future economy. Adopting MMC can help it to embrace innovation while ensuring safety, durability, and efficiency, ultimately transforming the way homes are built and maintained. This new specification provides a clear, unified framework for the adoption of MMC, which can help to accelerate the development of agile, resilient supply chains for the sector and the delivery of higher quality, new-build housing programmes across the UK.”

Image: Courtesy Premier Modular

You can find everything you need to know about PAS 8700:2025 at: https://knowledge. bsigroup.com/products/modern-methodsof-construction-for-new-build-residentialproperties-specification

An office fit-out project by Morris & Spottiswood that incorporates modular construction and circular economy approaches has delivered embodied carbon savings equivalent to driving 45,255km in a large diesel car – enough to circumnavigate the globe (40,000 km at the equator).

The project to relocate Morris & Spottiswood’s own Glasgow office to new premises Eastworks, in the Dalmarnock area of the city, offered a unique opportunity for the business to showcase its full endto-end service, drawing on expertise from the wider Morris & Spottiswood Group.

The use of an innovative ‘plug and play’ modular pod system has saved 1.790 tonnes CO2e compared to creating a similar build-up using traditional methods –equivalent to flying 11,701km in short haul economy flights to and from the UK. The prefabricated pods are manufactured offsite, with all necessary cabling, lighting and services already integrated within the partitions, ready to be quickly assembled on-site and simply connected to a standard power supply. Various pod configurations are available, all of which are fully demountable and can be easily reconfigured or even disassembled and moved elsewhere should the need arise.

This modular design vastly speeds up project delivery, with pods assembled in a matter of days rather than weeks, while waste is reduced thanks to the precision engineering and high-quality finish that can be achieved in a factory setting. With a clear focus on carbon reduction, the team committed to a circular approach, which included re-purposing existing flooring finishes and sourcing second hand furniture through partner company, Inspire Spaces. The reuse of materials has reduced the project’s carbon impact by 7.591 tonnes CO2e, which is a saving of 8.73% compared to procuring new materials and products.

“The pods have enabled us to deliver a highquality fit-out within much shorter timescales,” said Gordon Clyne, Joint Managing Director at Morris

& Spottiswood. “In this instance, we installed a glass-fronted boardroom, flanked by two adjoining multi-purpose office spaces. The three pods were assembled and functional within four days – a feat that would have taken several weeks if we were required to construct and connect the spaces using traditional methods.

“From work commencing on-site in early January, to project completion at the end of March, this project has been delivered at an accelerated pace without compromising on quality – a testament to the efficiencies, both in time and carbon savings, that can be achieved by a multi-disciplinary service provider, such as the wider Morris & Spottiswood Group.”

Decarbonisation has been a firm priority throughout the project and a Lifecycle Carbon Assessment (LCA) was undertaken by crbn solutions, another business within the Morris & Spottiswood Group that specialises in carbon reduction strategies. The LCA found that the project’s upfront embodied carbon was 93kg CO2e /sq m – significantly lower than the current 2025 threshold suggested by the UK Net Zero Carbon Building Standard (260kg CO2e /sq m) but also comfortably achieving the 2038 target of less than 100kg CO2e /sq m.

Oliver Connew, Associate at crbn solutions commented: “We viewed the Dalmarnock office move as an opportunity to deliver a flagship project that demonstrates our full service offering and incorporates the latest in fit-out approaches. The carbon reductions found in the LCA are a clear indication of this and reflect the careful decision making that has gone into every aspect of the project – from purposefully choosing a building that offers long term energy security, being part of a district heat network, to considering things such as the local transport facilities to help reduce travel-related carbon.”

Source: www.morrisandspottiswoodgroup.co.uk

A new report from the Offsite Alliance sets out the potential steps needed to transform the UK workforce to meet the scale of ambition demanded by housing, retrofit, net zero, and economic growth targets.

‘Building Capability: From Insights to Impact’ defines 19 Future Occupational Profiles (FOPs) aligned with the future of the industry, offsite, digital, and sustainable delivery models.

With input from over 150 leaders across industry, education, and training, the report provides a clear and practical roadmap to align recruitment, CPD, and qualifications with the skills the UK needs and the ones that are currently missing. The report sets out the findings of a Workforce Foresighting cycle commissioned by Innovate UK in partnership with the Offsite Alliance, Ministry of Building Innovation and Education (MOBIE), Mott MacDonald and the Manufacturing Technology Centre (MTC) and presents a future vision for how the construction sector should organise itself in terms of functions, roles and processes, to meet urgent demands around performance, safety and environmental impact.

“The construction sector is at a critical moment,” said Gaynor Tennant, Founder and Chair of the Offsite Alliance. “We have an opportunity and a responsibility to reshape how we work, how we collaborate and how we bring people into our industry. This report is more than a set of occupational profiles, it's a blueprint for building a more connected, capable and resilient workforce, one that's ready to deliver the quality, safety, and sustainability our built environment demands. These profiles reflect the lived experience of industry leaders, educators, manufacturers, designers and contractors, but this is just the beginning, we want to hear your voice in this. Read the report challenge it, build on it and help us shape what comes next.”

You can download the report ‘Building Capability: From Insights to Impact’ at: www.offsitealliance.org

Saint-Gobain UK has released a new detailed independent study that reveals the innovative concept eHome2 saves between 8 to 9.5 tonnes of embodied carbon emissions compared to traditionally built homes. The new study is an independently written and third-party verified Whole Life Carbon Assessment (WLCA) assesses the whole-life embodied carbon emissions, with analysis drawn on upfront embodied carbon (emissions associated with manufacturing and installing materials), of the innovative eHome2 concept, built in partnership with Barratt Redrow at the world-leading Energy House 2.0 climatic chamber at the University of Salford.

The eHome2 was constructed in 2023 as a unique collaboration between Saint-Gobain, Barratt Redrow and the University of Salford. It was designed and built to be a high-performing three-bedroom house, achieve net-zero carbon for regulated energy use, and demonstrate how homes can be constructed at scale to meet the Government’s Future Homes Standard.

The WLCA was carried out independently by Focus Consultants, alongside Saint-Gobain’s LCA Team and panel reviewed by eLoop. It compared the eHome2’s lightweight offsite manufactured timber frame construction approach with other alternative build approaches, including traditional brick and block construction. Barratt Redrow is supporting

the research as part of its work to achieve net zero greenhouse gas emissions by 2040 – the first major housebuilder to do so.

Key findings from the study, where eHome2 is compared to traditionally built masonry home using clay bricks and PIR insulation, show

• A 11% reduction in whole life embodied cared:bon (over 60 years)

• A 21% reduction in upfront embodied carbon (excluding biogenic carbon) emissions — equating to over 10 tonnes of CO2e savings per house

• A 57% reduction in upfront embodied carbon when biogenic carbon is included—representing the benefits of sustainably sourced timber

• Lighter construction reduces emissions related to reduced concrete foundations by approximately 1 tonne of CO2e, due to the reduced load requirements of the timber-frame, lightweight façade system – Enveovent developed by SaintGobain during the construction of eHome2

• The external walls, timber frame fabric and foundations contribute only 16% of the total carbon footprint of the building compared to 26% under traditional construction, over the building’s lifespan.

This study confirms the potential for lightweight timber frame and offsite construction solutions to not

only produce high-performing buildings at scale and speed but also significantly reduce embodied carbon emissions of new homes. From the testing carried out by the team at the University of Salford, eHome2 has already demonstrated its capability to maintain comfortable internal temperatures with ‘zero carbonready’ heating systems for less than £2 a day when the temperature is 5°C. Combining this with the new LCA results, it further demonstrates how construction can reduce its environmental impact whilst providing comfortable homes for residents at scale.

Mike Chaldecott, CEO of Saint-Gobain UK & Ireland said: “The development of eHome2, in collaboration with our partners Barratt Redrow, has again demonstrated the significant role lightweight construction made with high levels of offsite construction can create high-performing and lower carbon homes at scale. At a time of significant Government ambition for new housebuilding for both the private and public sectors, eHome2 has proven to be a research facility to help shape a transforming construction industry. The build has played a key role in helping us shape low-carbon solutions for new housing. These solutions are now being tested in the field in pilot social housing schemes and are being fully industrialised in preparation to support largescale housing growth in the UK.”

Source: www.saint-gobain.co.uk/ehome2

MiTek is continuing to drive machine automation across the construction industry and roof truss manufacture with its Mark 1 Easyjig Press. With the latest installation of presses bringing the total number now in operation across the UK and Ireland to 14, MiTek is meeting the growing demand for automation within the sector.

Dave Thomas, Commercial Leader, EMEA Automation, said: “The Mark 1 Easyjig Press puts our customers at the forefront of technological innovation. By driving efficiency and increasing output through automation, it helps manufacturers boost productivity. What’s more, the press is also fully compatible with MiTek’s design and production software, which means a connected experience for our customers.”

The Mark 1 Easyjig Press uses the latest technology to improve efficiency for manufacturers, streamlining operations and boosting roof truss production. The press is quicker and more accurate. A user-friendly operation helps workforces while increasing production capacity. Production is faster compared to non-automated presses. The Autojig feature reduces setup time by automatically positioning the jigs based on design specifications.

Customers particularly value the integrated Virtek laser system, which means manufacturing is exact,

consistent and of a higher quality. The Mark 1 Easyjig Press has an easy-to-use touchscreen monitor, and its inbuilt WiFi network connectivity offers a joined up and efficient experience for manufacturers. It’s intuitive design also means people can be trained quickly, operating the machine in a matter of weeks, in contrast to traditional systems which can take up to a month. Preset tables are available in a range of sizes, so a truss can be outlined in 40 seconds, for easier, quicker and more precise production across the board.

Crendon Timber Engineering has already invested in several presses across its business as part of its focus on automation and goals to futureproof its operations.

Speaking of the installation of its sixth Mark 1 machine at its East Harling site, Crendon Timber Engineering’s Regional Director Graeme Denham is a firm believer in what the machine can do, saying: “We're already seeing improvements in increased productivity using the Easyjig system. It's early days, but, you know, on a good day in a very short space of time, we’ve seen a significant improvement in productivity using the auto puck system. The key with MiTek is being able to buy all the manufacturing equipment as well as the software, as well as the plates. It's a one stop shop and that's a great buying power for us.”

Source: www.mitek.co.uk

Leading volumetric developer Tide has secured a resolution to grant planning permission for its 1,051-home Ilderton Road Scheme. Rationalising and enhancing a previously approved scheme, Tide together with award winning architects, tp bennett, has designed a deliverable scheme that increases the affordable housing provision by 55% to 186 units and the number of co-living homes from 605 to 865 units.

This development will significantly contribute towards Southwark’s overall housing targets, particularly the borough’s ever growing affordable housing requirements, with 100% of the affordable units offered at social rent.

Programmed to start in 2025, the redevelopment of this vacant, under-utilised brownfield site will be completed in 2027 using Tide’s sister company and offsite manufacturer Vision Volumetric. Tide’s volumetric approach, enables parallel workstreams on and offsite, enabling delivery up to 50% faster than traditional construction methods.

The efficiencies of this volumetric system allowed the number of storeys in each block to be increased without significantly impacting the overall height of the scheme, enabling the significant increase in

the number of homes. Tide’s volumetric approach also reduces embodied carbon, and the highprecision engineering of the building in controlled factory settings will contribute to strong operational performance, enabling the scheme to target BREEAM Excellent certification.

tp bennett‘s designs reflect the historical and emerging context of the area. The North block is inspired by Bermondsey’s industrial vernacular, referencing the area’s past with its brick façade. The South building takes a similar approach but is designed with square base modules, giving a more domestic feel. The four blocks cascade down from the station to the south, with the scheme retaining and enhancing the high-quality ‘pocket park’ at the heart of the site from the original proposal, guaranteeing a public space for locals and new residents.

Nenad Manasijevic, Principal Director at tp bennett, said: “Working on the Ilderton Road scheme from the start, we have focused on delivering much needed design-led, sustainable housing and co-living for Southwark. It has been great working with Tide to ensure the future of this proposal, now one step closer to being delivered. This partnership has allowed enhanced sustainability measures for the scheme,

utilising a volumetric method of construction to target a BREEAM ‘Excellent’ rating.”

This newly consented scheme significantly bolsters Tide’s portfolio of co-living developments. Tide’s previous developments include College Road, a benchmark-setting scheme in Croydon which completed in 2023, and is home to the largest operational co-living development in the UK, Enclave: Croydon. Tide and Vision are also nearing the completion of 462 co-living homes at The Castle in Acton, following an efficient 18-month construction programme.

Helen McManus, Head of Planning at Tide, added: “This project showcases how our volumetric construction approach can deliver more affordable housing for local authorities in a faster, sustainable, high quality and efficient way. Combined with the 55% uplift in affordable housing, increased shared living units, enhanced Pocket Park and improved public realm, this scheme will deliver considerable benefits to the area and its community.”

Image: Courtesy tp bennett

Source: www.tideconstruction.co.uk www.visionvolumetric.com www.tpbennett.com

SES is a pioneering force in delivering customised engineering and technology solutions that power some of the UK’s most sustainable, high-performing buildings.

Our expanding network of digitally enabled off-site manufacturing facilities allows us to minimise our impact on surrounding environments and communities while delivering sustainable, high-performance engineering solutions.

MB3 Framework

A total of 19 companies have been successful in their bid to join LHC Procurement Group’s £265million Modular Buildings (MB3) framework. MB3 covers the design, supply, installation and hire of permanent, temporary and refurbished modular buildings.

It is free to access for clients spanning the public sector, including local government, NHS, government departments and the MOD. All suppliers on the framework underwent thorough vetting to ensure they can adequately support the development of education facilities, healthcare settings, offices, community buildings, and mixed-use developments.

“As part of our in-depth evaluation process and Gold Standard principles, we review every submission in detail,” said Graham Collie, LHCPG’s interim head of TPO and supplier engagement. For MB3, this included conducting factory assessments, which took us across England, Scotland, Wales, Northern Ireland and the Republic of Ireland.”

Having been split into four workstreams, MB3 provides a full turnkey solution to manage all services required for a project from initial design through to final handover, with dedicated support from LHCPG’s technical team. The framework is available via all five of LHC Procurement Group’s (LHCPG) business units: LHC, Northern Procurement Alliance, South West Procurement Alliance, Welsh Procurement Alliance

and Scottish Procurement Alliance. By increasing the focus on offsite construction, MB3 aims to reduce environmental impact, streamline project timelines, and offer cost-effective alternatives to traditional construction methods. Almost £76million of public sector work was procured via the MB2 framework, and MB3 is set to be even more popular.

Graham added: “As the successor to the MB2 framework, MB3 facilitates the use of modular building solutions that prioritise offsite construction and its environmental benefits. This includes faster project delivery, reduced site disruption, and improved quality control through factory-based precision manufacturing. MB3 also responds to growing demand from public sector clients for sustainable, flexible and future-proofed building solutions. By creating opportunities for a wider range of suppliers – including SMEs and specialists in modern methods

Roger Bullivant Limited (RBL) announced the successful delivery of its in-house designed and manufactured innovative precast foundation system for a major residential development by Dundas in Bishopton, Scotland. This 46-unit development showcases RBL’s sustainable and cost-effective value engineered solutions, using low carbon concrete to minimise environmental impact.

The affordable homes section of the development features a mix of semi-detached and terraced homes, all supported by RBL’s precast piling and beam system. Over 500 No. Driven Precast Concrete Piles as well as 1,500 linear meters of RBeam, RBL’s precast ground beam system, were installed to provide a robust and efficient foundation solution. Piles were driven to design depths of 16m and 20m to accommodate challenging ground conditions.

Ground conditions consist of very soft to soft silts and clays (Linwood Paisley Formation) extending to depths of between 16.50mbgl and 22.00mbgl at which point stiff clays are encountered. Localised bands of silty sands were encountered at depths between 14.00-16.00mbgl across the site. These soils are typical of the Bishopton development area. Driven precast piling is ideally suited to these ground conditions, offering a quick and efficient method of pile installation.

of construction – the framework is designed to build both capacity and resilience across the supply chain.”

MB3 will run until May 2029 to provide a long-term pipeline of opportunities for both suppliers and public sector clients. The social value objectives for MB3 align with the nature of the framework and partner priorities.

Clive Feeney, LHCPG group CEO, added: “As is standard for all our frameworks, we will be actively measuring the genuine social value delivered via MB3. We will not only provide specialist technical support for each of the appointed companies but also help them to deliver and report on the social value impact of the projects delivered. This is all part of our efforts to ensure that all projects delivered via our frameworks leave a lasting positive impact.”

Source: www.lhcprocure.org.uk

This system not only ensures structural integrity but also provides a cost-effective alternative to traditional trench fill foundation solutions. RBL’s in-house design expertise ensures that the system is tailored to the unique requirements of every project, optimising efficiency and reducing material waste. By utilising standardised precast components, manufactured and stored at RBL’s headquarters, the process minimises waste on site, thereby reducing lorry movements, and keeps costs under control.

“We are pleased to work with Dundas to deliver a high-quality, sustainable foundation solution for this residential development,” said Gavin Hay, Scotland Area Manager at Roger Bullivant Limited. “Our precast system not only provides a reliable foundation but also supports the industry's drive towards lowercarbon construction methods.”

RBL’s Scotland team played a key role in the planning and execution of this project, ensuring seamless delivery and installation. This project highlights RBL’s expertise in foundation systems and reinforces the company’s position as a leader in sustainable foundation engineering.

Source: www.roger-bullivant.co.uk

The four-storey steel frame of Bradford College’s new £17million building is now in place – marking a key step in transforming its Thornton Road site. Led by Morgan Sindall, the new Junction Mills building will offer students specialist training in motor vehicle, advanced electrical, hybrid and hydrogen technologies, vital in supporting the growth of lowcarbon skills capabilities within West Yorkshire.

Precast elements such as lift shafts and stairs have been manufactured offsite. The building’s framework also incorporates 232 tonnes of hot-rolled steel. The heaviest pieces of the structure are two nine-tonne beams which support the first-floor workshop area. Sustainability is central to the project. A peer review of the RIBA Stage 3 foundation and steel frame design found efficiencies that decreased steel and concrete usage, resulting in a 56-tonne reduction in carbon dioxide equivalent (CO2e). Work on the cladding and internal walls saved a further 126 tonnes. This work brings the total CO2e saved so far to 182 tonnes –the equivalent of heating 67 UK homes annually.

Pamela Sheldon, Head of Projects at Bradford College, said: “It’s exciting to see our latest capital project take a step forward – purpose-built to deliver cutting-edge automotive training for the future.

With space for up to 650 students, this new facility represents a significant leap in how we equip young people with the skills needed for a low-carbon economy. It is also fitting that a building dedicated to low-carbon skills should be constructed with sustainability at its core.”

Ben Hall, Area Director for Morgan Sindall Construction’s Yorkshire business, added: “We’re thrilled to deliver what will be a game-changing new facility for Bradford. As part of our delivery of this project, we look forward to undertaking social value initiatives that benefit the people of Bradford, ensuring

this new facility has a positive impact on the city way ahead of opening.”

Bradford College is the largest regional leader in education and training, recruiting over 4,000 16-18 students, over 3,500 adult learners and over 1,000 technical and degree level students across diverse age groups and needs. Over the last three years, Bradford College has secured nearly £40million in funding. This substantial investment is helping the College reshape and rebuild aspirational new facilities in the heart of Bradford.

Source: www.bradfordcollege.ac.uk

Our AluSpace Interior Screening System is designed to divide or delineate both residential and commercial spaces, while at the same time providing an effective acoustic barrier. Choose from hinged single, double doors, pivot or sliding doors to accompany our stylish fixed glazed screen. This flexible and versatile system provides almost limitless design options whilst requiring minimal maintenance. AluSpace will provide many years of assured, reliable and robust performance.

For more information visit smartsystems.co.uk/aluspace

E sales@smartsystems.co.uk

A centre of excellence for mass timber research, innovation and manufacturing has been launched by Built Environment – Smarter Transformation (BE-ST). Supported by Scottish Funding Council and host institution Edinburgh Napier University, the Innovation Campus at BE-ST will now house £1.5million of newly acquired, state-of-the-art mass timber postprocessing equipment and SuperBlower extraction system. This will complement existing capabilities and further enhance precision finishing, production capacity, and health and safety processes.

The Mass Timber Centre of Excellence will provide the UK construction and built environment sector with the facilities, knowledge, and connections to accelerate the adoption of UK-grown mass timber solutions and access the benefits these can bring, such as lowering carbon emissions associated with construction, strengthening local supply chains, creating jobs, and improving the efficiency of the delivery of the built environment.

It offers access to the UK’s most advanced mass timber manufacturing equipment and hosts the largest commercially available CNC machine in the UK, while offering the full-scale production of cross laminated timber (CLT), nail laminated timber (NLT), and glue

laminated timber (Glulam). The factory is anticipated to have an annual manufacturing output capacity of approximately 8,000m³ once fully operational.

The UK faces the dual challenge of a climate emergency and a housing emergency. By advancing the use of mass timber, the Centre has been established to position the construction industry as a key part of the solutions to both challenges. Currently, the UK imports 73,000m3 of mass timber per year. By creating higher-value timber products in the UK, such as mass timber, and leveraging local supply chains, we can unlock significant economic and environmental benefits in the UK.

The Centre provides support to accelerate UK-grown mass timber adoption across the UK. As well as offering access to mass timber manufacturing equipment, the Centre offers research, innovation, and systems design support through partnerships with industry and academic experts to develop timber solutions, consultancy services to assist with product approvals, regulatory compliance, and manufacturing processes, and timber processing through trusted partners for felling, grading, kilning, and planing. Hands-on training and skills development can also be provided via the Centre to upskill the workforce in the expertise required to deliver mass timber products.

Sam Hart, Associate Director of Manufacturing and Housing, at BE-ST said: “The Mass Timber Centre of Excellence opens up huge opportunities for the construction sector. By investing in mass timber, we are not just advancing low carbon approaches to construction, we are also investing in economic growth, creating jobs, and addressing some of the UK’s key challenges.”

Stephen Good, CEO of BE-ST added: “The launch of this Centre will support the wider adoption of mass timber, helping to reduce carbon emissions, strengthen supply chains, and deliver muchneeded domestic, non-domestic, public, and private infrastructure where appropriate, in a more efficient, affordable, higher quality and sustainable way.” The Mass Timber Centre of Excellence is inviting businesses, policymakers, and construction professionals to explore the opportunities mass timber can offer, from adopting or manufacturing mass timber components or taking part in our skills programmes.

Source: www.be-st.build

Results of a new survey of UK timber frame manufacturers, published by MEDITE SMARTPLY and the Structural Timber Association (STA), reveal a sector with growing pressure on its shoulders – and diminishing clarity about how to meet it.

‘Framing the future: The state of timber frame construction’, captures responses from over 80 timber frame manufacturers working across residential, social housing and education. Although there is a clear desire to meet higher performance standards, many respondents pointed to a disconnect between policy ambition and the practical realities of delivery.

The urgency of net zero targets adds to the complexity. UK law requires net zero emissions by 2050, and homes currently account for 20% of all emissions. The Future Homes Standard (FHS), set to be introduced by 2025, will require newbuild homes to incorporate low-carbon heating and energy efficiency. The expectation is that homes built to the FHS will produce 75–80% fewer carbon emissions compared to previous regulations (Approved Document L 2013), with a strong focus on airtightness and high-performance building fabric – including walls, floors and roofs.

Chief among the concerns is the confusion surrounding pre-manufactured value (PMV), a metric central to many MMC funding models. Nearly half of all survey respondents declined to disclose their PMV score, pointing to unclear definitions, a lack of

The National Infrastructure and Service Transformation

relevance to smaller-scale operations or uncertainty about how the figure is even calculated. While Homes England and other government programmes incentivise high PMV through funding – such as capital grants for developments achieving 55% PMV or more – there remains no standardised industry process for calculation.

Compounding this is the perception that policy frameworks like the Future Homes Standard are increasingly geared toward volume developers. This is leaving smaller manufacturers, many of which are already building above-regulation, struggling to see where they fit into the picture.

“The industry isn’t short on innovation or intention, but a lack of clarity is knocking confidence,” said Roly Ward, Head of Business Development at MEDITE SMARTPLY. “We’re hearing a clear message from the sector: manufacturers are being asked to move fast without clear footing. That’s not sustainable. Fire safety is a prime example. It remains the number one challenge for almost half of respondents, yet testing regimes aren’t clearly defined and insurers still lack confidence. That’s a risky bottleneck. If we want

MMC to scale, we need regulatory clarity, joined-up standards, and products that simplify the compliance journey, not complicate it further.”

The survey also highlights broader systemic pressures. 73% of manufacturers are facing skilled labour shortages, with concerns raised about the availability of apprenticeships, local training pathways, and the general appeal of construction careers to younger workers. This presents a serious challenge as demand for low-carbon housing rises. Despite the concerns, product development needs show an industry still striving for innovation. 81% called for OSB panels with integrated fire resistance, with 43% naming fire performance as their number one challenge. Many manufacturers also expressed interest in multi-functional solutions that reduce the need for layered materials and on-site adaptations by streamlining compliance across airtightness, thermal performance and buildability.

The full report ‘Framing the future: The state of timber frame construction’, is available now from MEDITE SMARTPLY at: www.mdfosb.com/news/framing-the-future

announced plans to create a new National

Infrastructure and Service Transformation Authority (NISTA), bringing together the former Infrastructure and Projects Authority (IPA) and National Infrastructure Commission (NIC).

Formally launched on 1 April 2025, NISTA will look to fix the foundations of our infrastructure system by bringing strategy and delivery under one roof, addressing the systemic delivery challenges that have stunted growth for decades. Supporting delivery of our roads, railways, schools and hospitals, it will help overcome the barriers to delivery of UK infrastructure, as well as provide expertise on private finance. Under HM Treasury NISTA is part of a three-pronged approach to addressing the fundamental constraints to infrastructure investment, sitting alongside the 10-year infrastructure strategy, which sets out a longterm plan for the country’s infrastructure, and the new Planning and Infrastructure Bill to unblock planning constraints.

With extensive experience in infrastructure leadership, particularly in the UK transport and international sectors, Becky will bring significant expertise, skills and knowledge to the role.

“I am delighted that Becky is going to lead NISTA as the new CEO,” said Darren Jones, Chief Secretary to the Treasury. “She brings a wealth of experience from the public and private sector overseeing some of the biggest transport projects around the world in the past decade. Her appointment is an important milestone for NISTA’s work in getting a grip on infrastructure delivery, powering growth across the country and delivering on our Plan for Change.”

Becky Wood, NISTA Chief Executive Officer said: “It is an honour to be appointed to a role that has so much potential to make a vital difference to the everyday lives of people across the UK, ensuring robust delivery of infrastructure and enabling growth. I am very much looking forward to joining the team in June.”

Becky is currently a partner at the consultancy firm EY, and prior to that was a Commercial Advisor at the Infrastructure and Projects Authority, she will formally take up her role as CEO in June 2025.

Source: www.gov.uk/government/ organisations

Reds10 has unveiled a new senior leadership structure to drive the next phase of its ambitious growth strategy, targeting £500million in turnover and accelerating the integration of advanced technologies across the business.

At the heart of this evolution is the promotion of three senior leaders, Phil Cook, Joe Shepherd and Ryan Geldard to Managing Directors of their respective divisions. Together they will lead the delivery of Reds10’s strategy to revolutionise construction across Defence, Public Sector and Offsite Manufacture.

They will be supported by a strong and experienced leadership team. Scott Laird takes on the newly created role of AI & Technical Director, while Uthira Balachandar continues in her role as Design Director. David Newey and James Bateman remain in their positions as Construction Directors, and Stephanie Mehra continues as Finance Director. This blend of newly promoted and established leaders will drive Reds10’s mission to industrialise construction, embed AI across its operations, and deliver exceptional value to clients.

As part of the changes, Chief Executive Matt Bennion will assume a new role at Reds10’s sister company, Thrive-AI after six years in his current role. Matt will focus on accelerating growth at the smart building technology business. Thrive-AI applies machine

learning to help clients operate their buildings more efficiently, improve user experience, reduce energy consumption, save money, eliminate redundancy in design and optimise the lifespan of critical assets.

Founder and Chairman, Paul Ruddick will assume day to day leadership of the Reds10 business, working closely with the leadership team to scale operations and deepen Reds10’s technological capabilities.

Paul Ruddick, Reds10 Founder and Chairman said: “Following four years of strong growth, we are moving to the next phase of our strategy focused on advancing technologies to fully industrialise our design, production and construction processes and integrate AI across the business. As part of our plan, Matt Bennion is taking on the leadership of Thrive-AI to accelerate its development and growth, while a new generation of leaders takes the helm at Reds10. We thank Matt for his outstanding contribution to date, and we are excited to move forward on our mission to modernise construction, driving up productivity, quality, and sustainability and delivering exceptional value to clients.”

Matt Bennion, Reds10 Chief Executive, said: “I am delighted to be able to hand the baton on to the new leadership team. It has been a huge privilege to have worked with them and led such a talented Reds10 team over the past six years. These promotions

put Reds10 on a firm footing for the next stage of its development and allow me to hand over my CEO responsibilities, safe in the knowledge that the business will continue to go from strength to strength. I’m excited to be spending more time developing and growing our sister company Thrive-AI, our intelligent building platform that puts end users, operators and asset owners in control of their building, carbon footprint and operating costs. It’s a great business and gives Thrive-AI and Reds10 the opportunity to transform the use and operation of buildings for our customers.”

The changes come after Reds10 announced its fourth consecutive year of growth for the year ended 31 March 2024, with revenue rising by 70% YoY to £142.5million. The business has a secured pipeline of over £300million of work and turnover is forecast to rise to £160million in the current financial year. Reds10 has set out an ambitious plan to grow its revenue and is targeting an expansion into the healthcare sector, as well as the affordable housing and temporary accommodation sectors, providing high quality sustainable homes for local authorities to help them tackle the housing crisis in their communities.

Source: www.reds10.com

*For further technical information and fire test reports, contact us on +44 (0)161 905 5700 or e-mail info@glidevaleprotect.com www.glidevaleprotect.com/frsolutions

Work on a pioneering scheme to deliver affordable and sustainable housing across five sites in Bristol has started after receiving planning permission from Bristol City Council. Social and affordable housing developer EDAROTH (Everyone Deserves a Roof Over Their Head) is leading the design, production and delivery of 25 net zero homes as the pilot for a new model for providing council housing in Bristol –as part of its involvement in the UN Habitat Climate Smart Cities challenge.

The new homes will be a mix of 13 houses and 12 apartments and will be developed by EDAROTH using offsite manufacturing methods to create low energyuse homes which are net zero in use and will provide much needed social housing for the city. These homes are being delivered as part of the council’s

Telford-based Elements (Europe) Limited that specialised in volumetric modular and bathroom pods was placed into administration on 4 June, with around

New Home programme being led by the council’s Housing Delivery team.

Work is now starting on five sites on land owned by the council, using the innovative approach from EDAORTH (part of AtkinsRéalis) which involves manufacturing many parts offsite in a UK factory and delivering them to the site reducing the carbon impact of the development process. This approach also ensures the homes will be delivered up to 50% more quickly compared with traditional methods of construction – with minimal disruption to residents living near the development sites.

Councillor Barry Parsons, Chair of the Homes and Housing Delivery Committee, said: “The delivery of new council homes is really important for the city,

140 jobs expected to be lost. Sam Birchall and Steve Absolom from Interpath have been appointed joint administrators, saying that 141 staff have been made redundant with a further 76 kept on helping with the administration.

Key to the decline has been the move from subcontractor to main contractor with the East Road project in Hackney, and the Camp Hill scheme in Birmingham proving problematic. “Unfortunately, both these contracts have incurred losses, resulting in a significant cash requirement. In response, the directors sought to explore options for the sale, investment, and/or refinancing of the company, however, when it became clear that a solvent outcome was not possible, the directors took steps to protect the interest of creditors by placing the company into administration.”

and I am delighted to see our Housing Delivery Team exploring new and innovative means of building homes with partners such as EDAROTH. The learning from this and other projects will help drive delivery across small sites in the city, allowing us to make best use of our land to meet our priority housing need. The Climate Smart Cities Challenge has allowed us to look at delivering new homes on small sites which are integrated into existing communities, and with the highest levels of sustainability and energy performance for the people who live there. This is something to be really celebrated.”

The homes will be produced to the highest quality to ensure they are built to last, and they are expected to meet and exceed the Future Homes Standard coming into force this year, as well as meeting EPC (Energy Performance Certificate) A+.

Mark Powell, Managing Director at EDAROTH, added: “Like cities around the country, Bristol faces a huge demand for affordable homes. This scheme is really an exemplar of how local authorities can work in partnership to address the national housing crisis effectively, while at the same time reduce the level of local authority spend on temporary accommodation. We’re looking forward to starting work on this scheme which not only supports the city council’s ambition to meet demand for housing but also aims to provide homes where people need them, to enhance communities and create thriving places to live.”

The agreement between EDAROTH and Bristol City Council is based on an award-winning approach developed by the council, and the One City team, with partners including the Housing Festival, AtkinsRéalis and EDAROTH, as one of four winning projects in the UN Habitat Climate Smart Cities Challenge. Part of the challenge includes the delivery of new housing projects to illustrate how aggregating small sites for development, and overcoming systemic barriers, could unlock sites to deliver truly affordable social housing. Work is due to be completed by Spring 2026.

Source: www.edaroth.com

The intention is to pause work on both projects to explore options to rescue all or parts of the Elements business. Steve Absolom said: “We are also seeking buyers for the company’s assets and would invite interested parties to make contact with us as soon as possible.”

The firm had been in business since 2005 with its manufacturing facility located in Telford, Shropshire. Latest financial results for the year to 31 December 2023 showed a turnover of £42million with a pre-tax loss of £29.5million.

Interested parties should contact Hassan Rauf at Interpath on hassan.rauf@interpath.com

Source: www.interpath.com

Fit our Modulo bathroom easily without major work, considerably reducing installation time and costs

The Modulo is an all-in-one bathroom solution that can transform a room, adding value to your property. If you need the model with an integrated Saniflo to pump waste when gravity can’t, then as long as there is small bore pipework and electricity, the Modulo is still an optoin. With different profile and glass options, you can tailor the Modulo to your needs. Its black or white design create a modern space that fits in with any decor. The Kinedo team works with you; from site visits, installation training, technical assistance and first-class aftercare.

Published fortnightly, OFFSITE OPINION seeks out the thoughts and views from key personalities within the offsite world – from those making things happen in the factory environment and on-site – to all those thoughtleaders and board level decision makers. It captures the key conversations of those behind shaping the future of the built environment.

The May/June editions of OFFSITE OPINION explored the future of construction through digital collaboration, design freedom, and sector-wide innovation. Contributors highlighted the value of cross-industry learning, open ecosystems, and coordinated transformation. Meanwhile design-to-manufacture integration and emphasises on collaborative innovation to de-risk adoption also featured, with the main theme across the industry urging bold, joined-up thinking across the construction landscape.

Az Jasat, Senior Industry Manager, Industrialised Construction at Autodesk, outlines how a shift toward industrialised construction, underpinned by digital collaboration and cross-sector learning, can unlock transformative benefits.

“The AECO industry is currently experiencing challenges as traditional methods face new pressures and changing industry trends. Project stakeholders are contending with everything from flatlining productivity levels to fragmented production chains and environmental goals.

Collaborative digital platforms, combined with a cross-industry approach, will revolutionise the AECO industry and help overcome these roadblocks. Right now, we have a significant opportunity for our leading AECO and MFG (manufacturing) industries to learn from each other’s strengths to build a stronger and more scalable future.”

Read in full here: www.offsitehub.co.uk/offsite-opinion-reimagining-construction-through-industrialised-innovation

Wolf Mangelsdorf, partner and structural engineer at Buro Happold, offers a candid account of the lessons learned from decades at the intersection of design and construction.

“Lego is a great example, but we need to go beyond it. Lego does not create an ecosystem that others can connect into, you are bound to Lego. We cannot afford that. No individual player is big enough to cover the entire construction industry. As a client, I want freedom. I want the freedom to choose a solution suitable for my building from a range of offers. I do not want to be beholden to Lego from Day One.”

Read in full here:

www.offsitehub.co.uk/offsite-opinion-moving-beyond-the-lego-like-solution

Mike Pitts, Deputy Challenge Director at Innovate UK, examines some of the successes of the Transforming Construction initiative.

“The origins go back a couple of governments ago, when the Industrial Strategy was first introduced. That was the foundation for what became the Industrial Strategy Challenge Fund, where innovation funding was aligned around sector transformation.

“For construction, this meant tackling long-standing issues around productivity and the capacity to deliver the UK’s infrastructure needs, especially in light of an ageing and declining workforce. It was also tied into a Sector Deal, government promised to do some things, and the construction sector committed to others. It was one of the first times the sector really came together with that level of coordination.”

Read in full here: www.offsitehub.co.uk/offsite-opinion-building-a-better-future

Andy Barnes, Managing Director - Civil at the Manufacturing Technology Centre,

“Construction is a complex industrial sector with clients, regulatory and standards bodies, tier 1 contractors and a huge supply chain and trades-based workforce. So, being able to facilitate collaboration is crucial to foster innovation in this domain.

“It is worth highlighting too, that MTC and the wider Catapult network have an amazing array of leading technology groups and competencies, which can be drawn upon to de-risk the journey for adoption of innovative solutions and approaches.”

Read in full here: www.offsitehub.co.uk/offsite-opinion-forging-the-future-of-construction

Daniel Hall, Assistant Professor at TU Delft, champions a new paradigm – one where students challenge entrenched systems.

“Historically, investment in digital technology, particularly in the design phases, has primarily sat with architects, engineers and contractor-led design teams, while the supply chain has often lagged behind.

“This disconnect compounds silos in the sector, limiting the ability of manufacturers to influence early-stage design decisions. To truly industrialise construction, we need to better enable the supply chain, ensuring that the logic of manufacturing is digitalised and connected to the design.”

Read in full here: www.offsitehub.co.uk/offsite-opinion-leading-the-nextwave-of-industrialised-construction

All these industry snapshots plus much more are published on www.offsitehub.co.uk

OFFSITE OPINION is published every two weeks on LinkedIn via the Explore Offsite Page. Be sure to follow the page and subscribe to the newsletter to hear more about the latest views across the offsite industry and get them direct to your mailbox.

If you are interested in speaking to us for an upcoming Offsite Opinion get in touch with Harry Wright email: harry.wright@radar-media.co.uk

BUILDOFFSITE (BOS) launched its Manifesto 2025–2030 recently. Fareita Udoh outlines this ‘bold, practical five-year vision’ to make offsite construction the standard, not the exception for construction.

The pressures facing our sector today – climate change, housing shortages, skills gaps, economic uncertainty – are complex, interconnected, and urgent. But they are not insurmountable. Alongside these challenges, we see remarkable innovation, rising collaboration, and a shared determination to build a better future.

The BOS Manifesto 2025–2030 is not just another policy document. It is a roadmap that shows how we can build smarter, greener, and more productively – with evidence and with purpose. The Manifesto aligns with the UK Government’s wider industrial goals, from decarbonisation to digitalisation, from levelling up to export-led growth. The Manifesto is designed for clear impact and is anchored in six policy asks:

• Driving demand at scale

• Breaking down procurement barriers

• Championing digital transformation

• Incentivising assurance and performance standards

• Securing value through whole-life procurement

• Delivering the offsite-skilled workforce of tomorrow.

Each priority is backed by industry insight and aligned with national goals around housing, infrastructure, and net zero. But strategy alone will not move the dial. That is why the Manifesto is built around ‘Four Pillars for Action’ that act as the foundation of how we’ll deliver change:

• Influence – shape policy, regulation, and investment priorities

• Insight – equip the sector with the knowledge to adapt and lead

• Evidence – demonstrate what works with data, case studies, and impact

• Collaboration – break silos and align around shared goals.

These pillars drive BOS’s mission from national policy conversations to site-level innovation. That also includes assurance. Through schemes like BOPAS (Buildoffsite Property Assurance Scheme), we have helped over 100 organisations unlock investment, scale their delivery models, and build trust in their methods. It is living proof that performanceled assurance is not only possible, but also essential to mainstreaming MMC. The message is simple: MMC works. But to work at scale, we need shared ambition, aligned systems, and committed leadership.

Putting policy in practice

Later this year in September, we will bring the Manifesto to life at the BOS Two-Day Conference that will be a key part of Offsite Expo 2025. This conference is where that alignment begins. More than an event, it is a working forum and a blueprint for

action. A place where industry leaders, practitioners, and policymakers align around real delivery. Every session is rooted in a Manifesto priority. We’re not just talking about what needs to happen, we are showing how it’s already happening.

Through Innovation & Digital Transformation

We begin by recognising retrofit as national infrastructure. It is not an addon – it’s a strategic enabler for net zero, productivity, and resilience.

Session 1: The Retrofit Mandate Retrofit is an economic strategy, a climate imperative, and a social opportunity. This session explores the policy, finance, and delivery levers needed to treat retrofit like we would any critical infrastructure, with long-term planning and sustained investment.

Session 2: The Retrofit Bottleneck

Here we confront the institutional barriers that limit delivery: outdated procurement, fragmented regulation, and assurance gaps that create risk rather than reduce it.

Our focus is on unlocking retrofit at scale through systemic alignment — fixing procurement, modernising regulation, and embedding trusted assurance. At the centre of this ecosystem is BOPAS, the UK’s leading framework for demonstrating quality and durability in offsite housing. BOPAS de-risks investment and supports MMC adoption by providing lenders, insurers, and clients with longterm confidence.

Session 3: Standards in Action Trust is essential to scale. This session explores the evolving standards underpinning retrofit and MMC, including PAS 8700 and how they build market confidence and reduce delivery risk.

Innovation Hub Challenge: System Ready

In this interactive session, crosssector teams design scalable retrofit solutions. It is theory-meets-practice, judged on collaboration, feasibility, and impact and was a highly successful part of last year’s event that saw Abode Industries, and its modular BYGO

system incorporating a comprehensive and interchangeable kit-of-parts, and Qube with its Bio-SIP™ system, that fuses natural fibres and recycled plastic bottles into a structural solution, named worthy winners.

We shift from projects to systems, exploring how to scale MMC across the sector with digital, data, and skills at the core.

Session 4: Securing the Digital Future

Digital is not optional. It is the backbone of modern construction. From data governance to cyber resilience, this session highlights how digital infrastructure can enable safe, scalable delivery and why interoperability and performance data matter.

Session 5: Educating the Net Zero Workforce

MMC is only as strong as its workforce. This session tackles the growing skills gap, focusing on practical solutions — training MMC advisors, designing retrofit curricula, and opening inclusive career pathways across the built environment.

The Outcomes: From Words to Delivery

What makes this conference different? It is grounded in real-world delivery.

Every session responds to a tangible industry challenge. Every conversation is linked to a Manifesto pledge And most importantly, we are asking – how do we do all this together?

• How do we treat retrofit as infrastructure — funded and planned like roads or rail?

• How do we de-risk innovation through standards, data, and trusted assurance?

• How do we design procurement around performance, not process?

• How do we ensure the workforce, systems, and supply chains are ready to deliver the next 100,000 homes — faster, smarter, greener?

This is our invitation to the industry, and to everyone who cares about how we build, If you believe in homes that are affordable, sustainable, and fit for the future, if you believe in digital tools that empower delivery, and skills that build lasting careers and if you believe the construction sector can lead – not lag – in the race to net zero, then join us.

For more information visit: www.buildoffsite.com www.offsite-expo.co.uk

Images: 01-02. The BOS Manifesto is built around ‘Four Pillars for Action’ that act as the foundation of delivering change. Courtesy BOS & Stelling Properties

1

3 2

FP McCann has provided a striking new frontage to a high-end development in central London using a range products including precast concrete wall panels.

FP McCann’s architectural facade division has supplied and installed custom-made Portland Stone-clad precast concrete panels and acidetched banding to a new super-prime residential development in the central London district of Fitzrovia.

The prestigious design and build development at 204 Great Portland Street nestle between London’s Marylebone and Fitzrovia neighbourhoods and is a doublebasement formation and eight-storey RC frame with external features, including rainscreen cladding, bespoke cast aluminium balustrades and the natural stone clad precast concrete architectural panels. The 50,000sq building comprises 37 luxury apartments, communal areas and ground floor retail units.

Working on behalf of client Concord London, construction, refurbishment and fit-out specialist Make One Group and architect E8 Architecture were awarded the £24.5million design and build contract. Recognising FP McCann’s experience and contributions in this field, Make One ft