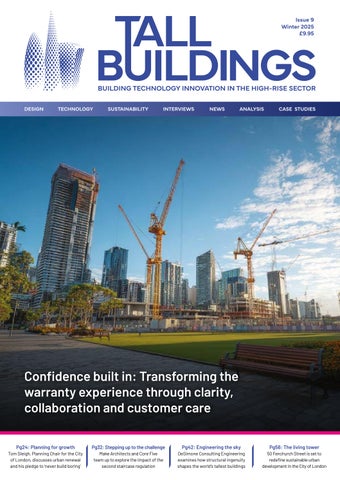

Issue 9 Winter 2025 £9.95

Confidence built in: Transforming the warranty experience through clarity, collaboration and customer care Pg24: Planning for growth

Pg32: Stepping up to the challenge

Pg42: Engineering the sky

Pg56: The living tower

Tom Sleigh, Planning Chair for the City of London, discusses urban renewal and his pledge to ‘never build boring’

Make Architects and Core Five team up to explore the impact of the second staircase regulation

DeSimone Consulting Engineering examines how structural ingenuity shapes the world’s tallest buildings

50 Fenchurch Street is set to redefine sustainable urban development in the City of London