LIGHT STEEL FRAMING MAGAZINE

Welcome to one of our regular magazine sections dedicated to businesses and developments affecting the light steel frame sector. These include a main feature from voestalpine Metsec on its MetWALL

Perform packs. These have seen a surge in interest as a way for architects, developers, and clients to have the ‘ultimate reassurance’ when specifying through-wall solutions incorporating Metsec steel framing systems. Crucially, this comprehensive digital package of design information can form part of the Golden Thread and help support building applications, including the Building Safety Act’s Gateway procedures.

Waste reduction and recycling are at the centre of two features. One from Nick Coubray, CEO of Howick, that focuses on how roll-forming innovation can help the construction and offsite sectors build better and be more efficient –waste should not be accepted as simply a ‘cost of doing business’ – it is basically ‘lost time, lost profit, and lost opportunity’. Plus, Frameclad have proudly launched ECO-LSF – produced from 100% recycled content, this milestone marks an exciting step in its long-term commitment to low-carbon construction, circular material uses and high-performance products.

We also highlight the winner of the Best Use of Steel Technology at this year’s Offsite Awards. Errigal Façade’s engineering team developed two bespoke steel systems – one for a ‘steel-clad crown’ and another for the sky terraces at the £450million regeneration scheme at the Elephant and Castle Town Centre – all exceptional. To cap things off, we had a quick chat with Angela Mansell, Managing Director of Mansell Building Solutions, who talked enthusiastically about building better skills and ‘manufacturing confidence’ across the world of offsite.

FRONT COVER: voestalpine Metsec

04 06 08 12 16 20 22

voestalpine Metsec provide a reminder of how its warranty-backed performance packs provide specifiers with the ‘ultimate’ reassurance, as it reports a marked increase for MetWALL Perform.

With significant challenges in bed capacity during the winter, Peterborough Hospital needed to meet space requirements quickly and efficiently – the hospital turned to modular building specialist Wernick for help.

Nick Coubray, CEO of Howick Ltd, outlines how roll-forming innovation can help the construction and offsite sectors build better and be more efficient and develop better waste strategies.

Frameclad is spearheading the charge to take sustainability to another level with the launch of ECO-LSF – a more environmentally conscious and circular-economy orientated light steel frame option.

Renowned for unearthing ‘hidden gems’ the 2025 winner of the Best Use of Steel Technology, Errigal Façades, designed, engineered and offsite manufactured ‘steel-clad crowns’ to grace the pinnacle of an acclaimed £450million regeneration scheme.

Light Steel Frame Association (LSFA) Chair, Ben Towe reveals how steel specialists are harnessing advanced design and industrialised manufacturing to help set new standards in precision-built structures.

Mansell Building Solutions are proving that culture, certainty and collaboration are the foundations of modern construction. Managing Director Angela Mansell, spoke to us about how this approach is building trust, not just buildings.

VOESTALPINE METSEC, PROVIDE A REMINDER OF HOW ITS WARRANTY-BACKED PERFORMANCE PACKS

PROVIDE SPECIFIERS WITH THE ‘ULTIMATE’ REASSURANCE.

voestalpine Metsec is reporting a marked increase in interest for its MetWALL Perform packs over recent months. The industry-leading digital information package and warranty programme gives architects, developers and clients ultimate reassurance when specifying through-wall solutions incorporating Metsec steel framing systems, including Metsec SFS and Metframe.

Chris Holleron, Sales Director for voestalpine Metsec’s Framing Division, explains: “The Building Safety Act (BSA) places building safety at the core of every new building project, whether newbuild, refurbishment or repurposing. We are finding that designers and contractors are increasingly looking

to systems manufacturers to provide solutions for safety critical aspects of their projects, particularly fire performance.

“With the BSA formalising the Golden Thread of information, these solutions need to be backed up by comprehensive design information, and this is where MetWALL Perform is proving invaluable, together, of course, with our in-house design department and team of chartered structural engineers.”

MetWALL Perform provides the designer, contractor and end client with a comprehensive digital package of design information which can form part of the Golden Thread and support building applications, such

as the BSA’s Gateway procedures. Founded on voestalpine Metsec’s relentless investment in independent testing, the MetWALL Perform packs not only include essential design and performance data but also enable the company to provide a 30-year warranty for its through-wall solutions.

Long recognised as market leaders in the design and production of light gauge, cold-rolled steel framing systems, voestalpine Metsec invests heavily in a continuous programme of independent testing for its through-wall solutions, covering acoustics, thermal efficiency, structural stability and, crucially, fire.

Using combinations of plasterboard (British Gypsum, Knauf and Siniat), sheathing board (RCM Y-Wall, Euroform Versaroc, Siniat Weather Defence, British Gypsum Glasroc X, Knauf Windliner and other leading manufacturers) and insulation (Rockwool and Knauf Rocksilk), voestalpine Metsec framing systems are used to create typical through-wall solutions for testing.

The result is one of the most extensive and comprehensive libraries of performance data available for framing solutions, comprising hundreds of different through-wall permutations using the industry’s most popular boarding products, verified to the highest possible performance standards under UKAS-accredited test procedures and relevant BS EN standards.

For architects and designers, this through-wall data is available via NBS source and is directly accessible through the NBS Chorus specification writing system. This ensures that information is held in a clear, standardised digital format for designers and contractors, enhancing the project’s digital record and contributing towards the application process.

Concluding, voestalpine Metsec’s Specification Manager for Framing, David Atkinson comments: “MetWALL Perform and its 30-year warranty give the designer, contractor and client with total peace of mind when specifying our through-wall solutions. They instil confidence that our solutions meet relevant Building Regulations and

enable projects to comply with the requirements of the BSA, including providing an accurate record of the design, which forms part of the Golden Thread. Together with our expert design services, MetWALL Perform is delivering a solutions package which is hard for the design and construction team to resist.”

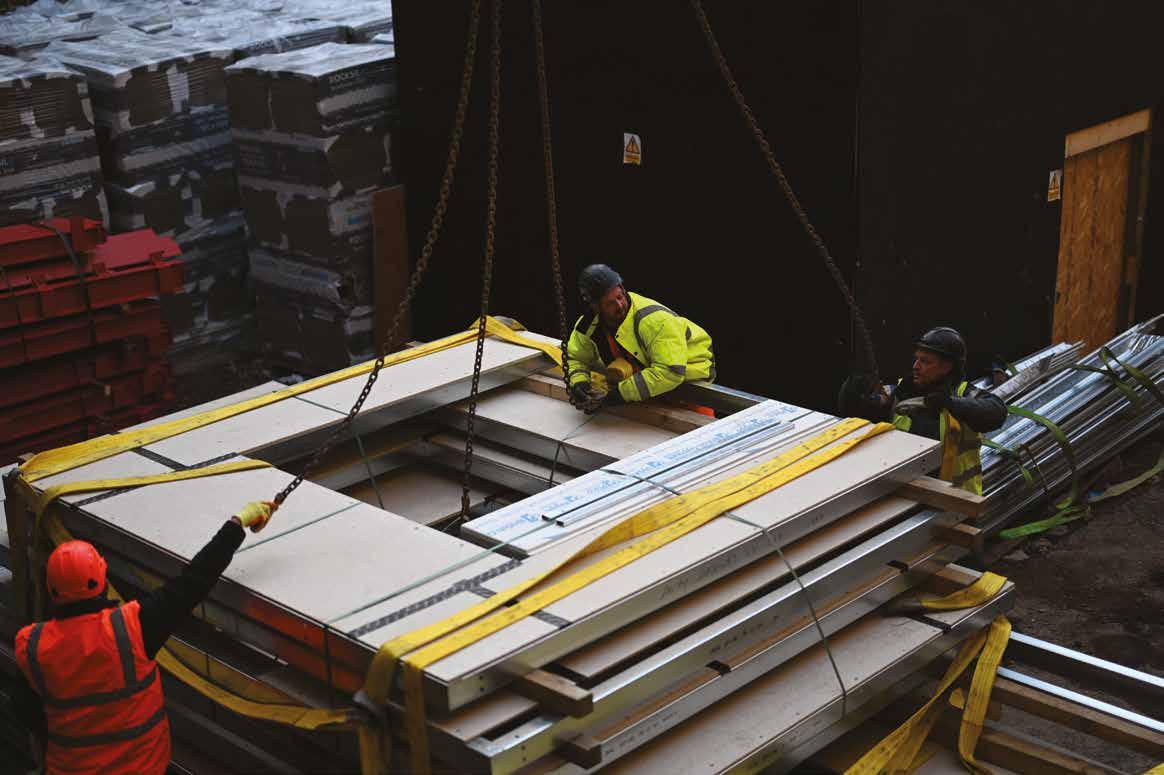

Find out more at: www.metsec.com or contact the Framing Division at: metsec.SFS@voestalpine.com IMAGES 01-05. MetWALL Perform is proving invaluable in helping work with the Golden Thread of information

WITH A SIGNIFICANT CHALLENGE IN INCREASING ITS BED CAPACITY DURING THE WINTER, PETERBOROUGH HOSPITAL FACED A TIME WHEN DEMAND FOR HEALTHCARE SERVICES DRASTICALLY PEAKED. TO MEET THIS NEED EFFICIENTLY, THE HOSPITAL TURNED TO MODULAR BUILDING SPECIALIST WERNICK.

The new two-storey building consisting of 22 modules added 20 beds with ensuite facilities and included essential hospital infrastructure such as a reception area, pantry, offices, and utility rooms. To ensure aesthetic harmony with the surrounding buildings, a terracotta rainscreen cladding was incorporated.

Wernick’s modular solution not only met the immediate requirements but also provided a flexible option for future expansion. The quick installation process helped minimise disruption to ongoing hospital operations, a crucial factor in a healthcare setting. This project is an example of how modern construction techniques can adapt to the evolving needs of the healthcare sector, offering both efficiency and high-quality patient environments.

Peterborough Hospital required an emergency facility delivered on time, with minimal disruption to hospital

activities. “The reason why we needed to expand our hospital bed base is because we were under real pressure in the winter months,” said David Moss, Director of Estates and Facilities at Peterborough Hospital. “The additional 20 beds will be used to alleviate some of the pressures that we will feel in the winter period. We needed a solution to be delivered quickly, so we went for a modular option.”

Manufacturing a building in a factory setting whilst building work takes place on-site cuts construction programmes by approximately 50%. Movement of vehicles and the number of personnel required for each project can be reduced by as much as 90% compared to many ‘traditional’ build programmes. This means lower noise pollution and disturbance to patients, as well as fewer carbon emissions. Sites with tight access points or a small footprint also benefit from decreased movements on-site. Where required, modules arrive

with interior fixtures and fittings in situ, decreasing the time required at the location further.

Modules are constructed to strict standards – Wernick’s modules are manufactured under ISO 9001 and 14001, in a dedicated facility, using a building system which fits the client’s budget and aesthetic. These systems are carefully designed to minimise material waste during the construction phase, and any waste produced is fully recycled, all without compromising the performance of the building for its intended use.

The look of the building was an important consideration for the hospital trust, which specified external cladding to match the buildings already onsite. The result is a building that is indistinguishable from the surrounding hospital building. A link to the main rehabilitation building, provided using an additional module, further creates the illusion of a building that has always been there.

For futureproofing, additional modules can be added to the building later, either alongside, linked to, or on top of the existing building. Again, this is ideally achieved with early engagement with a modular building supplier. You can expect a typical design life for a modular building of 50+ years, and with normal general maintenance, will provide all the comfort you’d expect from a ‘permanent’ building.

Mark Carter, Commercial Director at Wernick Buildings said: “Our work in Peterborough stands as a testament to how modular buildings can effectively relieve the pressures on healthcare facilities and support the growing demand for accommodation space. By employing our modular construction approach, we were able to deliver high-quality accommodation swiftly, minimising disruption to ongoing medical services. We are proud to deliver a building that helps Peterborough Hospital to continue their vital work in a well-equipped and supportive environment.”

Find out more at: www.wernick.co.uk

‘WASTE NOT’. NICK COUBRAY, CEO OF HOWICK LTD, OUTLINES HOW ROLL-FORMING INNOVATION CAN HELP THE CONSTRUCTION AND OFFSITE SECTORS BUILD BETTER AND BE MORE EFFICIENT.

The construction industry has always accepted waste as a cost of doing business. Materials ordered ‘just in case’, offcuts filling skips, and site delays caused by late changes. It all quickly adds up. But with thorough planning, smarter digital design and precision roll-forming systems, this no longer needs to be the case.

At Howick, we see waste for what it is – lost time, lost profit, and lost opportunity. Waste is everywhere in construction, but most of it is preventable when precision and planning lead the process. For nearly 50 years, we have pioneered rollforming technology to help streamline construction. Steel components are formed from digital models, precut, punched, and labelled to exact specifications for faster assembly onsite or offsite.

For internal framing projects, the onsite flexibility provided by our telescopic panels markedly reduce time and waste. These telescopic panels, manufactured by our X-TENDA™ 3600 were used in the £130million refurbishment of One Queen Street in Auckland, New Zealand, which included a 5-Star hotel,

14,000m2 of prime office space, and a breathtaking rooftop bar. The telescopic panels contributed to a 50% reduction in the embodied carbon footprint compared with an equivalent newbuild. The installation of the framing was 60% quicker than planned for traditional stud and track.

Roll-forming technology allows for the precision required to build expressive, complex forms with no re-work or waste, saving labour and time. For the Lucas Museum in Los Angeles, STUD-IO used Howick roll-forming machines to realise the mind-bending roof ribbon. Each of the 195 unique panels was pre-punched and shaped to follow the architect’s 3D model, then placed using a digitally fabricated rail and a robotic layout. The result was a repeatable approach to complex geometry, and a roof structure completed six months ahead of schedule.

From internal framing to large-span structures, the same roll-forming precision helps reduce waste at every scale. At British Offsite in Essex, Howick machines power their UNisystem –producing insulated wall panels that

combine multiple trades into one ready-to-install product, cutting waste and rework. The same principle drives X-CALIBR™, a roll-formed structural system that makes light gauge steel structures possible where they once required heavy steel fabrication. Back in New Zealand, Howick’s sister company Central Steel Framing has used this system to erect a 650m² honey storage shed in a single day without cutting or welding, or the associated waste.

Turn traditional waste into future opportunity

Whether simplifying modular production or enabling architectural freedom, roll-forming technology makes smarter construction possible. By moving more of the build into controlled factory environments, we reduce waste, risk, and carbon, while expanding what is achievable.

Find out more at: www.howickltd.com

IMAGE

01 Telescopic panels manufactured by the Howick X-TENDATM 3600

02 Lucas Museum, Los Angeles

03 Honey storage shed in Taupo, New Zealand

Achieve your vision with the right roll-forming technology – and the right team. With nearly 50 years of practical insights, 24/7 support, UK-based technicians, and a connection to a global community through our STEEL HORIZONS™ events, you can shape the future of construction.

4200 FRAMA™ 5600

5600

4200

5600

4200 FRAMA™ 5600 FRAMA™ 6800 FRAMA™ 6800

5600

6800

7600

7800

7600

7800

7600

7800

The precision is very very accurate which is what we’re all about… we need that accuracy in the machines that we use…. Machines are part of our business, critical to our business. We don’t have a business without the Howick roll-formers. Remagin Ireland

A big part of choosing Howick as our choice for the LGS was…the technical support was superior to others. Wernick Buildings

MODULAR FACTORY

7600

5600

6800

7800

Ready for steel framing automation? Are you ready to start or scale up your light steel framing operation? Take our 2-minute, no pressure quiz for an instant guide and resources sent to your inbox.

The growing demand for high-quality homes across the UK is driving interest in modular housing solutions. With the government recently pledging £20billion to support the construction of 1.5 million new homes by August 2029, the need for faster, more efficient building methods has never been greater. However, recent data indicates that the current pace of development falls short of what’s needed to hit these ambitious targets. Increasing offsite construction capacity will be essential and that’s where modular approaches provide a distinct advantage.

LGSF Ltd collaborates closely with modular builders to provide highquality light gauge steel frames, available in stick form, pre-panelised, or as volumetric units. These solutions allow the majority of construction to be carried out offsite in a controlled environment, significantly improving productivity while alleviating the pressure on on-site tradespeople who face unpredictable and often

challenging UK weather conditions. Homes can be erected and completed in days, not the weeks or months typical of traditional construction methods.

In response to increasing demand LGSF has recently invested in new plant and processes to increase production capacity to roll over 14 million linear metres of steel and assemble over 2.5 million square metres of panels every year using bespoke turning tables to enhance productivity.

“At LGSF, we’re always investing in smarter technology, smoother processes, and skilled people to make

sure our clients get high-volume outputs quickly and efficiently,” says Ian Cade, Technical Director at LGSF. “Our just-in-time manufacturing approach really helps us stay agile and deliver at pace. One of the things that makes us stand out is our ability to handle both hot- and cold-rolled steel completely in-house. That gives us full control over quality and timelines, which is a big advantage for construction and modular building projects. We use pregalvanised S450-grade structural steel as standard, and our ISO 9001:2015 accreditation backs up the consistency and quality of everything we produce.

“We’re also seeing more partners looking to cut carbon and work towards BREEAM certification, so we offer the option to use green steel for even more sustainable builds. At the end of the day, it’s all about collaboration. We’re always open to working with partners who share our drive for innovation and design efficiency. Together, we can keep pushing modular steel construction forward as a real, sustainable alternative to traditional building methods.”

This commitment to excellence was recognised in 2025, when LGSF was named Manufacturing SME of the Year in North Yorkshire’s Top 100 Business Awards, a category judged on metrics such as turnover, profit, growth, and headcount, using independently filed company data from across York and North Yorkshire.

LGSF clients extend beyond modular housing companies and include academic institutions and universities, defence, retail, hotels and leisure, and healthcare. As the UK accelerates its push to deliver more homes, LGSF stands ready to support the industry with scalable, sustainable, and precision-engineered steel frame solutions that help bring modular construction into the mainstream. Find out more at: www.lgsf.co.uk

FRAMECLAD IS ONCE AGAIN LEADING THE CHARGE TO TAKE SUSTAINABILITY TO ANOTHER LEVEL WITH THE LAUNCH OF ECO-LSF –A MORE ENVIRONMENTALLY CONSCIOUS LIGHT STEEL FRAME OPTION.

Produced from 100% recycled content, this milestone marks an exciting step in Frameclad’s commitment to low-carbon construction and the future of responsible building practices. Often referred to as ‘Green Steel’ – ECO-LSF is produced using Electric Arc Furnace (EAF) technology. Unlike traditional blast furnace methods, EAF uses electricity generated from renewable sources to melt and recycle scrap steel. The result is a product that not only delivers the performance and reliability expected from Frameclad but also offers major environmental advantages.

“Our steel has always been produced with a strong focus on sustainability, containing around 60% recycled content, says Nik Teagle, Joint Managing Director at Frameclad. “After significant time and research, we are

proud to give our construction clients an even more sustainable option to choose from. Taking it up to another level and remaining competitive has taken time, but we are extremely proud that our first full ECO-LSF loadbearing scheme in Guildford, constructed using 100% recycled steel – is now underway.”

A step change in sustainability ECO-LSF represents a transformative shift in steel production. With the potential to achieve up to 70% lower CO₂ emissions, ECO-LSF dramatically reduces the carbon footprint of construction projects. Conventional steelmaking typically produces 1.8–2.0 tonnes of CO₂ per tonne of steel. ECO-LSF cuts that figure down to just 0.4–0.7 tonnes, enabling developers and contractors to meet increasingly strict sustainability targets.

Steel is the world’s most recycled material with more than 500 million tonnes recycled every year – the equivalent of 180 Eiffel Towers every day. Once produced, steel is a valuable asset that can be reused or recycled infinitely. This unique characteristic gives steel a high value at all stages of its lifecycle. One of ECO-LSF’s most significant benefits is its use of up to 100% recycled scrap steel. This maximises the value of existing resources while reducing the demand for virgin raw materials such as iron ore and coal. By doing so, ECO-LSF supports a closed-loop, circular construction approach that replaces the traditional ‘take – make – dispose’ linear model.

Arkitech is a premier manufacturer and developer of Light Gauge Steel (LGS/CFS) technology. Our in-house design, manufacturing, and software development ensure efficient, high-volume production of LGS frames, enhancing construction efficiency and profitability. With over 15 years of experience, we provide reliable solutions for residential, commercial, and industrial projects, including modular and multistorey buildings, bathroom pods, site units, and prefabricated modules.

Arkitech is a premier manufacturer and developer of Light Gauge Steel (LGS/CFS) technology. Our in-house design, manufacturing, and software development ensure efficient, high-volume production of LGS frames, enhancing construction efficiency and profitability. With over 15 years of experience, we provide reliable solutions for residential, commercial, and industrial projects, including modular and multi-storey buildings, bathroom pods, site units, and prefabricated modules.

Arkitech is a premier manufacturer and developer of Light Gauge Steel (LGS/CFS) technology. Our in-house design, manufacturing, and software development ensure efficient, high-volume production of LGS frames, enhancing construction efficiency and profitability. With over 15 years of experience, we provide reliable solutions for residential, commercial, and industrial projects, including modular and multistorey buildings, bathroom pods, site units, and prefabricated modules.

Arkitech places a strong emphasis on machine and software development for all aspects of the LGS (CFS) construction industry.

By continually advancing its technology offerings, Arkitech aims to drive innovation and efficiency in LGS (CFS) construction and manufacturing processes, enabling clients to achieve higher productivity, cost savings, and superior quality in their projects whilst also contributing to carbon reduction efforts.

Our sustainable solutions align with environmental goals, supporting the reduction of carbon emissions in the construction sector.

Arkitech is a premier manufacturer and developer of technology. Our in-house design, manufacturing, and efficient, high-volume production of LGS frames, enhancing profitability. With over 15 years of experience, we provide reliable solutions for residential, commercial, and industrial projects, including modular and multistorey buildings, bathroom pods, site units, and prefabricated modules.

strong and all (CFS)

By its Arkitech

efficiency in LGS (CFS) construction and to achieve higher productivity, cost savings, and superior quality in their projects whilst also contributing to carbon reduction efforts. Our sustainable solutions align with environmental goals, supporting the reduction of carbon emissions in the construction sector.

Arkitech Advanced Construction Technologies Malıköy Anadolu OSB Mahallesi 8. Cadde No:21 Sincan 06909 Ankara Türkiye +90 312 496

technology offerings, Arkitech aims to drive innovation and

efficiency in LGS (CFS) construction and manufacturing processes, enabling clients to achieve higher productivity, cost savings, and superior quality in their projects whilst also

efficiency in LGS (CFS) construction and manufacturing achieve higher productivity, cost savings, and superior quality contributing to carbon reduction efforts. Our sustainable solutions goals, supporting the reduction of carbon emissions in the

As governments, regulators, and clients demand more sustainable building practices, ECO-LSF ensures Frameclad’s customers are well-positioned for the future. By specifying ECO-LSF, contractors and developers can align with green building certifications, meet Environmental, Social and Governance

Frameclad is a trusted UK-based manufacturer, designer and engineer of light steel frame systems. With a focus on innovation and quality, Frameclad offers a complete package of services to customers. The business has invested significantly in state-of-the-art manufacturing technology and fire test data.

The 14-strong highly knowledgeable in-house design and engineering team provide cost estimates within 10 days and detailed designs within one week. Their precision steel roll-forming machinery produces one of the largest ranges of steel sections available in the UK today from a single manufacturer. Serving residential, education, healthcare, commercial and industrial sectors – the light steel frame specialist is known for its technical expertise, innovative approach and dedication to sustainable construction solutions.

Find out more at: www.frameclad.com

(ESG) targets, and contribute to a low carbon built environment without compromising on strength, safety or performance.

“ECO-LSF is more than just a product launch – it’s our commitment to the future of sustainable construction,” adds Martin Jamieson, Joint Managing Director at Frameclad. “By harnessing the potential of Electric Arc Furnace technology, we can deliver steel that is not only high-performing but also dramatically lower in carbon. We are proud to give our customers a solution that supports their sustainability and safety goals whilst driving the industry forward.”

IMAGES

01. ECO-LSF is taking sustainability to another level as a more environmentally conscious light steel frame option

02-03. North Street, Guildford. The first project to use ECO-LSF

Using Totalkare’s mobile column lifts with infill plates when loading modular buildings for dispatch can save significant time and money. Ask us about our flexible finance options - including hire - today!

RENOWNED FOR UNEARTHING ‘HIDDEN GEMS’ THE 2025 WINNER OF THE BEST USE OF STEEL TECHNOLOGY, ERRIGAL FAÇADES – DESIGNED, ENGINEERED AND OFFSITE MANUFACTURED ‘STEEL-CLAD CROWNS’ TO GRACE THE PINNACLE OF AN ACCLAIMED £450MILLION REGENERATION SCHEME.

As part of a wider package, Errigal Façades were appointed to deliver the steel-clad crown and sky terrace facades on the landmark Elephant and Castle Town Centre redevelopment. The regeneration scheme provides 485 apartments, a university building for London College of Communication, shops, office and leisure space to include a multiscreen cinema. Originally designed as a stick-built on-site solution using hot rolled steel, light gauge framing, and aluminium cladding, Errigal reimagined the scheme through an offsite, steel-led modular construction approach that showcased the best of modern steel technology.

Errigal’s engineering team developed two bespoke steel systems – one for the crown features and another for the sky terraces – combining hot rolled

and light gauge steel frameworks with preinstalled rainscreen cladding. These were precision engineered using 3D modelling, with predrilled hot rolled steel components aligned to support hollo-bolt fixed modules. Structural considerations, including wind loads, deflections and thermal performance, were built into the design at the earliest stages. Changing the building design to enable a kit of parts and modular build for the steel crowns and sky terraces at Elephant and Castle had a real impact on programme performance and delivery.

Offsite solution versus on-site build

Looking at the offsite solution versus an on-site build, Errigal has been able to analyse the benefits around sustainability and carbon impact. Completing a review on the deliveries

of the materials both offsite and onsite has identified large benefits of reduced material wastage, reduced total deliveries to city centre site ensuring the offsite solution has major sustainability benefits when compared to the onsite stick-built option.

Quality of the offsite finished product has allowed Errigal Façades to reduce the potential impact on revisits for repairs or damage. The tolerances and installation have been carried out to ensure that the building performance is met if not enhanced and with the offsite solution allowing the design development and coordination of all other factors and sub-contractors.

Offsite manufacturing allowed both hot rolled and light gauge steel elements to be fabricated and assembled under

KingBuild is the result of a development process driven by market demand and innovation.

This high-quality, rapid-build, and cost-effective panelised Light Gauge Steel Frame (LGSF) system integrates seamlessly within a wide range of architectural styles and is ideal for both low- and mid-rise structures.

Developed by Kingspan, KingBuild delivers a comprehensive, single-source solution – from early design principles through to on-site structural erection. The result: a streamlined process that saves time, reduces cost, and ensures dependable quality.

Why choose KingBuild?

Up to 40% faster construction compared to traditional hot-rolled or concrete frame methods.

Lightweight and cost-effective - reduces foundation size, installation time, and overall build cost.

Reduced prelims and programme risk - shorter build times mean lower prelim costs and greater predictability.

Optimised labour - a typical five-person crew assembles efficiently on site, keeping costs low.

Offsite precision = onsite speed - factory manufacture limits weather delays and accelerates delivery.

Rapid dry envelope enables follow-on trades to start sooner, driving programme efficiency.

De-risked delivery - integrated design and manufacturing ensure consistency from start to finish.

For more information, technical specifications, or to discuss your next project, contact Andrew Waddell: email andrew.waddell@kingspan.com or call 07970 664160

KingBuild combines speed and precision with sustainability in a robust, engineered system that is ideal for residential apartments, student accommodation, hotels or care home developments, delivering shorter programmes, lower costs, and consistent quality - every time.

KingBuild faster, KingBuild smarter.

controlled conditions at Errigal’s offsite facility. This ensured quality, tight tolerances and safety while significantly reducing installation time – cutting the programme by up to 75% per tower for these elements of work.

The fully clad crown modules were assembled at a temporary on-site facility, lifted into position, and integrated seamlessly with the main structure. The sky terrace modules were built at Errigal’s offsite Facility in Antrim and shipped to site to be lifted in custom stillages and installed on rooftops without any need for external access. This innovative use of steel technology delivered high structural performance, design flexibility and enhanced aesthetics along with significantly reducing the risks.

The solution removed the need for extensive on-site fabrication, drastically reduced working at height and improved site and public safety. The result was a steel driven solution that not only met, but exceeded client expectations on safety, performance and delivery, while setting a benchmark for the use of steel in modern facade systems.

Errigal Façades integrated sustainability, circular economy principles and digital innovation into every stage of this offsite light gauge steel facade project. Modules were designed for disassembly and reuse, bolted (not welded) to enable future recyclability. Precision CNC fabrication and 3D clash detection cut waste to near zero, with all light steel offcuts recycled.

This project sets a benchmark for sustainable construction, with 90% of the work completed offsite, slashing dust, noise and emissions on-site. Sky terraces installation time per tower dropped, cutting costs and disruption. Fully modelled systems met thermal, structural and corrosion standards while reducing transport and site

congestion. Amid the Elephant and Castle redevelopment, the steel-clad crowns and sky terraces offer an iconic finish to the towers, with Errigal Façades innovative offsite solution, improving quality through its controlled factory conditions and reducing on-site installation from 16 to 6 weeks per tower.

Find out more at: www.errigal-group.com

IMAGES

01 - 03. Errigal Façades were contracted to design, manufacture and install the steel-clad crown and sky terrace facades for the Elephant and Castle Town Centre redevelopment scheme. Courtesy Errigal Façades

CONSTRUCTION, LIGHT STEEL FRAME ASSOCIATION (LSFA) MEMBERS ARE DRIVING A SAFER, FASTER AND MORE SUSTAINABLE FUTURE. CHAIR, BEN TOWE REVEALS HOW SPECIALISTS ARE HARNESSING ADVANCED DESIGN AND INDUSTRIALISED MANUFACTURING TO HELP SET NEW STANDARDS IN PRECISION-BUILT STRUCTURES.

every module and every connection are planned and digitally verified before reaching the manufacturing phase –ensuring that accuracy, quality and safety are built in from the outset.

The light steel frame sector supports a wide range of residential, healthcare, education and commercial developments. From non-combustible loadbearing systems for schools and colleges to infill walling systems for high-rise homes. The technology can accommodate diverse project requirements and cladding systems, without restriction on building height applications.

Precision manufacturing not only minimises waste but also ensures consistent, high-quality components that enhance structural integrity and safety. Lightweight steel elements can be reused or recycled at the end of a building’s life, supporting a circular economy. Through precision engineered, fire resistant construction, light steel frame buildings prioritise occupant safety, minimise structural risks and comply with the rigorous standards of the Building Safety Regulator, while also contributing to net zero goals.

Driving engagement and change

Light steel frame construction represents the pinnacle of industrialised construction techniques. Unlike traditional construction approaches and other less mechanised offsite construction methods, light steel frame benefits from a fully integrated, digitally driven workflow that spans design, engineering, manufacturing, and installation.

Digitally powered, seamlessly integrated Every component is engineered with exacting tolerances, ensuring a perfect fit on-site and reducing waste. By linking every stage through a single digital thread, light steel framing systems achieve a level of repeatability and accuracy that is unmatched in conventional building methods.

Design efficiency is another defining feature of light steel frame. Our sector operates in a mechanised,

factory-controlled environment where components are manufactured under strict quality controlled conditions and to exacting tolerances to meet complex design parameters. Controlled production reduces reliance on unpredictable onsite processes, minimises material waste and shortens build programmes. The outcome is not only faster delivery, but also consistent, high-quality results for every project –from single storey to high-rise.

Built-in safety with engineered quality The sector’s digital maturity gives it a unique advantage. By integrating digital design with precision engineering and automated manufacturing, light steel frame enables a seamless transition from concept to completion. This allows for greater flexibility in design while maintaining tight control over structural performance and compliance with Building Regulations. Every panel,

In an era where demand is high and construction challenges are complex, light steel frame construction offers a robust and resilient solution. By harnessing digital precision, industrial efficiency, and integrated workflows, the sector is setting new standards for speed, quality, and adaptability. The future of construction is industrialised, digital, and precise – and light steel frame construction is leading the way.

The LSFA’s mission is to champion change and is committed to supporting developers, designers and contractors in understanding the full potential of light steel technology. We are here to ensure that safety, quality, and sustainability are not competing priorities but shared outcomes.

Find out more at: www.lsf-association.co.uk

The Light Steel Frame Association is on a mission to champion change, influence specification decisions and inspire the construction industry to build safer and more sustainable buildings.

Members benefit from…

Direct representation across the wider construction sector

Collaboration opportunities to help make strategic partnerships and industry connections

Influencing conversations driving growth and expanding market share

Code of conduct underpins credibility, professional status for trusted businesses

Getting noticed amplify your voice through PR, marketing, and promotion across multiple channels

Showcasing expertise speak, exhibit and network at leading industry events

From manufacturers and installers to clients, architects, engineers, and consultants – our membership includes a wide spectrum of construction professionals across businesses large and small.

Change is coming… be part of it. Join the LSFA today!

FROM A FACTORY IN GREATER MANCHESTER, MANSELL BUILDING SOLUTIONS ARE PROVING THAT CULTURE, CERTAINTY AND COLLABORATION ARE THE FOUNDATIONS OF MODERN CONSTRUCTION. MANAGING DIRECTOR ANGELA MANSELL, EXPLAINS HOW THIS MANUFACTURER-CONTRACTOR IS BUILDING TRUST, NOT JUST BUILDINGS.

Few companies embody the spirit of modern construction quite like Mansell Building Solutions. Over more than three decades, they have evolved into a rare hybrid – both manufacturer and specialist contractor – capable of designing, producing and installing pre-panelised structural systems that deliver speed, safety and certainty onsite. Founded in 1991, the business has steadily grown into a fully-fledged MMC manufacturer, shaping projects that demonstrate what regional capability can achieve on a national scale.

For Managing Director Angela Mansell, that dual identity is their edge. “It gives us a unique position in the MMC landscape,” says Angela. “We design, manufacture and install systems with integrated finishes and fire protection. That bridges the gap between design and delivery, giving clients and main

contractors genuine certainty about cost, programme, buildability and compliance from start to finish.”

Certainty through collaboration has become a hallmark of the company’s approach. Mansell’s factory-first process begins with digital design data that follows every panel through production to installation, creating what Angela calls a “golden thread” of quality assurance. “Quality is built in, not inspected in,” she explains. “Every panel we produce is linked to digital data, and our site teams and factory teams work as one system, not two silos. As we grow, quality doesn’t dilute – it compounds.” That digital traceability now forms the backbone of Mansell’s quality system, aligning their operations with the same accountability expected of major national contractors.

The approach is paying off across residential and mixed-use developments, particularly in the public sector where MMC quotas, carbon targets and cost pressures collide. Angela notes that main contractors are increasingly looking for partners who can de-risk delivery. “They’re realising that working with a factoryled specialist who also understands site realities is the fastest way to achieve certainty and prove performance, not just promise it.”

Relationships are everything

That focus on results and relationships runs through every level of the business. At its core is The Mansell Way, a set of principles that Angela and her team live by. “Culture is everything,” says Angela. “Do it right first time, be honest, work as a team, be the best, look after each other, and create impact. We don’t overpromise, and we share ownership of outcomes with our clients and partners. It’s construction without the corporate ego, just people doing the right thing together.” The same principles underpin Mansell’s project delivery, where design integration and clear communication translate process discipline into on-site results.

Their recent project at Downley Drive in Ancoats, Manchester, demonstrates the method in action. Mansell’s prepanelised light gauge steel frame system, complete with integrated fire protection, delivered a complex residential scheme with absolute programme certainty. “Because our design, manufacturing and site teams were aligned from day one, we achieved zero rework, full compliance and a smooth handover,” says Angela. “It’s proof that MMC done properly isn’t experimental, it’s just smarter construction.”

If her language sounds direct, it’s because Angela herself is known for her straight-talking, people-first leadership. “I lead with purpose and pace, but always with connection and care at the centre,” she says. “My priority is clarity. People need to know where we’re going, why it matters, and what good looks like. I’m big on accountability but equally big on trust.

We’ve grown fast because we’ve stayed grounded, focused on facts, feedback and follow-through. I recognise effort, expect integrity, and back people who show resilience when things get tough. Leadership is about creating confidence in our people, our product and the promises we make.”

Looking ahead, Mansell’s focus is clear. The company is expanding capacity with both frame-only and fully integrated systems, strengthening digital integration across design and delivery, and investing heavily in its people. “We’re building skills, leaders and technical confidence

for the long term,” says Angela. “And we’re partnering with councils, main contractors and housing providers who share our ambition to deliver more homes, faster and better.”

For all the talk of transformation in construction, Mansell’s progress remains refreshingly practical. As Angela puts it: “At Mansell, we’re not just manufacturing panels, we’re manufacturing confidence. That’s what real transformation looks like.” It’s a sentiment that reflects the wider offsite movement and proves that innovation grows from a strong bonded team and wider industry collaboration.

Find out more at: www.mansellbuild.co.uk IMAGES

01. Angela Mansell, Managing Director, Mansell Building Solutions

02. Downley Drive, a new residential apartment scheme delivered for Rowlinson and Great Places Housing Group

ASH & LACY’S NEXT GENERATION OF LIGHT GAUGE STEEL SYSTEMS ARE GOING A LONG WAY IN MAKING CLIENTS AND SPECIFIERS THINK DIFFERENTLY ABOUT CONSTRUCTION AND ARE ENGINEERED FOR MANY BUILDING

As modern construction continues to evolve, efficiency, sustainability, and engineering certainty have become essential drivers in project delivery. At Ash & Lacy, we remain committed to developing systems that respond directly to these industry demands –combining innovation with reliability across every stage of the build process. Our comprehensive range of light gauge steel frame solutions is engineered to support the future of construction, whether delivering largescale loadbearing structures or flexible infill framing.

Our H.U.L.K. Loadbearing System has redefined what is achievable with light gauge steel. Using the latest swage edge technology and engineered predrilled holes with a countersunk 12mm bolted connection, these are designed for exceptional strength, precision, and efficiency.

H.U.L.K. provides a full loadbearing solution capable of accommodating structures up to 13 storeys using light gauge steel alone. The system offers full design integration, rigorous structural compliance, and a faster route to site – reducing both programme duration and environmental impact. Backed by our in-house engineering expertise and

extensive testing, H.U.L.K. gives project teams the confidence to build higher and smarter without compromise.

Standard SFS: flexible, highperformance framing for every project Light gauge steel frame construction is increasingly becoming the preferred method across multiple sectors –from multi-storey residential and commercial buildings to industrial facilities and modular developments. Its versatility makes it suitable for both permanent and temporary structures, offering strength without unnecessary weight and design freedom without complexity.

Alongside our H.U.L.K. system, Ash & Lacy provide a full range of standard infill and over-sail SFS solutions, engineered to suit an array of building envelopes and performance requirements. Our offer is built around flexibility including:

End-to-end capability – including design, engineering, manufacturing, and installation support via our network of recommended installers.

Full internal design service – with complete compliance to European standards.

Two pricing pathways – a full lump-sum option (including design, manufacture, delivery, fixings, and full take-off) for cost certainty, or an indicative pricing Using the Ash & lacy Price List route with competitive discounts Where you can price the scheme yourself to support early-stage budgeting.

£10million PI insurance cover –standard across all projects.

Comprehensive fire performance documentation – including certificates, warranties, and fire-test data with leading board manufacturers such as Siniat, Klasse, and Obex.

Brick slips and full façade systems –that give you a full wall build up with all accredited certifications.

Find out more at: www.ashandlacy.com

IMAGES

01-03. Light gauge steel frame construction is increasingly becoming the preferred method across multiple sectors

Brick, reimagined for offsite. Sustainable, rapid-install facades buil t for the future of construction.

Developed in collaboration with leading UK housebuilders, Mauer delivers the speed, quality and compliance today’s projects demand.

DESIGN WI THOUT LIMI TS

FASTER INSTALLATION SUSTAINABLE CHOICE FULLY COMPLIANT