INSIDE OFFSITE KINGSPAN

ENERGY EFFICIENT TO THE CORE

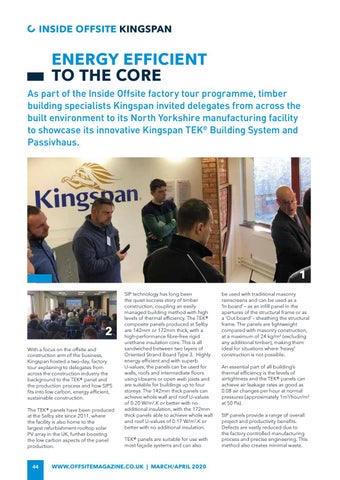

As part of the Inside Offsite factory tour programme, timber building specialists Kingspan invited delegates from across the built environment to its North Yorkshire manufacturing facility to showcase its innovative Kingspan TEK® Building System and Passivhaus.

1

2 With a focus on the offsite and construction arm of the business, Kingspan hosted a two-day, factory tour explaining to delegates from across the construction industry the background to the TEK® panel and the production process and how SIPS fits into low carbon, energy efficient, sustainable construction. The TEK® panels have been produced at the Selby site since 2011, where the facility is also home to the largest refurbishment rooftop solar PV array in the UK, further boosting the low carbon aspects of the panel production. 44

SIP technology has long been the quiet success story of timber construction, coupling an easily managed building method with high levels of thermal efficiency. The TEK® composite panels produced at Selby are 142mm or 172mm thick, with a high-performance fibre-free rigid urethane insulation core. This is all sandwiched between two layers of Oriented Strand Board Type 3. Highly energy efficient and with superb U-values, the panels can be used for walls, roofs and intermediate floors using I-beams or open web joists and are suitable for buildings up to four storeys. The 142mm thick panels can achieve whole wall and roof U–values of 0.20 W/m2.K or better with no additional insulation, with the 172mm thick panels able to achieve whole wall and roof U–values of 0.17 W/m2.K or better with no additional insulation. TEK® panels are suitable for use with most façade systems and can also

WWW.OFFSITEMAGAZINE.CO.UK | MARCH/APRIL 2020

be used with traditional masonry rainscreens and can be used as a ‘In board’ – as an infill panel in the apertures of the structural frame or as a ‘Out board’ – sheathing the structural frame. The panels are lightweight compared with masonry construction, at a maximum of 24 kg/m2 (excluding any additional timber), making them ideal for situations where ‘heavy’ construction is not possible. An essential part of all building’s thermal efficiency is the levels of airtightness and the TEK® panels can achieve air leakage rates as good as 0.08 air changes per hour at normal pressures (approximately 1m3/hour/m2 at 50 Pa). SIP panels provide a range of overall project and productivity benefits. Defects are vastly reduced due to the factory controlled manufacturing process and precise engineering. This method also creates minimal waste.