PUBLISHING

FRONT COVER

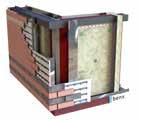

Fusion Steel Framing

PRINTED ON:

FSC Mix paper by Buxton Press

PUBLISHER:

Offsite Magazine is produced and published by Radar Communications: ©Radar Communications Ltd.

Radar Communications Ltd, 101 Longden Road, Shrewsbury, Shropshire, SY3 9PS

T: 01743 290001 www.radar-communications.co.uk

SUBSCRIBE TO RECEIVE OFFSITE:

This magazine is a bimonthly publication and the annual subscription fee for UK postage is £29.70 plus VAT for all six issues (£4.95 per copy). Visit www.offsitemagazine.co.uk

ADVERTISING ENQUIRIES PLEASE CONTACT:

Julie Williams // T: 01743 290001

E: julie.williams@offsitemagazine.co.uk

SEND US YOUR NEWS:

Gary Ramsay // T: 01743 290001

E: gary.ramsay@offsitemagazine.co.uk

BACK ISSUES VISIT: www.offsitemagazine.co.uk

FOR OFFSITE ENQUIRIES PLEASE CONTACT:

E: info@offsitemagazine.co.uk

DISCLAIMER: The content of Offsite Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

KEEP IN TOUCH:

HOME IS WHERE THE HEAT IS

Welcome to the first edition of Offsite Magazine for 2023. For everyone picking this up at Futurebuild, hopefully this magazine will show you some of the ways that offsite manufacture is improving the built environment.

This issue we cover our usual spread of core materials with a slant towards housing and volumetric modular. After just over a year in operation Make UK Modular is making huge progress. We heard from Steve Cole on how they have been progressing so far. With some leading industry names on the membership list, its first key output of 2023 will be a major report into modular’s role in solving the housing labour market crisis. You will be able to read more about that in our next issue.

I also spent some time inside the Energy House 2.0 facility at Salford University. It grabbed national TV and newspaper headlines for its work on better understanding how houses work from a thermal and fabric perspective. Based on an innovative i-Stud structural closed panel timber frame, the e2Home is based in an amazing facility that will see it bombarded with flexed weather conditions, with an array of embedded sensors tracking heat and fabric performance, with results published via Salford University later this year.

Across the construction sector, the need to embed a clear, futureproofed environmental strategy in how your building operates is so important. With running costs and energy bills an ever-present concern, creating a building without one is risky. The e2Home concept house will hopefully prove with hard data what can achieved. Perhaps the new Department for Energy Security and Net Zero will be convinced to help more? Perhaps government can stop the revolving door of housing ministers and/or construction ministers?

However, looking to the future, it was interesting to hear that the BSi is on a mission to create a ‘British Standard for MMC’ and is working with DLUHC to create a universally recognised British Standard geared towards creating recommended technical standards for building homes using a range of offsite categories. Another addition to the vast array of accreditations, quality marks and industry seals of approval but an indicator of the seriousness that offsite manufacture is being taken after decades of being side-lined.

Thanks to all our contributors, advertisers and supporters for their help and support this issue. Enjoy!

Gary Ramsay Consultant Editor

TheGramophoneWorks

YorkSt.JohnUniversityCreativeCentre

28.03.2023

THINK TANK, BIRMINGHAM

SHOWCASING THE BEST IN STRUCTURAL TIMBER

The Structural Timber Conference is open to architects, engineers, clients, contractors, local authorities, housebuilders and developers. The event will shine a spotlight on the 'best of the best' in structural timber, featuring stellar guest speakers from the Structural Timber Awards winners, highly commended and finalists.

CrosfieldsSeniorSchoolBuilding

In partnership with:

STRUCTURAL TIMBER MAGAZINE

PROMOTIONAL OPPORTUNITIES AVAILABLE

For more information, please contact the team on 01743 290044

COVER STORIES

P06

CONTENTS

P24 | MILESTONES IN MODULAR

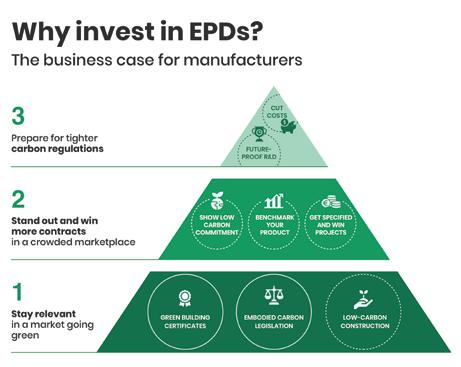

40 | Sustainability at Every Stage

Richard Hipkiss, MPBA’s Development Director, explains why we need to think of the ‘end’ at the initial design stages to enhance a project’s sustainability value chain.

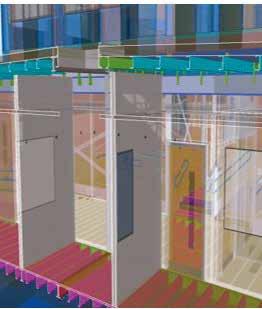

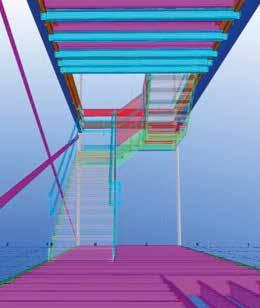

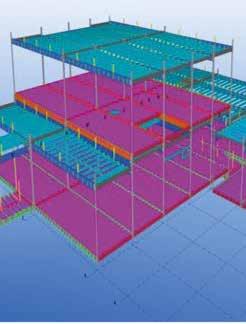

42 | Bringing Co-ordination & Accuracy to Offsite

One company using Trimble’s co-ordinated and constructible Tekla software and leading the way in the offsite sector with its full RIBA workflow approach is Design4Structures.

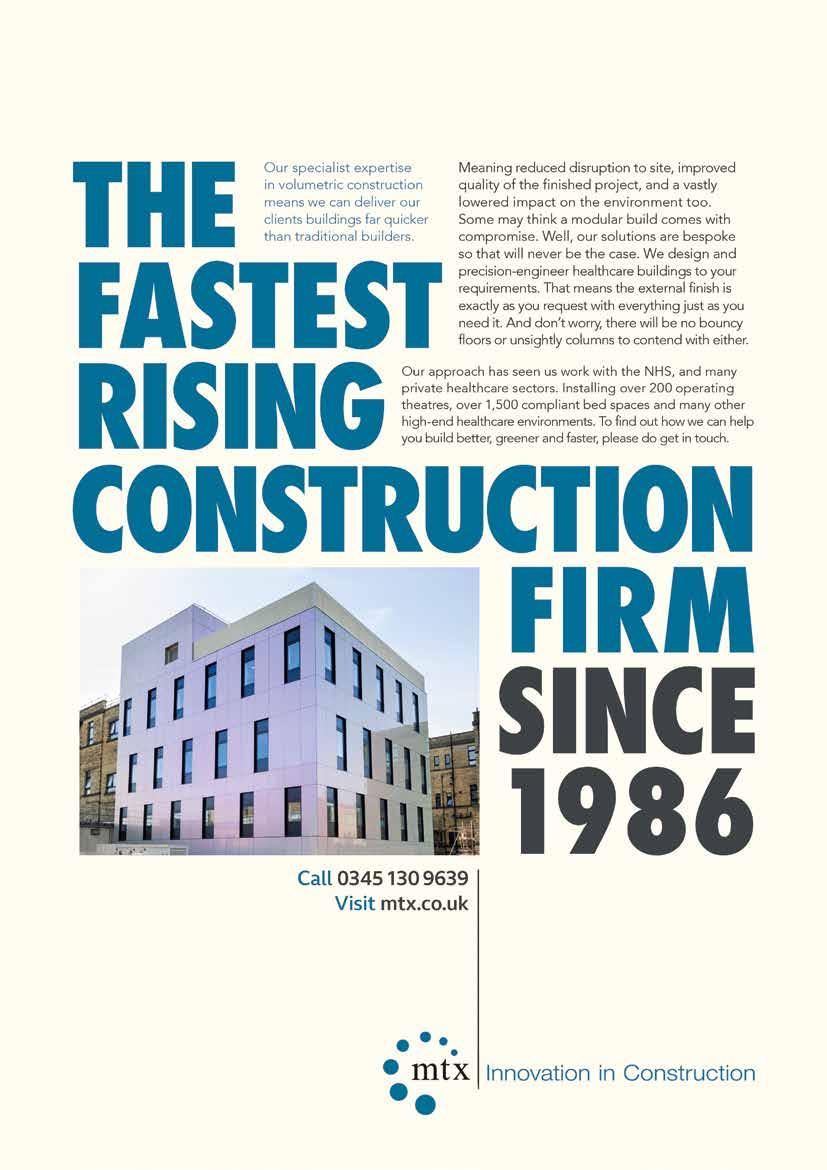

By delivering exceptional Pre-Manufactured Value (PMV), Fusion Steel Framing systems help construction clients achieve exceptional programme and performance benefits. With an eye firmly on the future, Managing Director Mike Fairey outlines his vision for a better built environment.

Make UK Modular is helping promote the benefits of modular homebuilding and bring a fresh focus to the use of offsite technology. Head of Make UK Modular Steve Cole, spoke to us about progress so far and a busy year ahead.

46 | Material Combination

James Mead from Saint-Gobain Weber and Mike Doolan from LoCal Homes, share their experience of combining traditional building products with offsite manufacturing.

54 | Opportunities for LSF Expansion

The UK Procurement Bill will have many implications for the UK’s built environment and should play to the strengths of an offsitedelivered light frame steel approach.

64 | Creating a New Construction Model

The way we build our homes and communities is changing. Richard Lankshear, Programme Director at the Future Homes Hub, outlines how the organisation is providing expertise on the major challenges surrounding carbon reduction and new homes.

As part of a wider project designed to accelerate progress towards low carbon and net zero housing, the pioneering eHome2 concept house built using offsite technology at Salford University will soon enter an intensive testing period to measure the different heating systems and fabric performance.

FEATURES

08 | Industry News

News and developments from across the UK offsite industry and wider construction arena including: Everton FC’s new stadium looks to offsite MEP, Algeco appoints a fresh UK MD, Crown Commercial Service awards huge offsite framework and Celtic Offsite teams up with one of the UK’s leading timber suppliers to reduce its carbon footprint and support the local economy.

30 | Precast Concrete Cladding & Fire Resilience

In recent years the construction industry has begun to re-evaluate building safety with the hope that we never again witness a tragedy on the same scale as Grenfell Tower. MPA UK Concrete explains how precast concrete can improve safety.

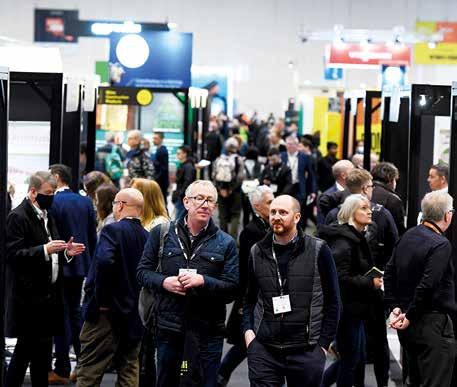

The fifth Modular Matters event recently took place at Birmingham’s NCC, with delegates benefiting from two days of discussion about the most efficient ways to transform the UK built environment.

68 | Modular Routes and Funding Options

Ecology Building Society is launching the UK’s first dedicated mortgage for modular construction homes – could this be a pivotal moment for offsite construction?

74 | Attainable Net Zero Goals

John Charles, General Manager at NG Bailey Offsite Manufacture, explains how the company is embedding a net zero mindset into factory-based design and delivery.

76 | Futurebuild 2023

What is on offer at this year’s show? There will be plenty to interest offsite designers and manufacturers to help them create net zero buildings faster, more safely and more efficiently.

ONLINE PROJECT GALLERY INCLUSIONS

Our project gallery is the perfect opportunity to shout about your successes! The gallery functionality allows visitors to filter by sector and/or technology, then tailor the results according to their specific interest. With over 5,000 visitors every month, the Offsite Hub provides the ideal opportunity for you to reach your target audience.

Our offsite portfolio includes an abundance of profile-raising opportunities and this is just one way you can get involved!

For more information contact a member of our team on 01743 290001

Prices start from £200 for more information visit www.offsitehub.co.uk

COVER STORY FUSION STEEL FRAMING

BOOSTING OFFSITE EFFICIENCY ONSITE

By delivering exceptional Pre-Manufactured Value (PMV), Fusion Steel Framing systems help construction clients achieve exceptional programme and performance benefits. With an eye firmly on the future, Managing Director Mike Fairey outlines his vision for a better built environment.

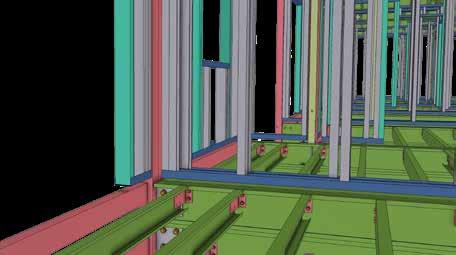

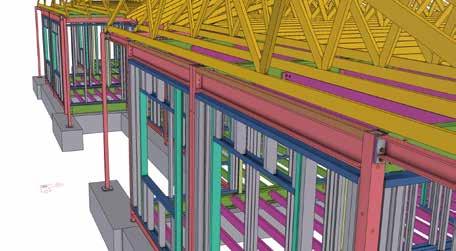

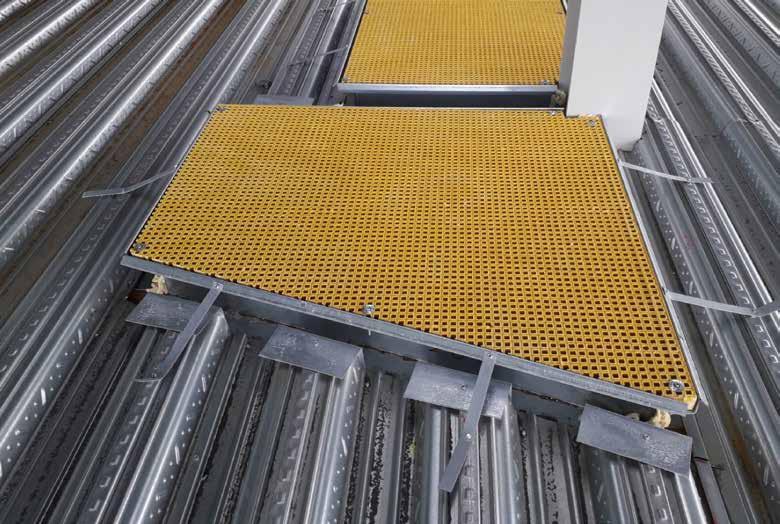

task virtually impossible on occasions. Using Design for Manufacture and Assembly (DfMA) principles, Fusion Steel Framing can take the detailed processes offsite into our advanced manufacturing facility. Our precisionengineered light steel framing systems offer high performance combined with numerous sustainability benefits, as well as creating a much safer working environment for operatives.

1 2

Since inception in 2000, we have delivered more light steel residential structures than any other European producer, working with some of the most prestigious contractors and developers in the UK construction industry. Our focus is now on improving the entire building process and streamlining supply chains through replacing a multitude of construction components with

complete integrated systems. While the supply chain involves many elements, synergy lies in bringing the sum of the parts together both offsite and onsite to achieve construction objectives.

Engineering Excellence

Construction sites can be tough environments. Periods of extreme heat and torrential rain make a challenging

We support our construction clients to achieve exceptional programme benefits through a range of fully integrated panelised solutions backed by comprehensive services from design to installation. Through taking ownership of every building component, we have created an industry-leading solution in our through-wall FusionX™ system which, when combined with the Fusion Xterion™ cladding range, offers a complete through-wall integrated system with precise value-engineering and tried and tested performance. We also have the capability to provide structural kits for volumetric modules, bathroom pods and prefabricated utility cupboards (PUCs) – offering the opportunity for fully integrated structures. From engineering excellence and meticulous manufacturing to fire test certification and acoustic performance, we tailor our light steel framing systems precisely to meet the brief – offering speed of build, high quality and great value.

Collaborative Approach

Our ethos at Fusion has always been one of collaboration, this starts at project inception. As leaders in light steel framing solutions, we have put more than twenty years of knowledge and experience into creating our five-

step construction process. Synergy between our team and the people we work with is key to yielding the best results – focusing on the theory that the combined value and performance of several companies will be greater than the sum of the separate individual parts.

Our digitally enabled methodology focuses on safety, sustainability, efficiency, performance, cost and added value. By being involved collaboratively throughout the supply chain process – visibility and traceability improves dramatically, enabling us to identify opportunities for optimisation and improvement at the right time and avoid complications further down the line. When you build robust relationships throughout the

SYSTEMS OF CHOICE

FusionX™ – Tried, Tested and Approved

supply chain, utilising the benefits of each party’s knowledge, the potential value of the total project is increased. This is what we bring to the table through our five-step Fusion FocusTM process.

Having a team of highly skilled installers results in the efficiency and quality embedded in the offsite design and manufacturing processes being carried right through to the onsite arena. Our vision at Fusion is to be the offsite supply chain partner of choice, helping clients to achieve net zero carbon targets using our FusionXeroTM light steel frame superstructure solution. Quality, innovation and collaboration are at the heart of our company.

As Fusion Steel Framing continues to further its reputation as a market leader at the forefront of the offsite sector, the team is eager to engage with new clients and project teams who would like to find out more about our innovative systems and the overall benefits of light gauge steel framing. The team offers a wealth of knowledge in the steel sector, having advised numerous government and industry bodies, and can provide guidance from project conception through to completion.

For more information visit:

www.fusionsteelframing.co.uk

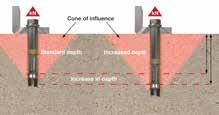

FusionX™ is a fully tested non-combustible integrated walling solution developed in response to Building Regulation changes. Approved by the NHBC, registered under NHBC Accepts, FusionX™ also holds LABC Warranty and is BOPAS accredited. This loadbearing external walling system is SCI and NHBC certified up to 10 storeys and can form part of a structure up to 14 storeys. FusionX™ is factory assembled for fast, cost-effective and quality-assured construction and has been tested thoroughly as an integrated system for thermal performance with fire resistance durations of 60, 90 and 120 minutes predictably achievable. Precision manufactured for rapid installation, FusionX™ can achieve U-values of 0.20W/m2k.

Xterion™ – Innovative Through-Wall Solution

Researched and developed specifically to enhance FusionX™ – Xterion™ is a high-performance, through-wall system that incorporates a range of cladding solutions. Creating a rapid dry building envelope, when combined with FusionX™ this warm frame solution delivers optimum performance values from 0.18W/m2K to Passivhaus standards – depending on the brief and specification. This complete through-wall system is manufactured with a standard build-up of insulation between the studs and a 100mm mineral wool slab outside the frame and is factory-fitted with noncombustible external boarding and is completed onsite with a range of lightweight render, brick and contemporary cladding finishes.

TraX™ – Infill Walling System

Non-loadbearing infill walling system developed for concrete or steel mainframes. Suitable for multi-storey construction across a range of building types, TraX™ is an economic and efficient method of providing facade walls. With layouts engineered to support windows and openings together with additional studs around for lateral tie back for brick channels and brackets for facades. The elements of the primary structural frame consist of a bottom track attached to the floor and a head track fixed to the underside of the floor above, allowing for building deflection.

CCS Announce New Agreement

Crown Commercial Service (CCS) recently awarded a new agreement for offsite construction, aiming to support the public sector to innovate, drive efficiency and continue to work towards their net zero carbon targets.

The Offsite Construction Solutions (RM6184) agreement reflects continuous offsite innovations and will broaden the premanufactured building solution provision currently available to public sector buyers through CCS agreements. It will have an increased scope to include more MMC categories, specifically 2D panelised structural systems and panelised external building retrofits, as specified within the new MMC Definition Framework.

The agreement will continue to align with the policies outlined in the Construction Playbook on offsite construction adoption. It replaces the Modular Buildings Agreement which closes on 1 April 2023. It has been designed to assist all public sector customers, with a specific focus on the health, housing, education, justice and defence sectors.

In a bid to help the public sector to continue to meet their carbon net zero targets, a specific lot (Thermal Efficiency Upgrades) has been introduced to address the increasing demand to retrofit existing estate portfolios with thermally efficient external systems. The new agreement aims to build on the progress made on making it easier for small and medium-

Launched in January 2023, The Offsite Guide (TOG) is a new B2B marketplace in the UK and Europe for businesses to explore options for using offsite methods and interact with specialist manufacturers.

As a marketplace TOG facilitates engagement between key market participants and drives awareness of the many benefits of MMC including more efficient production, economies of scale and repeatability. In doing so it provides a central point of reference for product variety, availability, and pricing specification. Crucially, it provides a platform for direct communication between a wide range of providers and their potential customers in this fragmented market.

Ingrid Orbie, TOG Director said: “At The Offsite Guide we attract and facilitate early interaction with customers, allowing manufacturers of commercial and domestic modular buildings and offsite solutions to

sized enterprises to become suppliers. It includes 29 suppliers, 18 (62%) of which are SMEs. The agreement will run for four years with the possibility of a three-year extension and there is no maximum duration for call off contracts. It includes:

• A simple six lot structure, encompassing an increased range of premanufactured building turnkey solutions within a single, consolidated agreement

• Promotes the standardisation of building design across large portfolios of government infrastructure, therefore enabling greater efficiencies of time and cost savings through the project lifecycle, saving the taxpayer money

• The new agreement aims to make it easier for clients to contract with SME organisations, with 62% of suppliers being classed as an SME

• Public sector contracting terms and conditions create an easier, more flexible route to market, tailorable to customers’ specific operational needs

• An evaluated pool of suppliers allowing customers to drive cost reductions and increase value for money through healthy competition.

John Welch, Deputy Director – Construction, Crown Commercial Service said: “This new framework will support the public sector in the design, delivery and commissioning of a whole range of offsite construction projects in the coming years, including social housing, new schools and hospital extensions. These projects, and the many more which will come, have the potential to improve services and the lives of millions of people. It is yet another example of how CCS is helping the public sector to support the government’s construction strategy and further supports the recently published refresh of the Construction Playbook with its MMC guidance note.”

To find out more about Offsite Construction Solutions (RM6184) visit www.crowncommercial.gov.uk or contact the CCS Service Desk at: info@crowncommercial.gov.uk

showcase a range of their products and help educate potential customers. We provide a trusted platform not only for showcasing offsite construction, but also to facilitate initial dialogue and ongoing interaction between customers, manufacturers and MMC suppliers.”

Whether listing as a TOG Partner on the marketplace or as Advertiser in the Directory, TOG offers an opportunity to raise brand awareness, increase a company’s visibility and gain access to new customers. Through TOG’s marketing and launch promotion campaigns TOG is striving to elevate MMC sales channels and engage with the market in a more efficient and effective way. The TOG marketplace facilitates that search for proven solutions and gives examples and case studies that show ways that organisations and developers can break tradition and drive efficiency using MMC.

Source: www.theoffsiteguide.com

wedi Sanwell® shower wall module

with factory-integrated, sealed Hansgrohe iBox & waterpipes

√ to suit over 200 thermostatic mixer designs

√ use as a fixed wall or as a free-standing partition

√ directly tileable, 100% waterproof and adjustable on site

√ in 900mm or 1200mm width and 80mm or 100mm thickness

√ individualisation options to meet customer specific needs (i.e. niche)

√ reinforcement plates for shower head attachments at selectable heights

M-AR Teams up with Centrepoint for New Homes

Specialist offsite contractor, M-AR is nearing completion on an ambitious newbuild project in partnership with the UK’s leading youth homelessness charity, Centrepoint. The project’s goal was to create single occupancy homes for young people experiencing homelessness in London – a first for the charity which up until now has relied on refurbished accommodation.

Centrepoint provides housing and support for almost 13,000 homeless young people every year in London, Manchester, Yorkshire and the North East. Its bold new Independent Living Programme aims to pair over 300 young people with a job and a home across London and Manchester within the next three years and this new development, which will be known as Reuben House, in Peckham is the first step.

M-AR manufactured 33 modular homes in its factory to create the new two storey apartment building. The design features repeatable modular units that can easily be delivered on multiple sites – which means Centrepoint and M-AR will be able to replicate this model on future projects as the Independent Living Programme rolls out to other locations over the next five years.

Each self-contained 21sq m home has its own private access, a small functional kitchen, dining area and a

bathroom as well as space to sleep and relax, making the units a comfortable home for young people to live independently. The homes were delivered to site fully fitted with the kitchen and bathroom, with all electrics and plumbing installed as well as being fully decorated throughout for greater programme efficiency.

Another key aspect of the project was to ensure each home was as energy efficient as possible to keep future running costs low for residents, which has become even more important as the cost of living crisis continues. The homes have energy-saving features including photovoltaic (PV) solar panels and air source heat pumps to reduce energy consumption and shield residents from spiralling costs.

As well as offering Centrepoint cost predictability from the outset, the use of offsite building techniques provided a solution to the specific constraints of this project including its location on an extremely tight site. By moving much of the first and second fix works offsite and into M-AR’s factory, it freed up space on site while also minimising disruption to the local community during the build.

The new homes had to meet the requirements of the London Plan, the new spatial development strategy for Greater London, as well as the latest

building regulations governing energy efficiency. The development also had to fit seamlessly into the local neighbourhood - the landscaping and exterior cladding works perfectly achieve this aim.

Ryan Geldard, Director at M-AR said: “It’s a privilege for us to be able to do our bit to help Centrepoint in its mission to end youth homelessness by delivering these new safe and secure independent living homes. We’ve worked closely with the whole team to make sure that the units are perfectly suited to the young people who will call them home and it’s great to see them starting to be occupied and know that our job is here is done. We’ve learnt a lot from this build and are looking forward to the next project with Centrepoint.”

Sally Orlopp, Director of Centrepoint’s Independent Living Programme, said: “It has been a real privilege to watch these units turn into homes over the last few months. M-AR and our other partners have been fantastic in helping us take this first step towards building 300 homes for those people under 25 ready to escape homeless but unable to afford skyrocketing rents. We can’t wait to hand over the keys to our new tenants who will now have the space and stability they need to stop worrying about the roof over their head and get on with achieving their ambitions.”

Source: www.m-ar.co.uk

ilke Homes and Man GPM Start Work at Glenvale Park

Leading modular housing pioneer ilke Homes has started work to deliver 146 energy-efficient, affordable homes at the Glenvale Park development in Wellingborough, as part of Man GPM’s community housing focus.

The announcement marks the second time ilke Homes and Man GPM have worked together to deliver an affordable-led scheme, having struck a £31million deal in December 2020 for a 226home affordable housing development in Grantham, Lincolnshire. The 7.8-acre site forms part of phase one at Glenvale Park, which once complete, will deliver a total of 3,000 homes, over 200 acres of parkland, a new local centre and two new schools.

The wider masterplan for Glenvale Park is expected to generate more than 3,000 jobs and £1.4billion in economic impact for the area – with £2 of social value generated for every £1 spent during construction. Having received approval from North Northamptonshire Council, ilke Homes has started work delivering a mix of multi-tenure single family houses, apartments and maisonettes, ranging in sizes from one to four bedrooms homes.

The homes – which are due for completion in 2024 – are being manufactured offsite at ilke Homes’ 25,000sq ft factory in North Yorkshire. With a likely EPC rating of A, the properties are in the top 5% nationally for energy efficiency, with the knock-on effect of saving consumers hundreds of pounds a year on energy bills. Thanks to most of the build stage taking place offsite, traffic disruption to the local community will be kept to a minimum.

Tom Heathcote, Executive Director of Development at ilke Homes, said: “This scheme is testament to the continued confidence our customers have in our product, and we’ve enjoyed working with local planning officials and other stakeholders throughout

Algeco UK Appoints New MD

Algeco has appointed Keith Dorling as UK Managing Director. The announcement comes as increased demand and recent acquisitions open up new opportunities for the UK business and its customers.

Keith takes overall responsibility for Algeco in the UK, a role that encompasses modular hire solutions and permanent offsite buildings. Algeco continues to grow its presence in the UK with the recent acquisition of Mobile Mini. This follows on from Carter Accommodation Ltd and Procomm Site Services Ltd being added to the Algeco portfolio in early 2021/2.

the planning process and into the construction phase. After the success of our first joint scheme in Lincolnshire, we’re delighted Man Group have shown the confidence in us to deliver a second sustainable urban development scheme together.”

Man Group’s Community Housing team seeks to achieve the dual objectives of providing both social and financial returns, addressing the housing crisis in the UK by building homes that are affordable to households. The UK has experienced a significant, long-term mismatch between supply and demand in the housing market, which has led to an affordability crisis impacting households earning the median income and below. The team deploys institutional capital to build new homes with the aim of generating positive returns for investors and delivering a demonstrable social impact.

Shamez Alibhai, Managing Director and Head of Community Housing at Man GPM, said: “The development at Wellingborough is an exciting

demonstration of how like-minded partners can deliver homes that address the housing challenges of families. ilke’s track record on housing delivery and its commitment to innovation fits naturally with our focus on social and environmental responsible investment.

Mark Best, Director of Midtown Capital Ltd, managing partner of Glenvale Park LLP also added: “As a leading provider of sustainable modular properties, we’re delighted to welcome ilke Homes and Man Group to Glenvale Park. With the range of properties and mix of tenures available, the new homes will be an exciting new offering to our growing community. With hundreds of families calling Glenvale Park home, there is already a strong sense of community spirit within the development. We can’t wait to see that grow further.”

Source: www.ilkehomes.co.uk

Keith joins Algeco with extensive senior leadership experience across construction, infrastructure and distribution: including successfully leading complex acquisitions and integrations across multiple sectors. This is an exciting time for Algeco and Keith will be supporting the team’s future success, and strengthening the business where it adds value to the customer proposition.

Keith explains: “I am delighted to have joined Algeco, an organisation that has solid foundations built on excellence, innovation and collaboration. The strong team of people and competitive positioning of the business means that I am confident we can continue to achieve great things on behalf of our customers.

We have a major role to play in delivering the Group’s sustainable strategy through our commitment to innovation and collaborative relationships. I look forward to working with all our stakeholders to make a lasting positive impact on the built environment.”

Mark Higson, Group Chief Executive Officer of Modulaire Group, added: “I am delighted Keith is joining us to lead the next phase of our growth in the UK. His focus on operational and commercial excellence along with his people-first approach, means that he is well-placed to lead the Algeco UK business and help to deliver our medium-term plan.”

Source: www.algeco.co.uk

Vinci Building Choose Pod Technology for Bristol

Offsite Solutions has been awarded its second student living contract at the University of the West of England’s Frenchay Campus in Bristol – a £1.7million project to manufacture 757 bathroom pods for VINCI Building.

Offsite Solutions has delivered 16 pod projects for VINCI Building to date which includes major student accommodation schemes for universities in Swansea, Cardiff, Coventry, and Liverpool. This latest project is for the University of the West of England (UWE Bristol) – and it is Offsite Solutions’ third for this university. This highly sustainable development is one of the largest Passivhaus projects in the UK. It is designed to provide a high level of comfort for students whilst using very little energy for heating and cooling, helping UWE Bristol and VINCI Building to meet their environmental aspirations.

As part of the certified low carbon strategy, the buildings aim to yield a reduction of around 50% in running costs and carbon emissions. To help achieve this, the cold water pipework in the bathroom pods will be insulated and the thermostatic shower and mixer taps for the hand basins are designed to run at lower temperatures. Both of these measures will reduce energy consumption for heating hot water.

Steve O’Leary, Regional Business Services Manager at VINCI Building, said: “I have managed the procurement and delivery of around 3,500 pods manufactured by Offsite Solutions in the past nine years. Their approach suits VINCI Building’s model of student accommodation very well. They have robust factory testing processes in place which mean the quality is better and more consistent. In my view, Offsite Solutions’ pods are the best in their sector and I would not hesitate to recommend.

“This solution reduces the numerous trades for bathroom construction to a single supplier, which results in a considerable time saving. Each bathroom typically takes around three weeks to construct traditionally, whereas with offsite manufacturing, we just have to position the pods, make connections, and hang the doors. This is incredibly fast.”

James Stephens, Managing Director of Offsite Solutions, said: “This is an exciting development

which will help to meet the rising demand for modern, high quality student living whilst demonstrating a clear commitment to addressing climate change issues. It is a ground-breaking project which will set new standards for the development of sustainable student accommodation.”

Due for completion for the 2023/24 student intake, this phase of the Frenchay Campus development will provide 900 bedspaces in three buildings spanning over 26,000sqm and in clusters of four, six and eight bedrooms and with ensuite or shared bathrooms. The shower pods have a robust and low maintenance GRP construction. Each will be fully finished in Offsite Solutions’ Somerset factory and will be fitted with a D-shaped wall-mounted hand basin, wall-hung toilet with dual flush, thermostatic shower, and sliding shower door.

Source: www.offsitesolutions.com

Britlift are a designer and manufacturer of lifting equipment, specialising in the lifting of modular homes, bathroom pods, commercial modules, containerised structures and pre-cast components.

With a wealth of experience in the design and manufacture of lifting frames and lifting systems to the Offsite Construction sector, Britlift are the Offsite sector partner of choice.

Celtic Offsite Teams up with Premier Forest Group

Caerphilly-based social enterprise, Celtic Offsite, has teamed up with one of the UK’s leading timber suppliers, Premier Forest Products, as part of their ambitious plan to develop a Welsh supply chain to reduce its carbon footprint and support the local economy.

Celtic Offsite, part of the United Welsh Group, manufactures low carbon homes by producing high quality, sustainable timber frame structures, complete with factory fitted insulation and windows, to build up to 250 low carbon homes a year.

Premier Forest Products was initially approached by Celtic Offsite to supply Oriented Strand Board (OSB) for sheathing for timber frame panels, plywood and chipboard. However, thanks to Premier’s growing product offering, they have recently started supplying roof trusses, engineered floor joists and Laminated Veneer Lumber (LVL) for structural beams, taking Celtic Offsite ever closer to their goal of using Welsh suppliers for more of their manufacturing work.

Neil Robins, Managing Director of Celtic Offsite said: “We are actively committed to making the areas in which we work better and more environmentally sound. We have been certified as a Climate Positive Business by Earthly, meaning we will remove more greenhouse emissions than we produce. One of the ways that we will do this is by working with local suppliers who have a similar mindset to our own. We have been so impressed by the service and quality of

Construction Starts on Europe’s Largest Modular Housing Facility

the products supplied by Premier Forest that we have consistently increased the range of items that we order from them.”

Co-founder and CEO of Premier Forest Products Terry Edgell said: “As an organisation, we firmly believe that the use of timber should be at the forefront of sustainable housing development. At the moment, wood in construction is the only commercially viable carbon capture and storage system so, simply by using more wood in construction, we can turn our built environment into a weapon against climate change. It is so inspiring to be working with an organisation in Wales that not only recognises the benefits of using timber but is actively working to build a sustainable supply chain, hopefully changing the way that homes are built.”

The new facility will bring together the latest robotics and TopHat’s proprietary technology to manufacture and distribute up to 4,000 homes per year. Construction will be commencing shortly at the new site and expected to be complete later this year. The factory will then be fitted out with its bespoke state-of the art robotic production line and will deliver its first units during 2024. The new facility will be built to BREEAM Excellent standard.

Key to the success of the new facility is the partnership TopHat has established with local colleges – branded the TopHat Academy – to support local people looking to train or retrain for roles in the new facility. A key part of the investment in skills will be supporting apprentices who will be approximately 5% of the employees on day 1 rising to 20% over three years.

Premier Forest Products is a vertically integrated timber operation engaged in the importation, sawmilling, processing, merchanting, and wholesale distribution of timber and timber products from its 12 sites in the UK. As part of its commitment to the local community, Celtic Offsite offers an on-site training suite to provide skills development and apprenticeships for green construction jobs. Celtic Offsite has also achieved PEFC certification for the chain of custody of forest-based products and was awarded Gold by the Structural Timber Association (STA) in their latest audit.

Photo: (L) Neil Robins, Celtic Offsite, and (R) Terry Edgell, Premier Forest Products

Source: www.unitedwelsh.com

Commenting on his visit to the site, Tom Pursglove MP for Corby & East Northamptonshire and Minister of State for Disabled People, Health and Work, said: “It is fantastic to see a major step forward in a scheme which will create a thousand new jobs here in Corby and play an important part in bringing making beautiful, low carbon 3D modular homes much more widely available. I am particularly pleased by the partnership with Bedford College and commitment to skills and training through the TopHat Academy. I look forward to seeing the factory again when all the robots have been installed.”

Tom Pursglove MP, the Conservative MP for Corby & East Northamptonshire, recently visited the construction site where 3D modular housebuilder TopHat will open Europe’s largest modular housing facility in 2024. The cutting-edge 650,000sq ft factory (equivalent to the size of 11 football pitches), will be capable of manufacturing a home every hour and will create 1,000 highly skilled new, green jobs across a wide range of roles.

TopHat is already at the forefront of a housebuilding revolution, applying robotics and lean manufacturing techniques to increase housing supply, improve quality, reduce costs and protect the environment. TopHat has pioneered an ultra-low carbon approach to building and operating homes, which significantly reduces household cost at a time when the cost-ofliving crisis threatens to plunge millions of families into fuel poverty.

Jordan Rosenhaus, CEO and Founder of TopHat, said: “The cost of living and housing crises, and climate emergency, require a bold approach that harnesses innovation to manufacture high-quality low carbon homes. TopHat’s new facility will ensure that Corby is at the heart of this revolution in house building, all the while creating 1,000 highly skilled, green jobs.”

James Atkinson, Development Director at GLP also commented: “Magna Park Corby is GLP’s third Magna Park site in the UK. With anchor tenants like TopHat, the site will make a huge contribution to the local community providing jobs, professional training and public realm for the benefit of all.”

Source: www.tophta.io

From interim housing for the homeless to on-the-spot overnight accommodation for keyworkers...

MODULHAUS™ provides award-winning, energy efficient and secure accommodation

...rigorously tested to ensure outstanding performance and quality

Offsite Transforms Worcester Nightclub into Student Accommodation

NHBC Accepts Welcomes Etopia and Istidama

The former site of Images Nightclub in Worcester has been transformed into 83 student flats, with Intrastack supplying the steel-frame structure and the installation being undertaken by installer, Intastruct, on behalf of the main developer, Spec Projects.

Intrastack, part of the Saint-Gobain Off-Site Solutions division, manufactured and delivered the light gauge steel frame (LGSF) system which saw three installers erect the seven-storey student accommodation block in just 10 weeks. A recent report considered there to be a lack of purpose-built accommodation (PBSA) in Worcester, with the existing stock made up mainly of conversions, houses in multiple occupation (HMO) and existing halls. With these low levels of vacant PBSA facilities in the city, the Images project aimed to provide modern rooms for the student population. With over 10,000 students at the University of Worcester, local plans to increase PBSA aim to reduce pressure on the on-street rental market to free up accommodation for families. Meanwhile, meeting the specific needs of students with purpose-built and managed schemes makes the city an attractive prospect to future learners.

The old Images nightclub site, demolished late in 2021, now houses the new seven-storey accommodation. The building comprises five selfsupporting storeys of light gauge steel frame panels atop a two-storey concrete base. The speed of construction was noticeable to onlookers, as the work took place over just 10 weeks – a reduction from the originally scheduled 12 weeks – and was noted as one of the reasons for the developers choosing LGSF for the project in the first place. The system also required fewer installers on-site at any given time, with most of the work completed by a team of three.

Rapid turnaround of design and materials, as well as the speed of installation and safety benefits, were also indicated as reasons for going with offsite steel frame manufacture. Capitalising on LGSF’s shorter construction times can provide developers with a quicker return on investment, as students are able to move in sooner than they would be able to with a traditional build.

The build site, which was first used over 150 years ago, is very restricted with limited space available for storage of the steel panels needed for the construction. Intrastack scheduled and delivered the panels to the site on a ‘just-in-time’ basis, working with the installer to ensure materials were on site as and when they were needed. This also reduced the waste on-site at any given time, with all system elements arriving cut to size.

Andy Higson, Business Director at Intrastack, said: “This year, PBSA in the UK has surpassed 30,000 rooms for the first time, showing that there’s demand for this type of housing. An offsite approach is essential to deliver on the scale required. LGSF systems can help developers to build accommodation faster while tackling on-site challenges such as safety risks and labour shortages. When you discover how much smoother it makes the process, it becomes a no-brainer.”

Paul Hazelwood, Contracts Manager at Intastruct, the system installers, added: “There’s no doubt that the steel frame system sped up the job, and allowed us to comfortably build a storey every two weeks. It’s a fast system, and incredibly robust.”

Source: www.intrastack.co.uk

NHBC, the UK’s leading warranty and insurance provider for newbuild homes has welcomed Etopia and Istidama to NHBC Accepts with its 4wall panel. NHBC Accepts enables quicker assessment of a home for warranty and reduces the risk to the builder of delays in their project. Any product or system with the NHBC Accepts logo will have been rigorously assessed to ensure it can meet NHBC’s robust standards, giving confidence to developers, investors, lenders and homeowners.

Etopia, a leading provider of offsite solutions, and Structural Insulated Panels (SIP) manufacturer Istidama are proud to announce that they have been awarded the NHBC Accepts accreditation for the 4wall patented hyper SIP. Etopia’s commitment is to innovate, design, manufacture, deliver and install a high-performance building system for residential and light commercial construction.

The flexibility of the system allows any housetype to be designed using ‘stock’ small or large panel formats. The system provides high structural strength, airtightness, and low U-values of 0.144 W/m²K creating incredibly energy efficient houses and buildings. Projects using the system will have a high pre-manufactured value (PMV) due to full elevations, internal walls, intermediate floors and roof trusses manufactured offsite; more than 55% can be achieved when combined with other PMV products.

Alexander Fink, Executive Director of Etopia, said: “Etopia is a pioneering force in the modern methods of construction industry, pushing the boundaries of what is possible and demonstrating the potential for offsite construction to revolutionise housebuilding and achieve net zero carbon emission. We look forward to working with NHBC on offering warranties on upcoming schemes. Our partnerships with leading financial institutions and global technology companies mean that Etopia offers the best sustainable product on the market.”

Nicholas Edwards, Managing Director of Istidama, added: “We are very pleased this year to add NHBC Accepts to our list of accreditations alongside Etopia's BOPAS, our KIWA BDA Agrément certification and triple ISO accreditations. The 4wall panel system is now one of the most widely accredited systems using modern methods of construction in the UK.”

Source: www.etopia.eco

Donaldson Timber Systems Secures OSHA Position

Donaldson Timber Systems (DTS), has secured a position on the Off-Site Homes Alliance (OSHA) national construction framework for volumetric (CAT 1) and panelised (CAT 2) Modern Methods of Construction (MMC). The framework is valued at £2billion. DTS will deliver offsite timber panelised system build for Category 2 housing over four years.

Working closely with 23 local authorities and housing associations nationally, DTS will design, manufacture and install timber frame wall panel building systems that meet build speed, fabric performance, building design and cost requirements. With a fabric-first approach that achieves net zero operational carbon, housing providers can use DTS’ timber systems to create sustainable, resilient, and affordable homes that meet the Future Homes Standard.

Earlier this year, DTS became one of the first manufacturers to achieve Buildoffsite Property Assurance Scheme Plus (BOPAS Plus) in recognition of the quality and durability of its offsite build systems. With DTS’ state-of-the-art open and closed panelised systems – Alpha, Delta or Sigma ll – works can still be carried out on-site, ensuring that social value potential is reached within the communities served.

Mike Perry, Business Development Director, Donaldson Timber Systems, said: “By securing a position on the OSHA MMC Cat 1 and Cat 2 Framework, we can build upon our strong relationship with affordable housing providers nationally and bring them along on DTS’ timber frame, fabric-first journey. We look forward to facilitating greater efficiency and value for clients who procure via this framework and supporting OSHA’s mission to deliver 20,000 homes with MMC technology.”

Matthew Harrison, Chief Executive of OSHA member Great Places Housing Group, said: “We’re delighted to be working with Donaldson Timber Systems on the new OSHA framework. We’re confident they will be able to work with us and the OSHA clients in delivering the sector’s extensive development

ambitions. We were pleased with the positive response from the market and received high quality proposals and substantial social value pledges for our communities. We are now looking forward to mobilising the framework and working together on new projects to realise our ambitions of delivering much-needed affordable homes.”

With unrivalled experience and knowledge in offsite construction, DTS has an established history of bringing new commercial and operational innovations to the market with the Sigma II closed panel system, offering near-Passivhaus standards of performance and sustainability.

Source: www.offsiteha.org

www.donaldsontimbersystems.com

Safety Storage Efficiency

Kier JV Created with McAvoy and Metek

Kier, with Joint Venture (JV) partners, McAvoy and Metek has been appointed to all six Lots of Crown Commercial Services’ (CCS) new £10billion Offsite Construction Solutions (OCS) framework. The new framework replaces the existing modular building framework and will run for the next four years.

Kier has created two unique JVs with external offsite manufacturing partners McAvoy and Metek, who are both experts in their method of construction, bringing high quality, innovative design, manufacturing and installation ability. The two JVs will allow Kier to deliver on every Lot in the OCS framework, which provides public sector organisations with all elements of offsite construction solutions, from design, fabrication, construction and installation, through to direct access to manufacturers.

• Kier with manufacturer McAvoy, known as Kier McAvoy, will deliver projects using pre manufactured 3D primary structural systems

• Kier with manufacturer Metek, known as Kier Metek, will deliver projects using pre-manufactured 2D primary structural systems.

Stuart Togwell, Group Managing Director at Kier Construction, said: “Building on the ambitions of the Construction Playbook of using MMC and offsite solutions to drive improvements is a core imperative

FHP MEP Specified for Huge Wembley Project

for Kier, and securing a place on all Lots means we are well-placed to support the delivery of vital new infrastructure in the UK. Our forward-thinking JVs with McAvoy and Metek will allow us to provide more capacity and high-quality end-to-end solutions for our public sector clients and to continue to deliver the best value through innovation across the wider industry.”

Ron Clarke, CEO, McAvoy, from the Kier McAvoy consortium, added: “This is a significant milestone for McAvoy, and we are delighted to be combining our leading-edge, high-quality precision manufacturing capabilities with Kier’s scale and expertise. We have been innovators and market leaders for more than 50 years. Our team is firmly focused on delivering consistently high-quality product and customer service across the UK and Ireland. With significant experience of MMC we are very much focused on helping our clients meet their ESG goals. We look forward to working in partnership with Kier to deliver on that commitment within the OCS framework.”

Oliver Rogan, Managing Director of Metek, said: “Winning this OCS framework has demonstrated the importance of working as a team. Metek and Kier have been working closely together for the past 12 months, driving a strategy to build projects in a more energy efficient and cost-effective manner, whilst maintaining the very highest health & safety standards. This ground-breaking collaboration unlocks Metek’s manufacturing and installation potential, whilst enabling us to grow, learn and develop alongside a formidable Kier team.

Building services and engineering consultants FHP has been specified to provide MEP and design services for a multi-million-pound residential led mixed-use regeneration project in North London.

The firm is providing a range of RIBA Stage 3, 4 and 5 MEP technical and construction Revit design services to the city’s leading residential-led mixeduse developer Regal London, which is leading the £270million redevelopment of the former Euro Parts headquarters in Wembley. The site is currently being transformed into 759 new residential units across five high-rise buildings, which will feature 78 three-bedroomed family homes and more than 200 affordable properties. It all comes under plans to deliver a sustainable mixed-use development in line with the local authority’s wider aspirations for the growth and prosperity of the Wembley area.

More than 33,000sq ft of flexible commercial space is also under construction to accommodate retail, light industrial and logistics businesses. New communal amenity spaces within the upper roof terraces and at podium level area will eventually feature along with new landscaping, improved public access along the Wealdstone Brook, and the creation of 31,000sq ft of children’s play space.

FHP has been closely involved in the project from the start of RIBA Stage 3 providing mechanical, electrical and public health services together with sustainability, building physics and digital engineering support for

“Here at Metek, we have been at the forefront of light steel framed Modern Methods of Construction for over 23 years. I feel that this new alliance is a game changer in terms of adding components to the manufacturing process. Working with the Kier team on this bid has been inspiring and the whole Metek team are excited to be embarking on this journey and committed to delivering the key requirements of the agreement, whilst continuing to champion UK manufacturing.”

Photo: Oliver Rogan, Managing Director, Metek with Kier’s, Chief People Officer, Louisa Finlay

Source: www.kier.co.uk

what is being seen as one of North London’s most prestigious regeneration projects.

A key aspect of FHP’s work centred on a review of proposed heating systems, developing two design options for either a 100% electric heating scheme or an alternative connection to a local district heat network. This allowed the developer to decide the best approach – a 1.7MW ASHP (air source heat pump) in conjunction with 1.7MW electric boilers –as part of a revised energy strategy submitted within the overall planning submission.

Services to facilitate design stage and As-Built SAP and SBEM energy use and carbon emissions calculations were also completed by FHP as part of a comprehensive package of support. The Regal London project is the latest success for rapidly growing FHP, which employs 52 people and continues to see strong demand for services and growth across its London and Leeds operations.

Tony Hewitt, FHP Managing Director, said: “Fulton Road demonstrates the added value and insight we bring to multi-million-pound investment projects through innovative design-led MEP services. It’s also a reflection of the excellent work our team provides as we develop our commercial offering. We expect to see a strong

Source: www.fhpp.com

what will you take a stand for?

Build a better future for the built environment

Futurebuild provides the stage for inspiring ideas, innovative solutions & knowledge sharing to drive sustainable construction and help us reach our goal of net zero. The exhibition brings together the entire supply chain to showcase, debate and understand the advancements in sustainable construction and the emerging technologies that will make net zero possible.

Futurebuild is taking a stand for a better built environment and is urging companies and professionals throughout the construction supply chain to make a similar commitment by ‘taking a stand’ on an issue they passionately believe will help propel the industry towards a more sustainable future. Join us in taking a stand.

SCAN HERE

Merit Expands Team and Factory Capacity

Northumberland-headquartered Merit has announced a 4000sq m factory expansion at its Cramlington site, to accommodate its plans for continued growth. Merit already has one of the largest construction manufacturing facilities in the UK at 270,000sq ft (25,084sq m) and it is now extending its factory space to address increasing demand and to better meet customers’ needs.

In line with its impressive growth plans, Merit has already doubled its workforce in the last two years and expects this facility expansion to add over 50 new jobs. The extended high-bay facility will accommodate two new manufacturing lines for Merit’s UltraPOD+ product, an expandable full building solution, and will enable the pre-assembly and testing of two-modules vertically stacked.

This provides an enhanced understanding of the alignment of modules prior to the transportation to the site. Additional equipment, such as two 50T gantry cranes and a module lifting frame, will also be included into the new setup. The factory expansion will enable Merit to compete even more successfully for larger contracts against global competition and deliver long term growth for the business and is expected to be operational by April 2023.

Net Zero Roadmap Examines Carbon & Cost Savings

Tony Wells, CEO of Merit, commented: “Merit’s strategic objective is to deliver a step change in productivity within the construction industry and to show that investment in R&D and leveraging innovative approaches, such as advanced 4D BIM modelling technology, can lead to significant improvements. Our factory expansion will enable us to further optimise our way of working and better serve our customers.”

Merit has also announced plans to double its apprenticeship targets in 2023, as part of its ongoing efforts to address future skills needs. This follows the latest report from the Construction Skills Network (CSN) which predicts that an extra 7,900 workers will be needed in the North East from 2023 to 2027 to meet construction demand. If projected growth is

met, the construction workforce in the UK will remain around 2.67 million.

Merit has been committed to investing in homegrown talent for many years, starting its apprenticeship programme back in 2013. It has so far worked with nearly 60 local apprentices, in which all have received a full-time employment offer once completing the programme. Now in its tenth year, Merit plans to create a further 20 opportunities this year to help meet the business’ need for more skilled workers following a string of successful project wins, including the UK’s first CAR-T cell manufacturing facility for Autolus Therapeutics and Piramal’s ACD manufacturing facility expansion. (For more on this project see p50.)

Source: www.merit.co.uk

to better meet the needs of a low-carbon world. Commissioned by Timber Development UK (TDUK) in collaboration with eleven UK timber trade associations, the Timber Industry Net Zero Roadmap was developed following a

comprehensive

effort to map and measure carbon emissions across the whole supply chain.

The first step of the roadmap has been to outline the size of the challenge, with 12 months of expert analysis showing the timber supply chain is responsible for 1,575,356 tonnes CO2e territorial emissions – which is about 0.35% of the UK total.

While this is very low compared to other manufacturing industries such as UK steel production, which is responsible for 12 million tonnes CO2e (2.7% of UK emissions), and concrete, which is responsible for 7.3 million tonnes CO2e (1.5% of UK emissions), the Roadmap starts from the position that no emissions are acceptable.

The Roadmap also seeks to influence the 3,655,715 tonnes CO2e of imported embodied emissions which comes from the processing of wood products in the country of origin. This figure, taken together with territorial emissions, would make the timber industry responsible for about 0.68% of the UK’s total emissions. Of the total consumption emissions, 49% of these emissions are from the transport of timber products, and 34% are embodied in imported materials. The remaining 17% are from the UK production processes within the industry, and waste.

One of the key aims of the Roadmap says Timber Development UK Sustainability Director Charlie Law, is to challenge the misconception that as the timber supply chain comes from a low-carbon base, there

are few opportunities for the timber supply chain to influence their emissions.

“There are some really quick wins in there for businesses – wherever you are in the supply chain –which can be put into practice now. And if you reduce your carbon, you reduce your costs. If you change the energy source for heat for your factory processes, reduce the waste from your product manufacture, or reduce your energy use by using better lightbulbs – there are literally thousands of ways both big and small you can start reducing your emissions.

“This includes for the single biggest contributor to the timber industries carbon profile – transport. While there aren’t yet many fully electric HGV options, to remove these emissions, there are ways to be more efficient. And if you’re using less diesel, you reduce your emissions and your fuel costs. Once you have an emissions profile for your business, you see not just your environmental impact, but also your operational inefficiencies. From here you can start your business on a pathway to be more competitive in a low-carbon market.”

With a range of pathways now set out in the Roadmap for the industry to achieve Net Zero by 2050 – at the very latest – this document has been made freely available for all businesses in the timber supply chain to adopt, alongside a set of ten highlevel policy recommendations.

Source: www.timberdevelopment.uk

Anew timber industry net zero roadmap aims to accelerate the productivity, sustainability, and innovation of the sector

Integra Buildings Appointed to CCS Offsite Framework

Modular specialist Integra Buildings has been appointed onto a £10billion Government framework to drive investment in the offsite construction sector. Integra has been named as a supplier on the newly launched Offsite Construction Solutions (OCS) framework, which spans a variety of sectors including health, housing, education and defence.

A total of 29 suppliers have been named on the new framework, which runs for four years, with the possibility of a three-year extension. It means Integra will be able to tender for major contracts with public sector clients across the UK.

Gary Parker, Managing Director at Integra Buildings, (pictured) said: “To be named on the new Offsite Construction Solutions framework is a huge vote of confidence in Integra and our proven capability to deliver major public sector projects to the very highest standards. Since being appointed onto the old framework four years ago, we’ve delivered some of the biggest projects in our 25-year history. Integra continues to grow and evolve, with clients right across the UK. The offsite and modular construction sector continues to expand at pace and being named on this framework ensures we’ll remain right at the forefront of that exciting journey.”

Integra has delivered a series of key projects for clients including Network Rail, the Environment Agency and the Department for Work and Pensions. Contracts completed under the previous framework include the construction of temporary housing for Reading Borough Council, a new job centre in Birmingham and modular units which were shipped to Cyprus for use by the Ministry of Defence.

Integra designs and constructs buildings offsite in controlled conditions at its purpose-built factories in Paull, East Yorkshire, before delivering and installing them in situ, a process that reduces project timescales and minimises disruption to customers, with no compromise on quality.

Plumbing as versatile as your modular design

You get complete freedom of design with our pipes and fittings, because our system fits in effortlessly with your plans.

• A vast range of fittings and pipes to suit all designs

• MLC pipes can be formed easily around corners and obstructions without having to add connections, saving on both time and cost

• Fast 3-step installation with no special skills required– designed to fit and forget

• S-Press PLUS fittings includes multiple observation windows for complete joint security

• Fewer connections for a faster install with less cost

• Optimal flow rates and reduced pressure drop

Integra enjoyed a busy 2022 which saw it complete significant contracts including the delivery of new offices for Triumph Motorcycles at its site in Coventry, providing school buildings across the country, from Merseyside to Surrey, and forge an exciting new partnership with More Housing to supply modular accommodation units to combat homelessness across the UK.

Source: www.integrabuildings.co.uk

Everton Stadium Build Employs Offsite MEP

The new Everton Stadium is set to enter a transformative phase in 2023, with work ramping up on the internal works. As the external appearance continues to develop, the race is on to make the build watertight to allow tradesmen to begin work in installing hundreds of miles of piping, wiring and the internal fittings.

“I think we should just warn spectators that in 2023 it will look like things are slowing down from an external perspective,” said Chief Stadium Development Officer Colin Chong. “A big milestone that people will want to see is the east stand steelwork that will fill in the gap between the north and south steelwork. However, it will slow down externally, although internally it’s going to be a hive of activity. In real terms, the fit-out is starting in January, when we will start putting all the wires and piping in. People won’t notice it as much, as it’s internal, but it’s equally as important to the stadium development as the roof going up.”

As with the external concrete and steel components, much of the internal walls are pre-manufactured in factory conditions and transported to site in just-intime slots for installation. All mechanical, electrical

Wee House Group Expands Premises & Executive Team

The Wee House Group has announced the opening of a significant additional working space in their East Ayrshire factory, taking their premises to 120,000sq feet, an area the size of almost two full-sized football pitches. The new space, Hall 4, is an additional area for the construction of modular homes, required to facilitate fulfilment of a burgeoning order book.

The facility is itself a repurposed entity, once home to the bustling Kingsmead Carpets factory – a major employer in the town of Cumnock at the turn of the century. Breathing new life into this enormous, historic building has been an outstanding achievement for The Wee House Group, especially in the short time since the company was formed, and the production of sustainable, modular housing, using modern techniques continues to provide a real boost to the local economy.

The Wee House Group comprises: The Wee House Company (bespoke solutions for small sites), Connect Modular (delivering large scale, affordable developments) and Hope South West (groundworks division) and provides a full, turnkey service from concept design including statutory consents, to the manufacturing of new homes and their completion on-site, to a variety of clients, from private individuals to local authorities and housing developers.

and plumbing (MEP) systems in the stadium will be manufactured offsite in the Oldbury (West Midlands) factory of Laing O’Rourke’s specialist MEP business, Crown House Manufacturing. The six-foot high modules and an innovative product called Techwall, will be delivered to site, lifted into place, connected and commissioned, in an approach that helps save time and energy.

“There are life-safe systems, resilience to be planned, and all the toilets on the concourses will be coming in in modules, pre-manufactured,” explained Chong, in a special club podcast on the stadium build. “The pipework will arrive pre-manufactured, tested in the factory, and be offered up and connected, so there

are less connections throughout the whole building. There’s less welding, so less risk of fire and it’s the modern way of building things.

“Again, we’ll be working on all four concourses simultaneously, along with the hospitality lounges starting, probably in March. The skeleton of the dressing rooms is already in place (in the west stand). We’ve got the pit for the hydrotherapy pools and all the apertures for all the incoming services. We ramp up with people and we’ll end up with 1,000 people there next year and probably up to around 1,400 on-site the year after.”

Source: www.evertonfc.com

Jennifer Higgins, Managing Director at The Wee House Group commented: “We’re absolutely thrilled to have expanded our manufacturing facility to cope with the growing pipeline of work. It’s wonderful to see the volume of houses increasing in the factory week on week and great that we have the space to maximise production.”

The Wee House Group has also announced a new Executive Management layer within their organisation, comprising Richard Reid, who will take on the role of (Acting) Chief Executive Officer and Emma Robertson who will step up to a new role as Chief Finance Officer, as Jennifer Higgins, current CEO of the group takes a step back due to maternity leave.

Emma Robertson, Chief Finance Officer comments: “I am really excited to work with Richard and the teams across the business to build on the tremendous

success we have already achieved. I am confident that as a team we can achieve all our ambitious goals and create an environment where people can grow and develop in their career.”

Richard Reid, Acting Chief Executive Officer, said: “I would like to sincerely thank Jennifer for giving me the opportunity at The Wee House Company in 2019, and putting her trust in me to continue to manage and push the company forward in line with our 5-year strategy. I would also like to thank our staff, sub-contractors, and consultants without whom, we would not be in this position. It is my intention to be bring the same enthusiasm and drive to the business as Jennifer, therefore I am asking for the continued support and effort from everyone over the next year to ensure we meet our targets for 2023 and beyond.”

Source: www.theweehousecompany.co.uk

Tide Construction Reaches New Heights at CTBUH Awards

UK modular developer and contractor, Tide Construction Limited with its volumetric modular company Vision Modular Systems recently received five Awards of Excellence at the Council on Tall Buildings and Urban Habitat (CTBUH) Awards in Chicago: Best Tall Building 100-199m, Best Tall Residential Building, Construction Award, Innovation Award, and an overall category win for Structural Engineering. These accolades were awarded to Tide and Vision alongside the design team, including MJH Structural Engineers, Barrett Mahony Consulting Engineers and HTA Design, for the work completed on Tide’s Croydon residential development, Ten Degrees.

This international recognition places Tide alongside iconic buildings and fellow 2022 winners, including Dubai's Museum of the Future and KPF's One Vanderbilt, the tallest office tower in Midtown Manhattan, and follows an award earlier in the year for Innovation at the World of Modular conference in Texas.

The CTBUH is a world-leading organisation for those working on the future of cities, the role of urban density and of vertical growth. Celebrating innovative developments in the construction of tall buildings worldwide, the annual CTBUH Conference and Awards recognises the achievements of those working at the height of these ambitions and how vertical construction can make our cities more sustainable and healthier.

Tide and Vision’s winning development, Ten Degrees, is an exemplar of its track record of building greener, safer, faster and better-quality homes. Comprising 44- and 38-storey towers and reaching a total height of 136m, Ten Degrees is the first modular building over 40 storeys to be delivered in the world and construction was completed in just 26 months. The towers were designed by HTA Design and delivered using Tide’s sister company Vision Modular Systems with engineering by MJH Structural Engineers and Barrett Mahony Consulting Engineers using advanced 3D volumetric methods. The scheme is now owned

by Greystar; a global leader in rental housing and Henderson Park; a pan-European private real estate equity platform.

Ten Degrees shows how modular construction can contribute to global industry innovation while responding to worldwide housing, skills and sustainability challenges. Providing 546 new Build-toRent homes for the London borough of Croydon, this development also puts Tide and Vision at the forefront of placemaking.

John Fleming, Chairman and Founder of Tide Construction & Vision Modular Systems, said: “These awards recognise Tide and Vision’s industry-leading position worldwide. The work delivered on Ten Degrees demonstrates how we can revolutionise construction methods while providing housing faster, safer, and more sustainably at scale, both in the UK and globally.

MAXIMISE THE OFFSITE OPPORTUNITY

“It is an honour to receive such high-profile accolades from the CTBUH, an organisation that continues to actively shape the future of the urban environment and lead the way in sustainable vertical urbanism. This recognition also testifies to the momentum building up for volumetric construction in the UK and across the globe. We believe we are demonstrating the potential of volumetric modular as a mainstream method of construction and our track record is showcasing the many benefits it brings. We are determined to drive forward the delivery of smarter, greener, quality homes with our significant pipeline planned for 2023 and beyond.”

Source: www.tideconstruction.co.uk

www.offsite-expo.co.uk/exhibit

OFFSITE EXPO has a range of exhibition packages available to suit any marketing aims, resources and budget.

MAKE UK MODULAR

MILESTONES IN MODULAR

Make UK Modular is helping promote the benefits of modular homebuilding and bring a fresh focus to the use of offsite technology. Head of Make UK Modular Steve Cole, spoke to us about progress so far and a busy year ahead.

the sector. Nearly £1billion of finance has been invested and modular alone is responsible for nearly 1/3 of all R&D investment in the construction of buildings sector. Between 2022 and 2025 we expect to see modular increase it’s delivery fivefold to roughly 15,000 new homes per annum.

Of course, the external operating environment remains extremely challenging. The construction industry as a whole saw over 2,500 insolvencies registered in 2021, amounting to 19% of all insolvencies and modular is certainly not immune to the pressures facing our economy. Which is why we believe it’s so important that Government continues to back the sector.

Q: Since your launch in December 2021 – with some of the sector’s leading names – how is Make UK Modular progressing as a trade body?

Steve Cole (SC): I’m delighted with Make UK Modular’s first year, though I must say I did not think we’d have got through five housing ministers. Year 1 was always going to be about getting the fundamentals right. We had five priorities to create the foundations we needed to deliver for the sector: establishing a strong working relationship with Government, the opposition, MPs, and the Civil Service, building a robust and credible evidence base about the benefits and potential of modular housing, establishing and delivering against a new set of sector policy priorities, delivering a consistent, positive media and public affairs presence and of course, growing our membership.

With more than 20 MP meetings, the publication of ‘Greener, Better, Faster: Modular’s Role in Solving the

Housing Crisis’ is the first ‘state of the sector’ report into UK Modular housing, establishment of five core policy asks, more than 80 pieces of positive media coverage and a 40% growth in membership, we really delivered in a political environment of unprecedented volatility. We couldn’t have done any of this without our amazing members who have taken the time to craft policy asks, attend party conference, host factory visits for MPs, journalists, and TV crews and provided data to inform our reports.

Q: There has been a lot of investment into UK modular businesses and offsite systems in the last 5-6 years with new industry entrants, but also some notable failures – is the sector at a crucial stage of development?

SC: Absolutely, if you look at the innovation curve the sector is now at the inflection point between innovators and early adopters. What is often unreported is the sheer scale of investment which has gone into

Q: The discussion surrounding the number of new homes required across the UK never ends. How can the modular sector make a dent in the oft-quoted 300,000 homes a year?

SC: Our ambition is for modular to deliver 30,000 new homes a year by 2030. 10% of all homes but, importantly, 30% of the current shortfall on the country’s new homes target. With 15,000 new homes a year expected to be delivered by 2025, we’re convinced that modular can make a real dent in that shortfall. Equally importantly, modular can do this without cannibalising the existing (and rapidly shrinking) housebuilding workforce as 65% of the jobs in modular are in manufacturing rather than construction.

Q: The built environment is under pressure to be more energy/ material-efficient, decarbonise and use more sustainable approaches to construction – how does modular construction fit into this equation?

SC: In my mind, net zero and modular are two sides of the same coin. The sort of efficient low carbon designs, net zero, ESG, and, more importantly, the physics of climate change demand of housing are ideally suited to modular. In 2022, an academic study of Vision Modular Systems’ modular high-rise development in Croydon found that it contained 40 to 45% less embodied carbon than an equivalent building built using traditional methods. For low-rise buildings, these savings are even greater.