THE LATEST IN LIGHT STEEL FRAMING TECHNOLOGY DEVELOPMENT

VOESTALPINE METSEC DOING IT THE RIGHT WAY

P12

INDUSTRY NEWS

A collective of industry bodies including LSFA and SCI launch new Offsite Construction Week, 16 – 20 September

P36

FOCUS ON FRAMING

Back for 2024, this conference will gather the experts in the LSF sector for an insightful and fascinating event

P42

FRAME BY FRAME: STEEL REUSE

With steel reuse in the construction spotlight explore the legislative changes required

LIGHT STEEL FRAMING MAGAZINE LIGHT STEEL FRAMING MAGAZINE

LIGHTSTEELFRAMINGMAGAZINE.CO.UK ISSUE 8 | SPRING 2024

BATHROOM & ENSUITE PODS Designed, engineered and manufactured by our multi awardwinning offsite experts. BATHROOM & ENSUITE PODS OFFSITE MANUFACTURED TO METICULOUS STANDARDS WITH A CHOICE OF FINISHES AND FITTINGS PRECISION ENGINEERED QUALITY ASSURED WWW.VOLUMETRIC.CO.UK For detailed and up to date information, to attend a factory tour or arrange a meeting please contact our team today. T: +44 1743 290020

PUBLISHING

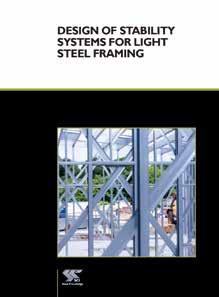

FRONT COVER: voestalpine Metsec

PRINTED ON: FSC Mix paper by Buxton Press

Welcome to the Light Steel Framing Magazine

Foreword from LSFA Chairman

Ben Towe

PUBLISHER:

Light Steel Framing Magazine is produced in partnership with the Light Steel Frame Association and published by Offsite Media Ltd: ©Offsite Media Ltd.

Radar Communications Ltd, 101 Longden Road, Shrewsbury, Shropshire, SY3 9PS

T: 01743 290001

www.radar-communications.co.uk

SUBSCRIBE TO RECEIVE: www.lightsteelframingmagazine.co.uk

ADVERTISING ENQUIRIES PLEASE CONTACT:

Julie Williams // T: 01743 290001

E: julie.williams@radar-communications.co.uk

SEND US YOUR NEWS:

T: 01743 290001

E: info@lsf-association.co.uk

FOR ENQUIRIES PLEASE CONTACT:

E: info@lsf-association.co.uk

DISCLAIMER: The content of Light Steel Framing Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

To introduce this issue, here is a word from Ben Towe, the new Chairman of the Light Steel Frame Association…

Buildings should not only be inherently safe but should also be constructed to stand the test of time. In his recent challenging book ‘Humanise’ – Thomas Heatherwick states the most sustainable building is one that is designed to last a thousand years. Many light steel frame buildings are BOPAS certified for a design life of 60 years. But according to the SCI, design life predictions for light steel in a ‘warm frame’ environment is in excess of 250 years.

Following the implementation of the Building Safety Act, it is widely acknowledged that there is a growing need to enhance contractual and relationship transparency as we navigate the ‘golden thread’ clarifying responsibilities of the designer, manufacturer and installer to determine project risk and connected to meaningful warranties for offsite and onsite works.

This supports principal contractors taking more control of the building process by selecting the ‘right fit’ of offsite construction partners to collaborate effectively and harness a larger project delivery capacity using recyclable primary structure materials. Steel has a unique characteristic as it can be reused and recycled repeatedly without losing its qualities as a building material. All steel used in today’s construction projects has some recycled content. The constructional steelwork used in the UK contains an average of 60% recycled content.

In this issue we feature the recent LSFA Building Safety Roundtable and also take a look at the great efforts companies in the sector are undertaking to independently validate light steel systems to offer greater assurance in building safety and performance.

We also review the latest industry news, projects in the planning stage, plus outstanding construction schemes currently ongoing across the UK.

Needless to say, with the increase in specification, it is exciting times for all in the light steel industry and I look forward to sharing the innovations within our sector in my role as Chairman of the LSFA.

Ben Towe

Chairman - Light Steel Frame Association Group Managing Director - Hadley Group

info@lsf-association.co.uk

3 LIGHTSTEELFRAMINGMAGAZINE.CO.UK

WELCOME

NEXT GENERATION STEEL FRAME CONSTRUCTION

British Offsite is bringing extra speed, flexibility and reliability to traditional construction with our next generation steel framing system and infill panels.

• UNisystem is adaptable to any sector including residential, health, education, commercial and regeneration.

• UNisystem infill panels and our UNisystem light gauge steel system are precision-manufactured on our advanced robotics assembly line and arrive on site with the cavity build-up included.

• Sheathing board, insulation, vapour control layer, cavity barriers, brick-tie channel or façade support, windows and doors can all be preinstalled, combining the work of up to five trades into one panel.

• Achieve high levels of performance on acoustics, energy efficiency and fire safety – meeting or exceeding current building regulations – already proven on over 1400 residential properties built to date

info@britishoffsite.com

www.britishoffsite.com

LB SFS

08

Industry News

Taking a look at the latest construction industry initiatives, project developments and building technology innovations in the UK light steel framing sector.

24

LSFA Roundtable

It might have passed some in the construction industry by, but the LSFA has been taking an in depth look at the implications of new safety legislation.

30

32

Fusion Kew Bridge Case Study

Find out how Fusion Steel Framing used their TRAX™ LSF system to support the large-scale redevelopment of a former car dealership in Kew Bridge Rise, Brentford.

Frameclad Case Study

Utilising innovative techniques, Frameclad navigated this complex site in Leeds and met all project requirements of the Concord Street development.

36

Focus on Framing

Bigger and better for 2024, industry experts will gather in Birmingham this May for a conference highlighting groundbreaking developments in the LSF sector

40

Regulating MMC

How the offsite construction sector can offset risks with digital technology and examine how MMC can be used effectively to ensure homes of the future are fire safe.

44

LSFA Sustainability

Building safety is a key concern of the LSFA, its members and end-clients, but safety does not have to come at the expense of sustainability.

5 LIGHTSTEELFRAMINGMAGAZINE.CO.UK

CONTENTS

growth and supporting the objectives of the light steel frame industry JOIN US TODAY! www.lsf-association.co.uk

Driving

In this issue...

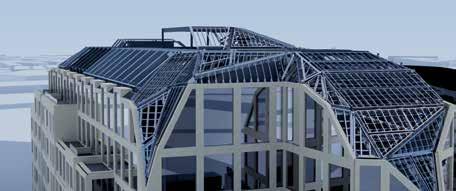

DOING IT THE RIGHT WAY

THE CONSTRUCTION INDUSTRY IS UNDER CONSTANT PRESSURE TO ESTABLISH AND MAINTAIN HIGH STANDARDS IN ALL AREAS OF ITS OPERATIONS AND IS UNDOUBTEDLY ONE OF THE MOST SCRUTINISED INDUSTRIES – FIRE SAFETY, ACOUSTIC AND THERMAL PERFORMANCE, ENERGY EFFICIENCY, SUSTAINABILITY, CLARITY OF INFORMATION AND QUALITY ARE GOVERNED BY A HOST OF TECHNICAL PERFORMANCE STANDARDS AND CODES – BOTH MANDATORY AND VOLUNTARY.

For the construction products manufacturer, success obviously relies on ensuring that their products and systems meet all necessary requirements in performance and quality, with independent verification of any claims made. It also requires the manufacturer to stay ahead of industry trends and developments, such as sustainability and accuracy of information, which are becoming increasingly important to specifiers and end clients.

voestalpine Metsec continues to raise the bar when it comes to conducting business in the right way, leading the industry when it comes to the early adoption of game-changing initiatives and innovations, particularly in the key areas of sustainability and product information.

A Sustainable Approach

Few, if any, construction materials, products, systems or methods can justifiably claim to have zero impact on the environment. The key is to ensure

that construction’s impact on the environment is minimised.

For the light steel framing industry, this means ensuring that a manufacturer’s operations are carbon neutral and that the steel it uses is as responsibly sourced as possible.

Carbon neutral operations may seem a far-off dream for many but as part of voestalpine AG, the global steel and technology group, voestalpine Metsec is committed to achieving net zero carbon emissions by 2035, some fifteen years ahead of the targets set by the Intergovernmental Panel on Climate Change.

Achieving this industry-leading target requires a focused effort within our company together with the co-operation of suppliers and others in the value chain.

To date, this initiative has seen us move our electricity requirements to 100% renewable sources, which has resulted in a 67% reduction in our carbon footprint, from 1500 tonnes of CO2 to 500 tonnes of CO2 per year. We have also embarked on a £2million investment in the installation of solar PV panels on the roofs of our manufacturing facilities. Phases One and Two have already been completed and Phase Three will commence soon.

In total, the solar panels will cover in excess of 10,000 square metres of roof space across three production unit. They will generate more than 2,000,000kWh of electricity per annum, which is the equivalent of powering more than 750 homes for a whole year.

Further measures aimed at reducing our impact on the environment include a host of energy-saving schemes throughout our facilities, replacing company cars with hybrid and electric vehicles, installing charging points across our site and reducing gas consumption.

Reduced Carbon Steel

voestalpine Metsec’s commitment to sustainable construction is emphasised by the introduction of responsibly sourced steel to our product ranges.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 6 COVER STORY VOESTALPINE METSEC

01

Manufactured by processes which minimise carbon output by using state-of-the-art electric arc furnaces powered by renewable energy rather than the traditional blast furnace which burn fossil fuels – Metsec Decarb promises to make a significant contribution towards reducing the carbon dioxide and carbon footprint of the building project.

Metsec Decarb is backed up by project-specific Environmental Product Declarations which accurately calculate the project savings on embodied carbon.

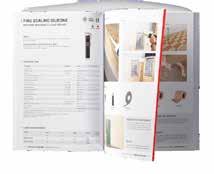

Integrity

Continuous investment in independent performance testing and quality assurance keeps voestalpine Metsec’s construction solutions at the forefront of the construction industry. Ensuring that the data and information derived from these tests is conveyed in a clear, unambiguous fashion is key to providing specifiers, installers and users with confidence in the systems’ capabilities and suitability for their projects.

It is why voestalpine Metsec has become one of the earliest adopters of the Code for Construction Products Information (CCPI), introduced by the Construction Products Association in response to Dame Judith Hackitt’s review of Building Regulations and Fire Safety, set up following the Grenfell Tower tragedy.

CCPI aims to address the stipulation from Dame Hackitt’s review that construction product information needs to be communicated in a clear and accurate way. Its aim is to help organisations drive for higher standards in the presentation of construction product information, with a priority on building safety. Assessments are undertaken by Construction Products Information Ltd. and are carried out on a company’s specific products and systems, not the company as a whole. As such, an organisation or brand cannot, in itself, gain verification or make any claims of conformance beyond a specific product set.

Recent company-wide investment in new systems and resources has seen

three of our ‘product sets’ achieve successful assessment to the CCPI. They are roof, side rail and mezzanine floor systems from our Purlins Division, dry lining metal framed components for gypsum plasterboard systems and SFS light gauge galvanized steel structural framing systems from our Dry Linings Division and SFS light gauge galvanized steel structural framing systems from our Framing Division.

Chris Holleron, Sales Director for voestalpine Metsec’s Framing Division, states: “SFS has been the construction industry’s leading steel framing system for years, enjoying a reputation for independently verified performance and quality. This is backed up by dedicated design and sales support which ensures that we deliver effective, valueengineered solutions that meet our customers’ requirements.

“Our messaging has always been founded on open, honest presentations of our capabilities and the recent CCPI verification is testament to this. It will give specifiers and customers even greater confidence when choosing SFS.”

Conveying the Message

Hot off the press is our latest Steel Framing Systems (SFS) Specification Manual, the industry’s most comprehensive resource for anyone involved in the specification, installation and use of light gauge steel framing systems.

Widely recognised as the industry bible for SFS, the 176-page manual is packed with just about every piece of information required to assure the successful design, specification, selection and application of voestalpine Metsec’s SFS.

Based on years of experience, expert technical knowledge and a vast library of independent testing, the manual is a perfect example of why voestalpine Metsec SFS light gauge galvanized steel structural framing systems have achieved verification to CCPI.

Its content includes details on SFS benefits versus alternative building systems, performance standards, BIM design, CPD presentations and installer training together with detailed information on the major SFS applications as infill walling, load bearing situations, continuous walling and high bay walling.

Each application area contains detailed information on relevant performance criteria, use of SFS with popular sheathing and cladding materials, architectural drawings showing typical wall build-ups and case studies.

Doing it the Right Way

The voestalpine Metsec experience underlines the importance not only of ensuring that products and systems meet the needs of the modern construction industry but also that they are supported by a company which has the interests of the construction industry at heart, providing professionals working in design, specification and installation with total assurance in the company and its products.

For more information visit: www.metsec.com

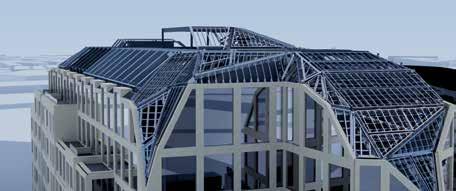

IMAGES

01. Metsec is committed to achieving net zero carbon emissions by 2035

02. Metsec’s latest Steel Framing Systems (SFS) Specification Manual

03. Providing professionals working in design, specification and installation with total assurance

7 LIGHTSTEELFRAMINGMAGAZINE.CO.UK COVER STORY VOESTALPINE METSEC

02 03

WOLVERHAMPTON LIGHT STEEL FRAME MANUFACTURER BENEFITS FROM WMCA INVESTMENT

A family-run Black Country manufacturer has moved and doubled the size of its factory, following a £7.59 million investment from the West Midlands Combined Authority (WMCA).

Drywall Steel Sections, which has invested alongside the WMCA into the wider £13 million scheme, has moved to a new 39,850 sq ft factory built on fourand-a-half acres of brownfield land in Ettingshall, Wolverhampton.

The firm was previously based in Cradley Heath, Dudley, for more than ten years but had outgrown

the facility, which was also no longer fit for purpose for its modern production methods.

The factory manufactures light gauge steel framing for the construction industry (including modular housing), as well as steel products for wall partitions and ceilings. It also has an engineering department, DrySpec, which specialises in designing and detailing steel framing for a vast range of buildings across the country.

Andy Street, Mayor for the West Midlands, and Chair of the WMCA, said: “I was here 12 months ago to watch work start on Drywall’s new factory so it’s

exciting to be back and see them up and running in their new home.

“Manufacturers like Drywall are incredibly important to our regional economy which is why we use the money we secure from government to support those businesses who want to grow and generate new jobs for local people.

“We are also continuing to protect our green belt by prioritising investment on the regeneration of brownfield sites like this one. It’s important we clean up these sites to provide high quality affordable housing for local people and modern commercial premises for our businesses, helping to attract further investment into our region.

“Now Drywall are in their new factory I can’t wait to see them continue to grow and prosper in the years ahead.”

Drywall Steel Sections Ltd is part of a family-owned group of companies set up by Rajinder and Sunita Gupta more than 20 years ago. Since joining the business six years ago, their son Mayank has taken over as the managing director, and the firm is seeing new growth through fresh vigour.

Mayank said: “We are proud to bring Drywall Steel Sections Ltd’s headquarters back to our home city of Wolverhampton.

“Our new headquarters is equipped to handle significantly more manufacturing capacity with a much more efficient production process, allowing us to remain competitive in the market. Alongside our family investment, we are most grateful to the WMCA for its support in unlocking this brownfield site.

“The new Drywall HQ and commercial starter units on G5 Industrial Park will help safeguard current jobs and provide a much improved facility for the existing team. It will also create new jobs, help smaller businesses to grow in brand new premises, and boost the region's economy.

“Drywall Steel Sections Ltd. has further expansion and growth plans, and this new facility will help us bring those plans to life.”

Image: Andy Street, Mayor of the West Midlands and Chairman of the WMCA; Mayank Gupta, director of DryWall, and Stephen Simkins, Leader of Wolverhampton City Council.

Image courtesy: West Midlands Combined Authority

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 8 INDUSTRY NEWS

VOESTALPINE METSEC ADOPTS CCPI VERIFICATION FOR STEEL FRAMING SYSTEMS

Following a company-wide investment in new systems and resources, voestalpine Metsec has adopted the Code for Construction Products Information (CCPI).

Introduced by the Construction Products Association, the CCPI was created in response to Dame Judith Hackitt’s review of Building Regulations and Fire Safety, set up following the Grenfell Tower tragedy.

The company has now achieved verification with the CCPI for several of its construction solutions, the latest of which is light steel framing systems.

Chris Holleron, Sales Director for voestalpine Metsec’s Framing Division, said: “SFS has been the construction industry’s leading steel framing system for years, enjoying a reputation for independently verified performance and quality.

“This is backed up by dedicated design and sales support which ensures that we deliver effective, value-engineered solutions that meet our customers’ requirements. Our messaging has always been founded on open, honest presentations of our capabilities and the recent CCPI verification is testament to this. It will give specifiers and customers even greater confidence when choosing SFS.”

CCPI aims to address the stipulation from Dame Hackitt’s review that construction product information needs to be communicated in a clear and accurate way. Its aim is to help organisations drive for higher standards in the presentation of construction product information, with a priority on building safety.

CCPI verifications are undertaken by Verifiers from Construction Products Information and are carried out on a company’s specific products and systems, not the company as a whole. As such, an

LSF WORKS BEGIN ON NEW PROJECTS IN BURY ST EDMUND, NOTTINGHAM AND JERSEY

Offsite construction and light steel frame specialist Remagin has begun work on three major projects, in Bury St Edmunds, Nottingham and Jersey.

75 Bed Care Home

The first project is to build a care home on behalf of Simply UK, a specialist developer and operator of care homes nationally. The new development will span three storeys and deliver 75 beds, within a projected 17-week programme.

While on site, the Remagin team will install the internal and external light steel wall and floor panels, along with a pitched roof. In total, the team will install a total of 4,167sqm GIFA .

“We have worked with the team at Simply UK on a number of previous schemes and are delighted to be on site with them again,” said Steve Blows, Contracts Manager at Remagin. By designing, manufacturing and installing the full structure, including the pitched roof element, we are demonstrating the full scope of our market offering. More importantly, we are able to hand over a fully weathertight structure to our customers more quickly, which means a quicker return on investment for them.”

Low Carbon Homes

The Remagin team are also starting on site for new client MyPad. Marking the first development together, the project embraces modern methods of construction (MMC), with MyPad selecting Remagin’s light steel framing solution thanks to its efficiencies on and offsite. The sustainability credentials of light steel frame also complement MyPad’s own approach to delivering low carbon homes across the Midlands. The boutique development is located in Stapleford, near Nottingham and will deliver 15 apartments over five storeys, and a total GIFA of 1,172sqm.

Apartment Development on Jersey

Lastly, works are progressing on a 184-apartment development in Jersey, in collaboration with St Hellier-based firm Rok Group. Members of Remagin visited the site in March, to see the latest stage of the development.

A spokesman for Remagin explained the works, saying: “Rok Group are raising the standards and we are delighted to be supporting them. By using the Remagin light steel system, the project will be able to benefit from offsite construction advantages such as speed of build

organisation or brand cannot gain verification or make any claims of conformance beyond a specific product set.

Alan Harris, Quality and BIM Compliance Director at voestalpine Metsec, said: “We pride ourselves on being the best in the markets in which we operate. Independently verified product performance is a key factor in maintaining our position at the forefront of our industry and CCPI verification provides specifiers and customers with added confidence of in the veracity of our product information.

“Our formal internal processes review all performance statements before they are released for external use, whether these be in technical, sales or marketing activity. The system ensures that the product performance statements we make are as clear and accurate as possible.”

Image courtesy: Code for Construction Products Information (CCPI)

as well as the subsequent sustainability benefits. We look forward to seeing the scheme develop further.”

Images:

01. Light steel frame specialist Remagin has begun work on a 75 bed care home in Bury St Edmunds. Image courtesy: Simply UK

02. Remagin visit Rok Group’s Jersey site Image courtesy: Remagin

INDUSTRY NEWS LIGHTSTEELFRAMINGMAGAZINE.CO.UK 10

01 02

LGSF SOLUTIONS IN STEEL

Modular Plantrooms

Offsite M&E Fabrications

Precision Manufacturing | Advanced Structural Design Expert Support | Hot Rolled M & E Offsite Fabrications

Load bearing and none-load bearing LGSF frames, for panelised, or volumetric modular build. Detailed utilising cold rolled LGSF, Hybrid LGSF and hot rolled steel or purely hot rolled fabricated steel components.

From design to installation, LGSF production have proven capacity for the dependable supply of frames for sizes of projects.

• Extensive manufacturing capacity

Over 100,000 ft² of manufacturing facilities

• Ongoing programme of investment & development

• In-house detailing services

• Engineering services

• Rigorous quality control BS EN 1090 Ex Class 2 & 3, ISO 9001

• Proven capability in the supply of high volume ‘Just In Time’ orders

• Expert team providing technical advice and support

LIGHT GAUGE STEEL FRAMING Unit 3, The Gateway, Dunslow Road, Eastfield, Scarborough, YO11 3UT 01944 710279 sales@lgsf.co.uk

NEW OFFSITE CONSTRUCTION WEEK UNVEILED

16-20 SEP 2024

16-20 SEP

2024

Innovative Thinking –Revolutionary Technologies

Innovative Thinking –Revolutionary Technologies

PARTNERS:

PARTNERS:

Offering unrivalled access to leading industry pioneers, demonstrators, dynamic factory tours, thought provoking roundtable discussions and CPD accredited masterclasses – a collective of industry bodies, including the Light Steel Frame Association and the Steel Construction Institute are collaborating to deliver Offsite Construction Week.

Taking place from 16-20 September 2024, Offsite Construction Week will revolve around three major industry events – Offsite Expo, the Offsite Summit and Offsite Awards, with a wide range of parallel activities taking place in the UK and overseas via a coordinated programme of offsite activity.

Unilateral Support

Offsite Construction Week is the brainchild of industry associations operating across the sector. Presenting a unique proposition, trade bodies, industry alliances and material groups including BUILDOFFSITE, Building Engineering Services Association (BESA), Light Steel Frame Association (LSFA), Modular and Portable Building Association (MPBA), Steel Construction Institute (SCI), Structural Timber Association (STA), Offsite Alliance, Chartered Institute of Architectural Technologists (CIAT) and others have come together to curate the most comprehensive series of offsite events the UK has ever seen.

Offsite Expo – The Main Event

Offsite Expo 2024 will be taking centre stage during Offsite Construction Week. Bringing together the sector’s big hitters in one easy to reach central UK location, the event will take place at the Coventry Building Society Arena on 17 and 18 September. As the first and foremost event of its kind, Offsite Expo is now established as the most technically advanced exhibition in the construction calendar. With a new international focus, it will be two days packed full of the latest technical innovations, ground-breaking manufacturing technology and digital ingenuity.

Offsite Summit

Bringing an international focus to Offsite Expo and being held in association with BUILDOFFSITE – the Offsite Summit sees the coming together of those making waves in offsite technology from across the globe. Delegates will have the opportunity to gain insight from those achieving worldwide recognition as the Offsite Summit showcases international innovation and best practice from across Europe and beyond including the USA and Australia.

Offsite Awards

In 2024 the Offsite Awards celebrate the 10th anniversary by awarding a special accolade for the Offsite Project of the Decade. Taking place alongside Offsite Expo on the evening of 17 September 2024, the Offsite Awards celebrate projects with

technical innovation and project performance that is world-beating. Rewarding excellence in precision building design and delivery, by recognising outstanding examples of prefabrication, factorybased methods and advanced delivery techniques, these awards offer a promotional platform to those who are leading the way in developing a safer and more sustainable built environment.

CPD Accredited Seminars

One of the reasons Offsite Expo has experienced incremental growth year-on-year is the quality of the speaker programme. Helping fulfil CPD obligations, the Offsite Masterclasses and Spotlight on Offsite Sessions support the development of new skills and specialisms. Curated by leading offsite experts, the free to access programmes provide a comprehensive and balanced perspective on this rapidly emerging sector from a host of renowned architects, engineers and offsite manufacturing pioneers.

To keep up to date with developments visit: www.offsiteconstructionweek.co.uk

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 12 INDUSTRY NEWS

FRAMECLAD ACHIEVES ISO CERTIFICATION

Kingswinford-based light steel frame specialist Frameclad has showcased its commitment to quality, safety and sustainability by attaining ISO certification.

The International Organisation for Standardisation (ISO) is an independent, non-governmental body based in Geneva, Switzerland. ISO standards are designed to ensure that products, services and processes are safe, reliable and of good quality. Frameclad recently achieved ISO 9001, ISO 14001 and ISO 45001.

Joint Managing Director Nik Teagle said: “Attaining ISO certification shows our commitment to continuous improvement which goes hand in hand with our determination to drive industry standards and to deliver outstanding results.”

ISO 45001 is an international standard that specifies requirements for an occupational health and safety (OH&S) management system. It enables organisations to better protect their workers and manage OH&S risks, making it an essential standard worldwide.

ISO 9001 is a globally recognised standard for quality management. It helps organisations of all sizes and sectors to improve their performance, meet customer expectations and demonstrate their commitment to quality.

ISO 14001 is the internationally recognised standard for environmental management systems. Businesses can ensure they are taking proactive measures to minimise their environmental impact, comply with relevant legal requirements and achieve their environmental objectives.

Also backed by BOPAS Accreditation to design at full scope, NHBC SCI, Infill and CE Certification, Frameclad has invested in a growing suite of fire test and performance data to offer assurances to main contractors, architects, engineers and public sector clients.

Image: Frameclad has maintained its commitment to excellence by attaining ISO certification

Image courtesy: Frameclad

INDUSTRY NEWS

Fastening Technologies for Future Generations

service

BeA Fastening Systems UK.

Reliable products, competitive prices and the kind of

and delivery you can depend on from

Fastening Technologies for Future Generations

Fastening Technologies Fastening Technologies for Future Generations 01482 889911 sales.uk@bea-group.com Website Reliable products, competitive prices and the kind of service and delivery BeA Fastening Systems UK.

for

Generations Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK. Fastening Technologies for Future Generations Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK.

for Future Generations

FOR AUTOMATION Fastening Technologies for Future Generations group.com competitive prices and the kind of

and

BeA Fastening Systems

Fastening Technologies Future Generations

889911

Website Reliable products, competitive prices and the kind of you can depend on from BeA Fastening Systems UK. Fastening Technologies Future Generations

889911

Website

products, competitive prices and the kind you can depend on from BeA Fastening Systems UK.

Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK.

Fastening Technologies

Future

Fastening Technologies

Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA Fastening Systems UK.

service

delivery

UK.

01482

sales.uk@bea-group.com

01482

sales.uk@bea-group.com

Reliable

BUILDOFFSITE ANNOUNCE NEW COLLABORATION

Leading offsite construction membership body BUILDOFFSITE (BOS) has announced it will be partnering with Offsite Expo for this year’s event.

Celebrating its 20th anniversary this year, BOS has members based in the UK, but also in Europe, Asia and North America. Building on these international connections, BOS will co-host the Offsite Summit at Offsite Expo, focusing on international best practice on day one of the event and showcasing their own activities on day two.

BOS will be joining many other industry partners at this year’s event, including the Light Steel Frame Association (LSFA), Steel Construction Institute (SCI), Modular and Portable Building Association (MPBA), Structural Timber Association (STA) and the Concrete Centre.

Dirk Vennix, Executive Director of BUILDOFFSITE, said: “Offsite Expo has regularly exhibited the best of the offsite construction industry, so to be able to highlight the international expertise of BOS members and other key stakeholders is very exciting.

“There has been a great amount of change in the offsite construction sector in the 20 years since BUILDOFFSITE was launched and Offsite Expo

being the biggest showcase for the offsite industry is the ideal platform to demonstrate that change and future innovations and ideas.”

Offsite Expo will take place on 17 and 18 September 2024 at the Coventry Building Society Arena. For more information, please visit www.offsite-expo.co.uk

HADLEY GROUP SECURE STAGE 1 SYSTEM CERTIFICATION FOR HADLEYFRAME SYSTEM

Hadley Group has secured a Stage 1 System Certification from the SCI, NHBC, LABC and Premier Guarantee, for demonstrating the effectiveness of its HadleyFRAME light steel framing system.

The certificates mean projects made using the HadleyFRAME system are insurable and therefore mortgageable, an essential standard for selling private homes.

The Stage 1 System Certification is the highest recognition for primary structural components of light steel framing systems. In recognition of the detailed technical system manual and testing

achieved by the HadleyFRAME team, the certification demonstrates that Hadley Group’s pre-panelised MMC solution can be utilised on buildings up to 15 stories.

Stage 1 System Certification covers structural strength, stability and durability and in the words of the SCI, “offer clear, unambiguous statements about compliance and are structured to follow the Basic Requirements for construction works as set out in the Construction Products Regulation.”

The Hadley Structural team worked closely with the SCI on the certification in an effort to raise industry standards.

A spokesman for Hadley Group said: “The work the SCI undertake in conjunction with key independent warranty providers is critical to ensuring light steel frame manufacturers provide a system that meets the demands of the construction industry.

“The SCI are the trusted, independent adviser for all forms of steel construction and have been providing information and engineering expertise for over 30 years.”

Image: HadleyFRAME

Image courtesy: Hadley Group

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 14 INDUSTRY NEWS

Innovative Thinking –Revolutionary Technologies

OFFSITE CONSTRUCTION WEEK shines a spotlight on the transformative digital, material and manufacturing innovations that are advancing the design and application of offsite construction processes.

Become a Host and Run Your Own EventWe Can Help!

If you would like to host an event of your own during Offsite Construction Week* we can utilise our platforms to promote your events.

To give you inspiration, events can include:

FACTORY TOURS

ROUNDTABLE EVENTS

SITE STUDY TOURS

WEBINARS & PODCASTS

BREAKFAST CLUBS

DRINKS RECEPTIONS

... just as long as you are talking about offsite technology!

* We recommend avoiding the 17 & 18 September due to major industry events taking place

All events during OFFSITE CONSTRUCTION WEEK are FREE to attend

Contact the team on 01743 290001 or info@offsiteconstructionweek.co.uk

www.offsiteconstructionweek.co.uk

PARTNERS:

MORGAN SINDALL TO BUILD

£20M R&D CENTRE TO DECARBONISE STEEL

Morgan Sindall Construction is to design and build a £20million R&D facility in Neath Port Talbot to help steel and metal industries decarbonise.

To be known as SWITCH – South Wales Industrial Transition from Carbon Hub – Harbourside it will be located close to Tata Steel’s Port Talbot plant and is expected to take 18 months to complete.

SWITCH Harbourside will be a purpose-built openaccess centre bringing together expertise across academia, industry and government with the aim of accelerating the region’s transition to net zero. The net zero facility is the brainchild of Neath Port Talbot Council in partnership with Swansea University. Morgan Sindall will include sustainable energy technologies in the building’s design.

This will support the council’s Decarbonisation and Renewable Energy strategy by incorporating technology such as photovoltaic panels to provide a significant clean source of energy and eliminating any fossil fuels used on site during the build. The facility will support the steel and metals industry to

decarbonise processes, develop a circular economy and create advanced materials for a net zero society.

Robert Williams, Area Director at Morgan Sindall Construction, said he was delighted to be helping develop the area. “It's a privilege to play a key role in the SWITCH Harbourside development which will help the region move towards a net zero future. We are working closely with Neath Port Talbot Council and partners Swansea University to ensure we bring together our experience and knowledge to deliver the best possible outcome for the project.”

Neath Port Talbot Cabinet Member for Climate Change and Economic Growth, Councillor Jeremy Hurley, said: “The exciting SWITCH Harbourside project will support the transformation and decarbonisation of our important steel and metals industry and associated supply chain.

Professor Helen Griffiths, Pro Vice Chancellor Research and Innovation at Swansea University, added: “SWITCH Harbourside will showcase what can be achieved in a net zero future, both

in its design and its purpose. It will build on Swansea University’s track record of bringing together academia, industry, local authorities and government.”

As an open-access facility, the development will also provide access to knowledge and equipment for a wider collaborative network of expertise across academia, industry and government.

The building forms part of the City Deal supporting innovation and low carbon growth programme and is aimed at establishing the region as a leader in low carbon growth and the green economy. The design and construction of SWITCH Harbourside is expected to be completed in early 2025.

Image: The development will be located close to the Tata Steelworks on the Neath Port Talbot Harbourside

Image courtesy: SWITCH Wales

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 16 INDUSTRY NEWS

HADLEY GROUP MD ANNOUNCED AS NEW LSFA CHAIR

The Light Steel Frame Association (LSFA) has announced Ben Towe as the new Chairman of the organisation. Founded in 2019, the LSFA works to drive engagement, champion change, and spread the word about the cost, productivity, performance and sustainability benefits of contemporary light steel framing systems.

Mike Fairey has been at the helm of the association since inception but after thanking him for his service and commitment, the Steering Group announced Ben Towe would replace him in 2024.

Starting his career at Carillion after qualifying as a Mechanical Engineer from Aston University, Ben Towe joined Hadley Group in January 2006, one of the UK’s largest manufacturers of cold rolled steel sections. He soon rose through the ranks joining the main board in 2011 and progressing to his current role of Group Managing Director in 2018.

“I would like to thank the LSFA Steering Group for their nomination and support,” said Ben Towe.

“The Association has some big challenges to address on behalf of our members over the next 12 months.

“As the construction industry grapples with the new Building Safety Act and legislation, my priority as Chair is to help our members get across the detail. Without doubt the new safety legislation plays to the strengths of light steel frame and we must help our members grasp the opportunities which are coming our way.

“We must also continue our campaign to raise awareness of the sustainability benefits of light

gauge steel. Circular construction is rising up the environmental agenda and as the only building material that can truly be reused or recycled for the same or a similar purpose - steel is supporting construction by enabling clients to achieve safety legislation and sustainability requirements.

“And then there’s promoting the innovation in our sector – so there’s a lot to do.”

Image: Ben Towe, new Chair of the LSFA

Image courtesy: Hadley Group

FLOOR DECK FOR LIGHT STEEL FRAME CONSTRUCTION.

DEDICATED LIGHT GAUGE DIVISION

Our dedicated Supply Only team are happy to help with customers design and installation queries.

FLOOR DECK SOLUTIONS

Our product range and crushed end finish are perfect for the light gauge solution.

DEDICATED PRODUCTION LINE

Due to demand, our dedicated production line manages large volumes and quick delivery times.

INDUSTRY NEWS

www.smdltd.co.uk

CADDICK CONSTRUCTION TO DELIVER UNIVERSITY OF CUMBRIA'S LEARNING QUARTER

Yorkshire-based construction firm Caddick Construction has been appointed as the main contractor to deliver the University of Cumbria's new Barrow-in-Furness campus, with voestalpine Metsec plc appointed to design and supply the light steel framing system.

Once complete, this state-of-the-art campus will deliver degree programmes in advanced manufacturing, computer science, including cyber security and business management – to help attract and retain talented graduates with higher-level skills to serve the region’s growing industries.

The unique design is inspired by the town’s submarine heritage. The dockside development will contain adaptable, specialist and interactive teaching areas across its two floors and social and library spaces. Features will include new teaching spaces, offices, catering facilities, landscaping and car parking. In November 2023, HRH The Princess Royal visited the site to ceremonially ‘break the ground’ on the project.

Paul Dodsworth, Managing Director of Caddick Construction Group, said the development would help bring new talent to the area, adding: “We are very proud to have been appointed to the University of Cumbria’s new campus and to be adding such a flagship project to our portfolio. We are working closely with the university to ensure the new campus becomes a world leading facility that attracts new talent and serves the industries of the region and beyond.”

University of Cumbria Vice Chancellor, Professor Julie Mennell, added: “This milestone takes us another step closer to developing the first university campus in Barrow-in-Furness. We’re delighted to be working with Caddick Construction and existing partners on a project serving our community in an area of such regional, national and international importance.

The development, known as the Barrow Learning Quarter, is part of a borough-wide programme of seven innovative projects across Barrow, which will develop and transform the surrounding area.

A collaborative creation, Barrow Learning Quarter is being developed by the University of Cumbria in partnership with Furness College and others including BAE Systems, Lancaster University and Westmorland & Furness Council.

Inspired by its location and links to Barrow’s history, the campus building design incorporates a two-story building with curved roof line, reminiscent of the surface of a submarine,

glazing to maximise natural light into the building, social space and green infrastructure, adaptable and specialist teaching spaces and a gross internal floor area of around 2,105sqm.

Image: Renders of Barrow Learning Quarter

Image courtesy: University of Cumbria

ICW LAUNCH A NEW CHAPTER FOR LIGHT STEEL FRAMING

Construction industry insurance provider ICW will become the latest building warranty provider to have a dedicated chapter on light steel framing in their technical manual, when their updated version is released later this year.

Recognising the growing significance of light steel framing in the UK construction industry and in particular in the residential sector, ICW has developed a chapter for their technical manual dedicated to light steel construction.

To assist them with this challenge ICW called upon the Steel Construction Institute (SCI). Drawing upon their extensive knowledge of light steel construction and the requirements of building warranty providers, SCI produced the new chapter for the ICW technical manual.

Included within the new chapter is a two-stage certification system for light steel framing which has proven to be successful for many light steel frame manufacturers and popular with other warranty providers. Stage 1 is a system-based certification carried out by SCI, followed by Stage 2 which is project specific.

Image courtesy: ICW

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 18 INDUSTRY NEWS

INTRASTACK JOINS FORCES TO DELIVER HOUSING SCHEMES

Intrastack, part of the Saint-Gobain Off-Site Solutions division and leader in steel framing systems has announced collaborations with two construction contractors.

Affordable Social Housing

The first collaboration is with John Southworth which looks to utilise modern methods of construction (MMC) to deliver affordable social housing to the north of England. With a current shortage of social housing in the UK, the collaboration comes at a time when investment into affordable housing is essential. In the Affordable Homes Programme (2021-26) by Homes England, it is outlined that 25 per cent of developments are targeted to be built using MMC by 2026.

By working together, Intrastack and John Southworth are helping to get closer to this target, providing more opportunities for affordable living. The first collaborative project for Intrastack and John Southworth includes a scheme of 24 houses. Looking to the future, additional projects are already in the pipeline for the businesses, with a key focus on using innovative offsite solutions from Intrastack for the affordable housing sector, projects include shared ownership, affordable and social rent properties.

Commenting on the new collaboration, Andy Higson, Business Director at Intrastack, said: “We’re delighted to be working with John Southworth, a company that shares similar ideals and standards as Intrastack; using innovative build methods, providing projects which exceed industry best practice, all with a commitment to helping local communities.”

Steven Brown, Director at John Southworth, added: “Innovative, modern methods of construction are targeted build methods for John Southworth and Intrastack’s light steel frame solutions not only meets our needs but exceeds them, with its precision, quality, recyclable benefits, and the longevity that light steel offers as a construction material. We are excited to be able to work with Intrastack, Manchester City Council and One Manchester to integrate MMC into affordable social housing.”

Low-Rise Residential Scheme

Intrastack has also joined forces with principal contractor, R&M Property Group, on a low-rise residential project set to deliver eight family homes in Didsbury, South Manchester.

At the heart of this development lies Intrastack’s light steel frame (LSF) solution, renowned for its versatility and ease of installation. By opting for the offsite light steel frame system, R&M Property say they

have been able to take advantage of a quick and hassle-free installation along with the relative health and safety benefits associated with constructing panels offsite.

Speaking about the collaboration, Thomas McKenna, CEO of R&M Property Group, said: “We are a principal contracting firm that specialises in the design and installation of new homes using modern methods of construction, delivering homes up to 40 per cent faster. For this recent project, we chose Intrastack’s light steel frame low-rise housing system. We found the design and installation to be fast and efficient, with superb professional support provided by the Intrastack sales and technical teams.”

In response, Intrastack’s National Sales Manager, Danny Johnson, expressed enthusiasm for the collaboration, saying: “It has been an absolute pleasure to be working alongside the team at R&M Property Group. After visiting the project, I was blown away with how meticulously organised the site is and the exceptional workmanship and care from all the team. The wider Intrastack Saint-Gobain Off-Site Solutions team and I are looking forward to working with R&M on many future schemes.”

Images:

01. Jackie Brown and Steven Brown, Business Directors at John Southworth

Image courtesy: John Southworth / Intrastack

02. Work underway at R&M Property Group’s site in Manchester

Image courtesy: Intrastack / R&M Property Group

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 20 INDUSTRY NEWS

01 02

OFFSITE AWARDS TO RETURN FOR 2024 2024

Being held alongside Offsite Expo on the evening of 17 September 2024, at the Coventry Building Society Arena, the Offsite Awards will return this year, showcasing the best and brightest of the offsite construction sector. The awards recognise projects large and small – it is technical innovation that catches the judge’s eye.

As the most technically advanced material in the offsite portfolio, light steel framing has its own dedicated category – the ‘Best Use of Steel’ award. The category rewards companies for their outstanding use of light steel frame in projects across any UK construction sector. Special attention will be given to buildings safety, material performance and the use of circular construction

principles, together with how light steel has been used to deliver accuracy, speed of installation, cost and programme predictability as well as wider design for manufacture and assembly (DfMA) protocols together with lean manufacturing principles.

Deadline for Entries 31 May 2024

If you have an outstanding project or ground-breaking innovation, now is the time to start planning for the 2024 awards. For more information, or to enter the awards, visit www.offsiteawards.co.uk

INDUSTRY NEWS

Best Use of Steel Winner 2023 Lucent W1 - Design4Structures

STANTA COMMENCE WORKS IN CAMBRIDGE AND LONDON

Light steel specialist Stanta has commenced work on new projects in Cambridge and London to develop housing solutions.

Knights Park, Eddington

The Knights Park scheme forms part of the vast north west Cambridge redevelopment plan and has been a project in which the Hill Group have had a large part to play.

Located within Eddington, a new area conceived by the University of Cambridge, the low carbon buildings range in height from three to five storeys, with most homes having dual aspect accommodation.

Lot M3 occupies a landmark site within Cambridge University’s Eddington development, providing 106 highly sustainable private sale apartments that will complete the central market square. The apartments are arranged in two terraces around a central long gallery and an east-facing facade of stepping box bay balconies overlooks the new cricket pitch. This compact courtyard and architectural modelling are designed to echo the intricacy of historic Cambridge in a contemporary manner.

Lot 4 is an 88 dwelling scheme and is the third of Alison Brooks Architects’ projects in Eddington –Cambridge’s first net zero carbon urban extension. The buildings are composed of a mix of one bed and two bed apartments and three bed and four bed houses with the buildings defining a strong street edge. The facades are broken down by inset balconies, projecting porches, dormer windows and double height inset entrances.

Stanta’s scope on the projects consists of a mix of steel framing systems, boarding, window and door support plates and more. Work began onsite in Q1 2024.

Friary Park, Acton, London

Stanta has also begun working with Mount Anvil for phase 1B and 2 at the large new Friary Park development in Acton, London. Situated near the new Acton Main Line station, Friary Park is an estate regeneration project which is a joint venture in the London Borough of Acton, with Catalyst and Mount Anvil working in partnership. The redevelopment will deliver around 990 new homes, with 45 per cent affordable.

The design of the new development, in a series of blocks of between three and 24 storeys high, will prioritise people, with green open spaces, podium gardens, allotments, an exercise trail and play areas aimed at improving the lives of residents.

The new homes will be spacious and well insulated, with economical heating, plenty of natural light and with every home enjoying private outdoor space in the form of a garden, balcony or terrace, as well as access to semi-private green spaces for each block. Stanta’s scope of works includes the design supply and installation of more than 15,000sqm of steel framing systems, boards and insulations, with work set to begin onsite in Q2 2024.

Images:

01. Renderings of the Stanta developments

Image courtesy: Hill Group 02-03. The Friary Park development in Acton

Image courtesy: Peabody New Homes

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 22 INDUSTRY NEWS

01 02 03

SFS WORKS BEGIN FOR BARRATT LONDON

Steel framing system (SFS) specialists T Lott has commenced work on two projects for Barratt London. Works are currently progressing at the 454 new build apartment project at Wembley Park Gardens.

This scheme sits adjacent to Wembley Park London Underground Station, less than a minute walk from Wembley Way which leads on to the home of English football, Wembley Stadium.

The new-build units are split over five blocks rising between 13 and 21 storeys high, with works currently progressing up through the first two blocks. T Lott’s current scope of works on the project includes SFS installation, sheathing board, cortex FR0500 EPDM and Tyvek FireCurbe breather membrane.

Meanwhile, internal drylining works have also commenced in the second block on T Lott’s

other Barratt London project at Bermondsey Heights. This project consists of 253 new build apartments, with second fix and jointing now in progress on the lower floors. The steel framing system and sheathing board install is in progress.

The scope of works for this project includes: voestalpine Metsec SFS installation, Glassroc X sheathing board and Procheck FR200, British

Gypsum metal stud partition systems and wall linings, suspended plasterboard ceiling systems with a tape and jointed finish.

Image: Bermondsey Heights 253 new build apartments for Barratt London

Image courtesy: T Lott Ltd/ Barratt London

INDUSTRY NEWS

UK WWW.PARTEL.CO.UK SALES@PARTEL.CO.UK TEL: 02037 401918 IRL & EU WWW.PARTEL.IE SALES@PARTEL.IE TEL: +353 (0)91 428 714 CONNECT WITH US EXCEED FiRE-SAFETY STANDARDS WiTH IZOPERM PLUS A2 , EXOPERM DURO A1 & EXOPERM A2 MONO DURO Robust Fire-performance Vapour Control Layers & Non-combustible Breathable Membranes a2

provide comprehensive CPD

equipping

with the

insights

sustainable building

Partel also

sessions,

professionals

latest

and techniques in

practices.

LSFA HOST DEBATE ON THE IMPLICATIONS OF NEW SAFETY LEGISLATION

CLAIMED TO BE THE BIGGEST CHANGE IN OVER 40 YEARS, THE NEW BUILDING SAFETY ACT CAME INTO FORCE WITH LITTLE FANFARE –CREATING BARELY A RIPPLE ACROSS THE CONSTRUCTION LANDSCAPE.

But the significance of this legislation was not lost on the Light Steel Frame Association (LSFA) which hosted a roundtable event to debate the implications of the secondary legislation. A specially invited group of legal professionals, construction consultants and light steel framing experts gathered in Birmingham for a lively discussion around the implications of the Act and the challenges of implementing it.

Building a Safer Future

With far reaching consequences, on 14 June 2017 a high-rise fire broke out at Grenfell Tower in North Kensington, West London – one of the UK’s most devastating modern disasters. In addition to the public inquiry, the government commissioned an independent review of building

regulations and fire safety. Coming in the wake of the Hackitt Review ‘Building a Safer Future’ and receiving Royal Assent on 28 April 2022, the Building Safety Act covers a raft of changes introducing new duties for the management of fire and safety in high-rise residential buildings. These include a new system of accountability for safety in projects and a refreshed regulatory framework. The Act also has wider implications across all construction sectors.

The Building Safety Regulator (BSR) based within the Health and Safety Executive, became operational from 01 April 2023 and the principal accountable person (legally responsible for the structure and exterior of the building) has been required to register high-rise residential buildings from that date.

The overhaul of regulations will require building owners to demonstrate safety at each of three new ‘gateways’ –planning and design, construction and occupation. Compliance will be monitored by the Building Safety Regulator with significant powers to demand documents and to stop works, and a new National Regulator for Construction Products with the power to remove dangerous products.

On 01 October 2023, the secondary legislation needed to support the practical implementation of the Building Safety Act came into force to help ensure responsible parties operate within the law. The Building Safety Regulator will now monitor the construction industry and will be able to impose fines, order alterations or the removal of non-compliant work.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 24

BUILDING SAFETY

How to Choose the Right Howick Framing System

Standard Howick Framing Systems. The quickfire guide to finding the right Howick machine

From the workhorses FRAMATM 3200 and 5600 – great for all standard framing needs – to specialised machines like the X-TENDATM 3600 (extendable frames for infill spaces) and the FRAMATM 6800 (floor joist system) that are highly optimised to produce specific components, you will find we have a system available that meets most framing component manufacturing needs.

If you are thinking of something out of the ordinary, we also provide a range of customised options for our standard machines; we have even designed and manufactured new innovations to help solve specific challenges. Just talk to us about what you are trying to do.

Want a great compact workhorse system that will produce most standard framing requirements for housing and low-rise? You do not need to look any further than the FRAMA™ 3200.

You want a workhorse capable of making heavier load-bearing framing for large build projects, low-rise and commercial with greater capacity and increased flexibility? The FRAMA™ 5600 is the right horse to jump on.

You want a dedicated truss system that is highly efficient and produces in volume? Step up to the FRAMA™ 4200 and try that for size. It is the system you can truss. (See what we did there?)

You want a dedicated flooring system that manufactures more efficiently than assembling lattice flooring? The FRAMA™ 6800 pops out floor joist cassettes with gusto. Plus, you will find them much more efficient to install.

You want a convertible frame and truss system with high output capacity that can be adjusted to handle 5 different profiles in the one machine? Welcome to the ultimate flexibility of the FRAMA™ 7600. It offers 5 different profiles and can be configured for floor joist production, framing production, or customised for both frame and joist tooling.

You want a convertible system that can handle heavier gauge than the FRAMA™ 7600? The FRAMATM 7800 is the big brother of all the rest, it offers everything the FRAMATM 7600 does, and it can handle thickness of up to 2.5mm / 13 gauge.

You want the fastest way to build retrofit and infill framing for interior spaces? The X-TENDATM 3600 makes telescopic framing that is extendable in any direction to fill any space fast. It is the latest innovation in infill framing technology.

You want to improve the efficiency of your framing plant by 5%? Just add the option of a Howick dedicated coil-loading system. Over a 7-hour shift, you will improve efficiency by 5%.

To find out more about setting up construction manufacturing with light gauge steel framing automation, simply scan the QR code to download our Machine Buyer Guide.

FRAMA™ 4200

FRAMA™ 3200

FRAMA™ 5600

FRAMA™ 6800

FRAMA™ 7800

FRAMA™ 7600

X-TENDA™ 3600

FRAMA™ 4200

FRAMA™ 3200

FRAMA™ 5600

FRAMA™ 6800

FRAMA™ 7800

FRAMA™ 7600

X-TENDA™ 3600

www.howickltd.com

BUILDING SAFETY

The LSFA would like to thank all roundtable participants for their valued input, including:

The extensive enforcement powers granted by the Building Safety Act means the Buildings Safety Regulator has the power to prosecute individuals of corporate bodies.

Imperative for Change

Roundtable facilitator Darren Richards, explained how the LSFA is helping members to understand that the Building Safety Act will change the construction landscape significantly. Through issuing initial guidance and further information highlighting the implications of the secondary legislation, the LSFA is helping members to understand their obligations.

Kicking off proceedings, Darren asked: “Is the industry prepared for the new era?”

The legal experts were the first to step forward with Victoria Ball, Partner at Trowers & Hamlins and Birmingham lead of the project and construction team, responding: “We are just starting to see an increase in requests for contractual advice but there is a lot of uncertainty around how it will play out for contractors getting through the gateways to achieve a legally occupied building.”

Farah Bandali, Legal Director specialising in real estate disputes at Shakespeare Martineau, supported this comment adding:

“We are just receiving requests for awareness training, there is definitely more tension around the BSA – everyone is concerned about safety and rightly so but typically unsure what to do to meet their obligations. I can certainly see potential disputes on the horizon but until it starts to play out, many are failing to acknowledge the implications.”

“Designers, contractors and clients have a lot of work to do to get across the detail,” added Tim Sims, Partner at Rider Levett Bucknall and lead of the Midlands Building Safety Fire Team. “On the regulatory side, we are getting teams together to ensure we have the right competencies to advise our construction clients as the levels of enquiries increase.”

Andrew Way, Associate Director at the Steel Construction Institute (SCI) also expressed concern: “The lack of

technical engineering enquiries the SCI is receiving is certainly not at the levels we were expecting. The light steel frame manufacturing sector is well advanced, with checks and balances in place. I firmly believe the certainty surrounding offsite construction, will meet the demands of regulatory requirements and offer greater opportunities for the industry.”

Collaborative Action Roundtable debates can expose a divergence of opinions but throughout the two-hour discussion, there was consensus around the table. Universally the light steel frame manufacturers, engineers and technology leads, welcomed the legislation. Darren Richards then asked: “What can the LSFA and its members do to support construction clients in meeting the requirements of the Building Safety Act?”

“There is a particular focus on record keeping, meeting the requirements of a ‘golden thread’ of information, documenting every construction project,” responded Matthew Grant, Head of Technical Development at Intrastack, part of Saint Gobain.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 26

Facilitator Darren Richards Director, Cogent Consulting

Ben Towe Group Managing Director, Hadley Group

Matthew Grant Head of Technical, Development & Sales Support, Intrastack part of Saint Gobain

Andrew Way Associate Director, SCI

Farah Bandali Legal Director, Shakespeare Martineau

Michael Rowell Engineering Manager, Fusion Steel Framing

Tim Sims Partner, Rider Levett Bucknall and Midlands Building Safety Fire Team Lead

Nik Teagle Joint Managing Director, Frameclad

Victoria Ball Partner, Trowers & Hamlins and Birmingham Project and Construction Lead

“This is a particular strength of Intrastack and the digital savvy light steel frame sector. We are well prepared.”

“This is seen as a positive step forward which will mark a differentiation between manufacturers with and without test data,” added Ben Towe, Group Managing Director at Hadley Group. “This legislation will reinforce the importance of being able to independently verify a systems’ performance in relation to building safety.”

Both Ben and Matthew highlighted examples of how the steel framing specialists are helping educate their customers and to support them in meeting the onerous demands of the Building Safety Act.

Michael Rowell, Engineering Manager for Fusion Steel Framing supported this point saying: “There is still a lack of understanding around the Building Safety Act and as an industry we need closer collective action to help educate and advise. It certainly plays to the strengths of the light steel frame sector.”

“We should use the opportunities presented by the Building Safety Act as a catalyst for collaboration to collectively grow the light steel sector,” said Nik Teagle, Joint Managing Director

at Frameclad. “By working together under the umbrella of the LSFA, we can achieve common goals for the good of the construction industry and building safety.”

It was proposed that the LSFA set up a working group to engage directly with the Building Safety Regulator to set a high bar and ensure that the light steel frame sector is at the forefront of implementation of new technology for traceability, design information management and robust construction details with validated performance.

More Stringent Regime

It was generally agreed that having the Building Safety Regulator sitting within the HSE will offer a certain level of gravitas and was a ‘smart move’ on the part of the government, but doubts were raised about recruitment of the regulatory team, and the levels of resource required to implement and police the new legislation, which could prove challenging.

Drawing conclusions, Darren Richards said: “The government has asked the industry and its trade associations to provide leadership to aid and support compliance with legislative requirements, and to work closely with the regulator. It is apparent that there is a consensus of support and those around the table do not appear to be particularly intimidated by the implications of the new more stringent regime.”

Michael Rowell concluded: “Through these changes the government has made it clear that those who commission, design and construct buildings assume the liability for ensuring compliance with the new regulations. This is reinforced by the obligation of clients to declare a project as compliant on completion. This is unambiguous and does not require interpretation.”

Matthew Grant added: “It is our duty as a sector to collaborate to promote what we are doing to meet regulatory requirements and help educate construction clients and supply chains by raising awareness and imparting expertise.”

Ben Towe reiterated and added to his initial point: “Only through robust test data can we meet legislative requirements and be fully confident in the systems that we promote and sell. Architects should demonstrate for example, that the design for the wall build up works and will meet the performance they have specified. All too frequently there is a disconnect between a designer’s expectations and in use performance. The LSFA needs to champion rigorous product testing, to help eliminate any potential gap between design and as built performance.”

Nik Teagle agreed: “Frameclad already has robust systems in place for quality control, with full traceability and a growing suite of test data. I would really like to see more collaboration across the light steel frame sector to collectively grow our market share, with for example – a portal of test and specification data impartially curated.”

It has been unclear until now how the government and Building Safety Regulator will put the legal requirements within the Building Safety Act into effect, however this new legislation is intended to help ensure responsible parties operate within the law.

27 LIGHTSTEELFRAMINGMAGAZINE.CO.UK BUILDING SAFETY

BUILDING SAFETY

“The Building Safety Act addresses key safety issues which should never have arisen but came sharply into focus as a result of the Grenfell tragedy,” said Farah Bandali. “The Act was a reaction to the lessons learned from this tragedy and has already been updated and amended a number of times as we learn more about its impact. Now, the construction industry needs to keep pace with the legislation. It does not seem that this will be easy or straightforward as there appears to be a lack of standardisation of processes and a lack of collaboration in the wider industry, but we are still hopeful that this is an opportunity which will result in long-term change for the good.”

“The building safety legislation is intended to drive a cultural sea change,” stated Victoria Ball. “This is not going to be a tick box exercise for the industry. Construction professionals will need to embrace significant behavioural changes and the sector will be forced to adopt a different approach. The biggest challenge is around gateway three, right at the end of the project. Structures cannot be legally occupied until they have been through the building safety process, therefore, we must consider how the new completion and handover processes will play out. What is the likely impact on programme and occupation timescales? Collaboration in the industry is key to assist contractors to get smoothly through the gateway process and provide ‘golden thread’ details to meet building safety requirements.”

Tim Sims added: “I totally agree that a significant cultural change is required. It is also important for industry bodies such as the LSFA to have a clear direction of travel and build a relationship with the regulator, so they can guide members through the building safety process and support compliance with regulatory requirements.”

In Summary

The new regulations deliver the recommendations laid out in the Hackitt Review and cover the technical detail underpinning the new, more stringent regime for the design and construction

of higher-risk buildings, wider changes to the building regulations for all buildings and the details of the new inoccupation safety regime for higher-risk buildings.

Now the secondary legislation is released there is a huge amount of work to be done, primarily in England as these regulations impact this country the most, with a significant amount relating to Wales and very little applying to Scotland or Northern Ireland. We now have confirmation that the transitional period began in October and the industry has less than six months to get everything in place ready for full implementation of the Building Safety Act in April 2024.

The LSFA works to drive engagement, champion change, and spread the word about the safety, cost, performance and sustainability benefits of contemporary light steel frame systems. Trusted and specified by the UK construction industry – light steel frame is the most technically advanced material in the offsite technology portfolio. Highly innovative, the light steel frame sector has developed panelised and modular solutions that deliver high quality buildings on fast-track construction programmes that are renowned for safety, strength and durability.

To download the Building Safety Guide, go to the LSFA Information Library:

WWW.LSF-ASSOCIATION.CO.UK

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 28

GET INVOLVED…

Through the strength of our members and the power of a united voice, the Light Steel Frame Association (LSFA) drives positive influence and engagement to increase market share for the light steel framing sector.

Membership of the LSFA gives access to numerous high-value opportunities, resources and direct representation within the wider construction industry.

JOIN US!

Membership starts from £500Find out more about LSFA membership by visiting WWW.LSF-ASSOCIATION.CO.UK/JOIN

BE INFORMED GET INSIGHT PROVIDE INFLUENCE

INNOVATIVE TRAX ™ SYSTEM

UTILISED ON BRENTFORD SCHEME

AWARD-WINNING MANUFACTURER OF LIGHT STEEL FRAMING SOLUTIONS, FUSION STEEL FRAMING, HAS BEEN BROUGHT ON BOARD AS A CONTRACTOR FOR FIVE-STAR HOUSEBUILDER THE HILL GROUP AND L&Q'S LARGE-SCALE REDEVELOPMENT OF A FORMER CAR DEALERSHIP IN KEW BRIDGE RISE, BRENTFORD.

Fusion will be fabricating 13,720sqm of its innovative TRAX™ product to form the steel frame system infill across five buildings of up to 18 storeys on the development.

TRAX™ is an economical nonloadbearing infill system and provides a custom design made with highprecision engineering, and exceptional thermal and acoustic insulation. This helps to create rapid dry building envelopes on a range of building types using steel framing.

Kew Bridge Rise, located within the heart of the Brentford regeneration area, will deliver 441 new homes, of which 50 per cent will be affordable. Construction of the steel frame system has already begun on site, with the development expected to complete in 2026.

In 2022

Fusion was acquired by The Hill Group to advance the housebuilders’ progress in offsite construction

practises and more efficiently integrate light steel frames on developments such as Kew Bridge Rise.

The works at Kew Bridge Rise will involve Fusion forming the openings, applying RCM DensGlas external board, Kingspan K-Roc insulation and fitting of brick tie channels. It is expected that this stage of the development will take around 12 months. Fusion will manufacture TRAX™ at the company's 80,000sqft manufacturing facility in Northampton, which has the capacity to deliver over 30,000sqm of light steel each year. The company's engineers will then deliver and install the TRAX™ system at the Kew Bridge Rise site.

The development will have a concrete frame structure and TRAX™ will be used for the infill between floors, sitting on the floor slab up to the ceiling. In addition, Fusion will create the window apertures, providing a complete solution for the project.

The key advantage of using Fusions' TRAX™ system is the ability to rapidly accelerate construction projects while reducing risks during the process of installing a structural framework system. Hill and L&Q began on site in Brentford in September 2022. The project also includes a new public square, alongside significant investment in local infrastructure improvements.

The joint venture partnership will also provide a range of social benefits for the local area during construction, including investment in significant employment, training and community focussed opportunities.

Hounslow Council Leader, Shantanu Rajawat, commented: "Kew Bridge Rise forms a major part of our regeneration strategy for this area, revitalising a previous brownfield site to deliver vital new homes, improve the existing infrastructure and provide new amenities for the local community. “It is exciting to see the rapid progress that Hill and L&Q are already making on site, alongside the training and employment benefits the project offers to local people."

For more information visit: www.fusionsteelframing.co.uk

IMAGES

01. TRAX™, a high-precision non-loadbearing light steel system delivering exceptional thermal, fire and acoustic performance. 02-03. Kew Bridge Rise, located within the heart of the Brentford regeneration area, will deliver 441 new homes, of which 50 per cent will be affordable.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK 30 PROJECT PROFILE

01 02 03

ARKITECH LIGHT STEEL FRAMING SYSTEM

ARKITECH LIGHT STEEL FRAMING